CN2731454Y - Probe unit - Google Patents

Probe unit Download PDFInfo

- Publication number

- CN2731454Y CN2731454Y CN 200420079191 CN200420079191U CN2731454Y CN 2731454 Y CN2731454 Y CN 2731454Y CN 200420079191 CN200420079191 CN 200420079191 CN 200420079191 U CN200420079191 U CN 200420079191U CN 2731454 Y CN2731454 Y CN 2731454Y

- Authority

- CN

- China

- Prior art keywords

- tube

- pitot tube

- utility

- model

- head

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Measuring Volume Flow (AREA)

Abstract

A speed probe with a sheathed tube of the utility model relates to the fluid speed measuring field, compising a pitot tube, a central tube, a casing tube, tubules on the side wall, a narrow tube and a differential manometer. The utility model is characterized in that the casing tube is arranged on the head of the pitot tube; on the side of the head, the fluid outside the casing tube is symmetrically connected to the inner chamber of the pitot tube by a plurality of tubules on the side wall. The speed probe with the sheathed tube has the advantages of simple structure, convenient use and low price. The utility model can obtain very high accuracy within certain range under the elaborated design and manufacture and the circumspective calibration and correction.

Description

Affiliated technical field

The measurement of fluid-flow rate is an importance of fluid mechanics experimental technique, and the utility model relates to the rate of flow of fluid fields of measurement, refers in particular to a kind of velocity probe with well, and it can adapt to some rate of flow of fluid Testing requirement.

Technical background

The probe of measurement flow rate commonly used has velocity probe, five-hole probe, seven-hole probe etc. at present.Velocity probe is simple in structure, but requires the measured deviation angle must not be greater than 5 degree in measuring process, otherwise error is very big.Five-hole probe and seven-hole probe allow center pressure tap and fluid flow direction that certain deviation is arranged, but the complex structure of five-hole probe and seven-hole probe is more difficult to their demarcation, and the expense of demarcation is also very expensive.Measurement result generally also needs computing machine to handle in addition.

Summary of the invention

For fear of with overcome above-mentioned deficiency, the purpose of this utility model provides a kind of velocity probe with well, can realize the measurement than the rate of flow of fluid of high attack angle.

The realization the technical solution of the utility model is:

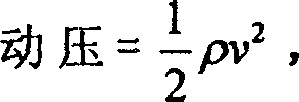

In the rate of flow of fluid measuring technique, flow velocity can draw indirectly by static pressure and the total head of measuring fluid: total head=static pressure+dynamic pressure,

Reading Δ h by differential manometer can calculate the velocity magnitude of incoming flow and is like this

K is a correction factor.

The feature of this device is that the head at Pitot tube (1) adds a sleeve pipe (3), and in the face of several the sidewall tubules of usefulness (4) that claim the inner chamber of the fluid outside the sleeve pipe (3) with Pitot tube (1) being coupled together in head side. differential manometer (7) is connected by the inner chamber of kapillary (6) with Pitot tube (1), and the other end is connected with pipe core (2) by kapillary (5).Pipe core (2) is transferred to differential manometer (7) by kapillary (5) with stagnation pressure like this, and the sidewall tubule is pressed by the inner chamber of Pitot tube (1) static pressure and passed to difference meter (7) via kapillary (6).

Because the scope of attack angle alpha with

Relevant.When

The time, α=± 40 °.Thereby increased the scope that liquid flows insensitive attack angle alpha.

The utility model has the advantages that simple in structure, easy to use, cheap.As long as well-designed manufacturing, the careful demarcation and correction can reach very high precision within the specific limits.

Description of drawings

The utility model is described in further detail below in conjunction with drawings and Examples.

Fig. 1 is the utility model structural representation

As shown in the figure, number in the figure is represented respectively: 1. Pitot tube 2. pipe cores 3. sleeve pipes 4. sidewall tubules 5. kapillaries 6. kapillaries 7. differential manometers.

Embodiment

The structure of probe is:

As shown in the figure, head at Pitot tube (1) adds a sleeve pipe (3), and use several sidewall tubules (4) that the inner chamber of the external world of sleeve pipe (3) and Pitot tube (1) is coupled together symmetrically in the sleeve pipe side, and pipe core (2) is contained in the inner chamber of Pitot tube (1), and two pipes are not connected.Differential manometer (7) is connected with the inner chamber of Pitot tube (1) by kapillary (6), and the other end is connected with pipe core (2) by kapillary (5).Pipe is transferred to differential manometer (7) with stagnation pressure like this, and the sidewall tubule is given differential manometer (7) with Hydrostatic Transfer Device.

During use, probe is faced toward to come flow path direction, the static pressure of measured like this point and total head will pass to differential manometer, read pressure differential deltap h from differential manometer, and then draw speed of incoming flow.

Claims (1)

1, a kind of velocity probe with well, it comprises: Pitot tube (1), pipe core (2), kapillary (5), kapillary (6), differential manometer (7), it is characterized in that adding a sleeve pipe (3) at the head of Pitot tube (1), and the inner chamber of fluid sleeve pipe (3) outside and Pitot tube (1) is coupled together in the face of several the sidewall tubules of usefulness (4) that claim in head side, differential manometer (7) passes through kapillary (6) and is connected with the inner chamber of Pitot tube (1), and the other end is connected with pipe core (2) by kapillary (5).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN 200420079191 CN2731454Y (en) | 2004-09-03 | 2004-09-03 | Probe unit |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN 200420079191 CN2731454Y (en) | 2004-09-03 | 2004-09-03 | Probe unit |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN2731454Y true CN2731454Y (en) | 2005-10-05 |

Family

ID=35051787

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN 200420079191 Expired - Fee Related CN2731454Y (en) | 2004-09-03 | 2004-09-03 | Probe unit |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN2731454Y (en) |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103245794A (en) * | 2013-05-24 | 2013-08-14 | 哈尔滨工业大学 | Five-hole dual-tube anemometer and wind metering method thereof |

| CN105259365A (en) * | 2015-11-16 | 2016-01-20 | 深圳飞马机器人科技有限公司 | Airspeed meter module |

| CN106404083A (en) * | 2016-12-08 | 2017-02-15 | 贵州大学 | Pitot tube device suitable for ventilation experiment |

| CN106768170A (en) * | 2016-12-28 | 2017-05-31 | 中国科学院上海应用物理研究所 | The fluid parameter measurement apparatus of high-temperature electric conduction liquid, method |

| CN110470859A (en) * | 2019-09-24 | 2019-11-19 | 西北工业大学 | A method of for the direction tachometric survey of air system interior air-flow |

-

2004

- 2004-09-03 CN CN 200420079191 patent/CN2731454Y/en not_active Expired - Fee Related

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103245794A (en) * | 2013-05-24 | 2013-08-14 | 哈尔滨工业大学 | Five-hole dual-tube anemometer and wind metering method thereof |

| CN103245794B (en) * | 2013-05-24 | 2014-12-10 | 哈尔滨工业大学 | Five-hole dual-tube anemometer and wind metering method thereof |

| CN105259365A (en) * | 2015-11-16 | 2016-01-20 | 深圳飞马机器人科技有限公司 | Airspeed meter module |

| CN106404083A (en) * | 2016-12-08 | 2017-02-15 | 贵州大学 | Pitot tube device suitable for ventilation experiment |

| CN106768170A (en) * | 2016-12-28 | 2017-05-31 | 中国科学院上海应用物理研究所 | The fluid parameter measurement apparatus of high-temperature electric conduction liquid, method |

| CN110470859A (en) * | 2019-09-24 | 2019-11-19 | 西北工业大学 | A method of for the direction tachometric survey of air system interior air-flow |

| CN110470859B (en) * | 2019-09-24 | 2021-04-20 | 西北工业大学 | Method for measuring direction and speed of airflow in air system |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN101354273B (en) | Method and device for measuring compound type gas flow | |

| US3678754A (en) | Flow measuring device | |

| CN109738030B (en) | Pressure potential difference type laminar flow measuring method and device | |

| CN210741584U (en) | Wet gas flow metering device | |

| CN205691278U (en) | Removable multifunctional pressure-measuring pipe | |

| CN210293314U (en) | Necking type precession vortex flowmeter | |

| CN2731454Y (en) | Probe unit | |

| CN201034644Y (en) | Annular pressure sampling type V awl flow rate sensor | |

| CN2919198Y (en) | V shaped wimble flowmeter | |

| CN201007662Y (en) | Wenke conical flowmeter | |

| CN202562533U (en) | A gas flow measuring device metering from zero | |

| CN201262559Y (en) | Plug-in flow measuring device based on MEMS sensor | |

| CN116337167A (en) | Double-bent-tube flow pressure measuring structure and method thereof | |

| CN2736778Y (en) | Speed probe with sheathed tube | |

| CN2492837Y (en) | Pointer-type pipe fluid flowmeter | |

| CN210625738U (en) | Strain sensing type water metering device based on micro-cantilever beam | |

| CN201083757Y (en) | Flow speed measuring device | |

| CN111504399A (en) | Ultrasonic V-cone flowmeter | |

| CN203772325U (en) | Integral pore plate flowmeter | |

| CN104280076A (en) | High-precision large-diameter vortex flowmeter | |

| CN204202658U (en) | One possesses caliber high-precision flowmeter | |

| CN2554602Y (en) | Constant differential pressure flowmeter | |

| CN201527285U (en) | High-pressure gas-liquid phase flow measuring device | |

| CN1028560C (en) | Pressure-measuring probe | |

| CN2433617Y (en) | High precision fluid density on-line measuring apparatus |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C19 | Lapse of patent right due to non-payment of the annual fee | ||

| CF01 | Termination of patent right due to non-payment of annual fee |