EP0064367A2 - Verfahren zum induktiven Erhitzen von Ventilsitzeinlagen - Google Patents

Verfahren zum induktiven Erhitzen von Ventilsitzeinlagen Download PDFInfo

- Publication number

- EP0064367A2 EP0064367A2 EP82302088A EP82302088A EP0064367A2 EP 0064367 A2 EP0064367 A2 EP 0064367A2 EP 82302088 A EP82302088 A EP 82302088A EP 82302088 A EP82302088 A EP 82302088A EP 0064367 A2 EP0064367 A2 EP 0064367A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- valve seat

- approximately

- insert

- energizing

- generally

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01L—CYCLICALLY OPERATING VALVES FOR MACHINES OR ENGINES

- F01L3/00—Lift-valve, i.e. cut-off apparatus with closure members having at least a component of their opening and closing motion perpendicular to the closing faces; Parts or accessories thereof

- F01L3/22—Valve-seats not provided for in preceding subgroups of this group; Fixing of valve-seats

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D9/00—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor

- C21D9/0068—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor for particular articles not mentioned below

Definitions

- This invention relates to the art of induction heating and, more particularly, to a method for inductively heating valve seat inserts for an engine component such as an engine head or the like.

- the invention is particularly applicable to heating exhaust valve seat inserts in a cast aluminum engine component and will be described with particular reference thereto; however, it will be appreciated that the invention has broader applications and may be used for heating a variety of conically shaped metal surfaces in other environments.

- valve seats which coact with reciprocating poppet valves for controlling the flow of gases to and from the engine cylinders.

- the valve seats for the exhaust valves must have extremely high wear characteristics at high engine operating temperatures.

- the conical seat surfaces are inductively heated during engine manufacture and then quench hardened by conventional liquid or mass quenching techniques.

- Induction heating of multiple valve seats in an engine component may be adapted to automatic processing in a single operation where, for example, a plurality of single turn inductors are positioned immediately adjacent the conically shaped exhaust valve seat.

- Such apparatus and methods are to which reference is directed.

- the inductors are independently movable on a common frame relative to the engine component and are biased toward the valve seats.

- the frame itself is moved into contact with the engine component so that each inductor contacts the valve seat which it is to heat.

- the inductors are then locked in position and the frame retracted slightly for purposes of establishing a desired magnetic coupling distance between the inductors and valve seats.

- the foregoing patents disclose methods which have provided extremely good results when induction heating ferrous exhaust valve seats in cast iron engine components.

- the present invention relates to inductively heating a metal valve seat insert within an engine component such as an engine head or the like subsequent to installation and machining of the insert within the component.

- the invention further relates to a method for inductively heating the insert prior to quench hardening while maintaining a pressure fit between the metal insert and a non-ferrous engine component.

- the method utilizes high power induction heating techniques which facilitate obtaining the necessary insert heating to a satisfactory preselected depth in a very short time interval.

- the method comprises the steps of:

- the step of energizing is performed at a frequency generally in the range of approximately 250-500 kilohertz at a selected power generally in the range of 15-25 kilowatts and with said step of machining being performed in a time period of less than 1 second.

- the frequency is approximately 400 kilohertz at a selected power of approximately 20 kilowatts.

- the step of maintaining continues until the metal forming the valve seat is formed into an austenitic structure to a depth of generally no greater than 0.035 inches. In the preferred method, this depth is maintained at approximately 0.024 inches.

- the principal object of the present invention is the provision of a new method which is extremely reliable and effective for purposes of inductively heating a conical surface on a ferrous ring insert, such as a cast iron insert, disposed in a non-ferrous component and, in particular, an internal combustion engine component.

- Another object of the invention is the provision of such a method which will not cause deleterious heat transfer through the insert and/or to the component metal immediately surrounding and adjacent to the insert.

- Still another object of the invention is the provision of a new method for inductively heating a ferrous valve seat insert having a pressure fit in an aluminum engine component so that such heating will not deleteriously affect the pressure fit and wherein an inexpensive ferrous material like cast iron may be used for the insert.

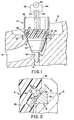

- FIGURE 1 shows an induction heating device A disposed in operative communication with a cast aluminum engine component B.

- induction heating device A disposed in operative communication with a cast aluminum engine component B.

- Specific details of the features and operation of induction heating device A are disclosed in detail in the commonly assigned United States Pat. No. Re 29,046. Essential and non-essential subject matter from that patent, as well as from commonly assigned U. S. Pat. No. 3,837,934, are incorporated hereinto by reference.

- engine component B includes at least one exhaust passageway 10 having an annular valve seat insert 12 formed of cast iron and closely disposed coaxially within a recessed cylindrical exhaust port 14.

- a guide opening or port 16 is coaxial with exhaust port 14 and receives the stem of a conventional poppet valve (not shown) when the engine is assembled.

- Annular valve seat insert 12 includes a conically shaped valve seat surface 30 which is installed into the engine component, machined and thereafter hardened in accordance with the subject invention.

- Insert 12 comprises a standard component typically constructed from steel or cast iron; however, cast iron is preferred because of costs.

- Installation of insert 12 into the receiving bore at exhaust port 14 may be by any one of a number of conventional methods including, for example, a pressure or force fit and the like. When a pressure fit technique is employed, the insert is normally chilled to obtain some degree of contraction and thereby more readily accommodate installation. Following installation, the insert is fixedly-retained in port 14 by opposed forces particularly occurring at interface area 32 between the outer side wall of the.insert and the receiving bore side wall. ' It will be readily appreciated that a plurality of exhaust ports with associated inserts A are typically involved with any engine component B in the same manner best described in U. S. Pat. No. Re 29,046.

- induction heating device A includes a generally cylindrical electrically insulated body 40 having a somewhat smaller cylindrical electrically insulated body insert 42 extending coaxially outward from the inner end thereof.

- a locating pin or nose 44 extends coaxially outward from body insert 42 to accommodate locating the induction heating device coaxially of exhaust port 14 in a known manner.

- a single turn inductor Interposed between body 40 and body insert 42 of the induction heating device is a single turn inductor generally designated 50.

- This inductor comprises a split circular ring of copper of generally rectangular cross-section and includes a pair of spaced legs 52,54 extending therefrom axially through body 40 and outwardly from the body outer end.

- Inductor 50 as well as legs 52,54 are hollow and communicate with each other in such fashion to define a continuous fluid passageway therethrough. This passageway accommodates passage of a suitable coolant from a source (not shown) disposed adjacent to or spaced from the overall induction heating device as is known.

- a power source 60 is operatively connected by leads 62,64 to conductor 50 as at, for example, legs 52,54, 'respectively.

- the power source comprises an oscillator having an output frequency capability generally in the range of 200-500 kilohertz (kHz) and a power capability of generally between 12-25 kilowatts (kw).

- kHz kilohertz

- kw kilowatts

- the preferred power is approximately 20 kw.

- the power density is in the general range of 40 kw/in 2 . This is drastically higher than any power density previously used for heating the valve seats of internal combustion engines.

- a time delay device is advantageously incorporated between leads 62,64 for turning the power source 60 off after a preselected heating time or interval. In accordance with the present new method, this heating time is quite short and is typically less than 1 second.

- aluminum engine component B will typically have a plurality of exhaust ports 14 which all have similar inserts 12 which are to be inductively heated in a simultaneous manner.

- Apparatus adapted for this purpose is shown in U. S. Pat. No. Re 29,046 and includes means for causing induction heating device A to be positioned in an associated exhaust port 14 with locating pin 44 coaxially aligning the device relative to the exhaust port.

- Device A is bottomed out with inductor 50 engaging conical valve seat surface 30 of seat insert 12. Thereafter, the heating device is backed out slightly so that some preselected gap is present between.the inductor and conical valve seat surface 30 to effect a desired coupling relationship therebetween.

- this gap is generally designated by letter a and comprises a distance of approximately 0.040 inches. While this particular gap has been found.particularly suitable in most cases where-a ferrous valve seat insert disposed in an aluminum engine component is to have a conical valve seat surface hardened, it will be appreciated that it may be varied somewhat as deemed necessary or appropriate for a specific application of the new method.

- the side or flat surface 70 of inductor 50 is generally parallel to seat surface 30 and has a width at least slightly greater than that of the seat surface.

- a high power, low time induction heating method is employed whereby seat surface 30 of seat insert 12 is sufficiently heated to an acceptable depth for purposes of transforming the seat material into the austenitic range for subsequent transformation into the martensitic range.

- the depth of such transformation is generally designated by the letter d and may comprise a depth of up to approximately 0.035 inches, although 0.024 inches is generally preferred.

- the prefrred frequency of approximately 400 kHz a relatively shallow reference depth is heated in the seat surface and by using the preferred power of approximately 20 kw to obtain a power density of about 40 kw/in 2 , the valve seat is heated to an acceptable transformation temperature at a very rapid rate. Indeed, and when using the preferred ranges noted, it has been found that a time interval of approximately 0.5 seconds will provide entirely satisfactory heating and hardening results to a depth of approximately 0.024 inches..

- the seat rings or the entire engine component are subjected to quenching in a manner known in the art. Because heating of seat surfaces 30 is so rapid and is substantially limited to or isolated at these surfaces to a preselected shallow depth, there is no deleterious heating of the whole insert or heat transfer through seat inserts 12. These factors might otherwise adversely affect or alter the close fitting relationship between the seat inserts and exhaust ports. This result represents a substantial improvement over results obtained from prior known techniques in inductively heating valve seats or valve seat inserts.

- cast iron valve seat inserts have been successfully hardened to a case depth of 0.030 inches using a heat cycle of 0.5 seconds with a radio frequency oscillator (400 kw) and a power density of 40 kw/in 2 .

- the advantages of using a soft cast iron insert in an aluminum cylinder head rather than a prehardened alloy steel insert resides in the fact that it permits easy machining of the soft cast insert with subsequent hardening of the valve seat by induction hardening techniques. This then achieves the requisite seat durability while, at the same time, yielding considerable improvement by way of increased productivity.

- Valve seat inserts have also been hardened at a 0.2 second heat time with this new method to approximately the case depth of 0.030 inches by using considerably more than 40 kw/in 2 power density. Even though it reduces the tendency to induce heat into the insert, the 0.5 second heating cycle is considered somewhat more tolerable in that it provides a more uniform and constant case depth.

- the preferred parameters of the subject method using a primary power source having a frequency of approximately 400 kHz and a power of approximately 20 kw with a heating cycle of approximately 0.5 seconds provides a case depth of approximately 0.024 inches and a hardness of "58" on the Rockwell C scale in cast iron seat inserts.

- Prior techniques which typically employ the same frequency at a power of approximately 7 kw with a heating cycle of approximately 7-8 seconds provides a case depth of between 0.050-0.060 inches and a hardness of "58" on the Rockwell C scale.

- Such parameters, while acceptable for gray cast iron engine components having integral cast iron valve seats simply will not provide suitable results in the environment of cast aluminum engine components utilizing ferrous seat ring inserts.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Mechanical Engineering (AREA)

- Materials Engineering (AREA)

- Crystallography & Structural Chemistry (AREA)

- Thermal Sciences (AREA)

- Physics & Mathematics (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- General Engineering & Computer Science (AREA)

- Heat Treatment Of Articles (AREA)

- Details Of Valves (AREA)

- General Induction Heating (AREA)

- Lift Valve (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT82302088T ATE17814T1 (de) | 1981-05-04 | 1982-04-23 | Verfahren zum induktiven erhitzen von ventilsitzeinlagen. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US25985681A | 1981-05-04 | 1981-05-04 | |

| US259856 | 1981-05-04 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0064367A2 true EP0064367A2 (de) | 1982-11-10 |

| EP0064367A3 EP0064367A3 (en) | 1983-03-30 |

| EP0064367B1 EP0064367B1 (de) | 1986-01-29 |

Family

ID=22986708

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP82302088A Expired EP0064367B1 (de) | 1981-05-04 | 1982-04-23 | Verfahren zum induktiven Erhitzen von Ventilsitzeinlagen |

Country Status (6)

| Country | Link |

|---|---|

| EP (1) | EP0064367B1 (de) |

| JP (1) | JPS6047884B2 (de) |

| AT (1) | ATE17814T1 (de) |

| CA (1) | CA1187142A (de) |

| DE (1) | DE3268757D1 (de) |

| MX (1) | MX151639A (de) |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0727565A1 (de) * | 1995-02-16 | 1996-08-21 | Yamaha Hatsudoki Kabushiki Kaisha | Eine Ventilsitzanordnung und ein Verfahren zu ihrer Herstellung |

| EP0730085A1 (de) * | 1995-02-28 | 1996-09-04 | Yamaha Hatsudoki Kabushiki Kaisha | Zylinderkopf und Verfahren zur Herstellung eines Ventilsitzes |

| US5745993A (en) * | 1996-02-27 | 1998-05-05 | Yamaha Hatsudoki Kabushiki Kaisha | Valve seat |

| US5768779A (en) * | 1995-09-14 | 1998-06-23 | Yamaha Hatsudoki Kabushiki Kaisha | Method of manufacturing cylinder head for engine |

| US5778531A (en) * | 1995-09-14 | 1998-07-14 | Yamaha Hatsudoki Kabushiki Kaisha | Method of manufacturing cylinder head for engine |

| US6138351A (en) * | 1995-03-13 | 2000-10-31 | Yamaha Hatsudoki Kabushiki Kaisha | Method of making a valve seat |

| CN110375078A (zh) * | 2018-04-12 | 2019-10-25 | Cla-Val公司 | 供水设备阀装置和模制阀体的方法 |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1035179B (de) * | 1955-05-20 | 1958-07-31 | Saviem | Verfahren zur Waermebehandlung von Ventilsitzen |

| USRE29046E (en) * | 1971-06-09 | 1976-11-23 | Park-Ohio Industries, Inc. | Method and apparatus for inductively heating valve seats |

| US3837934A (en) * | 1971-06-09 | 1974-09-24 | Park Ohio Industries Inc | Method for inductively heating valve seats |

| DE3175203D1 (en) * | 1980-05-08 | 1986-10-02 | Park Ohio Industries Inc | Method and apparatus for inductively heating valve seat inserts for hardening the seat surfaces |

-

1982

- 1982-04-23 EP EP82302088A patent/EP0064367B1/de not_active Expired

- 1982-04-23 AT AT82302088T patent/ATE17814T1/de not_active IP Right Cessation

- 1982-04-23 DE DE8282302088T patent/DE3268757D1/de not_active Expired

- 1982-05-03 CA CA000402185A patent/CA1187142A/en not_active Expired

- 1982-05-03 MX MX192538A patent/MX151639A/es unknown

- 1982-05-04 JP JP57075062A patent/JPS6047884B2/ja not_active Expired

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0727565A1 (de) * | 1995-02-16 | 1996-08-21 | Yamaha Hatsudoki Kabushiki Kaisha | Eine Ventilsitzanordnung und ein Verfahren zu ihrer Herstellung |

| US5787853A (en) * | 1995-02-16 | 1998-08-04 | Yamaha Hatsudoki Kabushiki Kaisha | Valve seat-bonding area structures and valve seat-bonded cylinder head with the structures |

| EP0730085A1 (de) * | 1995-02-28 | 1996-09-04 | Yamaha Hatsudoki Kabushiki Kaisha | Zylinderkopf und Verfahren zur Herstellung eines Ventilsitzes |

| EP0819836A3 (de) * | 1995-02-28 | 1998-02-04 | Yamaha Hatsudoki Kabushiki Kaisha | Zylinderkopf und Verfahren zur Herstellung eines Ventilsitzes |

| US6138351A (en) * | 1995-03-13 | 2000-10-31 | Yamaha Hatsudoki Kabushiki Kaisha | Method of making a valve seat |

| US5768779A (en) * | 1995-09-14 | 1998-06-23 | Yamaha Hatsudoki Kabushiki Kaisha | Method of manufacturing cylinder head for engine |

| US5778531A (en) * | 1995-09-14 | 1998-07-14 | Yamaha Hatsudoki Kabushiki Kaisha | Method of manufacturing cylinder head for engine |

| US5745993A (en) * | 1996-02-27 | 1998-05-05 | Yamaha Hatsudoki Kabushiki Kaisha | Valve seat |

| CN110375078A (zh) * | 2018-04-12 | 2019-10-25 | Cla-Val公司 | 供水设备阀装置和模制阀体的方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| MX151639A (es) | 1985-01-23 |

| ATE17814T1 (de) | 1986-02-15 |

| DE3268757D1 (en) | 1986-03-13 |

| JPS57194212A (en) | 1982-11-29 |

| JPS6047884B2 (ja) | 1985-10-24 |

| CA1187142A (en) | 1985-05-14 |

| EP0064367B1 (de) | 1986-01-29 |

| EP0064367A3 (en) | 1983-03-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4438310A (en) | Method and apparatus for inductively heating valve seat inserts | |

| US4299401A (en) | Piston ring and method of making same | |

| EP0064367A2 (de) | Verfahren zum induktiven Erhitzen von Ventilsitzeinlagen | |

| US3649380A (en) | Method of manufacturing hard faced exhaust valves | |

| US4643079A (en) | Iron piston having selectively hardened ring groove | |

| US4247972A (en) | Method of manufacturing a piston ring | |

| GB2031104A (en) | High pressure tubing | |

| CA1117158A (en) | Piston ring and method of manufacture | |

| US4643781A (en) | Method of heat treating valve inserts | |

| USRE29046E (en) | Method and apparatus for inductively heating valve seats | |

| US3837934A (en) | Method for inductively heating valve seats | |

| US4791259A (en) | Method and apparatus for retaining a valve seat insert | |

| US4336432A (en) | Induction hardening of valve seat inserts | |

| US3743809A (en) | Method and apparatus for inductively heating valve seats | |

| US4547229A (en) | Solution heat treating of engine poppet valves | |

| US4673784A (en) | Valve seat inductor and method of using same | |

| US4737201A (en) | Solution heat treatment of engine poppet valves and valves made therefrom | |

| US3737612A (en) | Apparatus for inductively heating valve seats | |

| CA1177903A (en) | Method and apparatus for inductively heating valve seat inserts | |

| Doyon et al. | Induction hardening of crankshafts and camshafts | |

| US4728374A (en) | Solution heat treated engine poppet valves | |

| US3777096A (en) | Apparatus for inductively heating valve seats | |

| US2439246A (en) | Pressure welding machine | |

| ES8705046A1 (es) | Un aparato para calentar por induccion la superficie troncoconica del asiento de valvula de una lumbrera de valvula o un componente de motor. | |

| US3761669A (en) | Method and apparatus for inductively heating valve seats |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LU NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| 17P | Request for examination filed |

Effective date: 19821118 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| ITF | It: translation for a ep patent filed | ||

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 17814 Country of ref document: AT Date of ref document: 19860215 Kind code of ref document: T |

|

| ET | Fr: translation filed | ||

| REF | Corresponds to: |

Ref document number: 3268757 Country of ref document: DE Date of ref document: 19860313 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19860421 Year of fee payment: 5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19860430 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19870430 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19880423 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19880424 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19880430 Ref country code: CH Effective date: 19880430 |

|

| BERE | Be: lapsed |

Owner name: PARK-OHIO INDUSTRIES INC. Effective date: 19880430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19881101 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Effective date: 19890430 |

|

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19920410 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19920521 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19930408 Year of fee payment: 12 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19930423 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19930423 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19940101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19941229 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 82302088.8 Effective date: 19890726 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |