EP0122397B1 - Carrier for two rows of bottles - Google Patents

Carrier for two rows of bottles Download PDFInfo

- Publication number

- EP0122397B1 EP0122397B1 EP84101674A EP84101674A EP0122397B1 EP 0122397 B1 EP0122397 B1 EP 0122397B1 EP 84101674 A EP84101674 A EP 84101674A EP 84101674 A EP84101674 A EP 84101674A EP 0122397 B1 EP0122397 B1 EP 0122397B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- bottle

- carrier

- bottles

- rows

- handle

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 210000003739 neck Anatomy 0.000 claims description 11

- 210000002105 tongue Anatomy 0.000 description 6

- 238000004806 packaging method and process Methods 0.000 description 2

- 230000006641 stabilisation Effects 0.000 description 2

- 238000011105 stabilization Methods 0.000 description 2

- 241001411320 Eriogonum inflatum Species 0.000 description 1

- 239000000853 adhesive Substances 0.000 description 1

- 230000001070 adhesive effect Effects 0.000 description 1

- 238000010009 beating Methods 0.000 description 1

- 239000000969 carrier Substances 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 238000004080 punching Methods 0.000 description 1

- 125000006850 spacer group Chemical group 0.000 description 1

- 230000000087 stabilizing effect Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D71/00—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans or pop bottles; Bales of material

- B65D71/06—Packaging elements holding or encircling completely or almost completely the bundle of articles, e.g. wrappers

- B65D71/12—Packaging elements holding or encircling completely or almost completely the bundle of articles, e.g. wrappers the packaging elements, e.g. wrappers being formed by folding a single blank

- B65D71/14—Packaging elements holding or encircling completely or almost completely the bundle of articles, e.g. wrappers the packaging elements, e.g. wrappers being formed by folding a single blank having a tubular shape, e.g. tubular wrappers without end walls

- B65D71/16—Packaging elements holding or encircling completely or almost completely the bundle of articles, e.g. wrappers the packaging elements, e.g. wrappers being formed by folding a single blank having a tubular shape, e.g. tubular wrappers without end walls with article-locating elements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D71/00—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans or pop bottles; Bales of material

- B65D71/06—Packaging elements holding or encircling completely or almost completely the bundle of articles, e.g. wrappers

- B65D71/12—Packaging elements holding or encircling completely or almost completely the bundle of articles, e.g. wrappers the packaging elements, e.g. wrappers being formed by folding a single blank

- B65D71/14—Packaging elements holding or encircling completely or almost completely the bundle of articles, e.g. wrappers the packaging elements, e.g. wrappers being formed by folding a single blank having a tubular shape, e.g. tubular wrappers without end walls

- B65D71/28—Packaging elements holding or encircling completely or almost completely the bundle of articles, e.g. wrappers the packaging elements, e.g. wrappers being formed by folding a single blank having a tubular shape, e.g. tubular wrappers without end walls characterised by the handles

- B65D71/30—Packaging elements holding or encircling completely or almost completely the bundle of articles, e.g. wrappers the packaging elements, e.g. wrappers being formed by folding a single blank having a tubular shape, e.g. tubular wrappers without end walls characterised by the handles unitary, i.e. integral with the tubular packaging elements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2571/00—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans, pop bottles; Bales of material

- B65D2571/00123—Bundling wrappers or trays

- B65D2571/00129—Wrapper locking means

- B65D2571/00135—Wrapper locking means integral with the wrapper

- B65D2571/00154—Wrapper locking means integral with the wrapper interlocked

- B65D2571/0016—Wrapper locking means integral with the wrapper interlocked by tabs protruding from one end and co-operating with openings at the other end

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2571/00—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans, pop bottles; Bales of material

- B65D2571/00123—Bundling wrappers or trays

- B65D2571/00129—Wrapper locking means

- B65D2571/00135—Wrapper locking means integral with the wrapper

- B65D2571/00154—Wrapper locking means integral with the wrapper interlocked

- B65D2571/00172—Wrapper locking means integral with the wrapper interlocked by tabs cut within one end and facing towards the other end when blank is unfolded, and co-operting with openings at the other end

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2571/00—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans, pop bottles; Bales of material

- B65D2571/00123—Bundling wrappers or trays

- B65D2571/00246—Locating elements for the contents

- B65D2571/00253—Locating elements for the contents integral with the wrapper

- B65D2571/00277—Slits or openings formed along a fold line

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2571/00—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans, pop bottles; Bales of material

- B65D2571/00123—Bundling wrappers or trays

- B65D2571/00246—Locating elements for the contents

- B65D2571/00253—Locating elements for the contents integral with the wrapper

- B65D2571/0029—Openings in top or bottom walls

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2571/00—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans, pop bottles; Bales of material

- B65D2571/00123—Bundling wrappers or trays

- B65D2571/00246—Locating elements for the contents

- B65D2571/0032—Locating elements for the contents inserted the wrapper

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2571/00—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans, pop bottles; Bales of material

- B65D2571/00123—Bundling wrappers or trays

- B65D2571/00432—Handles or suspending means

- B65D2571/00456—Handles or suspending means integral with the wrapper

- B65D2571/00475—Handles or suspending means integral with the wrapper and extending ion a substantially vertical plane

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2571/00—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans, pop bottles; Bales of material

- B65D2571/00123—Bundling wrappers or trays

- B65D2571/00432—Handles or suspending means

- B65D2571/00518—Handles or suspending means with reinforcements

- B65D2571/00524—Handles or suspending means with reinforcements integral

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2571/00—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans, pop bottles; Bales of material

- B65D2571/00123—Bundling wrappers or trays

- B65D2571/00648—Elements used to form the wrapper

- B65D2571/00654—Blanks

- B65D2571/0066—Blanks formed from one single sheet

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2571/00—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans, pop bottles; Bales of material

- B65D2571/00123—Bundling wrappers or trays

- B65D2571/00709—Shape of the formed wrapper, i.e. shape of each formed element if the wrapper is made from more than one element

- B65D2571/00716—Shape of the formed wrapper, i.e. shape of each formed element if the wrapper is made from more than one element tubular without end walls

Definitions

- the invention relates to a two-row, sleeve-shaped bottle carrier, in particular for bottles with a conical neck part, with a bottom wall and two side walls, and a top wall, possibly equipped with inclined walls, in which openings are provided for at least partially projecting through the upper bottle ends, and with one additional bottle holder, which has a flat, horizontally running surface with recesses in which the bottle necks are able to engage and which are arranged at least a short distance from the top wall.

- the object of the present invention is to fix bottles with in particular conical neck parts in sleeve-shaped bottle carriers so that the bottles cannot move.

- the additional bottle holder for each of the two rows of bottles has a flat, horizontally running section which is provided with the recesses for the bottle necks.

- the bottle holder has approximately semicircular recesses which are arranged on both longitudinal edges of the bottle holder, the advantages mentioned above can be achieved with a minimum of material.

- the bottle holder has approximately circular recesses for the passage of the bottle necks, and that two side surfaces are articulated on the longitudinal edges of the horizontally running surfaces via fold lines, which lie against the inner sides of the side walls of the bottle carrier.

- the advantage of this configuration of the bottle holder lies primarily in the easier attachment of the sleeve-shaped bottle carrier. The bottles are held reliably and cannot evade when the bottle carrier blank is folded and closed. The side stripes serve to further stabilize and stiffen the packaging.

- holding tongues are arranged on the edge of the recesses, which protrude into the recesses and are supported on their closure parts when bottles are inserted.

- the retaining tongues which are located under the projections on the bottle head or on the bottle stopper, e.g. B. on the underside of crown corks, prevent an upward movement of the entire bottle holder in the bottle carrier, so that it always lies firmly on the bottles.

- the top wall has two sections which run obliquely upwards towards the center of the bottle carrier and continue in a handle which also has two part walls, these two part walls of the handle being connected to one another in a hinge-like manner and each having a passage opening , wherein the cardboard strip punched out of the one partial wall has two sections connected by a folding line, one section of which extends between the two partial walls of the handle and the other section is fixed to the other partial wall.

- the bottle holder is provided with an additional stabilizing handle, which allows the bottle holder to be carried correctly and also precisely defines the angle between the two part walls of the handle, thereby avoiding uncontrolled loading of the bottle holder walls and thus their tearing open.

- the bottle holder according to the invention consists of two sections which are connected via an inverted V-shaped middle section which is between the two partial walls of the handle is folded.

- the inverted V-shaped central section of the bottle holder is provided with punched-out areas which are arranged at least approximately congruently with the through openings of the handle.

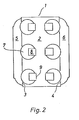

- FIG. 1 shows a bottle holder with a top wall 10, upper inclined walls 11, side walls 12, lower inclined walls 13 and a bottom wall 14.

- a bottle holder 1 is inserted into this bottle holder.

- this has a horizontal surface 2 on which side surfaces 5 and 6 are articulated via two folding lines 3 and 4.

- recesses 7 are provided, which also extend to a small extent via the folding lines 3 and 4 into the side surfaces 5 and 6.

- the two side surfaces 5 and 6 are folded down about the folding lines 3 and 4 and lie against the inner surfaces of the side walls 12 of the bottle carrier.

- Bottles 15 are held on their conical neck parts in the recesses 7 of the horizontal surface 2.

- the retaining tongues 8 are bent upward about the articulation line 9 by approximately 90 ° and are supported on the underside of crown caps 16 of the bottles 15.

- FIGS. 3 and 4 show two further configurations of bottle holders, 20 and 200 denote the horizontal surfaces, 70 and 700 semicircular recesses and 80 holding tongues.

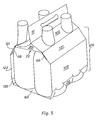

- FIG. 5 shows a bottle carrier with a top wall 100, on which a handle 17 is formed, which has the shape of an inverted “V”.

- the bottle carrier also consists of side walls 120 with upper side wall sections 121 and lower side wall sections 122 as well as lower inclined walls 130 and a bottom wall 140.

- a bottle holder 23 is inserted into this bottle holder, which is designed like the bottle holder shown in FIG. 2, only the retaining tongues 8 have been omitted.

- the two side surfaces 50 and 60 are supported on the inner sides of the two upper side wall sections 121.

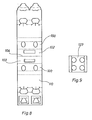

- FIG. 6 shows a bottle carrier 101, which is unfolded from the blank 110 shown in FIG. 8 and closed at its bottom.

- the bottle carrier 101 On its upper side, the bottle carrier 101 is provided with a handle which is formed from two part walls 102 and 103 which are connected to one another via a folding line 104 and which are articulated to the adjacent sections of the top wall 100.

- a bottle holder 123 which is shown lying flat in FIG. 9, is arranged below this top wall.

- a cardboard strip with two sections 107 and 108 is formed on the handle part wall 103, of which the outer section 108 is articulated to the handle part wall 102 on the outside and glued to it.

- the section 107 represents a spacer for the two handle part walls 102 and 103.

- the bottle carrier 101 is configured in the same way as in FIG. 6.

- the bottle holder consists of two sections 223, 224, which are connected via a central section consisting of two walls 225, 226.

- This middle section 225, 226 is reversed, folded in a V-shape and extends between the handle part walls 102, 103. Both walls 225, 226 of this middle section are provided with punchings (not shown) which are congruent with the through openings of the handle.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Packages (AREA)

Description

Die Erfindung bezieht sich auf einen zweireihigen, hülsenförmigen Flaschenträger, insbesondere für Flaschen mit einem konischen Halsteil, mit einer Bodenwand und zwei Seitenwänden sowie einer evtl. mit Schrägwänden ausgerüsteten Deckwand, in der Öffnungen zum wenigstens teilweisen Durchragen der oberen Flaschenenden vorgesehen sind, sowie mit einer zusätzlichen Flaschenhalterung, die eine ebene, horizontal verlaufende Fläche mit Ausnehmungen aufweist, in welche die Flaschenhälse einzugreifen vermögen und die in wenigstens geringem Abstand von der Deckwand angeordnet sind.The invention relates to a two-row, sleeve-shaped bottle carrier, in particular for bottles with a conical neck part, with a bottom wall and two side walls, and a top wall, possibly equipped with inclined walls, in which openings are provided for at least partially projecting through the upper bottle ends, and with one additional bottle holder, which has a flat, horizontally running surface with recesses in which the bottle necks are able to engage and which are arranged at least a short distance from the top wall.

Aus der FR-A 1470 577 ist ein derartiger zweireihiger Flaschenträger mit einer zusätzlichen Flaschenhalterung bekannt. Insbesondere für die Verpackung und Festlegung von Fiaschen mit konischen Halspartien ist dieser Flaschenhalter jedoch nicht geeignet. Eine Stabilisierung der Flaschen ist hierbei auch gar nicht vorgesehen, vielmehr soll das Aneinanderschlagen der Flaschen vermindert werden.From FR-A 1470 577 such a two-row bottle carrier with an additional bottle holder is known. However, this bottle holder is particularly unsuitable for packaging and fixing bottles with conical neck areas. A stabilization of the bottles is also not provided here, rather the beating of the bottles together should be reduced.

