EP0111136A2 - Fountain solution additive for lithographic printing - Google Patents

Fountain solution additive for lithographic printing Download PDFInfo

- Publication number

- EP0111136A2 EP0111136A2 EP83110755A EP83110755A EP0111136A2 EP 0111136 A2 EP0111136 A2 EP 0111136A2 EP 83110755 A EP83110755 A EP 83110755A EP 83110755 A EP83110755 A EP 83110755A EP 0111136 A2 EP0111136 A2 EP 0111136A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- fountain solution

- solution additive

- diol

- dimethyl

- wetting agents

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41N—PRINTING PLATES OR FOILS; MATERIALS FOR SURFACES USED IN PRINTING MACHINES FOR PRINTING, INKING, DAMPING, OR THE LIKE; PREPARING SUCH SURFACES FOR USE AND CONSERVING THEM

- B41N3/00—Preparing for use and conserving printing surfaces

- B41N3/08—Damping; Neutralising or similar differentiation treatments for lithographic printing formes; Gumming or finishing solutions, fountain solutions, correction or deletion fluids, or on-press development

Definitions

- the present invention relates to a fountain solution additive for offset printing, which contains wetting agents, pH-regulating substances, humectants, optionally film formers, softening agents, preservatives and solvents.

- the present invention has set itself the task of providing an improved fountain solution additive for offset printing, which leads to lower water flow and the resulting printing advantages, ensures a quick adjustment of the emulsification conditions, facilitates the washability of the dampening rollers, enables a fast free running of the printing plate and thereby leads to a reduction in waste, the ink deposits on the rubber blanket in the non-image area and does not foam. Furthermore, the invention has for its object to develop a fountain solution that contains no water or only a small amount of water, so that it can be made in paste, powder or tablet form.

- wetting agents can additionally contain certain amounts of other customary wetting agents, in particular those which are also available in solid form or can be converted into solid form.

- a solid acidic buffer is used as the pH-regulating substance.

- a mixture of trisodium citrate and citric acid has proven particularly useful.

- polyalcohols having 5 or 6 carbon atoms are used as humectants.

- Hexite has proven particularly useful.

- the fountain solution additive according to the invention preferably contains ethylenediaminetetraacetic acid as the sodium salt as softening agent. Potassium sorbate has proven particularly useful as a preservative.

- a liquid fountain solution concentrate can contain 0.1 to 50 parts of group A wetting agent. The concentration depends solely on the solvent. Not all Group A wetting agents are clearly soluble in higher concentrations in pure water, while solvents such as ethanol or isopropanol are able to clearly dissolve the Group A wetting agents in a ratio of 1: 1. A solvent mixture of ethanol or isopropanol to water in a ratio of 30:70 is able to clearly dissolve sufficient amounts of group A wetting agent.

- the group A wetting agents in pure form are water-soluble in a sufficient concentration in ready-to-use fountain solution, even without the addition of alcohols.

- a liquid concentrate can contain between 0.01 and 2 parts of group A wetting agent, 10-90 parts of water and, if desired, 0 to 30 parts of alcohol being used as the solvent.

- a fountain solution additive according to the invention in powder form can contain 0.05-5 parts of group A wetting agent in addition to 2-90 parts of buffer salt, 0-60 parts of softening agent, 0-80 parts of humectant, 0-80 parts of film former and 0.2-5 parts Preservative.

- group A wetting agent in addition to 2-90 parts of buffer salt, 0-60 parts of softening agent, 0-80 parts of humectant, 0-80 parts of film former and 0.2-5 parts Preservative.

- Such a powder can easily be compressed into tablets. These tablets dissolve quickly and easily in water and thus allow easy and simple dosing and preparation of the fountain solution for ⁇ offset printing. However, this powder can also be dissolved directly in water without difficulty or offered in the form of a paste with only a low water content will.

- the advantage of the powder and tablet form, but also the paste form is the small storage volume, the smaller packaging, the reduction in freight costs and the stability.

- a content of 0.001-0.1 g of wetting agent per liter of fountain solution leads to the advantages of the fountain solution compared to conventional formulations which can be achieved according to the invention, namely the improvement of the color, water and emulsification behavior, the enabling of extremely low water flow and the resulting printing advantages.

- the dampening rollers can be cleaned faster and more thoroughly, and the re-contamination of the dampening rollers covered is reduced.

- the printing plates run free extremely quickly, thereby reducing the amount of waste.

- color deposits on the blanket in the non-image area are also significantly reduced.

- group A wetting agent preferably 0.5 to 2 parts, with 2 to 90 parts of buffer salt (trisodium citrate / citric acid in a ratio of 5: 1 to 2: 1), 0.2 to 5 parts, preferably 1 to 3 parts of potassium sorbate, 0 to 80 parts, preferably 20 to 40 parts of sorbitol as a humectant, 0 to 60 parts, preferably 2 to 20 parts of sodium ethylenediaminetetraacetic acid as a softening agent and 0 to 80 parts, preferably 0 to 5 parts of gum arabic as a film former in a powder mixer mixed until homogeneous.

- the powder can be instantized or compressed into tablets.

- the powder is added in amounts of 1 to 10 g, preferably 3 to 5 g, per liter of fountain solution.

Abstract

Description

Gegenstand der vorliegenden Erfindung ist ein Feuchtwasser-Zusatz für den Offsetdruck, welcher Netzmittel, pH-regulierende Substanzen, Feuchthaltemittel, ggf. Filmbildner, Enthärtungsmittel, Konservierungsmittel und Lösungsmittel enthält.The present invention relates to a fountain solution additive for offset printing, which contains wetting agents, pH-regulating substances, humectants, optionally film formers, softening agents, preservatives and solvents.

Beim Offsetdruck werden dem Feuchtwasser verschiedene Zusätze zugegeben, um das Drucken zu erleichtern und die Qualität der Druckerzeugnisse zu erhöhen. Diese Zusätze werden bisher entweder vom Drucker selbst beigemischt oder in Form von Konzentraten in den Handel gebracht. Diese Konzentrate enthalten meist schwache Säuren oder einen Puffer, Feuchthaltemittel wie Glyzerin oder Glykole, Filmbildner wie Gummiarabicum, Konservierungsmittel, zum Teil auch Enthärtungsmittel und Netzmittel sowie ggf. Alkohole wie Ethanol oder Isopropanol. Sämtliche Feuchtwasser-Konzentrate enthalten erhebliche Mengen Wasser.In offset printing, various additives are added to the fountain solution to make printing easier and to increase the quality of the printed products. So far, these additives have either been added by the printer itself or sold in the form of concentrates. These concentrates usually contain weak acids or a buffer, humectants such as glycerin or glycols, film formers such as gum arabic, preservatives, some also softeners and wetting agents, and possibly alcohols such as ethanol or isopropanol. All fountain solution concentrates contain considerable amounts of water.

Die vorliegende Erfindung hat sich die Aufgabe gestellt, einen verbesserten Feuchtwasser-Zusatz für den Offsetdruck zu liefern, welcher zu niedrigerer Wasserführung und daraus resultierenden drucktechnischen Vorteilen führt, eine schnelle Einstellung der Emulgationsverhältnisse gewährleistet, die Auswaschbarkeit der Feuchtwalzen erleichtert, ein schnelles Freilaufen der Druckplatte ermöglicht und dadurch zu einer Verminderung der Makulatur führt, die Farbablagerungen auf dem Gummituch im bildfreien Bereich vermindert und dabei nicht schäumt. Weiterhin hat sich die Erfindung die Aufgabe gestellt, einen Feuchtwasser-Zusatz zu entwickeln, der kein Wasser oder nur geringe Mengen Wasser enthält, so daß er in Pasten-, Pulver- oder Tablettenform hergestellt werden kann.The present invention has set itself the task of providing an improved fountain solution additive for offset printing, which leads to lower water flow and the resulting printing advantages, ensures a quick adjustment of the emulsification conditions, facilitates the washability of the dampening rollers, enables a fast free running of the printing plate and thereby leads to a reduction in waste, the ink deposits on the rubber blanket in the non-image area and does not foam. Furthermore, the invention has for its object to develop a fountain solution that contains no water or only a small amount of water, so that it can be made in paste, powder or tablet form.

Diese Aufgabe wurde überraschenderweise gelöst durch einen Feuchtwasser-Zusatz, welcher Netzmittel, pH-regulierende Substanzen, Feuchthaltemittel, ggf. Filmbildner, Enthärtungsmittel, Konservierungsmittel und ggf. Lösungsmittel enthält und dadurch gekennzeichnet ist, daß er als Netzmittel eine oder mehrere Substanzen der Gruppe A bestehend aus

- a) Polypropylenglykol (400 - 2000)

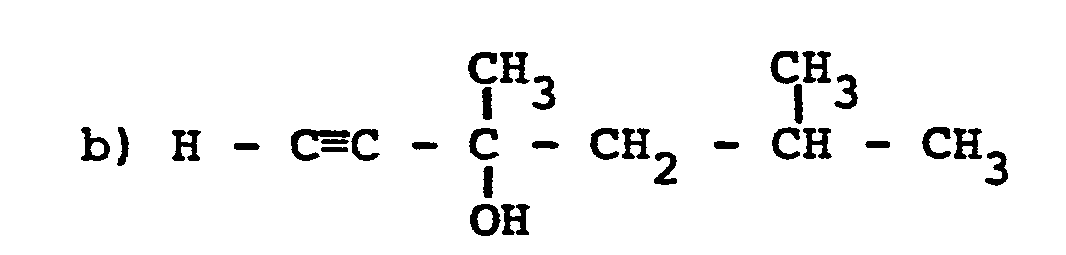

- b) 3,5 Dimethyl-l-hexin-3-ol

- c) 3,6 Dimethyl-4-octin-3,6-diol

- d) 2,4,7,9-Tetramethyl-5-decin-4,7-diol

- e) Ethoxylierungsprodukte von b, c und/oder d

- f) Kombinationen von a, b, c, d und/oder e mit weiteren üblichen Netzmitteln

enthält.This object was surprisingly achieved by adding a fountain solution which contains wetting agents, pH-regulating substances, humectants, optionally film formers, softening agents, preservatives and optionally solvents and is characterized in that it comprises one or more substances of group A as wetting agents out

- a) polypropylene glycol (400 - 2000)

- b) 3,5 dimethyl-l-hexin-3-ol

- c) 3,6 dimethyl-4-octyne-3,6-diol

- d) 2,4,7,9-tetramethyl-5-decyne-4,7-diol

- e) ethoxylation products of b, c and / or d

- f) combinations of a, b, c, d and / or e with other customary wetting agents

contains.

Die Netzmittel der Gruppe A haben die folgenden Formeln:

- e) in den Ethoxylierungsprodukten von b, c und d sind die Hydroxyl-Gruppen teilweise oder vollständig ersetzt durch die Gruppe -[0 - CH2-CH2]m-OH

- (m = 1 - 40)

- e) in the ethoxylation products of b, c and d, the hydroxyl groups are partially or completely replaced by the group - [0 - CH 2 -CH 2 ] m -OH

- (m = 1 - 40)

Ggf. können diese Netzmittel zusätzlich gewisse Mengen weiterer üblicher Netzmittel enthalten, insbesondere solche, die auch in fester Form erhältlich sind oder in feste Form überführt werden können.Possibly. These wetting agents can additionally contain certain amounts of other customary wetting agents, in particular those which are also available in solid form or can be converted into solid form.

Als pH-regulierende Substanz wird erfindungsgemäß ein fester saurer Puffer verwendet. Ein Gemisch aus Trinatriumcitrat und Citronensäure hat sich besonders bewährt.According to the invention, a solid acidic buffer is used as the pH-regulating substance. A mixture of trisodium citrate and citric acid has proven particularly useful.

Als Feuchthaltemittel werden erfindungsgemäß Polyalkohole mit 5 oder 6 Kohlenstoffatomen verwendet. Besonders bewährt hat sich Hexit.According to the invention, polyalcohols having 5 or 6 carbon atoms are used as humectants. Hexite has proven particularly useful.

Der erfindungsgemäße Feuchtwasser-Zusatz enthält als Enthärtungsmittel vorzugsweise Ethylendiamintetraessigsäure als Natriumsalz. Als Konservierungsmittel hat sich insbesondere Kaliumsorbat bewährt.The fountain solution additive according to the invention preferably contains ethylenediaminetetraacetic acid as the sodium salt as softening agent. Potassium sorbate has proven particularly useful as a preservative.

