EP0075813B1 - Application of a pasty cleaning agent in dish washers - Google Patents

Application of a pasty cleaning agent in dish washers Download PDFInfo

- Publication number

- EP0075813B1 EP0075813B1 EP82108636A EP82108636A EP0075813B1 EP 0075813 B1 EP0075813 B1 EP 0075813B1 EP 82108636 A EP82108636 A EP 82108636A EP 82108636 A EP82108636 A EP 82108636A EP 0075813 B1 EP0075813 B1 EP 0075813B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- cleaner

- weight

- sodium

- potassium

- viscosity

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 235000011837 pasties Nutrition 0.000 title claims description 8

- 239000012459 cleaning agent Substances 0.000 title description 3

- ZAMOUSCENKQFHK-UHFFFAOYSA-N Chlorine atom Chemical compound [Cl] ZAMOUSCENKQFHK-UHFFFAOYSA-N 0.000 claims abstract description 28

- 239000000460 chlorine Substances 0.000 claims abstract description 28

- 229910052801 chlorine Inorganic materials 0.000 claims abstract description 28

- DGAQECJNVWCQMB-PUAWFVPOSA-M Ilexoside XXIX Chemical compound C[C@@H]1CC[C@@]2(CC[C@@]3(C(=CC[C@H]4[C@]3(CC[C@@H]5[C@@]4(CC[C@@H](C5(C)C)OS(=O)(=O)[O-])C)C)[C@@H]2[C@]1(C)O)C)C(=O)O[C@H]6[C@@H]([C@H]([C@@H]([C@H](O6)CO)O)O)O.[Na+] DGAQECJNVWCQMB-PUAWFVPOSA-M 0.000 claims abstract description 20

- 239000000203 mixture Substances 0.000 claims abstract description 16

- 239000011734 sodium Substances 0.000 claims abstract description 15

- 229910052708 sodium Inorganic materials 0.000 claims abstract description 14

- ZLMJMSJWJFRBEC-UHFFFAOYSA-N Potassium Chemical compound [K] ZLMJMSJWJFRBEC-UHFFFAOYSA-N 0.000 claims abstract description 10

- 229910052700 potassium Inorganic materials 0.000 claims abstract description 10

- 239000011591 potassium Substances 0.000 claims abstract description 10

- 150000001805 chlorine compounds Chemical class 0.000 claims abstract description 8

- 230000009974 thixotropic effect Effects 0.000 claims abstract description 4

- KWLMIXQRALPRBC-UHFFFAOYSA-L hectorite Chemical compound [Li+].[OH-].[OH-].[Na+].[Mg+2].O1[Si]2([O-])O[Si]1([O-])O[Si]([O-])(O1)O[Si]1([O-])O2 KWLMIXQRALPRBC-UHFFFAOYSA-L 0.000 claims description 15

- 229910000271 hectorite Inorganic materials 0.000 claims description 15

- 235000019353 potassium silicate Nutrition 0.000 claims description 13

- KWYUFKZDYYNOTN-UHFFFAOYSA-M Potassium hydroxide Chemical compound [OH-].[K+] KWYUFKZDYYNOTN-UHFFFAOYSA-M 0.000 claims description 10

- HEMHJVSKTPXQMS-UHFFFAOYSA-M sodium hydroxide Inorganic materials [OH-].[Na+] HEMHJVSKTPXQMS-UHFFFAOYSA-M 0.000 claims description 10

- NTHWMYGWWRZVTN-UHFFFAOYSA-N sodium silicate Chemical compound [Na+].[Na+].[O-][Si]([O-])=O NTHWMYGWWRZVTN-UHFFFAOYSA-N 0.000 claims description 10

- 235000019832 sodium triphosphate Nutrition 0.000 claims description 8

- 239000000126 substance Substances 0.000 claims description 7

- UNXRWKVEANCORM-UHFFFAOYSA-I triphosphate(5-) Chemical compound [O-]P([O-])(=O)OP([O-])(=O)OP([O-])([O-])=O UNXRWKVEANCORM-UHFFFAOYSA-I 0.000 claims description 7

- BPQQTUXANYXVAA-UHFFFAOYSA-N Orthosilicate Chemical compound [O-][Si]([O-])([O-])[O-] BPQQTUXANYXVAA-UHFFFAOYSA-N 0.000 claims description 5

- 229910052911 sodium silicate Inorganic materials 0.000 claims description 5

- 239000004115 Sodium Silicate Substances 0.000 claims description 4

- 239000005708 Sodium hypochlorite Substances 0.000 claims description 3

- -1 alkali metal hypochlorite Chemical class 0.000 claims description 3

- 239000000470 constituent Substances 0.000 claims description 3

- 229910052913 potassium silicate Inorganic materials 0.000 claims description 3

- CDBYLPFSWZWCQE-UHFFFAOYSA-L sodium carbonate Substances [Na+].[Na+].[O-]C([O-])=O CDBYLPFSWZWCQE-UHFFFAOYSA-L 0.000 claims description 3

- SUKJFIGYRHOWBL-UHFFFAOYSA-N sodium hypochlorite Chemical compound [Na+].Cl[O-] SUKJFIGYRHOWBL-UHFFFAOYSA-N 0.000 claims description 3

- 230000008719 thickening Effects 0.000 claims description 3

- 239000004111 Potassium silicate Substances 0.000 claims description 2

- 229910052783 alkali metal Inorganic materials 0.000 claims description 2

- 239000012736 aqueous medium Substances 0.000 claims description 2

- 159000000007 calcium salts Chemical class 0.000 claims description 2

- 238000004851 dishwashing Methods 0.000 claims description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-M hydroxide Chemical compound [OH-] XLYOFNOQVPJJNP-UHFFFAOYSA-M 0.000 claims description 2

- NNHHDJVEYQHLHG-UHFFFAOYSA-N potassium silicate Chemical compound [K+].[K+].[O-][Si]([O-])=O NNHHDJVEYQHLHG-UHFFFAOYSA-N 0.000 claims description 2

- 229910000029 sodium carbonate Inorganic materials 0.000 claims description 2

- 235000019351 sodium silicates Nutrition 0.000 claims description 2

- BWHMMNNQKKPAPP-UHFFFAOYSA-L potassium carbonate Chemical compound [K+].[K+].[O-]C([O-])=O BWHMMNNQKKPAPP-UHFFFAOYSA-L 0.000 claims 2

- WQYVRQLZKVEZGA-UHFFFAOYSA-N hypochlorite Inorganic materials Cl[O-] WQYVRQLZKVEZGA-UHFFFAOYSA-N 0.000 claims 1

- 229910000027 potassium carbonate Inorganic materials 0.000 claims 1

- 239000003599 detergent Substances 0.000 abstract description 20

- 238000004140 cleaning Methods 0.000 abstract description 15

- 239000002562 thickening agent Substances 0.000 abstract description 10

- 230000000694 effects Effects 0.000 abstract description 7

- 150000004760 silicates Chemical class 0.000 abstract description 5

- 150000001875 compounds Chemical class 0.000 abstract description 4

- 230000009471 action Effects 0.000 abstract description 3

- 229910000323 aluminium silicate Inorganic materials 0.000 abstract description 2

- 150000004649 carbonic acid derivatives Chemical class 0.000 abstract description 2

- 150000002500 ions Chemical class 0.000 abstract description 2

- 229920000388 Polyphosphate Polymers 0.000 abstract 1

- 150000004679 hydroxides Chemical class 0.000 abstract 1

- 239000001205 polyphosphate Substances 0.000 abstract 1

- 235000011176 polyphosphates Nutrition 0.000 abstract 1

- 239000003795 chemical substances by application Substances 0.000 description 12

- 238000003860 storage Methods 0.000 description 12

- 239000000243 solution Substances 0.000 description 10

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Chemical compound O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 9

- 238000000034 method Methods 0.000 description 8

- 239000000047 product Substances 0.000 description 8

- 238000012360 testing method Methods 0.000 description 8

- IAYPIBMASNFSPL-UHFFFAOYSA-N Ethylene oxide Chemical class C1CO1 IAYPIBMASNFSPL-UHFFFAOYSA-N 0.000 description 7

- 239000000843 powder Substances 0.000 description 7

- 239000007844 bleaching agent Substances 0.000 description 6

- 230000008569 process Effects 0.000 description 6

- 239000013543 active substance Substances 0.000 description 5

- 230000006698 induction Effects 0.000 description 5

- 102000005701 Calcium-Binding Proteins Human genes 0.000 description 4

- 108010045403 Calcium-Binding Proteins Proteins 0.000 description 4

- FAPWRFPIFSIZLT-UHFFFAOYSA-M Sodium chloride Chemical compound [Na+].[Cl-] FAPWRFPIFSIZLT-UHFFFAOYSA-M 0.000 description 4

- 238000007792 addition Methods 0.000 description 4

- 239000008139 complexing agent Substances 0.000 description 4

- 230000002378 acidificating effect Effects 0.000 description 3

- 239000003513 alkali Substances 0.000 description 3

- JYIMWRSJCRRYNK-UHFFFAOYSA-N dialuminum;disodium;oxygen(2-);silicon(4+);hydrate Chemical compound O.[O-2].[O-2].[O-2].[O-2].[O-2].[O-2].[Na+].[Na+].[Al+3].[Al+3].[Si+4] JYIMWRSJCRRYNK-UHFFFAOYSA-N 0.000 description 3

- 238000005187 foaming Methods 0.000 description 3

- 239000007788 liquid Substances 0.000 description 3

- 238000011068 loading method Methods 0.000 description 3

- 238000005259 measurement Methods 0.000 description 3

- 230000007246 mechanism Effects 0.000 description 3

- 238000002156 mixing Methods 0.000 description 3

- 239000002736 nonionic surfactant Substances 0.000 description 3

- 235000019795 sodium metasilicate Nutrition 0.000 description 3

- 238000003756 stirring Methods 0.000 description 3

- 230000008961 swelling Effects 0.000 description 3

- 235000011178 triphosphate Nutrition 0.000 description 3

- 239000001226 triphosphate Substances 0.000 description 3

- UNXRWKVEANCORM-UHFFFAOYSA-N triphosphoric acid Chemical compound OP(O)(=O)OP(O)(=O)OP(O)(O)=O UNXRWKVEANCORM-UHFFFAOYSA-N 0.000 description 3

- ALSTYHKOOCGGFT-KTKRTIGZSA-N (9Z)-octadecen-1-ol Chemical compound CCCCCCCC\C=C/CCCCCCCCO ALSTYHKOOCGGFT-KTKRTIGZSA-N 0.000 description 2

- BVKZGUZCCUSVTD-UHFFFAOYSA-L Carbonate Chemical compound [O-]C([O-])=O BVKZGUZCCUSVTD-UHFFFAOYSA-L 0.000 description 2

- 229910000503 Na-aluminosilicate Inorganic materials 0.000 description 2

- IGFHQQFPSIBGKE-UHFFFAOYSA-N Nonylphenol Natural products CCCCCCCCCC1=CC=C(O)C=C1 IGFHQQFPSIBGKE-UHFFFAOYSA-N 0.000 description 2

- 229910019142 PO4 Inorganic materials 0.000 description 2

- GOOHAUXETOMSMM-UHFFFAOYSA-N Propylene oxide Chemical compound CC1CO1 GOOHAUXETOMSMM-UHFFFAOYSA-N 0.000 description 2

- PMZURENOXWZQFD-UHFFFAOYSA-L Sodium Sulfate Chemical compound [Na+].[Na+].[O-]S([O-])(=O)=O PMZURENOXWZQFD-UHFFFAOYSA-L 0.000 description 2

- YKTSYUJCYHOUJP-UHFFFAOYSA-N [O--].[Al+3].[Al+3].[O-][Si]([O-])([O-])[O-] Chemical compound [O--].[Al+3].[Al+3].[O-][Si]([O-])([O-])[O-] YKTSYUJCYHOUJP-UHFFFAOYSA-N 0.000 description 2

- 239000003082 abrasive agent Substances 0.000 description 2

- 229910052910 alkali metal silicate Inorganic materials 0.000 description 2

- 239000007864 aqueous solution Substances 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- 150000001768 cations Chemical class 0.000 description 2

- 239000004927 clay Substances 0.000 description 2

- 239000013065 commercial product Substances 0.000 description 2

- 230000000052 comparative effect Effects 0.000 description 2

- 238000001816 cooling Methods 0.000 description 2

- LQZZUXJYWNFBMV-UHFFFAOYSA-N dodecan-1-ol Chemical compound CCCCCCCCCCCCO LQZZUXJYWNFBMV-UHFFFAOYSA-N 0.000 description 2

- 150000002191 fatty alcohols Chemical class 0.000 description 2

- 238000011049 filling Methods 0.000 description 2

- 238000001914 filtration Methods 0.000 description 2

- 239000011521 glass Substances 0.000 description 2

- 239000008187 granular material Substances 0.000 description 2

- 238000010438 heat treatment Methods 0.000 description 2

- BXWNKGSJHAJOGX-UHFFFAOYSA-N hexadecan-1-ol Chemical compound CCCCCCCCCCCCCCCCO BXWNKGSJHAJOGX-UHFFFAOYSA-N 0.000 description 2

- 238000011086 high cleaning Methods 0.000 description 2

- 239000004615 ingredient Substances 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- SNQQPOLDUKLAAF-UHFFFAOYSA-N nonylphenol Chemical compound CCCCCCCCCC1=CC=CC=C1O SNQQPOLDUKLAAF-UHFFFAOYSA-N 0.000 description 2

- GLDOVTGHNKAZLK-UHFFFAOYSA-N octadecan-1-ol Chemical compound CCCCCCCCCCCCCCCCCCO GLDOVTGHNKAZLK-UHFFFAOYSA-N 0.000 description 2

- 229940055577 oleyl alcohol Drugs 0.000 description 2

- XMLQWXUVTXCDDL-UHFFFAOYSA-N oleyl alcohol Natural products CCCCCCC=CCCCCCCCCCCO XMLQWXUVTXCDDL-UHFFFAOYSA-N 0.000 description 2

- 239000010452 phosphate Substances 0.000 description 2

- 229920001451 polypropylene glycol Polymers 0.000 description 2

- 238000005029 sieve analysis Methods 0.000 description 2

- 239000002002 slurry Substances 0.000 description 2

- 239000000429 sodium aluminium silicate Substances 0.000 description 2

- 235000012217 sodium aluminium silicate Nutrition 0.000 description 2

- 239000011780 sodium chloride Substances 0.000 description 2

- 229910052938 sodium sulfate Inorganic materials 0.000 description 2

- 235000011152 sodium sulphate Nutrition 0.000 description 2

- 239000004094 surface-active agent Substances 0.000 description 2

- 238000003786 synthesis reaction Methods 0.000 description 2

- YRIZYWQGELRKNT-UHFFFAOYSA-N 1,3,5-trichloro-1,3,5-triazinane-2,4,6-trione Chemical compound ClN1C(=O)N(Cl)C(=O)N(Cl)C1=O YRIZYWQGELRKNT-UHFFFAOYSA-N 0.000 description 1

- COKIOUWMXONTKQ-UHFFFAOYSA-N 1-phosphonopropane-1,2,3-tricarboxylic acid Chemical compound OC(=O)CC(C(O)=O)C(C(O)=O)P(O)(O)=O COKIOUWMXONTKQ-UHFFFAOYSA-N 0.000 description 1

- XHOLUELOOKEFMH-UHFFFAOYSA-N 3-methyl-2,2-diphosphonobutanedioic acid Chemical compound OC(=O)C(C)C(C(O)=O)(P(O)(O)=O)P(O)(O)=O XHOLUELOOKEFMH-UHFFFAOYSA-N 0.000 description 1

- SNSWUGOOACKRRJ-UHFFFAOYSA-N 3-phosphonobutane-1,2,3-tricarboxylic acid Chemical compound OC(=O)C(P(O)(O)=O)(C)C(C(O)=O)CC(O)=O SNSWUGOOACKRRJ-UHFFFAOYSA-N 0.000 description 1

- 229910021532 Calcite Inorganic materials 0.000 description 1

- YCKRFDGAMUMZLT-UHFFFAOYSA-N Fluorine atom Chemical compound [F] YCKRFDGAMUMZLT-UHFFFAOYSA-N 0.000 description 1

- WHXSMMKQMYFTQS-UHFFFAOYSA-N Lithium Chemical compound [Li] WHXSMMKQMYFTQS-UHFFFAOYSA-N 0.000 description 1

- 229920003171 Poly (ethylene oxide) Polymers 0.000 description 1

- 239000004743 Polypropylene Substances 0.000 description 1

- 229910004298 SiO 2 Inorganic materials 0.000 description 1

- 229920002472 Starch Polymers 0.000 description 1

- 241001122767 Theaceae Species 0.000 description 1

- 239000002253 acid Substances 0.000 description 1

- 150000007513 acids Chemical class 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 230000032683 aging Effects 0.000 description 1

- 150000001298 alcohols Chemical class 0.000 description 1

- 229910001854 alkali hydroxide Inorganic materials 0.000 description 1

- 150000008044 alkali metal hydroxides Chemical class 0.000 description 1

- 150000001340 alkali metals Chemical class 0.000 description 1

- 125000002947 alkylene group Chemical group 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- 125000000129 anionic group Chemical group 0.000 description 1

- 239000007900 aqueous suspension Substances 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 238000004061 bleaching Methods 0.000 description 1

- 239000006227 byproduct Substances 0.000 description 1

- BVKZGUZCCUSVTD-UHFFFAOYSA-N carbonic acid Chemical class OC(O)=O BVKZGUZCCUSVTD-UHFFFAOYSA-N 0.000 description 1

- 239000000969 carrier Substances 0.000 description 1

- 229960000541 cetyl alcohol Drugs 0.000 description 1

- 235000011967 chocolate pudding Nutrition 0.000 description 1

- 239000002734 clay mineral Substances 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- 239000003086 colorant Substances 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- GUJOJGAPFQRJSV-UHFFFAOYSA-N dialuminum;dioxosilane;oxygen(2-);hydrate Chemical compound O.[O-2].[O-2].[O-2].[Al+3].[Al+3].O=[Si]=O.O=[Si]=O.O=[Si]=O.O=[Si]=O GUJOJGAPFQRJSV-UHFFFAOYSA-N 0.000 description 1

- 230000004069 differentiation Effects 0.000 description 1

- 238000004090 dissolution Methods 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 239000000975 dye Substances 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 239000000945 filler Substances 0.000 description 1

- 239000012065 filter cake Substances 0.000 description 1

- 239000000706 filtrate Substances 0.000 description 1

- 229910052731 fluorine Inorganic materials 0.000 description 1

- 239000011737 fluorine Substances 0.000 description 1

- 239000006260 foam Substances 0.000 description 1

- 239000010794 food waste Substances 0.000 description 1

- 239000003205 fragrance Substances 0.000 description 1

- PMYUVOOOQDGQNW-UHFFFAOYSA-N hexasodium;trioxido(trioxidosilyloxy)silane Chemical compound [Na+].[Na+].[Na+].[Na+].[Na+].[Na+].[O-][Si]([O-])([O-])O[Si]([O-])([O-])[O-] PMYUVOOOQDGQNW-UHFFFAOYSA-N 0.000 description 1

- 230000001771 impaired effect Effects 0.000 description 1

- 239000012535 impurity Substances 0.000 description 1

- 229940094522 laponite Drugs 0.000 description 1

- 229910052744 lithium Inorganic materials 0.000 description 1

- LWXVCCOAQYNXNX-UHFFFAOYSA-N lithium hypochlorite Chemical compound [Li+].Cl[O-] LWXVCCOAQYNXNX-UHFFFAOYSA-N 0.000 description 1

- XCOBTUNSZUJCDH-UHFFFAOYSA-B lithium magnesium sodium silicate Chemical compound [Li+].[Li+].[OH-].[OH-].[OH-].[OH-].[OH-].[OH-].[OH-].[OH-].[OH-].[OH-].[OH-].[OH-].[Na+].[Na+].[Mg+2].[Mg+2].[Mg+2].[Mg+2].[Mg+2].[Mg+2].[Mg+2].[Mg+2].[Mg+2].[Mg+2].[Mg+2].[Mg+2].[Mg+2].[Mg+2].[Mg+2].[Mg+2].O1[Si](O2)([O-])O[Si]3([O-])O[Si]1([O-])O[Si]2([O-])O3.O1[Si](O2)([O-])O[Si]3([O-])O[Si]1([O-])O[Si]2([O-])O3.O1[Si](O2)([O-])O[Si]3([O-])O[Si]1([O-])O[Si]2([O-])O3.O1[Si](O2)([O-])O[Si]3([O-])O[Si]1([O-])O[Si]2([O-])O3.O1[Si](O2)([O-])O[Si]3([O-])O[Si]1([O-])O[Si]2([O-])O3.O1[Si](O2)([O-])O[Si]3([O-])O[Si]1([O-])O[Si]2([O-])O3 XCOBTUNSZUJCDH-UHFFFAOYSA-B 0.000 description 1

- 239000000391 magnesium silicate Substances 0.000 description 1

- 235000012243 magnesium silicates Nutrition 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 238000000691 measurement method Methods 0.000 description 1

- 235000013372 meat Nutrition 0.000 description 1

- MBKDYNNUVRNNRF-UHFFFAOYSA-N medronic acid Chemical compound OP(O)(=O)CP(O)(O)=O MBKDYNNUVRNNRF-UHFFFAOYSA-N 0.000 description 1

- 235000013336 milk Nutrition 0.000 description 1

- 239000008267 milk Substances 0.000 description 1

- 210000004080 milk Anatomy 0.000 description 1

- 239000011707 mineral Substances 0.000 description 1

- 229910052901 montmorillonite Inorganic materials 0.000 description 1

- GOQYKNQRPGWPLP-UHFFFAOYSA-N n-heptadecyl alcohol Natural products CCCCCCCCCCCCCCCCCO GOQYKNQRPGWPLP-UHFFFAOYSA-N 0.000 description 1

- 238000004806 packaging method and process Methods 0.000 description 1

- NBIIXXVUZAFLBC-UHFFFAOYSA-K phosphate Chemical compound [O-]P([O-])([O-])=O NBIIXXVUZAFLBC-UHFFFAOYSA-K 0.000 description 1

- 150000003009 phosphonic acids Chemical class 0.000 description 1

- ZJAOAACCNHFJAH-UHFFFAOYSA-N phosphonoformic acid Chemical class OC(=O)P(O)(O)=O ZJAOAACCNHFJAH-UHFFFAOYSA-N 0.000 description 1

- 229920000642 polymer Polymers 0.000 description 1

- 229920001155 polypropylene Polymers 0.000 description 1

- 159000000001 potassium salts Chemical class 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

- 150000003839 salts Chemical class 0.000 description 1

- 229910001575 sodium mineral Inorganic materials 0.000 description 1

- 159000000000 sodium salts Chemical class 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 239000012265 solid product Substances 0.000 description 1

- 239000007921 spray Substances 0.000 description 1

- 239000008107 starch Substances 0.000 description 1

- 235000019698 starch Nutrition 0.000 description 1

- 229940012831 stearyl alcohol Drugs 0.000 description 1

- 230000035882 stress Effects 0.000 description 1

- NVBFHJWHLNUMCV-UHFFFAOYSA-N sulfamide Chemical class NS(N)(=O)=O NVBFHJWHLNUMCV-UHFFFAOYSA-N 0.000 description 1

- 239000000725 suspension Substances 0.000 description 1

- 229950009390 symclosene Drugs 0.000 description 1

- 239000003826 tablet Substances 0.000 description 1

- 239000013008 thixotropic agent Substances 0.000 description 1

- 238000012546 transfer Methods 0.000 description 1

- 150000003918 triazines Chemical class 0.000 description 1

- SOBHUZYZLFQYFK-UHFFFAOYSA-K trisodium;hydroxy-[[phosphonatomethyl(phosphonomethyl)amino]methyl]phosphinate Chemical class [Na+].[Na+].[Na+].OP(O)(=O)CN(CP(O)([O-])=O)CP([O-])([O-])=O SOBHUZYZLFQYFK-UHFFFAOYSA-K 0.000 description 1

- AZJYLVAUMGUUBL-UHFFFAOYSA-A u1qj22mc8e Chemical compound [F-].[F-].[F-].[F-].[F-].[F-].[F-].[F-].[F-].[F-].[F-].[F-].[F-].[F-].[F-].[F-].[F-].[F-].[Na+].[Na+].[Na+].[Na+].[Na+].[Na+].[Na+].[Na+].[Na+].[Na+].[Mg+2].[Mg+2].[Mg+2].[Mg+2].[Mg+2].[Mg+2].[Mg+2].[Mg+2].[Mg+2].[Mg+2].[Mg+2].[Mg+2].[Mg+2].[Mg+2].[Mg+2].[Mg+2].O=[Si]=O.O=[Si]=O.O=[Si]=O.O1[Si](O2)([O-])O[Si]3([O-])O[Si]1([O-])O[Si]2([O-])O3.O1[Si](O2)([O-])O[Si]3([O-])O[Si]1([O-])O[Si]2([O-])O3.O1[Si](O2)([O-])O[Si]3([O-])O[Si]1([O-])O[Si]2([O-])O3.O1[Si](O2)([O-])O[Si]3([O-])O[Si]1([O-])O[Si]2([O-])O3.O1[Si](O2)([O-])O[Si]3([O-])O[Si]1([O-])O[Si]2([O-])O3.O1[Si](O2)([O-])O[Si]3([O-])O[Si]1([O-])O[Si]2([O-])O3 AZJYLVAUMGUUBL-UHFFFAOYSA-A 0.000 description 1

- 238000005406 washing Methods 0.000 description 1

- 239000001993 wax Substances 0.000 description 1

Classifications

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D17/00—Detergent materials or soaps characterised by their shape or physical properties

- C11D17/0008—Detergent materials or soaps characterised by their shape or physical properties aqueous liquid non soap compositions

- C11D17/003—Colloidal solutions, e.g. gels; Thixotropic solutions or pastes

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D3/00—Other compounding ingredients of detergent compositions covered in group C11D1/00

- C11D3/02—Inorganic compounds ; Elemental compounds

- C11D3/12—Water-insoluble compounds

- C11D3/124—Silicon containing, e.g. silica, silex, quartz or glass beads

- C11D3/1246—Silicates, e.g. diatomaceous earth

- C11D3/1253—Layer silicates, e.g. talcum, kaolin, clay, bentonite, smectite, montmorillonite, hectorite or attapulgite

- C11D3/1266—Layer silicates, e.g. talcum, kaolin, clay, bentonite, smectite, montmorillonite, hectorite or attapulgite in liquid compositions

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D3/00—Other compounding ingredients of detergent compositions covered in group C11D1/00

- C11D3/395—Bleaching agents

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D3/00—Other compounding ingredients of detergent compositions covered in group C11D1/00

- C11D3/395—Bleaching agents

- C11D3/3956—Liquid compositions

Definitions

- the detergents used in dishwashers usually consist of powders or granules or tablets. Accordingly, the input devices in which the detergents are deposited prior to rinsing in these machines are also designed for solid products and usually consist of lockable chambers which open during the main rinse cycle and release the contents.

- a number of disadvantages result from this method of working. When entering the cleaner, the housewife has to shake the storage pack or the measuring cup so that the powder slides into the chamber, and it often happens that more or less large parts of the powder are spilled and / or get on the skin. These spilled parts are usually lost for the rinsing process, since they are pumped out together with the cold prewash solution at the end of the pre-rinse cycle.

- the object of the invention is to develop a cleaner which can be used in dishwashers and which does not have the disadvantages described and which can be used both in conventional dishwashers and can also be used in machines still to be developed with a stored cleaner. In these cases, automatic dosing from a detergent supply would then take place.

- the viscosity of the cleaner is preferably 70 to 200 Pa-s and in particular 80 to 150 Pa-s.

- the thixotropy of the cleaner is not significantly disturbed by the measuring process. Such disturbances do not occur at a rotational speed of the spindle inserted into the sample of 5 rpm.

- a Brookfield viscometer for example, is suitable, but other measurement methods can also be used for the determination, which allow measurement under comparable conditions.

- the rheological behavior of the cleaner is such that the gel-like paste is able to penetrate Exposure to mechanical forces, for example by shaking or pressure on a deformable storage bottle or tube. or liquefied by means of a metering pump and easily squeezed out of a spray nozzle or transferred into the induction chamber. As soon as the mechanical action has ended, the agent solidifies again into a gel, which remains unchanged in the induction chamber when the flap is closed. It can thus be achieved that the product survives one or two pre-rinse cycles as a paste and is therefore only available as intended in the cleaning cycle.

- the gel instantaneously liquefies and the agent distributes itself in the detergent solution in a short time. It is therefore available to the cleaner from the moment the cleaner is released, which is why the cleaning effect is more intensive than in the conventional rinsing process.

- the tripolyphosphate used in the cleaners used according to the invention can be completely or partially replaced by water-insoluble, finely divided, bound water-containing alkali alumosilicates which have a calcium binding capacity of 50 to 200 mg CaO / g active substance (AS) and the formula preferably correspond.

- AS CaO / g active substance

- Such compounds are known, for example, under the name SASIL ".

- the calcium binding capacity of the aluminosilicates is determined in the following way:

- component (A) is also suitable for commercially operated dishwashers. Less preferred constituents of component (A) are the carbonates or hydrogen carbonates of sodium or potassium, which are generally only used together with alkali compounds which have a more cleaning action.

- Component (B) preferably consists of sodium, potassium or lithium hypochlorite. Chlorinated trisodium or tripotassium o-phosphate can be used as further useful active chlorine compounds.

- Organic chlorine carriers such as trichloroisocyanuric acid or alkali metal dichloroisocyanurates or N-chlorinated sulfamides or triazines, are less preferred since they are less stable in storage in the cleaners to be used according to the invention.

- the amount of active chlorine carrier is preferably such that the Hopter contain 0.1 to 3.0 wt .-%, in particular 0.5 to 2.0 wt .-% of active chlorine.

- Component (C) consists of a thickener resistant to alkalis and active chlorine, which is able to form a thixotropic gel in water.

- Swellable layered silicates of the montmorillonite type have proven to be suitable which, in 5% by weight aqueous suspension after complete swelling with a conventional rotary viscometer and a speed of the measuring spindle of 5 revolutions per minute, have a viscosity of at least 30 Pa - s (20 ° C) .

- Natural or synthetic layered silicates of the hectorite type have proven to be particularly suitable for component (C). Both the processed natural and the synthetic hectorites can still contain certain impurities which do not interfere with the use of the compositions according to the invention. In the processed natural hectorites, these are other layered silicate types or small additions to calcite, with synthetically produced z. B. sodium carbonate or: sodium sulfate. The water-soluble by-products of the synthesis do not need to be washed out or not completely, which considerably reduces the production outlay.

- synthetic hectorite If synthetic hectorite is used, it does not need to be dewatered before the cleaner is produced, but can, after the majority of the water has been separated off, be further processed by centrifuging or filtration as an aqueous slurry or moist filter cake to form the cleaners to be used according to the invention without further pretreatment.

- Hectorites are generally understood to mean trioctahedral layered magnesium silicates of the general formula wherein x is a value greater than 0 and less than 6, y is a value from 0 to 4 and n is an integer from 1 to 3 and M is a cation.

- the water content of an air-dry product is generally 5 to 10% by weight.

- the layered silicates are used in fine-grained form, i. H. the proportion of the sieve analysis on a sieve with a mesh size of 0.25 mm should be less than 5% by weight, preferably less than 1% by weight.

- the amount of the layered silicate to be used depends primarily on its ability to swell. In the case of hectorite, 1 to 10% by weight, preferably 2 to 6% by weight (based on hectorite dried at 105 ° C.) are generally used.

- Optional non-ionic surfactants with low foaming power are used as optional components, which do not decompose in the presence of active chlorine compounds and possibly alkali hydroxides.

- Suitable addition products are the adduct of 10 to 30% by weight of ethylene oxide with a polypropylene glycol with a molecular weight of 1750, the adduct of 20 mol of ethylene oxide or 9 mol of ethylene oxide and 10 mol of propylene oxide with nonylphenol, the adduct of 5 to 12 mol of ethylene oxide to a fatty alcohol mixture of chain lengths C 12 -C 18 with a share of about 30% in oleyl alcohol and the like.

- This exemplary list is not a limitation.

- the proportion of the nonionic surfactants can be up to 5% by weight, preferably 0.1 to 1% by weight.

- chlorine and alkali-resistant colors and fragrances can be added to the dish detergents.

- Additional components of the active substances used such as sodium sulfate, sodium chloride or mineral admixtures of the layered silicate, are also suitable as optional components.

- complexing agents that can be used are active chlorine-resistant, generally nitrogen-free complexing agents, e.g. B. polyvalent phosphonic acids, such as methylene diphosphonic acid or polyvalent phosphonocarboxylic acids, such as 1,1-diphosphonopropane-1,2-dicarboxylic acid, 1-phosphonopropane-1,2,3-tricarboxylic acid or 2-phosphonobutane-2,3,4-tricarboxylic acid or its sodium - or potassium salts.

- the active chlorine-resistant polycarboxylic acids and their salts are also useful complexing agents.

- the cleaning agents to be used according to the invention are advantageously prepared by combining an aqueous solution or slurry containing the cleaning components of component (A), in particular the tripolyphosphate and optionally the alkali silicate (water glass), or a part thereof stirred with the thickener while heating to 40 to 65 ° C. with a high shear agitator, for example a UItra-Turrax • device, until the thickening has taken place.

- a high shear agitator for example a UItra-Turrax • device

- the remaining constituents of component (A) e.g. B. metasilicate, water glass and possibly the residues of triphosphate and the optional components, such as nonionic surfactants and dyes, are stirred in.

- the active chlorine compound is finally added, for example in the form of a sodium hypochlorite solution (chlorine bleach).

- the agents can be filled into the storage containers immediately after their manufacture.

- the maximum value of the viscosity is generally reached after a standing time of 2 to 10 days.

- a brief liquefaction occurs through vigorous shaking or pressing, however, the gel state is restored just a few seconds after the mechanical stress has ended, ie the cleaner introduced into the dishwasher's storage chamber solidifies sufficiently quickly that it does not flow out after the closing flap of the pantry or the loading door of the dishwasher.

- the cleaners to be used according to the invention are distinguished by a high cleaning power and in particular by a long shelf life.

- the active chlorine loss during a 6-month service life at 25 ° C was of the same order of magnitude as that of commercially available detergent granules stored in a dry place.

- repeated heating of the cleaner to temperatures of around 60 ° C. has not proven to be disadvantageous to the storage stability or the active chlorine content.

- the detergent paste which was repeatedly warmed up by heat transfer, did not suffer any loss of active chlorine which would have an adverse effect on the wash result within the test period of 5 days (2 rinse cycles per day).

- the agents can be dosed much more easily and precisely than conventional granular or powdered cleaners, which are often spilled in part when filling into the spatially limited induction chambers because of the mostly necessary shaking of the storage package or the dosing cup.

- the majority contain foam-active surfactants, bleaches containing active chlorine, clay-like fillers, including hectorite, and a special abrasive component as the main component.

- the thickener primarily serves to prevent the specific light abrasive from settling.

- DE-A-28 10 187 discloses alkaline agents and a method for pretreating heavily soiled kitchen appliances which are free of abrasives, about 0.25 to about 20% of a clay as a thickener and about 0.5 to about 9% of one Contain alkali metal silicate with a ratio of SiO 2 : M 2 O of more than about 1 with M equal to sodium or potassium, which have a hypohalite concentration with an active chlorine content of about 0.5 to 10% and whose viscosity is about 1 to about 10,000 Pa - s and are applied to kitchen appliances with dirt that is difficult to remove. Then everything is covered with an excess of water at a temperature greater than about 38 ° C.

- the viscosity of the preferably thixotropic agents tends to be considerably higher than in the agents of the present invention, since they should adhere well and long to the soiled surfaces in order to be able to act there, while the consistency of the cleaners according to the invention is only intended to ensure their meterability. In addition, they should be released quickly in the dishwasher cleaning cycle.

- the devices pre-cleaned according to DE-A-28 10 187 can subsequently be introduced into dishwashers. Their used coating is supposed to suppress foam, but then no longer has a cleaning effect due to a lack of tripolyphosphates.

- Hectorite I is a commercial product from Lanco

- Hectorite II is the commercial product Laponite B * from Laporte Ind. Ltd.

- the water content of the products was 7-8% by weight, the grain size (sieve analysis) was less than 0.2 mm with an average grain size of approx. 0.006-0.008 mm.

- the viscosity of a 5% by weight aqueous gel was 75 Pas for Hectorite I and 95 Pas for Hectorite II.

- the commercial granular cleaner used for comparison has the following composition:

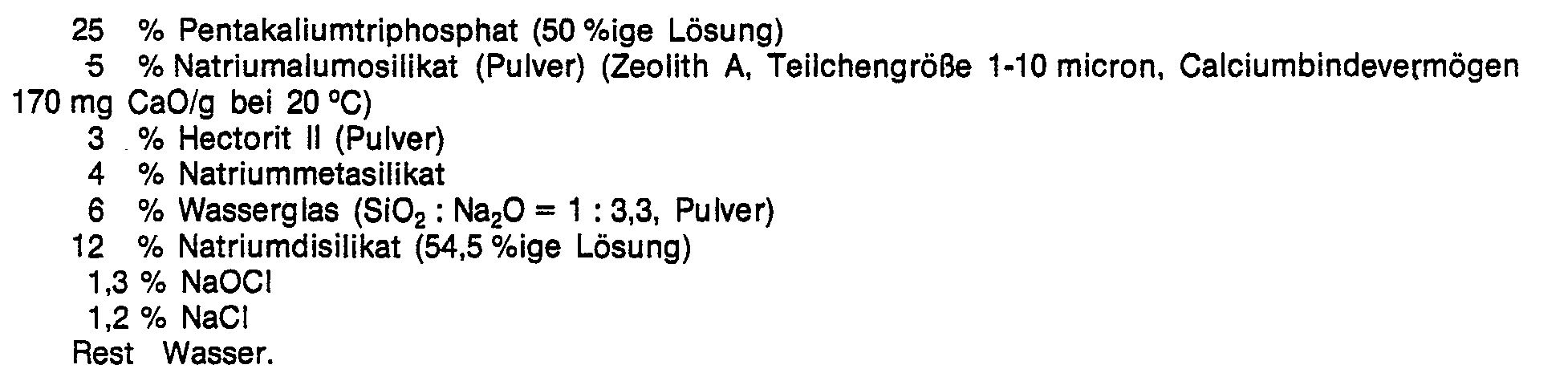

- a pasty cleaner containing (in% by weight) was produced by stirring the 50% triphosphate solution heated to 55 ° C. with the addition of the hectorite until it had thickened with an intensive stirrer (Ultra-Turrax®). Then 2% by weight sodium metasilicate was stirred in as a powdery powder. After the disilicate had been added in the form of a 54.5% by weight solution, the paste was cooled and the sodium hypochlorite in the form of a NaCl-containing chlorine bleach (active chlorine content 13%) and the rest of the sodium metasilicate were incorporated.

- the viscosity measured after a standing time of 10 days under the specified conditions was 125 Pa ⁇ s.

- Example 1 was repeated, except that dry potassium tripolyphosphate was stirred into an aqueous swelling made from filter-moist hectorite I with an unchanged amount of water. The further processing was carried out as indicated in Example 1. The viscosity of the paste determined under the specified conditions was 115 Pa. s.

- Example 3 was repeated using the thickener labeled "Hectorite I.”

- the viscosity of the agent was 103 Pa. s.

- the cleaner of the following composition was prepared by mixing the ingredients in the order given at 55 ° with an intensive stirrer.

- the chlorine bleach was incorporated after the paste cooled.

- the viscosity determined by definition after 10 days of standing was 98 Pa ⁇ s.

- the chlorine bleach was added after the mixture had been heated to 60 ° C.

- the viscosity was 120 Pa - s after 10 days of standing.

- Example 6 was repeated, with an additional 0.3% of a nonionic, non-foaming surfactant from the class of the polypropylene oxide-polyethylene oxide block polymers being added before the chlorine bleaching solution was added.