Der vorliegenden Erfindung liegt die Aufgabe zugrunde, Flaschen mit insbesondere konischen Halspartien in hülsenförmigen Flaschenträgern so festzulegen, dass sich die Flaschen nicht bewegen können.The object of the present invention is to fix bottles with in particular conical neck parts in sleeve-shaped bottle carriers so that the bottles cannot move.

Diese Aufgabe wird erfindungsgemäss dadurch gelöst, dass die zusätzliche Flaschenhalterung für jede der beiden Flaschenreihen einen ebenen, horizontal verlaufenden Abschnitt aufweist, der mit den Ausnehmungen für die Flaschenhälse versehen ist.This object is achieved according to the invention in that the additional bottle holder for each of the two rows of bottles has a flat, horizontally running section which is provided with the recesses for the bottle necks.

Diese Ausnehmungen in der horizontalen Fläche der Flaschenhalterung verhindern, dass sich die Flaschen im Träger relativ zueinander bewegen können. Eine solche Relativbewegung in Richtung der Flaschenreihe würde ein Herausfallen der Flaschen aus der Tragepackung bewirken. Ebenfalls verhindert die Flaschenhalterung eine Relativbewegung der oberen Flaschenenden beider Reihen aufeinander zu, wie sie beim unsachgemässen Ergreifen der Tragepackung vorkommt. Die dabei infolge der Flaschenform auftretende extreme Belastung des Steck- oder Klebeverschlusse an der Bodenseite des Flaschenträgers würde sonst zu dessen Beschädigung führen.These recesses in the horizontal surface of the bottle holder prevent the bottles in the carrier from moving relative to one another. Such a relative movement in the direction of the row of bottles would cause the bottles to fall out of the carrier pack. The bottle holder also prevents the upper bottle ends of both rows from moving relative to one another, as occurs when the carrier pack is gripped improperly. The extreme load on the plug or adhesive closure on the bottom side of the bottle carrier that occurs as a result of the bottle shape would otherwise lead to its damage.

Weist die Flaschenhalterung erfindungsgemäss etwa halbkreisförmige Ausnehmungen auf, die an beiden Längskanten der Flaschenhalterung angeordnet sind, so können bereits mit minimalem Materialaufwand die vorher genannten Vorteile erreicht werden.If, according to the invention, the bottle holder has approximately semicircular recesses which are arranged on both longitudinal edges of the bottle holder, the advantages mentioned above can be achieved with a minimum of material.

Bei einer weiteren Ausgestaltung der Erfindung ist vorgesehen, dass die Flaschenhalterung etwa kreisförmige Ausnehmungen für den Durchtritt der Flaschenhälse aufweist, und dass an den Längskanten der horizontal verlaufenden Flächen über Faltlinien zwei Seitenflächen angelenkt sind, welche an den Innenseiten der Seitenwände des Flaschenträgers anliegen. Der Vorteil dieser Ausgestaltung des Flaschenhalters liegt in erster Linie beim erleichterten Anbringen des hülsenförmigen Flaschenträgers. Dabei werden die Flaschen zuverlässig gehalten und können beim Herumfalten und Verschliessen des Flaschenträger-Zuschnittes nicht ausweichen. Die Seitenstreifen dienen zur weiteren Stabilisierung und Versteifung der Verpackung.In a further embodiment of the invention it is provided that the bottle holder has approximately circular recesses for the passage of the bottle necks, and that two side surfaces are articulated on the longitudinal edges of the horizontally running surfaces via fold lines, which lie against the inner sides of the side walls of the bottle carrier. The advantage of this configuration of the bottle holder lies primarily in the easier attachment of the sleeve-shaped bottle carrier. The bottles are held reliably and cannot evade when the bottle carrier blank is folded and closed. The side stripes serve to further stabilize and stiffen the packaging.

Gemäss einer vorteilhaften Ausgestaltung der Erfindung kann auch vorgesehen sein, dass am Rand der Ausnehmungen Haltezungen angeordnet sind, welche in die Ausnehmungen hineinragen und sich beim Einsetzen von Flaschen an an deren Verschlussteilen abstützen.According to an advantageous embodiment of the invention, it can also be provided that holding tongues are arranged on the edge of the recesses, which protrude into the recesses and are supported on their closure parts when bottles are inserted.

Die Haltezungen, die unter am Flaschenkopf oder am Flaschenverschluss befindliche Vorsprünge, z. B. an der Unterseite von Kronenkorken, angreifen, verhindern damit eine Aufwärtsbewegung der gesamten Flaschenhalterung im Flaschenträger, wodurch diese immer fest auf den Flaschen aufliegt.The retaining tongues, which are located under the projections on the bottle head or on the bottle stopper, e.g. B. on the underside of crown corks, prevent an upward movement of the entire bottle holder in the bottle carrier, so that it always lies firmly on the bottles.

Sehr vorteilhaft ist es auch, wenn erfindungsgemäss die Deckwand zwei Abschnitte aufweist, die zur Mitte des Flaschenträgers hin schräg nach oben verlaufen und sich in einem ebenfalls zwei Teilwände aufweisenden Handgriff fortsetzen, wobei diese beiden Teilwände des Handgriffes scharnierartig miteinander verbunden sind und jeweils eine Durchgriffsöffnung aufweisen, wobei der aus der einen Teilwand ausgestanzte Kartonstreifen zwei durch eine Faltlinie verbundene Abschnitte aufweist, von denen der eine Abschnitt sich zwischen den beiden Teilwänden des Handgriffs erstreckt und der andere Abschnitt an der anderen Teilwand festgelegt ist.It is also very advantageous if, according to the invention, the top wall has two sections which run obliquely upwards towards the center of the bottle carrier and continue in a handle which also has two part walls, these two part walls of the handle being connected to one another in a hinge-like manner and each having a passage opening , wherein the cardboard strip punched out of the one partial wall has two sections connected by a folding line, one section of which extends between the two partial walls of the handle and the other section is fixed to the other partial wall.

Hierdurch ist der Flaschenträger mit einem zusätzlich stabilisierenden Handgriff versehen, der ein einwandfreies Tragen des Flaschenträgers erlaubt und ausserdem den Winkel zwischen den beiden Handgriff-Teilwänden exakt definiert, wodurch eine unkontrollierte Belastung der Flaschenträgerwände und damit deren Aufreissen vermieden wird.As a result, the bottle holder is provided with an additional stabilizing handle, which allows the bottle holder to be carried correctly and also precisely defines the angle between the two part walls of the handle, thereby avoiding uncontrolled loading of the bottle holder walls and thus their tearing open.

Bei einem zweireihigen Flachenträger mit einer oberen, aus zwei Abschnitten bestehenden Deckwand, an die ein aus zwei Teilwänden gebildeter Handgriff angeformt ist, besteht erfindungsgemäss die Flaschenhalterung aus zwei Abschnitten, die über einen umgekehrt V-förmig gefalteten Mittelabschnitt verbunden sind, der zwischen die beiden Teilwände des Handgriffs eingefaltet ist.In the case of a two-row flat beam with an upper cover wall consisting of two sections, to which a handle formed from two partial walls is molded, the bottle holder according to the invention consists of two sections which are connected via an inverted V-shaped middle section which is between the two partial walls of the handle is folded.

Damit wird eine weitere Versteifung und Stabilisierung des Flaschenträgers erreicht, was besonders vorteilhaft ist, wenn er zum Zusammenhalten und Tragen vieler und grosser Flaschen dienen soll.This results in a further stiffening and stabilization of the bottle carrier, which is particularly advantageous if it is intended to hold together and carry many and large bottles.

Als sehr günstig hat sich auch erwiesen, wenn erfindungsgemäss der umgekehrt V-förmige Mittelabschnitt der Flaschenhalterung mit Ausstanzungen versehen ist, die wenigstens annähernd deckungsgleich mit den Durchgriffsöffnungen des Handgriffs angeordnet sind.It has also proven to be very favorable if, according to the invention, the inverted V-shaped central section of the bottle holder is provided with punched-out areas which are arranged at least approximately congruently with the through openings of the handle.

Dadurch ist es möglich, beim Tragen einen Teil des Flaschengewichtes auch über die Flaschenhalterung zu übertragen und damit den eigentlichen Flaschenträger zu entlasten. In der Zeichnung ist der Gegenstand der Erfindung anhand von Ausführungsbeispielen dargestellt. Dabei zeigen:

- Fig. 1 eine perspektivische Ansicht eines Flaschenträgers mit eingesetzter Flaschenhalterung,

- Fig. 2 Zuschnitte für Flaschenhalterung in bis 4 flachliegendem Zustand,

- Fig. 5 eine perspektivische Ansicht eines Flaschenträgers mit Handgriff und eingesetzter Flaschenhalterung,

- Fig. 6 eine schaubildliche Darstellung eines Flaschenträgers mit Handgriff,

- Fig. 7 den Handgriff in vergrössertem Massstab und aufgeschnitten,

- Fig. 8 einen flachliegenden Zuschnitt zur Herstellung des Flaschenträgers,

- Fig. 9 eine flachliegende Flaschenhalterung und

- Fig. 10 eine Stirnansicht eines Flaschenträgers mit dazwischen eingefaltetem Mittelabschnitt einer Flaschenhalterung.

- 1 is a perspective view of a bottle carrier with inserted bottle holder,

- 2 blanks for bottle holder in up to 4 lying flat state,

- 5 is a perspective view of a bottle carrier with a handle and inserted bottle holder,

- 6 is a diagrammatic representation of a bottle carrier with a handle,

- 7 the handle on an enlarged scale and cut open,

- 8 shows a flat blank for producing the bottle carrier,

- Fig. 9 is a flat bottle holder and

- 10 shows an end view of a bottle carrier with a middle section of a bottle holder folded in between.

Fig. 1 zeigt einen Flaschenträger mit einer Deckwand 10, oberen Schrägwänden 11, Seitenwänden 12, unteren Schrägwänden 13 sowie einer Bodenwand 14. In diesen Flaschenträger ist eine Flaschenhalterung 1 eingesetzt. Diese weist, wie in Fig. 2 gezeigt, eine horizontale Fläche 2 auf, an der über zwei Faltlinien 3 und 4 Seitenflächen 5 und 6 angelenkt sind. In der horizontalen Fläche 2 sind Ausnehmungen 7 vorgesehen, die sich über die Faltlinien 3 und 4 zu einem geringen Teil auch noch in die Seitenflächen 5 und 6 hinein erstrekken. Haltezungen 8, die über Anlenklinien 9 mit der horizontalen Fläche 2 in Verbindung stehen, ragen teilweise in die Ausnehmungen 7 hinein. Die beiden Seitenflächen 5 und 6 sind im eingesetzten Zustand der Flaschenhalterung um die Faltlinien 3 und 4 nach unten gefaltet und liegen an den inneren Oberflächen der Seitenwände 12 des Flaschenträgers an. Flaschen 15 sind an ihren konischen Halspartien in den Ausnehmungen 7 der horizontalen Fläche 2 gehalten. Die Haltezungen 8 sind um die Anlenklinie 9 um etwa 90° nach oben abgebogen und stützen sich an der Unterseite von Kronenkorken 16 der Flaschen 15 ab.1 shows a bottle holder with a

Die Figuren 3 und 4 zeigen zwei weitere Ausgestaltungen von Flaschenhalterungen, mit 20 bzw. 200 sind die horizontalen Flächen, mit 70 bzw. 700 halbkreisförmige Ausnehmungen und mit 80 Haltezungen bezeichnet.FIGS. 3 and 4 show two further configurations of bottle holders, 20 and 200 denote the horizontal surfaces, 70 and 700 semicircular recesses and 80 holding tongues.

Fig. 5 zeigt einen Flaschenträger mit einer Deckwand 100, an welcher ein Handgriff 17 angeformt ist, welcher die Form eines umgekehrten «V» aufweist. Der Flaschenträger besteht ferner aus Seitenwänden 120 mit oberen Seitenwandabschnitten 121 und unteren Seitenwandabschnitten 122 sowie unteren Schrägwänden 130 und einer Bodenwand 140. In diesen Flaschenträger ist eine Flaschenhalterung 23 eingesetzt, welche ebenso wie die in Fig. 2 gezeigte Flaschenhalterung ausgebildet ist, wobei lediglich die Haltezungen 8 weggelassen wurden. Die beiden Seitenflächen 50 und 60 stützen sich an den Innenseiten der beiden oberen Seitenwandabschnitten 121 ab.5 shows a bottle carrier with a

Es ist auch möglich, in einen derartigen Flaschenträger, wie er in Fig. 5 dargestellt ist, eine Flaschenhalterung einzusetzen, welche sich zwar von einer Seitenwand zur anderen erstreckt, die aber keine Seitenflächen 50 und 60 aufweist.It is also possible to use a bottle holder in such a bottle carrier, as shown in FIG. 5, which extends from one side wall to the other, but has no

In Fig. 6 ist ein Flaschenträger 101 dargestellt, der aus dem in Fig. 8 dargestellten Zuschnitt 110 aufgefaltet und an seinem Boden verschlossen ist. An seiner Oberseite ist der Flaschenträger 101 mit einem Handgriff versehen, der aus zwei Teilwänden 102 und 103 gebildet ist, die über eine Faltlinie 104 miteinander verbunden sind und die an die angrenzenden Abschnitte der Deckwand 100 angelenkt sind. Unterhalb dieser Deckwand ist eine Flaschenhalterung 123 angeordnet, die in Fig. 9 flachliegend dargestellt ist.FIG. 6 shows a

In Fig. 7 ist die Ausgestaltung des Handgriffes besonders deutlich zu sehen. An die Handgriff-Teilwand 103 ist ein Kartonstreifen mit zwei Abschnitten 107 und 108 angeformt, von denen der äussere Abschnitt 108 an die Handgriff-Teilwand 102 aussen angelenkt und mit dieser verklebt ist. Der Abschnitt 107 stellt dabei einen Abstandhalter für die beiden Handgriff-Teilwände 102 und 103 dar.The design of the handle can be seen particularly clearly in FIG. 7. A cardboard strip with two

Bei dem in Fig. 10 dargestellten Ausführungsbeispiel ist der Flaschenträger 101 in gleicher Weise ausgestaltet wie in Fig. 6. Der Flaschenhalter besteht jedoch aus zwei Abschnitten 223, 224, die über einen aus zwei Wänden 225, 226 bestehenden Mittelabschnitt verbunden sind. Dieser Mittelabschnitt 225, 226 ist umgekehrt, V-förmig gefaltet und erstreckt sich zwischen den Handgriff-Teilwänden 102, 103. Beide Wände 225, 226 dieses Mitteiabschnittes sind mit Ausstanzungen (nicht dargestellt) versehen, die mit den Durchgriffsöffnungen des Handgriffs deckungsgleich sind.In the exemplary embodiment shown in FIG. 10, the

Claims (7)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT84101674T ATE38197T1 (en) | 1983-04-15 | 1984-02-17 | DOUBLE ROW SLEEVE-SHAPED BOTTLE CARRIER. |

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19833313714 DE3313714A1 (en) | 1983-04-15 | 1983-04-15 | Sleeve-type bottle carrier in two rows |

| DE3313714 | 1983-04-15 | ||

| DE19833323413 DE3323413A1 (en) | 1983-06-29 | 1983-06-29 | Two-row, sleeve-type bottle carrier |

| DE3323413 | 1983-06-29 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0122397A2 EP0122397A2 (en) | 1984-10-24 |

| EP0122397A3 EP0122397A3 (en) | 1985-10-30 |

| EP0122397B1 true EP0122397B1 (en) | 1988-10-26 |

Family

ID=25810036

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP84101674A Expired EP0122397B1 (en) | 1983-04-15 | 1984-02-17 | Carrier for two rows of bottles |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0122397B1 (en) |

| DE (1) | DE3474805D1 (en) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| NZ244842A (en) * | 1991-10-24 | 1995-04-27 | Mead Corp | Package for group of articles such as bottles formed from wraparound sleeve, and from rigid panel secured to articles and used to return empty articles |

| GB9215257D0 (en) * | 1992-07-17 | 1992-09-02 | Riverwood Int Ltd | Container for articles |

| GB0019589D0 (en) | 2000-08-10 | 2000-09-27 | Mead Corp | Article carrier and blank |

| US6945390B2 (en) | 2000-03-24 | 2005-09-20 | Meadwestvaco Packaging Systems, Llc | Article carrier with handle-reinforcing bridging structure |

| ATE431304T1 (en) * | 2000-03-24 | 2009-05-15 | Meadwestvaco Packaging Systems | ARTICLE CARRIER AND CUTTING |

| GB0010734D0 (en) | 2000-05-04 | 2000-06-28 | Mead Corp | Carton and carton blank |

| US6866144B2 (en) | 2000-08-11 | 2005-03-15 | Meadwestvaco Packaging Systems, Llc | Carton and carton blank |

| DE102015110483A1 (en) * | 2015-06-30 | 2017-01-05 | Thomas Weser | Packaging, in particular for beverage bottles |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2074477A (en) * | 1932-09-01 | 1937-03-23 | Southern Kraft Corp | Carton and blank for forming the same |

| US2179109A (en) * | 1938-10-31 | 1939-11-07 | American Coating Mills Inc | Carrier and display device |

| US3168963A (en) * | 1963-10-01 | 1965-02-09 | Container Corp | Bottle carrier |

| FR1447463A (en) * | 1965-06-19 | 1966-07-29 | Dropsy | Advanced basket for bottle packaging |

| FR2067947A5 (en) * | 1969-11-21 | 1971-08-20 | Valfuret Papeterie Du | |

| DE2723957C3 (en) * | 1977-05-27 | 1986-01-02 | The Mead Corp., Dayton, Ohio | Collapsible cover for bottles arranged in two rows |

-

1984

- 1984-02-17 DE DE8484101674T patent/DE3474805D1/en not_active Expired

- 1984-02-17 EP EP84101674A patent/EP0122397B1/en not_active Expired

Also Published As

| Publication number | Publication date |

|---|---|

| EP0122397A3 (en) | 1985-10-30 |

| EP0122397A2 (en) | 1984-10-24 |

| DE3474805D1 (en) | 1988-12-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE1586821C3 (en) | Bottle carrier | |

| DE3305467C2 (en) | ||

| DE1296565B (en) | Wrapper for bottles | |

| DE1931896B2 (en) | ||

| DE2058856B2 (en) | Plate blank to create a carrier for bottles | |

| EP0122397B1 (en) | Carrier for two rows of bottles | |

| EP0352589B1 (en) | Blank for a collective package | |

| DE3807444C2 (en) | ||

| DE1271016B (en) | Paper stock container | |

| DE1985965U (en) | CARTON. | |

| DE1231615B (en) | One-piece cardboard made from paper stock | |

| DE2105440C3 (en) | Display box for fragile objects, especially eggs | |

| EP0241026B1 (en) | Blank for a round box | |

| DE69600360T2 (en) | Corrugated cardboard packaging for car body panels or similar, plate-shaped objects | |

| DE2631195A1 (en) | PACKING OR CARRYING DEVICE FOR BOTTLES OR THE SAME CONTAINER | |

| DE602004011469T2 (en) | A sleeve of semi-rigid material for protecting and securing an elongated article in a package | |

| DE3321036C2 (en) | ||

| DE69806771T2 (en) | EGG PACKAGING FROM A ONE-PIECE CUT | |

| DE60006774T2 (en) | Case with wedge-shaped chambers | |

| DE3429688A1 (en) | CARRYING PACKAGING | |

| EP0413986B1 (en) | Container carrier | |

| DE2037185A1 (en) | Packaging for a number of objects of the same shape | |

| AT521053B1 (en) | folding | |

| EP0658487B1 (en) | Wrap-around package | |

| DE3050059C2 (en) | Foldable blank with holding device for bottle-like containers |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19860415 |

|

| 17Q | First examination report despatched |

Effective date: 19870602 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19881026 |

|

| REF | Corresponds to: |

Ref document number: 38197 Country of ref document: AT Date of ref document: 19881115 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3474805 Country of ref document: DE Date of ref document: 19881201 |

|

| ET | Fr: translation filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| ITF | It: translation for a ep patent filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19890228 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19891220 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19900228 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19910217 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19910417 Year of fee payment: 8 |

|

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19920229 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19921103 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19930127 Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PUE Owner name: 4P NICOLAUS KEMPTEN GMBH |

|

| ITPR | It: changes in ownership of a european patent |

Owner name: CESSIONE;HP NICOLAUS KEMPTEN GMBH |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19930901 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19940127 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19940211 Year of fee payment: 11 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19940228 Ref country code: CH Effective date: 19940228 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: TP |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 732E |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19950217 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Effective date: 19950228 |

|

| BERE | Be: lapsed |

Owner name: 4P EMBALLAGE FRANCE Effective date: 19950228 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19950217 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20030129 Year of fee payment: 20 |