Gegenstand der vorliegenden Erfindung ist somit ein Feuchtwasser-Zusatz für den Offsetdruck, enthaltend Netzmittel, pH-regulierende Substanzen, Feuchthaltemittel, ggf. Filmbildner, Enthärtungsmittel, Konservierungsmittel und ggf. Lösungsmittel, dadurch gekennzeichnet, daß er als Netzmittel eine oder mehrere Substanzen der Gruppe A bestehend aus

- a) Polypropylenglykol (400 - 2000)

- b) 3,5 Dimethyl-l-hexin-3-ol

- c) 3,6 Dimethyl-4-octin-3,6-diol

- d) 2,4,7,9-Tetramethyl-5-decin-4,7-diol

- e) Ethoxylierungsprodukte von b, c und/oder d

- f) Kombinationen von a, b, c, d und/oder e mit weiteren üblichen Netzmitteln

enthält.The present invention thus relates to a fountain solution additive for offset printing Wetting agents, pH-regulating substances, humectants, if appropriate film formers, softening agents, preservatives and optionally solvents, characterized in that it comprises one or more Group A substances as wetting agent

- a) polypropylene glycol (400 - 2000)

- b) 3,5 dimethyl-l-hexin-3-ol

- c) 3,6 dimethyl-4-octyne-3,6-diol

- d) 2,4,7,9-tetramethyl-5-decyne-4,7-diol

- e) ethoxylation products of b, c and / or d

- f) combinations of a, b, c, d and / or e with other customary wetting agents

contains.

Ein besonderer Vorteil dieses Zusatzes ist, daß er in Pasten-, Pulver- oder Tablettenform hergestellt werden kann..Ein weiterer Gegenstand der vorliegenden Erfindung ist die Verwendung von einer oder mehrerer Substanzen der Gruppe A bestehend aus

- a) Polypropylenglykol (400 - 2000)

- b) 3,5 Dimethyl-1-hexin-3-ol

- c) 3,6 Dimethyl-4-octin-3,6-diol

- d) 2,4,7,9-Tetramethyl-5-decin-4,7-diol

- e) Ethoxylierungsprodukte von b, c und/oder d

- f) Kombinationen von'a, b, c, d und/oder e mit weiteren üblichen Netzmitteln

als Feuchtwasser-Zusatz beim Offsetdruck und insbesondere deren Verwendung in Feuchtwasser-Konzentraten in Pasten-, Pulver- oder Tablettenform.A particular advantage of this additive is that it can be produced in paste, powder or tablet form. Another object of the present invention is the use of one or more substances from group A consisting of

- a) polypropylene glycol (400 - 2000)

- b) 3,5 dimethyl-1-hexin-3-ol

- c) 3,6 dimethyl-4-octyne-3,6-diol

- d) 2,4,7,9-tetramethyl-5-decyne-4,7-diol

- e) ethoxylation products of b, c and / or d

- f) combinations of a, b, c, d and / or e with other customary wetting agents

as a fountain solution additive in offset printing and especially its use in fountain solution concentrates in paste, powder or tablet form.

Die Mengen der einzelnen Komponenten des erfindungsgemäßen Feuchtwasser-Zusatzes sind nicht kritisch. So kann ein flüssiges Feuchtwasser-Konzentrat 0,1 bis 50 Teile Netzmittel der Gruppe A enthalten. Die Konzentration hängt allein von dem Lösungsmittel ab. Im reinen Wasser sind nicht alle Netzmittel der Gruppe A in höheren Konzentrationen klar löslich, während Lösungsmittel wie Ethanol oder Isopropanol in der Lage sind, die Netzmittel der Gruppe A im Verhältnis 1:1 klar zu lösen. Ein Lösungsmittelgemisch Ethanol oder Isopropanol zu Wasser im Verhältnis 30:70 ist in der Lage ausreichende Mengen Netzmittel der Gruppe A klar zu lösen. Die Netzmittel der Gruppe A in reiner Form sind in gebrauchsfertigem Feuchtwasser auch ohne Zusatz von Alkoholen in ausreichender Konzentration wasserlöslich.The amounts of the individual components of the Invention according to the fountain solution additive are not critical. A liquid fountain solution concentrate can contain 0.1 to 50 parts of group A wetting agent. The concentration depends solely on the solvent. Not all Group A wetting agents are clearly soluble in higher concentrations in pure water, while solvents such as ethanol or isopropanol are able to clearly dissolve the Group A wetting agents in a ratio of 1: 1. A solvent mixture of ethanol or isopropanol to water in a ratio of 30:70 is able to clearly dissolve sufficient amounts of group A wetting agent. The group A wetting agents in pure form are water-soluble in a sufficient concentration in ready-to-use fountain solution, even without the addition of alcohols.

Ein flüssiges Konzentrat kann erfindungsgemäß zwischen 0,01 und 2 Teile Netzmittel der Gruppe A enthalten, wobei als Lösungsmittel 10 - 90 Teile Wasser und gewünschtenfalls 0 bis 30 Teile Alkohol zur Anwendung kommen können.According to the invention, a liquid concentrate can contain between 0.01 and 2 parts of group A wetting agent, 10-90 parts of water and, if desired, 0 to 30 parts of alcohol being used as the solvent.

Ein erfindungsgemäßer Feuchtwasser-Zusatz in Pulverform kann 0,05 - 5 Teile Netzmittel der Gruppe A enthalten neben 2 - 90 Teilen Puffersalz, 0 - 60 Teilen Enthärtungsmittel, 0 - 80 Teilen Feuchthaltemittel, 0 - 80 Teilen Filmbildner und 0,2 - 5 Teilen Konservierungsmittel. Ein solches Pulver kann ohne weiteres zu Tabletten verpreßt werden. Diese Tabletten lösen sich rasch und leicht in Wasser auf und gestatten somit eine leichte und einfache Dosierung und Zubereitung des Feuchtwassers für den ^ Offsetdruck. Dieses Pulver kann aber auch ohne Schwierigkeiten direkt in Wasser gelöst werden oder in Form einer Paste nur mit geringem Wassergehalt angeboten werden. Der Vorteil der Pulver- und Tablettenform, aber auch der Pastenform, ist das geringe Lagervolumen, die kleinere Packung, die Verminderung der Frachtkosten und die Stabilität.A fountain solution additive according to the invention in powder form can contain 0.05-5 parts of group A wetting agent in addition to 2-90 parts of buffer salt, 0-60 parts of softening agent, 0-80 parts of humectant, 0-80 parts of film former and 0.2-5 parts Preservative. Such a powder can easily be compressed into tablets. These tablets dissolve quickly and easily in water and thus allow easy and simple dosing and preparation of the fountain solution for ^ offset printing. However, this powder can also be dissolved directly in water without difficulty or offered in the form of a paste with only a low water content will. The advantage of the powder and tablet form, but also the paste form, is the small storage volume, the smaller packaging, the reduction in freight costs and the stability.

Zur Herstellung eines Feuchtwassers benötigt man je nach Gehalt an Netzmitteln der Gruppe A 0,1 - 10 g des erfindungsgemäßen Zusatzes. Ein Gehalt von 0,001 - 0,1 g Netzmittel pro Liter Feuchtwasser führt zu den erfindungsgemäß erzielbaren Vorteilen des Feuchtwassers gegenüber herkömmlichen Rezepturen, nämlich der Verbesserung des Farb-, Wasser-und Emulgationsverhaltens, der Ermöglichung einer extremen geringen Wasserführung und der daraus resultierenden drucktechnischen Vorteile. Erfindungsgemäß ist es möglich, auf den Zusatz von Alkohol zum Feuchtwasser ganz zu verzichten, was aus arbeitstechnischen und umweltstechnischen Gründen erwünscht sein kann. Weiterhin lassen sich die Feuchtwalzen schneller und gründlicher reinigen, und es wird die Wiederverschmutzung bezogener Feuchtwalzen reduziert.To produce a fountain solution, depending on the content of group A wetting agents, 0.1-10 g of the additive according to the invention are required. A content of 0.001-0.1 g of wetting agent per liter of fountain solution leads to the advantages of the fountain solution compared to conventional formulations which can be achieved according to the invention, namely the improvement of the color, water and emulsification behavior, the enabling of extremely low water flow and the resulting printing advantages. According to the invention, it is possible to completely dispense with the addition of alcohol to the fountain solution, which may be desirable for reasons of work and environmental technology. Furthermore, the dampening rollers can be cleaned faster and more thoroughly, and the re-contamination of the dampening rollers covered is reduced.

Die Druckplatten laufen extrem schnell frei und vermindern dadurch den Anfall an Makulatur. Insbesondere werden auch Farbablagerungen auf dem Gummituch im bildfreien Bereich wesentlich vermindert.The printing plates run free extremely quickly, thereby reducing the amount of waste. In particular, color deposits on the blanket in the non-image area are also significantly reduced.

Die erfindungsgemäßen Feuchtwasser-Zusätze sind in den folgenden Beispielen näher erläutert.The fountain solution additives according to the invention are explained in more detail in the following examples.

Rezepturen für flüssige Konzentrate:

- 0,01 bis 2 Teile Netzmittel der Gruppe A werden mit 2 bis 20 Teilen Puffersalz (Trinatriumcitrat/Citronensäure im Gewichtsverhältnis 5:1 bis 2:1), 0,1 bis 5 Teilen Konservierungsmittel (Kaliumsorbat oder Promitent, Dr. Bode GmbH) und 10 bis 90 Teilen Wasser gelöst. Es werden 0 bis 50 Teile, vorzugsweise 3 bis 10 Teile Feuchthaltemittel, beispielsweise Sorbit, 0 bis 20 Teile, vorzugsweise 2 bis 10 Teile Enthärtungsmittel, wie Ethylendiamintetraessigsäure-Natriumsalz, 0 bis 50 Teile, vorzugsweise 2 bis 5 Teile-Filmbildner, wie Gummiarabicum, und falls erforderlich bis zu 30 Teilen Alkohol (Ethanol oder Isopropanol) als Hilfslösungsmittel zugegeben und innig vermischt. Diese Konzentrate können unmittelbar abgefüllt und verwendet werden. Dem Feuchtwasser werden 1 bis 100 g, vorzugsweise ca. 10 g pro Liter des Konzentrates zugesetzt.

- 0.01 to 2 parts of group A wetting agent are added 2 to 20 parts of buffer salt (trisodium citrate / citric acid in a weight ratio of 5: 1 to 2: 1), 0.1 to 5 parts of preservative (potassium sorbate or Promitent, Dr. Bode GmbH) and 10 to 90 parts of water are dissolved. 0 to 50 parts, preferably 3 to 10 parts, of humectant, for example sorbitol, 0 to 20 parts, preferably 2 to 10 parts of softening agent, such as ethylenediaminetetraacetic acid sodium salt, 0 to 50 parts, preferably 2 to 5 parts, film former, such as gum arabic, and if necessary up to 30 parts of alcohol (ethanol or isopropanol) are added as auxiliary solvents and mixed intimately. These concentrates can be filled and used immediately. 1 to 100 g, preferably about 10 g, per liter of the concentrate are added to the fountain solution.

0,05 bis 5 Teile Netzmittel der Gruppe A, vorzugsweise 0,5 bis 2 Teile werden mit 2 bis 90 Teilen Puffersalz (Trinatriumcitrat/Citronensäure im Verhältnis 5:1 bis 2:1), 0,2 bis 5 Teilen, vorzugsweise 1 bis 3 Teilen Kaliumsorbat, 0 bis 80 Teilen, vorzugsweise 20 bis 40 Teilen Sorbit als Feuchthaltemittel, 0 bis 60 Teilen, vorzugsweise 2 bis 20 Teilen Ethylendiamintetraessigsäure-Natriumsalz als Enthärtungsmittel und 0 bis 80 Teilen, vorzugsweise 0 bis 5 Teilen Gummiarabicum als Filmbildner in einem Pulvermischer bis zur Homogenität gemischt. Das Pulver kann auf Wunsch instantisiert oder zu Tabletten verpreßt werden. Das Pulver wird in Mengen von 1 bis 10 g, vorzugsweise 3 bis 5 g pro Liter Feuchtwasser zugesetzt.0.05 to 5 parts of group A wetting agent, preferably 0.5 to 2 parts, with 2 to 90 parts of buffer salt (trisodium citrate / citric acid in a ratio of 5: 1 to 2: 1), 0.2 to 5 parts, preferably 1 to 3 parts of potassium sorbate, 0 to 80 parts, preferably 20 to 40 parts of sorbitol as a humectant, 0 to 60 parts, preferably 2 to 20 parts of sodium ethylenediaminetetraacetic acid as a softening agent and 0 to 80 parts, preferably 0 to 5 parts of gum arabic as a film former in a powder mixer mixed until homogeneous. If desired, the powder can be instantized or compressed into tablets. The powder is added in amounts of 1 to 10 g, preferably 3 to 5 g, per liter of fountain solution.

Claims (8)

enthält.1. fountain solution additive for offset printing, containing wetting agents, pH-regulating substances, humectants, if appropriate film formers, softening agents, preservatives and optionally solvents, characterized in that it comprises one or more substances of group A as wetting agents

contains.

als Feuchtwasser-Zusatz beim Offsetdruck.7. Use of one or more substances of group A consisting of

as a fountain solution additive for offset printing.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT83110755T ATE44499T1 (en) | 1982-12-14 | 1983-10-27 | DAMPING WATER ADDITIVE FOR OFFSET PRINTING. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3246153 | 1982-12-14 | ||

| DE3246153 | 1982-12-14 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0111136A2 true EP0111136A2 (en) | 1984-06-20 |

| EP0111136A3 EP0111136A3 (en) | 1986-08-27 |

| EP0111136B1 EP0111136B1 (en) | 1989-07-12 |

Family

ID=6180572

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP83110755A Expired EP0111136B1 (en) | 1982-12-14 | 1983-10-27 | Fountain solution additive for lithographic printing |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0111136B1 (en) |

| AT (1) | ATE44499T1 (en) |

| DE (1) | DE3380173D1 (en) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0269760A1 (en) * | 1986-12-02 | 1988-06-08 | Bernd Schwegmann GmbH & Co. KG | Fountain solution for lithographic printing |

| EP0411883A1 (en) * | 1989-08-02 | 1991-02-06 | Fuji Photo Film Co., Ltd. | Dampening water composition for lithographic plate |

| US5288678A (en) * | 1990-10-19 | 1994-02-22 | Beckman Instruments, Inc. | Indirect potentiometric method and diluent for analysis of lithium |

| US5340495A (en) * | 1993-04-30 | 1994-08-23 | Siebert, Inc. | Compositions for cleaning ink from a printing press and methods thereof |

| US6660454B2 (en) | 2001-05-18 | 2003-12-09 | Kodak Polychrome Graphics Llc | Additive composition for both rinse water recycling in water recycling systems and simultaneous surface treatment of lithographic printing plates |

| DE102008061735A1 (en) * | 2008-12-11 | 2010-06-17 | Weros Technology Gmbh | Printing method, in particular offset printing method, and release agent for this |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1807647A1 (en) | 1967-11-16 | 1969-06-12 | Eastman Kodak Co | Process for improving the printing properties of planographic printing forms |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4246843A (en) * | 1976-07-23 | 1981-01-27 | The Dow Chemical Company | Method for treating imaged lithographic printing plates |

-

1983

- 1983-10-27 EP EP83110755A patent/EP0111136B1/en not_active Expired

- 1983-10-27 DE DE8383110755T patent/DE3380173D1/en not_active Expired

- 1983-10-27 AT AT83110755T patent/ATE44499T1/en active

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1807647A1 (en) | 1967-11-16 | 1969-06-12 | Eastman Kodak Co | Process for improving the printing properties of planographic printing forms |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0269760A1 (en) * | 1986-12-02 | 1988-06-08 | Bernd Schwegmann GmbH & Co. KG | Fountain solution for lithographic printing |

| EP0411883A1 (en) * | 1989-08-02 | 1991-02-06 | Fuji Photo Film Co., Ltd. | Dampening water composition for lithographic plate |

| US5288678A (en) * | 1990-10-19 | 1994-02-22 | Beckman Instruments, Inc. | Indirect potentiometric method and diluent for analysis of lithium |

| US5340495A (en) * | 1993-04-30 | 1994-08-23 | Siebert, Inc. | Compositions for cleaning ink from a printing press and methods thereof |

| US6660454B2 (en) | 2001-05-18 | 2003-12-09 | Kodak Polychrome Graphics Llc | Additive composition for both rinse water recycling in water recycling systems and simultaneous surface treatment of lithographic printing plates |

| DE102008061735A1 (en) * | 2008-12-11 | 2010-06-17 | Weros Technology Gmbh | Printing method, in particular offset printing method, and release agent for this |

Also Published As

| Publication number | Publication date |

|---|---|

| DE3380173D1 (en) | 1989-08-17 |

| ATE44499T1 (en) | 1989-07-15 |

| EP0111136A3 (en) | 1986-08-27 |

| EP0111136B1 (en) | 1989-07-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2504594C2 (en) | Aqueous desensitizing solution for use in the production of lithographic printing forms and use of the solution | |

| DE2625604A1 (en) | MOISTURIZING SOLUTION | |

| DE2950736A1 (en) | INK FOR THE INK JET OR INKJET PROCESS | |

| DE2934897A1 (en) | Desensitizing solution and process for treating a diazo photosensitive printing plate | |

| EP0219719B1 (en) | Fountain solution for lithographic printing | |

| DE747690C (en) | Agent for making the non-printing areas of planographic and offset printing forms receptive to water | |

| EP0111136B1 (en) | Fountain solution additive for lithographic printing | |

| DE3149258A1 (en) | CLEANING AND SCRATCH REMOVAL PREPARATION, METHOD FOR THEIR PRODUCTION AND THEIR USE | |

| DE60209172T2 (en) | Fountain solution composition for planographic printing plate and planographic printing process | |

| EP0192813B1 (en) | Fountain solution for offset printing plates | |

| EP0522435B1 (en) | Fountain concentrate and fountain solution as well as its use in offset-printing | |

| DE1121632B (en) | Dampening and cleaning agents for the offset printing process | |

| DE2901664A1 (en) | MEANS FOR PRODUCING A MOISTURE SOLUTION FOR LITHOGRAPHIC PRINTING PROCESSES | |

| EP0279164B1 (en) | Solvent mixture for the development of lithographic printing plates, without organic solvents and having an extremely neutral ph | |

| DE1180869B (en) | Varnish for printing plates | |

| EP0456074B1 (en) | Fountain solution for use in offset printing | |

| EP0200913A1 (en) | Developing mixture, use and method of preparation of lithographic printing plates with this developer | |

| EP0269760A1 (en) | Fountain solution for lithographic printing | |

| DE1807647A1 (en) | Process for improving the printing properties of planographic printing forms | |

| DE3439220A1 (en) | Developer mixture containing propanol and process for the production of reprographic materials | |

| DE1105439B (en) | Fountain solution for offset printing | |

| DE3820984A1 (en) | Developer mixture for printing plates | |

| EP0293596B1 (en) | Correction fluid and process for the treatment of scratches on lithographic printing plates | |

| DE3143986A1 (en) | POST-TREATMENT AND CONVERSION AGENTS FOR LITHOGRAPHIC PLATES AND THE USE THEREOF | |

| WO1992019455A1 (en) | Moistening agent for use in the offset printing process |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19860927 |

|

| 17Q | First examination report despatched |

Effective date: 19880120 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 44499 Country of ref document: AT Date of ref document: 19890715 Kind code of ref document: T |

|

| ITF | It: translation for a ep patent filed |

Owner name: ING. C. GREGORJ S.P.A. |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| REF | Corresponds to: |

Ref document number: 3380173 Country of ref document: DE Date of ref document: 19890817 |

|

| ET | Fr: translation filed | ||

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| 26 | Opposition filed |

Opponent name: BASF AKTIENGESELLSCHAFT, LUDWIGSHAFEN Effective date: 19900411 |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: BASF AG |

|

| PLBM | Termination of opposition procedure: date of legal effect published |

Free format text: ORIGINAL CODE: 0009276 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: OPPOSITION PROCEDURE CLOSED |

|

| 27C | Opposition proceedings terminated |

Effective date: 19910405 |

|

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19921031 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19921110 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19921111 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19921112 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19921117 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19921118 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19921119 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19921204 Year of fee payment: 10 |

|

| EPTA | Lu: last paid annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19931027 Ref country code: GB Effective date: 19931027 Ref country code: AT Effective date: 19931027 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19931028 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19931031 Ref country code: CH Effective date: 19931031 Ref country code: BE Effective date: 19931031 |

|

| BERE | Be: lapsed |

Owner name: BERND SCHWEGMANN G.M.B.H. & CO. K.G. Effective date: 19931031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19940501 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19931027 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19940630 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| EUG | Se: european patent has lapsed |

Ref document number: 83110755.2 Effective date: 19940510 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19971125 Year of fee payment: 15 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990901 |