CN213946190U - Portable adjustable supporting device for die machining - Google Patents

Portable adjustable supporting device for die machining Download PDFInfo

- Publication number

- CN213946190U CN213946190U CN202022867753.6U CN202022867753U CN213946190U CN 213946190 U CN213946190 U CN 213946190U CN 202022867753 U CN202022867753 U CN 202022867753U CN 213946190 U CN213946190 U CN 213946190U

- Authority

- CN

- China

- Prior art keywords

- top plate

- bevel gear

- transmission wheel

- supporting

- roof

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Workshop Equipment, Work Benches, Supports, Or Storage Means (AREA)

Abstract

The utility model discloses a strutting arrangement is used in processing of portable adjustable mould, including roof, sleeve and lead screw, both ends are provided with the landing leg about the roof below, and landing leg top fixed connection terminal surface under the roof to landing leg lower extreme fixed mounting has the pulley, the terminal surface is fixed to be provided with two sleeves under the roof, and the sleeve is located the inboard of landing leg, two draw-in grooves have been seted up to the terminal surface under the roof, and the draw-in groove is located position between landing leg and the sleeve. The clamping device formed by the spring and the clamping block is arranged on the top plate of the supporting device for portable adjustable die machining, the die on the top plate can be clamped and fixed, the conical gear arranged below the top plate drives the lead screw and the sleeve to move in a telescopic mode so that the height of the whole device can be freely adjusted, the supporting legs fixedly connected with the two ends of the bottom of the top plate are provided with the pulleys, and when the top plate is adjusted to the position away from the lowest position on the ground, the device can be pushed to freely move on the ground, and great convenience is brought to a user.

Description

Technical Field

The utility model relates to a mould processing equipment technical field specifically is a strutting arrangement is used in processing of portable adjustable mould.

Background

The die processing refers to the processing of forming and blank-making tools, and also comprises a shearing die and a die cutting die, under the normal condition, the die comprises an upper die and a lower die, a steel plate is placed between the upper die and the lower die, the forming of materials is realized under the action of a press, when the press is opened, a workpiece determined by the shape of the die can be obtained or corresponding waste materials can be removed, and in the manufacturing industry, workpieces as small as electronic connectors and workpieces as large as automobile instrument panels can be formed by the die. The die processing technology comprises the following steps: cutting die, blank punching die, compound die, extrusion die, four-slide rail die, progressive die, stamping die, die cutting die and the like.

When the mold machining is related to, the supporting device for mold machining needs to be used, but the supporting device for mold machining in the current market is usually of a fixed structure, occupies a relatively large space when not used, and is inconvenient to adjust and move when used.

Disclosure of Invention

An object of the utility model is to provide a portable adjustable strutting arrangement for mould processing to solve the strutting arrangement for mould processing on the existing market that proposes in the above-mentioned background art, be fixed structure usually, comparatively occupation space when not using, adjust when using simultaneously and remove inconvenient scheduling problem.

In order to achieve the above object, the utility model provides a following technical scheme: the support leg structure comprises a top plate, sleeves and a screw rod, wherein the left end and the right end below the top plate are provided with support legs, the top ends of the support legs are fixedly connected to the lower end face of the top plate, the lower ends of the support legs are fixedly provided with pulleys, the lower end face of the top plate is fixedly provided with two sleeves, the sleeves are positioned on the inner sides of the support legs, the lower end face of the top plate is provided with two clamping grooves, the clamping grooves are positioned between the support legs and the sleeves, the sleeves are internally provided with the screw rods, the screw rods are in threaded connection with the sleeves, a fixing plate is arranged below the screw rods, two ends of the fixing plate are fixedly connected with supporting rods, a first driving wheel and a second driving wheel are arranged in the fixing plate in a penetrating manner, the second driving wheel is positioned on the left side of the first driving wheel, the peripheries of the first driving wheel and the second driving wheel are provided with belts, the belts are in fit connection with the first driving wheel and the second driving wheel, and the upper ends of the second driving wheel are fixedly connected with the lower ends of the left screw rods, first drive wheel upper end and the lead screw lower extreme fixed connection on the right, and the first bevel gear of first drive wheel lower extreme fixedly connected with, first bevel gear right side below is provided with second bevel gear, and second bevel gear right-hand member runs through the right side bracing piece to second bevel gear surpasss the outer terminal surface fixed mounting of part of bracing piece and has the rocker, the mounting groove has been seted up to the roof up end, and controls both ends in the mounting groove and all be provided with spring and grip block, the terminal surface fixed connection of spring one end and mounting groove, and the other end and the grip block fixed connection of spring.

Preferably, the top plate is horizontally arranged, two clamping grooves formed in the lower end face of the top plate are located right above the supporting rod, and the inner diameter of each clamping groove is slightly larger than the outer diameter of the supporting rod.

Preferably, the top plate and the screw rod form a lifting structure through a sleeve.

Preferably, the supporting legs, the screw rods and the supporting rods are arranged in parallel, and the supporting legs, the screw rods and the supporting rods are perpendicular to the top plate.

Preferably, the second bevel gear is arranged perpendicular to the first bevel gear, and the second bevel gear is in meshed connection with the first bevel gear.

Preferably, the clamping block and the top plate form an elastic telescopic structure through a spring.

Compared with the prior art, the beneficial effects of the utility model are that:

the clamping device formed by the spring and the clamping block is arranged on the top plate of the supporting device for portable adjustable die machining, the die on the top plate can be clamped and fixed, the conical gear arranged below the top plate drives the lead screw and the sleeve to move in a telescopic mode so that the height of the whole device can be freely adjusted, the supporting legs fixedly connected with the two ends of the bottom of the top plate are provided with the pulleys, and when the top plate is adjusted to the position away from the lowest position on the ground, the device can be pushed to freely move on the ground, and great convenience is brought to a user.

Drawings

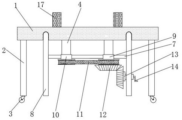

FIG. 1 is a schematic view of the overall structure of the present invention;

FIG. 2 is a schematic top view of the present invention;

FIG. 3 is a schematic view of the connecting cross-sectional structure of the clamping block and the top plate of the present invention;

fig. 4 is an enlarged schematic view of a portion a of fig. 1 according to the present invention;

fig. 5 is a structural schematic diagram of the overall folded state of the present invention.

In the figure: 1. a top plate; 2. a support leg; 3. a pulley; 4. a sleeve; 5. a card slot; 6. a screw rod; 7. a fixing plate; 8. a support bar; 9. a first drive pulley; 10. a second transmission wheel; 11. a belt; 12. a first bevel gear; 13. a second bevel gear; 14. a rocker; 15. mounting grooves; 16. a spring; 17. and (4) clamping the block.

Detailed Description

The technical solutions in the embodiments of the present invention will be described clearly and completely with reference to the accompanying drawings in the embodiments of the present invention, and it is obvious that the described embodiments are only some embodiments of the present invention, not all embodiments. Based on the embodiments in the present invention, all other embodiments obtained by a person skilled in the art without creative work belong to the protection scope of the present invention.

Referring to fig. 1-5, the present invention provides a technical solution: comprises a top plate 1, sleeves 4 and a screw rod 6, wherein the left end and the right end below the top plate 1 are provided with supporting legs 2, the top ends of the supporting legs 2 are fixedly connected with the lower end surface of the top plate 1, the lower ends of the supporting legs 2 are fixedly provided with pulleys 3, the lower end surface of the top plate 1 is fixedly provided with two sleeves 4, the sleeves 4 are positioned at the inner sides of the supporting legs 2, the lower end surface of the top plate 1 is provided with two clamping grooves 5, the clamping grooves 5 are positioned between the supporting legs 2 and the sleeves 4, the screw rods 6 are arranged in the sleeves 4, the screw rods 6 are in threaded connection with the sleeves 4, a fixing plate 7 is arranged below the screw rods 6, two ends of the fixing plate 7 are fixedly connected with supporting rods 8, a first driving wheel 9 and a second driving wheel 10 are arranged in the fixing plate 7 in a penetrating manner, the second driving wheel 10 is positioned at the left side of the first driving wheel 9, the upper end of the second transmission wheel 10 is fixedly connected with the lower end of the left screw rod 6, the upper end of the first transmission wheel 9 is fixedly connected with the lower end of the right screw rod 6, a first bevel gear 12 is fixedly connected with the lower end of the first transmission wheel 9, a second bevel gear 13 is arranged below the right side of the first bevel gear 12, the right end of the second bevel gear 13 penetrates through the right supporting rod 8, a rocker 14 is fixedly mounted on the outer end face of the portion, exceeding the supporting rod 8, of the second bevel gear 13, a mounting groove 15 is formed in the upper end face of the top plate 1, a spring 16 and a clamping block 17 are arranged at the left end and the right end of the mounting groove 15, one end of the spring 16 is fixedly connected with the end face of the mounting groove 15, and the other end of the spring 16 is fixedly connected with the clamping block 17.

The level of roof 1 sets up, and two draw-in grooves 5 that the terminal surface was seted up under the roof 1 are located bracing piece 8 directly over to the internal diameter of draw-in groove 5 slightly is greater than the external diameter of bracing piece 8, when roof 1 descends to the extreme lower position, 8 tops of bracing piece can just go into in the draw-in groove 5, make landing leg 2 and pulley 3's the overall height be a little higher than the height of bracing piece 8, make things convenient for this strutting arrangement to remove on ground through pulley 3.

The top plate 1 and the screw rod 6 form a lifting structure through the sleeve 4, and the height of the top plate 1 can be adjusted up and down according to working conditions.

The second bevel gear 13 is perpendicular to the first bevel gear 12, the second bevel gear 13 is meshed with the first bevel gear 12 and connected with the first bevel gear 12, and the rocker 14 on the outer end face of the second bevel gear 13 is rocked, so that the second bevel gear 13 rotates and simultaneously drives the first bevel gear 12 and the first transmission wheel 9 to rotate, the second transmission wheel 10 and the screw rod 6 are further driven to rotate, and the whole device forms a linkage structure.

The clamping block 17 and the top plate 1 form an elastic telescopic structure through the spring 16, and clamping and fixing of the die on the top plate 1 are facilitated.

The working principle is as follows: when the portable adjustable supporting device for die processing is used, firstly, a rocker 14 at the outer end of a second bevel gear 13 is manually rotated, so that the second bevel gear 13 rotates and drives a first bevel gear 12 meshed with the second bevel gear to rotate, the first bevel gear 12 rotates and drives a first transmission wheel 9 fixedly connected with the first bevel gear to rotate, the first transmission wheel 9 rotates and simultaneously drives a second transmission wheel 10 to rotate towards the same direction through a belt 11, meanwhile, the first transmission wheel 9 and the second transmission wheel 10 drive a left screw rod 6 and a right screw rod 6 to rotate towards the same direction, at the moment, a top plate 1 is slowly lifted upwards through the spiral motion of the screw rods 6 and a sleeve 4, when the top plate 1 is lifted to a proper height, the die is placed in the middle position of two clamping blocks 17 above the top plate 1, at the moment, dies with different sizes can be supported and fixed, and when the device is not needed to be used or needs to be shifted, rocker 14 of reverse rotating second cone gear 13 outer end, roof 1 can descend gradually opposite with above-mentioned step, the in-process that roof 1 descends, draw-in groove 5 can be gone into to the bracing piece 8 top for landing leg 2 and pulley 3's overall height are a little higher than the height of bracing piece 8, promote this strutting arrangement accessible pulley 3 and remove on ground, accomplished this strutting arrangement's folding aversion this moment, this strutting arrangement brings very big facility for the user, this is this portable adjustable mould processing and uses strutting arrangement's theory of operation.

Although embodiments of the present invention have been shown and described, it will be appreciated by those skilled in the art that changes, modifications, substitutions and alterations can be made in these embodiments without departing from the principles and spirit of the invention, the scope of which is defined in the appended claims and their equivalents.

Claims (6)

1. The utility model provides a portable adjustable strutting arrangement for mould processing, includes roof (1), sleeve (4) and lead screw (6), its characterized in that: the supporting legs (2) are arranged at the left end and the right end below the top plate (1), the top ends of the supporting legs (2) are fixedly connected to the lower end face of the top plate (1), pulleys (3) are fixedly mounted at the lower ends of the supporting legs (2), two sleeves (4) are fixedly arranged on the lower end face of the top plate (1), the sleeves (4) are located on the inner sides of the supporting legs (2), two clamping grooves (5) are formed in the lower end face of the top plate (1), the clamping grooves (5) are located between the supporting legs (2) and the sleeves (4), lead screws (6) are arranged in the sleeves (4), the lead screws (6) are in threaded connection with the sleeves (4), a fixing plate (7) is arranged below the lead screws (6), supporting rods (8) are fixedly connected to the two ends of the fixing plate (7), a first driving wheel (9) and a second driving wheel (10) penetrate through the fixing plate (7), the second transmission wheel (10) is positioned on the left side of the first transmission wheel (9), a belt (11) is arranged on the peripheries of the first transmission wheel (9) and the second transmission wheel (10), the belt (11) is connected with the first transmission wheel (9) and the second transmission wheel (10) in a laminating manner, the upper end of the second transmission wheel (10) is fixedly connected with the lower end of the left screw rod (6), the upper end of the first transmission wheel (9) is fixedly connected with the lower end of the right screw rod (6), the lower end of the first transmission wheel (9) is fixedly connected with a first bevel gear (12), a second bevel gear (13) is arranged on the lower right side of the first bevel gear (12), the right end of the second bevel gear (13) penetrates through the right supporting rod (8), a rocker (14) is fixedly mounted on the outer end face of the part, exceeding the supporting rod (8), of the second bevel gear (13), a mounting groove (15) is formed in the upper end face of the top plate (1), and both ends all are provided with spring (16) and grip block (17) about in mounting groove (15), the terminal surface fixed connection of spring (16) one end and mounting groove (15), and the other end and grip block (17) fixed connection of spring (16).

2. The supporting device for portable adjustable mold processing according to claim 1, wherein: the top plate (1) is horizontally arranged, two clamping grooves (5) formed in the lower end face of the top plate (1) are located right above the supporting rod (8), and the inner diameter of each clamping groove (5) is slightly larger than the outer diameter of the supporting rod (8).

3. The supporting device for portable adjustable mold processing according to claim 1, wherein: the top plate (1) and the screw rod (6) form a lifting structure through the sleeve (4).

4. The supporting device for portable adjustable mold processing according to claim 1, wherein: landing leg (2), lead screw (6) and bracing piece (8) all parallel arrangement each other, and landing leg (2), lead screw (6) and bracing piece (8) all perpendicular to roof (1).

5. The supporting device for portable adjustable mold processing according to claim 1, wherein: the second bevel gear (13) is arranged perpendicular to the first bevel gear (12), and the second bevel gear (13) is in meshed connection with the first bevel gear (12).

6. The supporting device for portable adjustable mold processing according to claim 1, wherein: the clamping block (17) and the top plate (1) form an elastic telescopic structure through a spring (16).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202022867753.6U CN213946190U (en) | 2020-12-04 | 2020-12-04 | Portable adjustable supporting device for die machining |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202022867753.6U CN213946190U (en) | 2020-12-04 | 2020-12-04 | Portable adjustable supporting device for die machining |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN213946190U true CN213946190U (en) | 2021-08-13 |

Family

ID=77213557

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202022867753.6U Expired - Fee Related CN213946190U (en) | 2020-12-04 | 2020-12-04 | Portable adjustable supporting device for die machining |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN213946190U (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113910501A (en) * | 2021-09-09 | 2022-01-11 | 苏州鸿裕鑫精密机械有限公司 | Mould and mould supporting mechanism thereof |

-

2020

- 2020-12-04 CN CN202022867753.6U patent/CN213946190U/en not_active Expired - Fee Related

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113910501A (en) * | 2021-09-09 | 2022-01-11 | 苏州鸿裕鑫精密机械有限公司 | Mould and mould supporting mechanism thereof |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN111687803A (en) | Fixing device is used in case and bag production | |

| CN210412235U (en) | Fixing clamp for bolt punch forming | |

| CN213946190U (en) | Portable adjustable supporting device for die machining | |

| CN206169053U (en) | Novel structure mould | |

| CN214417412U (en) | Automobile part stamping device stable in clamping | |

| CN214447073U (en) | Efficient cutting device for furniture | |

| CN215202817U (en) | Novel multitool marble cutter | |

| CN214977057U (en) | Punching device for inner groove of hexagonal nut | |

| CN117001615A (en) | Electric power fitting fixing device | |

| CN116690258A (en) | Manufacturing device and process for machining high-torque universal joint fork | |

| CN217493724U (en) | Burr polishing equipment for plastic part production | |

| CN212652738U (en) | Punching device for automobile parts | |

| CN216461927U (en) | Aviation standard component perforating device | |

| CN214818369U (en) | Clamp for mold machining | |

| CN210550668U (en) | Support frame suitable for industrial design palm model preparation | |

| CN114284169A (en) | Novel automatic silicon chip splitting machine | |

| CN210435217U (en) | Convenient strutting arrangement for mould processing who adjusts | |

| CN221716353U (en) | Drilling device with piece clearance function for oil circuit board processing | |

| CN221890761U (en) | Hardware product lamination shaping device | |

| CN218475911U (en) | Table press for producing arc-shaped steel | |

| CN213225546U (en) | Movable type sanding equipment for metal stamping parts | |

| CN219379736U (en) | Positioning and punching device for steel processing | |

| CN221110144U (en) | Cutting device is used in mould processing production | |

| CN219357576U (en) | Punch a hole and use punch press on bar copper | |

| CN221019850U (en) | Adjustable fixture for new energy part machining |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20210813 Termination date: 20211204 |

|

| CF01 | Termination of patent right due to non-payment of annual fee |