EP0074061B1 - Modular electrical terminal post - Google Patents

Modular electrical terminal post Download PDFInfo

- Publication number

- EP0074061B1 EP0074061B1 EP82107994A EP82107994A EP0074061B1 EP 0074061 B1 EP0074061 B1 EP 0074061B1 EP 82107994 A EP82107994 A EP 82107994A EP 82107994 A EP82107994 A EP 82107994A EP 0074061 B1 EP0074061 B1 EP 0074061B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- groove

- contact

- contacts

- electrical

- longitudinal

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R12/00—Structural associations of a plurality of mutually-insulated electrical connecting elements, specially adapted for printed circuits, e.g. printed circuit boards [PCB], flat or ribbon cables, or like generally planar structures, e.g. terminal strips, terminal blocks; Coupling devices specially adapted for printed circuits, flat or ribbon cables, or like generally planar structures; Terminals specially adapted for contact with, or insertion into, printed circuits, flat or ribbon cables, or like generally planar structures

- H01R12/70—Coupling devices

- H01R12/82—Coupling devices connected with low or zero insertion force

- H01R12/85—Coupling devices connected with low or zero insertion force contact pressure producing means, contacts activated after insertion of printed circuits or like structures

- H01R12/88—Coupling devices connected with low or zero insertion force contact pressure producing means, contacts activated after insertion of printed circuits or like structures acting manually by rotating or pivoting connector housing parts

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R12/00—Structural associations of a plurality of mutually-insulated electrical connecting elements, specially adapted for printed circuits, e.g. printed circuit boards [PCB], flat or ribbon cables, or like generally planar structures, e.g. terminal strips, terminal blocks; Coupling devices specially adapted for printed circuits, flat or ribbon cables, or like generally planar structures; Terminals specially adapted for contact with, or insertion into, printed circuits, flat or ribbon cables, or like generally planar structures

- H01R12/70—Coupling devices

- H01R12/71—Coupling devices for rigid printing circuits or like structures

- H01R12/712—Coupling devices for rigid printing circuits or like structures co-operating with the surface of the printed circuit or with a coupling device exclusively provided on the surface of the printed circuit

- H01R12/716—Coupling device provided on the PCB

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R12/00—Structural associations of a plurality of mutually-insulated electrical connecting elements, specially adapted for printed circuits, e.g. printed circuit boards [PCB], flat or ribbon cables, or like generally planar structures, e.g. terminal strips, terminal blocks; Coupling devices specially adapted for printed circuits, flat or ribbon cables, or like generally planar structures; Terminals specially adapted for contact with, or insertion into, printed circuits, flat or ribbon cables, or like generally planar structures

- H01R12/70—Coupling devices

- H01R12/71—Coupling devices for rigid printing circuits or like structures

- H01R12/75—Coupling devices for rigid printing circuits or like structures connecting to cables except for flat or ribbon cables

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/648—Protective earth or shield arrangements on coupling devices, e.g. anti-static shielding

- H01R13/658—High frequency shielding arrangements, e.g. against EMI [Electro-Magnetic Interference] or EMP [Electro-Magnetic Pulse]

- H01R13/6581—Shield structure

Definitions

- each of the contact supports 1 and 1 ′ is in the form of an elongated parallelepipedic block with internal longitudinal groove 10 open on almost all of its upper face .

Landscapes

- Coupling Device And Connection With Printed Circuit (AREA)

Description

La présente invention porte sur les raccordements électriques entre conducteurs d'un câble électrique et broches électriques telles que broches montées sur un substrat de circuit imprimé et/ou bornes électriques rigides de composants, en particulier pour les interconnexions entre châssis d'équipement électrique, circuits imprimés, composants électroniques ou éléments électriques à connexions rigides.The present invention relates to electrical connections between conductors of an electrical cable and electrical pins such as pins mounted on a printed circuit substrate and / or rigid electrical terminals of components, in particular for interconnections between chassis of electrical equipment, circuits printed matter, electronic components or electrical elements with rigid connections.

De tels raccordements entre conducteurs et broches rigides peuvent être réalisés par des connexions enroulées de type standard.Such connections between conductors and rigid pins can be made by standard type coiled connections.

On connaît par le document US-A-4 008 939 une borne de raccordement électrique entre câbles électriques et broches électriques rigides montées par exemple sur un substrat de circuit imprimé. Cette borne de raccordement électrique comporte une pluralité de contacts individuels de forme allongée et sensiblement linéaire. Ces contacts sont raccordés, par l'une de leurs portions terminales, dites premières extrémités, aux câbles respectifs; ils assurent par l'autre de leurs portions terminales, dites secondes extrémités, un contact par pression sur les broches respectives. La borne de raccordement comporte aussi un support pour lesdits contacts individuels. Ce support se présente sous la forme générale d'un parallélépipède allongé. Il comporte deux parties de support montées emboîtées l'une sur l'autre et rétractables l'une en regard de l'autre par un moyen de blocage actionnable, tel qu'un arbre ou vis quart de tour de commande. L'une de ces parties de support des contacts présente une rainure longitudinale ouverte sur l'une de ses petites faces longitudinales, dans laquelle l'autre partie de support vient s'emboîter à fond ou se rétracter. Cette même partie de support de contacts présente en outre une pluralité d'alvéoles internes parallèles à ses grandes faces longitudinales et débouchant sur le fond de la rainure. Ces alvéoles constituent les logements des contacts respectifs dont les secondes extrémités destinées à assurer un contact par pression avec les broches débordent dans ladite rainure longitudinale. L'autre partie de support présente une série de passages correspondant aux alvéoles respectifs, ces passages sont destinés à recevoir les broches; en outre, leurs extrémités, en regard de ladite rainure longitudinale sont profilées pour constituer des cames sur lesquelles les secondes extrémités des contacts viennent en appui pour assurer le contact à pression souhaité sur lesdites broches lorsque cette partie de support est emboîtée à fond dans la rainure.Document US-A-4 008 939 discloses an electrical connection terminal between electrical cables and rigid electrical pins mounted for example on a printed circuit substrate. This electrical connection terminal comprises a plurality of individual contacts of elongated shape and substantially linear. These contacts are connected, by one of their terminal portions, called first ends, to the respective cables; they provide by the other of their terminal portions, said second ends, a pressure contact on the respective pins. The connection terminal also includes a support for said individual contacts. This support is in the general form of an elongated parallelepiped. It comprises two support parts mounted nested one on the other and retractable one opposite the other by an actuatable locking means, such as a shaft or quarter-turn control screw. One of these contact support parts has a longitudinal groove open on one of its small longitudinal faces, in which the other support part fits fully or retracts. This same contact support part also has a plurality of internal cells parallel to its large longitudinal faces and opening onto the bottom of the groove. These cells constitute the housings of the respective contacts, the second ends of which intended to ensure pressure contact with the pins project into said longitudinal groove. The other support part has a series of passages corresponding to the respective cells, these passages are intended to receive the pins; in addition, their ends, facing said longitudinal groove, are profiled to form cams on which the second ends of the contacts come to bear in order to ensure the desired pressure contact on said pins when this support part is fully fitted into the groove .

Dans cette borne de raccordement, c'est le moyen de blocage des deux parties de support en position emboîtée l'une dans l'autre qui permet le maintien en contact par pression desdits contacts individuels et des broches respectives. Au fur et à mesure de l'actionnement de ce moyen de blocage, les secondes extrémités concernées desdits contacts individuels glissent le long des cames, se déforment et viennent assurer à pression croissante le contact sur les broches. Ces effets, au cours de l'actionnement du moyen de blocage, risquent d'endommager les contacts sollicités simultanément en pression de plus en plus grande contre les cames et les broches, ils rendent ainsi la borne de raccordement fragile.In this connection terminal, it is the means of blocking the two support parts in the nested position one inside the other which allows said individual contacts and the respective pins to be kept in contact by pressure. As the locking means are actuated, the second affected ends of said individual contacts slide along the cams, deform and come into contact with the pins at increasing pressure. These effects, during the actuation of the blocking means, risk damaging the contacts which are pressed simultaneously under increasing pressure against the cams and the pins, thus making the connection terminal fragile.

La présente invention a pour but d'éviter ces inconvénients et, de plus, de permettre d'adopter une structure modulaire à commande simultanée de la borne résultante rendue ainsi adaptable aux raccordements entre conducteurs et broches à réaliser.The object of the present invention is to avoid these drawbacks and, in addition, to make it possible to adopt a modular structure with simultaneous control of the resulting terminal thus made adaptable to the connections between conductors and pins to be produced.

La présente invention a donc pour objet une borne modulaire de raccordement électrique entre conducteurs électriques d'un câble et broches électriques rigides, comportant une pluralité de contacts individuels d'une part raccordés par une première de leurs extrémités aux conducteurs respectifs et d'autre part assurant par leur deuxième extrémité en forme de lame plate un contact par pression sur lesdites broches respectives, un support de contacts, de forme allongée et sensiblement parallélépipédique, présentant une rainure interne longitudinale ouverte sur l'une de ses faces longitudinales, dite face supérieure, et une pluralité d'alvéoles parallèles à ses faces latérales et débouchant sur le fond de ladite rainure, pour le logement desdits contacts dont la deuxième extrémité de chacun d'eux déborde dans ladite rainure, et des moyens de blocage en contact à pression desdites secondes extrémités desdits contacts sur lesdites broches électriques, caractérisée en ce que:

- - lesdits contacts individuels sont en forme générale de U dont l'une des branches définit ladite première extrémité de l'autre ladite deuxième extrémité pour chacun des contacts,

- - ledit support de contacts est modulaire et ladite série d'alvéoles est constituée par des alvéoles dits externes formés dans les grandes faces latérales de chacun des supports modulaires et par des alvéoles dits internes formés dans les parois longitudinales de ladite rainure et débouchant sur la face longitudinale opposée à celle portant la rainure et dite face inférieure, chacun des alvéoles externes de l'un des côtés de ladite rainure recevant la branche de contact avec le conducteur électrique de l'un des contacts et étant en vis-à-vis avec l'un des alvéoles internes de l'autre côté de ladite rainure recevant d'une part la branche en forme de lame plate s'étendant le long du sommet de cet alvéole interne et d'autre part la broche correspondante s'insérant par la face inférieure dudit support,

- - et lesdits moyens de blocage sont constitués par une came rotative de forme générale cylindrique présentant deux méplats diamétralement opposés, montée dans la rainure de chaque support de contacts en étant contre les branches de contact en forme de lame et en appui sur le fond de cette rainure, assurant la mise simultanée en contact par pression des contacts avec les broches respectives lorsque ses portions semi-cylindriques sont amenées contre les branches de contact en forme de lame,

- - et en ce qu'elle comporte, en outre, un élément isolant fixé sur chaque support de contacts et ménageant un logement interne supérieur pour lesdits conducteurs électriques.

- said individual contacts are generally U-shaped, one of the branches of which defines said first end of the other, said second end for each of the contacts,

- - Said contact support is modular and said series of cells consists of so-called external cells formed in the large lateral faces of each of the modular supports and by said internal cells formed in the longitudinal walls of said groove and opening onto the face longitudinal opposite to that carrying the groove and called the underside, each of the external cells of one of the sides of said groove receiving the branch of contact with the electrical conductor of one of the contacts and being opposite one of the internal cells on the other side of said groove receiving on the one hand the branch in the form of a flat blade extending along the top of this internal cell and on the other hand the corresponding pin inserted by the face lower of said support,

- - And said blocking means are constituted by a rotary cam of generally cylindrical shape having two diametrically opposite flats, mounted in the groove of each contact support while being against the blade-shaped contact branches and resting on the bottom of this groove, ensuring simultaneous contact by pressure of the contacts with the respective pins when its semi-cylindrical portions are brought against the blade-shaped contact branches,

- - And in that it further comprises an insulating element fixed on each contact support and providing an upper internal housing for said electrical conductors.

L'invention sera décrite ci-après plus en détail à l'aide d'un mode de réalisation donné à titre d'exemple et illustré dans le dessin ci-annexé. Dans ce dessin:

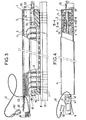

- - la figure 1 représente en perspective éclatée la borne modulaire de raccordement électrique selon l'invention,

- - la figure 2 représente en perspective l'un des contacts de la borne de raccordement électrique de la figure 1 et le conducteur électrique qui lui sera raccordé,

- - la figure 3 et la figure 4 représentent respectivement vue en élévation et vue de dessus la borne de raccordement électrique de la figure 1, avec coupe longitudinale de ses extrémités,

- - les figures 5A et 5B sont deux vues en coupe transversale de la borne de raccordement électrique, effectuées selon la ligne V-V de la figure 4, respectivement en position dite de repos et en position dite de contact,

- - la figure 6 est une vue en coupe transversale de la borne de raccordement électrique, effectuée selon la ligne VI-VI de la figure 4, en position dite de repos,

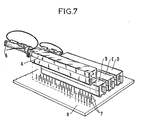

- - la figure 7 illustre les raccordements entre conducteurs d'un ou plusieurs câbles sur une carte de circuit imprimé dite d'interconnexion.

- FIG. 1 shows in exploded perspective the modular electrical connection terminal according to the invention,

- FIG. 2 represents in perspective one of the contacts of the electrical connection terminal of FIG. 1 and the electrical conductor which will be connected to it,

- FIG. 3 and FIG. 4 represent respectively an elevation view and a top view of the electrical connection terminal of FIG. 1, with longitudinal section of its ends,

- FIGS. 5A and 5B are two cross-sectional views of the electrical connection terminal, taken along the line VV in FIG. 4, respectively in the so-called rest position and in the so-called contact position,

- FIG. 6 is a cross-sectional view of the electrical connection terminal, taken along line VI-VI of FIG. 4, in the so-called rest position,

- - Figure 7 illustrates the connections between conductors of one or more cables on a so-called interconnection printed circuit board.

En regard notamment des figures 1, 3 ou 4, on voit que la borne de raccordement électrique selon l'invention est de type modulaire.With particular reference to Figures 1, 3 or 4, it can be seen that the electrical connection terminal according to the invention is of the modular type.

Elle comporte des supports de contacts tels que 1 et 1' identiques, qui recevront chacune douze contacts tels que 2, un élément isolant 3 pour l'alignement des supports de contacts 1 et 1', un boîtier-capot 4 assurant le blocage de l'élément 3 sur les supports de contacts et une came 5 montée rotative dans les supports de contacts 1 et 1' pour l'actionnement simultané de tous les contacts 2 et donc leur mise en position dite de repos ou en position dite de contact.It includes identical contact supports such as 1 and 1 ', which will each receive twelve contacts such as 2, an

En regard des figures 3 et 7 notamment, on voit que cette borne est destinée à assurer le raccordement entre conducteurs électriques 6 et des broches électriques alignées 7.With reference to FIGS. 3 and 7 in particular, it can be seen that this terminal is intended to ensure the connection between

En se référant plus particulièrement à nouveau à la figure 1, on voit que chacun des supports de contacts 1 et 1' se présente sous la forme d'un bloc parallélépipédique allongé à rainure longitudinale interne 10 ouverte sur la quasi-totalité de sa face supérieure.Referring more particularly again to FIG. 1, it can be seen that each of the contact supports 1 and 1 ′ is in the form of an elongated parallelepipedic block with internal

Chacun de ces supports 1 et l'comporte, le long de chacune de leurs deux grandes faces latérales six alvéoles externes 11 formés sur la hauteur de ces grandes faces latérales et disposés, de l'une des faces à l'autre, en quinconce. Chacun comporte également le long des parois longitudinales de la rainure 10 six autres alvéoles, dits alvéoles internes, 12, se prolongeant jusqu'à la face inférieure du support. Ces six alvéoles internes 12 sont intercalés entre les six alvéoles externes formés sur la grande face latérale correspondante du support, c'est-à-dire sont en vis-à-vis respectivement avec les six alvéoles externes de la grande face latérale opposée. Ainsi les douze alvéoles internes 12 du support, avec les douze alvéoles externes 11 de ce même support, définissent les logements pour les douze contacts 2 que chaque support 1 ou 1' peut recevoir.Each of these supports 1 and comprises, along each of their two large lateral faces six

Chacun des supports 1 et 1' présente également une rainure longitudinale 13 sur chacune de ses deux grandes faces latérales, au voisinage du bord inférieur de ces faces, venant couper les six alvéoles externes 11.Each of the

Dans chacun des supports 1 et 1' la rainure interne 10 est de profondeur voisine de la moitié de la hauteur du support et est à fond 14 arrondi. Elle définit le logement de la came 5, le fond arrondi en constitue la surface d'appui. Cette rainure 10 débouche sur les deux petites faces latérales présentant chacune une ouverture 15 en forme d'arche ouverte du côté de la face inférieure, le sommet semi-circulaire de ces ouvertures en arche et le fond arrondi de la rainure 10 limitant le débattement vertical possible de la came 5 dans son logement.In each of the

Ces supports 1 et 1' sont en matière plastique, par exemple en polycarbonate; ils sont avantageusement issus de moulage.These

Les contacts 2 dont l'un est représenté à plus grande échelle dans la figure 2 sont des contacts du type ressort de forme générale en U. Ainsi qu'il apparait dans cette figure 2 et/ou dans les figures 5A, 5B et 6, l'une des branches du contact 2, repérée en 20, est destinée à être raccordée au conducteur 6 gainé d'isolant, en réalisant un contact par arêtes dénudantes. A cet effet, cette branche 20 se présente elle-même en forme de U ouvert vers l'extérieur du contact 2 et présente, latéralement des arêtes internes 21 embouties venant traverser la gaine isolante du conducteur 6 lors de son insertion selon la flèche F et son maintien dans cette branche 20, pour réaliser le raccordement électrique du conducteur 6 et du contact 2.The

Cette branche 20 présente, en outre, des ergots emboutis découpés 22, orientés vers l'intérieur du contact 2, venant s'agripper dans le logement 11 du support 1 ou 1', recevant cette branche pour le maintien de ce contact.This

L'autre branche 23 du contact 2 est en forme de lame plate et présente dans une partie intermédiaire une simple déformation 24 formant un bossage vers l'extérieur du contact 2. Cette branche 23 est destinée à venir en contact avec l'une des broches 7, la déformation 24 localisant alors le contact électrique à réaliser.The

Les contacts 2 seront en métal élastique et avantageusement recouverts d'un revêtement de protection contre la corrosion; ce revêtement protecteur sera par exemple en étain-plomb. Ainsi qu'il ressort de la figure 1 et des figures 5A et 6 correspondant à deux coupes transversales de la borne faites par deux logements successifs 11-12 de contacts, les ressorts sont insérés dans leur logement à partir de la face inférieure du support 1 ou 1' qui les reçoit, en étant, un sur deux montés alternés de 180°. Ainsi les branches 23 des contacts 2 successifs sur l'un des supports 1 ou 1' seront disposés dans les alvéoles internes successifs 12 de ce support, qui sont alternativement sur l'une et l'autre des parois de la rainure 10, tandis que les branches 20 des contacts successifs viennent se loger dans les alvéoles externes 11 qui sont alternativement sur l'une et l'autre des faces latérales du support concerné. Compte tenu de l'épaisseur des supports 1 et 1' choisie telle que la distance entre les fonds des alvéoles internes et externes en vis-à-vis est supérieure à l'écartement entre les branches 20 et 23 des contacts 2, les branches 23 s'étendront au sommet de leurs alvéoles internes respectifs.The

Le maintien en alignement des supports 1 et 1' ainsi équipés de leurs contacts 2 est assuré par l'élément isolant 3 et le blocage de l'ensemble par le boîtier-capot 4, cet élément 3 et le boîtier-capot 4 étant montés emboîtés l'un dans l'autre sur les supports 1 et 1'.Maintaining alignment of the

En regard de la figure 1 notamment, on voit que l'élément isolant 3 est un profilé de section en U renversé et de longueur égale à celle de l'ensemble des supports 1 et 1' qu'il va recouvrir. Ce profilé 3 présente deux bossages longitudinaux 30 sur des portions de ses branches, au voisinage de sa base, ces bossages étant obtenus par une sur- épaisseur donnée à sa base et aux portions adjacentes de ses branches latérales. Il présente, aussi deux languettes longitudinales 31 en saillie vers sa partie interne et formant des rebords sur ses deux branches latérales. Ces languettes 31 viennent maintenir en alignement les supports 1 et 1' par encastrement dans les rainures 13 des supports. Ce profilé 3 est de hauteur prévue supérieure à celle des supports 1 et l'et vient, lorsqu'il les recouvre, ménager au-dessus d'eux (figures 3, 5A, 5B et 6) un espace libre 33 formant un logement pour les conducteurs 6 qui seront raccordés aux contacts 2.With reference to FIG. 1 in particular, it can be seen that the insulating

Le boîtier-capot 4 est en un matériau conducteur ferro-magnétique, par exemple en acier connu sous les références Z8 C17. Ce boîtier-capot 4 est, comme l'élément 3 qu'il recouvre, de section en U et présente deux déformations longitudinales 40 sur ces deux branches latérales, correspondant aux bossages longitudinaux 30. Il présente à une extrémité une patte 41 sensiblement dans le prolongement de sa face supérieure, sur laquelle vient se loger un collier 42 à serrage par vis 43 qui maintiendra le câble de conducteurs 6 (figures 3, 4) à raccorder aux contacts 2. Ce collier 42 assurera également, ainsi que visible dans les figures 3 et 4, le raccordement électrique du boîtier-capot 4 à une masse électrique et à l'écran du câble, par un fil de continuité d'écran 61 à cosse Faston terminale 62, le boîtier-capot 4 servant d'écran électro-magnétique aux circuits qu'il renferme.The housing-

A l'opposé de cette patte d'extrémité 41 et du collier 42, la face frontale 44 du boîtier-capot 4 est fermée par une portion terminale rabattue de sa face supérieure. Cette face frontale 44 est munie d'un passage circulaire 45 d'accès pour la came 5, dans son logement des supports 1 et 1'; elle est munie, en outre, d'une petite ouverture ou perçage 46, circulaire pour le maintien de la came 5 en position pour laquelle la fermeture des contacts est assurée.Opposite this

Ainsi qu'il a été dit ci-avant, après insertion de l'élément 3 dans le boîtier-capot 4, cet ensemble 3-4 est monté sur les supports 1 et 1' équipés de leurs contacts 2.As has been said above, after inserting the

Enfin la borne rigide ainsi réalisée comporte en outre sa came de commande 5. En regard de la figure 1 notamment, on voit que cette came 5 est de longueur légèrement supérieure à celle de l'ensemble 3-4 recouvrant les supports 1 et 1'. Elle est de forme générale cylindrique et présente sur la quasi-totalité de sa longueur deux méplats 50 diamétralement opposés (figures 5A, 5B et 6). A une extrémité formant bout arrondi elle présente une gorge périphérique 51, tandis que l'extrémité opposée forme une manette d'actionnement 52. Cette manette d'actionnement qui sera extérieure au boîtier-capot 4 présente un ergot de positionnement 53 en saillie vers la face frontale 44 du boîtier-capot, disposé sensiblement dans le plan axial de la came coupant les méplats et pour pouvoir venir pénétrer dans le perçage 46 pour le maintien de cette came en position.Finally, the rigid terminal thus produced also has its

Cette came 5 est en matériau isolant. Elle est introduite, à travers le passage 45 de la face frontale du boîtier-capot dans la rainure 10 des supports en venant reposer sur le fond arrondi de la rainure des supports, son extrémité en bout arrondi débordant des supports 1 et 1'. Cette came 5 introduite dans les supports améliore leur alignement. Elle est maintenue en position à l'aide d'un clips 55 inséré dans la gorge 51.This

L'assemblage ainsi réalisé forme une borne de raccordement commandable prête à être insérée sur des broches 7, de type à connexions enroulées, alignées en deux rangées ainsi qu'il apparaît en regard des figures 3 et 4 et plus particulièrement dans la figure 7. Dans cette figure 7, on voit quatre bornes de raccordement désignées par A, B, C, et D identiques entre elles et du type de celle illustrée dans les figures 1, 3 et 4. Ces bornes sont insérées ou prêtes à être insérées sur des doubles rangées de broches 7, débordant d'un substrat de circuit imprimé 8, ce substrat pouvant être une carte d'interconnexion de circuits ou éléments électriques ou composants électroniques à raccorder par l'intermédiaire des bornes de raccordement à différents conducteurs de câbles électriques.The assembly thus produced forms a controllable connection terminal ready to be inserted on

Cette opération d'insertion de chacune des bornes de raccordement sur les broches 7 et le fonctionnement de la borne sont expliqués plus en détail en regard des coupes effectuées sur la figure 4 et données dans les figures 5A, 5B et 6.This operation of inserting each of the connection terminals on the

Dans ces figures, on voit l'un des contacts 2 de la borne de raccordement, raccordé à son conducteur 6 et disposé en relation avec l'une des broches 7 débordant la carte d'interconnexion 8. Cette broche 7 appartient comme les autres broches semblables à un ou plusieurs éléments électriques 9 tels que celui schématisé en pointillés, par exemple à un connecteur à force d'insertion nulle pour cartes de circuit imprimé portant divers composants, réalisant par des contacts individuels sur des pistes imprimées sur l'un des bords de cette carte les entrées ou les sorties pour le circuit formé sur cette carte (non représentés).In these figures, one sees one of the

Lors du montage de la borne de raccordement sur la carte d'interconnexion 8, les broches 7 viennent s'insérer au fond des alvéoles internes 12 du support de contacts 1 (ou du support de contacts 1'). Cette insertion est rendue possible lors du positionnement des branches 23 des contacts 2 le long du sommet de leurs alvéoles internes 12 respectifs, c'est-à-dire par actionnement de la came 5 dont l'un des méplats vient alors en regard de la branche 23 de chacun des contacts 2 qui libère alors totalement le fond de son alvéole. La branche 23 du contact 2 et la broche 7 logées toutes deux dans le même alvéole interne sont alors sans contact l'une avec l'autre.When mounting the connection terminal on the

La borne étant montée sur la carte d'interconnexion 8, l'actionnement de la came 5, par sa manette 52 en amenant l'ergot 53 porté par la manette dans le perçage 46 du boîtier-capot 4, provoque la mise des portions semi-cylindriques de la came en regard des branches 23 des contacts 2. Dans ces conditions la pression exercée sur ces branches, provoque leur enfoncement vers le fond de leurs alvéoles 12 et donc leur mise en contact avec les broches 7 qui y sont respectivement logées.The terminal being mounted on the

On notera, en outre, que par l'actionnement de la came de 90°, on commandera à volonté la borne de raccordement en position dite de repos pour laquelle les contacts 2 et les broches 7 sont sans contact et pour laquelle elle peut être librement dégagée de la carte 8 ou en position dite de contact pour laquelle les broches 7 seront reliées aux conducteurs 6.It will also be noted that by actuating the 90 ° cam, the connection terminal will be controlled at will in the so-called rest position for which the

En regard des figures ci-annexées, il a été indiqué ci-avant que la borne comportait deux supports de contacts chacun pouvant recevoir douze contacts. Il est évident que la borne peut comporter un nombre différent de supports de contacts et que ces derniers peuvent aussi recevoir un nombre différent de contacts. Bien entendu également, il est possible de monter tout ou partie des contacts 2 sur le support qui les reçoit en fonction de la disposition des broches 7 dans les deux rangées de broches à raccorder à un même nombre de conducteurs électriques.With reference to the appended figures, it has been indicated above that the terminal included two contact supports each capable of receiving twelve contacts. It is obvious that the terminal can have a different number of contact supports and that these can also receive a different number of contacts. Of course also, it is possible to mount all or part of the

Claims (8)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR8116840 | 1981-09-04 | ||

| FR8116840A FR2512595A1 (en) | 1981-09-04 | 1981-09-04 | MODULAR ELECTRICAL CONNECTION TERMINAL |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0074061A1 EP0074061A1 (en) | 1983-03-16 |

| EP0074061B1 true EP0074061B1 (en) | 1986-10-08 |

Family

ID=9261903

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP82107994A Expired EP0074061B1 (en) | 1981-09-04 | 1982-08-31 | Modular electrical terminal post |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US4469385A (en) |

| EP (1) | EP0074061B1 (en) |

| CA (1) | CA1175514A (en) |

| DE (1) | DE3273697D1 (en) |

| FR (1) | FR2512595A1 (en) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB9306177D0 (en) * | 1993-03-25 | 1993-05-19 | Amp Gmbh | Smart card connector |

| FR2787641B1 (en) * | 1998-12-22 | 2001-03-09 | Sc2N Sa | ELECTRICAL CONNECTOR WITH PIVOTING PIECE |

| US6749452B2 (en) * | 2002-03-14 | 2004-06-15 | General Motors Corporation | Fuel cell monitor connector |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2169962A (en) * | 1937-11-30 | 1939-08-15 | Cinch Mfg Corp | Electrical connection |

| GB1053027A (en) * | 1963-03-14 | |||

| FR1395879A (en) * | 1963-03-14 | 1965-04-16 | Sperry Rand Corp | Electrical connector and its manufacturing process |

| US3277426A (en) * | 1964-04-30 | 1966-10-04 | Amphenol Corp | Cable connectors and methods for the manufacture thereof |

| US4008939A (en) * | 1973-05-18 | 1977-02-22 | Amp Incorporated | Axially cammed housing for low insertion force connector |

| US4208083A (en) * | 1977-03-04 | 1980-06-17 | Trw Inc. | Solderless electrical connector |

| US4176900A (en) * | 1977-12-23 | 1979-12-04 | Everett/Charles, Inc. | Low insertion force connector |

| JPS6044789B2 (en) * | 1978-03-20 | 1985-10-05 | 富士通株式会社 | IDC connector |

| US4235500A (en) * | 1978-11-08 | 1980-11-25 | Trw Inc. | Circuit connector |

| DE3021283C2 (en) * | 1980-06-06 | 1983-11-24 | Krone Gmbh, 1000 Berlin | Connection unit as a connection strip and / or as a pressure-tight cable termination device for PCM cables |

-

1981

- 1981-09-04 FR FR8116840A patent/FR2512595A1/en active Granted

-

1982

- 1982-08-31 US US06/413,320 patent/US4469385A/en not_active Expired - Fee Related

- 1982-08-31 EP EP82107994A patent/EP0074061B1/en not_active Expired

- 1982-08-31 DE DE8282107994T patent/DE3273697D1/en not_active Expired

- 1982-09-03 CA CA000410768A patent/CA1175514A/en not_active Expired

Also Published As

| Publication number | Publication date |

|---|---|

| FR2512595B1 (en) | 1983-10-21 |

| DE3273697D1 (en) | 1986-11-13 |

| EP0074061A1 (en) | 1983-03-16 |

| FR2512595A1 (en) | 1983-03-11 |

| US4469385A (en) | 1984-09-04 |

| CA1175514A (en) | 1984-10-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CA2034494C (en) | Electrical connector for connecting a sheilded multi-conductor cable to an electrical assembly inside a frame | |

| EP0735629B1 (en) | Arrangement for the connection of electrical wire conductors and especially connection module equipped with such an arrangement | |

| EP0683547A1 (en) | Connection device for insuring the connection between a coaxim cable and a printed circuit and printed circuit equipped with such a device | |

| FR2514560A1 (en) | INTEGRATED CIRCUIT SUPPORT ASSEMBLY | |

| EP0684662A1 (en) | Insulation displacement connector | |

| FR2538963A1 (en) | ELECTRICAL CONNECTOR | |

| EP0311537B1 (en) | Connection terminal for the junction of several electrical cables to different sections entering the same side of the terminal and locked in individual superposed receptacles | |

| EP0074061B1 (en) | Modular electrical terminal post | |

| CA1183229A (en) | Multiple coupling electrical connector and measure multiple connectors for chassis pluggable electronic equipmet circuit boards | |

| EP2745661B1 (en) | Electrical connection device, assembly including such a device and an electronic board, and method for electrically connecting an electronic board | |

| CH674598A5 (en) | ||

| FR3025947A1 (en) | INSULATING BODY FOR DETACHABLE CONNECTOR | |

| FR2797353A1 (en) | Connector for electric conductors e.g. for motor vehicles, has at least one electrically conductive bridge with as many end sections as electric conductors to be connected | |

| EP0308307B1 (en) | Separable connection device between a conductive pin and at least one connection wire | |

| FR2703192A1 (en) | Assembly of a plug connector and a coaxial cable plug. | |

| EP2503644B1 (en) | Electrical device of terminal block type | |

| EP0062579B1 (en) | Connection device | |

| EP0251909B1 (en) | Connection element for a monoconductor electrical cable with an axial connection | |

| EP0852824A1 (en) | Device for connecting at least two sheathed conductive wires | |

| EP0891627B1 (en) | Modular electric switch | |

| WO1986003063A1 (en) | Connection device | |

| FR2762145A1 (en) | METHOD AND DEVICE FOR PLACING A LEG IN CONTACT WITH A CONDUCTIVE TAPE | |

| FR2569047A1 (en) | ANTI-SHOCK FUSE HOLDER | |

| EP1255327A1 (en) | Coaxial electrical connector element | |

| EP0489642B1 (en) | Prewireable terminal block |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): BE DE FR GB IT LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19830823 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: ALCATEL |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): BE DE FR GB IT LU NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19861008 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 19861008 |

|

| REF | Corresponds to: |

Ref document number: 3273697 Country of ref document: DE Date of ref document: 19861113 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19870831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19870901 |

|

| 26N | No opposition filed | ||

| BERE | Be: lapsed |

Owner name: ALCATEL Effective date: 19870831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19880503 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19881121 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19890831 Ref country code: BE Effective date: 19890831 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| EUG | Se: european patent has lapsed |

Ref document number: 82107994.4 Effective date: 19880907 |