EP0010254B1 - Process for generating electric power in a counter pressure steam system - Google Patents

Process for generating electric power in a counter pressure steam system Download PDFInfo

- Publication number

- EP0010254B1 EP0010254B1 EP79103882A EP79103882A EP0010254B1 EP 0010254 B1 EP0010254 B1 EP 0010254B1 EP 79103882 A EP79103882 A EP 79103882A EP 79103882 A EP79103882 A EP 79103882A EP 0010254 B1 EP0010254 B1 EP 0010254B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- steam

- heat

- pressure

- expanded

- temperature

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 238000000034 method Methods 0.000 title claims description 23

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 7

- 238000010438 heat treatment Methods 0.000 description 4

- 230000005494 condensation Effects 0.000 description 3

- 238000009833 condensation Methods 0.000 description 3

- 238000001816 cooling Methods 0.000 description 3

- QGZKDVFQNNGYKY-UHFFFAOYSA-N Ammonia Chemical compound N QGZKDVFQNNGYKY-UHFFFAOYSA-N 0.000 description 2

- 238000007796 conventional method Methods 0.000 description 2

- 230000005611 electricity Effects 0.000 description 2

- 239000000446 fuel Substances 0.000 description 2

- FNYLWPVRPXGIIP-UHFFFAOYSA-N Triamterene Chemical compound NC1=NC2=NC(N)=NC(N)=C2N=C1C1=CC=CC=C1 FNYLWPVRPXGIIP-UHFFFAOYSA-N 0.000 description 1

- 150000001336 alkenes Chemical class 0.000 description 1

- 229910021529 ammonia Inorganic materials 0.000 description 1

- 239000000498 cooling water Substances 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- JRZJOMJEPLMPRA-UHFFFAOYSA-N olefin Natural products CCCCCCCC=C JRZJOMJEPLMPRA-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01K—STEAM ENGINE PLANTS; STEAM ACCUMULATORS; ENGINE PLANTS NOT OTHERWISE PROVIDED FOR; ENGINES USING SPECIAL WORKING FLUIDS OR CYCLES

- F01K7/00—Steam engine plants characterised by the use of specific types of engine; Plants or engines characterised by their use of special steam systems, cycles or processes; Control means specially adapted for such systems, cycles or processes; Use of withdrawn or exhaust steam for feed-water heating

- F01K7/16—Steam engine plants characterised by the use of specific types of engine; Plants or engines characterised by their use of special steam systems, cycles or processes; Control means specially adapted for such systems, cycles or processes; Use of withdrawn or exhaust steam for feed-water heating the engines being only of turbine type

- F01K7/22—Steam engine plants characterised by the use of specific types of engine; Plants or engines characterised by their use of special steam systems, cycles or processes; Control means specially adapted for such systems, cycles or processes; Use of withdrawn or exhaust steam for feed-water heating the engines being only of turbine type the turbines having inter-stage steam heating

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01K—STEAM ENGINE PLANTS; STEAM ACCUMULATORS; ENGINE PLANTS NOT OTHERWISE PROVIDED FOR; ENGINES USING SPECIAL WORKING FLUIDS OR CYCLES

- F01K17/00—Using steam or condensate extracted or exhausted from steam engine plant

- F01K17/02—Using steam or condensate extracted or exhausted from steam engine plant for heating purposes, e.g. industrial, domestic

Definitions

- the invention relates to a method for obtaining electrical energy in a counter-pressure steam system, in which water vapor is expanded while performing work.

- counter-pressure steam systems are power plants which serve to cover the power and heat requirements at the same time and which allow the fuel heat to be fully utilized.

- the steam of high pressure and high temperature generated in a steam boiler first serves to drive a high-pressure turbine, in which the steam is expanded to a required temperature or a required pressure level in a first steam rail.

- steam can be drawn off from this steam rail both to cover the heat requirement of the system and can be expanded in a turbine into another steam rail with a lower pressure level.

- the invention is therefore based on the object of developing a method with which the power-heat ratio can be increased in a gas pressure steam system of the type described.

- This object is achieved in that steam of one of the existing pressure levels before said work-relieving relaxation is heated first isobarically by heat exchange with the relaxed steam and then with external heat and isobarically cooled to one of the existing lower pressure levels after said relaxation .

- the steam is initially recuperative according to the invention by heat from the relaxed steam and then with external heat, e.g. B. in a fuel-fired heater, reheated and only then, optionally in several stages, relaxed.

- the steam can be subjected to any of the available pressure levels in these process steps. In this way, the proportion of the mechanical energy generated in the turbines and thus the power-heat ratio is increased.

- the utilization of primary energy for the provision of external heat is far superior to the previous additional electricity generation. Due to the recuperative heating, the steam is raised to a relatively high temperature level, so that the external heat that is subsequently supplied to the steam is optimally used. H.

- recuperative heating is to be seen in the fact that with increasing temperature of the heat source, by which the external heat is provided, the temperature of the steam supplied to the heat source also increases, and thus the heat of the heat source is optimally used in all temperature ranges. With an ideal gas and with any small temperature differences during recuperative heat exchange, the turbine output would be the same as the external heat absorbed.

- the additional energy of the method according to the invention is therefore generated with a much better efficiency than, for example, the energy provided by a pure force process.

- the relaxed steam after the isobaric cooling still has a higher heat content than e.g. B. the steam expanded by a conventional method only in a turbine. Therefore, according to an advantageous embodiment of the inventive concept, this excess heat can be used to heat a heat consumer.

- the working medium to be heated can serve as a heat consumer in an additional power process.

- the steam throughput of the back pressure steam system can be reduced.

- the method according to the invention enables the increase in the power-heat ratio within the counter-pressure operation with a much better efficiency than in conventional methods.

- the high efficiency is due to the higher specific energy generation corresponding to the higher temperature level of the steam before the expansion or to the reduction of the required external heat. If condensation turbines are used in a system that works according to the proposed method, the amount of cooling water is also reduced in comparison to conventional systems with condensation turbines, since the amount of steam for the condensation turbines can be reduced as a result of the increased power-heat ratio of the counter-pressure operation.

- the steam of the back pressure steam system shown is generated in an evaporator 1, in a high pressure turbine 2 to a pressure of z. B. 39.2 - 10 5 N / m z relaxed and fed at a temperature of 642 K in the medium pressure steam rail.

- the steam from this rail insofar as it was not consumed by heat consumers 11, was expanded directly into the low-pressure steam rail 16 via a turbine.

- the steam is first heated essentially isobarically.

- a recuperator 3 is used, in which part of the steam of the medium-pressure steam rail is heated to a temperature of 770 K, and a fuel-fired heater 4, in which the steam temperature is raised to 993 K.

- the steam of this high temperature levels is in a load connected to the heater turbine 5 to the pressure of the rail 16 with, for example 9.8 - initiated 10 5 N / m 2 relaxed and isobaric cooling in heat exchange with Anlagenangendem vapor via line 8 into the recuperator 3 .

- the temperature of the steam emerging from the turbine at 791 K drops to 653 K in recuperator 3.

- This steam has a higher heat content than the conventional solution. This excess heat is dissipated in the exemplary embodiment shown in the heat exchange with feed water for the evaporator 1.

- the recuperator 3 is connected to a heat exchanger 6, from which the steam emerges at 494 K and enters the low-pressure steam rail 16.

- the feed water is fed to the heat exchanger 6 via a line 14, which branches off from the line 17 for the condensate recirculation, and is then fed back into line 17.

- the steam of the low-pressure steam rail 16 is fed to low-pressure process steam consumers 10 and condensed.

- a number of pumps 12, 13 corresponding to the number of steam rails increases the pressure of the condensate and supplies the steam boiler 1 with feed water.

- the following table 1 shows the temperature, pressure, specific enthalpy and specific entropy of the steam for the exemplary embodiment described at the points designated by letters a to f in the sketch.

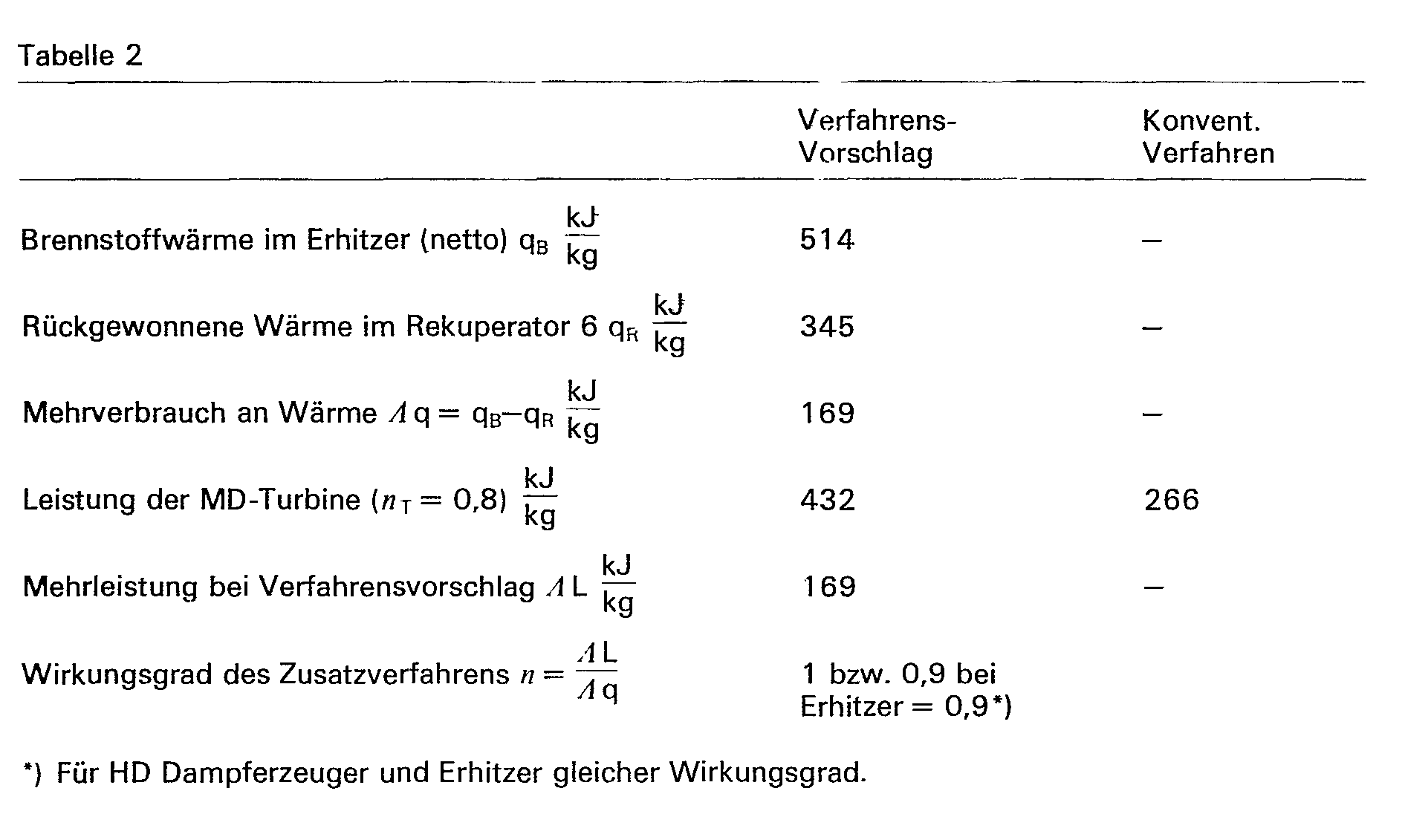

- Table 2 shows the specific consumption figures and outputs of the process example shown.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Engine Equipment That Uses Special Cycles (AREA)

- Control Of Turbines (AREA)

Description

Die Erfindung betrifft ein Verfahren zur Gewinnung von elektrischer Energie in einem Gegendruckdampfsystem, bei dem Wasserdampf arbeitsleistend entspannt wird.The invention relates to a method for obtaining electrical energy in a counter-pressure steam system, in which water vapor is expanded while performing work.

Als Gegendruckdampfsysteme werden hierbei Kraftanlagen bezeichnet, die zur gleichzeitigen Deckung des Kraft- und Wärmebedarfs dienen und eine umfassende Ausnutzung der Brennstoffwärme ermöglichen. In derartigen Systemen dient der in einem Dampfkessel erzeugte Wasserdampf hohen Druckes und hoher Temperatur zunächst dem Antrieb einer Hochdruckturbine, in der der Dampf in eine erste Dampfschiene auf eine geforderte Temperatur oder ein benötigtes Druckniveau entspannt wird. Aus dieser Dampfschiene kann nach bekannten Verfahren Dampf sowohl zur Deckung des Wärmebedarfs der Anlage abgezogen als auch in einer Turbine in eine andere Dampfschiene mit einem niedrigeren Druckniveau entspannt werden.In this context, counter-pressure steam systems are power plants which serve to cover the power and heat requirements at the same time and which allow the fuel heat to be fully utilized. In such systems, the steam of high pressure and high temperature generated in a steam boiler first serves to drive a high-pressure turbine, in which the steam is expanded to a required temperature or a required pressure level in a first steam rail. According to known methods, steam can be drawn off from this steam rail both to cover the heat requirement of the system and can be expanded in a turbine into another steam rail with a lower pressure level.

Anlagen der angegebenen Art sind in »Linde-Berichte aus Technik und Wissenschaft« 38, 1976, Seiten 3 bis 8 beschriebenPlants of the specified type are described in "Linde reports from technology and science" 38, 1976,

Bei kraftintensiven Industriezweigen kann der Bedarf an elektrischer oder auch mechanischer Energie durch eine Anlage der erläuterten Art nicht vollständig gedeckt werden. Dies ist beispielsweise bei dem Dampfsystem der im obengenannten Artikel beschriebenen Olefin- und Ammoniak-Anlagen der Fall. Es ist dahei erforderlich, zusätzlich Strom oder mechanische Energie in einem reinen Kraft-Prozeß mit verhältnismäßig unbefriedigender Primärbnergieausnutzung zu erzeugen oder teuren Fremdstrom zu beziehen.In the case of power-intensive industries, the need for electrical or mechanical energy cannot be fully met by a system of the type described. This is the case, for example, with the steam system of the olefin and ammonia plants described in the above-mentioned article. It is necessary Dahei, additional electricity or mechanical power in a pure power process with relatively unsatisfactory primary b nergieausnutzung to produce or obtain expensive external power source.

Eine derartige Anlage, in der ausschließlich mechanische bzw. elektrische Energie erzeugt wird, ist in der US-A-1 732 009 beschrieben. Hierbei wird in einem Verdampfer Wasser verdampft, der Dampf überhitzt, zweistufig entspannt und zwischen den Entspannungsstufen erneut erhitzt. Dabei wird der aus der ersten Entspannungsstufe austretende Dampf durch Dampf aus dem Verdampfer erhitzt Bei diesem Wärmetausch kühlt bzw. kondensiert der Dampf aus dem Verdampfer.Such a system, in which only mechanical or electrical energy is generated, is described in US-A-1 732 009. Here, water is evaporated in an evaporator, the steam overheats, expanded in two stages and reheated between the relaxation stages. The steam emerging from the first expansion stage is heated by steam from the evaporator. During this heat exchange, the steam from the evaporator cools or condenses.

Der Erfindung liegt daher die Aufgabe zugrunde, ein Verfahren zu entwickeln, mit dem in einem Gcgendruckdampfsystem der beschriebenen Art das Kraft-Wärme-Verhältnis erhöht werden kann.The invention is therefore based on the object of developing a method with which the power-heat ratio can be increased in a gas pressure steam system of the type described.

Diese Aufgabe wird erfindungsgemäß dadurch gelöst, daß Dampf eines der vorhandenen Druckniveaus vor der genannten arbeitsleistenden Entspannung zunächst durch Wärmetausch mit dem entspannten Dampf und anschließend mit Fremdwärme im wesentlichen isobar erhitzt und nach der genannten Entspannung auf eines der vorhandenen tiefer gelegenen Druckniveaus im wesentlichen isobar gekühlt wird.This object is achieved in that steam of one of the existing pressure levels before said work-relieving relaxation is heated first isobarically by heat exchange with the relaxed steam and then with external heat and isobarically cooled to one of the existing lower pressure levels after said relaxation .

Wurde nach dem bekannten Verfahren Dampf einer Dampfmaschine einfach über eine Turbine auf eine Dampfschiene eines niedrigeren Druckniveaus entspannt, so wird der Dampf erfindungsgemäß zunächst rekuperativ durch Wärme des entspannten Dampfes und anschließend mit Fremdwärme, z. B. in einem Brennstoff befeuerten Erhitzer, nacherhitzt und erst dann, gegebenenfalls in mehreren Stufen, entspannt. Diesen Verfahrensschritten kann der Dampf jedes beliebigen der vorhandenen Druckniveaus unterzogen werden Auf dieser Weise wird der Anteil der in den Turbinen erzeugten mechanischen Energie und damit das Kraft-Wärme-Verhältnis erhöht. Dabei ist die Ausnutzung der Primärenergie für die Bereitstellung der Fremdwärme der bisherigen Zusatzstromerzeugung weit überlegen. Durch die rekuperative Erhitzung wird der Dampf auf eine relativ hohes Temperaturniveau gehoben, so daß die Fremdwärme, die dem Dampf nachfolgend zugeführt wird, optimal genutzt, d. h. auf sehr hohem Temperaturniveau aufgenommen wird. Da die Energieausbeute der zusätzlichen Energieerzeugung mit wachsender Temperatur des Dampfes vor der Entspannung steigt, ist eine möglichst hohe Temperatur des Dampfes wünschenswert. Die im Erhitzer erzielbare höchste Temperatur ist nur durch die Materialeigenschaften des Erhitzers begrenzt. Ein weiterer Vorteil der rekuperativen Erhitzung ist darin zu sehen, daß mit steigender Temperatur der Wärmequelle, durch die die Fremdwärme bereitgestellt wird, auch die Temperatur des der Wärmequelle zugeführten Dampfes wächst und somit die Wärme der Wärmequelle in allen Temperaturbereichen optimal genutzt wird. Bei einem idealen Gas und bei beliebig kleinen Temperaturdifferenzen beim rekuperativen Wärmetausch wäre die abgegebene Turbinenleistung gieich der aufgenommenen Fremdwärme.If, according to the known method, steam from a steam engine was simply expanded via a turbine onto a steam rail of a lower pressure level, the steam is initially recuperative according to the invention by heat from the relaxed steam and then with external heat, e.g. B. in a fuel-fired heater, reheated and only then, optionally in several stages, relaxed. The steam can be subjected to any of the available pressure levels in these process steps. In this way, the proportion of the mechanical energy generated in the turbines and thus the power-heat ratio is increased. The utilization of primary energy for the provision of external heat is far superior to the previous additional electricity generation. Due to the recuperative heating, the steam is raised to a relatively high temperature level, so that the external heat that is subsequently supplied to the steam is optimally used. H. is recorded at a very high temperature level. Since the energy yield of the additional energy generation increases with the temperature of the steam before the expansion, the highest possible temperature of the steam is desirable. The highest temperature that can be achieved in the heater is only limited by the material properties of the heater. Another advantage of the recuperative heating is to be seen in the fact that with increasing temperature of the heat source, by which the external heat is provided, the temperature of the steam supplied to the heat source also increases, and thus the heat of the heat source is optimally used in all temperature ranges. With an ideal gas and with any small temperature differences during recuperative heat exchange, the turbine output would be the same as the external heat absorbed.

Die zusätzliche Energie des erfindungsgemäßen Verfahrens wird also mit einem wesentlich besseren Wirkungsgrad erzeugt, als etwa die durch einen reinen Kraft-Prozeß bereitgestellte Energie.The additional energy of the method according to the invention is therefore generated with a much better efficiency than, for example, the energy provided by a pure force process.

Der entspannte Dampf besitzt nach der isobaren Kühlung noch immer einen höheren Wärmeinhalt als z. B. der nach einem konventionellen Verfahren nur in einer Turbine entspannte Dampf. Daher kann nach einer vorteilhaften Ausgestaltung des Erfindungsgedankens dieser Wärmeüberschuß zur Erwärmung eines Wärmeabnehmers verwendet werden. Als Wärmeabnehmer kann das zu erhitzende Arbeitsmedium eines zusätzlichen Kraftprozesses dienen. Es ist aber von Vorteil, den Wärmeüberschuß zur Speisewasservorwärmung des Gegendruckdampfsystems selbst heranzuziehen, da sich dann für das Zusatzverfahren unter Berücksichtigung der Verluste im Erhitzer ein Wirkungsgrad von 0,9 ergibt. In einer alternativen Verfahrensweise kann - mit dem gleichen Wirkungsgrad für das Zusatzverfahren - der Dampfdurchsatz des Gegendruckdampfsystems reduziert werden. Schließlich ist es möglich, den Wärmeüberschuß des entspannten und isobar gekühlten Dampfes direkt in eine Dampfschiene niedrigeren Druckniveaus zu leiten, d. h. den isobar gekühlten Dampf ohne weitere Kühlung mit einem Wärmeabnehmer direkt in diese Dampfschiene einzuspeisen.The relaxed steam after the isobaric cooling still has a higher heat content than e.g. B. the steam expanded by a conventional method only in a turbine. Therefore, according to an advantageous embodiment of the inventive concept, this excess heat can be used to heat a heat consumer. The working medium to be heated can serve as a heat consumer in an additional power process. However, it is advantageous to use the excess heat to preheat the feed water of the counterpressure steam system itself, since this results in an efficiency of 0.9 for the additional process, taking into account the losses in the heater. In an alternative procedure - with the same efficiency for the additional process - the steam throughput of the back pressure steam system can be reduced. Finally, it is possible to direct the excess heat of the expanded and isobarically cooled steam directly into a steam rail of lower pressure levels, ie the isobar Cooled steam can be fed directly into this steam rail with a heat consumer without further cooling.

Insgesamt kann festgestellt werden, daß das erfindungsgemäße Verfahren die Erhöhung des Kraft-Wärmeverhältnisses innerhalb des Gegendruckbetriebes mit einem wesentlich besseren Wirkungsgrad als in konventionellen Verfahren ermöglicht. Wie beschrieben, ist der hohe Wirkungsgrad auf die dem höheren Temperaturniveau des Dampfes vor der Entspannung entsprechende höhere spezifische Energieerzeugung bzw. auf die Verringerung der erforderlichen Fremdwärme zurückzuführen. Werden in einer Anlage, die nach dem vorgeschlagenen Verfahren arbeitet, Kondensationsturbinen eingesetzt, verringert sich darüber hinaus im Vergleich zu herkömmlichen Anlagen mit Kondensationsturbinen die Kühlwassermenge, da infolge des erhöhten Kraft-Wärmeverhältnisses des Gegendruckbetriebes die Dampfmenge für die Kondensationsturbinen reduziert werden kann.Overall, it can be stated that the method according to the invention enables the increase in the power-heat ratio within the counter-pressure operation with a much better efficiency than in conventional methods. As described, the high efficiency is due to the higher specific energy generation corresponding to the higher temperature level of the steam before the expansion or to the reduction of the required external heat. If condensation turbines are used in a system that works according to the proposed method, the amount of cooling water is also reduced in comparison to conventional systems with condensation turbines, since the amount of steam for the condensation turbines can be reduced as a result of the increased power-heat ratio of the counter-pressure operation.

Anhand einer schematischen Skizze soll im folgenden ein Ausführungsbeispiel einer Anlage beschrieben und erläutert werden, die nach dem erfindungsgemäßen Verfahren arbeitet.An exemplary embodiment of a system which operates according to the method according to the invention is to be described and explained below using a schematic sketch.

Der Übersichtlichkeit halber sind lediglich zwei Dampfschienen, eine Mitteldruckdampfschiene 15 und eine Niederdruckdampfschiene 16, dargestellt. Die Zahl der Damptschienen ist aber nicht auf zwei begrenzt.For the sake of clarity, only two steam rails, a medium

Der Dampf des dargestellten Gegendruckdampfsystems wird in einem Verdampfer 1 erzeugt, in einer Hochdruckturbine 2 auf einen Druck von z. B. 39,2 - 105N/mz entspannt und mit einer Temperatur von 642 K in die Mitteldruckdampfschiene eingespeist. In herkömmlichen Verfahren wurde der Dampf dieser Schiene, soweit er nicht von Wärmeabnehmern 11 verbraucht wurde, über eine Turbine direkt in die Niederdruckdampfschiene 16 entspannt. Erfindungsgemäß wird der Dampf jedoch zunächst im wesentlichen isobar erhitzt. Dazu dient ein Rekuperator 3, in dem ein Teil des Dampfes der Mitteldruckdampfschiene auf eine Temperatur von 770 K erhitzt, und ein brennstoffbefeuerter Erhitzer 4, in dem die Dampftemperatur auf 993 K gehoben wird. Der Dampf dieses hohen Temperaturniveaus wird in einer an den Erhitzer angeschlossenen Turbine 5 auf den Druck der Schiene 16 mit beispielsweise 9,8 - 105 N/m2 entspannt und zur isobaren Kühlung im Wärmetausch mit anzuwärmendem Dampf über Leitung 8 in den Rekuperator 3 eingeleitet. Die Temperatur des mit 791 K aus der Turbine austretenden Dampfes sinkt im Rekuperator 3 auf 653 K. Dieser Dampf besitzt im Vergleich mit der konventionellen Lösung einen höheren Wärmeinhalt. Dieser vvärmeüberschuß wird im dargestellten Ausführungsbeispiel im Wärmetausch mit Speisewasser für den Verdampfer 1 abgeführt. Dazu ist der Rekuperator 3 mit einem Wärmetauscher 6 verbunden, aus dem der Dampf mit 494 K aus- und in die Niederdruckdampfschiene 16 eintritt. Das Speisewasser wird dem Wärmetauscher 6 über eine Leitung 14, die von der Leitung 17 für die Kondensatrückführung abzweigt, zugeleitet und anschließend wieder in Leitung 17 eingespeist. Der Dampf der Niederdruckdampfschiene 16 wird Niederdruck-Prozeßdampf-Verbrauchern 10 zugeführt und kondensiert. Eine der Zahl der Dampfschienen entsprechende Zahl an Pumpen 12, 13 erhöht den Druck des Kondensats und versorgt den Dampfkessel 1 mit Speisewasser.The steam of the back pressure steam system shown is generated in an evaporator 1, in a

In der folgenden Tabelle 1 sind Temperatur, Druck, spezifische Enthalpie und spezifische Entropie des Dampfes für das beschriebene Ausführungsbeispiel an den in der Skizze mit Buchstaben a bis f bezeichneten Stellen angegeben.The following table 1 shows the temperature, pressure, specific enthalpy and specific entropy of the steam for the exemplary embodiment described at the points designated by letters a to f in the sketch.

In der Tabelle 2 sind die spezifischen Verbrauchszahlen bzw. Leistungen des dargestellten Verfahrensbeispiels aufgeführt.Table 2 shows the specific consumption figures and outputs of the process example shown.

Wurde bei der konventionellen Lösung Dampf über eine zwischen die Dampfschienen 15 und 16 geschaltete Turbine entspannt, so konnte dieser Turbine pro kg Dampf eine Energie von 266 kJ entnommen werden. Erfindungsgemäß wird der Dampf der Mitteldruckdampfschiene erhitzt. Dazu werden im Erhitzer (4) 514 kJ pro kg Dampf übertragen. Im Rekuperator 6 werden davon 345 kJ pro kg rückgewonnen, so daß sich ein Mehrverbrauch von 169 kJ pro kg Dampf ergibt, da die im Rekuperator rückgewonnene Wärme Brennstoffwärme für den Verdampfer 1 ersetzt. Gegenüber der konventionellen Lösung liefert die Turbine pro kg Dampf 169 kJ (ohne Berücksichtigung des Erhitzerwirkungsgrades) mehr Energie. Der Wirkungsgrad des Zusatzverfahrens ist somit 1 bzw. 0,9, wenn der Erhitzerwirkungsgrad, der für den Verdampfer 1 und den Erhitzer 4 gleich sein soll, berücksichtigt wird.

Claims (3)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE2844742 | 1978-10-13 | ||

| DE19782844742 DE2844742A1 (en) | 1978-10-13 | 1978-10-13 | METHOD FOR OBTAINING ELECTRICAL ENERGY IN A BACK-PRESSURE STEAM SYSTEM |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0010254A1 EP0010254A1 (en) | 1980-04-30 |

| EP0010254B1 true EP0010254B1 (en) | 1981-11-04 |

Family

ID=6052160

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP79103882A Expired EP0010254B1 (en) | 1978-10-13 | 1979-10-10 | Process for generating electric power in a counter pressure steam system |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US4328675A (en) |

| EP (1) | EP0010254B1 (en) |

| JP (1) | JPS5591708A (en) |

| AT (1) | AT378038B (en) |

| CA (1) | CA1150955A (en) |

| DE (2) | DE2844742A1 (en) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5622605A (en) * | 1993-11-05 | 1997-04-22 | Simpson; Gary D. | Process for desalinating water while producing power |

| JP3315800B2 (en) | 1994-02-22 | 2002-08-19 | 株式会社日立製作所 | Steam turbine power plant and steam turbine |

| JP4486391B2 (en) * | 2004-03-30 | 2010-06-23 | 株式会社神戸製鋼所 | Equipment for effective use of surplus steam |

| USRE46316E1 (en) * | 2007-04-17 | 2017-02-21 | Ormat Technologies, Inc. | Multi-level organic rankine cycle power system |

| US8438849B2 (en) * | 2007-04-17 | 2013-05-14 | Ormat Technologies, Inc. | Multi-level organic rankine cycle power system |

| EP2290200A1 (en) * | 2009-07-15 | 2011-03-02 | Siemens Aktiengesellschaft | Steam plant assembly with steam turbine unit, process steam consumer and method for operating same with steam turbine unit and process steam consumer |

| US20110271676A1 (en) * | 2010-05-04 | 2011-11-10 | Solartrec, Inc. | Heat engine with cascaded cycles |

| US8789371B2 (en) * | 2011-01-03 | 2014-07-29 | General Electric Company | Power generation apparatus |

| CN104329127B (en) * | 2014-11-10 | 2016-03-30 | 中国电力工程顾问集团华东电力设计院有限公司 | Multicomputer associating capacity-enlarging system |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1732009A (en) * | 1927-11-03 | 1929-10-15 | W S Garstow & Company | Method and apparatus for development of power |

| DE884802C (en) * | 1944-08-03 | 1953-07-30 | Rudolf Dipl-Ing Hingst | Steam power plant with reheating |

| US2643519A (en) * | 1949-03-02 | 1953-06-30 | Richard C Powell | Regenerative steam power plant in which an extraction turbine supplies steam to desuperheaters which serve to heat feed water |

| DE1004203B (en) * | 1954-02-06 | 1957-03-14 | Siemens Ag | Thermal power plant with back pressure turbine |

| US3376706A (en) * | 1965-06-28 | 1968-04-09 | Angelino Gianfranco | Method for obtaining mechanical energy from a thermal gas cycle with liquid phase compression |

| US3391539A (en) * | 1967-08-16 | 1968-07-09 | Gen Electric | Pressure control and flow dispatching system for steam turbine powerplant |

| US4178761A (en) * | 1977-06-17 | 1979-12-18 | Schwartzman Everett H | Heat source and heat sink pumping system and method |

| US4249384A (en) * | 1978-08-03 | 1981-02-10 | Harris Marion K | Isothermal compression-regenerative method for operating vapor cycle heat engine |

| US4214451A (en) * | 1978-11-13 | 1980-07-29 | Systems Control, Inc. | Energy cogeneration system |

-

1978

- 1978-10-13 DE DE19782844742 patent/DE2844742A1/en not_active Withdrawn

-

1979

- 1979-03-01 AT AT0156579A patent/AT378038B/en not_active IP Right Cessation

- 1979-10-10 DE DE7979103882T patent/DE2961270D1/en not_active Expired

- 1979-10-10 EP EP79103882A patent/EP0010254B1/en not_active Expired

- 1979-10-11 CA CA000337431A patent/CA1150955A/en not_active Expired

- 1979-10-11 JP JP13127179A patent/JPS5591708A/en active Pending

- 1979-10-12 US US06/084,195 patent/US4328675A/en not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| EP0010254A1 (en) | 1980-04-30 |

| US4328675A (en) | 1982-05-11 |

| AT378038B (en) | 1985-06-10 |

| JPS5591708A (en) | 1980-07-11 |

| CA1150955A (en) | 1983-08-02 |

| DE2961270D1 (en) | 1982-01-14 |

| DE2844742A1 (en) | 1980-04-24 |

| ATA156579A (en) | 1984-10-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1649147B1 (en) | Method and device for carrying out a thermodynamic cycle | |

| EP1613841B1 (en) | Method and device for carrying out a thermodynamic cyclic process | |

| DE69218206T2 (en) | ENERGY SYSTEM BASED ON THE ORGANIC RANKINE CYCLE AND METHOD FOR OPERATING THE SYSTEM | |

| DE102008045450B4 (en) | Method for operating a thermodynamic cycle and thermodynamic cycle | |

| DE69407261T2 (en) | Method and device for converting heat from geothermal liquid and geothermal steam into electrical energy | |

| EP1771641B1 (en) | Method and device for the transfer of heat from a heat source to a thermodynamic circuit with a working medium of at least two substances with non-isothermal evaporation and condensation | |

| EP3362739B1 (en) | Generation of process steam by means of a high-temperature heat pump | |

| DE10335143B4 (en) | Method for increasing the efficiency of a gas turbine plant and suitable gas turbine plant | |

| WO2004033859A1 (en) | Method and device for recovering energy | |

| DE102010060064A1 (en) | Method for increasing the power output of a gas and steam combined cycle power plant during selected operating periods | |

| EP0008680A2 (en) | Method of producing thermal energy by the combination of a heat engine with a heat pump | |

| EP0010254B1 (en) | Process for generating electric power in a counter pressure steam system | |

| DE2201397A1 (en) | Method and device for regenerative preheating in thermal power plants | |

| EP1038094B1 (en) | Multistep steam power operating method for generating electric power in a cycle and device for the implementation thereof | |

| EP3232023A1 (en) | Method and installation for energy conversion of pressure energy to electrical energy | |

| EP3559564A1 (en) | Method and apparatus for generating process cold and process steam | |

| DE1906144A1 (en) | Thermal power plant for the utilization of the heat generated in a nuclear reactor, with a combined gas turbine-steam turbine plant | |

| EP2385223A1 (en) | Procedure for the increase of the efficiency of gas and steam turbine power plants | |

| DE2651888A1 (en) | Steam turbine waste heat recovery circuit - has part of heat exchange medium passed through condenser driven by turbine | |

| DE10355782A1 (en) | Device for carrying out thermal circulating process comprises using working substance having temperature in primary circulation which is higher than temperature of working substance in secondary circulation | |

| AT68741B (en) | Method for combining a steam power plant with changing steam consumption with one or more waste steam recycling plants. | |

| DE102010046584A1 (en) | Method for generating mechanical or electrical energy from waste heat or renewable heating using thermodynamic cyclic process, involves liquefying thermal back compression of efficiently expanded working medium vapor in absorber | |

| DE202015103407U1 (en) | Combined heat and power system | |

| DE102022128628A1 (en) | System and method for energy conversion and energy storage | |

| DE102023201290A1 (en) | Method for operating a fuel cell system, fuel cell system |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): BE CH DE FR IT NL SE |

|

| 17P | Request for examination filed |

Effective date: 19801006 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): BE CH DE FR IT NL SE |

|

| REF | Corresponds to: |

Ref document number: 2961270 Country of ref document: DE Date of ref document: 19820114 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19820930 Year of fee payment: 4 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19821031 Year of fee payment: 4 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19821231 Year of fee payment: 4 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19831011 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Effective date: 19831031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19840501 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19841009 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19841106 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19841231 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Effective date: 19871031 |

|

| BERE | Be: lapsed |

Owner name: LINDE A.G. Effective date: 19871031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19880630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19880701 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| EUG | Se: european patent has lapsed |

Ref document number: 79103882.1 Effective date: 19850607 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |