CN219230844U - Glass fiber reinforced plastic assembled overground disinfection equipment - Google Patents

Glass fiber reinforced plastic assembled overground disinfection equipment Download PDFInfo

- Publication number

- CN219230844U CN219230844U CN202223386388.2U CN202223386388U CN219230844U CN 219230844 U CN219230844 U CN 219230844U CN 202223386388 U CN202223386388 U CN 202223386388U CN 219230844 U CN219230844 U CN 219230844U

- Authority

- CN

- China

- Prior art keywords

- disinfection

- glass fiber

- fiber reinforced

- reinforced plastic

- suction pipe

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Abstract

The utility model provides glass fiber reinforced plastic assembled ground disinfection equipment, which comprises a base, glass fiber reinforced plastic, a cover plate, a pushing handle, a right liquid adding port, a left liquid adding port, a universal wheel, a motor, a steel pipe, a rotary joint, a left liquid suction pipe, a right liquid suction pipe, a sieve bucket, a disinfection device and a disinfection nozzle; in the utility model, the right liquid adding port and the left liquid adding port are used for adding disinfection and liquid, so that the use is more convenient, and the right liquid adding port and the left liquid adding port are provided with the air inlets, so that the device has more practicability; the disinfection device is matched with the steel pipe, the added disinfection liquid is sucked through the left side liquid suction pipe and the right side liquid suction pipe, the steel pipe reaches the inside of the steel pipe through the rotary joint, the steel pipe is connected with the disinfection device, the disinfection device sprays the atomized disinfection liquid onto the ground through a plurality of disinfection nozzles, the disinfection effect is achieved, the damage to the human body is reduced, and the use of equipment is wider; through the setting of universal wheel, the user can be convenient remove through promoting the pushing hands, facilitates the use.

Description

Technical Field

The utility model belongs to the technical field of disinfection equipment, and particularly relates to glass fiber reinforced plastic assembled ground disinfection equipment.

Background

Ultraviolet disinfection is a sterilization and disinfection method utilizing the sterilization effect of ultraviolet rays. Currently, ultraviolet sterilizing lamps are mainly used in three aspects, the first aspect is used for surface sterilization in the fields of food, electronics, semiconductors, liquid crystal displays, plasma televisions, crystal vibrators, precision devices, chemical industry, medicine, health care, biology, beverages, agriculture, clothing, etc.; the second aspect is for submerged sterilization in a water treatment process; the third aspect is for air sterilization in medical environmental sanitation.

Along with the continuous improvement of living standard, ultraviolet disinfection also gradually enters our clothing and food residence, especially the application in the aspect of indoor disinfection is continuously improved, and bacteria, viruses and the like carried in the room can be killed by irradiation of an ultraviolet disinfection lamp on ultraviolet disinfection equipment for about 5min, so that the disinfection and sterilization effect is realized.

When the prior ultraviolet disinfection equipment has relatively large damage to eyes of people, people usually need to go outdoors, wait and have extremely inconvenience when disinfecting and sterilizing, and the disinfection and sterilization effect of ultraviolet disinfection is relatively weak, so that the glass fiber reinforced plastic assembled type overground disinfection equipment is needed.

Disclosure of Invention

In order to solve the technical problems, the utility model provides glass fiber reinforced plastic assembled ground disinfection equipment, which comprises a base, glass fiber reinforced plastic, a cover plate, a pushing handle, a right side liquid adding port, a left side liquid adding port, a universal wheel, a motor, a steel pipe, a rotary joint, a left side liquid suction pipe, a right side liquid suction pipe, a sieve bucket, a disinfection device and a disinfection nozzle, wherein a plurality of glass fiber reinforced plastic are fixedly arranged at the upper end of the base, and the glass fiber reinforced plastic is connected through welding; the base is connected with a plurality of glass fiber reinforced plastics through welding; and one end of the plurality of glass fiber reinforced plastics, which is far away from the base, is provided with a cover plate through welding.

Preferably, a connecting frame is fixedly arranged on one side of the base, and a pushing handle is fixedly arranged at one end, far away from the base, of the connecting frame; the universal wheels are arranged in four, and the four universal wheels are fixedly arranged at four corners of the lower end of the base.

Preferably, the inner sides of the glass fiber reinforced plastics are fixedly provided with the partition plates through welding; a right liquid adding port is fixedly arranged on one side of the glass fiber reinforced plastic; and a left liquid adding port is fixedly arranged on one side of the glass fiber reinforced plastic, which is far away from the right liquid adding port.

Preferably, a bracket is fixedly arranged at the upper end of the partition plate; a motor is fixedly arranged at the upper end of the bracket; the upper end of the motor is connected with the steel pipe in a matched mode.

Preferably, a rotary joint is fixedly arranged at one third of the steel pipe; a left liquid suction pipe is fixedly arranged on one side of the rotary joint, and a right liquid suction pipe is fixedly arranged on one side of the rotary joint, which is far away from the left liquid suction pipe; the screen hoppers are fixedly arranged at one ends of the left side liquid suction pipe and the right side liquid suction pipe, which are far away from the rotary joint; the steel pipe penetrates through the cover plate and is connected with the disinfection device; the sterilizing device is arranged on the upper side of the cover plate; a plurality of disinfection nozzles are arranged around the disinfection device.

Compared with the prior art, the utility model has the following beneficial effects:

1. when the disinfection and liquid adding device is used, disinfection and liquid are added through the right liquid adding port and the left liquid adding port, so that the disinfection and liquid adding device is more convenient to use, and the air inlets are arranged at the right liquid adding port and the left liquid adding port, so that the disinfection and liquid adding device has more practicability.

2. According to the utility model, the disinfection device is matched with the steel pipe, the added disinfection liquid is sucked through the left side liquid suction pipe and the right side liquid suction pipe, and reaches the inside of the steel pipe through the rotary joint, the steel pipe is connected with the disinfection device, the disinfection device sprays the atomized disinfection liquid onto the ground through a plurality of disinfection nozzles, so that the disinfection effect is achieved, the injury to human bodies is reduced, and the use of equipment is wider.

3. According to the utility model, through the arrangement of the universal wheels, a user can conveniently move by pushing the pushing hands, so that the equipment is convenient to use.

Drawings

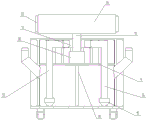

Fig. 1 is a schematic plan view of the present utility model.

Fig. 2 is a left side view of fig. 1 in the present utility model.

Fig. 3 is a schematic view of the inside structure of the present utility model.

In the figure:

the device comprises a base, 2-glass fiber reinforced plastic, a 3-cover plate, a 4-connecting frame, a 5-pushing handle, a 6-right side liquid filling opening, a 7-left side liquid filling opening, 8-universal wheels, a 9-bracket, a 10-motor, 11-steel pipes, 12-rotary joints, 13-left side liquid suction pipes, 14-right side liquid suction pipes, 15-sieve hoppers, 16-sterilizing devices, 17-sterilizing nozzles and 18-partition plates.

Detailed Description

The utility model is further described below with reference to the accompanying drawings:

examples:

as shown in fig. 1 to 3

The utility model provides glass fiber reinforced plastic assembled ground disinfection equipment, which comprises a base 1, glass fiber reinforced plastic 2, a cover plate 3, a pushing handle 5, a right liquid adding port 6, a left liquid adding port 7, a universal wheel 8, a motor 10, a steel pipe 11, a rotary joint 12, a left liquid suction pipe 13, a right liquid suction pipe 14, a sieve bucket 15, a disinfection device 16 and a disinfection nozzle 17, wherein a plurality of glass fiber reinforced plastic 2 are fixedly arranged at the upper end of the base 1, and the glass fiber reinforced plastic 2 are connected through welding; the base 1 is connected with a plurality of glass fiber reinforced plastics 2 through welding; and one end, far away from the base 1, of the plurality of glass fiber reinforced plastics 2 is provided with a cover plate 3 by welding.

In this embodiment, a connecting frame 4 is fixedly installed on one side of the base 1, and a pushing handle 5 is fixedly installed on one end of the connecting frame 4 away from the base 1; the four universal wheels 8 are arranged, and the four universal wheels 8 are fixedly arranged at four corners of the lower end of the base 1; through the setting of universal wheel 8, the user can be convenient through promoting the removal of pushing hands 5, makes things convenient for the use of equipment.

In this embodiment, the inner sides of the glass reinforced plastics 2 are fixedly provided with the partition plates 18 by welding; a right liquid adding port 6 is fixedly arranged on one side of the glass fiber reinforced plastic 2; one side fixed mounting that glass steel 2 kept away from right side liquid filling port 6 have left side liquid filling port 7, constitute by a plurality of welds through glass steel 2, its structure is simpler, and it is more convenient to install, low in manufacturing cost, will disinfect and liquid add through right side liquid filling port 6 and left side liquid filling port 7, more facilitate the use, and right side liquid filling port 6 and left side liquid filling port 7 department are provided with the air inlet for equipment more has the practicality.

In the embodiment, the upper end of the partition 18 is fixedly provided with a bracket 9; a motor 10 is fixedly arranged at the upper end of the bracket 9; the upper end of the motor 10 is connected with a steel pipe 11 in a matching way; a rotary joint 12 is fixedly arranged at one third of the steel pipe 11; a left liquid suction pipe 13 is fixedly arranged on one side of the rotary joint 12, and a right liquid suction pipe 14 is fixedly arranged on one side of the rotary joint 12 away from the left liquid suction pipe 13; the screen bucket 15 is fixedly arranged at one end of the left side liquid suction pipe 13 and one end of the right side liquid suction pipe 14, which are far away from the rotary joint 12; the steel pipe 11 passes through the cover plate 3 and is connected with the sterilizing device 16; the sterilizing device 16 is arranged on the upper side of the cover plate 3; a plurality of disinfection nozzles 17 are arranged around the disinfection device 16; through degassing unit 16 cooperation steel pipe 11, the disinfection liquid that will add is inhaled through left side pipette 13 and right side pipette 14, reaches in the steel pipe 11 through rotary joint 12, and the steel pipe is connected with degassing unit 16, and degassing unit 16 spouts the disinfection liquid of atomizing to the ground through a plurality of disinfection spouts 17, reaches sterile effect, and reduces the injury jealoy to the human body for the use of equipment is more extensive.

Principle of operation

In the utility model, when in use, disinfection and liquid are added through the right liquid adding port 6 and the left liquid adding port 7, so that the use is more convenient, and the positions of the right liquid adding port 6 and the left liquid adding port 7 are provided with air inlets, so that the device has more practicability; the disinfection device 16 is matched with the steel pipe 11, the added disinfection liquid is sucked through the left side liquid suction pipe 13 and the right side liquid suction pipe 14, and reaches the inside of the steel pipe 11 through the rotary joint 12, the steel pipe is connected with the disinfection device 16, the disinfection device 16 sprays the atomized disinfection liquid to the ground through a plurality of disinfection nozzles 17, the disinfection effect is achieved, the damage to the human body is reduced, and the equipment is widely used; through the setting of universal wheel 8, the user can be convenient through promoting the removal of pushing hands 5, makes things convenient for the use of equipment.

By utilizing the technical scheme of the utility model or under the inspired by the technical scheme of the utility model, a similar technical scheme is designed by a person skilled in the art, so that the technical effects are achieved, and the technical scheme falls into the protection scope of the utility model.

Claims (5)

1. Glass fiber reinforced plastic assembled ground disinfection equipment is characterized in that: the device comprises a base (1), glass fiber reinforced plastic (2), a cover plate (3), a pushing handle (5), a right side liquid adding opening (6), a left side liquid adding opening (7), a universal wheel (8), a motor (10), a steel pipe (11), a rotary joint (12), a left side liquid suction pipe (13), a right side liquid suction pipe (14), a sieve bucket (15), a sterilizing device (16) and a sterilizing nozzle (17), wherein a plurality of glass fiber reinforced plastic (2) are fixedly arranged at the upper end of the base (1), and the glass fiber reinforced plastic (2) are connected through welding; the base (1) is connected with a plurality of glass fiber reinforced plastics (2) through welding; one end of the plurality of glass fiber reinforced plastics (2) far away from the base (1) is provided with a cover plate (3) through welding.

2. A glass fiber reinforced plastic assembled ground disinfection apparatus as defined in claim 1, wherein: one side of the base (1) is fixedly provided with a connecting frame (4), and one end of the connecting frame (4) far away from the base (1) is fixedly provided with a pushing handle (5); the four universal wheels (8) are arranged, and the four universal wheels (8) are fixedly arranged at four corners of the lower end of the base (1).

3. A glass fiber reinforced plastic assembled ground disinfection apparatus as defined in claim 1, wherein: the inner sides of the glass fiber reinforced plastics (2) are fixedly provided with partition plates (18) through welding; a right liquid adding port (6) is fixedly arranged at one side of the glass fiber reinforced plastic (2); the glass fiber reinforced plastic (2) is fixedly provided with a left liquid adding port (7) at one side far away from the right liquid adding port (6).

4. A glass fiber reinforced plastic assembled ground disinfection apparatus as claimed in claim 3, wherein: a bracket (9) is fixedly arranged at the upper end of the partition plate (18); a motor (10) is fixedly arranged at the upper end of the bracket (9); the upper end of the motor (10) is connected with the steel pipe (11) in a matching way.

5. A glass fiber reinforced plastic assembled ground disinfection apparatus as defined in claim 4, wherein: a rotary joint (12) is fixedly arranged at one third of the steel pipe (11); a left liquid suction pipe (13) is fixedly arranged on one side of the rotary joint (12), and a right liquid suction pipe (14) is fixedly arranged on one side, far away from the left liquid suction pipe (13), of the rotary joint (12); one end of the left side liquid suction pipe (13) and one end of the right side liquid suction pipe (14) far away from the rotary joint (12) are fixedly provided with a sieve bucket (15); the steel pipe (11) passes through the cover plate (3) to be connected with the disinfection device (16); the disinfection device (16) is arranged on the upper side of the cover plate (3); a plurality of disinfection nozzles (17) are arranged around the disinfection device (16).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202223386388.2U CN219230844U (en) | 2022-12-14 | 2022-12-14 | Glass fiber reinforced plastic assembled overground disinfection equipment |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202223386388.2U CN219230844U (en) | 2022-12-14 | 2022-12-14 | Glass fiber reinforced plastic assembled overground disinfection equipment |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN219230844U true CN219230844U (en) | 2023-06-23 |

Family

ID=86839478

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202223386388.2U Active CN219230844U (en) | 2022-12-14 | 2022-12-14 | Glass fiber reinforced plastic assembled overground disinfection equipment |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN219230844U (en) |

-

2022

- 2022-12-14 CN CN202223386388.2U patent/CN219230844U/en active Active

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN202665701U (en) | Multifunctional debridement and sterilization trolley | |

| CN203841959U (en) | Multifunctional treatment cart for internal medicine | |

| CN219230844U (en) | Glass fiber reinforced plastic assembled overground disinfection equipment | |

| CN210384301U (en) | Nursing medical instrument places support | |

| CN213251547U (en) | Epidemic prevention spray disinfection machine | |

| CN215504560U (en) | Spraying and disinfecting device for nursing in operating room | |

| CN212913390U (en) | Medical internal medicine utensil cleaning and disinfection places structure with apparatus | |

| CN214718867U (en) | Cleaning and sterilizing device for medical instruments of obstetrics and gynecology department | |

| CN215536886U (en) | Public health is with disinfection car that has response shower nozzle | |

| CN210754011U (en) | Cleaning and sterilizing device for nursing instruments in supply room | |

| CN212662273U (en) | Medical instrument disinfecting equipment with classifying and disinfecting functions | |

| CN213219023U (en) | A fumigation and washing device for upper limbs function is recovered | |

| CN114543250A (en) | Disinfection and killing robot | |

| CN106215312B (en) | Automatic auxiliary treatment device | |

| CN219558146U (en) | Disinfectant water sprayer | |

| CN206228765U (en) | Automatic adjuvant therapy device | |

| CN220860424U (en) | Sterilizer for infectious diseases | |

| CN215022980U (en) | Infection nursing degassing unit | |

| CN109077329A (en) | A kind of efficient fruits and vegetables purification device | |

| CN210631520U (en) | Clinical degassing unit of diversified internal medicine | |

| CN213251633U (en) | Cleaning and sterilizing device for public places | |

| CN211535801U (en) | ICU medical staff disinfection nursing device | |

| CN217525866U (en) | Portable disinfection and sterilization equipment for hospital | |

| CN205252111U (en) | Tuberculosis prevention and cure degassing unit | |

| CN204972681U (en) | Skin disinfection device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |