EP0000727B1 - 3-(4-(1,3-diazacycloalkene-2-yl)-phenyl)-1,2-benzisothiazoles, process for their preparation and medicaments containing them. - Google Patents

3-(4-(1,3-diazacycloalkene-2-yl)-phenyl)-1,2-benzisothiazoles, process for their preparation and medicaments containing them. Download PDFInfo

- Publication number

- EP0000727B1 EP0000727B1 EP78100498A EP78100498A EP0000727B1 EP 0000727 B1 EP0000727 B1 EP 0000727B1 EP 78100498 A EP78100498 A EP 78100498A EP 78100498 A EP78100498 A EP 78100498A EP 0000727 B1 EP0000727 B1 EP 0000727B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- phenyl

- benzisothiazole

- general formula

- compound

- acid

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 0 CC(C)CNC(c1ccc(C=C2C(S*)=CC=CC2)cc1)N Chemical compound CC(C)CNC(c1ccc(C=C2C(S*)=CC=CC2)cc1)N 0.000 description 1

Classifications

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07D—HETEROCYCLIC COMPOUNDS

- C07D275/00—Heterocyclic compounds containing 1,2-thiazole or hydrogenated 1,2-thiazole rings

- C07D275/04—Heterocyclic compounds containing 1,2-thiazole or hydrogenated 1,2-thiazole rings condensed with carbocyclic rings or ring systems

Definitions

- the invention relates to new 3- (4- (1,3-diazacycloalken-2-yl) phenyl] -1,2-benzisothiazoles and their acid addition salts, their preparation and pharmaceutical preparations containing these compounds.

- Hydrogen is particularly preferred for R and Y is preferred for Y. to emphasize.

- the compounds of the invention can be prepared by using a compound of general formula II in which R has the meanings given above, with a diamine of the general formula III, in which Y has the meanings given above, and elemental sulfur is advantageously reacted in an inert organic solvent and, if appropriate, the compound obtained in one transferred physiologically acceptable acid addition salt.

- the reaction is expediently carried out at temperatures from 40 to 150 ° C., preferably at temperatures from 70 to 120 ° C.

- Appropriate solvents for the reaction are aromatic hydrocarbons, especially benzene hydrocarbons, such as benzene or toluene, lower alcohols, such as methanol, ethanol, propanol, isopropanol, butanol or isobutanol, saturated cyclic or aliphatic ethers, such as dibutyl ether or dioxane, glycol ether, especially monoalkyl ether of glycol , such as glycol monomethyl ether or glycol monoethyl ether, or mixtures of the solvents mentioned.

- aromatic hydrocarbons especially benzene hydrocarbons, such as benzene or toluene

- lower alcohols such as methanol, ethanol, propanol, isopropanol, butanol or isobutanol

- saturated cyclic or aliphatic ethers such as dibutyl ether or dioxane

- glycol ether especially monoalkyl ether of glyco

- the benzene hydrocarbons in particular benzene and toluene, and monoalkyl ethers of glycol, in particular glycol monomethyl ether, are preferred.

- the diamine of the general formula III calculated on the compound of the general formula 11, is used in a stoichiometric or in excess amount, optionally up to 3 times the stoichiometric amount.

- the elemental sulfur calculated on the chloromethyl compound used, is used in stoichiometric or in excess amount up to 1.2 times.

- the stoichiometric amount of elemental sulfur is preferably used.

- the starting compounds of the general formula II can be obtained, for example, by side chain chlorination of 3- (4-methylphenyl) -1,2-benzisothiazoles with chlorine at about 170 ° C. and under UV radiation.

- the starting material IV, ammonia and elemental sulfur are used in approximately stoichiometric amounts, but a ratio of 2 to 10 moles of ammonia and 0.9 to 1.1 gram atom of sulfur per mole of starting material IV is preferably used.

- This reaction is generally carried out at a temperature of 20 to 250 ° C., advantageously from 20 to 200 ° C., preferably from 40 to 180 ° C., in particular from 40 to 120 ° C., without pressure or under pressure, continuously or batchwise.

- the reaction pressure is generally determined by the total vapor pressure of the components at the reaction temperature. If appropriate, organic solvents which are inert under the reaction conditions can be used, e.g.

- aromatic hydrocarbons such as toluene, ethylbenzene, o-, m-, p-xylene, isopropylbenzene; Alkanols and cycloalkanols, such as ethanol, n-butanol, isobutanol, methylglycol, cyclohexanol, propanol, methanol, 2-ethylhexanol; Ether, e.g.

- the solvent is expediently used in an amount of 200 to 10,000 percent by weight, preferably 300 to 1,000 percent by weight, based on starting material IV.

- the reaction can be carried out as follows: starting material IV, elemental sulfur and ammonia, optionally in the presence of a solvent, are combined in one Pressure reactor reacted with one another at the aforementioned temperature for 3 to 10 hours.

- the 1,2-benzisothiazole is obtained from the reaction mixture by the customary methods, for example by fractional distillation, filtration and, if appropriate, subsequent recrystallization from a suitable solvent, for example ligroin.

- the reaction mixture can also be poured into water, the mixture formed extracted with a suitable solvent, for example methylene chloride, benzene, and the extract worked up.

- the compounds of general formula 1 according to the invention are optionally converted in a conventional manner into the acid addition salt of a physiologically tolerated acid.

- suitable physiologically compatible organic or inorganic acids are hydrochloric acid, hydrobromic acid, phosphoric acid or sulfuric acid, and organic acids are, for example, oxalic acid, maleic acid, fumaric acid, lactic acid, tartaric acid, malic acid, citric acid, salicylic acid, adipic acid or benzoic acid or can be based on advances in drug research 10, pages 224 to 225, Birkhäuser Verlag, Basel and Stuttgart, 1966.

- the compounds according to the invention and their physiologically tolerated acid addition salts are distinguished by a strong antriarrhythmic effect and are particularly suitable for the pharmacotherapy of cardiac arrhythmias.

- the substances were administered orally to rats (strain: Sprague Dawley, weight: 180-240 g) 45 min before the start of anesthesia (thiobuteal barbital 100 mg / kg i.p.).

- Aconitin was used as the arrhythmogenic substance, which i.v. 60 min after the substance application. was infused (dosing rate: 0.005 mg / kg. min).

- arrhythmias occur after an average of 3.7 ⁇ 0.9 min, the onset of which can be delayed by antiarrhythmics depending on the dose.

- the acute toxicity was determined in groups of 10 or 20 female Swiss mice, weight 20-26 g, with intraperitoneal application.

- the LD 50 was calculated as the dose (probit analysis) after which 50% of the animals died within 7 days.

- Table 1 shows that the compounds of Examples 2 and 3, compared to the antiarrhythmicum procainamide, are around 5 times more antiarrhythmic. Another advantage is that the effect of the maximum dose reaches 114 (example 2) or 73% (example 3) higher values than that of procainamide; i.e. that the aconitine antagonism of the tested compounds is significantly more pronounced than that of procainamide.

- the therapeutic range as the quotient of the lethal dose (LD 50) and the antiarrhythmic dose (ED 50%) is 2 times (example 2) and 1.9 times (example 3) greater than that of procainamide.

- the invention accordingly also relates to therapeutic agents or preparations which, in addition to conventional carriers and diluents, contain a compound of the general formula I or its physiologically tolerable acid addition salt as active ingredient, and the use of the new compounds for therapeutic purposes.

- the therapeutic agents or preparations are produced in a known manner with the usual carriers or diluents and the commonly used pharmaceutical-technical auxiliaries according to the desired type of application with a suitable dosage.

- the preferred preparations are in a dosage form which is suitable for oral administration.

- Dosage forms of this type are, for example, tablets, film-coated tablets, coated tablets, capsules, pills, powders, solutions or suspensions or depot forms.

- parenteral forms of preparation such as injection solutions or additives to infusion solutions, can also be used.

- Suppositories may also be mentioned as preparations.

- the corresponding tablets can, for example, by mixing the active ingredient with known auxiliaries, for example inert diluents such as dextrose, sugar, sorbitol, mannitol, polyvinylpyrrolidone, calcium carbonate, calcium phosphate or milk sugar, disintegrants such as corn, starch, alginic acid or polyvinylpyrrolidone, binders such as starch or Gelatin, lubricants such as magnesium stearate or talc and / or agents for achieving the depot effect, such as carboxypolymethylene, carboxymethyl cellulose, cellulose acetate phthalate or polyvinyl acetate can be obtained.

- auxiliaries for example inert diluents such as dextrose, sugar, sorbitol, mannitol, polyvinylpyrrolidone, calcium carbonate, calcium phosphate or milk sugar, disintegrants such as corn, starch, alginic acid or polyvinylpyrrol

- coated tablets can be produced by coating cores produced analogously to the tablets with agents conventionally used in coated tablet coatings, for example collidone or shellac, gum arabic, talc, titanium dioxide or sugar.

- the coated tablet cover can also consist of several layers, wherein the auxiliaries mentioned above for the tablets can be used.

- Solutions or suspensions with the active compounds according to the invention can additionally contain taste-improving agents such as saccharin, cyclamate or sugar and, for example, flavorings such as vanillin or orange extract. They can also contain suspending aids such as sodium carboxymethyl cellulose or preservatives such as parahydroxybenzoates.

- Capsules containing active ingredients can be produced, for example, by mixing the active ingredient with an inert carrier, such as milk sugar or sorbitol, and encapsulating it in gelatin capsules.

- Suitable suppositories can be produced, for example, by mixing with the carrier material provided, such as neutral fats or polyethylene glycols or their derivatives.

- the single dose of a substance according to the invention in humans is 5 to 100 mg, preferably 10 to 80 mg.

- the hydrochloride of the compound has a melting point of 318 ° C.

- the active ingredient is moistened with polyvinylpyrrolidone in 10% strength aqueous solution, passed through a sieve with a mesh size of 1.0 mm and dried at 50.degree. These granules are mixed with polyethylene glycol (average M.G. 4000), hydroxypropylmethyl cellulose, talc and magnesium stearate and pressed into 280 mg tablets.

- the mixture of the active ingredient with lactose and corn starch is granulated with an 8% aqueous solution of the polyvinylpyrrolidone through a 1.5 mm sieve, dried at 50 ° C. and rubbed again through a 1.0 mm sieve.

- the granules thus obtained are mixed with magnesium stearate and pressed to dragee cores.

- the dragee cores obtained are coated in a conventional manner with a casing which consists essentially of sugar and talc.

Description

Die Erfindung betrifft neue 3-(4-(1,3-Diazacycloalken-2-yl)-phenyl]-1,2-benzisothiazole und ihre Säureadditionssalze, ihre Herstellung und diese Verbindungen enthaltende pharmazeutische Zubereitungen.The invention relates to new 3- (4- (1,3-diazacycloalken-2-yl) phenyl] -1,2-benzisothiazoles and their acid addition salts, their preparation and pharmaceutical preparations containing these compounds.

Es wurde gefunden, daß Verbindungen der allgemeinen Formel I

Von den genannten Bedeutungen sind als bevorzugt für R Wasserstoff, ein Halogenatom, insbesondere Chlor oder Brom, oder eine Nitrogruppe und für Y 1-Methyläthylen-t,2 und Trimethylen-1,3 zu nennen.Of the meanings mentioned, hydrogen, a halogen atom, in particular chlorine or bromine, or a nitro group and for Y 1-methylethylene-t, 2 and trimethylene-1,3 are to be mentioned as preferred for R.

Als besonders bevorzugt sind für R Wasserstoff, und für Y

Dementsprechend sind als erfindungsgemäße Verbindungen, die summarisch als 3-[4-(1,3-Diazacyclo-2-yl)]-1,2-benzoisothiazole bezeichnet werden können, der allgemeinen Formel 1 beispielsweise zu nennen:

- 3-[4-(Imidazolin-2-yl)-phenyl]-1,2-benzisothiazol

- 3-[4-(Methylimidazolin-2-yl)-phenyl]-1,2-benzisothiazol

- 3-[4-(Tetrahydropyrimidin-2-yl)-phenyl]-1,2-benzisothiazol

- 5-Chlor-3-[4-(imidazolin-2-yl)-phenyl]-1,2-benzisothiazol

- 5-Chlor-3-[4-(methylimidazolin-2-yl)-phenyll-1,2-benzisothiazol

- 4-Methoxy-3-[(4-(methylimidazolin-2-yl)-phenyl]-1,2-benzisothiazol

- 5-Nitro-3-[4-(imidazolin-2-yl)-phenyl]-1,2-benzisothiazol

- 5-Nitro-3-[4-(tetrahydropyrimidin-2-yl)-phenyl]-1,2-benzisothiazol

- 3- [4- (imidazolin-2-yl) phenyl] -1,2-benzisothiazole

- 3- [4- (Methylimidazolin-2-yl) phenyl] -1,2-benzisothiazole

- 3- [4- (tetrahydropyrimidin-2-yl) phenyl] -1,2-benzisothiazole

- 5-chloro-3- [4- (imidazolin-2-yl) phenyl] -1,2-benzisothiazole

- 5-chloro-3- [4- (methylimidazolin-2-yl) phenyl-1,2-benzisothiazole

- 4-methoxy-3 - [(4- (methylimidazolin-2-yl) phenyl] -1,2-benzisothiazole

- 5-nitro-3- [4- (imidazolin-2-yl) phenyl] -1,2-benzisothiazole

- 5-nitro-3- [4- (tetrahydropyrimidin-2-yl) phenyl] -1,2-benzisothiazole

Die erfindungsgemäßen Verbindungen können hergestellt werden, indem man eine Verbindung der allgemeinen Formel II

Die Umsetzung wird zweckmäßig bei Temperaturen von 40 bis 150°C, bevorzugt bei Temperaturen von 70 bis 120°C, durchgeführt.The reaction is expediently carried out at temperatures from 40 to 150 ° C., preferably at temperatures from 70 to 120 ° C.

Zweckmäßige Lösungsmittel für die Umsetzung sind aromatische Kohlenwasserstoffe, insbesondere Benzolkohlenwasserstoffe, wie Benzol oder Toluol, niedere Alkohole, wie Methanol, Äthanol, Propanol, Isopropanol, Butanol oder Isobutanol, gesättigte cyclische oder aliphatische Äther, wie Dibutyläther oder Dioxan, Glykoläther, insbesondere Monoalkyläther des Glykols, wie Glykolmonomethyläther oder Glykolmonoäthyläther, oder Mischungen der genannten Lösungsmittel.Appropriate solvents for the reaction are aromatic hydrocarbons, especially benzene hydrocarbons, such as benzene or toluene, lower alcohols, such as methanol, ethanol, propanol, isopropanol, butanol or isobutanol, saturated cyclic or aliphatic ethers, such as dibutyl ether or dioxane, glycol ether, especially monoalkyl ether of glycol , such as glycol monomethyl ether or glycol monoethyl ether, or mixtures of the solvents mentioned.

Von den genannten Lösungsmitteln sind die Benzolkohlenwasserstoffe, insbesondere Benzol und Toluol, and Monoalkyläther des Glykols, insbesondere Glykolmonomethyläther, bevorzugt.Of the solvents mentioned, the benzene hydrocarbons, in particular benzene and toluene, and monoalkyl ethers of glycol, in particular glycol monomethyl ether, are preferred.

Das Diamin der allgemeinen Formel 111 wird, berechnet auf die Verbindung der allgemeinen Formel 11, in stöchiometrischer oder in überschüssiger Menge, gegebenenfalls bis zur 3-fachen stöchiometrischen Menge, verwendet.The diamine of the general formula III, calculated on the compound of the general formula 11, is used in a stoichiometric or in excess amount, optionally up to 3 times the stoichiometric amount.

Der elementare Schwefel wird, berechnet auf die verwendete Chlormethylverbindung, in stöchiometrischer oder in überschüssiger Menge bis zum 1,2-fachen verwendet. Bevorzugt wird die stöchiometrische Menge elementarer Schwefel eingesetzt.The elemental sulfur, calculated on the chloromethyl compound used, is used in stoichiometric or in excess amount up to 1.2 times. The stoichiometric amount of elemental sulfur is preferably used.

Die Umsetzung von beispielsweise 3-(4-Chlormethylphenyl)-1,2-benzisothiazol mit Äthylendiamin und Schwefel kann durch die folgende Reaktionsgleichung beschrieben werden:

Die Ausgangsverbindungen der allgemeinen Formel II können beispielsweise durch Seitenkettenchlorierung von 3-(4-Methylphenyl)-1,2-benzisothiazolen mit Chlor bei etwa 170°C und unter UV-Bestrahlung erhalten werden.The starting compounds of the general formula II can be obtained, for example, by side chain chlorination of 3- (4-methylphenyl) -1,2-benzisothiazoles with chlorine at about 170 ° C. and under UV radiation.

Die 3-(4-Methylphenyl)-1,2-benzisothiazole, die den Verbindungen der allgemeinen Formel II zugrundeliegen, können erhalten werden, indem man ein o-Halogenarylketon der allgemeinen Formel IV

Der Ausgangsstoff IV, Ammoniak und elementarer Schwefel werden in etwa stöchiometrischen Mengen verwendet, jedoch verwendet man vorzugsweise ein Verhältnis von 2 bis 10 Mol Ammoniak und von 0,9 bis 1,1 Grammatom Schwefel je Mol Ausgangsstoff IV.The starting material IV, ammonia and elemental sulfur are used in approximately stoichiometric amounts, but a ratio of 2 to 10 moles of ammonia and 0.9 to 1.1 gram atom of sulfur per mole of starting material IV is preferably used.

Diese Umsetzung wird in der Regel bei einer Temperatur von 20 bis 250°C, vorteilhaft von 20 bis 200°C, vorzugsweise von 40 bis 180°C, insbesondere von 40 bis 120°C, drucklos oder unter Druck, kontinuierlich oder diskontinuierlich durchgeführt. Der Reaktionsdruck wird im allgemeinen durch den Gesamtdampfdruck der Komponenten bei der Umsetzungstemperatur bedingt. Gegebenenfalls kann man unter den Reaktionsbedingungen inerte organische Lösungsmittel verwenden, z.B. aromatische Kohlenwasserstoffe, wie Toluol, Äthylbenzol, o-, m-, p-Xylol, Isopropylbenzol; Alkanole und Cycloalkanole, wie Äthanol, n-Butanol, Isobutanol, Methylglykol, Cyclohexanol, Propanol, Methanol, 2-Äthylhexanol; Äther, z.B. Äthylpropyläther, Diisobutyläther, Methyl-tert.-butyläther, n-Butyläthyläther, Di-n-butyläther, Dioxan, Diisoamyläther, Diisopropyläther, Anisol, Phenetol, Cyclohexylmethyläther, Diäthyläther, Tetrahydrofuran, Thioanisol; und entsprechende Gemische. Zweckmäßig verwendet man das Lösungsmittel in einer Menge von 200 bis 10 000 Gewichtsprozent, vorzugsweise von 300 bis 1 000 Gewichtsprozent, bezogen auf Ausgangsstoff IV.This reaction is generally carried out at a temperature of 20 to 250 ° C., advantageously from 20 to 200 ° C., preferably from 40 to 180 ° C., in particular from 40 to 120 ° C., without pressure or under pressure, continuously or batchwise. The reaction pressure is generally determined by the total vapor pressure of the components at the reaction temperature. If appropriate, organic solvents which are inert under the reaction conditions can be used, e.g. aromatic hydrocarbons, such as toluene, ethylbenzene, o-, m-, p-xylene, isopropylbenzene; Alkanols and cycloalkanols, such as ethanol, n-butanol, isobutanol, methylglycol, cyclohexanol, propanol, methanol, 2-ethylhexanol; Ether, e.g. Ethyl propyl ether, diisobutyl ether, methyl tert-butyl ether, n-butyl ethyl ether, di-n-butyl ether, dioxane, diisoamyl ether, diisopropyl ether, anisole, phenetol, cyclohexyl methyl ether, diethyl ether, tetrahydrofuran, thioanisole; and corresponding mixtures. The solvent is expediently used in an amount of 200 to 10,000 percent by weight, preferably 300 to 1,000 percent by weight, based on starting material IV.

Im einzelnen kann die Reaktion wie folgt durchgeführt werden: Ausgangsstoff IV, elementarer Schwefel und Ammoniak, gegebenenfalls in Gegenwart eines Lösungsmittels, werden in einem Druckreaktor während 3 bis 10 Stunden bei der vorgenannten Temperatur miteinander umgesetzt. Aus dem Reaktionsgemisch erhält man das 1,2-Benzisothiazol nach den üblichen Verfahren, z.B. durch fraktionierte Destillation, Filtration und gegebenenfalls anschließender Umkristallisation aus einem geeigneten Lösungsmittel, z.B. Ligroin. Man kann das Reaktionsgemisch auch nach der Entfernung überflüssigen Ammoniaks und Lösungsmittels in Wasser gießen, das gebildete Gemisch mit einem geeigneten Lösungsmittel, z.B. Methylenchlorid, Benzol, extrahieren und den Extrakt aufarbeiten.In detail, the reaction can be carried out as follows: starting material IV, elemental sulfur and ammonia, optionally in the presence of a solvent, are combined in one Pressure reactor reacted with one another at the aforementioned temperature for 3 to 10 hours. The 1,2-benzisothiazole is obtained from the reaction mixture by the customary methods, for example by fractional distillation, filtration and, if appropriate, subsequent recrystallization from a suitable solvent, for example ligroin. After removing the excess ammonia and solvent, the reaction mixture can also be poured into water, the mixture formed extracted with a suitable solvent, for example methylene chloride, benzene, and the extract worked up.

Die erfindungsgemäßen Verbindungen der allgemeinen Formel 1 werden gegebenenfalls in an sich üblicher Weise in das Säureadditionssalz einer physiologisch verträglichen Säure überführt. Als übliche physiologisch verträgliche organische oder anorganische Säuren kommen beispielsweise in Betracht Salzsäure, Bromwasserstoffsäure, Phosphorsäure oder Schwefelsäure und als organische Säuren beispielsweise Oxalsäure, Maleinsäure, Fumarsäure, Milchsäure, Weinsäure, Apfelsäure, Zitronensäure, Salicylsäure, Adipinsäure oder Benzoesäure oder können aus Fortschritte der Arzneimittelforschung Band 10, Seiten 224 bis 225, Birkhäuser Verlag, Basel und Stuttgart, 1966 entnommen werden.The compounds of general formula 1 according to the invention are optionally converted in a conventional manner into the acid addition salt of a physiologically tolerated acid. Examples of suitable physiologically compatible organic or inorganic acids are hydrochloric acid, hydrobromic acid, phosphoric acid or sulfuric acid, and organic acids are, for example, oxalic acid, maleic acid, fumaric acid, lactic acid, tartaric acid, malic acid, citric acid, salicylic acid, adipic acid or benzoic acid or can be based on advances in drug research 10, pages 224 to 225, Birkhäuser Verlag, Basel and Stuttgart, 1966.

Die erfindungsgemäßen Verbindungen und ihre physiologisch verträglichen Säureadditionssalze zeichnen sich durch eine starke antriarrhythmische Wirkung aus und sind besonders zur Pharmakotherapie von Herzrhythmusstörungen geeignet.The compounds according to the invention and their physiologically tolerated acid addition salts are distinguished by a strong antriarrhythmic effect and are particularly suitable for the pharmacotherapy of cardiac arrhythmias.

Zur Bestimmung ihrer antiarrhythmischen Wirksamkeit wurden die Substanzen Ratten (Stamm: Sprague Dawley, Gewicht: 180-240 g) 45 min vor Beginn der Narkose (Thiobutäbarbital 100 mg/kg i.p.) oral appliziert.To determine their antiarrhythmic activity, the substances were administered orally to rats (strain: Sprague Dawley, weight: 180-240 g) 45 min before the start of anesthesia (thiobuteal barbital 100 mg / kg i.p.).

Als arrhythmogene Substanz diente Aconitin, das 60 min nach der Substanzapplikation i.v. infundiert wurde (Dosierungsgeschwindigkeit: 0,005 mg/kg. min). Bei nichtbehandelten Tieren (N = 30) treten nach durchschnittlich 3,7 ± 0,9 min Arrhythmien auf, deren Eintritt durch Antiarrhythmica dosisabhängig verzögert werden kann.Aconitin was used as the arrhythmogenic substance, which i.v. 60 min after the substance application. was infused (dosing rate: 0.005 mg / kg. min). In untreated animals (N = 30) arrhythmias occur after an average of 3.7 ± 0.9 min, the onset of which can be delayed by antiarrhythmics depending on the dose.

Zur quantitativen Auswertung der linearen Beziehung zwischen log Dosis (mg/kg) der Prüfsubstanzen und der relativen Verlängerung der Aconitininfusionsdauer (A%) wurde die Dosis bestimmt, welche die Infusionsdauer um 50% verlängert (ED 50%). Als Vergleichssubstanz diente das bekannte Antiarrhythmicum Procainamid.For the quantitative evaluation of the linear relationship between log dose (mg / kg) of the test substances and the relative extension of the aconitine infusion duration (A%), the dose was determined, which prolongs the infusion duration by 50% (ED 50%). The well-known antiarrhythmicum procainamide was used as the reference substance.

Die akute Toxizität wurde an Gruppen von je 10 oder 20 weiblichen Swiss-Mäusen, Gewicht 20-26 g, bei intraperitonealer Applikation ermittelt. Als LD 50 wurde die Dosis berechnet (Probit-Analyse), nach der 50% der Tiere innerhalb von 7 Tagen starben.The acute toxicity was determined in groups of 10 or 20 female Swiss mice, weight 20-26 g, with intraperitoneal application. The LD 50 was calculated as the dose (probit analysis) after which 50% of the animals died within 7 days.

Die Tabelle 1 zeigt, daß die Verbindungen der Beispiele 2 und 3, verglichen mit dem Antiarrhythmicum Procainamid, rund 5 mal stärker antiarrhythmisch wirksam sind. Ein weiterer Vorteil besteht darin, daß die Wirkung der Maximaldosis um 114 (Beispiel 2) bzw. 73% (Beispiel 3) höhere Werte erreicht, als die von Procainamid; d.h., daß der Aconitinantagonismus der geprüften Verbindungen deutlich stärker ausgeprägt ist als bei Procainamid.Table 1 shows that the compounds of Examples 2 and 3, compared to the antiarrhythmicum procainamide, are around 5 times more antiarrhythmic. Another advantage is that the effect of the maximum dose reaches 114 (example 2) or 73% (example 3) higher values than that of procainamide; i.e. that the aconitine antagonism of the tested compounds is significantly more pronounced than that of procainamide.

Die therapeutische Breite als Quotient aus der letalen Dosis (LD 50) und der antiarrhythmisch wirkenden Dosis (ED 50%) ist 2 mal (Beispiel 2) bzw. 1,9 mal (Beispiel 3) größer als beim Procainamid.

In Testmodellen auf antiarrhythmische Wirkung wurden folgende Befunde erhoben:

- Reizzeitspannungsbeziehung (isol. Vorhof):

- Beispiel 2 (Tetrahydropyrimidinderivat): 1,24-fache Chinidinwirkung

- Beispiel 3 (Methylimidazolinderivat): 1,5-fache Chinidinwirkung

- Flimmerschwelle am Meerschweinchen:

- Beispiel 2: i.v. = 1,8-fache Chinidinwirkung

- Maximale Folgefrequenz am unnarkotisierten Kaninchen:

- Beispiel 2: i.v. = 7-fache Chinidinwirkung.

- Irritation time voltage relationship (isol. Atrium):

- Example 2 (tetrahydropyrimidine derivative): 1.24-fold quinidine activity

- Example 3 (methylimidazoline derivative): 1.5-fold quinidine effect

- Flicker threshold on guinea pigs:

- Example 2: iv = 1.8-fold quinidine action

- Maximum repetition rate on the non-anesthetized rabbit:

- Example 2: iv = 7-fold quinidine action.

Gegenstand der Erfindung sind demnach auch therapeutische Mittel oder Zubereitungen, die neben üblichen Träger- und Verdünnungsmittel eine Verbindung der allgemeinen Formel I oder dessen physiologisch verträgliches Säureadditionssalz als Wirkstoff enthalten sowie die Verwendung der neuen Verbindungen zu therapeutischen Zwecken.The invention accordingly also relates to therapeutic agents or preparations which, in addition to conventional carriers and diluents, contain a compound of the general formula I or its physiologically tolerable acid addition salt as active ingredient, and the use of the new compounds for therapeutic purposes.

Die therapeutischen Mittel bzw. Zubereitungen werden mit den üblichen Trägerstoffen oder Verdünnungsmitteln und den üblicherweise verwendeten pharmazeutisch-technischen Hilfsstoffen entsprechend der gewünschten Applikationsart mit einer geeigneten Dosierung in bekannter Weise hergestellt.The therapeutic agents or preparations are produced in a known manner with the usual carriers or diluents and the commonly used pharmaceutical-technical auxiliaries according to the desired type of application with a suitable dosage.

Die bevorzugten Zubereitungen bestehen in einer Darreichungsform, die zur oralen Applikation geeignet ist. Solche Darreichungsformen sind beispielsweise Tabletten, Filmtabletten, Dragees, Kapseln, Pillen, Pulver, Lösungen oder Suspensionen oder Depotformen.The preferred preparations are in a dosage form which is suitable for oral administration. Dosage forms of this type are, for example, tablets, film-coated tablets, coated tablets, capsules, pills, powders, solutions or suspensions or depot forms.

Selbstverständlich kommen auch parenterale Zubereitungsformen, wie Injektionslösungen oder Zusätze zu Infusionslösungen, in Betracht. Weiterhin seien als Zubereitungen beispielsweise auch Suppositorien genannt.Of course, parenteral forms of preparation, such as injection solutions or additives to infusion solutions, can also be used. Suppositories may also be mentioned as preparations.

Die entsprechenden Tabletten können beispielsweise durch Mischen des Wirkstoffs mit bekannten Hilfsstoffen, beispielsweise inerte Verdünnungsmittel, wie Dextrose, Zucker, Sorbit, Mannit, Polyvinylpyrrolidon, Kalziumcarbonat, Kalziumphosphat oder Milchzucker, Sprengmitteln, wie Mais, Stärke, Alginsäure oder Polyvinylpyrrolidon, Bindemitteln, wie Stärke oder Gelatine, Gleitmitteln, wie Magnesiumstearat oder Talkum und/oder Mitteln zur Erzielung des Depoteffektes, wie Carboxypolymethylen, Carboxymethylcellulose, Celluloseacetatphthalat oder Polyvinylacetat erhalten werden. Die Tabletten können auch aus mehreren Schichten bestehen.The corresponding tablets can, for example, by mixing the active ingredient with known auxiliaries, for example inert diluents such as dextrose, sugar, sorbitol, mannitol, polyvinylpyrrolidone, calcium carbonate, calcium phosphate or milk sugar, disintegrants such as corn, starch, alginic acid or polyvinylpyrrolidone, binders such as starch or Gelatin, lubricants such as magnesium stearate or talc and / or agents for achieving the depot effect, such as carboxypolymethylene, carboxymethyl cellulose, cellulose acetate phthalate or polyvinyl acetate can be obtained. The tablets can also consist of several layers.

Entsprechend können Dragees durch Überziehen von analog den Tabletten hergestellten Kernen mit üblicherweise in Drageeüberzügen verwendeten Mitteln, beispielsweise Kollidon oder Schellack, Gummi arabicum, Talk, Titandioxid oder Zucker, hergestellt werden. Dabei kann auch die Drageehülle aus mehreren Schichten bestehen, wobei die oben bei den Tabletten erwähnten Hilfsstoffe verwendet werden können.Correspondingly, coated tablets can be produced by coating cores produced analogously to the tablets with agents conventionally used in coated tablet coatings, for example collidone or shellac, gum arabic, talc, titanium dioxide or sugar. The coated tablet cover can also consist of several layers, wherein the auxiliaries mentioned above for the tablets can be used.

Lösungen oder Suspensionen mit den erfindungsgemäßen Wirkstoffen können zusätzlich geschmackverbessemde Mittel, wie Saccharin, Cyclamat oder Zucker sowie beispielsweise Aromastoffe, wie Vanillin oder Orangenextrakt, enthalten. Sie können außerdem Suspendierhilfsstoffe, Wie Natriumcarboxymethylcellulose oder Konservierungsstoffe, wie Parahydroxybenzoate, enthalten. Wirkstoffe enthaltende Kapseln können beispielsweise hergestellt werden, indem man den Wirkstoff mit einem inerten Träger, wie Milchzucker oder Sorbit, mischt und in Gelatinekapseln einkapselt.Solutions or suspensions with the active compounds according to the invention can additionally contain taste-improving agents such as saccharin, cyclamate or sugar and, for example, flavorings such as vanillin or orange extract. They can also contain suspending aids such as sodium carboxymethyl cellulose or preservatives such as parahydroxybenzoates. Capsules containing active ingredients can be produced, for example, by mixing the active ingredient with an inert carrier, such as milk sugar or sorbitol, and encapsulating it in gelatin capsules.

Geeignete Suppositorien lassen sich beispielsweise durch Vermischen mit dafür vorgesehenem Trägermaterial, wie Neutralfetten oder Polyäthylenglykolen bzw. dessen Derivaten, herstellen.Suitable suppositories can be produced, for example, by mixing with the carrier material provided, such as neutral fats or polyethylene glycols or their derivatives.

Die Einzeldosis einer erfindungsgemäßen Substanz am Menschen liegt bei 5 bis 100 mg, vorzugsweise bei 10 bis 80 mg.The single dose of a substance according to the invention in humans is 5 to 100 mg, preferably 10 to 80 mg.

Die Erfindung wird durch die nachfolgenden Ausführungsbeispiele näher erläutert.The invention is explained in more detail by the following exemplary embodiments.

In einem Emailleautoklav werden 230,5 Teile 2-Chlor-4'-methyl-benzophenon, 32 Teile Schwefel und 100 Teile NH3 in 800 Teilen Methylglykol 6 Stunden bei 160°C umgesetzt. Man erhält 200 Teile 3-(4'-Methylphenyl)-1,2-benzisothiazol mit Fp 56°C. Die Ausbeute entspricht 89% der Theorie.230.5 parts of 2-chloro-4'-methyl-benzophenone, 32 parts of sulfur and 100 parts of NH 3 are reacted in 800 parts of methylglycol at 160 ° C. for 6 hours in an enamel autoclave. 200 parts of 3- (4'-methylphenyl) -1,2-benzisothiazole with mp 56 ° C. are obtained. The yield corresponds to 89% of theory.

In entsprechender Weise wird aus 2,5-Dichlor-4'-methylbenzophenon, im selben Molverhältnis und unter denselben Bedingungen mit Schwefel und Ammoniak umgesetzt, 5-Chlor-3-(4'-methylphenyl)-1,2-benzisothiazol vom Fp. 121°C in 85% Ausbeute erhalten.Correspondingly, 2,5-dichloro-4'-methylbenzophenone, in the same molar ratio and reacted with sulfur and ammonia under the same conditions, 5-chloro-3- (4'-methylphenyl) -1,2-benzisothiazole of mp. 121 ° C in 85% yield.

Aus 2-Chlor-5-nitro-4-methylbenzophenon wird 5-Nitro-3-(4'-methylphenyl)-1,2-benzisothiazol vom Fp. 179°C in 90% Ausbeute erhalten.From 2-chloro-5-nitro-4-methylbenzophenone 5-nitro-3- (4'-methylphenyl) -1,2-benzisothiazole of mp 179 ° C is obtained in 90% yield.

225 g 3-(4'-Methylphenyl)-1,2-benzisothiazol werden in einer Rührapparatur auf 170°C erhitzt und unter Bestrahlung mit einer UV-Lampe werden innerhalb von 2 Stunden 100 g Chlor eingeleitet. Der Endpunkt der Reaktion wird gaschromatographisch bestimmt (Verschwinden des Ausgangsprodukts). Anschließend wird das Reaktionsgemisch abgekühlt, abgesaugt und aus Methanol umkristallisiert. Man erhält 208 g 3-(4-Chlormethylphenyl)-1,2-benzisothiazol von einem Schmelzpunkt von 86 bis 89°C, was einer Ausbeute von 80% der Theorie entspricht.225 g of 3- (4'-methylphenyl) -1,2-benzisothiazole are heated to 170 ° C. in a stirrer apparatus and 100 g of chlorine are introduced within 2 hours while being irradiated with a UV lamp. The end point of the reaction is determined by gas chromatography (disappearance of the starting product). The reaction mixture is then cooled, suction filtered and recrystallized from methanol. 208 g of 3- (4-chloromethylphenyl) -1,2-benzisothiazole with a melting point of 86 to 89 ° C. are obtained, which corresponds to a yield of 80% of theory.

In entsprechender Weise wird 5-Chlor-3-(4'-Chlormethylphenyl)-1,2-benzisothiazol vom Fp. 116°C mit 78% Ausbeute hergestellt.5-Chloro-3- (4'-chloromethylphenyl) -1,2-benzisothiazole, mp 116 ° C., is prepared in a corresponding manner in 78% yield.

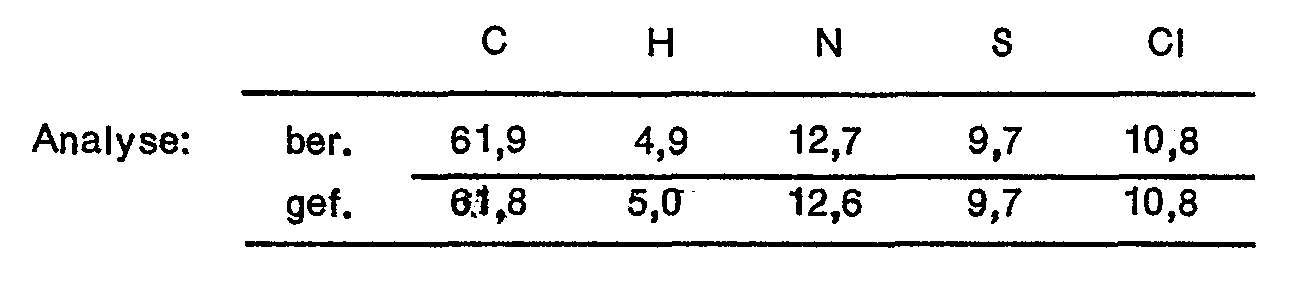

26 g 3-(4-Chlormethylphenyl)-1,2-benzisothiazol, 6,4 g Schwefel und 300 ml Toluol werden auf 50°C erwärmt und bei dieser Temperatur 12 g Äthylendiamin langsam zugegeben. Anschließend wird das Reaktionsgemisch 15 Stunden bei Rückflußtemperatur gerührt, heiß abfiltriert und das Filtrat auf 10° bis 15°C abgekühlt. Man erhält 21 g 3-(4-lmidazolin-2-yl-phenyl)-1,2-benzisothiazol mit einem Schmelzpunkt von 177°C. Das entspricht einer Ausbeute von 75% der Theorie.

Das Hydrochlorid der Verbindung hat einen Schmelzpunkt von 318°C.The hydrochloride of the compound has a melting point of 318 ° C.

26 g 3-(4-Chlormethylphenyl)-1,2-benzisothiazol, 6,4 g Schwefel und 300 ml Toluol werden auf 50°C erwärmt. Bei dieser Temperatur werden 15 g 1,3-Diaminopropan langsam zugegeben. Das Reaktionsgemisch wird noch 20 Stunden bei Rückflußtemperatur gerührt. Anschließend werden innerhalb 1 Stunde 20 g Chlorwasserstoffgas eingeleitet, es wird auf Raumtemperaturen abgekühlt und der entstandene Feststoff abgesaugt. Nach dem Umkristallisieren aus Wasser unter Zusatz von Aktivkohle erhält man 18 g 3-[4-(Tetrahydropyrimidin-2-yl)-phenyl]-1 ,2-benzisothiazol-hydrochlorid mit einem Schmelzpunkt von 314°C (Z). Die Ausbeute entspricht 54,6% der Theorie.

26 g 3-(4'-Chlormethylphenyl)-1,2-benzisothiazol, 6,4 g Schwefel und 15 g 1,2-Diaminopropan werden in 400 ml Glykolmonomethyläther 15 Stunden auf 110°C erwärmt. Nach dem Abdestillieren des Lösungsmittels wird der Rückstand in 50 ml Methanol gelöst und unter Kühlen in 400 ml ätherische Salzsäure (15 g HCI in Diäthyläther) eingerührt. Die gebildeten Kristalle werden abgesaugt, in 300 ml Wasser gelöst, filtriert, das Filtrat mit conc. NaOH alkalisch gestellt und mit Methylenchlorid extrahiert. Die Methylenchloridphase wird getrocknet und 20 g Chlorwasserstoffgas eingeleitet. Man erhält 17 g des gewünschten Endstoffs als farblose Kristalle vom Schmelzpunkt 243°C. Die Ausbeute entspricht 52% der Theorie.

44 g 5-Chlor-3-(4'-chlormethylphenyl)-1,2-benzisothiazol, 9,6 g Schwefel und 18,0 g Äthylendiamin werden in 500 ml Toluol 20 Stunden unter Rückfluß gekocht. Das Reaktionsgemisch wird heiß filtriert, das Filtrat abgekühlt und die gebildeten Kristalle werden abgesaugt. Nach dem Umkristallisieren aus Toluol unter Zusatz von Aktivkohle werden 26 g β-Chlor-3-[4-(imidazolin-2-yl)-phenyl]-1,2-benzisothiazol vom Schmelzpunkt 195°C erhalten. Die Ausbeute entspricht 55% der Theorie.

44 g 5-Chlor-3-(4'-chlormethylphenyl)-1,2-benzisothiazol, 9,6 g Schwefel und 22,5 g 1,2-Diaminopropan werden in 600 ml Toluol 24 Stunden unter Rückfluß gekocht. Das Reaktionsgemisch wird heiß filtriert und am Rotationsverdampfer eingeengt. Der Rückstand wird in 500 ml Äther gelöst und 30 g Chlorwasserstoffgas unter Kühlen eingeleitet. Die gebildeten Kristalle werden abgesaugt und aus Wasser umkristallisiert. Man erhält 31 g, Schmelzpunkt 248°C (Z). Die Ausbeute entspricht 57% der Theorie.

Formulierungsbeispiele, die in üblicher Weise hergestellt werdenFormulation examples that are prepared in the usual way

Der Wirkstoff wird mit Polyvinylpyrrolidon in 10%iger wäßriger Lösung befeuchtet, durch ein Sieb mit der lichten Maschenweite 1,0 mm getrieben und bei 50°C getrocknet. Dieses Granulat wird mit Polyäthylenglykol (mittl. M.G. 4000), Hydroxypropylmethylcellulose, Talkum und Magnesiumstearat vermischt und zu Tabletten ä 280 mg verpreßt.The active ingredient is moistened with polyvinylpyrrolidone in 10% strength aqueous solution, passed through a sieve with a mesh size of 1.0 mm and dried at 50.degree. These granules are mixed with polyethylene glycol (average M.G. 4000), hydroxypropylmethyl cellulose, talc and magnesium stearate and pressed into 280 mg tablets.

Die Mischung der Wirkstoffsubstanz mit Lactose und Maisstärke wird mit einer 8%igen wäßrigen Lösung des Polyvinylpyrrolidons durch Sieb 1,5 mm granuliert, bei 50°C getrocknet und nochmals durch Sieb 1,0 mm gerieben. Das so erhaltene Granulat wird mit Magnesiumstearat gemischt und zu Drageekernen verpreßt. Die erhaltenen Drageekerne werden in üblicher Weise mit einer Hülle überzogen, die im wesentlichen aus Zucker und Talkum besteht.The mixture of the active ingredient with lactose and corn starch is granulated with an 8% aqueous solution of the polyvinylpyrrolidone through a 1.5 mm sieve, dried at 50 ° C. and rubbed again through a 1.0 mm sieve. The granules thus obtained are mixed with magnesium stearate and pressed to dragee cores. The dragee cores obtained are coated in a conventional manner with a casing which consists essentially of sugar and talc.

Claims (7)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19772734882 DE2734882A1 (en) | 1977-08-03 | 1977-08-03 | 3-SQUARE BRACKETS ON 4- (1,3-DIAZACYCLOALKEN-2-YL) -PHENYL SQUARE BRACKETS FOR -1,2-BENZISOTHIAZOLS, THE METHOD FOR THEIR MANUFACTURING AND THE MEDICINAL PRODUCTS CONTAINED |

| DE2734882 | 1977-08-03 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0000727A1 EP0000727A1 (en) | 1979-02-21 |

| EP0000727B1 true EP0000727B1 (en) | 1980-08-20 |

Family

ID=6015470

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP78100498A Expired EP0000727B1 (en) | 1977-08-03 | 1978-07-26 | 3-(4-(1,3-diazacycloalkene-2-yl)-phenyl)-1,2-benzisothiazoles, process for their preparation and medicaments containing them. |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US4206217A (en) |

| EP (1) | EP0000727B1 (en) |

| AT (1) | AT364841B (en) |

| DE (2) | DE2734882A1 (en) |

| IT (1) | IT1105391B (en) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| NZ182325A (en) * | 1975-11-18 | 1979-03-16 | Beecham Group Ltd | 2-substituted-1,2-benzisothiazol-3-ones |

| DE2734866A1 (en) * | 1977-08-03 | 1979-02-22 | Basf Ag | NEW 1,2-BENZISOTHIAZOLES AND THE METHOD FOR PRODUCING THEM |

| US4957931A (en) * | 1987-07-08 | 1990-09-18 | Ciba-Geigy Corporation | Certain 1,2-benzisoxazole and 1,2-benzisothiazole derivatives |

| MX2017000996A (en) * | 2016-01-20 | 2017-07-19 | Rehrig Pacific Co | Bakery tray stacker. |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3549624A (en) * | 1967-08-17 | 1970-12-22 | Pfizer & Co C | 2-substituted-2-delta**2-tetrahydropyrimidines and delta**2-im |

| US3557115A (en) * | 1968-11-29 | 1971-01-19 | Sandoz Ag | 2 - (2 - imidazolin and pyrimidin substituted methylthio) - imidazoles and pyrimidines |

| US4147698A (en) * | 1978-07-13 | 1979-04-03 | E. R. Squibb & Sons, Inc. | 3-(Heterocyclicalkylamino)benzisothiazole-1,1-dioxides |

| US4148798A (en) * | 1978-02-03 | 1979-04-10 | E. R. Squibb & Sons, Inc. | [(1,1-dioxo-1,2-benzisothiazol-3-yl)amino]alkanoic acids and esters thereof |

-

1977

- 1977-08-03 DE DE19772734882 patent/DE2734882A1/en not_active Withdrawn

-

1978

- 1978-07-26 DE DE7878100498T patent/DE2860232D1/en not_active Expired

- 1978-07-26 EP EP78100498A patent/EP0000727B1/en not_active Expired

- 1978-07-28 US US05/928,815 patent/US4206217A/en not_active Expired - Lifetime

- 1978-07-31 IT IT50533/78A patent/IT1105391B/en active

- 1978-08-02 AT AT0559778A patent/AT364841B/en not_active IP Right Cessation

Also Published As

| Publication number | Publication date |

|---|---|

| AT364841B (en) | 1981-11-25 |

| DE2734882A1 (en) | 1979-02-22 |

| DE2860232D1 (en) | 1980-12-04 |

| IT7850533A0 (en) | 1978-07-31 |

| US4206217A (en) | 1980-06-03 |

| ATA559778A (en) | 1981-04-15 |

| IT1105391B (en) | 1985-10-28 |

| EP0000727A1 (en) | 1979-02-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2430237C2 (en) | Ethanolamino derivatives and pharmaceutical compositions containing them | |

| AT363096B (en) | METHOD FOR PRODUCING NEW PHTHALAZINE DERIVATIVES AND THEIR SALTS | |

| EP0204269B1 (en) | Pyridine derivatives, their preparation and use | |

| DE2420618C2 (en) | Aminoalkylanilides, processes for their production and pharmaceutical preparations which contain these aminoalkylanilides | |

| EP0101574B1 (en) | 2-substituted 1-aminoalkyl-1,2,3,4-tetrahydro-beta-carbolines, their preparation and use as medicaments | |

| DE2830884C2 (en) | ||

| EP0000727B1 (en) | 3-(4-(1,3-diazacycloalkene-2-yl)-phenyl)-1,2-benzisothiazoles, process for their preparation and medicaments containing them. | |

| EP0018360B1 (en) | N-(5-methoxybenzofuran-2-ylcarbonyl)-n'-benzylpiperazine and process for its preparation | |

| DE3025238A1 (en) | BASIC CYCLOAL CANON OXIMETERS, METHOD FOR THE PRODUCTION THEREOF AND MEDICINAL PRODUCTS CONTAINING THEM | |

| DD153550A5 (en) | PROCESS FOR THE PREPARATION OF NEW 1,2,4-OXADIAZOLIN-5-ON DERIVATIVES | |

| DE1915230B2 (en) | HYDROXYPHENYLALKYLAMINE DERIVATIVES, PROCESS FOR THEIR PRODUCTION AND MEDICINAL PRODUCTS ON THE BASIS OF THEM | |

| DD205682A5 (en) | METHOD OF PREPARING (-) - 2- (1- (2,6-DICHLORPHENOXY) -ETHYL) -1,3-DIAZACYCLOPENT-2-EN AND ITS SALTS | |

| EP0027928B1 (en) | Piperidine derivatives of 4,5-dialkyl-3-hydroxy-pyrrole-2-carboxylic acid esters, their preparation and pharmaceutical compositions containing them | |

| DE2003744C2 (en) | 3-Amino-2-bicyclo [2.2.2] octan-2-ols disubstituted in the 3- and 4-positions, processes for their preparation and pharmaceuticals containing the same | |

| AT389872B (en) | METHOD FOR PRODUCING NEW SUBSTITUTED 2-PHENYLMETHYLENE-1AMINOALKYLOXIMINOCYCLOALCANES AND THEIR ACID ADDITION SALTS | |

| DE2507429A1 (en) | AMINO ACID ESTERS, THE METHOD OF MANUFACTURING THEREOF AND MEDICINAL PRODUCTS CONTAINING THEM | |

| DE2624918A1 (en) | MEDICINAL PRODUCTS WITH ANTIARRHYTHMIC EFFECT | |

| CH630895A5 (en) | METHOD FOR PRODUCING NEW OXIMETHER COMPOUNDS. | |

| EP0000750A1 (en) | 1,2-Benzisothiazoles and process for their preparation | |

| DE2738131A1 (en) | AMINO KETONES, THE METHOD OF MANUFACTURING THEM AND THE MEDICINAL PRODUCTS CONTAINING THEM | |

| CH634828A5 (en) | METHOD FOR PRODUCING NEW OXIMETHER COMPOUNDS. | |

| EP0152556A1 (en) | Aminopropanol derivatives of substituted 2-hydroxy-propiophenones, process for their preparation and therapeutic agents containing them | |

| DE2166270B2 (en) | Nicotinoylaminoethanesulfonyl-2amino-thiazole | |

| DE2530768C3 (en) | PhenoxyaUcylaminpyridyläther, process for their production and pharmaceutical preparations containing them | |

| DE2442158A1 (en) | NEW SUBSTITUTED ANGLE CLAMP ON L- (3,4-METHYLENDIOXYPHENYL) PROPYL (2) ANGLE CLAMP FOR -N'-SUBST. PHENYLPIPERAZINE |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): BE CH DE FR GB NL |

|

| 17P | Request for examination filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): BE CH DE FR GB NL |

|

| REF | Corresponds to: |

Ref document number: 2860232 Country of ref document: DE Date of ref document: 19801204 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19840622 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19840625 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19840627 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19840630 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19860731 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19870727 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Effective date: 19870731 |

|

| BERE | Be: lapsed |

Owner name: BASF A.G. Effective date: 19870731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19880201 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19880331 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee | ||

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19881117 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Effective date: 19890731 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |