EP0124871A2 - Dispositif doseur de céréales pour broyeurs à cylindres - Google Patents

Dispositif doseur de céréales pour broyeurs à cylindres Download PDFInfo

- Publication number

- EP0124871A2 EP0124871A2 EP84104956A EP84104956A EP0124871A2 EP 0124871 A2 EP0124871 A2 EP 0124871A2 EP 84104956 A EP84104956 A EP 84104956A EP 84104956 A EP84104956 A EP 84104956A EP 0124871 A2 EP0124871 A2 EP 0124871A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- cereal

- roller

- baffle

- deviator element

- feed roller

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C4/00—Crushing or disintegrating by roller mills

- B02C4/28—Details

- B02C4/286—Feeding devices

Definitions

- This invention relates to a cereal flow regulator device for roller mills.

- Cereal roller mills are known in which the product to be ground is introduced from the outside into a feed hopper from which it is transferred between two grinding rolls. In order to utilise said rolls over their entire length and at the same time attain high mill productivity, it is known to interpose between said feed hopper and said rolls a pair of rollers having the double purpose of distributing the cereal to be ground over the entire length of the underlying grinding rolls, and of feeding it in a quantity corresponding to the quantity of product entering the mill.

- Each grinding section of known roller mills currently comprises two rollers, which are together called feed rollers but in reality perform different tasks.

- this feed roller essentially performs the task of distributing the cereal over the entire width of the underlying grinding rolls, whereas the other essentially performs the task of feeding the cereal to be ground.

- this feed roller is provided with a baffle which when there are no external stresses substantially adheres to its lateral surface, but becomes spaced apart by a greater or lesser extent therefrom according to the quantity of material entering the feed hopper, in order to cause a corresponding quantity of it to become discharged on to the grinding rolls.

- the object of the invention is to obviate these drawbacks by providing a roller mill which has its feed roller disposed downstream of the distributor roller, but which at the same time operates under conditions of maximum efficiency and maximum quietness over the entire performance range for which the machine has been dimensioned.

- a cereal flow regulator device for roller mills comprising a feed roller disposed downstream of the feed hopper, and a mobile baffle which can be spaced apart from said feed roller in order to regulate the flow of cereal towards the grinding rolls as a function of the cereal throughput at the machine inlet, characterised by comprising a deviator of length substantially equal to the length of said baffle, and which is disposed downstream of this latter and is mounted on a hinged support which varies its position in relation to the cereal throughput in order to always direct it between the grinding rolls.

- the deviator element can be of such a configuration that its tangential plane at the zone of impact of the sheet of cereal substantially coincides with the plane which at that zone is tangential to the parabola through which the sheet of cereal falls.

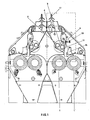

- the device according to the invention is essentially used in cereal roller mills comprising a pair of grinding rolls which receive the cereal to be ground from a pair of overlying feed rollers.

- known roller mills comprise two constructionally identical grinding sections which are disposed back-to-back and can perform either the same or different operations on the cereal, and therefore for reasons of simplicity only one section is described hereinafter, the same description also being valid for the other.

- the roller mill to which the device according to the invention is fitted comprises, for each section, a pair of grinding rolls 1,1', which are in contact along a generating line which constitutes the grinding generating line, and are rotated in opposite directions at different speeds.

- the two rollers 2 and 3 constituting respectively the distributor roller and feed roller are disposed above the grinding rolls 1,1' in a position substantially corresponding with the lower discharge aperture of a hopper 4 which receives the cereal to be ground.

- the roller 2, which as stated constitutes the distributor roller comprises a plurality of radial blades (not shown) inclined in such a direction as to distribute the cereal to be ground from its centre towards its end. It is rotated in the direction of the arrow 5.

- the roller 3, which constitutes the actual feed roller, is disposed side-by-side with the roller 2 in a slightly lower position than this latter, and is rotated in the same direction as the roller 2 but at greater speed.

- a baffle 6 essentially constituted by a curved section bar of length equal to the length of the roller 3.

- Two lugs 7 are welded to the baffle 6 in order to connect two forked rods 8, which themselves are connected to two arms 9.

- the arms 9 are operated by conventional systems in relation to the upward or downward variation in the quantity of cereal entering the hopper 4.

- the connection between the forked rods 8 and the relative arms 9 is made by way of screw elements 10 in order to set the minimum opening of the baffle 6, as described hereinafter.

- baffle 6 The lateral supports by which the baffle 6 is moved during opening are not shown for simplicity of representation, said baffle rotating about an axis coinciding with the axis of curvature thereof so that the curved surface of said baffle always remains adhering to the wall of the hopper 4.

- a deviator element 11 rests longitudinally against the baffle 6. It is constituted by a curved section bar of the same length as the baffle 6, and is provided with lugs 12 to which there are hinged arms 13, which are also hinged to the machine shoulders 14. In order to set the position of the deviator element 11 in the required manner, the connection between the lugs 12 and arms 13 is made by means of slotted holes, and the connection between the arms 13 and shoulders 14 is made by means of eccentric pins.

- the deviator element adheres by gravity to the baffle 6 at its upper longitudinal edge, as can be clearly seen from the drawings. It is also curved lowerly in such a manner as to "embrace" the roller 3 and extend into an underlying channel 15 for feeding the cereal to the grinding rolls 1,1'.

- one wall 16 of said channel 15 can assume several positions (two possible positions are shown on the drawings), as it has been found that on varying the cereal throughput it is advisable to also vary the degree of opening of said channel 15 so that the quantity of air drawn in is such as not to break the cereal sheet down, and not to cause irregularity in the machine operation.

- a conventional member 17 sensitive to the weight of the cereal to be ground, and arranged to adjust the degree of opening of the baffle 6 in relation to this latter, using conventional methods.

- the deviator element 11 rests upperly on the baffle 6 by gravity, and is just separated lowerly from the roller 3 and wall 16 of the channel 15, to which it substantially adheres.

- the two constantly rotating grinding rolls 1,1' are spaced apart, and the machine is in its waiting state. If the cereal to be ground is now fed into the hopper 4, the member 17 is urged downwards by a distance proportional to the quantity of said cereal, and firstly causes the two rolls 1,1' to approach each other until they have reached their correct working position.

- the two rollers 2 and 3 are then started, and the shaft 19, to which the arms 9 are keyed, is then rotated by an amount relative to the quantity of cereal striking the member 17, with the result that the baffle 6 opens in the direction of the arrow 20.

- the upper edge of the baffle 6 urges the deviator element 11 in the direction of the arrow 21, and withdraws it from the roller 3.

- the configuration of the deviator element 11 is such that its tangential plane where it makes contact with the sheet of cereal which has left the roller 3 substantially coincides, at every position, with the plane tangential to the parabola through which said sheet falls, this latter therefore being progressively deviated towards the grinding zone for the two rolls 1,1' without undergoing any breakdown.

- the deviator element 11 also performs another important function, in that by virtue of its embracing configuration and its lower elongation, it comes into contact with the flow of material before this has left the roller 3, and thus right from the beginning it opposes its tendency to diverge by centrifugal action. Because of this, said deviator element not only prevents breakdown of the material sheet, but instead by exercising a effect, ie a transverse constricting effect on the sheet of cereal, it adjusts it to the required thinness before conveying it along the channel 15 into the grinding zone.

- the correct configuration of the deviator element 11 can be determined theoretically, but is preferably determined empirically, after the necessary experimental tests.

Landscapes

- Engineering & Computer Science (AREA)

- Food Science & Technology (AREA)

- Crushing And Grinding (AREA)

- Adjustment And Processing Of Grains (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| IT84113/83A IT1172827B (it) | 1983-05-06 | 1983-05-06 | Dispositivo regolatore del flusso di cereale per laminatoi |

| IT8411383 | 1983-05-06 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0124871A2 true EP0124871A2 (fr) | 1984-11-14 |

| EP0124871A3 EP0124871A3 (fr) | 1986-02-05 |

Family

ID=11324180

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP84104956A Ceased EP0124871A3 (fr) | 1983-05-06 | 1984-05-03 | Dispositif doseur de céréales pour broyeurs à cylindres |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0124871A3 (fr) |

| ES (1) | ES8503971A1 (fr) |

| IT (1) | IT1172827B (fr) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108787031A (zh) * | 2018-07-20 | 2018-11-13 | 福建美斯拓机械设备有限公司 | 一种重锤式破碎机 |

| CN109985692A (zh) * | 2019-03-05 | 2019-07-09 | 广东技术师范学院天河学院 | 一种立式磨粉机 |

| US11185867B2 (en) | 2018-05-25 | 2021-11-30 | Bühler AG | Distribution metering device for a roller mill, roller mill with such a distribution metering device, method for grinding grinding stock, and roller mill comprising a switching cabinet with a cooling system |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN114367341A (zh) * | 2021-12-30 | 2022-04-19 | 浙江百姿化妆品股份有限公司 | 一种水性持久型唇彩及其制备方法和系统 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1058697A (fr) * | 1952-06-25 | 1954-03-18 | Perfectionnements de l'alimentation des moulins à cylindres | |

| FR1161609A (fr) * | 1956-11-08 | 1958-09-02 | Socam Sa | Dispositif d'alimentation accélérée pour appareils à cylindres utilisés notamment en meunerie |

| DE1137289B (de) * | 1958-01-13 | 1962-09-27 | Buehler Ag Geb | Speisevorrichtung fuer Muellereiwalzenstuhl |

| FR2320780A1 (fr) * | 1975-08-13 | 1977-03-11 | Siraga | Dispositif d'alimentation d'un broyeur a cylindres |

-

1983

- 1983-05-06 IT IT84113/83A patent/IT1172827B/it active

-

1984

- 1984-05-03 EP EP84104956A patent/EP0124871A3/fr not_active Ceased

- 1984-05-04 ES ES532681A patent/ES8503971A1/es not_active Expired

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1058697A (fr) * | 1952-06-25 | 1954-03-18 | Perfectionnements de l'alimentation des moulins à cylindres | |

| FR1161609A (fr) * | 1956-11-08 | 1958-09-02 | Socam Sa | Dispositif d'alimentation accélérée pour appareils à cylindres utilisés notamment en meunerie |

| DE1137289B (de) * | 1958-01-13 | 1962-09-27 | Buehler Ag Geb | Speisevorrichtung fuer Muellereiwalzenstuhl |

| FR2320780A1 (fr) * | 1975-08-13 | 1977-03-11 | Siraga | Dispositif d'alimentation d'un broyeur a cylindres |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11185867B2 (en) | 2018-05-25 | 2021-11-30 | Bühler AG | Distribution metering device for a roller mill, roller mill with such a distribution metering device, method for grinding grinding stock, and roller mill comprising a switching cabinet with a cooling system |

| CN108787031A (zh) * | 2018-07-20 | 2018-11-13 | 福建美斯拓机械设备有限公司 | 一种重锤式破碎机 |

| CN109985692A (zh) * | 2019-03-05 | 2019-07-09 | 广东技术师范学院天河学院 | 一种立式磨粉机 |

Also Published As

| Publication number | Publication date |

|---|---|

| IT8384113A0 (it) | 1983-05-06 |

| ES532681A0 (es) | 1985-04-16 |

| EP0124871A3 (fr) | 1986-02-05 |

| ES8503971A1 (es) | 1985-04-16 |

| IT1172827B (it) | 1987-06-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0771590A1 (fr) | Appareil de décorticage | |

| US4661025A (en) | Apparatus for forming a fiber column in a chute feed | |

| EP0124871A2 (fr) | Dispositif doseur de céréales pour broyeurs à cylindres | |

| US4815170A (en) | Waste separator for a licker-in in a carding machine | |

| US6345417B2 (en) | Sliver trumpet for forming a sliver from a fiber web | |

| US3930571A (en) | Apparatus for aligning elongated articles | |

| US4162767A (en) | Impacting crusher with variable flow feed distributor | |

| US3709406A (en) | Method and apparatus for producing an even continuous layer of fibers | |

| US5845367A (en) | Double-cylinder opener and relative process for opening and cleaning staple fiber by progressive action | |

| US5530994A (en) | Dust and trash removal system for carding machines | |

| US5277204A (en) | Device for the directed supply of tobacco ribs to a cutting tool | |

| US4009803A (en) | Web former | |

| US5839166A (en) | Carding machine and process for producing an aerodynamic card web | |

| CN102894464B (zh) | 用于分散烟草、如烟纤维、烟叶或部分烟叶的装置 | |

| CN110756442B (zh) | 物料分离设备及物料投放系统 | |

| US4064598A (en) | Taker-in-part of the conventional flat card | |

| US4126913A (en) | Opening machinery for textile fibers | |

| US5926918A (en) | Apparatus and method for opening and for reclaiming fibers | |

| US2619011A (en) | Paper machinery | |

| US4100650A (en) | Adjustable feed plate | |

| US2785683A (en) | davidson | |

| NO129411B (fr) | ||

| US1355093A (en) | Grinding-machine | |

| US4324353A (en) | Apparatus for handling textile filamentary material | |

| US1842053A (en) | Cap feeding machine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT CH DE FR GB IT LI SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): AT CH DE FR GB IT LI SE |

|

| 17P | Request for examination filed |

Effective date: 19861005 |

|

| 17Q | First examination report despatched |

Effective date: 19880518 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN REFUSED |

|

| 18R | Application refused |

Effective date: 19891107 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: PIACENTINI, FRANCESCO Inventor name: CRIVELLARO, ANTONIO |