EP0129337A2 - Mechanical spacer for towed acoustic array - Google Patents

Mechanical spacer for towed acoustic array Download PDFInfo

- Publication number

- EP0129337A2 EP0129337A2 EP84303387A EP84303387A EP0129337A2 EP 0129337 A2 EP0129337 A2 EP 0129337A2 EP 84303387 A EP84303387 A EP 84303387A EP 84303387 A EP84303387 A EP 84303387A EP 0129337 A2 EP0129337 A2 EP 0129337A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- spacer

- recesses

- strain

- shaped

- array

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02G—INSTALLATION OF ELECTRIC CABLES OR LINES, OR OF COMBINED OPTICAL AND ELECTRIC CABLES OR LINES

- H02G9/00—Installations of electric cables or lines in or on the ground or water

- H02G9/06—Installations of electric cables or lines in or on the ground or water in underground tubes or conduits; Tubes or conduits therefor

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01V—GEOPHYSICS; GRAVITATIONAL MEASUREMENTS; DETECTING MASSES OR OBJECTS; TAGS

- G01V1/00—Seismology; Seismic or acoustic prospecting or detecting

- G01V1/16—Receiving elements for seismic signals; Arrangements or adaptations of receiving elements

- G01V1/20—Arrangements of receiving elements, e.g. geophone pattern

- G01V1/201—Constructional details of seismic cables, e.g. streamers

-

- G—PHYSICS

- G10—MUSICAL INSTRUMENTS; ACOUSTICS

- G10K—SOUND-PRODUCING DEVICES; METHODS OR DEVICES FOR PROTECTING AGAINST, OR FOR DAMPING, NOISE OR OTHER ACOUSTIC WAVES IN GENERAL; ACOUSTICS NOT OTHERWISE PROVIDED FOR

- G10K11/00—Methods or devices for transmitting, conducting or directing sound in general; Methods or devices for protecting against, or for damping, noise or other acoustic waves in general

- G10K11/004—Mounting transducers, e.g. provided with mechanical moving or orienting device

- G10K11/006—Transducer mounting in underwater equipment, e.g. sonobuoys

- G10K11/008—Arrays of transducers

Definitions

- This invention relates to a mechanical spacer for a towed acoustic array, such as is used in a so-called “seismic streamer”.

- a typical towed acoustic array comprises a long flexible tube, e.g. of PVC, in which a set of hydrophones are placed at spaced intervals.

- the hydrophones are spaced by being affixed to a strain member(s), e.g. wire rope(s) and are electrically connected to a wiring harness, both the strain member(s) and the electrical wiring passing down the inside of the tube.

- a strain member(s) e.g. wire rope(s) and are electrically connected to a wiring harness, both the strain member(s) and the electrical wiring passing down the inside of the tube.

- the hydrophones may be spaced apart at considerable distances, in relation to the tube diameter, it is customary to include one or more spaces in between successive hydrophones to prevent the strain member(s) and electrical wires from becoming twisted and entangled.

- the tube is also generally filled with a filling liquid of predetermined specific gravity to provide the completed structure with a required buoyancy in order that when towed it

- a known form of mechanical spacer for towed acoustic arrays is in the shape of a "doughnut", i.e. an anchor-ring, having a central aperture through which a strain wire is threaded and a number of equi-angularly spaced apertures disposed near the outer diameter through which electrical wires are threaded, the spacer being secured to the strain wire and to the electrical wires to prevent longitudinal movement therebetween.

- a spacer is difficult to assemble together with its strain wire and electrical wiring within the tube. Moreover, when assembled it restricts the ready flow of liquid down the tube when filling and emptying the array. Also it generates undesirable acoustic reflections within the tube due to the fact that it almost completely blocks the tube.

- a mechanical spacer for a towed array comprising an annular structure with a central aperture whereby electrical cables are located within an outer sheath with the spacers being secured to strain members passing within the outer sheath, characterised in that the annular structure is fabricated from a strip structure defining the central aperture, the strip being formed to provide angularly spaced outwardly facing recesses with respect to the central aperture in which recesses rope or like strain members can be secured to be held in parallel relationship between adjacent spacers distributed at intervals along the strain members.

- the arcuate strip sections are each formed with one or more radially outwardly resilient protrusions.

- the arcuate strip sections are each formed with one or more radially inwardly protruding locating means for locating and securing in the centre of the spacer an electronic equipment module.

- the spacer of Figs. 1-4 is a plastics moulding comprising three arcuate strip sections 10 joined together by intervening portions 11 which form radially outwardly facing U-shaped recesses 12 between the strip sections 10.

- the parallel inner walls of the recesses 12 are shaped with dovetail ridges 13.

- the portion 11 forming the base of each U-shaped recess has two arcuate support webs l5 projecting therefrom.

- a bunch of spacers are stacked together and loosely threaded with electrical cables passing down the centre space 16.

- the cables can then be drawn together with three Kevlar strain members not threaded through the stack of spacers.

- the three Kevlar ropes 17 are dropped one each into a respective U-shaped recess and a spring metal clip 18'is inserted into the recess to secure the spacer to the rope.

- the metal clips are W-shaped, the base 18a of the W passing on the rope and, in cooperation with the base of the recess, gripping the rope.

- the legs of the W have slots which engage the dovetail ridges B in the recess as the metal clips are pushed home, thus preventing the clips from being dislodged by any strain on the rope.

- the legs of the W also have sharp tines 18b which engage the walls of the recess to secure the clip under pressure against the rope.

- the loosely threaded electrical cables can then be caught up between one of the support webs 15 and the web portions 10.

- the spacer thus fitted in place secures the strain members and electrical cables in parallel relation to.the plastics hose. It presents little acoustic reflection and, being such an open structure, allows easy filling and emptying of the hose by a filling liquid or gel to achieve the desired net buoyancy.

- spacers of the type shown in Figs. 5 and 6 can be inserted. These spacers do not have any electrical cables threaded through them, so they can be simply inserted into the array with the three Kevlar ropes being dropped into the recesses and secured by metal clips.

- the three arcuate strip sections 10a together with the joining portions lla make a closed circle and the web portions lla are provided with rod-like members 21 which are a close fit on a hydrophone casing 22 (shown in dotted outline in Fig. 5).

- the ends of the plastic rods can be simply deformed by being brought briefly into contact with a hot iron so that, as shown in Fig. 6, they secure the casing 22 from longitudinal movement in the spacer.

- the electric cables are allowed to be in the outer spaces between the recesses 12. If the hydrophone spacer is placed between two other closely spaced spacers of the first type then, when the Kevlar ropes are kept in tension during towing, the hydrophone spacer will be maintained out of contact with the hose wall. The hydrophone will not then be subject to mechanical noise generated by contact between its supporting spacer and the hose. The only acoustic signals the hydrophone will receive will be those transmitted from the surrounding sea water through the hose wall and the filling liquid or gel in contact with the hydrophone.

- the rope may be encased in resilient material, and the base of the U-shaped recess may be formed with a ridge across the line of the rope.

- the resilient material When compressed into a recess by the metal clip the resilient material is indented by the transverse ridge.

- the base of the W-shaped clip may also have holes punched through it so that some of the compressed resilient material deforms through the holes, thus providing extra grip.

- the spacers of Figs. 5 and 6 can carry instead of hydrophones other electronic component modules, e.g. telemetry instrumentation.

Landscapes

- Physics & Mathematics (AREA)

- Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Acoustics & Sound (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Environmental & Geological Engineering (AREA)

- Geology (AREA)

- Remote Sensing (AREA)

- Multimedia (AREA)

- General Physics & Mathematics (AREA)

- Geophysics (AREA)

- Measurement Of Velocity Or Position Using Acoustic Or Ultrasonic Waves (AREA)

- Supports For Pipes And Cables (AREA)

- Support Of Aerials (AREA)

- Details Of Aerials (AREA)

- Transducers For Ultrasonic Waves (AREA)

Abstract

Description

- This invention relates to a mechanical spacer for a towed acoustic array, such as is used in a so-called "seismic streamer".

- A typical towed acoustic array comprises a long flexible tube, e.g. of PVC, in which a set of hydrophones are placed at spaced intervals. Conventionally the hydrophones are spaced by being affixed to a strain member(s), e.g. wire rope(s) and are electrically connected to a wiring harness, both the strain member(s) and the electrical wiring passing down the inside of the tube. Because the hydrophones may be spaced apart at considerable distances, in relation to the tube diameter, it is customary to include one or more spaces in between successive hydrophones to prevent the strain member(s) and electrical wires from becoming twisted and entangled. The tube is also generally filled with a filling liquid of predetermined specific gravity to provide the completed structure with a required buoyancy in order that when towed it will attain and maintain a given depth in the water.

- A known form of mechanical spacer for towed acoustic arrays is in the shape of a "doughnut", i.e. an anchor-ring, having a central aperture through which a strain wire is threaded and a number of equi-angularly spaced apertures disposed near the outer diameter through which electrical wires are threaded, the spacer being secured to the strain wire and to the electrical wires to prevent longitudinal movement therebetween. Such a spacer is difficult to assemble together with its strain wire and electrical wiring within the tube. Moreover, when assembled it restricts the ready flow of liquid down the tube when filling and emptying the array. Also it generates undesirable acoustic reflections within the tube due to the fact that it almost completely blocks the tube.

- According to the present invention there is provided a mechanical spacer for a towed array comprising an annular structure with a central aperture whereby electrical cables are located within an outer sheath with the spacers being secured to strain members passing within the outer sheath, characterised in that the annular structure is fabricated from a strip structure defining the central aperture, the strip being formed to provide angularly spaced outwardly facing recesses with respect to the central aperture in which recesses rope or like strain members can be secured to be held in parallel relationship between adjacent spacers distributed at intervals along the strain members.

- In a preferred embodiment the arcuate strip sections are each formed with one or more radially outwardly resilient protrusions.

- In an alternative embodiment the arcuate strip sections are each formed with one or more radially inwardly protruding locating means for locating and securing in the centre of the spacer an electronic equipment module.

- described with reference to the accompanying drawings, in which:-

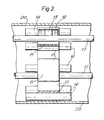

- Fig. 1 is an end view of a spacer,

- Fig. 2 is a part section view of the spacer of Fig. 1,

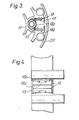

- Fig. 3 illustrates a detail of Fig. 1 showing security of a strain member,

- Fig. 4 is another view of the detail of Fig. 3,

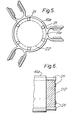

- Fig. 5 is an end view of an alternative spacer to that of Fig. 1, and

- Fig. 6 illustrates a partial detail of the spacer of Fig. 5.

- The spacer of Figs. 1-4 is a plastics moulding comprising three

arcuate strip sections 10 joined together by interveningportions 11 which form radially outwardly facing U-shapedrecesses 12 between thestrip sections 10. The parallel inner walls of therecesses 12 are shaped withdovetail ridges 13. Around the outer surfaces of the strip sections there are formed a number ofresilient protrusions 14, each being in the shape of a hollow tube-like structure having a comparatively thin wall section at its point furthermost from the centre of the spacer. Theportion 11 forming the base of each U-shaped recess has two arcuate support webs l5 projecting therefrom. - In use a bunch of spacers are stacked together and loosely threaded with electrical cables passing down the

centre space 16. The cables can then be drawn together with three Kevlar strain members not threaded through the stack of spacers. At intervals, the threeKevlar ropes 17 are dropped one each into a respective U-shaped recess and a spring metal clip 18'is inserted into the recess to secure the spacer to the rope. The metal clips are W-shaped, the base 18a of the W passing on the rope and, in cooperation with the base of the recess, gripping the rope. The legs of the W have slots which engage the dovetail ridges B in the recess as the metal clips are pushed home, thus preventing the clips from being dislodged by any strain on the rope. The legs of the W also havesharp tines 18b which engage the walls of the recess to secure the clip under pressure against the rope. The loosely threaded electrical cables can then be caught up between one of thesupport webs 15 and theweb portions 10. When the spacer has been secured to all three Kevlar ropes that section of the completed cable/rope assembly can be drawn into the plastics hose. The dimensions of the hose 20 (shown in dotted outline) and the outer diameter of the spacer are such that the spacer is a close fit in the hose. - The spacer thus fitted in place secures the strain members and electrical cables in parallel relation to.the plastics hose. It presents little acoustic reflection and, being such an open structure, allows easy filling and emptying of the hose by a filling liquid or gel to achieve the desired net buoyancy.

- At intervals along the seismic array additional spacers of the type shown in Figs. 5 and 6 can be inserted. These spacers do not have any electrical cables threaded through them, so they can be simply inserted into the array with the three Kevlar ropes being dropped into the recesses and secured by metal clips. The three

arcuate strip sections 10a together with the joining portions lla make a closed circle and the web portions lla are provided with rod-like members 21 which are a close fit on a hydrophone casing 22 (shown in dotted outline in Fig. 5). The ends of the plastic rods can be simply deformed by being brought briefly into contact with a hot iron so that, as shown in Fig. 6, they secure thecasing 22 from longitudinal movement in the spacer. The electric cables are allowed to be in the outer spaces between therecesses 12. If the hydrophone spacer is placed between two other closely spaced spacers of the first type then, when the Kevlar ropes are kept in tension during towing, the hydrophone spacer will be maintained out of contact with the hose wall. The hydrophone will not then be subject to mechanical noise generated by contact between its supporting spacer and the hose. The only acoustic signals the hydrophone will receive will be those transmitted from the surrounding sea water through the hose wall and the filling liquid or gel in contact with the hydrophone. - To assist the gripping of the Kevlar rope in the U-shaped recess, the rope may be encased in resilient material, and the base of the U-shaped recess may be formed with a ridge across the line of the rope. When compressed into a recess by the metal clip the resilient material is indented by the transverse ridge. The base of the W-shaped clip may also have holes punched through it so that some of the compressed resilient material deforms through the holes, thus providing extra grip.

- The spacers of Figs. 5 and 6 can carry instead of hydrophones other electronic component modules, e.g. telemetry instrumentation.

Claims (7)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| GB08313796A GB2140220B (en) | 1983-05-18 | 1983-05-18 | Mechanical spacer for towed acoustic array |

| GB8313796 | 1983-05-18 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0129337A2 true EP0129337A2 (en) | 1984-12-27 |

| EP0129337A3 EP0129337A3 (en) | 1986-11-12 |

Family

ID=10542989

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP84303387A Withdrawn EP0129337A3 (en) | 1983-05-18 | 1984-05-18 | Mechanical spacer for towed acoustic array |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US4638469A (en) |

| EP (1) | EP0129337A3 (en) |

| JP (1) | JPS59229994A (en) |

| CA (1) | CA1214404A (en) |

| GB (1) | GB2140220B (en) |

| NO (1) | NO841999L (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1995026514A1 (en) * | 1994-03-29 | 1995-10-05 | Thomson-Csf | Acoustic linear antenna and method for making same |

Families Citing this family (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2162638A (en) * | 1984-08-03 | 1986-02-05 | Britoil Plc | Vibration isolation section for a seismic streamer |

| GB2162637B (en) * | 1984-08-03 | 1987-12-16 | Britoil Plc | Seismic streamer section |

| DE3445489C2 (en) * | 1984-12-13 | 1986-11-20 | Messerschmitt-Bölkow-Blohm GmbH, 8012 Ottobrunn | Device for fastening several electrical lines in an aircraft |

| DE69429586T2 (en) * | 1993-04-06 | 2002-09-05 | Thomson Marconi Sonar Pty Ltd., Rydalmere | hydrophone |

| CA2116487A1 (en) * | 1993-05-07 | 1994-11-08 | Paul Howard Morris | Tubular guide and support system |

| US5943293A (en) * | 1996-05-20 | 1999-08-24 | Luscombe; John | Seismic streamer |

| GB2378758B (en) * | 1998-06-19 | 2003-04-09 | Nexans | A seismic cable |

| US6170783B1 (en) | 1998-07-29 | 2001-01-09 | Hendrix Wire & Cable, Inc. | Aerial cable retainer with resilient pad |

| US6997420B2 (en) * | 2003-09-03 | 2006-02-14 | Panduit Corp. | Pneumatic lockout device |

| US9097817B2 (en) * | 2008-06-30 | 2015-08-04 | Westerngeco L.L.C. | Seismic sensor cable |

| US8727024B2 (en) * | 2009-02-13 | 2014-05-20 | Board Of Regents Of The Nevada System Of Higher Education, On Behalf Of The Desert Research Institute | Sampling system and method |

| US9001617B2 (en) * | 2009-08-21 | 2015-04-07 | Westerngeco L.L.C. | Marine seismic streamer with increased skin stiffness |

| US8593906B2 (en) * | 2009-08-21 | 2013-11-26 | Westerngeco L.L.C. | Seismic sensor holder and method |

| US8783629B2 (en) * | 2010-07-29 | 2014-07-22 | Hydac Accessories Gmbh | Attachment system for lines, in particular for cables for wind turbines |

| EP3304131A4 (en) * | 2015-06-08 | 2019-03-13 | Schlumberger Technology B.V. | Seismic sensor cable |

| US10613241B2 (en) | 2016-06-24 | 2020-04-07 | Pgs Geophysical As | Streamer manufacturing |

| US10557953B2 (en) * | 2016-06-30 | 2020-02-11 | Pgs Geophysical As | Molded snap-in plug and device and method for using same |

| US10433926B2 (en) * | 2017-02-10 | 2019-10-08 | Maurice-Andre Recanati | Cable, wire and tube organizer for laparoscopic and hysteroscopic surgery |

| CN110164594B (en) * | 2019-06-06 | 2020-11-13 | 义乌市佳倩科技有限公司 | Compression-resistant composite cable |

| CN111799029B (en) * | 2020-07-17 | 2022-02-22 | 安徽徽宁电器仪表集团有限公司 | Fire-resistant and high-temperature-resistant control cable and manufacturing method thereof |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3290645A (en) * | 1964-02-13 | 1966-12-06 | Whitehall Electronics Corp | Method and underwater streamer apparatus for improving the fidelity of recorded seismic signals |

| US4296481A (en) * | 1979-12-17 | 1981-10-20 | Exploration Company | Streamer bulkhead |

| FR2496902A1 (en) * | 1980-12-24 | 1982-06-25 | Saint Gaudens Atel Meca | Reinforced sheathing for extended seismic probe segments - to increase sensitivity by minimising spurious noise |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB570000A (en) * | 1943-11-19 | 1945-06-18 | Standard Telephones Cables Ltd | Improvements in or relating to electric insulators |

| GB1011540A (en) * | 1961-06-22 | 1965-12-01 | Int Computers & Tabulators Ltd | Improvements in or relating to apparatus for supporting electrical conductors |

| US3463870A (en) * | 1968-02-14 | 1969-08-26 | Preformed Line Products Co | Spacer/damper |

| US3476868A (en) * | 1968-03-13 | 1969-11-04 | Preformed Line Products Co | Cable spreader |

| US3978276A (en) * | 1975-05-02 | 1976-08-31 | Preformed Line Products Company | Spacer-damper |

| ZA792473B (en) * | 1978-06-08 | 1980-07-30 | Dulmison Pty Ltd | Spacer damper |

| US4178467A (en) * | 1978-07-07 | 1979-12-11 | Aluminum Company Of America | Boltless spacer device |

-

1983

- 1983-05-18 GB GB08313796A patent/GB2140220B/en not_active Expired

-

1984

- 1984-05-18 NO NO841999A patent/NO841999L/en unknown

- 1984-05-18 CA CA000454728A patent/CA1214404A/en not_active Expired

- 1984-05-18 US US06/611,976 patent/US4638469A/en not_active Expired - Fee Related

- 1984-05-18 JP JP59100351A patent/JPS59229994A/en active Pending

- 1984-05-18 EP EP84303387A patent/EP0129337A3/en not_active Withdrawn

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3290645A (en) * | 1964-02-13 | 1966-12-06 | Whitehall Electronics Corp | Method and underwater streamer apparatus for improving the fidelity of recorded seismic signals |

| US4296481A (en) * | 1979-12-17 | 1981-10-20 | Exploration Company | Streamer bulkhead |

| FR2496902A1 (en) * | 1980-12-24 | 1982-06-25 | Saint Gaudens Atel Meca | Reinforced sheathing for extended seismic probe segments - to increase sensitivity by minimising spurious noise |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1995026514A1 (en) * | 1994-03-29 | 1995-10-05 | Thomson-Csf | Acoustic linear antenna and method for making same |

| FR2718316A1 (en) * | 1994-03-29 | 1995-10-06 | Thomson Csf | Acoustic linear antenna and its manufacturing process. |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0129337A3 (en) | 1986-11-12 |

| GB2140220B (en) | 1987-01-07 |

| GB2140220A (en) | 1984-11-21 |

| US4638469A (en) | 1987-01-20 |

| CA1214404A (en) | 1986-11-25 |

| JPS59229994A (en) | 1984-12-24 |

| NO841999L (en) | 1984-11-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4638469A (en) | Mechanical spacer for towed acoustic array | |

| EP1123518B1 (en) | Marine seismic streamer and method of making it | |

| EP0085072B1 (en) | Hydrophone cable | |

| US5069254A (en) | Conduit assembly for cabling | |

| US8611180B2 (en) | Ocean bottom seismic station | |

| US9170344B2 (en) | System and method for deployment of seismic data recorders | |

| EP2293115B1 (en) | Towed marine sensor streamer having concentric stress member | |

| US4295212A (en) | Linear acoustic array | |

| US5335620A (en) | Protective fairing for underwater sensor line array | |

| EP0113623B1 (en) | Construction and method for elongated towed underwater sonar | |

| US5130954A (en) | Leader cable anchor for a geophone | |

| AU600373B2 (en) | Submarine telecommunication line comprising optical fibers | |

| US4716833A (en) | Method of assembling a tanged charge holder | |

| US4636998A (en) | Elongated retaining and electromagnetic shielding member for a towed underwater acoustic array | |

| US10605936B2 (en) | Geophysical sensor cable methods and systems | |

| US4716554A (en) | Tapered wiring harness | |

| US6292431B1 (en) | Marine seismic cable termination | |

| US20020114219A1 (en) | Seismic cables and a method for manufacturing such | |

| US6294727B1 (en) | Takeout anchor and protective cover | |

| US6783100B1 (en) | Fluted link for wiring | |

| US4606593A (en) | Electric wire connector | |

| MXPA01004253A (en) | Method of making a marine seismic streamer | |

| Irish et al. | Coil-Cord Conductors on Compliant Elastic Moorings | |

| CA2064453A1 (en) | Method and apparatus for shallow water seismic operations |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): BE DE FR IT NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): BE DE FR IT NL SE |

|

| 17P | Request for examination filed |

Effective date: 19870331 |

|

| 17Q | First examination report despatched |

Effective date: 19881007 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19890218 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: BRYANT, MICHAEL JOHN Inventor name: SYKES, CHRISTOPHER GRAHAM Inventor name: ATTENBOROUGH, FRANK RICHARD Inventor name: CAMERON, NEIL WILSON |