- the viscosity of the paste after 118 days of standing was 118 Pa ⁇ s.

Landscapes

- Chemical & Material Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Wood Science & Technology (AREA)

- Organic Chemistry (AREA)

- Dispersion Chemistry (AREA)

- Inorganic Chemistry (AREA)

- Detergent Compositions (AREA)

- Cosmetics (AREA)

Abstract

Description

Die in Geschirrspülmaschinen eingesetzten Reiniger bestehen üblicherweise aus Pulvern bzw. Granulaten oder aus Tabletten. Dementsprechend sind in diesen Maschinen auch die Eingabevorrichtungen, in denen die Reiniger vor dem Spülen deponiert werden, auf feste Produkte ausgelegt und bestehen üblicherweise aus verschließbaren Kammern, die sich während des Hauptspülgangs öffnen und den Inhalt freigeben. Aus dieser Arbeitsweise resultiert eine Reihe von Nachteilen. Beim Eingeben des Reinigers muß die Hausfrau die Vorratspackung bzw. den Meßbecher rütteln, damit das Pulver in die Kammer gleitet, wobei es häufig vorkommt, daß mehr oder weniger große Anteile des Pulvers verschüttet werden und/oder auf die Haut gelangen. Diese verschütteten Anteile gehen für den Spülvorgang meist verloren, da sie am Ende des Vorspülgangs zusammen mit der kalten Vorspüllauge abgepumpt werden. Gelangt Pulver beim Einfüllen in den Öffnungsmechanismus der Kammer, so kann es geschehen, daß sich der Deckel nicht vollständig schließen läßt bzw. der bei einigen Konstruktionen übliche Magnetverschluß oder mechanisch/elektrische Verschluß nicht fest genug schließt, so daß beim Schließen der Beschickungstüre der Spülmaschine das Pulver oder ein Teil davon herausrieselt und ebenfalls im Hauptspülgang nicht mehr zur Verfügung steht. Probleme können weiterhin in solchen Maschinen auftreten, in denen die Kammer zusätzlich mit einem Schutzgitter gesichert ist und Reiniger verwendet werden, die hinsichtlich ihrer Lösungsgeschwindigkeit nicht optimiert oder durch längeres Stehenlassen angebrauchter Packungen zusammengeballt sind. Ein nicht vollständig während des Spülvorgangs gelöster Reiniger führt zu einem schlechteren Reinigungsergebnis und beeinträchtigt die Wirkung des sauren Klarspülmittels. Bei Leitfähigkeitsmessungen hat sich weiterhin gezeigt, daß auch leichtlösliche Reiniger nach der Freigabe längere Zeit, unter ungünstigen Umständen bis zu 10 Minuten, zur vollständigen Auflösung benötigen, was dazu führt, daß während einer erheblichen Zeitspanne mit einer Unterkonzentration an Reinigern gearbeitet wird. Soweit in den letzten Jahren Verbesserungen angestrebt und erzielt wurden, bezogen sie sich auf der apparativen Seite auf den Einspülmechanismus, auf der Reinigerseite auf eine verbesserte Rieselfähigkeit und erhöhte Lösungsgeschwindigkeit des stets festen Reinigers. Die Möglichkeit, flüssige Mittel einzusetzen, beschränkte sich auf saure Klarspüler, die in der Regel in einem Vorratsbehälter deponiert werden.The detergents used in dishwashers usually consist of powders or granules or tablets. Accordingly, the input devices in which the detergents are deposited prior to rinsing in these machines are also designed for solid products and usually consist of lockable chambers which open during the main rinse cycle and release the contents. A number of disadvantages result from this method of working. When entering the cleaner, the housewife has to shake the storage pack or the measuring cup so that the powder slides into the chamber, and it often happens that more or less large parts of the powder are spilled and / or get on the skin. These spilled parts are usually lost for the rinsing process, since they are pumped out together with the cold prewash solution at the end of the pre-rinse cycle. If powder gets into the opening mechanism of the chamber during filling, it may happen that the lid cannot be closed completely or the magnetic lock or mechanical / electrical lock that is common in some constructions does not close tight enough, so that when the loading door of the dishwasher closes Powder or part of it trickles out and is also no longer available in the main wash cycle. Problems can also occur in machines in which the chamber is additionally secured with a protective grille and cleaners are used which are not optimized in terms of their dissolution speed or are agglomerated due to the packaging having been left standing for a long time. A detergent that is not completely dissolved during the rinsing process will lead to a poorer cleaning result and impair the effect of the acidic rinse aid. Conductivity measurements have also shown that even slightly soluble cleaners take a long time to dissolve under unfavorable circumstances, up to 10 minutes under unfavorable circumstances, which means that a low concentration of cleaners is used for a considerable period of time. Insofar as improvements have been sought and achieved in recent years, on the apparatus side they relate to the induction mechanism, and on the cleaner side to improved flowability and increased dissolving speed of the permanently solid cleaner. The ability to use liquid agents was limited to acidic rinse aids, which are usually deposited in a storage container.

Der Gedanke, flüssige Reiniger anstelle der Pulver in Geschirrspülmaschinen einzusetzen, lag völlig fern, da die weithin üblichen Eingabevorrichtungen aufgrund ihrer Konstruktion sich nicht für flüssige Mittel eignen und weiterhin befürchtet werden mußte, daß sich ein in der Maschine integrierter Vorratstank bei jedem Spülvorgang erheblich erwärmen und der im Reiniger üblicherweise enthaltene Aktivchlorträger zersetzen würde.The idea of using liquid detergents instead of powders in dishwashers was completely remote, since the widely used input devices are not suitable for liquid detergents due to their design and there was also the fear that a storage tank integrated in the machine would heat up considerably with each washing process and the active chlorine carrier normally contained in the cleaner would decompose.

Der Erfindung liegt die Aufgabe zugrunde, einen in Geschirrspülmaschinen verwendbaren Reiniger zu entwickeln, der die geschilderten Nachteile nicht besitzt und sowohl in herkömmlichen Spülmaschinen eingesetzt werden kann als auch in noch zu entwickelnden Maschinen mit bevorratetem Reiniger brauchbar ist. In diesen Fällen würde dann also eine automatische Dosierung aus einer Reinigerbevorratung erfolgen.The object of the invention is to develop a cleaner which can be used in dishwashers and which does not have the disadvantages described and which can be used both in conventional dishwashers and can also be used in machines still to be developed with a stored cleaner. In these cases, automatic dosing from a detergent supply would then take place.

Gegenstand der Erfindung ist die Verwendung eines wäßrigen im Ruhezustand bei Raumtemperatur pastösen, thixotropen Reinigers in Geschirrspülmaschinen mit einem Gehalt an (A) mindestens einer reinigend wirkenden bzw. härtebildenden, Ionen bindenden Verbindung, (B) einer Aktivchlorverbindung und (C) einem damit verträglichen Verdickungsmittel, dessen bei 20 °C mittels eines Rotationsviskosimeters bei 5 Spindelumdrehungen pro Minute bestimmte Viskosität mindestens 30 Pa - s beträgt und der

- (A)

- 3 bis 40 Gew.-% Natrium- und/oder Kaliumtripolyphosphat,

- 5 bis 30 Gew.-% Natrium- und/oder Kaliumsilikate, bestehend aus einem Gemisch von Metasilikaten und Disilikaten bzw. Wasserglas im Mischungsverhältnis 2 : 1 bis 1 : 10, berechnet auf die wasserfreien Substanzen,

- 0 bis 25 Gew.-% feinteiliges, Calciumsalze bindendes Natriumalumosilikat, und

- 0 bis 20 Gew.-% Carbonat und/oder Hydroxid des Natriums und/oder Kaliums,

- (B) eine Aktivchlorverbindung mit einem Aktivchlorgehalt, bezogen auf den gesamten Reiniger, von 0,1 bis 3,0 Gew.-% und

- (C) 1 bis 10 Gew.-% eines quellfähigen Schichtsilikats mit hohem Verdickungsvermögen in wäßrigen Medien enthält.

- (A)

- 3 to 40% by weight sodium and / or potassium tripolyphosphate,

- 5 to 30% by weight of sodium and / or potassium silicates, consisting of a mixture of metasilicates and disilicates or water glass in a mixing ratio of 2: 1 to 1:10, calculated on the anhydrous substances,

- 0 to 25 wt .-% finely divided, calcium salts binding sodium aluminosilicate, and

- 0 to 20% by weight of carbonate and / or hydroxide of sodium and / or potassium,

- (B) an active chlorine compound with an active chlorine content, based on the total cleaner, of 0.1 to 3.0% by weight and

- (C) contains 1 to 10% by weight of a swellable layered silicate with a high thickening capacity in aqueous media.

Vorzugsweise beträgt die unter den angegebenen Bedingungen bestimmte Viskosität des Reinigers 70 bis 200 Pa - s und insbesondere 80 bis 150 Pa - s.The viscosity of the cleaner, determined under the specified conditions, is preferably 70 to 200 Pa-s and in particular 80 to 150 Pa-s.

Bei der Bestimmung der Viskosität ist zu beachten, daß die Thixotropie des Reinigers durch den Meßvorgang nicht wesentlich gestört wird. Bei einer Umdrehungsgeschwindigkeit der in die Probe eingeführten Spindel von 5 Upm treten derartige Störungen nicht auf. Geeignet ist beispielsweise ein Brookfield-Viskosimeter, jedoch können auch andere Meßmethoden zur Bestimmung herangezogen werden, die eine Messung unter vergleichbaren Bedingungen zulassen.When determining the viscosity, it should be noted that the thixotropy of the cleaner is not significantly disturbed by the measuring process. Such disturbances do not occur at a rotational speed of the spindle inserted into the sample of 5 rpm. A Brookfield viscometer, for example, is suitable, but other measurement methods can also be used for the determination, which allow measurement under comparable conditions.

Das rheologische Verhalten des Reinigers ist so bemessen, daß sich die gelartige Paste durch Einwirkung mechanischer Kräfte, beispielsweise durch Schütteln oder Druckeinwirkung auf eine verformbare Vorratsflasche bzw. Tube. oder mittels einer Dosierpumpe verflüssigt und leicht aus einer Spritzdüse ausdrücken bzw. in die Einspülkammer überführen läßt. Sobald die mechanische Einwirkung beendet ist, erstarrt das Mittel wieder zu einem Gel, das bei geschlossener Klappe unverändert in der Einspülkammer verbleibt. So läßt sich erreichen, daß das Produkt einen oder zwei Vorspülgänge als Paste überdauert und damit erst im Reinigungsgang bestimmungsgemäß zur Verfügung steht. Sobald sich die Verschlußklappe geöffnet hat und das Mittel mit der bewegten Spüllauge in Berührung kommt, tritt eine augenblickliche Verflüssigung des Gels ein, und das Mittel verteilt sich in kurzer Zeit in der Spüllauge. Es steht daher vom Augenblick der Freigabe des Reinigers an dessen Reinigungskraft zur Verfügung, weshalb die Reinigungswirkung intensiver als beim herkömmlichen Spülprozeß ist.The rheological behavior of the cleaner is such that the gel-like paste is able to penetrate Exposure to mechanical forces, for example by shaking or pressure on a deformable storage bottle or tube. or liquefied by means of a metering pump and easily squeezed out of a spray nozzle or transferred into the induction chamber. As soon as the mechanical action has ended, the agent solidifies again into a gel, which remains unchanged in the induction chamber when the flap is closed. It can thus be achieved that the product survives one or two pre-rinse cycles as a paste and is therefore only available as intended in the cleaning cycle. As soon as the closure flap has opened and the agent comes into contact with the moving detergent solution, the gel instantaneously liquefies and the agent distributes itself in the detergent solution in a short time. It is therefore available to the cleaner from the moment the cleaner is released, which is why the cleaning effect is more intensive than in the conventional rinsing process.

Das in den erfindungsgemäß verwendeten Reinigern eingesetzte Tripolyphosphat kann ganz oder teilweise ersetzt sein durch wasserunlösliche, feinteilige, gebundenes Wasser enthaltende Alkalialumosilikate, die ein Calciumbindevermögen von 50 bis 200 mg CaO/g Aktivsubstanz (AS) aufweisen und der Formel

1 I einer wäßrigen, 0,594 g CaCI (= 300 mg CaO/l =30 °C) enthaltenden und mit verdünnter NaOH auf einen pH-Wert von 10 eingestellten Lösung wird mit 1 g Aluminiumsilikat versetzt (auf AS bezogen). Dann wird die Suspension 15 Minuten lang bei einer Temperatur von 22 °C (±2°C) kräftig gerührt. Nach Abfiltrieren des Aluminiumsilikates bestimmt man die Resthärte x des Filtrates. Daraus erreichnet sich das Calciumbindevermögen in mg CaO/g AS nach der Formel :

Bestimmt man das Calciumbindevermögen bei höheren Temperaturen, z. B. bei 60 °C, so findet man durchweg bessere Werte als bei 22 °C. Dieser Umstand zeichnet die Aluminiumsilikate gegenüber den meisten der bisher zur Verwendung als Phosphatersatz vorgeschlagenen löslichen Komplexbildnern aus und stellt bei ihrer Verwendung einen besonderen technischen Fortschritt dar.If one determines the calcium binding capacity at higher temperatures, e.g. B. at 60 ° C, you will find consistently better values than at 22 ° C. This fact distinguishes aluminum silicates from most of the soluble complexing agents previously proposed for use as a phosphate substitute and represents a special technical advance in their use.

Für gewerblich betriebene Geschirrspülmaschinen, ist ferner der Zusatz von Natriumhydroxid bzw. Kaliumhydroxid geeignet. Weniger bevorzugte Bestandteile der Komponente (A) sind die Carbonate bzw. Hydrogencarbonate des Natriums- oder Kaliums, die in der Regel nur zusammen mit stärker reinigend wirkenden Alkaliverbindungen eingesetzt werden.The addition of sodium hydroxide or potassium hydroxide is also suitable for commercially operated dishwashers. Less preferred constituents of component (A) are the carbonates or hydrogen carbonates of sodium or potassium, which are generally only used together with alkali compounds which have a more cleaning action.

Die Komponente (A) weist in einer besonders bevorzugten Anwendungsform die folgende Zusammensetzung auf :

- 5-30 Gew.-% Natrium- und/oder Kaliumtripolyphosphat,

- 5-30 Gew.-% Natrium- und/oder Kaliumsilikat, als Gemisch von Metasilikaten und Disilikaten bzw. Wasserglas im Mischungsverhältnis 2:1 bis 1 : 10, vorzugsweise 1 : bis 1 5, berechnet auf die wasserfreien Substanzen,

- 0-10 Gew.-% Natriumalumosilikat,

- 0- 5 Gew.-% Natrium- und/oder Kaliumhydroxid.

- 5-30% by weight sodium and / or potassium tripolyphosphate,

- 5-30% by weight sodium and / or potassium silicate, as a mixture of metasilicates and disilicates or water glass in a mixing ratio of 2: 1 to 1:10, preferably 1: to 15, calculated on the anhydrous substances,

- 0-10% by weight sodium aluminosilicate,

- 0- 5 wt .-% sodium and / or potassium hydroxide.

Das Natrium- oder Kaliummetasilikat hat die Zusammensetzung Me20 : Sio2 = 1 : 1 und die Disilikate bzw. Wasserglas die Zusammensetzung Me20 : Si02 = 1 : 2 bis 1 : 3,5.The sodium or potassium metasilicate has the composition Me 2 0: Sio 2 = 1: 1 and the disilicates or water glass has the composition Me 2 0: Si0 2 = 1: 2 to 1: 3.5.

Die Komponente (B) besteht vorzugsweise aus Natrium-, Kalium- oder Lithiumhypochlorit. Als weitere brauchbare Aktivchlorverbindungen kommen chloriertes Trinatrium- oder Trikalium-o-phosphat in Frage. Organische Chlorträger, wie Trichlorisocyanursäure oder Alkalimetall-dichlorisocyanurate bzw. N-chlorierte Sulfamide oder Triazine sind weniger bevorzugt, da sie in den erfindungsgemäß zu verwendenden Reinige- i weniger lagerbeständig sind. Die Menge der Aktivchlorträger ist vorzugsweise so bemessen, daß die Heiniger 0,1 bis 3,0 Gew.-%, insbesondere 0,5 bis 2,0 Gew.-% an aktivem Chlor enthalten.Component (B) preferably consists of sodium, potassium or lithium hypochlorite. Chlorinated trisodium or tripotassium o-phosphate can be used as further useful active chlorine compounds. Organic chlorine carriers, such as trichloroisocyanuric acid or alkali metal dichloroisocyanurates or N-chlorinated sulfamides or triazines, are less preferred since they are less stable in storage in the cleaners to be used according to the invention. The amount of active chlorine carrier is preferably such that the Heiniger contain 0.1 to 3.0 wt .-%, in particular 0.5 to 2.0 wt .-% of active chlorine.

Die Komponente (C) besteht aus einem gegen Alkalien und Aktivchlor beständigen Verdickungsmittel, das in Wasser ein thixotropes Gel zu bilden vermag. Als geeignet haben sich quellfähige Schichtsilikate vom Montmorillonit-Typ erwiesen, die in 5-gewichtsprozentiger wäßriger Suspension nach vollständiger Quellung mit einem üblichen Rotationsviskosimeter bei einer Drehzahl der Meßspindel von 5 Umdrehungen pro Minute eine Viskosität von mindestens 30 Pa - s (20 °C) aufweisen. Eine vollständige Quellung bedeutet, daß nach vollständiger Verteilung des Verdickungsmittels in Wasser, die zweckmäßigerweise unter Zuhilfenahme einer hochwirksamen Rührvorrichtung bei Temperaturen von 30-60 °C vorgenommen wird, nach mehrtägiger Alterung bzw. Standzeit bei Raumtemperatur auch bei weiterer thermischer bzw. mechanischer Behandlung die Viskosität nicht mehr zunimmt.Component (C) consists of a thickener resistant to alkalis and active chlorine, which is able to form a thixotropic gel in water. Swellable layered silicates of the montmorillonite type have proven to be suitable which, in 5% by weight aqueous suspension after complete swelling with a conventional rotary viscometer and a speed of the measuring spindle of 5 revolutions per minute, have a viscosity of at least 30 Pa - s (20 ° C) . Complete swelling means that after the thickener has been completely distributed in water, this is expediently carried out with the aid of a highly effective stirring device at Tempera ture of 30-60 ° C, after several days of aging or standing at room temperature, even with further thermal or mechanical treatment, the viscosity no longer increases.

Als für die Komponente (C) besonders geeignet haben sich natürliche oder synthetische Schichtsilikate vom Hectorit-Typ erwiesen. Sowohl die aufbereiteten natürlichen als auch die synthetischen Hectorite können noch gewisse Verunreinigungen enthalten, die bei der erfindungsgemäßen Verwendung der Mittel nicht stören. Bei den aufbereiteten natürlichen Hectoriten sind dies andere Schichtsilikat-Typen bzw. geringe Beimengungen an Calcit, bei synthetisch hergestellten z. B. Natriumcarbonat bzw: Natriumsulfat. Die wasserlöslichen Nebenprodukte der Synthese brauchen nicht oder nicht vollständig ausgewaschen zu werden, was den Herstellungsaufwand erheblich vermindert. Wird synthetischer Hectorit eingesetzt, braucht dieser vor der Herstellung des Reinigers auch nicht entwässert zu werden, sondern kann nach Abtrennung der Hauptmenge des Wassers durch Zentrifugieren oder Filtration als wäßrige Aufschlämmung bzw. feuchter Filterkuchen ohne weitere Vorbehandlung zu den erfindungsgemäß zu verwendenden Reinigern weiterverarbeitet werden.Natural or synthetic layered silicates of the hectorite type have proven to be particularly suitable for component (C). Both the processed natural and the synthetic hectorites can still contain certain impurities which do not interfere with the use of the compositions according to the invention. In the processed natural hectorites, these are other layered silicate types or small additions to calcite, with synthetically produced z. B. sodium carbonate or: sodium sulfate. The water-soluble by-products of the synthesis do not need to be washed out or not completely, which considerably reduces the production outlay. If synthetic hectorite is used, it does not need to be dewatered before the cleaner is produced, but can, after the majority of the water has been separated off, be further processed by centrifuging or filtration as an aqueous slurry or moist filter cake to form the cleaners to be used according to the invention without further pretreatment.

Unter Hectoriten versteht man im allgemeinen trioctaedrische Magnesium-Schichtsilikate der allgemeinen Formel

Die Synthese der Hectorite ist beispielsweise aus der Zeitschrift « Clay and Clay Minerals", Vol. 8, (1960), Seiten 150-169 bzw. der DE-PS11 84742 bekannt.The synthesis of hectorites is known, for example, from the journal "Clay and Clay Minerals", Vol. 8, (1960), pages 150-169 and DE-PS11 84742.

Die SchichtsiliKate kommen in feinkörniger Form zum Einsatz, d. h. der Anteil der bei der Siebanalyse auf einem Sieb mit 0,25 mm Maschenweite soll weniger als 5 Gew.-% vorzugsweise weniger als 1 Gew.-% betragen. Die Menge des einzusetzenden Schichtsilikats hängt in erster Linie von dessen Quellfähigkeit ab. Im Falle des Hectorits werden im allgemeinen 1 bis 10 Gew.-%, vorzugsweise 2 bis 6 Gew.-% (bezogen auf bei 105°C getrockneten Hectorit) eingesetzt.The layered silicates are used in fine-grained form, i. H. the proportion of the sieve analysis on a sieve with a mesh size of 0.25 mm should be less than 5% by weight, preferably less than 1% by weight. The amount of the layered silicate to be used depends primarily on its ability to swell. In the case of hectorite, 1 to 10% by weight, preferably 2 to 6% by weight (based on hectorite dried at 105 ° C.) are generally used.

Als fakultative Bestandteile kommen nichtionische Tenside mit geringem Schäumvermögen zum Einsatz, die sich in Gegenwart von Aktivchlorverbindungen und ggf. Alkalihydroxiden nicht zersetzen. Es handelt sich vorzugsweise um Ethylenoxidaddukte an höhermolekulare Polypropylenglycole der Molgewichte 900 bis 4000 sowie Addukte von Ethylenoxid bzw. Ethylenoxid und Propylenoxid an höhere Fettalkohole wie Dodecylalkohol, Palmitylalkohol, Stearylalkohol, Oleylalkohol oder deren Gemische sowie synthetische, beispielsweise durch Oxosynthese hergestellte Alkohole der Kettenlängen C,2-C,8 und entsprechende Alkylenoxidaddukte an Alkylphenole, vorzugsweise Nonylphenol in Betracht. Beispiele für geeignete Anlagerungsprodukte sind das Addukt von 10 bis 30 Gew.-% Ethylenoxid an ein Polypropylenglycol des Molgewichtes 1750, das Addukt von 20 Mol Ethylenoxid bzw. von 9 Mol Ethylenoxid und 10 Mol Propylenoxid an Nonylphenol, das Addukt von 5 bis 12 Mol Ethylenoxid an ein Fettalkoholgemisch der Kettenlängen C12-C18 mit einem Anteil an etwa 30 % an Oleylalkohol und ähnliche. Diese beispielhafte Aufzählung stellt keine Beschränkung dar. Der Anteil der nichtionischen Tenside kann bis 5 Gew.-%, vorzugsweise 0,1 bis 1 Gew.-% betragen.Optional non-ionic surfactants with low foaming power are used as optional components, which do not decompose in the presence of active chlorine compounds and possibly alkali hydroxides. There are preferably ethylene oxide adducts of higher molecular weight polypropylene glycols of molecular weights of 900-4000, as well as adducts of ethylene oxide or ethylene oxide and propylene oxide with higher fatty alcohols such as dodecyl alcohol, palmityl alcohol, stearyl alcohol, oleyl alcohol or mixtures thereof as well as synthetic, produced for example by oxo process alcohols of chain length C, 2 -C, 8 and corresponding alkylene oxide adducts with alkylphenols, preferably nonylphenol. Examples of suitable addition products are the adduct of 10 to 30% by weight of ethylene oxide with a polypropylene glycol with a molecular weight of 1750, the adduct of 20 mol of ethylene oxide or 9 mol of ethylene oxide and 10 mol of propylene oxide with nonylphenol, the adduct of 5 to 12 mol of ethylene oxide to a fatty alcohol mixture of chain lengths C 12 -C 18 with a share of about 30% in oleyl alcohol and the like. This exemplary list is not a limitation. The proportion of the nonionic surfactants can be up to 5% by weight, preferably 0.1 to 1% by weight.

Bei Bedarf können den Geschirreinigungsmitteln auch chlor- und alkalibeständige Farb- und Duftstoffe zugesetzt werden.If necessary, chlorine and alkali-resistant colors and fragrances can be added to the dish detergents.

Als fakultative Bestandteile kommen ferner Begleitstoffe der eingesetzten Wirkstoffe, wie Natriumsulfat, Natriumchlorid oder mineralische Beimengungen des Schichtsilikats in Betracht.Additional components of the active substances used, such as sodium sulfate, sodium chloride or mineral admixtures of the layered silicate, are also suitable as optional components.

Weitere einsetzbare Komplexbildner sind gegen Aktivchlor beständige, in der Regel stickstofffreie Komplexbildner, z. B. mehrwertige Phosphonsäuren, wie Methylendiphosphonsäure bzw. mehrwertige Phosphonocarbonsäuren, wie 1,1-Diphosphonopropan-1,2-dicarbonsäure, 1-Phosphonopropan-1,2.3-tricarbonsäure oder 2-Phosphonobutan-2,3,4-tricarbonsäure bzw. deren Natrium- oder Kaliumsalze. Zusätzlich brauchbare Komplexbildner sind auch die aktivchlorbeständigen Polycarbonsäuren und deren Salze.Other complexing agents that can be used are active chlorine-resistant, generally nitrogen-free complexing agents, e.g. B. polyvalent phosphonic acids, such as methylene diphosphonic acid or polyvalent phosphonocarboxylic acids, such as 1,1-diphosphonopropane-1,2-dicarboxylic acid, 1-phosphonopropane-1,2,3-tricarboxylic acid or 2-phosphonobutane-2,3,4-tricarboxylic acid or its sodium - or potassium salts. The active chlorine-resistant polycarboxylic acids and their salts are also useful complexing agents.

Die Herstellung der erfindungsgemäß zu verwendenden Reiniger erfolgt vorteilhaft in der Weise, daß man eine wäßrige Lösung bzw. Aufschlämmung, enthaltend die reinigend wirkenden Bestandteile der Komponenten (A), insbesondere das Tripolyphosphat und ggf. das Alkalisilikat (Wasserglas), oder einen Teil derselben zusammen mit dem Verdickungsmittel unter Erwärmen auf 40 bis 65 °C mit einem hohe Scherkräfte ausübenden Rührwerk, beispielsweise einem UItra-Turrax•-Gerät, bis zur erfolgten Verdickung verrührt. Anschließend können die restlichen, in fester oder gelöster Form vorliegenden Bestandteile der Komponente (A), z. B. Metasilikat, Wasserglas und ggf. der Reste des Triphosphats sowie die fakultativen Bestandteile, wie nichtionische Tenside und Farbstoffe, eingerührt werden. Nach dem Abkühlen auf Raumtemperatur erfolgt abschließend die Zugabe der Aktivchlorverbindung, beispielsweise in Form einer Natriumhypochloritlösung (Chlorbleichlauge).The cleaning agents to be used according to the invention are advantageously prepared by combining an aqueous solution or slurry containing the cleaning components of component (A), in particular the tripolyphosphate and optionally the alkali silicate (water glass), or a part thereof stirred with the thickener while heating to 40 to 65 ° C. with a high shear agitator, for example a UItra-Turrax • device, until the thickening has taken place. The remaining constituents of component (A), e.g. B. metasilicate, water glass and possibly the residues of triphosphate and the optional components, such as nonionic surfactants and dyes, are stirred in. After cooling to room temperature, the active chlorine compound is finally added, for example in the form of a sodium hypochlorite solution (chlorine bleach).

Die Mittel können unmittelbar nach ihrer Herstellung in die Vorratsbehälter abgefüllt werden. Der Maximalwert der Viskosität ist im allgemeinen nach einer Standzeit von 2 bis 10 Tagen erreicht. Durch kräftiges Schütteln oder Anpressen tritt eine kurzzeitige Verflüssigung ein, jedoch stellt sich der Gelzustand bereits wenige Sekunden nach Beendigung der mechanischen Beanspruchung wieder ein, d. h. der in die Vorratskammer der Spülmaschine eingebrachte Reiniger erstarrt hinreichend schnell, so daß er nach Schließen der Verschlußklappe der Vorratskammer bzw. der Beschickungstür der Spülmaschine nicht ausfließt.The agents can be filled into the storage containers immediately after their manufacture. The maximum value of the viscosity is generally reached after a standing time of 2 to 10 days. A brief liquefaction occurs through vigorous shaking or pressing, however, the gel state is restored just a few seconds after the mechanical stress has ended, ie the cleaner introduced into the dishwasher's storage chamber solidifies sufficiently quickly that it does not flow out after the closing flap of the pantry or the loading door of the dishwasher.

Die erfindungsgemäß zu verwendenden Reiniger zeichnen sich durch eine hohe Reinigungskraft und insbesondere durch hohe Lagerbeständigkeit aus. Der Aktivchlorverlust während einer 6 monatigen Standzeit bei 25 °C lag in der gleichen Größenordnung wie der bei trocken gelagerten handelsüblichen Reiniger-Granulaten. Überraschenderweise erwies sich auch ein wiederholtes Erwärmen des Reinigers auf Temperaturen um 60 °C als nicht nachteilig auf die Lagerbeständigkeit bzw. den Aktivchlorgehalt. Dies zeigte sich bei einer Versuchsanordnung, bei der ein für 10 Spülgänge ausreichender Vorratsbehälter mit angeschlossener Dosierpumpe in die Beschickungstür einer handelsüblichen Spülmaschine eingebaut und das Zudosieren des Reinigers über eine Programmsteuerung vorgenommen wurde. Die durch Wärmeübergang wiederholt angewärmte Reinigerpaste erlitt innerhalb des Versuchszeitraums von 5 Tagen (2 Spülgänge pro Tag) keinen das Spülergebnis beeinträchtigenden Aktivchlorverlust.The cleaners to be used according to the invention are distinguished by a high cleaning power and in particular by a long shelf life. The active chlorine loss during a 6-month service life at 25 ° C was of the same order of magnitude as that of commercially available detergent granules stored in a dry place. Surprisingly, repeated heating of the cleaner to temperatures of around 60 ° C. has not proven to be disadvantageous to the storage stability or the active chlorine content. This was shown in a test arrangement in which a storage container for 10 rinsing cycles with a connected metering pump was installed in the loading door of a standard dishwasher and the detergent was added using a program control. The detergent paste, which was repeatedly warmed up by heat transfer, did not suffer any loss of active chlorine which would have an adverse effect on the wash result within the test period of 5 days (2 rinse cycles per day).

Bei der Beobachtung des Einspülverhaltens durch Leitfähigkeitsmessungen wurde festgestellt, daß der Reiniger innerhalb von 1 bis 4 Minuten nach Öffnen der Vorratskammer vollständig ausgespült und innerhalb von 2 bis 5 Minuten vollständig gelöst bzw. suspendiert war. Bei pulverförmigen bzw. granulierten Reinigern nimmt dieser Vorgang in der Regel 7 bis 15 Minuten, in ungünstigen Fällen bis zu 20 Minuten in Anspruch.When observing the induction behavior by conductivity measurements, it was found that the cleaner was completely rinsed out within 1 to 4 minutes after opening the storage chamber and completely dissolved or suspended within 2 to 5 minutes. In the case of powdered or granulated cleaners, this process usually takes 7 to 15 minutes, in unfavorable cases up to 20 minutes.

Als besonderer Vorteil ist weiterhin anzusehen, daß die Mittel sich wesentlich einfacher und genauer dosieren lassen als übliche körnige bzw. pulverförmige Reiniger, die beim Einfüllen in die räumlich begrenzten Einspülkammern wegen des meist notwendigen Rüttelns der Vorratspakkung bzw. des Dosierbechers häufig zum Teil verschüttet werden. Die Gefahr, daß durch verschütteten Reiniger die Funktion des Öffnungsmechanismusses beeinträchtigt wird, insbesondere bei Kammern mit Magnetverschluß der Kontakt nicht ausreichend fest ist, so daß die Klappe vorzeitig aufspringt, ist bei Verwendung der erfindungsgemäßen Mittel nicht gegeben.It is also a particular advantage that the agents can be dosed much more easily and precisely than conventional granular or powdered cleaners, which are often spilled in part when filling into the spatially limited induction chambers because of the mostly necessary shaking of the storage package or the dosing cup. The risk that the function of the opening mechanism is impaired by spilled cleaner, in particular in the case of chambers with a magnetic lock, the contact is not sufficiently firm, so that the flap opens prematurely, when using the agents according to the invention.

Es waren aus der GB-PS 1 237199 zwar pastöse Bleichmittel bekannt, die zwei verschiedenartige Tone, darunter Hectorit, als Verdickungsmittel sowie Aktivchlorverbindungen enthalten, wobei die Mittel bei der Anwendung auf das zu bleichende Gut aufgetragen werden und aufgrund ihrer Gelstruktur längere Zeit auf der Kontaktstelle verbleiben und daher besonders nachhaltig wirken. Dieser Patentschrift war jedoch nicht zu entnehmen, daß Mittel, wie sie in der vorstehenden Erfindung beschrieben sind, sich als Reiniger in Geschirrspülmaschinen eignen würden. Weiterhin sind in den US-A-4 051 055 und 4051 056 sowie den DE-A-25 39 733 und 27 39 776 pastöse Scheuermittel beschrieben, die anionische, nichtionische, zwitterionische oder ampholytische, d. h. in der Mehrzahl schaumaktive Tenside, ferner aktivchlorhaltige Bleichmittel, tonartige Füllmittel, darunter auch Hectorit, sowie als Hauptbestandteil eine spezielle Abrasivkomponente enthalten. Das Verdickungsmittel dient vor allem dazu, das Absetzen des spezifisch leichten Abrasivmittels zu verhindern. Der Gedanke, schaumarme, von Abrasivstoffen freie Reiniger anstelle üblicher pulverförmiger bzw. granulierter Produkte in Geschirrspülmaschinen einzusetzen, ist diesen Veröffentlichungen völlig fremd, zumal auch die Aufgabenstellung eine gänzlich andere ist.From GB-PS 1 237199 pasty bleaching agents were known, which contain two different types of clays, including hectorite, as a thickening agent and active chlorine compounds, the agents being applied to the material to be bleached during use and, due to their gel structure, for a long time on the contact point remain and therefore have a particularly sustainable effect. However, it was not apparent from this patent that agents as described in the above invention would be suitable as detergents in dishwashers. Furthermore, in US-A-4 051 055 and 4051 056 and DE-A-25 39 733 and 27 39 776 pasty abrasives are described, the anionic, nonionic, zwitterionic or ampholytic, i.e. H. the majority contain foam-active surfactants, bleaches containing active chlorine, clay-like fillers, including hectorite, and a special abrasive component as the main component. The thickener primarily serves to prevent the specific light abrasive from settling. The idea of using low-foaming, abrasive-free cleaning agents instead of conventional powdered or granulated products in dishwashers is completely foreign to these publications, especially since the task is also completely different.

Aus der DE-A-28 10 187 sind alkalische Mittel und ein Verfahren zum Vorbehandeln stark verschmutzter Küchengeräte bekannt, die frei von Schleifmitteln sind, etwa 0,25 bis etwa 20% eines Tons als Verdickungsmittel und etwa 0,5 bis etwa 9 % eines Alkalimetallsilikats mit einem Verhältnis von SiO2 : M2O von mehr als etwa 1 mit M gleich Natrium oder Kalium enthalten, die eine Hypohalogenitkonzentration mit einem Aktivchlorgehalt von etwa 0,5 bis 10 % aufweisen und deren Viskosität etwa 1 bis etwa 10 000 Pa - s beträgt und die auf Küchengeräte mit schwer entfernbarem Schmutz aufgebracht werden. Danach wird alles mit einem Überschuß an Wasser mit einer Temperatur von mehr als etwa 38 °C bedeckt. Die Viskosität der vorzugsweise thixotropen Mittel ist tendenziell erheblich höher als bei den Mitteln der vorliegenden Erfindung, da sie ja gut und lange an den verschmutzten Oberflächen haften sollen, um dort einwirken zu können, während die Konsistenz der erfindungsgemäßen Reiniger nur deren Dosierfähigkeit gewährleisten soll. Im übrigen sollen sie sich schnell im Reinigungsgang von Geschirrspülmaschinen lösen. Natürlich kann man auch die nach der DE-A-28 10 187 vorgereinigten Geräte anschließend in Geschirrspülmaschinen einbringen. Deren verbrauchte Beschichtung soll zwar eine Schaumunterdrückung bewirken, wirkt dann aber auch wegen eines Mangels an Tripolyphosphaten nicht mehr reinigend.DE-A-28 10 187 discloses alkaline agents and a method for pretreating heavily soiled kitchen appliances which are free of abrasives, about 0.25 to about 20% of a clay as a thickener and about 0.5 to about 9% of one Contain alkali metal silicate with a ratio of SiO 2 : M 2 O of more than about 1 with M equal to sodium or potassium, which have a hypohalite concentration with an active chlorine content of about 0.5 to 10% and whose viscosity is about 1 to about 10,000 Pa - s and are applied to kitchen appliances with dirt that is difficult to remove. Then everything is covered with an excess of water at a temperature greater than about 38 ° C. The viscosity of the preferably thixotropic agents tends to be considerably higher than in the agents of the present invention, since they should adhere well and long to the soiled surfaces in order to be able to act there, while the consistency of the cleaners according to the invention is only intended to ensure their meterability. In addition, they should be released quickly in the dishwasher cleaning cycle. Of course, the devices pre-cleaned according to DE-A-28 10 187 can subsequently be introduced into dishwashers. Their used coating is supposed to suppress foam, but then no longer has a cleaning effect due to a lack of tripolyphosphates.

Als Verdickungsmittel wurden zwei verschiedene, Lithium und Fluor enthaltende Schichtsilikate vom Hectorit-Typ verwendet. Bei dem im Folgenden mit « Hectorit I » bezeichneten Produkt handelt es sich um ein Handelsprodukt der Fa. Lanco, bei dem mit « Hectorit II » bezeichneten um das Handelsprodukt Laponite B* der Fa. Laporte Ind. Ltd. Der Wassergehalt der Produkte (Trockenverlust bei 105 °C) lag bei 7-8 Gew.-%, die Korngröße (Siebanalyse) unter 0,2 mm bei einer mittleren Korngröße von ca. 0,006-0,008 mm. Die mit einem Rotationsviskosimeter nach Brookfield bei einer Spindeldrehzahl von 5 UpM (20 °C) bestimmte Viskosität eines 5 gewichtsprozentigen wäßrigen Gels betrug 75 Pa - s bei Hectorit I bzw. 95 Pa - s bei Hectorit II.Two different lithium and fluorine-containing layer silicates of the hectorite type were used as thickeners. The product referred to below as "Hectorite I" is a commercial product from Lanco, while the product referred to as "Hectorite II" is the commercial product Laponite B * from Laporte Ind. Ltd. The water content of the products (loss on drying at 105 ° C) was 7-8% by weight, the grain size (sieve analysis) was less than 0.2 mm with an average grain size of approx. 0.006-0.008 mm. The viscosity of a 5% by weight aqueous gel, determined with a Brookfield rotary viscometer at a spindle speed of 5 rpm (20 ° C.), was 75 Pas for Hectorite I and 95 Pas for Hectorite II.

Das Reinigungsvermögen der in den folgenden Beispielen aufgeführten pastenförmigen Reiniger wurde im sogenannten Normalprogramm einer marktüblichen Haushaltsgeschirrspülmaschine (Miele G 5039) geprüft.The cleaning power of the paste-like cleaners listed in the following examples was tested in the so-called normal program of a standard household dishwasher (Miele G 503 9 ).