CN216865736U - Metal archaize arc inclined roof construction structure - Google Patents

Metal archaize arc inclined roof construction structure Download PDFInfo

- Publication number

- CN216865736U CN216865736U CN202122476141.9U CN202122476141U CN216865736U CN 216865736 U CN216865736 U CN 216865736U CN 202122476141 U CN202122476141 U CN 202122476141U CN 216865736 U CN216865736 U CN 216865736U

- Authority

- CN

- China

- Prior art keywords

- metal

- arc

- tile

- antique

- galvanized

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Abstract

The utility model discloses a construction structure of a metal antique arc-shaped inclined roof, which comprises a plurality of purlins paved on primary and secondary purlins of the roof, profiled galvanized steel sheets and flat galvanized steel sheets paved on the primary and secondary purlins, galvanized tile supports, antiskid ventilation noise reduction nets, galvanized square steel, full-length tiles and cylindrical tiles, ridge carved granite, metal antique arc-shaped tiles for dripping, cylindrical tile dripping and drainage gutter aluminum sheet batch installation.

Description

Technical Field

The utility model relates to the technical field of roof construction structures, in particular to a metal antique arc inclined roof construction structure.

Background

Compared with the traditional oblique roof structure node method, the ridge structural part and the roof panel are fixed through self-tapping screws, the common butyl daub is paved between the ridge and the ridge cover plate through the covering, the sealing and waterproof treatment is carried out, the heat preservation treatment is not carried out, the method for node treatment has the advantages that the ridge is not necessarily perpendicularly connected to the oblique roof connecting plate, the gap is large, and the ridge is difficult to be connected with the highest position of the roof panel. Because the sun exposure night exposure component is disconnected, the waterproof problem of the gap is solved by only using common waterproof glue, and the waterproof durability of the inclined roof is difficult to guarantee, so that the traditional inclined roof ridge leaks water and seeps water, most of the traditional inclined roof ridge is concentrated at the joint of the abutted seams of the roofs, and the traditional method can not meet the requirements of economic and social development.

Roof metal tiles slowly appear in the market, although the defects of a part of traditional inclined roofs are overcome, the roof is single in structural form and needs a large number of purlins to be welded and matched, the metal tiles are generally fixed on primary and secondary purlins in a screw embedding type connection mode, when the length of each metal plate tile is long, the metal plate tile is matched with the edge of each metal tile to be screwed together, the metal tiles have high precision in the manufacturing process, and the metal tiles in the prior art are poor in transportation condition, so that the metal tiles are extremely difficult to install on the purlins, the metal tile roof structure in the prior art needs a large number of raw materials and secondary purlins, the installation is complex, and the cost of the roof structure is high; and the existing metal tile roof structure is limited, the buckling mode and the self-tapping screw are exposed, so that the wind resistance, rain resistance and low heat insulation performance of the roof structure are caused, and the popularization significance is not realized. Therefore, the energy-saving heat-insulating windproof anti-seepage fabric has better energy-saving heat-insulating, windproof and anti-seepage performances, and is a necessary need for solving the problems.

Study and discuss with oblique roofing structure form of aluminium magnesium manganese metal archaize arc, optimize comparatively traditional metal tile, the oblique roofing surface of aluminium magnesium manganese metal archaize arc does not have the screw to pierce through, and the molding is honorable, pleasing to the eye, atmosphere, and the third dimension is strong, makes the oblique roofing building of metal archaize arc and then is applied to ancient building, factory building, the oblique roofing of floor, gardens ancient building etc. after taking shape, realizes reduce cost, optimization performance.

SUMMERY OF THE UTILITY MODEL

Technical problem to be solved

The utility model aims to provide a metal archaized arc inclined roof construction structure which aims to solve the problems of low wind resistance, rain resistance and heat insulation performance in the background technology.

(II) technical scheme

In order to achieve the above object, the present invention is realized by the following techniques: the utility model provides a metal oblique roofing construction structures of archaizing arc, its process flow measurement unwrapping wire → primary and secondary purlin installation → heat preservation rock wool is laid → installation of zinc-plated profiled steel sheet → installation of zinc-plated flat steel sheet → self-adhesion waterproofing membrane is laid → installation of zinc-plated steel sheet support → antiskid ventilates and falls silk screen laying → installation of metal arc tile modelizing in the past (bottom tile) → fixed bushing tile is with square pipe installation → bushing tile (cover tile) installation → roof ridge installation is laid → rainwater ditch and drainage gutter installation, the construction technology is simple and easy convenient, and the construction is simple and easy, laborsaving, saves the time limit for a project, saves unnecessary extravagant material.

