EP0050626B1 - Method and device for the continuous production of non-ferrous metal ingots with self-blocking stacking from a blank obtained from a casting machine on grooved wheel - Google Patents

Method and device for the continuous production of non-ferrous metal ingots with self-blocking stacking from a blank obtained from a casting machine on grooved wheel Download PDFInfo

- Publication number

- EP0050626B1 EP0050626B1 EP81900965A EP81900965A EP0050626B1 EP 0050626 B1 EP0050626 B1 EP 0050626B1 EP 81900965 A EP81900965 A EP 81900965A EP 81900965 A EP81900965 A EP 81900965A EP 0050626 B1 EP0050626 B1 EP 0050626B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- blank

- jaws

- impressions

- self

- ingots

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D5/00—Machines or plants for pig or like casting

- B22D5/005—Devices for stacking pigs; Pigforms to be stacked

Definitions

- the invention relates to a method and a device for continuously obtaining, from a non-ferrous metal blank from a continuous casting machine on a grooved wheel, ingots of constant section and having bosses at their ends. suitable for making self-blocking stacks.

- ingots having hollow and / or raised portions on one or more of their faces can be produced from molds of suitable shape, in order to prevent any relative movement of the ingots with respect to each other when they are assembled in the form of stacks and thus making their transport convenient.

- the process according to the invention consists, in a known manner, of casting a blank on a grooved wheel temporarily closed by a ribbon and periodically making this blank integral with a device responsible for sharing it in ingots, but it is characterized in that that the blank is first clamped progressively on two opposite longitudinal side faces using two jaws in order to form imprints in line with these jaws, these imprints each comprising an edge extending over the entire height of the blank, and to develop at least one boss on at least one of the two other lateral faces, the boss or bosses being in a transverse plane passing through the imprints, the blank then being sheared in line with the imprints.

- the method uses, as a raw material, a blank from a casting machine on a grooved wheel temporarily closed by a ribbon to form a mold with movable walls.

- the preform leaving the casting machine is first brought in a horizontal direction to be threaded between the cylinders of a straightener which gives it a suitable straightness, then it engages in the device responsible for sharing it in ingots.

- This device is fixed by a mobile carriage which includes means for making it integral with the blank.

- the blank drives the carriage with it, which allows the device to move synchronously with the blank and to exercise its sharing action on a determined section of the latter. .

- the blank is first of all clamped progressively on two opposite longitudinal side faces using two jaws connected to the carriage so as to form imprints in line with these jaws and to develop on at at least one of the other two faces, at least one boss.

- imprints which extend over the entire height of the blank are preferably symmetrical with respect to a vertical plane passing through the axis of the blank and they more or less follow the slope of the lateral faces.

- the depth of these imprints can vary depending on the nature of the product or the shape of the blank.

- the bosses which develop on the lower and / or upper face of the blank are located in a transverse plane passing through the imprints and appear on a section in line with the imprints as two nipples separated by a hollow; these nipples dominate the plane of these faces with a height which can be of the order of 1/10 of the height of the blank and join this face according to a convex curve.

- the blank is cut in a plane perpendicular or oblique to its axis, to the right of the imprints, that is to say so as to share the bosses by their median plane.

- Each ingot thus obtained has, in the lengthwise direction, a projecting profile at each of its ends, which constitutes the means of making it self-locking in a conventional stacking system.

- each ingot is taken up by a processing chain in which sheets are formed where one ingot out of two can be turned over in order to bring its lateral faces into close contact with the neighboring ingot; then, the different layers are superimposed successively in the long direction and in the cross direction so as to constitute stacks.

- the present invention also relates to a device making it possible to implement the method described above.

- This device is characterized in that it comprises, connected to a mobile carriage, two jaws placed opposite two longitudinal lateral faces of the blank and intended, on the one hand to form imprints in line with these jaws, these- ci each comprising an edge extending over the entire height of the blank and on the other hand to develop at least one boss on at least one of the two other lateral faces, the device further comprising a knife responsible for shearing l roughing on at least part of its section in line with the impressions and the boss.

- These jaws are schematically made up of a right prism of triangular section surmounted by a trihedron whose base has the same section as the prism. They are in relation to the lateral uprights of the carriage by one of their faces while the other two free faces intersect along an edge contained in a vertical plane perpendicular or oblique to the axis of movement of the blank.

- each jaw In general, the height of each jaw is close to the height of the blank so that the impression is made from top to bottom of the lateral surfaces. Associated with these jaws, there is a knife fixed on the carriage and whose cutting edge is placed in line with the edges of the jaws. At rest, the edge of the knife is placed slightly behind the roughing pass line.

- the movements of the carriage, the jaws and the knife are automatically controlled according to a sequence comprising the following steps: the carriage being in the rest position, the blank pushed by the straightener runs between the elements of the device.

- the carriage is made integral with the blank by any means and is driven at the same speed as the draft.

- This movement of joining causes the jaws to come into operation which come to be applied on the lateral faces of the blank to sink gradually and mark these faces with their imprint.

- the jaws are quickly withdrawn while the knife gradually shears the blank over at least part of its section. Then, the knife is quickly withdrawn, the carriage is detached from the blank, animated by a rapid movement of translation in the opposite direction to that of the blank over a distance of the order of that of the length of the ingot and the solidarity is established again for a new cut.

- the present invention finds its application in particular in the aluminum industry, in all cases where it is sought, starting from a continuously cast product, to obtain ingots having a constant section, a known length and suitable for a self-locking stacking.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Continuous Casting (AREA)

- Metal Rolling (AREA)

- Forging (AREA)

- Shearing Machines (AREA)

Abstract

Description

L'invention concerne un procédé et un dispositif d'obtention en continu à partir d'une ébauche de métal non ferreux issue d'une machine de coulée continue sur roue à gorge, de lingots de section constante et possédant à leurs extrémités des bossages se prêtant à la réalisation d'empilages auto-bloquants.The invention relates to a method and a device for continuously obtaining, from a non-ferrous metal blank from a continuous casting machine on a grooved wheel, ingots of constant section and having bosses at their ends. suitable for making self-blocking stacks.

L'homme de l'art sait que l'on peut réaliser, à partir de moules de forme convenable, des lingots présentant des parties en creux et/ou en relief sur une ou plusieurs de leurs faces et ce, afin d'empêcher tout déplacement relatif des lingots les uns par rapport aux autres lorsqu'ils sont assemblés sous forme de piles et d'en rendre ainsi le transport commode.Those skilled in the art know that ingots having hollow and / or raised portions on one or more of their faces can be produced from molds of suitable shape, in order to prevent any relative movement of the ingots with respect to each other when they are assembled in the form of stacks and thus making their transport convenient.

Cependant, cette technique recourt à des opérations discontinues de moulage, lingot par lingot, conduisant à des produits de structure et de composition assez hétérogènes, de poids variables et présentant une retassure de fin de solidification.However, this technique uses discontinuous molding operations, ingot by ingot, leading to products of fairly heterogeneous structure and composition, of variable weight and having a shrinkage at the end of solidification.

C'est pourquoi l'homme de l'art, pour parer à ces insuffisances, a cherché à utiliser des appareils fonctionnant en continu, et notamment, dans le cas de lingots de section voisine ou inférieure au décimètre carré, des machines de coulée sur roue à gorge fermée par un ruban. L'ébauche continue de métal obtenue à la sortie de ces machines étant alors partagée en lingots distincts soit par sciage à la volée, soit, comme dans le brevet français 1 224 969, par matriçage suivi d'un cisaillage.This is why a person skilled in the art, in order to overcome these shortcomings, has sought to use devices operating continuously, and in particular, in the case of ingots with a section close to or less than a square decimetre, casting machines on grooved wheel closed by a ribbon. The continuous blank of metal obtained at the outlet of these machines is then divided into separate ingots either by sawing on the fly or, as in French patent 1 224 969, by stamping followed by shearing.

Cependant, chacun de ces procédés présente des inconvénients importants. Ainsi, dans le sciage, outre l'usure rapide des scies, une quantité appréciable de métal est dévalorisée sous forme de copeaux qu'il faut séparer de l'huile de coupe avant de les recycler. Dans le procédé par matriçage suivi d'un cisaillage, il est nécessaire de disposer d'une presse à matricer, et de plus, les lingots obtenus présentent sur leur longueur un renflement dû à l'effet d'écrasement de la matrice ; d'où une section irrégulière et un espacement plus ou moins grand entre eux lorsqu'ils sont alignés les uns à côté des autres et en conséquence une compacité relativement faible des piles qu'ils permettent de réaliser.However, each of these methods has significant drawbacks. Thus, in sawing, in addition to the rapid wear of the saws, an appreciable quantity of metal is devalued in the form of chips which must be separated from the cutting oil before being recycled. In the method of stamping followed by shearing, it is necessary to have a stamping press, and moreover, the ingots obtained have, along their length, a bulge due to the crushing effect of the matrix; hence an irregular section and a greater or lesser spacing between them when they are aligned one next to the other and consequently a relatively low compactness of the stacks which they make it possible to produce.

Mais un inconvénient majeur de ces procédés, c'est que les lingots résultant de leur utilisation ne comportent aucun moyen susceptible de former un assemblage à bloc lorsqu'ils sont empilés. C'est pourquoi la demanderesse a cherché et mis au point un procédé et un dispositif qui permettent la fabrication en continu, sans perte de métal, de lingots de section constante, présentant les moyens nécessaires à l'édification de piles auto-bloquantes.However, a major drawback of these methods is that the ingots resulting from their use have no means capable of forming a block assembly when they are stacked. This is why the applicant has sought and developed a method and a device which allow the continuous production, without loss of metal, of ingots of constant section, presenting the means necessary for the construction of self-blocking batteries.

Le procédé suivant l'invention consiste, de façon connue, à couler une ébauche sur une roue à gorge fermée temporairement par un ruban et à rendre périodiquement solidaire cette ébauche d'un dispositif chargé de la partager en lingots, mais il se caractérise en ce que l'ébauche est d'abord pincée de façon progressive sur deux faces latérales longitudinales opposées à l'aide de deux mors afin de former des empreintes au droit de ces mors, ces empreintes comportant chacune une arête s'étendant sur toute la hauteur de l'ébauche, et de développer au moins un bossage sur au moins une des deux autres faces latérales, le ou les bossages se trouvant dans un plan transversal passant par les empreintes, l'ébauche étant ensuite cisaillée au droit des empreintes.The process according to the invention consists, in a known manner, of casting a blank on a grooved wheel temporarily closed by a ribbon and periodically making this blank integral with a device responsible for sharing it in ingots, but it is characterized in that that the blank is first clamped progressively on two opposite longitudinal side faces using two jaws in order to form imprints in line with these jaws, these imprints each comprising an edge extending over the entire height of the blank, and to develop at least one boss on at least one of the two other lateral faces, the boss or bosses being in a transverse plane passing through the imprints, the blank then being sheared in line with the imprints.

Ainsi, le procédé met en oeuvre, comme matière première, une ébauche issue d'une machine de coulée sur roue à gorge fermée temporairement par un ruban pour constituer un moule à parois mobiles.Thus, the method uses, as a raw material, a blank from a casting machine on a grooved wheel temporarily closed by a ribbon to form a mold with movable walls.

L'ébauche sortant de la machine de coulée est d'abord ramenée dans une direction horizontale pour être enfilée entre les cylindres d'une dresseuse qui lui confère une rectitude convenable, puis elle s'engage dans le dispositif chargé de la partager en lingots.The preform leaving the casting machine is first brought in a horizontal direction to be threaded between the cylinders of a straightener which gives it a suitable straightness, then it engages in the device responsible for sharing it in ingots.

Ce dispositif est fixé par un chariot mobile qui comporte des moyens pour le rendre solidaire de l'ébauche. Ainsi, sous la poussée des cylindres de la dresseuse, l'ébauche entraîne avec elle le chariot, ce qui permet au dispositif de se déplacer de façon synchrone avec l'ébauche et d'exercer son action de partage sur une section déterminée de cette dernière. Au cours de ce déplacement synchrone, l'ébauche est d'abord pincée de façon progressive sur deux faces latérales longitudinales opposées à l'aide de deux mors reliés au chariot de façon à former des empreintes au droit de ces mors et à développer sur au moins une des deux autres faces, au moins un bossage.This device is fixed by a mobile carriage which includes means for making it integral with the blank. Thus, under the thrust of the cylinders of the straightener, the blank drives the carriage with it, which allows the device to move synchronously with the blank and to exercise its sharing action on a determined section of the latter. . During this synchronous movement, the blank is first of all clamped progressively on two opposite longitudinal side faces using two jaws connected to the carriage so as to form imprints in line with these jaws and to develop on at at least one of the other two faces, at least one boss.

Ces empreintes qui s'étendent sur toute la hauteur de l'ébauche sont, de préférence, symétriques par rapport à un plan vertical passant par l'axe de l'ébauche et elles épousent plus ou moins la pente des faces latérales. La profondeur de ces empreintes peut varier suivant la nature du produit ou la forme de l'ébauche.These imprints which extend over the entire height of the blank are preferably symmetrical with respect to a vertical plane passing through the axis of the blank and they more or less follow the slope of the lateral faces. The depth of these imprints can vary depending on the nature of the product or the shape of the blank.

Les bossages qui se développent sur la face inférieure et/ou supérieure de l'ébauche se trouvent dans un plan transversal passant par les empreintes et se présentent sur une coupe au droit des empreintes comme deux mamelons séparés par un creux ; ces mamelons dominent le plan de ces faces d'une hauteur qui peut être de l'ordre du 1/10 de la hauteur de l'ébauche et rejoignent cette face suivant une courbe convexe. Après pinçage, l'ébauche est coupée dans un plan perpendiculaire ou oblique à son axe, au droit des empreintes, c'est-à-dire de façon à partager les bossages par leur plan médian. Chaque lingot, ainsi obtenu, présente, dans le sens de la longueur, un profil en saillie à chacune de ses extrémités ce qui constitue le moyen de le rendre auto-bloquant dans un système d'empilage classique.The bosses which develop on the lower and / or upper face of the blank are located in a transverse plane passing through the imprints and appear on a section in line with the imprints as two nipples separated by a hollow; these nipples dominate the plane of these faces with a height which can be of the order of 1/10 of the height of the blank and join this face according to a convex curve. After pinching, the blank is cut in a plane perpendicular or oblique to its axis, to the right of the imprints, that is to say so as to share the bosses by their median plane. Each ingot thus obtained has, in the lengthwise direction, a projecting profile at each of its ends, which constitutes the means of making it self-locking in a conventional stacking system.

A la sortie du dispositif, chaque lingot est repris par une chaîne de traitement dans laquelle on forme des nappes où un lingot sur deux peut être retourné afin d'amener ses faces latérales en contact étroit avec le lingot voisin ; puis, on superpose les différentes nappes successivement dans le sens long et dans le sens travers de façon à constituer des piles.On leaving the device, each ingot is taken up by a processing chain in which sheets are formed where one ingot out of two can be turned over in order to bring its lateral faces into close contact with the neighboring ingot; then, the different layers are superimposed successively in the long direction and in the cross direction so as to constitute stacks.

Dans ces piles, les bossages placés sur les deux côtés opposés de chaque nappe bloquent à la fois les faces latérales de la nappe supérieure et de la nappe inférieure, ces dernières nappes bloquant elles-mêmes par leurs bossages les faces latérales de la nappe considérée. Les piles ainsi obtenues sont alors cerclées et peuvent être véhiculées sans aucun risque de déplacement relatif des lingots.In these stacks, the bosses placed on the two opposite sides of each ply block both the lateral faces of the upper ply and the lower ply, the latter plies themselves blocking by their bosses the lateral faces of the ply considered. The piles thus obtained are then encircled and can be transported without any risk of relative displacement of the ingots.

La présente invention concerne également un dispositif permettant de mettre en oeuvre le procédé décrit ci-dessus.The present invention also relates to a device making it possible to implement the method described above.

Ce dispositif est caractérisé en ce qu'il comporte, reliés à un chariot mobile, deux mors placés en regard de deux faces latérales longitudinales de l'ébauche et destinés, d'une part à former des empreintes au droit de ces mors, celles-ci comportant chacune une arête s'étendant sur toute la hauteur de l'ébauche et d'autre part à développer au moins un bossage sur au moins une des deux autres faces latérales, le dispositif comportant, en outre, un couteau chargé de cisailler l'ébauche sur au moins une partie de sa section au droit des empreintes et du bossage.This device is characterized in that it comprises, connected to a mobile carriage, two jaws placed opposite two longitudinal lateral faces of the blank and intended, on the one hand to form imprints in line with these jaws, these- ci each comprising an edge extending over the entire height of the blank and on the other hand to develop at least one boss on at least one of the two other lateral faces, the device further comprising a knife responsible for shearing l roughing on at least part of its section in line with the impressions and the boss.

Ces mors, de préférence identiques, sont de façon schématique constitués d'un prisme droit de section triangulaire surmonté d'une trièdre dont la base a la même section que le prisme. Ils sont en relation avec les montants latéraux du chariot par l'une de leurs faces tandis que les deux autres faces libres se coupent suivant une arête contenue dans un plan vertical perpendiculaire ou oblique à l'axe de déplacement de l'ébauche.These jaws, preferably identical, are schematically made up of a right prism of triangular section surmounted by a trihedron whose base has the same section as the prism. They are in relation to the lateral uprights of the carriage by one of their faces while the other two free faces intersect along an edge contained in a vertical plane perpendicular or oblique to the axis of movement of the blank.

En général, la hauteur de chaque mors est voisine de la hauteur de l'ébauche de façon que l'empreinte se fasse du haut en bas des surfaces latérales. Associé à ces mors, se trouve un couteau fixé sur le chariot et dont le tranchant est placé au droit des arêtes des mors. Au repos, le tranchant du couteau est placé légèrement en retrait de la ligne de passe de l'ébauche.In general, the height of each jaw is close to the height of the blank so that the impression is made from top to bottom of the lateral surfaces. Associated with these jaws, there is a knife fixed on the carriage and whose cutting edge is placed in line with the edges of the jaws. At rest, the edge of the knife is placed slightly behind the roughing pass line.

De point de vue fonctionnement, les mouvements du chariot, des mors et du couteau sont commandés automatiquement suivant une séquence comprenant les étapes suivantes : le chariot étant en position de repos, l'ébauche poussée par la dresseuse défile entre les éléments du dispositif. Au moment où la longueur de l'ébauche correspondant à celle des lingots qu'on veut obtenir est passée au droit des mors, le chariot est rendu solidaire de l'ébauche par un moyen quelconque et se trouve entraîné à la même vitesse que l'ébauche. Ce mouvement de solidarisation entraîne la mise en route des mors qui viennent s'appliquer sur les faces latérales de l'ébauche pour s'enfoncer progressivement er marquer ces faces de leur empreinte. Dès que ces empreintes ont atteint la profondeur souhaitée, les mors se retirent rapidement tandis que le couteau vient cisailler progressivement l'ébauche sur au moins une partie de sa section. Puis, le couteau se retire rapidement, le chariot est désolidarisé de l'ébauche, animé d'un mouvement rapide de translation de sens contraire à celui de l'ébauche sur une distance de l'ordre de celle de la longueur du lingot et la solidarisation s'établit à nouveau en vue d'une nouvelle coupe.From an operational point of view, the movements of the carriage, the jaws and the knife are automatically controlled according to a sequence comprising the following steps: the carriage being in the rest position, the blank pushed by the straightener runs between the elements of the device. When the length of the blank corresponding to that of the ingots which one wishes to obtain has passed in line with the jaws, the carriage is made integral with the blank by any means and is driven at the same speed as the draft. This movement of joining causes the jaws to come into operation which come to be applied on the lateral faces of the blank to sink gradually and mark these faces with their imprint. As soon as these impressions have reached the desired depth, the jaws are quickly withdrawn while the knife gradually shears the blank over at least part of its section. Then, the knife is quickly withdrawn, the carriage is detached from the blank, animated by a rapid movement of translation in the opposite direction to that of the blank over a distance of the order of that of the length of the ingot and the solidarity is established again for a new cut.

La présente invention sera mieux comprise à l'aide des dessins accompagnant la demande qui n'ont rien de limitatif et ont pour seul but de l'illustrer.

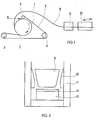

- La figure 1 représente une installation possible de coulée équipée de l'ensemble chariot- dispositif suivant l'invention.

- La figure 2 est une section perpendiculaire à son axe de déplacement de l'ensemble chariot- dispositif.

- La figure 3 montre en perspective une extrémité du lingot obtenu suivant le procédé de l'invention.

- La figure 4 représente un assemblage de lingots auto-bloquants suivant l'invention.

- Figure 1 shows a possible casting installation equipped with the carriage-device assembly according to the invention.

- Figure 2 is a section perpendicular to its axis of movement of the carriage-device assembly.

- Figure 3 shows in perspective one end of the ingot obtained according to the method of the invention.

- FIG. 4 represents an assembly of self-locking ingots according to the invention.

Sur la figure 1, on peut voir une machine de coulée continue à roue à gorge du type quatre roues comprenant la roue de coulée proprement dite 1, les trois roues auxiliaires 2, 3, 4 et le ruban 5. Le métal liquide est introduit dans la machine suivant 6 et ressort en 7 sous forme d'ébauche 8. Cette ébauche est amenée dans une dresseuse 9 puis, vers un chariot mobile 10 équipé des mors et du couteau.

- La figure 2 est une section perpendiculaire à son axe de déplacement de l'ensemble chariot- dispositif où on peut distinguer, d'une part, reliés à chacun des

montants 11, lesmors 12 et lecouteau 13 avec sontranchant 14 placé à la partie inférieure du chariot, et, d'autre part, l'ébauche 8 à partager. - La figure 3 est une vue en perspective d'une extrémité de lingot montrant les

bossages 15 qui permettent le blocage des lingots entre eux. - La figure 4 représente un assemblage de lingots auto-bloquants suivant l'invention.

- Figure 2 is a section perpendicular to its axis of movement of the carriage-device assembly where we can distinguish, on the one hand, connected to each of the

uprights 11, thejaws 12 and theknife 13 with itscutting edge 14 placed at the lower part of the carriage, and, on the other hand, the blank 8 to share. - Figure 3 is a perspective view of an ingot end showing the

bosses 15 which allow the ingot to be locked together. - FIG. 4 represents an assembly of self-locking ingots according to the invention.

La présente invention trouve son application notamment dans l'industrie de l'aluminium, dans tous les cas où on cherche, partant d'un produit coulé en continu, à obtenir des lingots présentant une section constante, une longueur connue et se prêtant à un empilage auto-bloquant.The present invention finds its application in particular in the aluminum industry, in all cases where it is sought, starting from a continuously cast product, to obtain ingots having a constant section, a known length and suitable for a self-locking stacking.

Claims (4)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR8010116A FR2481161A1 (en) | 1980-04-28 | 1980-04-28 | METHOD AND DEVICE FOR THE CONTINUOUS PRODUCTION OF NON-FERROUS NON-FERROUS METALS WITH SELF-BLOCKING STACKS FROM A DRAFT OBTAINED FROM A GROOVED WHEEL CASTING MACHINE |

| FR8010116 | 1980-04-28 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0050626A1 EP0050626A1 (en) | 1982-05-05 |

| EP0050626B1 true EP0050626B1 (en) | 1983-12-07 |

Family

ID=9241681

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP81900965A Expired EP0050626B1 (en) | 1980-04-28 | 1981-04-24 | Method and device for the continuous production of non-ferrous metal ingots with self-blocking stacking from a blank obtained from a casting machine on grooved wheel |

Country Status (13)

| Country | Link |

|---|---|

| US (1) | US4518028A (en) |

| EP (1) | EP0050626B1 (en) |

| JP (1) | JPS615822B2 (en) |

| AU (1) | AU544142B2 (en) |

| BE (1) | BE888552A (en) |

| CA (1) | CA1154571A (en) |

| DE (1) | DE3161576D1 (en) |

| ES (2) | ES8207001A1 (en) |

| FR (1) | FR2481161A1 (en) |

| GR (1) | GR73149B (en) |

| IE (1) | IE50875B1 (en) |

| IT (1) | IT1137152B (en) |

| WO (1) | WO1981003135A1 (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19629632C2 (en) * | 1996-07-23 | 1999-01-14 | Aluhett Aluminium Halbzeugwerk | Cooling device for a casting wheel |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2206930A (en) * | 1938-07-29 | 1940-07-09 | William R Webster | Continuous molding machine |

| DE823322C (en) * | 1948-10-02 | 1951-12-03 | Eisenwerke Gelsenkirchen A G | Method and device for casting metals in endless stretches |

| CH336161A (en) * | 1955-12-13 | 1959-02-15 | Aluminium Ind Ag | Process for the production of large blocks of aluminum or aluminum alloy intended for remelting |

| DE1068436B (en) * | 1956-02-10 | 1959-11-05 | Eisenwerk-Gesellschaft Maximilianshütte A.-G., Sulzbach-Rosenberg Hütte | Process for the production of raw material for bumper by continuously casting pipe sections |

| FR1224969A (en) * | 1959-02-10 | 1960-06-28 | Pechiney | Manufacturing process for fluted ingots |

| CH363763A (en) * | 1959-02-10 | 1962-08-15 | Pechiney Prod Chimiques Sa | Manufacturing process for crenellated ingots |

| FI45423C (en) * | 1964-10-15 | 1972-06-12 | Olsson Erik Allan | Method of producing blanks or steel for rolling into rods, rods or wire by means of continuous casting. |

| SE307117B (en) * | 1965-04-01 | 1968-12-23 | Iit Res Inst | |

| DE1947282B1 (en) * | 1969-09-18 | 1972-03-23 | Messer Griesheim Gmbh | Support device for a strand cutting device |

| US3731512A (en) * | 1971-05-07 | 1973-05-08 | Essex International Inc | Rolling mill cutting apparatus and method |

| JPS547497A (en) * | 1977-06-21 | 1979-01-20 | Hitachi Ltd | Thermosetting resin composition |

-

1980

- 1980-04-28 FR FR8010116A patent/FR2481161A1/en active Granted

-

1981

- 1981-04-21 GR GR64765A patent/GR73149B/el unknown

- 1981-04-22 IT IT21320/81A patent/IT1137152B/en active

- 1981-04-22 CA CA000375953A patent/CA1154571A/en not_active Expired

- 1981-04-24 EP EP81900965A patent/EP0050626B1/en not_active Expired

- 1981-04-24 WO PCT/FR1981/000055 patent/WO1981003135A1/en active IP Right Grant

- 1981-04-24 AU AU70706/81A patent/AU544142B2/en not_active Ceased

- 1981-04-24 JP JP56501287A patent/JPS615822B2/ja not_active Expired

- 1981-04-24 US US06/325,433 patent/US4518028A/en not_active Expired - Fee Related

- 1981-04-24 BE BE0/204598A patent/BE888552A/en not_active IP Right Cessation

- 1981-04-24 DE DE8181900965T patent/DE3161576D1/en not_active Expired

- 1981-04-27 ES ES501656A patent/ES8207001A1/en not_active Expired

- 1981-04-27 ES ES1981267200U patent/ES267200Y/en not_active Expired

- 1981-04-27 IE IE934/81A patent/IE50875B1/en unknown

Also Published As

| Publication number | Publication date |

|---|---|

| CA1154571A (en) | 1983-10-04 |

| WO1981003135A1 (en) | 1981-11-12 |

| JPS57500424A (en) | 1982-03-11 |

| ES267200Y (en) | 1983-10-16 |

| FR2481161B1 (en) | 1982-03-19 |

| DE3161576D1 (en) | 1984-01-12 |

| EP0050626A1 (en) | 1982-05-05 |

| ES501656A0 (en) | 1982-09-01 |

| ES8207001A1 (en) | 1982-09-01 |

| FR2481161A1 (en) | 1981-10-30 |

| JPS615822B2 (en) | 1986-02-21 |

| GR73149B (en) | 1984-02-10 |

| BE888552A (en) | 1981-10-26 |

| US4518028A (en) | 1985-05-21 |

| IT1137152B (en) | 1986-09-03 |

| ES267200U (en) | 1983-03-16 |

| IT8121320A0 (en) | 1981-04-22 |

| AU7070681A (en) | 1981-11-26 |

| IE810934L (en) | 1981-10-28 |

| AU544142B2 (en) | 1985-05-16 |

| IE50875B1 (en) | 1986-08-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0310306B1 (en) | Form-fill-seal machine for automatic production of sealed packages | |

| FR2528386A1 (en) | METHOD AND INSTALLATION OF PACKAGING A PRODUCT | |

| EP0230433B1 (en) | Method and machine for continuous casting of a thin metal product | |

| EP0072742A2 (en) | Paper container internally covered with a foil of synthetics material, comprising reliefs created by slits, the sides of which are set off | |

| EP0050626B1 (en) | Method and device for the continuous production of non-ferrous metal ingots with self-blocking stacking from a blank obtained from a casting machine on grooved wheel | |

| CH644250A5 (en) | Method for cutting half shell formed in sheet of waffle type. | |

| FR2505781A1 (en) | INSTALLATION FOR THE SEPARATION OF PLASTIC PACKAGINGS FILLED AND MANUFACTURED IN THE FORM OF BUCKETS BY STAMPING FROM SHEET RIBBONS | |

| EP0071584B1 (en) | Device for automatically boxing bags in cartons | |

| EP1507636B1 (en) | Method of producing plaster boards comprising four tapered edges | |

| EP0391824A1 (en) | Method and device for casting thin metallic products with thickness reduction under the casting mould | |

| GB2091329A (en) | Door or window frames | |

| EP2722155B1 (en) | Device for manufacturing containers by thermoforming | |

| EP0091855B1 (en) | A burr removing apparatus for a continuously cast slab | |

| FR2644425A1 (en) | Device for separating full containers in an installation for making up packages using a thermoplastic strip | |

| US3783725A (en) | Mechanical shears | |

| EP0006820B1 (en) | Method of moulding bodies from wood particles, apparatus therefor and the moulded bodies | |

| EP2622059B1 (en) | Unit for piercing and moulding, by means of striking, pressing or stamping, for the production of pierced shampoo bars, and method for producing such bars, particularly in such a unit | |

| EP2505731B1 (en) | Method for manufacturing a sheet with open ribs intended for forming a framework for a composite floor | |

| FR2543028A1 (en) | METHOD FOR FORMING A METALLIC RAIL BLADE | |

| BE440328A (en) | ||

| EP0150859A2 (en) | Process and device for making tiles, slabs and similar construction blocks by means of pressing a powder mixture | |

| EP0937671B1 (en) | Method and device for straightening or rotating a leaned pile of sheet material on a roller conveyer | |

| EP1233838B1 (en) | Easily stacked metal bars obtained by continuous or semi-continuous casting | |

| EP0419372A1 (en) | Method for portioning cheese and portions obtained | |

| FR2512361A1 (en) | Conveyor for removing sheet metal from shears - has endless belt with vertically reciprocating deck between belts to take impact |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19811204 |

|

| AK | Designated contracting states |

Designated state(s): CH DE GB LU NL |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): CH DE GB LI LU NL |

|

| REF | Corresponds to: |

Ref document number: 3161576 Country of ref document: DE Date of ref document: 19840112 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19840312 Year of fee payment: 4 Ref country code: CH Payment date: 19840312 Year of fee payment: 4 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19840323 Year of fee payment: 4 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19840430 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19870430 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19880424 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19880430 Ref country code: CH Effective date: 19880430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19881101 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| GBPC | Gb: european patent ceased through non-payment of renewal fee | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19890103 |