EP0048889B1 - Réceptacle à fermeture - Google Patents

Réceptacle à fermeture Download PDFInfo

- Publication number

- EP0048889B1 EP0048889B1 EP19810107276 EP81107276A EP0048889B1 EP 0048889 B1 EP0048889 B1 EP 0048889B1 EP 19810107276 EP19810107276 EP 19810107276 EP 81107276 A EP81107276 A EP 81107276A EP 0048889 B1 EP0048889 B1 EP 0048889B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- plug

- closure

- neck member

- neck

- closure according

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 230000002093 peripheral effect Effects 0.000 claims description 6

- 230000002401 inhibitory effect Effects 0.000 claims description 4

- 238000003780 insertion Methods 0.000 claims description 3

- 230000037431 insertion Effects 0.000 claims description 3

- 230000000977 initiatory effect Effects 0.000 claims description 2

- 238000007789 sealing Methods 0.000 claims description 2

- 229910052751 metal Inorganic materials 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 238000013022 venting Methods 0.000 description 2

- 239000000853 adhesive Substances 0.000 description 1

- 230000001070 adhesive effect Effects 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 239000013589 supplement Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D47/00—Closures with filling and discharging, or with discharging, devices

- B65D47/04—Closures with discharging devices other than pumps

- B65D47/06—Closures with discharging devices other than pumps with pouring spouts or tubes; with discharge nozzles or passages

- B65D47/12—Closures with discharging devices other than pumps with pouring spouts or tubes; with discharge nozzles or passages having removable closures

- B65D47/14—Closures with discharging devices other than pumps with pouring spouts or tubes; with discharge nozzles or passages having removable closures and closure-retaining means

- B65D47/141—Closures with discharging devices other than pumps with pouring spouts or tubes; with discharge nozzles or passages having removable closures and closure-retaining means for stoppers

Definitions

- the present invention relates to containers or bottles of the type consisting of a cylindrical body with either an integral or seamed bottom and having a narrow upper end with a neck which is associated with a closure.

- German Published Application No. 2,338,777 discloses a closure for a container including a cup-shaped flexible plug which is axially movable with respect to a cap.

- the cap has a stem which projects into the plug to deflect the plug radially outwardly into engagement with the interior surface of the container neck when the cap is moved axially toward the plug.

- the plug resumes its original shape.

- the object of this invention is to provide a closure for a container which provides a positive seal and yet may be opened relatively easily.

- the present invention provides a closure for a container having a neck member and a closure member including a plastic deflectable plug insertable in said neck member for closing a pour opening in the neck member, means for inhibiting deflection of said plug in a preselected region, and means for displacing said last-mentioned means to reduce the resistance to deflection of said plug and for deflecting the plug in said region and thereat initiating removal of the plug from the neck member, said means for inhibiting deflection of said plug comprising a vent assembly having a closed position in which the parts thereof act to rigidify said plug and an open position accommodating flexure of said plug to facilitate release of said plug from said neck member.

- the closure of the present invention minimizes the amount of material used, facilitates opening of the container and enhances the integrity of the seal.

- venting mechanism is placed in a position wherein when the parts are interlocked in closing position, they supplement the closure function and when these parts are separated to vent, the plug is unsupported in the area of initial separation and thus is more flexible in this area and more readily deflects to release the interlocking parts whereby facilitating opening of the closure.

- a hinge connects the plug and leverage structure and the hinge is formed' to releasably interlock with a catch formed on one of the other parts of the closure.

- a structure which permits easy insertion of the plug into the bore in the neck member.

- the structure guides the plug into the bore in a canted position and interlocking a portion of the shoulder on the plug partly under a portion of the shoulder on the neck.

- the portions which are hooked together provide a fulcrum for the plug at one side and the plug being canted, invites the user to press down on the opposite or high side.

- the radial expanse of the plug serves as a lever between the fulcrum and the point of pressure and because of the mechanical advantage obtained, the plug is easily pivoted to upright position in alignment with the neck bore and snapped down thus locking the shoulders.

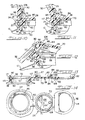

- a container 2 made of metal such as aluminum and comprises a cylindrical body 3 with an integral outwardly convexed bottom 5 which is provided with outwardly protruding dimples 6 upon which the container rests.

- the upper open end portion 8 of the body portion is necked in at 9 and fits into an annular skirt portion 10 of a dome member 12 which forms the upper end of the container.

- a suitable adhesive 13 bonds the portion 8 to the skirt 10.

- the dome portion has a series of stepped annular sections 14 and 16 and at its uppermost end is formed with an inturned frusto-conical lip 18 converging inwardly and providing a sharp closure- retaining edge 20 and defining the pour opening 22 at the upper end of the container.

- a plastic closure 25 is provided at the upper end of the container and comprises a neck portion 26, a closure plug portion or cap 28 and a venting portion 30 to which is attached a finger grip or handle 32.

- the neck portion 26 is a cylindrical member which at its lower end 34 is tapered at 36 and is tightly wedged through the opening 22 and then expands radially outwardly and engages its shoulder 38 under the edge 20 of the lip 18.

- the neck portion 26 has a pair of axially spaced sealing rings 40, 42; triangular shaped in cross section tightly pressed at their apices 44, 46 against the frusto-conical external surface 45 of the lip 18 to provide a fluid-tight pressure seal.

- the interior bore surface 50 of the neck portion is provided with a locking ring member or shoulder 52 which has a downwardly sloping upper surface 56 merging into an apical edge 58 with a bottom locking surface or face 60 which extends normal to the axis of the neck portion.

- a locking ring member or shoulder 52 which has a downwardly sloping upper surface 56 merging into an apical edge 58 with a bottom locking surface or face 60 which extends normal to the axis of the neck portion.

- the bore surface is of frusto-conical shape which widens toward the upper end to facilitate entry of the lower end portion 62 of the closure plug portion 28.

- the plug portion 28 has a cylindrical side wall 65 which intermediate its upper and lower edges is provided with an annular locking ring or shoulder 66 which is of triangular cross-section having a lower downwardly tapered pilot surface 67 which is adapted to be guided upon engagement with the upper similarly tapered face 56 of the neck locking ring past the apex 58 when the plug portion is pressed into the neck opening or bore 50 whereupon an apical edge 68 of the rib 66 is deflected with edge 58 and the rib portion 66 is stepped under the shoulder 52 of the neck portion and a flat radially outwardly extending surface 69 at the upper end of the shoulder 66, normal to the axis of the neck portion, locks under the face 60.

- the plug portion 28 has a top wall 70 integral with its upper end 64 and wall 70 has a peripheral portion 72 extending beyond the perimeter of the side wall 65.

- the peripheral portion 72 is annular and has a rib 74 on its underside pressed, in the closed position, against the top surface 75 of an annular flange 76 integral with and extending radially outwardly from the upper end of the neck portion 26.

- the bottom side 77 of flange 76 presses against the crest of an annular U-shaped ridge 78 formed at the juncture of the dome wall 79 and the lip 18.

- a tether in the form of a narrow strap 80 connects a peripheral edge portion 81 of flange 72 with a peripheral edge portion 82 of the flange 76 of the neck portion 26.

- the cap is provided with a vent opening 84 in an area diametrically opposite to the tether 80 close to the plug adjacent to its interior surface and the vent opening 84 is coaxial with a depending hollow tubular extension 85 formed on the underside of the top wall of the cap.

- a frusto-conical pilot cavity 86 is formed at the upper end of opening 84 for guiding an enlarged head 88 of a vent pin or male closure element 89.

- the head has a downwardly taped peripheral surface 90 which at its upper end has an annular shoulder 92 which in the closed position engages under a lower complimentary lower edge 93 on the bottom end of the tubular extension 85.

- the upper end of the vent pin 89 depends from and is integrally connected with a lever lug 95 intermediate its ends, the lever 95 has an inner fulcrum end 96 which engages with the top side 97 of the top wall radially inwardly of the vent opening.

- the other end 98 of the lever lug 95 extends radially outwardly and is connected to the inner periphery 99 of a lift ring 32 which in the closed position of the closure lies flat with its lower side 102 against the flat upper face 97 of the cap top wall 70.

- the ring has its outer periphery 106 connected to one end of a narrow strap 108 which is folded and which has its other end 109 connected to the outer edge of wall 70 in an area diametrically opposite the strap 80.

- Removal of the pin 89 removes the support for the plug wall in the immediate area and thus enhances the flexure of the portion of the neck wall in the region of the vent opening whereby as the ring is further lifted, it pulls on the tether 108 which, in turn, curls the portion 120 of the top wall 70 upwardly and causes the adjacent portion of the wall 70 contiguous to the vent opening to warp radially inwardly thus facilitating partially unhooking of the ledge or shoulder 66 from the shoulder 52 and disengaging the locking face 69 from face 60.

- the plug then easily lifts out of the neck opening and with the handle portion lays to one side of the pour opening the neck.

- the plug of the cap is pressed into the neck opening until the shoulder 52 snaps under the shoulder 66. Then the handle is folded over the cap and the vent plug or pin 89 is pressed into the vent opening until the shoulder 92 snaps under the lower edge 93 of the vent tube.

- FIG. 7 A second embodiment of the invention is shown in Figures 7 through 15 in which like reference numerals refer to parts already described with reference to Figures 1 through 6.

- the container 2 has an upper portion or dome member 12 which provides at its neck 115 a shoulder 116 and an access opening 22 (Fig. 10) at the upper end of the container, the neck 115 terminating in a curl 24.

- the neck portion 26 of plastic closure 25 is tightly wedged through the opening 22 and then expands radially outwardly and engages its shoulder 38 under the edge of shoulder 116 of the neck 115.

- the neck portion has an upper outwardly projecting annular flange 117 which engages the top edge of the curl 24 and provides a fluid-tight pressure seal.

- the plug portion or cap 28 has a top wall 70 integral with the upper end of the plug 28, the wall 70 extending beyond the perimeter of the plug and forms an annular rim portion 72 which on its underside is pressed in position against the top surface 75 of the annular flange 117 integral with and extending radially outwardly from the upper end of the neck portion 26.

- the bottom side 77 of flange 117 presses against the crest (Fig. 9) of the curl 24 of the metal neck 14.

- a fulcrum post 97 is formed on the top side of the flange 40.

- Removal of the pin or plug 30 removes the support for the plug wall 65 in the immediate area and thus enhances the flexure of that portion of the wall 65, that is, in the region of the vent opening whereby as the lever is fulcrumed, it pulls on the tether 108 which, in turn, curls the adjacent portion 72 of the top wall 70 upwardly and causes the portion of the wall 70 contiguous to the vent opening to warp radially inwardly thus facilitating partially unhooking of the ledge or shoulder 66 from under the shoulder 52 and disengaging the locking face 69 from the face 60.

- the plug 28 then easily lifts out of the neck or sleeve opening and with the handle or lever portion 30 lays to one side of the pour opening 50 and may be grasped by the user as seen in Fig. 15.

- the plug 28 of the closure is pressed into the sleeve opening until the shoulder 52 snaps under the shoulder 66. Then the handle or lever is folded over the cap 28 and the vent plug or pin 30 is pressed into the vent opening 84.

- the closure 25 includes a novel hinge arrangement 125 which comprises not only the straps 80 which define a gap or slot 126 therebetween, but also an upright post 128 of fusiform shape having a middle thick diameter section 130 and upper and lower tapered ends 132 and 133.

- the post is connected at its inner side by a thin upright stand-off bracket wall 135 to the outside periphery 136 of a mounting ring 138 which is tightly fitted over the outer edge of the curl 24 of the neck portion 14 of the container and an enlarged lower end portion 140 of the neck 14.

- the straps 80 in the closed position of the closure flank the upper end portion 132 of the post and are partially spread apart and will wedge past the central enlarged catch section 130 when the plug is withdrawn and is positioned with the lever 32 at one side of the neck 14. It will be seen in Figure 20 that portions of the straps 80 outwardly of the vertical axis of the post are below the enlarged catch portion 130 and thus will hold the plug and handle essentially as shown in Figure 17. Of course, the container may be rotated 90° from that shown in Figure 18 so that the user may drink over the lip 118.

- the handle 32 is lifted with the plug 28, releasing it from the post catch 130 and allowing the plug 28 to be snapped into the neck sleeve whereupon the handle 32 is folded over the top of the plug entering member 30 into opening 84.

- the hinge 125 then assumes the position of Figure 20 with the straps 80, 80 partly embracing the upper portion 132.

- the interior bore surface 50 of the neck portion is provided with a locking ring member or shoulder 52 which at one diametrical side has a downwardly sloping upper C-shaped surface 56 (Figures 23 and 24) in top plan merging into an apical edge 58 which a bottom locking surface 60 extends normal to the axis of the neck portion.

- the limited bore surface 56 is of frusto-conical shape which widens toward its upper end to facilitate entry of the lower end portion 62 of the closure plug 28.

- a portion 59 of the shoulder 52 diametrically opposite the sloping portion 56 is formed semi-cylindrical in shape and curved in plan about the axis X (Fig. 24) of the closure and provides an unobstructed downward entry for a contiguous portion of the shoulder the locking ring 66 on a cylindrical side wall 65 of the plug 28 so that the plug will locate in a canted position as shown in Figure 24 upon its being initially pressed downwardly within the bore 50 as seen in Figure 25.

- the radial extent L (Fig. 21) diametrically of the plug serves as a lever between the point or area of application of force at P and the fulcrum point F in the region of the limited catch of the shoulder 66 under the shoulder 52. Since the plug will invariably cant when pressed-in, the natural inclination for the person closing the closure is to press at P. The leverage obtained multiplies the force application such that even a young child can, without much difficulty, snap the closure shut.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Closures For Containers (AREA)

Claims (11)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT81107276T ATE12615T1 (de) | 1980-09-26 | 1981-09-15 | Behaelter mit verschluss. |

Applications Claiming Priority (8)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US191227 | 1980-09-26 | ||

| US06/191,227 US4327842A (en) | 1980-09-26 | 1980-09-26 | Container and closure therefor |

| US06/209,556 US4328906A (en) | 1980-11-24 | 1980-11-24 | Container and closure therefor |

| US06/242,756 US4369888A (en) | 1981-03-11 | 1981-03-11 | Closure for container |

| US06/242,758 US4356924A (en) | 1981-03-11 | 1981-03-11 | Container closure with retainer hinge |

| US242756 | 1981-03-11 | ||

| US242758 | 1988-09-09 | ||

| US209556 | 1994-03-11 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0048889A1 EP0048889A1 (fr) | 1982-04-07 |

| EP0048889B1 true EP0048889B1 (fr) | 1985-04-10 |

Family

ID=27497880

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19810107276 Expired EP0048889B1 (fr) | 1980-09-26 | 1981-09-15 | Réceptacle à fermeture |

Country Status (8)

| Country | Link |

|---|---|

| EP (1) | EP0048889B1 (fr) |

| AU (1) | AU546097B2 (fr) |

| BR (1) | BR8106169A (fr) |

| DE (1) | DE3169851D1 (fr) |

| DK (1) | DK425881A (fr) |

| ES (1) | ES510420A0 (fr) |

| GB (1) | GB2085853B (fr) |

| GR (1) | GR75771B (fr) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4362254A (en) * | 1981-08-10 | 1982-12-07 | The Continental Group, Inc. | Closure and container neck structure therefor |

| US4397400A (en) * | 1982-03-08 | 1983-08-09 | The Continental Group, Inc. | Nondetachable resealable closure |

| US4738376A (en) * | 1986-01-22 | 1988-04-19 | Markus Richard N | Plastic covering cap |

| GB2300854A (en) * | 1995-02-22 | 1996-11-20 | Mark Richard Jennings | Closure; tamper evidencing; child resisting |

| GB2410494A (en) * | 2004-01-30 | 2005-08-03 | Francis Showering | Pressure venting container closure |

| GB201107989D0 (en) * | 2011-05-13 | 2011-06-29 | Britvic Soft Drinks Ltd | Improvements in or relating to manually operated dispense heads for fluid containers |

| US20230373693A1 (en) * | 2023-07-17 | 2023-11-23 | Huacheng Li | Container sealing plug and container having same |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3160327A (en) * | 1961-01-23 | 1964-12-08 | Polymold Plastics Inc | Dispensing spout with rupturable breathing diaphragm and closure therefor |

| DE2338777A1 (de) * | 1973-07-31 | 1975-02-13 | Christoph Berkmueller | Loesbarer und wiederverwendbarer verschluss fuer behaelter, insbesondere fuer flaschen |

| SE395866B (sv) * | 1974-12-23 | 1977-08-29 | Rigello Pak Ab | Forslutningsanordning for forpackningsbehallare |

-

1981

- 1981-09-15 EP EP19810107276 patent/EP0048889B1/fr not_active Expired

- 1981-09-15 DE DE8181107276T patent/DE3169851D1/de not_active Expired

- 1981-09-17 GR GR66081A patent/GR75771B/el unknown

- 1981-09-18 GB GB8128281A patent/GB2085853B/en not_active Expired

- 1981-09-25 AU AU75685/81A patent/AU546097B2/en not_active Ceased

- 1981-09-25 DK DK425881A patent/DK425881A/da not_active Application Discontinuation

- 1981-09-25 BR BR8106169A patent/BR8106169A/pt unknown

- 1981-09-25 ES ES510420A patent/ES510420A0/es active Granted

Also Published As

| Publication number | Publication date |

|---|---|

| GB2085853A (en) | 1982-05-06 |

| EP0048889A1 (fr) | 1982-04-07 |

| AU546097B2 (en) | 1985-08-15 |

| AU7568581A (en) | 1982-04-01 |

| BR8106169A (pt) | 1982-06-15 |

| DE3169851D1 (en) | 1985-05-15 |

| GR75771B (fr) | 1984-08-02 |

| GB2085853B (en) | 1985-05-22 |

| ES8303229A1 (es) | 1983-02-01 |

| ES510420A0 (es) | 1983-02-01 |

| DK425881A (da) | 1982-03-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4327842A (en) | Container and closure therefor | |

| US4369888A (en) | Closure for container | |

| CA1161795A (fr) | Fermeture inviolable | |

| US4344545A (en) | Pilferproof closure with mechanical interlock | |

| EP0088185B1 (fr) | Fermeture non séparable et resertissable | |

| US5351853A (en) | Beverage can closure | |

| EP1945528B1 (fr) | Dispositif d'obturation de récipient | |

| US4431110A (en) | Child resistant tamper indicating closure | |

| EP1834892B1 (fr) | Obturation avec panneau de couvercle anti-sabotage | |

| CA1299142C (fr) | Bouchon verseur | |

| US4407423A (en) | Detachable resealable closure | |

| AU2002360059B2 (en) | Cup-shaped receptacle and lid | |

| US4328906A (en) | Container and closure therefor | |

| US4712707A (en) | Closure for a container | |

| US4440310A (en) | Closure for domed beverage containers and the like | |

| EP0048889B1 (fr) | Réceptacle à fermeture | |

| US5462183A (en) | Closure with a tamper-evident element | |

| US4077537A (en) | One piece dispensing closure | |

| WO1999052785A1 (fr) | Bouchon encliquetable inviolable a levier de dechirement | |

| GB2178732A (en) | Sealable containers | |

| US4356924A (en) | Container closure with retainer hinge | |

| CA1164825A (fr) | Contenant et fermeture connexe | |

| US4781303A (en) | Container with a non-removable opening tab apparatus | |

| EP0060454A1 (fr) | Fermeture de sûreté contre le vol avec verrouillage mécanique | |

| GB2086361A (en) | An improved container closure |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR IT LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19820924 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR IT LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 12615 Country of ref document: AT Date of ref document: 19850415 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3169851 Country of ref document: DE Date of ref document: 19850515 |

|

| ET | Fr: translation filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19850812 Year of fee payment: 5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19850930 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19850930 Year of fee payment: 5 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19860915 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19860916 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19860930 Ref country code: CH Effective date: 19860930 Ref country code: BE Effective date: 19860930 |

|

| BERE | Be: lapsed |

Owner name: THE CONTINENTAL GROUP INC. Effective date: 19860930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19870401 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19870527 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19870602 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| EUG | Se: european patent has lapsed |

Ref document number: 81107276.8 Effective date: 19870812 |