Preferably, the metal archaized arc inclined roof construction structure has the advantages that the metal archaized arc inclined roof plate tiles have integrity and smooth drainage, the metal is made of aluminum-magnesium-manganese alloy, an aluminum oxide film is formed between the metal and the atmosphere, the metal archaized arc inclined roof construction structure can resist acid rain corrosion, the service life of the metal archaized arc inclined roof construction structure in a common environment is more than 50 years, and the metal archaized arc inclined roof construction structure is free of maintenance throughout the year; the fireproof material belongs to A-level fireproof materials, can not spread fire during fire, is safe to use, and can bear the high temperature of more than 300 ℃. Achieving better corrosion resistance and durability.

Preferably, the aluminum-magnesium-manganese metal archaized arc inclined roof is thin in thickness, light in dead weight, good in flexibility, extensibility and plasticity and particularly suitable for large-span, large-space, special-shaped three-dimensional curved surfaces, spherical surfaces and other complex-shaped roofs; the material has certain hardness and good toughness, can recover the original shape after being bent to a certain degree, and cannot age and deform after being used for a long time; can design diversified colour and multiple pattern, wash easily after the foul is stained on the surface, its superstrong self-cleaning function makes the roofing up new ever, improves firm and stability when the oblique roofing structure of metal archaize arc constructs.

Preferably, the ridge is made of 50 × 3 galvanized square steel and M6 back bolt hanging pieces which are connected with stone, carved granite with the thickness of 30mm is installed, a high and bright landscape is formed on the roof, and waste and loss of the traditional tile ridge are reduced.

As preferred, the oblique roofing drainage gutter of metal archaize arc, gutter adopt 3mm perforation aluminum plate, and both sides aluminum plate criticize water fixed with the oblique roofing plate tile galvanizing support below of metal archaize arc, aluminum plate criticize on the fixed gutter angle steel of side under water, through installing metal archaize oblique roofing plate tile drip and the oblique roofing pantile of metal archaize arc and as converging the gutter, form smooth roofing drainage system one.

Preferably, the thickness of the metal antique arc inclined roof aluminum magnesium manganese plate is 1.2mm, the steel consumption is reduced while the strength is ensured by limiting the thickness through design, and the actual manufacturing cost is reduced.

Preferably, the metal antique arc inclined roof structure is connected with the flat-head self-tapping screw in a matched mode through the galvanized support, the free fixing structure of the component and the component can be achieved through the matched mode of the galvanized square steel and the flat-head self-tapping screw, and the structure of the metal antique arc inclined roof structure is simple and convenient to construct in compliance with inclined roof construction.

(III) advantageous effects

Compared with the prior art, the utility model provides a construction structure of a metal antique arc inclined roof, which has the following obvious effects:

1. compared with the traditional inclined roof metal tile roof system of the ancient architecture, the construction structure of the metal antique-imitation arc inclined roof has the advantages that the aluminum-magnesium-manganese metal antique-imitation arc inclined roof is superior in heat preservation, energy conservation and water prevention, the overall effect is attractive, the economic benefit and the social benefit are obvious, the automatic production of components can be realized, and the construction structure comprises large-span industrial buildings, factory buildings, inclined roof buildings, gardens, antique ancient architectures and the like.

2. The metal archaized arc inclined roof is connected and matched with the steel member, so that the metal archaized arc inclined roof is simple in structure, low in production cost and high in bending resistance and torsion resistance, construction is changed from paving to assembling, construction is fast, production and installation of the metal archaized arc inclined roof are more mechanized and assembled, the fixed seat is hidden, construction is convenient, and strength is high.

3. Compared with the traditional metal tile roof system, the utility model obtains higher wind pressure resistance bearing capacity by using the thickness of the thinner metal antique arc-shaped plate tile, thereby having higher economic advantage. The aluminum-magnesium-manganese metal antique arc inclined roof is light in material dead weight, corrosion resistant, good in waterproof and drainage performance and long in service life, is more economical, more attractive and more practical than a traditional roof, can well retain a zinc coating of raw materials, and achieves better corrosion resistance.

4. The utility model relates to a construction structure of a metal antique arc inclined roof, which optimizes the mechanical property of the structure by changing the structural system of the traditional metal tile, and the novel structure has the greatest characteristic of optimizing the relationship between the mechanical property of the roof and the overall structure to a greater extent, so that the roof tends to be more reasonable and scientific.

Drawings

In order to more clearly illustrate the embodiments of the present invention or the prior art mapping, a brief description of the drawings needed for carrying out the embodiments will be given below, it being understood that the drawings described below are only some of the embodiments of the present invention, and that further understanding of the embodiments of the present invention, which form a part of this application, and are not intended to limit the embodiments of the present invention, wherein:

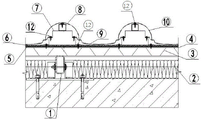

FIG. 1 is a schematic view of a metal archaized arc inclined roof construction structure inclined roof node structure of the utility model;

FIG. 2 is a schematic view of a construction of a sloping roof ridge structure of a metal antique curved sloping roof according to the present invention;

FIG. 3 is a schematic structural view of a front ridge of a sloping roof constructed by the metal antique arc sloping roof construction of the utility model;

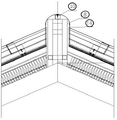

FIG. 4 is a schematic view of a metal archaized arc inclined roof construction structure inclined roof gutter node of the present invention;

reference numbers and corresponding component names in the drawings: 1. primary and secondary purlins; 2. heat preservation rock wool; 3. galvanized profiled steel sheets; 4. a galvanized flat steel sheet; 5. self-adhesive waterproof coiled material; 6. an anti-skid ventilation noise reduction net; 7. a galvanized support; 9. plate tile: 10. a pantile; 12. a flat head self-tapping screw; 14. a lower connecting plate; 8. galvanizing square steel; 18 galvanized L-shaped angle steel; 19. a back bolt hanger; 20. engraving granite; 22. perforating an aluminum plate; 23. aluminum plate batching water; 24 watts of water drops; 25 expanding the bolt.

Detailed Description

The technical solutions in the embodiments of the present invention will be described below with reference to the drawings in the embodiments of the present invention, and the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments. All other embodiments, which can be obtained by a person skilled in the art without making any inventive step based on the embodiments of the present invention, belong to the protection scope of the present invention.

Example 1: please refer to fig. 1, 2 and show, a metal oblique roofing construction structure of arc modelled after an antique, include that set up full length primary and secondary purlin 1 along the oblique roofing slope direction of concrete, lay heat preservation rock wool 2 in 1 neutral position of primary and secondary purlin, lay galvanized profiled sheet 3 along extending the purlin simultaneously, lay galvanized plain steel sheet 4 above galvanized profiled sheet 3, self-adhered waterproofing membrane 5 is laid to top-down, its characterized in that: self-adhesive waterproofing membrane 5 is laid to 4 component vertical directions of each galvanized flat steel sheet, and self-adhesive waterproofing membrane 5 is laid anti-skidding ventilation and is fallen the net of making an uproar and lay 6 along the ridge slope direction that hangs down, with self tapping screw 11 fixed metal archaize arc shape sheet tile zinc-plating support 7, metal archaize arc shape sheet tile zinc-plating support 7 component is located central point and puts fixed zinc-plating square steel 8, metal archaize arc shape sheet tile zinc-plating support 7 is located corresponding zinc-plating square steel 8 intermediate position, at metal archaize arc shape sheet tile zinc-plating support 7 with self tapping screw 12 fixed full length metal archaize arc shape sheet tile 9, follows the ridge slope of extending and uses self tapping screw 13 fixed metal archaize arc shape pantile 10, metal archaize arc shape sheet tile 9 slope direction is the same with metal archaize arc shape pantile 10 slope direction, metal archaize arc shape inclined roof component includes 2 heat preservation rock wools. At oblique roofing room vertical spine part of metal archaize arc, constitute space ridge skeleton by oblique roofing component zinc-plating square steel 8 of metal archaize arc, even 14 fixed component zinc-plating square steel 8 both sides of board down, fix metal archaize arc pantile 10 in zinc-plating square steel component both sides position with self tapping screw, even board 14 and metal archaize arc board tile down, pantile handing-over department embedding PE foam rod, the outside adopts neutral silicone building weather resistant adhesive to seal the reality, the ridge curb plate adopts rivet connection with even board down.

The working principle is as follows:

example 2: referring to fig. 3 and 4, the metal antique arc inclined roof construction structure can be spliced and used according to the use environment and places during use, the longitudinal galvanized square steel 8 fixes the metal antique arc inclined roof structure on two sides of the edge of a main roof ridge, the transverse galvanized square steel fixes two ways of the longitudinal galvanized square steel 8, the L-shaped steel 18 is implanted on the upper side and the lower side of the galvanized square steel 8, the back bolt hanging pieces 19 fix two ways of the L-shaped steel 18, the back bolt hanging pieces 19 are installed on two sides of the top of the transverse galvanized square steel 8, the back bolt hanging pieces 19 fix the carved granite 20, PE foam bars are embedded at the joints of the carved granite 20, the metal antique arc roof plate tiles 9 and the metal antique arc barrel tiles 10, and the outer sides of the carved granite 20 are sealed by neutral silicone weather-resistant building glue. On the fixed galvanized square steel 8 space skeleton in primary and secondary purlin 1 metal oblique roofing drainage gutter both sides modelled after an antique arc, shelve perforation aluminum plate 22 in galvanized square steel both sides, aluminum plate criticize water 22 and fix in advance reservation position galvanized support 7 below, lower part aluminum plate criticize water and fix at galvanized square steel 8, the installation of dripping of metal oblique roofing plate tile modelled after an antique arc, pantile to form the gutter drainage unblocked.

It is noted that in this document, relational terms such as galvanized square steel 8, self-tapping grub screws 11, self-tapping grub screws 12, self-tapping grub screws 13, self-tapping grub screws 16 are used only to distinguish one element or operation from another element or operation, and do not necessarily require or suggest an actual relationship or order between such elements or operations. Moreover, the terms "comprises," "comprising," "includes," "including," "has," "having" or any other variation thereof, are intended to cover a non-exclusive inclusion.

Having thus described embodiments of the present invention, it will be appreciated by those skilled in the art that various changes, modifications, substitutions and alterations can be made herein without departing from the spirit and scope of the utility model as defined by the appended claims and their equivalents.

Claims (7)

1. The utility model provides a metal archaize arc roofing construction structure to one side, includes along the oblique roofing slope direction of concrete sets up logical long primary and secondary purlin (1), lays heat preservation rock wool (2) in primary and secondary purlin (1) neutral gear department, lays zinc-plated profiled steel sheet (3) simultaneously along extending on the purlin, lays zinc-plated flat steel sheet (4) above zinc-plated profiled steel sheet (3), and self-adhered waterproofing membrane (5) are laid to top-down, its characterized in that: self-adhesive waterproof coiled materials (5) are laid on each galvanized flat steel plate (4) component in the vertical direction, an anti-skidding ventilating noise reduction net (6) is fully laid on each self-adhesive waterproof coiled material (5) along the gradient direction of a ridge, a metal antique arc-shaped tile galvanized support (7) is fixed, a galvanized square steel (8) is fixed at the central position of each metal antique arc-shaped tile galvanized support (7), the metal antique arc-shaped tile galvanizing support (7) component is positioned in the middle of the corresponding galvanizing square steel (8), a full-length metal antique arc-shaped tile (9) is fixed, a metal antique arc-shaped barrel tile (10) is fixed along the slope surface of the ridge, the slope direction of the metal antique arc-shaped plate tile (9) is the same as the slope direction of the metal antique arc-shaped cylindrical tile (10), and when seen from the overlooking direction, the edge of the metal antique arc-shaped plate tile (9) is overlapped with the longitudinal part of the corresponding metal antique arc-shaped cylinder tile (10) on the same line.

2. The construction structure of the metal archaized arc inclined roof as claimed in claim 1, wherein: each major-minor purlin (1) corresponds a plurality of inferior purlin component equipartition intervals along its slope direction, and both sides major-minor purlin extends to be the level setting with inferior purlin component, and every metal arc tile modelled after an antique (9) are fixed in galvanized support (7) both sides and are formed the slope, and galvanized support (7) intermediate position is fixed zinc-plated square steel (8), should be in the same direction as metal arc tile modelled after an antique (9) direction installation metal arc shell tile modelled after an antique (10), major-minor purlin (1) includes a plurality of expansion bolts connecting piece that pass through, forms space skeleton on the roofing concrete face to one side.

3. The construction structure of the metal archaized arc inclined roof as claimed in claim 2, wherein: the galvanized support (7) needs to be connected and fixed through flat-head self-tapping screws (12), the metal antique arc-shaped plate tile (9) needs to be connected and fixed through the flat-head self-tapping screws (12), and the metal antique arc-shaped barrel tile (10) of the inclined roof needs to be vertically and fixedly connected to the surface of the galvanized square steel (8) through the flat-head self-tapping screws (12).

4. The construction structure of the metal archaized arc inclined roof as claimed in claim 3, wherein: perpendicular roof ridge line top metal arc section of jurisdiction under the ancient style tile (10) downside is equipped with zinc-plated square steel (8), even board (14) under the fixed connection, perpendicular roof ridge line metal arc section of jurisdiction under the ancient style tile (10) need be fixed on the horizontal connection roof face with self tapping screw vertical fixation.

5. The construction structure of the metal archaized arc inclined roof as claimed in claim 4, wherein: each positive roof ridge line is positioned on vertical galvanized square steel (8), is connected with galvanized L-shaped angle steel (18) and is applied to an M6 stone back bolt hanging piece (19), and the corresponding three sides of the positive roof ridge are provided with carved granite (20) which is connected with the M6 stone back bolt hanging piece (19) to form a straight line.

6. The construction structure of the metal archaized arc inclined roof as claimed in claim 5, wherein: oblique roofing bottom drainage gutter adopts zinc-plated square steel (8) to be fixed in concrete gutter both sides, installs sewer pipe block and drainage perforation aluminum plate (22), and aluminum plate batches water (23) through connection tile and drips (24) downside simultaneously.

7. The construction structure of the metal archaized arc inclined roof as claimed in claim 1, wherein: and a metal bottom plate fixing connecting piece (25) which is an expansion bolt is arranged between two adjacent primary and secondary purlins of the primary and secondary purlins (1).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202122476141.9U CN216865736U (en) | 2021-10-14 | 2021-10-14 | Metal archaize arc inclined roof construction structure |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202122476141.9U CN216865736U (en) | 2021-10-14 | 2021-10-14 | Metal archaize arc inclined roof construction structure |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN216865736U true CN216865736U (en) | 2022-07-01 |

Family

ID=82120985

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202122476141.9U Active CN216865736U (en) | 2021-10-14 | 2021-10-14 | Metal archaize arc inclined roof construction structure |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN216865736U (en) |

-

2021

- 2021-10-14 CN CN202122476141.9U patent/CN216865736U/en active Active

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN110552450A (en) | Construction method of large-span short-vertical-edge vertical double-lock-edge titanium-zinc alloy metal roof | |

| CN205134762U (en) | Individual layer roof waterproof profiled sheet | |

| CN216865736U (en) | Metal archaize arc inclined roof construction structure | |

| CN208764857U (en) | A kind of light pipe hardened system | |

| CN207988131U (en) | A kind of integrated house | |

| CN110821210A (en) | House system of assembled positive energy room | |

| CN215106448U (en) | Novel slope roof building structure | |

| CN2353821Y (en) | Composite leakage-proof structure for roof | |

| CN201883613U (en) | Double-pitch roof ridge tile | |

| CN210563122U (en) | Thermal insulation decorative composite ALC peripheral wall panel | |

| CN107587660A (en) | A kind of sloping roof system of titanium roofing tile | |

| CN211369128U (en) | External wall heat preservation waterproof system | |

| CN202248576U (en) | Light-collecting ventilation structure of arched corrugated steel cover roof | |

| CN205531042U (en) | Upright lock stitches steel tile roofing system | |

| CN212926748U (en) | Waterproof eaves structure of pitched roof | |

| CN216446369U (en) | Eave roof structure is draped over one's shoulders in outer facade sparrow of archaize building | |

| CN220377703U (en) | Building outer wall assembled UHPC photovoltaic sunshade decoration integrated plate | |

| CN216042224U (en) | Waterproof connection structure of gutter in various steel tile sloping roof | |

| CN217759652U (en) | Steel construction building roofing drainage structures | |

| CN218758339U (en) | Circular daylighting courtyard of building roofing | |

| CN210459786U (en) | Profiled sheet roofing becomes slope department waterproof construction | |

| Jones | Roofing materials for thermal performance and environmental integration of buildings | |

| CN211873592U (en) | Waterproof treatment node structure of steel structure downslope dormer side and roofing planking | |

| CN217054074U (en) | Mounting structure for sun shield of outer vertical surface of fabricated building | |

| CN207277702U (en) | A kind of sloping roof system of titanium roofing tile |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |