CN213860835U - Device extracts oil fast convenient to take out residue - Google Patents

Device extracts oil fast convenient to take out residue Download PDFInfo

- Publication number

- CN213860835U CN213860835U CN202021737466.7U CN202021737466U CN213860835U CN 213860835 U CN213860835 U CN 213860835U CN 202021737466 U CN202021737466 U CN 202021737466U CN 213860835 U CN213860835 U CN 213860835U

- Authority

- CN

- China

- Prior art keywords

- squeezing

- sides

- filter screen

- plate

- box

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Fats And Perfumes (AREA)

Abstract

The utility model discloses a device extracts oil fast convenient to take out residual, the power distribution box comprises a box body, the inboard top fixed mounting of box has the pneumatic cylinder, the output of pneumatic cylinder passes through transfer line fixed mounting has the mounting panel, mounting panel bottom fixed mounting has the stripper plate, the inner wall fixed mounting of box has the platform of squeezing, the holding tank has all been seted up to stripper plate top both sides, the inboard bottom swing joint of holding tank has electronic jar, electronic jar's output is rotated with the middle part of bracing piece and is connected, the top of bracing piece is rotated and is connected with the bearing plate, the central authorities of the platform of squeezing run through and are equipped with the tube-shape casing, the terminal fixed mounting of bearing plate has the gear, the second feed opening has been seted up to the central authorities of the platform of squeezing, second feed opening below slope is equipped with the filter screen, the bottom fixedly connected with stock guide of filter screen, box inboard bottom is equipped with the oil tank, the oil tank both sides all are equipped with scrap collecting box. The utility model discloses be convenient for collect the walnut sediment after squeezing, save operating time, improved work efficiency greatly.

Description

Technical Field

The utility model relates to a technical field extracts oil, in particular to device extracts oil fast convenient to take out residue.

Background

The walnut oil is vegetable oil which is prepared by squeezing walnut kernels serving as a raw material. Belongs to edible oil. The grease content of the walnut reaches 65-70 percent, and the walnut oil belongs to all woody oil and is reputed as oil depots on trees. The essence is extracted by the modern process, and the product is walnut oil which is a new generation product of walnut. The walnut oil is natural fruit oil juice which is prepared by selecting high-quality walnuts as raw materials and adopting an internationally advanced process. In the international market, the walnut oil is known as the oriental olive oil and is like the olive oil, so that the walnut oil is highly favored by consumers.

In the walnut oil squeezing process, the oil squeezing hydraulic cylinder piston moves to achieve walnut oil squeezing, walnut residues need to be taken out after squeezing, and in the prior art, the walnut residue taking-out process is time-consuming and labor-consuming, and oil squeezing efficiency is affected.

SUMMERY OF THE UTILITY MODEL

The main object of the utility model is to provide a device extracts oil fast convenient to take out residue can effectively solve the problem in the background art.

In order to achieve the above purpose, the utility model adopts the following technical scheme:

a quick oil expression device convenient for taking out residues comprises a box body, wherein a feed hopper is arranged in the middle of one side of the box body in a penetrating manner, a hydraulic cylinder is fixedly arranged at the top of the inner side of the box body, an output end of the hydraulic cylinder is vertically and downwards fixedly connected with a transmission rod, a mounting plate is fixedly arranged at the bottom of the transmission rod, a squeezing plate is fixedly arranged at the bottom of the mounting plate, the bottom of the squeezing plate is V-shaped, a squeezing table is fixedly arranged between the inner walls of the two sides of the box body, both sides of the top of the squeezing table are provided with holding grooves, one end inner wall of each holding groove is hinged with a supporting rod, the inner bottom of each holding groove is movably connected with an electric cylinder, the output end of each electric cylinder is rotatably connected with the middle of the corresponding supporting rod, a bearing plate is rotatably connected with the top of the corresponding supporting rod, a cylindrical shell is arranged in the center of the squeezing table in a penetrating manner, and the tail end of the bearing plate extends to the cylindrical shell and is fixedly provided with a gear, the utility model discloses a press, including tube-shape casing, the inboard bottom fixed mounting of tube-shape casing has the push rod motor, the vertical two-sided rack of fixedly connected with that makes progress of output of push rod motor, the gear with two-sided rack toothing connects, the bearing plate is close to first feed opening has been seted up to tube-shape casing's one end, first feed opening internal rotation is connected with the triangle baffle, the second feed opening has been seted up to the central authorities of squeezing the platform, the below slope of second feed opening is equipped with the filter screen, the bottom fixedly connected with stock guide of filter screen, the inboard bottom of box is equipped with the oil tank, the both sides of oil tank all are equipped with scrap collecting box.

Preferably, a plurality of supporting blocks are fixed on the surface of the press table, and the upper end surfaces of the supporting blocks are in contact with the bottom of the bearing plate.

Preferably, the upper ends of the two sides of the cylindrical shell are provided with openings matched with the pressure bearing plate.

Preferably, the two sides of the double-sided rack are fixedly connected with first sliding blocks, the inner walls of the two sides of the cylindrical shell are symmetrically and fixedly provided with first sliding rails, and the first sliding blocks are matched with the first sliding rails.

Preferably, the bottom of the second feed opening is fixedly connected with a baffle plate, the baffle plate is parallel to the filter screen, and a vibrating motor is fixed at the bottom of the filter screen.

Preferably, a second sliding block is fixed at the bottom of the oil tank, a second sliding rail is fixed at the bottom of the inner side of the tank body, and the second sliding block is matched with the second sliding rail.

Compared with the prior art, the utility model discloses following beneficial effect has: the quick oil pressing device convenient for taking out residues comprises a feeding hopper, a walnut after being processed is thrown into the interior of a box body through the feeding hopper and falls on a bearing plate, a hydraulic cylinder is started, the hydraulic cylinder drives a pressing plate to move downwards through a transmission rod to press the walnut, after pressing, an included angle between the bearing plate and a pressing platform is increased, walnut oil flows downwards along the gradient of the bearing plate at the moment, the oil sequentially passes through a first discharging port and a second discharging port and falls on a filter screen, the oil enters an oil tank after being filtered by the filter screen, the hydraulic cylinder contracts the transmission rod to restore the pressing plate to the original position, a push rod motor and an electric cylinder are started, the push rod motor drives a double-sided rack to move upwards, the double-sided rack drives a gear to rotate, the gear then drives the bearing plate to rotate, the electric cylinder drives a supporting rod to rotate, and the supporting rod further drives the bearing plate to rotate, and then make two bearing plates draw close to the tube-shape casing to make the walnut sediment on bearing plate surface roll down along the bearing plate surface and fall, and from what second feed opening falls, then fall on the filter screen, start vibrating motor this moment and drive the filter screen vibrations, make the walnut sediment along filter screen and stock guide get into waste material collecting box in, be convenient for collect the walnut sediment after squeezing, save operating time, improved work efficiency greatly.

Drawings

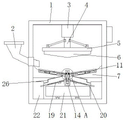

Fig. 1 is a first schematic structural view of a rapid oil press device convenient for taking out residues according to the present invention;

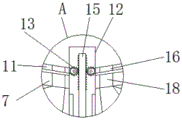

fig. 2 is an enlarged schematic structural diagram of a portion B in fig. 1 of the rapid oil squeezing device for conveniently taking out residues according to the present invention;

fig. 3 is a second schematic structural view of the rapid oil squeezing device for conveniently taking out residues according to the present invention;

fig. 4 is an enlarged schematic structural diagram of B in fig. 3 of the rapid oil squeezing device convenient for taking out residues of the present invention.

In the figure: 1. a box body; 2. a feed hopper; 3. a hydraulic cylinder; 4. a transmission rod; 5. mounting a plate; 6. a millboard; 7. a press table; 8. accommodating grooves; 9. a support bar; 10. an electric cylinder; 11. a pressure bearing plate; 12. a cylindrical housing; 13. a gear; 14. a push rod motor; 15. a double-sided rack; 16. a first feed opening; 17. a vibration motor; 18. a second feed opening; 19. a filter screen; 20. a material guide plate; 21. an oil tank; 22. a waste collection tank; 23. a support block; 24. a first slider; 25. a first slide rail; 26. a striker plate; 27. a second slider; 28. a second slide rail.

Detailed Description

In order to make the technical means, creation features, achievement purposes and functions of the present invention easy to understand, the present invention is further described below with reference to the following embodiments.

As shown in fig. 1-4, a quick oil expression device convenient for taking out residues comprises a box body 1, a feed hopper 2 is arranged in the middle of one side of the box body 1 in a penetrating manner, a hydraulic cylinder 3 is fixedly arranged at the top of the inner side of the box body 1, an output end of the hydraulic cylinder 3 is vertically and downwardly fixedly connected with a transmission rod 4, a mounting plate 5 is fixedly arranged at the bottom of the transmission rod 4, a pressing plate 6 is fixedly arranged at the bottom of the mounting plate 5, the bottom of the pressing plate 6 is in a V shape, a pressing platform 7 is fixedly arranged between the inner walls of the two sides of the box body 1, both sides of the top of the pressing platform 7 are respectively provided with a holding tank 8, an inner wall at one end of the holding tank 8 is hinged with a support rod 9, the inner bottom of the inner side of the holding tank 8 is movably connected with an electric cylinder 10, the output end of the electric cylinder 10 is rotatably connected with the middle of the support rod 9, the top of the support rod 9 is rotatably connected with a bearing plate 11, the central authorities that squeeze platform 7 run through and are equipped with tube-shape casing 12, the end of bearing plate 11 extends to tube-shape casing 12 and fixed mounting have gear 13, the inboard bottom fixed mounting of tube-shape casing 12 has push rod motor 14, the vertical two-sided rack 15 of fixedly connected with that makes progress of push rod motor 14's output, gear 13 with two-sided rack 15 meshes and connects, bearing plate 11 is close to first feed opening 16 has been seted up to tube-shape casing 12's one end, squeeze platform 7's central authorities have seted up second feed opening 18, the below slope of second feed opening 18 is equipped with filter screen 19, the bottom fixedly connected with stock guide 20 of filter screen 19, the inboard bottom of box 1 is equipped with oil tank 21, the both sides of oil tank 21 all are equipped with waste material collecting box 22.

In this embodiment, it is preferable that a plurality of supporting blocks 23 are fixed to a surface of the press table 7, and an upper end surface of the supporting block 23 is in contact with a bottom of the pressure bearing plate 11.

In this embodiment, preferably, openings adapted to the pressure-bearing plate 11 are formed at upper ends of two sides of the cylindrical housing 12.

In this embodiment, preferably, both sides of the double-sided rack 15 are fixedly connected with first sliding blocks 24, the inner walls of both sides of the cylindrical shell 12 are symmetrically and fixedly provided with first sliding rails 25, and the first sliding blocks 24 are adapted to the first sliding rails 25.

In this embodiment, preferably, the bottom of the second feed opening 18 is fixedly connected with a baffle plate 26, the baffle plate 26 is parallel to the filter screen 19, and the bottom of the filter screen 19 is fixed with the vibration motor 17.

In this embodiment, preferably, a second sliding block 27 is fixed at the bottom of the oil tank 21, a second sliding rail 28 is fixed at the bottom of the inner side of the box body 1, and the second sliding block 27 is adapted to the second sliding rail 28.

It should be noted that, the utility model relates to a quick oil expression device convenient to take out residues, when using, firstly, throw the walnut after handling into the box 1 through the feeder hopper 2, and fall on the bearing plate 11, then start the hydraulic cylinder 3, the hydraulic cylinder 3 drives the squeeze board 6 to move downwards through the transmission rod 4, squeeze the walnut, after squeezing, along with the included angle between the bearing plate 11 and the squeezing platform 7 is bigger and bigger, at this moment, the walnut oil flows downwards along the gradient of the bearing plate 11, the oil passes through the first feed opening 16 and the second feed opening 18 in sequence and falls on the filter screen 19, enter the oil tank 21 after being filtered by the filter screen 19, the hydraulic cylinder 3 contracts the transmission rod to restore the squeeze board 6 to the original position, then start the push rod motor 14 and the electric cylinder 10, the push rod motor 14 drives the double-sided rack 15 to move upwards, the double-sided rack 15 drives the gear 13 to rotate, gear 13 then drives bearing plate 11 and rotates, electronic jar 10 drives bracing piece 9 and rotates simultaneously, bracing piece 9 further drives bearing plate 11 and rotates, and then make two bearing plates 11 draw close to tube-shape casing 12, thereby make the walnut sediment on bearing plate 11 surface roll down along bearing plate 11 surface, and from first feed opening 16 what second feed opening 18 fall down, then fall on filter screen 19, start vibrating motor 17 this moment and drive the vibrations of filter screen 19, make the walnut sediment follow filter screen 19 and stock guide 20 get into in garbage collection box 22, be convenient for collect the walnut sediment after squeezing, and the time of operation is saved, and the work efficiency is greatly improved.

The basic principles and the main features of the invention and the advantages of the invention have been shown and described above. It will be understood by those skilled in the art that the present invention is not limited to the above embodiments, and that the foregoing embodiments and descriptions are provided only to illustrate the principles of the present invention without departing from the spirit and scope of the present invention. The scope of the invention is defined by the appended claims and equivalents thereof.

Claims (6)

1. The utility model provides a device extracts oil fast convenient to take out residue, includes box (1), its characterized in that: the automatic conveying device is characterized in that a feed hopper (2) is arranged in the middle of one side of the box body (1) in a penetrating mode, a hydraulic cylinder (3) is fixedly mounted at the top of the inner side of the box body (1), a transmission rod (4) is fixedly connected to the output end of the hydraulic cylinder (3) vertically and downwards, a mounting plate (5) is fixedly mounted at the bottom of the transmission rod (4), a squeezing plate (6) is fixedly mounted at the bottom of the mounting plate (5), the bottom of the squeezing plate (6) is V-shaped, a squeezing table (7) is fixedly mounted between the inner walls of the two sides of the box body (1), accommodating grooves (8) are formed in the two sides of the top of the squeezing table (7), a support rod (9) is hinged to the inner wall of one end of each accommodating groove (8), an electric cylinder (10) is movably connected to the bottom of the inner side of each accommodating groove (8), and the output end of each electric cylinder (10) is rotatably connected with the middle of each support rod (9), the top of bracing piece (9) is rotated and is connected with bearing plate (11), the central authorities that squeeze platform (7) run through and are equipped with tube-shape casing (12), the end of bearing plate (11) extends to tube-shape casing (12) and fixed mounting have gear (13), the inboard bottom fixed mounting of tube-shape casing (12) has push rod motor (14), the vertical two-sided rack (15) of upwards fixedly connected with of output of push rod motor (14), gear (13) with two-sided rack (15) meshing is connected, first feed opening (16) have been seted up to the one end that bearing plate (11) are close to tube-shape casing (12), second feed opening (18) have been seted up to the central authorities that squeeze platform (7), the below slope of second feed opening (18) is equipped with filter screen (19), the bottom fixedly connected with guide plate (20) of filter screen (19), an oil tank (21) is arranged at the bottom of the inner side of the tank body (1), and waste collecting tanks (22) are arranged on two sides of the oil tank (21).

2. The quick oil expeller device as set forth in claim 1, wherein: a plurality of supporting blocks (23) are fixed on the surface of the pressing table (7), and the upper end surfaces of the supporting blocks (23) are in contact with the bottom of the pressure bearing plate (11).

3. The quick oil expeller device as set forth in claim 1, wherein: the upper ends of the two sides of the cylindrical shell (12) are provided with openings matched with the bearing plates (11).

4. The quick oil expeller device as set forth in claim 1, wherein: the two sides of the double-sided rack (15) are fixedly connected with first sliding blocks (24), the inner walls of the two sides of the cylindrical shell (12) are symmetrically and fixedly provided with first sliding rails (25), and the first sliding blocks (24) are matched with the first sliding rails (25).

5. The quick oil expeller device as set forth in claim 1, wherein: the bottom fixedly connected with striker plate (26) of second feed opening (18), striker plate (26) with filter screen (19) parallel, the bottom of filter screen (19) is fixed with vibrating motor (17).

6. The quick oil expeller device as set forth in claim 1, wherein: the bottom of oil tank (21) is fixed with second slider (27), the inboard bottom of box (1) is fixed with second slide rail (28), second slider (27) with second slide rail (28) looks adaptation.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202021737466.7U CN213860835U (en) | 2020-08-19 | 2020-08-19 | Device extracts oil fast convenient to take out residue |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202021737466.7U CN213860835U (en) | 2020-08-19 | 2020-08-19 | Device extracts oil fast convenient to take out residue |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN213860835U true CN213860835U (en) | 2021-08-03 |

Family

ID=77046874

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202021737466.7U Active CN213860835U (en) | 2020-08-19 | 2020-08-19 | Device extracts oil fast convenient to take out residue |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN213860835U (en) |

-

2020

- 2020-08-19 CN CN202021737466.7U patent/CN213860835U/en active Active

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN110193411B (en) | Waste paper recycling device for garbage station and using method thereof | |

| CN109731632B (en) | Concrete waste recovery device for civil engineering | |

| CN207839129U (en) | A kind of fruit-vegetable food safety monitoring crushing filtrate separator | |

| CN210752919U (en) | Waste recovery device for producing lunch box | |

| CN210357325U (en) | Domestic waste crushing apparatus | |

| CN108889017A (en) | Rural area waste reduction and disposal equipment | |

| CN213860835U (en) | Device extracts oil fast convenient to take out residue | |

| CN108312601B (en) | Machining iron fillings briquetting collection device | |

| CN108130386B (en) | Sugarcane squeezing device for sugarcane sugar making equipment | |

| CN212915954U (en) | Kitchen garbage squeezes dewatering device | |

| CN211284405U (en) | Five roller sugarcane of ancient ways squeeze environmental protection equipment | |

| CN211467587U (en) | Kitchen waste pretreatment equipment | |

| CN111545319A (en) | Novel kitchen garbage treatment device | |

| CN210586337U (en) | Garbage collection device for food production | |

| CN217916903U (en) | Food processing machinery is with squeezing device | |

| CN216961403U (en) | Orange juice production is with novel equipment that squeezes | |

| CN109228484A (en) | A kind of throwaway chopsticks compacting recyclable device | |

| CN215736764U (en) | Apple juice squeezing device for apple beverage production | |

| CN211913977U (en) | Solid waste treatment equipment | |

| CN218663546U (en) | Garbage compression station | |

| CN220071875U (en) | Marine bioactive substance extractor | |

| CN220841568U (en) | Grape wine raw material screw press | |

| CN215969088U (en) | Green environmental protection type die-cutting machine guide type waste discharge device | |

| CN213340493U (en) | Filter pressing mechanism of lead storage battery | |

| CN220411617U (en) | Garbage can with built-in crushing and compressing structure |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |