CN217051857U - Landfill leachate purifier - Google Patents

Landfill leachate purifier Download PDFInfo

- Publication number

- CN217051857U CN217051857U CN202220413326.7U CN202220413326U CN217051857U CN 217051857 U CN217051857 U CN 217051857U CN 202220413326 U CN202220413326 U CN 202220413326U CN 217051857 U CN217051857 U CN 217051857U

- Authority

- CN

- China

- Prior art keywords

- garbage

- component

- sieve plate

- wall

- pressurizing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Processing Of Solid Wastes (AREA)

Abstract

The utility model discloses a garbage leachate purifying device, which comprises a garbage can body, a supporting component, a filtering component, a disinfecting component, a purifying component and a pressurizing component, wherein a feeding port is arranged at the top of the garbage can body, the supporting component is arranged at the bottom of the garbage can body, the filtering component is arranged inside the garbage can body, the garbage can pressurize solid garbage, the solid garbage can be extruded into blocks to be centralized, the solid garbage can be prevented from blocking a sieve plate, the filtering effect of the sieve plate is ensured, meanwhile, the solid garbage can be automatically cleaned through the reciprocating motion of the sieve plate, the manual cleaning of a user is not needed, the working strength of the user is reduced, meanwhile, liquid can be filtered for many times, the garbage leachate can be fully purified, the pollution to the environment is avoided, the corrosion to the device is avoided, the resource utilization rate is greatly improved, the work efficiency of purifier is improved, user's user demand can be effectively satisfied.

Description

Technical Field

The utility model relates to a landfill leachate purifies technical field, specifically is a landfill leachate purifier.

Background

The landfill leachate has complex water quality and contains various toxic and harmful inorganic and organic substances, and the landfill leachate also contains non-chlorinated aromatic compounds such as naphthalene, phenanthrene and the like, chlorinated aromatic compounds, phosphoric acid vinegar, phenolic compounds, aniline compounds and the like which are difficult to biodegrade.

Disclose a landfill leachate purifier in utility model that bulletin number is CN212315785U, the device is provided with leakage plate and first honeycomb duct, and cooperation filter tube and water pipe make the device can purify landfill leachate, through antiseptic solution and atomizing gondola water faucet, make the device cleaning and disinfecting.

But the seepage board that sets up among the above-mentioned device can't shake, blocks up the seepage board easily when rubbish is dropped into purifier to influence the filter effect of seepage board, these accumulational rubbish fall on the seepage board and still need the manual work to clear up, have strengthened user's intensity of labour, and then have reduced purifier's work efficiency, can't satisfy user's user demand.

Therefore, we propose a landfill leachate purification device.

SUMMERY OF THE UTILITY MODEL

An object of the utility model is to provide a landfill leachate purifier to solve the problem that proposes in the above-mentioned background art.

In order to achieve the above purpose, the utility model provides a following technical scheme:

a garbage leachate purification device comprises a garbage can body, a supporting component, a filtering component, a disinfecting component, a purification component and a pressurizing component, wherein a feeding port is formed in the top of the garbage can body, the supporting component is arranged at the bottom of the garbage can body, the filtering component is arranged inside the garbage can body, the disinfecting component is arranged below the filtering component, the bottom of the disinfecting component is communicated with the top of a second hopper, the bottom of the second hopper is communicated with the top of the purification component, an L-shaped feeding pipe is arranged on the left side of the garbage can body, and one end of the L-shaped feeding pipe extends into the garbage can body and is positioned above the disinfecting component;

the filter assembly is used for filtering impurities in garbage and comprises a sieve plate obliquely arranged in a garbage can body, one end of the sieve plate is rotatably connected with one side of an installation seat, one side, away from the sieve plate, of the installation seat is slidably connected with the left side of the inner wall of the garbage can body through a guide assembly, the rear side of the sieve plate is connected with one end of a connecting rod, one end, away from the sieve plate, of the connecting rod penetrates through the garbage can body and extends to the outside of the garbage can body to be connected with an installation disc, an opening for accommodating the connecting rod to move up and down is formed in the garbage can body, a power assembly for driving the sieve plate to reciprocate is arranged below the installation disc, one end, away from the installation seat, of the sieve plate penetrates through a through groove and extends to the inside of a pressurizing shell, the through groove is formed in the right side of the garbage can body, and the pressurizing shell is internally provided with a pressurizing assembly;

the pressurizing assembly is used for automatically cleaning garbage blocked on the sieve plate and comprises a pressurizing machine arranged on the top of the inner wall of a pressurizing shell, the output end of the pressurizing machine is connected with the top of a pressure plate, and a sealing door is movably arranged at the bottom of the pressurizing shell;

the disinfection component is used for sterilizing the landfill leachate and comprises a mixing drum arranged below the inner part of a garbage can body, a rotating shaft is transversely arranged in the mixing drum, a plurality of stirring rods are arranged on two sides of the rotating shaft at equal intervals, one end of the rotating shaft is rotatably connected with one side of the inner wall of the mixing drum, the other end of the rotating shaft penetrates through the mixing drum and the garbage can body and is connected with the output end of a second motor arranged on the outer wall of the garbage can body, a silencing shell is arranged outside the second motor and is connected with one side of the garbage can body;

purify the subassembly for filter landfill leachate, including setting up the purifying box in garbage bin body inner wall bottom, the purifying box is inside from last to being equipped with first activated carbon plate, second activated carbon plate and third activated carbon plate down in proper order, purifying box bottom center and discharging pipe top intercommunication, and the discharging pipe bottom runs through the garbage bin body and extends to its below.

As a further aspect of the present invention: the top of the inner wall of the garbage can body is provided with a first hopper, and the top of the first hopper is communicated with the bottom of the feeding port.

As a further aspect of the present invention: the supporting assembly comprises supporting legs, the tops of the supporting legs are connected with four corners of the bottom of the garbage can body, and the bottoms of the supporting legs are connected with the tops of the stabilizing seats.

As a further aspect of the present invention: the guide assembly comprises a mounting groove arranged on the left side of the inner wall of the garbage can body, a sliding rod is arranged inside the mounting groove, a sliding sleeve is arranged outside the sliding rod, and one side of the sliding sleeve is connected with one side of the mounting seat far away from the sieve plate.

As a further aspect of the present invention: the outer wall of the sliding rod is wound with a return spring, the top of the return spring is connected with the bottom of the sliding sleeve, and the bottom of the return spring is connected with the bottom of the inner wall of the mounting groove.

As a further aspect of the present invention: the power assembly comprises a first motor fixed on one side of the outer wall of the garbage can body, the output end of the first motor is connected with one side of the cam, and the top of the cam is attached to the bottom of the mounting disc.

As a further aspect of the present invention: a liquid inlet is formed in the top of the mixing cylinder, a liquid outlet is formed in the bottom of the mixing cylinder, and an electromagnetic valve for controlling the flowing speed of liquid is arranged in the second hopper.

Compared with the prior art, the beneficial effects of the utility model are that:

1. the utility model discloses the during operation, the user starts first motor, first motor drives the cam and rotates, when the cam rotates a week, through the connecting rod, the sieve, the slide bar, the cooperation of sliding sleeve and mount pad can drive the sieve and shake from top to bottom, be convenient for carry the solid waste to the pressurization shell inside along the sieve that the slope set up, start the presser after that, the presser drives the clamp plate and pressurizes solid waste, be convenient for extrude solid waste into the piece and carry out centralized processing, can avoid solid waste to block up the sieve, the filter effect of sieve has been guaranteed, carry out automatic clearance to solid waste through the reciprocating motion of sieve simultaneously, need not the manual clearance of user, user's working strength has been reduced.

2. The utility model discloses the inside first activated carbon board of purifying box, second activated carbon board and the third activated carbon board that set up can carry out a lot of to liquid and filter, can make landfill leachate obtain abundant purification, avoid causing the pollution to the environment, avoid causing the corruption to the device, have promoted resource utilization greatly, have improved purifier's work efficiency, can effectively satisfy user's user demand.

Drawings

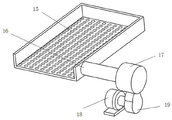

Fig. 1 is a three-dimensional view of the present invention.

Fig. 2 is a rear three-dimensional view of the present invention.

Fig. 3 is a schematic structural diagram of the present invention.

Fig. 4 is a schematic structural view of the middle sieve plate of the present invention.

Fig. 5 is a schematic structural view of the mixing drum of the present invention.

Wherein: 11-a garbage can body; 110-a feed opening; 111-through slots; a 112-L shaped feed tube; 12-a first hopper; 13-a slide bar; 130-a sliding sleeve; 14-a mounting seat; 15-sieve plate; 16-a connecting rod; 17-mounting a disc; 18-a first electric machine; 19-a cam; 20-a mixing drum; 200-liquid inlet; 201-a liquid outlet; 21-a second motor; 22-a rotating shaft; 23-a stirring rod; 24-a second hopper; 30-a purification box; 31-a first activated carbon plate; 32-a second activated carbon plate; 33-a third activated carbon plate; 34-a discharge pipe; 40-supporting legs; 50-pressing the shell; 51-pressing machine.

Detailed Description

Example 1

Referring to fig. 1-5, in an embodiment of the present invention, a garbage leachate purifying device includes a garbage can body 11, a supporting component, a filtering component, a disinfecting component, a purifying component and a pressurizing component, the present invention improves the work efficiency of the purifying device, and can effectively meet the use requirements of users, a feeding opening 110 is disposed at the top of the garbage can body 11, the supporting component is disposed at the bottom of the garbage can body 11, the filtering component is disposed inside the garbage can body 11, the disinfecting component is disposed below the filtering component, the bottom of the disinfecting component is communicated with the top of the second hopper 24, the bottom of the second hopper 24 is communicated with the top of the purifying component, an "L" -shaped feeding pipe 112 is disposed at the left side of the garbage can body 11, and one end of the "L" -shaped feeding pipe 112 extends to the inside of the garbage can body 11 and is located above the disinfecting component;

the filtering component is used for filtering impurities in garbage and comprises a sieve plate 15 which is obliquely arranged inside a garbage can body 11, one end of the sieve plate 15 is rotatably connected with one side of a mounting seat 14, one side, far away from the sieve plate 15, of the mounting seat 14 is in sliding connection with the left side of the inner wall of the garbage can body 11 through a guide component, the rear side of the sieve plate 15 is connected with one end of a connecting rod 16, one end, far away from the sieve plate 15, of the connecting rod 16 penetrates through the garbage can body 11 and extends to the outside of the garbage can body to be connected with a mounting disc 17, an opening for accommodating the connecting rod 16 to move up and down is formed in the garbage can body 11, a power component for driving the sieve plate 15 to move in a reciprocating mode is arranged below the mounting disc 17 and comprises a first motor 18 fixed on one side of the outer wall of the garbage can body 11, the output end of the first motor 18 is connected with one side of a cam 19, the top of the cam 19 is attached to the bottom of the mounting disc 17, one end, far away from the mounting seat 14, of the sieve plate 15 penetrates through a through groove 111 and extends to the inside a pressurizing shell 50, the through groove 111 is formed in the right side of the garbage can body 11, and a pressurizing assembly is arranged inside the pressurizing shell 50;

inside the user drops into garbage bin body 11 with rubbish from dog-house 110, the sieve 15 of setting can carry out solid-liquid separation to rubbish, the rubbish of solid is stayed at sieve 15 top, the penetrant passes through sieve 15 and flows downwards, in order to avoid solid rubbish to block up sieve 15, the user starts first motor 18, first motor 18 drives cam 19 and rotates, when cam 19 rotates one week, can drive sieve 15 vibrations from top to bottom through the cooperation of connecting rod 16, sieve 15, slide bar 13, sliding sleeve 130 and mount pad 14, be convenient for carry solid rubbish to the pressurization shell 50 inside along the sieve 15 of slope setting.

The pressurizing assembly is used for automatically cleaning garbage blocked on the sieve plate 15 and comprises a pressurizing machine 51 arranged at the top of the inner wall of a pressurizing shell 50, the output end of the pressurizing machine 51 is connected with the top of a pressing plate, the pressurizing machine 51 is started, the pressurizing machine 51 drives the pressing plate to pressurize the solid garbage, the solid garbage is conveniently extruded into blocks to be centrally treated, manual cleaning by a user is not needed, the working strength of the user is reduced, a sealing door is movably arranged at the bottom of the pressurizing shell 50, a handle for the user to rapidly open and close the sealing door is arranged on the sealing door, and the handle is convenient for opening the pressurizing shell 50 so as to treat formed solid garbage blocks;

the disinfection component is used for sterilizing the landfill leachate and comprises a mixing drum 20 arranged below the inner part of the garbage can body 11, a rotating shaft 22 is transversely arranged inside the mixing drum 20, a plurality of stirring rods 23 are equidistantly arranged on two sides of the rotating shaft 22, one end of the rotating shaft 22 is rotatably connected with one side of the inner wall of the mixing drum 20, the other end of the rotating shaft 22 penetrates through the mixing drum 20 and the garbage can body 11 and is connected with the output end of a second motor 21 arranged on the outer wall of the garbage can body 11, a silencing shell 210 is arranged outside the second motor 21, and the silencing shell 210 is connected with one side of the garbage can body 11;

purify the subassembly for filter landfill leachate, including setting up the purifying box 30 in 11 inner wall bottoms of garbage bin body, purifying box 30 is inside from last to being equipped with first activated carbon plate 31, second activated carbon plate 32 and third activated carbon plate 33 down in proper order, purifying box 30 bottom center and discharging pipe 34 top intercommunication, and discharging pipe 34 bottom runs through garbage bin body 11 and extends to its below.

Inside leachate through solid-liquid separation gets into mixing drum 20, user's accessible "L" type filling tube 112 pours into the antiseptic solution into mixing drum 20 inside, and start second motor 21, second motor 21 drives pivot 22 and rotates, the puddler 23 of setting in pivot 22 both sides can carry out abundant mixture with leachate and antiseptic solution, be convenient for carry out effectual disinfection of disinfecting to landfill leachate, liquid through preliminary purification gets into inside purifying box 30 along second hopper 24, the inside first active carbon plate 31 of purifying box 30 that sets up, second active carbon plate 32 and third active carbon plate 33 can filter liquid many times, can make landfill leachate obtain fully purified, avoid causing the pollution to the environment, avoid causing the corruption to the device, resource utilization has been promoted greatly, liquid after the purification can discharge along discharging pipe 34.

The top of the inner wall of the garbage can body 11 is provided with a first hopper 12, the top of the first hopper 12 is communicated with the bottom of the feeding port 110, and the arranged first hopper 12 is convenient for guiding garbage onto the sieve plate 15.

The supporting component comprises supporting legs 40, the tops of the supporting legs 40 are connected with the four corners of the bottom of the garbage can body 11, the bottoms of the supporting legs 40 are connected with the top of the stabilizing seat, and the supporting legs 40 and the stabilizing seat can improve the stabilizing effect of the purifying device and facilitate the use of a user.

The direction subassembly is including seting up at the left mounting groove of 11 inner walls of garbage bin body, and the inside slide bar 13 that is equipped with of mounting groove, and slide bar 13 outside is equipped with sliding sleeve 130, and sliding sleeve 130 one side is kept away from sieve 15 one side with mount pad 14 and is connected, when the vibrations of making a round trip at sieve 15, drives sliding sleeve 130 through the connection of mount pad 14 and reciprocates along slide bar 13 to guarantee that sieve 15 is in the state of high frequency vibrations, make things convenient for rubbish to carry out solid-liquid separation, the practicality is stronger.

A liquid inlet 200 is formed in the top of the mixing drum 20, a liquid outlet 201 is formed in the bottom of the mixing drum 20, an electromagnetic valve for controlling the liquid flowing speed is arranged in the second hopper 24, the set electromagnetic valve is convenient for controlling the liquid to enter the flowing speed in the purifying box 30, and the practicability is high.

Example 2

The difference from example 1 is: the outer wall of the sliding rod 13 is wound with a return spring, the top of the return spring is connected with the bottom of the sliding sleeve 130, the bottom of the return spring is connected with the bottom of the inner wall of the mounting groove, and when the sliding sleeve 130 slides up and down along the sliding rod 13, the return spring can ensure that the sliding sleeve 130 can reset in time.

The utility model discloses a theory of operation is: a user puts garbage into the garbage can body 11 from the feeding port 110, the arranged sieve plate 15 can carry out solid-liquid separation on the garbage, the solid garbage is left at the top of the sieve plate 15, penetrating fluid flows downwards through the sieve plate 15, in order to avoid the solid garbage from blocking the sieve plate 15, the user starts the first motor 18, the first motor 18 drives the cam 19 to rotate, when the cam 19 rotates for one week, the sieve plate 15 can be driven to vibrate up and down through the cooperation of the connecting rod 16, the sieve plate 15, the sliding rod 13, the sliding sleeve 130 and the mounting seat 14, the solid garbage is conveniently conveyed into the pressurizing shell 50 along the obliquely arranged sieve plate 15, then the pressurizing machine 51 is started, the pressurizing machine 51 drives the pressing plate to pressurize the solid garbage, the solid garbage is conveniently extruded into blocks to be centrally treated, the solid garbage can be prevented from blocking the sieve plate 15, the filtering effect of the sieve plate 15 is ensured, and the solid garbage is automatically cleaned through the reciprocating motion of the sieve plate 15, the manual cleaning of a user is not needed, the working strength of the user is reduced, the percolate after solid-liquid separation enters the mixing drum 20, the user can inject disinfectant into the mixing drum 20 through the L-shaped feed pipe 112, the second motor 21 is started, the second motor 21 drives the rotating shaft 22 to rotate, the stirring rods 23 arranged at two sides of the rotating shaft 22 can fully mix the percolate and the disinfectant, so that the effective sterilization and disinfection of the garbage percolate can be conveniently carried out, the primarily purified liquid enters the purifying box 30 along the second hopper 24, the first activated carbon plate 31, the second activated carbon plate 32 and the third activated carbon plate 33 arranged in the purifying box 30 can filter the liquid for multiple times, the garbage percolate can be fully purified, the pollution to the environment is avoided, the corrosion to the device is avoided, the resource utilization rate is greatly improved, the purified liquid can be discharged along the discharge pipe 34, the utility model provides high purifier's work efficiency can effectively satisfy user's user demand.

Claims (7)

1. A landfill leachate purification device comprises a garbage can body (11), a supporting component, a filtering component, a disinfecting component, a purifying component and a pressurizing component, wherein a feeding port (110) is formed in the top of the garbage can body (11), the supporting component is arranged at the bottom of the garbage can body (11), the garbage can is characterized in that the filtering component is arranged inside the garbage can body (11), the disinfecting component is arranged below the filtering component, the bottom of the disinfecting component is communicated with the top of a second hopper (24), the bottom of the second hopper (24) is communicated with the top of the purifying component, an L-shaped feeding pipe (112) is arranged on the left side of the garbage can body (11), and one end of the L-shaped feeding pipe (112) extends into the garbage can body (11) and is positioned above the disinfecting component;

the filter assembly is used for filtering impurities in garbage, and comprises a sieve plate (15) which is obliquely arranged inside a garbage can body (11), one end of the sieve plate (15) is rotatably connected with one side of a mounting seat (14), one side of the mounting seat (14), which is far away from the sieve plate (15), is in sliding connection with the left side of the inner wall of the garbage can body (11) through a guide assembly, the rear side of the sieve plate (15) is connected with one end of a connecting rod (16), one end of the connecting rod (16), which is far away from the sieve plate (15), penetrates through the garbage can body (11) and extends to the outside of the garbage can body to be connected with a mounting disc (17), an opening for accommodating the connecting rod (16) to move up and down is formed in the garbage can body (11), a power assembly for driving the sieve plate (15) to move back and forth is arranged below the mounting disc (17), one end of the sieve plate (15), which is far away from the mounting seat (14), penetrates through a through groove (111) and extends to the inside a pressurizing shell (50), a through groove (111) is formed in the right side of the garbage can body (11), a pressurizing assembly is arranged in the pressurizing shell (50);

the pressurizing assembly is used for automatically cleaning garbage blocked on the sieve plate (15) and comprises a pressurizing machine (51) arranged at the top of the inner wall of the pressurizing shell (50), the output end of the pressurizing machine (51) is connected with the top of the pressure plate, and a sealing door is movably arranged at the bottom of the pressurizing shell (50);

the disinfection component is used for sterilizing landfill leachate and comprises a mixing drum (20) arranged below the inner part of a garbage can body (11), a rotating shaft (22) is transversely arranged inside the mixing drum (20), a plurality of stirring rods (23) are equidistantly arranged on two sides of the rotating shaft (22), one end of the rotating shaft (22) is rotatably connected with one side of the inner wall of the mixing drum (20), the other end of the rotating shaft (22) penetrates through the mixing drum (20) and the garbage can body (11) and is connected with the output end of a second motor (21) arranged on the outer wall of the garbage can body (11), a silencing shell (210) is arranged outside the second motor (21), and the silencing shell (210) is connected with one side of the garbage can body (11);

purify the subassembly for filter landfill leachate, including setting up purifying box (30) in garbage bin body (11) inner wall bottom, purifying box (30) are inside from last to being equipped with first activated carbon plate (31), second activated carbon plate (32) and third activated carbon plate (33) down in proper order, purifying box (30) bottom center and discharging pipe (34) top intercommunication, and discharging pipe (34) bottom is run through garbage bin body (11) and is extended to its below.

2. The landfill leachate purification device of claim 1, wherein the top of the inner wall of the garbage can body (11) is provided with a first hopper (12), and the top of the first hopper (12) is communicated with the bottom of the feed port (110).

3. The landfill leachate purification apparatus of claim 1, wherein the support assembly comprises support legs (40), the tops of the support legs (40) are connected with four corners of the bottom of the garbage can body (11), and the bottoms of the support legs (40) are connected with the tops of the stabilizing seats.

4. The landfill leachate purification apparatus of claim 1, wherein the guiding assembly comprises a mounting groove provided on the left side of the inner wall of the garbage can body (11), a sliding rod (13) is provided inside the mounting groove, a sliding sleeve (130) is provided outside the sliding rod (13), and one side of the sliding sleeve (130) is connected with one side of the mounting seat (14) far away from the screen plate (15).

5. The landfill leachate purification device according to claim 4, wherein the outer wall of the sliding rod (13) is wound with a return spring, the top of the return spring is connected with the bottom of the sliding sleeve (130), and the bottom of the return spring is connected with the bottom of the inner wall of the installation groove.

6. The landfill leachate purification apparatus of claim 1, wherein the power assembly comprises a first motor (18) fixed on one side of the outer wall of the garbage can body (11), an output end of the first motor (18) is connected with one side of a cam (19), and the top of the cam (19) is attached to the bottom of the mounting plate (17).

7. The landfill leachate purification apparatus according to claim 1, wherein a liquid inlet (200) is formed at the top of the mixing drum (20), a liquid outlet (201) is formed at the bottom of the mixing drum (20), and an electromagnetic valve for controlling the flow rate of the liquid is arranged inside the second hopper (24).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202220413326.7U CN217051857U (en) | 2022-02-28 | 2022-02-28 | Landfill leachate purifier |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202220413326.7U CN217051857U (en) | 2022-02-28 | 2022-02-28 | Landfill leachate purifier |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN217051857U true CN217051857U (en) | 2022-07-26 |

Family

ID=82487060

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202220413326.7U Active CN217051857U (en) | 2022-02-28 | 2022-02-28 | Landfill leachate purifier |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN217051857U (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115317992A (en) * | 2022-08-12 | 2022-11-11 | 杨成 | Dry-wet separation intelligent garbage disposer |

| CN118529884A (en) * | 2024-06-04 | 2024-08-23 | 江苏华宇智能科技有限公司 | Environment-friendly garbage room with sewage treatment function |

-

2022

- 2022-02-28 CN CN202220413326.7U patent/CN217051857U/en active Active

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115317992A (en) * | 2022-08-12 | 2022-11-11 | 杨成 | Dry-wet separation intelligent garbage disposer |

| CN118529884A (en) * | 2024-06-04 | 2024-08-23 | 江苏华宇智能科技有限公司 | Environment-friendly garbage room with sewage treatment function |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN217051857U (en) | Landfill leachate purifier | |

| CN111115904B (en) | High-efficient sewage treatment device | |

| CN112607900B (en) | Industrial production is with copper-containing effluent treatment plant | |

| KR100738908B1 (en) | Purifying and Treatment System of Contaminated Waste Water and the Method thereof | |

| CN111747572A (en) | Environment-friendly kitchen waste treatment device and treatment method | |

| CN220012388U (en) | Vegetable washing wastewater treatment device | |

| CN117125858A (en) | Railway sewage treatment device and method based on MABR | |

| CN210140488U (en) | Chemical wastewater purification device | |

| CN111960587A (en) | Intelligent self-cleaning center water outlet system and water outlet method thereof | |

| CN219079123U (en) | Wastewater treatment device | |

| CN106430393A (en) | Activated carbon water treatment device and method | |

| CN214936583U (en) | Water circulation purification device for farm | |

| CN114409155A (en) | Sewage treatment method | |

| CN209292116U (en) | A kind of efficient chemical industry station-service sewage disposal device | |

| CN218115169U (en) | Water treatment device with good filtering and disinfecting effects | |

| CN117285207B (en) | Washing wastewater purifying and circulating device | |

| CN219751933U (en) | Wastewater deodorizing treatment device | |

| CN212832885U (en) | Agent sprinkler for industrial sewage treatment | |

| CN217323733U (en) | Pretreatment device for pesticide-containing waste liquid | |

| CN215756920U (en) | Hydroxyethyl cellulose production is with industry waste water biological treatment device | |

| CN213652181U (en) | Kitchen sewage biochemical degradation's device | |

| CN220766773U (en) | Ultrasonic sewage treatment device | |

| CN219771918U (en) | Sewage layered treatment water purifier device | |

| CN221797157U (en) | Advanced wastewater treatment device based on water pollution control | |

| CN220078647U (en) | Sewage suction filtration device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |