EP0132484A2 - Flexible plastics material can for liquids - Google Patents

Flexible plastics material can for liquids Download PDFInfo

- Publication number

- EP0132484A2 EP0132484A2 EP83830184A EP83830184A EP0132484A2 EP 0132484 A2 EP0132484 A2 EP 0132484A2 EP 83830184 A EP83830184 A EP 83830184A EP 83830184 A EP83830184 A EP 83830184A EP 0132484 A2 EP0132484 A2 EP 0132484A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- whereof

- extension

- bag

- sleeve

- sleeve extension

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D33/00—Details of, or accessories for, sacks or bags

- B65D33/06—Handles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D75/00—Packages comprising articles or materials partially or wholly enclosed in strips, sheets, blanks, tubes, or webs of flexible sheet material, e.g. in folded wrappers

- B65D75/52—Details

- B65D75/58—Opening or contents-removing devices added or incorporated during package manufacture

- B65D75/5861—Spouts

- B65D75/5866—Integral spouts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D77/00—Packages formed by enclosing articles or materials in preformed containers, e.g. boxes, cartons, sacks or bags

- B65D77/10—Container closures formed after filling

- B65D77/14—Container closures formed after filling by flattening and subsequently folding or rolling the mouth portion

Definitions

- the present invention relates to a resilient or flexible material can for liquids in general, in particular fuels.

- the rigid material cans even if they are of small size,are however bulky and they may be hardly held on a vehicle,in a proper position,for a possible use.

- the task of the present invention is to solve the above mentioned problem,by providing a flexible or resilient can,for liquids in general,which is so designed as to be flexible and light as well as effective to be easily and safely used for transporting small amounts of fuel or liquids and pouring them into a tank or vessel without the need of using funnels or the like means.

- Another object of the present invention is to provide such a flexible plastics material can which is very reliable in use and of long duration.

- Yet another object of the invention is to provide such a flexible plastics material can which is construction-wise very simple and of very reduced cost.

- a flexible material can for liquids in general and fuels in particular, characterized in that it comprises a bag-shaped body provided,at a peripheral portion whereof,with a sleeve extension,effective to provide an elongated filler member,effective to be used as a funnel for dispensing said liquid therefrom,closure means being further provided movably engageable with said sleeve extension.

- the flexible material can according to the invention comprises a bag-shaped body,indicated at 1,which, advantageously,is of flattened out configuration and is made from a flexible thermoplastic material, such as polyvinylchloride,polyethylene and the like plastics materials.

- the mentioned bag-shaped body is made starting from a plastics tubolar member,of predetermined thickness,produced by blowing and the like known methods,and it is closed at the bottom by a sealing line 2,made by thermosealing methods or the like.

- the can is so shaped as to present a sleeve extension or tubular lug 3 which is closed,along its curved extension and up to the opposite end,by a sealed portion 4, analogous to the mentioned sealing line 2.

- That sleeve extension provides,in actual practice,an effective funnel member for facilitating the dispensing or pouring of the contained liquid.

- the mentioned sleeve extension extends for a lenght which is proportional to the size of the can.

- the mentioned sleeve extension 3 forms a narrower region of the tubular body 1 and is oriented perpendicularly to the bottom of the can.

- the lenght of said sleeve extension is effective to allow for a full can,as it is shown in fig.2,to be easily transported even with a slanted orientation,without the need of closing the can itself and without the danger that the top surface 5 of the contained liquid may overflow from the mouth defined by the 'open end portion of said sleeve extension 3.

- That mouth may be advantageously closed by closure means provided for being movably engaged with the sleeve extension.

- the mentioned closure means (figs.5,6 and 7) consists advantageously of a key,indicated overally by the reference number 10,which,on the substantially cylindrical elongated stem whereof, indicated at ll,is provided with a through slot l2;the latter,advantageously even not necessarily, has a tapering shape with a wider edge than the opposite edge,as it will be clear from fig.6.

- said elongated stem 11 extends from a butterfly member l3,provided for allowing for said key to be easily used.

- the key 10 will be turned by some revolutions in such a way as to wind a portion of the sleeve extension 3 about the mentioned stem 11.

- a resilient clamp or band 20 provided,at the end portions whereof,with through holes 21,effective to permit one end of the resilient clamp 20 to be inserted into the coupling zone of the stem 11 to the butterfly member 13 and into the other through hole 2l,at the free end of the stem 11,in such a way as to prevent said sleeve extension 3 wound about the key from being unwound.

- the bag is provided at the top whereof, on the opposite side to the funnel shaped side,with a handle 6,made of a plastics material and shaped as an elongated slot which is anchored,by means of a welded portion 6a,between the two opposite walls of said bag.

- the handle is obtained by means of a plurality of through holes 7,formed through said bag body,upon closing the can through a transversal or cross sealing line, as indicated at 8.

- closure means which,while being structurally very simple,since they may be obtained by a simple shaped key member,advantageously made from a plastics material,are effective to provide a firm and safe closure of the can.

- the can according to the invention may be easily folded over and stored in a very reduced space.

- the used materials even if the best results have been obtained by using the above mentioned materials,as well as the contingent shapes and size,may be any,according to requirements.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Package Frames And Binding Bands (AREA)

- Cooling, Air Intake And Gas Exhaust, And Fuel Tank Arrangements In Propulsion Units (AREA)

Abstract

Description

- The present invention relates to a resilient or flexible material can for liquids in general, in particular fuels.

- As it is known there are many cases therein a motorist is restrained from preceding with his 'vehicle because of the exhaustion of fuel,or other cases therein a user has to collect liquids,such as water and the like.

- Thus a need is felt of a vessel er can for containing spare fuel or the liquid to be used.

- The rigid material cans,even if they are of small size,are however bulky and they may be hardly held on a vehicle,in a proper position,for a possible use.

- Also the flexible sealed bags presently commercially available are not effective to solve the problem of an occasional refuelling,both because they require the use of a funnel for pouring fuel and because they are difficult to handle in a full condition.

- Thus,the task of the present invention is to solve the above mentioned problem,by providing a flexible or resilient can,for liquids in general,which is so designed as to be flexible and light as well as effective to be easily and safely used for transporting small amounts of fuel or liquids and pouring them into a tank or vessel without the need of using funnels or the like means.

- Within that task,it is a primary object of the present invention to provide such a flexible or resilient plastics material can which is provided with a handle effective to be easily engaged for safely transporting the full can without any liquid leaks.

- Another object of the present invention is to provide such a flexible plastics material can which is very reliable in use and of long duration.

- Yet another object of the invention is to provide such a flexible plastics material can which is construction-wise very simple and of very reduced cost.

- According to one aspect of the present invention,the above task and objects,as well as yet other objects,which will become more apparent thereinafter,are achieved by a flexible material can for liquids in general and fuels in particular, characterized in that it comprises a bag-shaped body provided,at a peripheral portion whereof,with a sleeve extension,effective to provide an elongated filler member,effective to be used as a funnel for dispensing said liquid therefrom,closure means being further provided movably engageable with said sleeve extension.

- Further characteristics and advantages of the resilient material can according to the present invention will become more apparent from the following detailed description of a preferred embodiment whereof,being illustrated, by way of example,in the accompanying drawings, where:

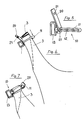

- fig.l schematically illustrates a bag 'flexible or resilient can according to the present invention;

- fig.2 illustrates that same can,in a full condition and during the transportation whereof;

- fig.3 illustrates that same can during the pouring step of the fuel or liquid contained therein;

- fig.4 illustrates an embodiment of the handle member associated to the can according to the invention;

- fig. 5 illustrates, by a perspective view, the closure means associated to the can according to the invention;

- fig.6 is a side view illustrating the can according to the present invention as provided, at the sleeve whereof,with the above mentioned closure means; and

- fig.7 illustrates the closure means applied to the can in such a way as to close said sleeve.

- With reference to the mentioned figures, the flexible material can according to the invention comprises a bag-shaped body,indicated at 1,which, advantageously,is of flattened out configuration and is made from a flexible thermoplastic material, such as polyvinylchloride,polyethylene and the like plastics materials.

- Preferably,though not necessarily,the mentioned bag-shaped body is made starting from a plastics tubolar member,of predetermined thickness,produced by blowing and the like known methods,and it is closed at the bottom by a

sealing line 2,made by thermosealing methods or the like. - At the top whereof,the can is so shaped as to present a sleeve extension or

tubular lug 3 which is closed,along its curved extension and up to the opposite end,by a sealedportion 4, analogous to the mentionedsealing line 2. - That sleeve extension provides,in actual practice,an effective funnel member for facilitating the dispensing or pouring of the contained liquid.

- Moreover, the mentioned sleeve extension extends for a lenght which is proportional to the size of the can.

- Thus,the mentioned

sleeve extension 3 forms a narrower region of thetubular body 1 and is oriented perpendicularly to the bottom of the can. - It should be noted that the lenght of said sleeve extension is effective to allow for a full can,as it is shown in fig.2,to be easily transported even with a slanted orientation,without the need of closing the can itself and without the danger that the

top surface 5 of the contained liquid may overflow from the mouth defined by the 'open end portion of saidsleeve extension 3. - That mouth,as it is schematically illustrated in figs.5 to 7 may be advantageously closed by closure means provided for being movably engaged with the sleeve extension.

- The mentioned closure means(figs.5,6 and 7) consists advantageously of a key,indicated overally by the

reference number 10,which,on the substantially cylindrical elongated stem whereof, indicated at ll,is provided with a through slot l2;the latter,advantageously even not necessarily, has a tapering shape with a wider edge than the opposite edge,as it will be clear from fig.6. - More specifically said

elongated stem 11 extends from a butterfly member l3,provided for allowing for said key to be easily used. - In order to apply the mentioned closure means to the can, it will be sufficient to fold on itself,along a longitudinal line,the

sleeve extension 3 and insert it into theslot 12,from the wide portion,and cause it to exit the narrow portion for a given lenght. - Then the

key 10 will be turned by some revolutions in such a way as to wind a portion of thesleeve extension 3 about the mentionedstem 11. - In order to carry out the locking operation,there is provided a resilient clamp or

band 20 provided,at the end portions whereof,with throughholes 21,effective to permit one end of theresilient clamp 20 to be inserted into the coupling zone of thestem 11 to thebutterfly member 13 and into the other through hole 2l,at the free end of thestem 11,in such a way as to prevent saidsleeve extension 3 wound about the key from being unwound. - Thus a perfectly tight closure of the can is obtained and any leaks will be prevented, even in the presence of high inner pressures.

- In order to provide for an easy handling of the full can, and an easy transportation whereof, the bag is provided at the top whereof, on the opposite side to the funnel shaped side,with a

handle 6,made of a plastics material and shaped as an elongated slot which is anchored,by means of a welded portion 6a,between the two opposite walls of said bag. - As it is shown in fig.4,the handle is obtained by means of a plurality of through

holes 7,formed through said bag body,upon closing the can through a transversal or cross sealing line, as indicated at 8. - From the above disclosure it should be noted that the invention fully achieves the intended task and objects.

- In particular it is to be pointed out that the provision of a

sleeve extension 3,made in a single piece with the bag-shaped can,affords the possibility of using said extension as an element for filling the can as well as like a funnel. - This is particularly useful as the liquid contained in the bag is to be poured into the mouth of a vehicle fuel tank or other like vessels, without any dangers of causing liquid leaks.

- Especially important are moreover the closure means which,while being structurally very simple,since they may be obtained by a simple shaped key member,advantageously made from a plastics material,are effective to provide a firm and safe closure of the can.

- It should also be noted that,in the non use condition,the can according to the invention may be easily folded over and stored in a very reduced space.

- In practicing the invention the used materials,even if the best results have been obtained by using the above mentioned materials,as well as the contingent shapes and size,may be any,according to requirements.

Claims (9)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| IT2247083U IT8322470V0 (en) | 1983-07-22 | 1983-07-22 | CONTAINERS IN FLEXIBLE MATERIALS FOR LIQUIDS IN GENERAL AND FUELS IN PARTICULAR. |

| IT2247083U | 1983-07-22 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0132484A2 true EP0132484A2 (en) | 1985-02-13 |

| EP0132484A3 EP0132484A3 (en) | 1986-05-14 |

Family

ID=11196717

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP83830184A Withdrawn EP0132484A3 (en) | 1983-07-22 | 1983-09-26 | Flexible plastics material can for liquids |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0132484A3 (en) |

| IT (1) | IT8322470V0 (en) |

Cited By (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3508050A1 (en) * | 1985-03-07 | 1986-09-11 | Mauser-Werke GmbH, 5040 Brühl | Liquid container with carrying handle |

| DE3612895A1 (en) * | 1986-04-17 | 1987-10-29 | Altstaedter Verpack Vertrieb | LIQUID PACK WITH HANDLE |

| DE8807593U1 (en) * | 1988-06-10 | 1988-09-08 | INDAG Gesellschaft für Industriebedarf mbH, 6900 Heidelberg | Refill bag |

| EP0283447A2 (en) * | 1987-03-17 | 1988-09-21 | PLASTIBAG S.r.l. | A collapsible can with a handle arrangement for pouring the liquid held therein |

| DE4124307A1 (en) * | 1991-07-23 | 1993-01-28 | Nordenia Verpackung | Disposable pack of paint or other fluid - is bag with cut off end for fitting into support bucket |

| WO2002060764A2 (en) * | 2001-01-29 | 2002-08-08 | Sheldon Sturgis | Bag with ergonomically disposed handle |

| WO2003004379A1 (en) * | 2001-07-04 | 2003-01-16 | Horticultural Coir Limited | Reconstitution package |

| GB2395190A (en) * | 2002-11-15 | 2004-05-19 | Simon Mark Dix | Collapsible bag for liquid fuel |

| ITMI20111280A1 (en) * | 2011-07-08 | 2013-01-09 | Goglio Spa | HANDLE FOR FLEXIBLE PACKAGING AND FLEXIBLE PACKAGE PROVIDED WITH SUCH A HANDLE |

| US8764292B2 (en) | 2008-11-20 | 2014-07-01 | Performance Seed | Article for holding product and methods |

| US8794833B2 (en) | 2008-08-28 | 2014-08-05 | North American Salt Company | Two-handled bag |

| EP3299313A1 (en) * | 2016-09-23 | 2018-03-28 | YARA International ASA | Pouch assembly for holding a liquid urea solution for use in an scr system for treating the exhaust gases of an internal combustion engine of a vehicle and system for treating the exhaust gases of an internal combustion engine of a vehicle using the liquid urea solution |

| DE102019118007A1 (en) * | 2019-07-03 | 2021-01-07 | Huhtamaki Flexible Packaging Germany Gmbh & Co. Kg | Hygienic film packaging for pourable products with an integrated outlet, especially a mouthpiece |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2789728A (en) * | 1955-06-10 | 1957-04-23 | James H Britton | Manually portable, selectively operable dispensing spout type, carrying container for liquid |

| FR2176605A1 (en) * | 1972-03-24 | 1973-11-02 | Mesrouze Michel | |

| FR2295884A1 (en) * | 1974-12-27 | 1976-07-23 | Hureau Jean Claude | Plastic bag with array of air holes - has handholds formed in two strips across bottom |

-

1983

- 1983-07-22 IT IT2247083U patent/IT8322470V0/en unknown

- 1983-09-26 EP EP83830184A patent/EP0132484A3/en not_active Withdrawn

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2789728A (en) * | 1955-06-10 | 1957-04-23 | James H Britton | Manually portable, selectively operable dispensing spout type, carrying container for liquid |

| FR2176605A1 (en) * | 1972-03-24 | 1973-11-02 | Mesrouze Michel | |

| FR2295884A1 (en) * | 1974-12-27 | 1976-07-23 | Hureau Jean Claude | Plastic bag with array of air holes - has handholds formed in two strips across bottom |

Cited By (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3508050A1 (en) * | 1985-03-07 | 1986-09-11 | Mauser-Werke GmbH, 5040 Brühl | Liquid container with carrying handle |

| DE3612895A1 (en) * | 1986-04-17 | 1987-10-29 | Altstaedter Verpack Vertrieb | LIQUID PACK WITH HANDLE |

| EP0283447A2 (en) * | 1987-03-17 | 1988-09-21 | PLASTIBAG S.r.l. | A collapsible can with a handle arrangement for pouring the liquid held therein |

| EP0283447A3 (en) * | 1987-03-17 | 1989-09-06 | Plastibag S.R.L. | A collapsible can with a handle arrangement for pouring the liquid held therein |

| DE8807593U1 (en) * | 1988-06-10 | 1988-09-08 | INDAG Gesellschaft für Industriebedarf mbH, 6900 Heidelberg | Refill bag |

| EP0345647A1 (en) * | 1988-06-10 | 1989-12-13 | INDAG Gesellschaft für Industriebedarf mbH | Refillable bag |

| WO1989012006A1 (en) * | 1988-06-10 | 1989-12-14 | INDAG Gesellschaft für Industriebedarf mbH | Refillable bag |

| DE4124307A1 (en) * | 1991-07-23 | 1993-01-28 | Nordenia Verpackung | Disposable pack of paint or other fluid - is bag with cut off end for fitting into support bucket |

| WO2002060764A3 (en) * | 2001-01-29 | 2003-04-24 | Sheldon Sturgis | Bag with ergonomically disposed handle |

| WO2002060764A2 (en) * | 2001-01-29 | 2002-08-08 | Sheldon Sturgis | Bag with ergonomically disposed handle |

| WO2003004379A1 (en) * | 2001-07-04 | 2003-01-16 | Horticultural Coir Limited | Reconstitution package |

| GB2393433A (en) * | 2001-07-04 | 2004-03-31 | Horticultural Coir Ltd | Reconstitution package |

| GB2393433B (en) * | 2001-07-04 | 2005-05-25 | Horticultural Coir Ltd | Reconstitution package |

| AU2002317292B2 (en) * | 2001-07-04 | 2008-09-25 | Horticultural Coir Limited | Reconstitution package |

| US7819244B2 (en) | 2001-07-04 | 2010-10-26 | Horticultural Coir Limited | Reconstitution package |

| GB2395190A (en) * | 2002-11-15 | 2004-05-19 | Simon Mark Dix | Collapsible bag for liquid fuel |

| US8794833B2 (en) | 2008-08-28 | 2014-08-05 | North American Salt Company | Two-handled bag |

| US8764292B2 (en) | 2008-11-20 | 2014-07-01 | Performance Seed | Article for holding product and methods |

| ITMI20111280A1 (en) * | 2011-07-08 | 2013-01-09 | Goglio Spa | HANDLE FOR FLEXIBLE PACKAGING AND FLEXIBLE PACKAGE PROVIDED WITH SUCH A HANDLE |

| EP3299313A1 (en) * | 2016-09-23 | 2018-03-28 | YARA International ASA | Pouch assembly for holding a liquid urea solution for use in an scr system for treating the exhaust gases of an internal combustion engine of a vehicle and system for treating the exhaust gases of an internal combustion engine of a vehicle using the liquid urea solution |

| DE102019118007A1 (en) * | 2019-07-03 | 2021-01-07 | Huhtamaki Flexible Packaging Germany Gmbh & Co. Kg | Hygienic film packaging for pourable products with an integrated outlet, especially a mouthpiece |

Also Published As

| Publication number | Publication date |

|---|---|

| IT8322470V0 (en) | 1983-07-22 |

| EP0132484A3 (en) | 1986-05-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0132484A2 (en) | Flexible plastics material can for liquids | |

| US4934654A (en) | Valve for bulk container | |

| US3212681A (en) | Container structure | |

| US3090526A (en) | Disposable-type dispensing container package | |

| US4484351A (en) | Non-glass chemical container | |

| US2866488A (en) | Container | |

| EP0041763B1 (en) | Container for transporting and dispensing liquids | |

| US2872081A (en) | Disposable container for liquid and holder for container | |

| US3100587A (en) | Pouring type fluid container | |

| JPH04215957A (en) | Flexible bag | |

| US4247020A (en) | Liquid containing and dispensing device | |

| US20200017269A1 (en) | Flexible Reinforcement for Flexible Container | |

| US3642172A (en) | Bulk containers | |

| US3299927A (en) | Envelope bag with filling neck and means for closing the same | |

| US6988639B2 (en) | Bottom draining tank with disposable liner and method | |

| US7648276B2 (en) | Sealing device for flexible liquor container | |

| EP0816243A1 (en) | Intrinsic closure for flexible wall container | |

| US3285495A (en) | Reusable food package with integral adjustable closure | |

| US5104012A (en) | Flexible tube attachable to a spout having a finger tab to maintain attachment | |

| US2566838A (en) | Closure for liquid containers | |

| US5975380A (en) | Container including an accordion like pouring spout | |

| US3228444A (en) | Specimen container | |

| FI97043C (en) | A device used to store a material, such as a liquid, in metal barrels | |

| US2526629A (en) | Seal structure for controlling flow of liquids | |

| US4865464A (en) | Water tank |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB LI NL SE |

|

| 17P | Request for examination filed |

Effective date: 19850709 |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE FR GB LI NL SE |

|

| 17Q | First examination report despatched |

Effective date: 19861105 |

|

| R17C | First examination report despatched (corrected) |

Effective date: 19870309 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN WITHDRAWN |

|

| 18W | Application withdrawn |

Withdrawal date: 19880104 |