EP0054467A1 - Hermetisch gekapselter Kühlkompressor - Google Patents

Hermetisch gekapselter Kühlkompressor Download PDFInfo

- Publication number

- EP0054467A1 EP0054467A1 EP81401913A EP81401913A EP0054467A1 EP 0054467 A1 EP0054467 A1 EP 0054467A1 EP 81401913 A EP81401913 A EP 81401913A EP 81401913 A EP81401913 A EP 81401913A EP 0054467 A1 EP0054467 A1 EP 0054467A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- turbine

- compressor according

- rotor

- stator

- suction

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B31/00—Compressor arrangements

- F25B31/02—Compressor arrangements of motor-compressor units

Definitions

- the present invention relates to a hermetic refrigeration compressor comprising at least one compression stage actuated by an electric motor.

- An object of the present invention is to significantly increase the latter by providing means for boosting and increasing the kinetic energy of the gas, these means being arranged before the compression stage of the gas proper, inside the compressor casing.

- the refrigerant gas sucked into a compressor can sometimes contain droplets of refrigerant, so that if precautions are not taken to eliminate them, they may damage the cylinder head, gaskets, valves suction, etc ... which are arranged at the entrance of the compression chambers.

- Another object of the present invention is to prevent such a danger by eliminating the droplets of refrigerant before they arrive at the gas suction valves.

- these hermetic compressors especially those of the household type, must be as silent as possible. It is therefore essential to minimize engine noise and that caused by the flow of refrigerant gas. This is why another object of the invention is to reduce the noise level of these compressors.

- the compressor according to the invention overcomes very economically to the aforementioned drawbacks.

- a hermetic refrigeration compressor comprising, inside a sealed envelope, an electric motor comprising a stator, a rotor coupled to a crankshaft and driving a compression means, with cylinder and piston, of a gas refrigerant, and a centrifugal turbine driven by this motor, is characterized in that the turbine makes it possible to boost the refrigerant gas before it enters the compression means with cylinder and piston.

- part of the stator winding is housed in the suction chamber and that it is arranged concentrically with the centrifugal turbine.

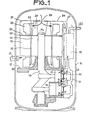

- Figure 1 shows a schematic view, in vertical section, of the hermetic refrigeration compressor according to the invention.

- FIG. 2 represents a curve of the gas pressure pulsations obtained by the turbine and the positioning of the opening of the valves when the phasing is obtained.

- the compressor according to the invention is housed in a sealed metal casing 10.

- the lower part intended to be fixed on a frame, is constituted by a tank and its upper part by a cover, both having a substantially semi-cylindrical shape.

- the tank and the cover are welded together by their edges and in such a way that the envelope 10 is sealed against the refrigerant gas filling this envelope 10.

- the electric motor consisting of a rotor 13 and a stator 19, is placed in the upper part of the casing 10, above a body 12 made of cast iron from the compressor.

- This rotor 13 is coupled to a crankshaft 14 which is arranged in the height direction of the envelope 10.

- crankshaft 14 and the engine have been offset with respect to the longitudinal axis of the casing 10, as shown in FIG. 1, in order to be able to accommodate a high-pressure tank 18 which serves as a discharge silencer.

- This tank 18 is mounted between the stator 19 of the engine and the wall of the casing 10, and it is provided with a pipe 20 for external delivery of the compressed gas.

- a suction chamber 21 a turbine 28 arranged above the front faces 22 and 23 of the rotor 13 and the stator 19.

- This chamber 21 is obtained by covering these front faces 22, 23 by a cover 24, of substantially semi-cylindrical shape, for example, and whose peripheral edge 25 is held contiguous with that of the stator 19.

- This chamber 21 communicates, through a suction orifice 26, with the volume of the casing 10, and by an internal delivery pipe 27 with the inlet of the two cylinders 150, 160 with pistons 15 and 16.

- the refrigerant gas arriving in the casing 10 through the inlet pipe 17 is sucked through the orifice 26 in the suction chamber 21 by means of the turbine 28, then is discharged, in the state of pressurized gas, in the internal delivery pipe 27 to the compression cylinders 150, 160 respectively.

- a cylinder head cover 31 provided with pipes connected, on the one hand, to the pipe 27 and, on the other hand, to the cylinders 150 and 160 respectively, allows the successive supplies of the cylinders 150 and 160 with pressurized refrigerant gas which allows '' achieve a significant increase in compressor efficiency.

- the tubing 28 and the carcass of the rotor 13 can be molded in one piece.

- part of the electric winding 29 of the stator 19 exceeds the axial face 22 of the frame of the stator 19 and advances into the chamber 21 concentrically with the turbine 28.

- the refrigerant gas arriving by the inlet pipe 17 contains droplets of refrigerant, these are sucked up with the gas and projected by the turbine 28 in rotation on the hot part of the electric coil 29 surrounding the turbine 28.

- the droplets volatilize in refrigerant gas. Consequently, there is no longer any risk of damaging the cylinder head assembly 30 placed at the inlet of the piston cylinders 15 and 16.

- the gas set in motion by the turbine 28 scans and cools in its passage the front surfaces 22 and 23 of the rotor 13 and the stator 19.

- a certain amount of refrigerant gas, sucked into the suction chamber 21 by the turbine 28 is pushed into the air gap 32 of the rotor 13 and of the stator 19 which contributes to cooling the surfaces facing the latter.

- the gas leaves between the two lower front faces of the rotor 13 and the stator 19 and bypasses the ends of the winding 29 leaving the lower front face of the stator 19 to mix with the refrigerant gas arriving through the pipe. 17 of entry into the envelope 10.

- the suction chamber 21 also acts as a silencer by reducing towards the outside the various internal noises due in particular to the circulation of the sucked gas.

- the length of the discharge pipe 27 is, in an exemplary embodiment, determined so as to phase the gas pulsations created by the turbine 28 with paddle blades 'entry of the compression means, that is to say at the valves 1,2; 3,4 suction cylinders 150, 160, and the movement of these valves 1.2; 3,4 suction, so that at the opening of these valves 1,2; 3,4 correspond, at the level of these, gas suppression bellies.

- the blades of the turbine 28 are integral with the movement of the piston or pistons in their cylinder.

- the opening of the suction valves 1,2 occurs between 60 ° and 180 ° of rotation angle of the motor shaft, the origin of the measurement being taken at top dead center (TDC).

- TDC top dead center

- a corresponding angular setting of the blades of the turbine 28 creates, for an angle of rotation substantially equal to 120 °, an overpressure at the inlet of the internal delivery pipe 27.

- the speed of rotation of the engine, the number of blades of the turbine, the desired pressure and temperature of the refrigerant gas make it possible to easily calculate the wavelength of the pulsations thus created of this gas. We can then deduce the length of the internal delivery pipe 27.

- FIG. 2 represents, in curve (a), the pulsations of the gases at the inlet of the cylinder 150, that is to say the cyclic variation of the pressure of these gases at the level of the suction valves 1, 2 and in curve (b), the valve opening positions 1,2 as a function of the angle O of rotation of the crankshaft 14.

- the length of the internal delivery pipe 27 is determined, taking into account the length of the pipes which extend it in the cylinder head cover 31, so that the total lengths of the tubing 27 and of the pipes which extend it and lead to the inlet of one and the other cylinder 150, 160, ensure a substantially maximum value of the gas pressure at the valves 1, 2 and 3.4 respectively.

- This exemplary embodiment of the means used to obtaining maximum overpressure at the inlet of the cylinders 150, 160 is not limiting.

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Mechanical Engineering (AREA)

- Thermal Sciences (AREA)

- General Engineering & Computer Science (AREA)

- Compressor (AREA)

- Applications Or Details Of Rotary Compressors (AREA)

- Sampling And Sample Adjustment (AREA)

- Structures Of Non-Positive Displacement Pumps (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT81401913T ATE18298T1 (de) | 1980-12-12 | 1981-12-02 | Hermetisch gekapselter kuehlkompressor. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR8026412 | 1980-12-12 | ||

| FR8026412A FR2496241A1 (fr) | 1980-12-12 | 1980-12-12 | Compresseur frigorifique hermetique |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0054467A1 true EP0054467A1 (de) | 1982-06-23 |

| EP0054467B1 EP0054467B1 (de) | 1986-02-26 |

Family

ID=9249002

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP81401913A Expired EP0054467B1 (de) | 1980-12-12 | 1981-12-02 | Hermetisch gekapselter Kühlkompressor |

Country Status (6)

| Country | Link |

|---|---|

| EP (1) | EP0054467B1 (de) |

| AT (1) | ATE18298T1 (de) |

| DE (1) | DE3173920D1 (de) |

| DK (1) | DK549781A (de) |

| ES (1) | ES8301351A1 (de) |

| FR (1) | FR2496241A1 (de) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1329658C (zh) * | 2002-08-19 | 2007-08-01 | 乐金电子(天津)电器有限公司 | 双容量压缩机 |

Citations (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2509377A (en) * | 1946-03-16 | 1950-05-30 | Trask Allen | Compressor |

| US2963218A (en) * | 1959-07-03 | 1960-12-06 | Worthington Corp | Enclosed motor-compressor unit |

| US2963216A (en) * | 1958-10-09 | 1960-12-06 | Westinghouse Electric Corp | Refrigerating apparatus |

| US3075106A (en) * | 1961-03-09 | 1963-01-22 | Gen Electric | Dynamoelectric machine |

| US3145914A (en) * | 1962-08-03 | 1964-08-25 | Worthington Corp | Enclosed motor compressor unit |

| US3239132A (en) * | 1964-02-03 | 1966-03-08 | Trane Co | Compressor |

| US3288357A (en) * | 1961-08-31 | 1966-11-29 | Copeland Refrigeration Corp | Refrigeration motor-compressor |

| US3387774A (en) * | 1966-11-21 | 1968-06-11 | Copeland Refrigeration Corp | Means for inhibiting noise and slugging in refrigerant compressors |

| US3465949A (en) * | 1967-10-23 | 1969-09-09 | Lennox Ind Inc | Pressurizing arrangement for a compressor |

| FR2228164A1 (de) * | 1973-03-12 | 1974-11-29 | Sundstrand Corp | |

| US3876339A (en) * | 1973-08-06 | 1975-04-08 | Sundstrand Corp | Reciprocating piston gas compressor |

| FR2380513A1 (fr) * | 1977-02-10 | 1978-09-08 | Copeland Corp | Dispositif comportant un compresseur de refrigeration et procede de montage |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR892138A (fr) * | 1942-03-12 | 1944-03-29 | Hermes Patentverwertungs Gmbh | Machine frigorifique à compression |

| GB652215A (en) * | 1947-10-07 | 1951-04-18 | James Harold Evans | Thermo-pump heating systems |

| US3462075A (en) * | 1967-11-06 | 1969-08-19 | Lennox Ind Inc | Hermetic compressor construction |

| US3498530A (en) * | 1968-02-21 | 1970-03-03 | Tecumseh Products Co | Hermetic compressor crankcase construction |

| US3942912A (en) * | 1974-10-04 | 1976-03-09 | Lennox Industries Inc. | Method for controlling the operation of two-speed, refrigerant motor compressors |

-

1980

- 1980-12-12 FR FR8026412A patent/FR2496241A1/fr active Granted

-

1981

- 1981-12-02 DE DE8181401913T patent/DE3173920D1/de not_active Expired

- 1981-12-02 EP EP81401913A patent/EP0054467B1/de not_active Expired

- 1981-12-02 AT AT81401913T patent/ATE18298T1/de not_active IP Right Cessation

- 1981-12-11 ES ES507898A patent/ES8301351A1/es not_active Expired

- 1981-12-11 DK DK549781A patent/DK549781A/da not_active Application Discontinuation

Patent Citations (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2509377A (en) * | 1946-03-16 | 1950-05-30 | Trask Allen | Compressor |

| US2963216A (en) * | 1958-10-09 | 1960-12-06 | Westinghouse Electric Corp | Refrigerating apparatus |

| US2963218A (en) * | 1959-07-03 | 1960-12-06 | Worthington Corp | Enclosed motor-compressor unit |

| US3075106A (en) * | 1961-03-09 | 1963-01-22 | Gen Electric | Dynamoelectric machine |

| US3288357A (en) * | 1961-08-31 | 1966-11-29 | Copeland Refrigeration Corp | Refrigeration motor-compressor |

| US3145914A (en) * | 1962-08-03 | 1964-08-25 | Worthington Corp | Enclosed motor compressor unit |

| US3239132A (en) * | 1964-02-03 | 1966-03-08 | Trane Co | Compressor |

| US3387774A (en) * | 1966-11-21 | 1968-06-11 | Copeland Refrigeration Corp | Means for inhibiting noise and slugging in refrigerant compressors |

| US3465949A (en) * | 1967-10-23 | 1969-09-09 | Lennox Ind Inc | Pressurizing arrangement for a compressor |

| FR2228164A1 (de) * | 1973-03-12 | 1974-11-29 | Sundstrand Corp | |

| US3876339A (en) * | 1973-08-06 | 1975-04-08 | Sundstrand Corp | Reciprocating piston gas compressor |

| FR2380513A1 (fr) * | 1977-02-10 | 1978-09-08 | Copeland Corp | Dispositif comportant un compresseur de refrigeration et procede de montage |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1329658C (zh) * | 2002-08-19 | 2007-08-01 | 乐金电子(天津)电器有限公司 | 双容量压缩机 |

Also Published As

| Publication number | Publication date |

|---|---|

| ES507898A0 (es) | 1982-11-16 |

| ATE18298T1 (de) | 1986-03-15 |

| EP0054467B1 (de) | 1986-02-26 |

| DK549781A (da) | 1982-06-13 |

| DE3173920D1 (en) | 1986-04-03 |

| FR2496241A1 (fr) | 1982-06-18 |

| FR2496241B1 (de) | 1984-06-22 |

| ES8301351A1 (es) | 1982-11-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| FR2677076A1 (fr) | Silencieux d'aspiration pour compresseurs hermetiques. | |

| CA2632360A1 (fr) | Compresseur a reinjection d'air | |

| JPH06299962A (ja) | 2重押退けポンプ | |

| EP0054467B1 (de) | Hermetisch gekapselter Kühlkompressor | |

| FR2572770A1 (fr) | Moteur rotatif a combustion interne | |

| KR100816359B1 (ko) | 부스터형 가스 압축기의 구동방법 | |

| FR2655378A1 (fr) | Systeme de moteur a 2 temps ayant 4 cycles. | |

| CN1125293A (zh) | 椭圆转子压缩机和泵 | |

| KR0130239Y1 (ko) | 밀폐형 압축기의 소음기 오일유입방지구조 | |

| FR2496166A1 (fr) | Moteur a deux temps avec distribution d'aspiration par deux soupapes a disques | |

| KR0184180B1 (ko) | 밀폐형 압축기의 토출소음기 | |

| BE341480A (de) | ||

| RU2286462C2 (ru) | Газогидравлическая турбомашина | |

| EP0217374B1 (de) | Kolben-Zylinder Einheit einer Zweitaktbrennkraftmaschine | |

| KR0129387Y1 (ko) | 밀폐형 압축기의 흡입구조 | |

| KR100301072B1 (ko) | 플런저 왕복식 이중펌프 | |

| RU2015363C1 (ru) | Двухтактный двигатель внутреннего сгорания | |

| WO2009004185A4 (fr) | Dispositif et procédé d'ouverture de soupape, de lubrification et de refroidissement des moteurs à pistons alternatifs | |

| EP0094872B1 (de) | Zweitaktbrennkraftmaschine mit Direkteinspritzung | |

| RU2386045C2 (ru) | Поршневой мотор | |

| FR2833647A1 (fr) | Moteur a combustion interne entrainant un compresseur | |

| KR950000958Y1 (ko) | 로터리 콤프레서의 토출 밸브장치 | |

| BE393651A (de) | ||

| FR2545157A1 (fr) | Perfectionnement aux pistons utilises notamment dans les moteurs a deux temps | |

| FR2617242A1 (fr) | Compresseur a rendement ameliore |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT DE FR GB IT SE |

|

| 17P | Request for examination filed |

Effective date: 19821004 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): AT DE FR GB IT SE |

|

| REF | Corresponds to: |

Ref document number: 18298 Country of ref document: AT Date of ref document: 19860315 Kind code of ref document: T |

|

| ITF | It: translation for a ep patent filed | ||

| REF | Corresponds to: |

Ref document number: 3173920 Country of ref document: DE Date of ref document: 19860403 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19921112 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19921113 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19921118 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19921211 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19921230 Year of fee payment: 12 |

|

| ITTA | It: last paid annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19931202 Ref country code: AT Effective date: 19931202 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19931203 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19931202 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19940831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19940901 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| EUG | Se: european patent has lapsed |

Ref document number: 81401913.9 Effective date: 19940710 |