CN213132288U - Rural sewage is sewage collection device for sewage treatment - Google Patents

Rural sewage is sewage collection device for sewage treatment Download PDFInfo

- Publication number

- CN213132288U CN213132288U CN202021832388.9U CN202021832388U CN213132288U CN 213132288 U CN213132288 U CN 213132288U CN 202021832388 U CN202021832388 U CN 202021832388U CN 213132288 U CN213132288 U CN 213132288U

- Authority

- CN

- China

- Prior art keywords

- sewage

- box body

- filter screen

- face

- collecting box

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Abstract

The utility model discloses a rural sewage collection device for sewage treatment, including the collection box of built-in preliminary treatment mechanism, collect the box inside by the barrier plate separate become about two parts, the barrier plate left side slope sets up coarse filtration net board, the right side sets up thin filter screen basket, sewage is by advancing dirty pipe entering collection box, filter on guide plate water conservancy diversion to stainless steel coarse filtration net board, then deposit in the box of left side, then get into right side box through thin filter screen basket secondary filtration through running through the chamber on the barrier plate, later get into follow-up sewage treatment device through the outlet pipe by gate valve control flow. The utility model discloses can carry out preliminary treatment and flow control to rural sewage, alleviate follow-up sewage treatment device load, and it is effectual through secondary filter treatment, later maintenance is convenient, simple structure.

Description

Technical Field

The utility model belongs to the technical field of sewage treatment device technique and specifically relates to a sewage collection device for handling rural sewage is related to.

Background

Sewage treatment is a process of purifying sewage to meet the water quality requirement of discharging the sewage into a certain water body or reusing the sewage. Sewage treatment is widely applied to various fields such as buildings, agriculture, traffic, energy, petrifaction, environmental protection, urban landscape, medical treatment, catering and the like, and is increasingly used in daily life of common people.

In the rural sewage treatment process, sewage needs to be collected firstly, but the existing collecting device has a single structure, can only store sewage, cannot pretreat the sewage, and cannot adjust the flow, so that the workload of sewage treatment equipment is increased when the sewage is treated due to the change of the sewage flow.

In view of this, the utility model is especially provided.

SUMMERY OF THE UTILITY MODEL

For solving the technical problem who proposes among the background art, the utility model aims at providing a rural collection device for sewage treatment has rational in infrastructure, can carry out secondary filter to sewage, and the preliminary treatment is effectual, and later maintenance is convenient, simple structure, and the characteristics that the practicality is strong effectively alleviate follow-up sewage treatment device's work load.

The technical scheme of the utility model is that, a rural sewage treatment collecting device is provided, including collecting the box, the welding of collecting box left end face upper portion has into dirty pipe, is equipped with pretreatment mechanism in the collecting box, pretreatment mechanism includes barrier plate, thin filter screen basket, thick filter screen board, sediment box body, outlet pipe and gate valve, barrier plate erects and establishes in collecting box inside left side, and the barrier plate front and back terminal surface welds with collecting box inner wall front and back both sides, divides collecting the box into left and right parts, and collecting box left end face upside has seted up the landing chamber, the thick filter screen board erects and establishes in the middle of the upper end face left side of barrier plate and landing chamber, and the landing chamber link up with the sediment box body, the sediment box body laminating is established at collecting the left end face of box; a fine filter screen basket is arranged on the right side in the collection box body on the right side of the barrier plate; a water outlet pipe is welded on the lower side of the right end face of the collecting box body, a gate valve is installed at the right end of the water outlet pipe, and water outlet flow can be controlled.

Preferably, the upper end face of the collecting box body is clamped with an openable box cover plate, and a lifting handle is welded in the middle of the upper end face of the box cover plate. The left side and the right side of the upper end face of the fine filter screen basket are symmetrically welded with hanging rings, and the right side of the upper end face of the coarse filter screen plate is welded with a lifting seat.

Preferably, the coarse filter screen plate is arranged in an inclined mode, specifically in a mode of being low at the left side and high at the right side, and inclines from one end, which is positioned on the left side of the upper end face of the barrier plate, of the coarse filter screen plate to the other end, which is arranged in the sliding cavity, so that large-particle impurities coarsely filtered out can fall into the sliding cavity by means of gravity.

Preferably, a guide plate is arranged below the sewage inlet pipe orifice on the left side of the inner wall of the collecting box body and can guide sewage to the center of the coarse filter screen plate.

Preferably, the lower side of the left end face of the collecting box body is welded with a drain pipe, and the left end face of the drain pipe is provided with a quick drain valve for discharging precipitated sludge.

Preferably, the inside upside of barrier plate has seted up and has run through the chamber, and sewage can follow and run through the chamber and get into collection box right side.

Preferably, a hanging seat is welded on the lower portion of the right end face of the slag storage box body, a clamping groove is formed in the middle of the left end face of the collecting box body and matched with the hanging seat, and the slag storage box body is attached and fixed to the left end face of the collecting box body.

Preferably, the coarse screen plate and the fine screen basket are made of stainless steel.

The utility model has the advantages that: the left side in the collecting box body of the utility model is provided with the baffle plate, the left side of the baffle plate is provided with the stainless steel coarse filter screen plate, when sewage flows into the collecting box body from the sewage inlet pipe, the sewage falls on the inclined stainless steel coarse filter screen plate through the guide plate to carry out coarse filtration, and then falls on the left side in the collecting box body to be precipitated, and large granular impurities which are coarsely filtered are collected by the slag storage box body which is arranged on the left end surface of the collecting box body through the left sliding cavity of the collecting box body; after the liquid level of the sewage rises, the sewage enters the right side of the collection box body, secondary filtration is carried out through the arranged stainless steel coarse filter screen basket, and the pretreated sewage can be conveyed to external sewage treatment equipment by opening the gate valve of the water outlet pipe on the lower side of the right end face of the collection box body; the coarse filter screen plate and the fine filter screen basket can be detached in a lifting mode and can be installed and used again after being cleaned. Adopt above-mentioned technical scheme, can solve current sewage collection device and can not carry out the preliminary treatment to sewage, also can not carry out flow control and lead to the big problem of follow-up sewage treatment device load, and can carry out secondary filter to sewage, compare with once filtering and can improve the preliminary treatment effect, equipment maintenance is convenient.

Drawings

In order to more clearly illustrate the embodiments of the present invention or the technical solutions in the prior art, the drawings used in the description of the embodiments or the prior art will be briefly described below, and it is obvious that the drawings in the following description are some embodiments of the present invention, and other drawings can be obtained by those skilled in the art without creative efforts.

FIG. 1 is a schematic structural view of a sewage collecting device for rural sewage treatment of the present invention;

FIG. 2 is a front sectional view of a pretreatment mechanism of a sewage collection device for rural sewage treatment of the utility model;

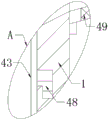

fig. 3 is an enlarged view of a in fig. 2 according to the present invention.

In the figure: 1: collection box, 2: case lid board, 3: sewage inlet pipe, 4: pretreatment mechanism, 21: lifting handle, 41: stainless steel fine filter screen basket, 42: deflector, 43: slag storage box body, 44: quick blowoff valve, 45: blocking plate, 46: water outlet pipe, 47: gate valve, 48: hanging seat, 49: stainless steel coarse filter screen plate, 441: blow off pipe, 451: through the cavity.

Detailed Description

It should be noted that the following detailed description is exemplary and is intended to provide further explanation of the disclosure. Unless defined otherwise, all technical and scientific terms used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this application belongs.

It is noted that the terminology used herein is for the purpose of describing particular embodiments only and is not intended to be limiting of example embodiments according to the present application. As used herein, the singular forms also include the plural forms unless the context clearly dictates otherwise, and further, it is understood that when the terms "comprises" and/or "comprising" are used in this specification, they specify the presence of the stated features, steps, operations, devices, components, and/or combinations thereof.

The technical solutions of the present invention will be described clearly and completely with reference to the following embodiments, and it should be understood that the described embodiments are some, but not all, embodiments of the present invention. All other embodiments, which can be derived by a person skilled in the art from the embodiments given herein without making any creative effort, shall fall within the protection scope of the present invention.

Example 1

Referring to fig. 1, the present invention provides a technical solution: a sewage collecting device for rural sewage treatment comprises a collecting box body 1 and a sewage inlet pipe 3, wherein a box cover plate 2 is clamped on the upper end face of the collecting box body 1, the sewage inlet pipe 3 is welded on the upper side of the left end face of the collecting box body 1, and a pretreatment mechanism 4 is arranged inside the collecting box body 1;

referring to fig. 2 and 3, the preprocessing mechanism includes: a stainless steel fine filter screen basket 41, a guide plate 42, a slag storage box body 43, a quick blowoff valve 44, a baffle plate 45, a water outlet pipe 46, a gate valve 47, a hanging seat 48 and a stainless steel coarse filter screen plate 49, wherein the left side inside the collection box body 1 is welded with the baffle plate 45, the front end face, the rear end face and the bottom of the baffle plate 45 are connected with the inner wall of the collection box body 1 in a welding way to divide the collection box body 1 into a left part and a right part, the upper side of the left end face of the collection box body 1 is provided, the sliding cavity is communicated with the upper side of the right end face of the slag storage box body 43, the stainless steel coarse filter screen plate 49 is erected between the left side of the upper end face of the barrier plate 45 and the sliding cavity, the stainless steel coarse filter screen plate 49 is obliquely arranged, specifically in a mode of being low at the left side and high at the right side, and is obliquely arranged from one end, positioned on the left side of the upper end face of the barrier plate 45, to the other end of the sliding cavity, and the left side of the inner wall of the collection box body 1 is welded with a guide plate 42 which can guide sewage flowing in from a sewage pipe to the middle of the; collect 1 left end face laminating of box and have storage sediment box body 43, the welding of storage sediment box body 43 right-hand member face downside has a seat of hanging 48, collect 1 left side of box and install quick blowoff valve 44, baffle 45 inside upside has been seted up and has been run through the chamber 451, sewage flows into the inside right side of collection box 1 through running through the chamber 451, carry out secondary filter by stainless steel fine filter screen basket 41, collect 1 right-hand member face downside welding of box and have outlet pipe 46, outlet pipe 46 right-hand member face installs gate valve 47 with the controlled water yield, collect 1 inside right side of box and placed stainless steel fine filter screen basket 41.

A lifting handle 21 is welded in the middle of the upper end face of the box cover plate 2, the lifting handle 21 is convenient for lifting and opening the box cover plate 2, a stainless steel coarse filter screen plate and a stainless steel fine filter screen basket are convenient to clean, a drain pipe 441 is welded on the lower side of the left end face of the collection box body 1, the drain pipe 441 is convenient for discharging sludge accumulated in the collection box body 1 due to sewage precipitation, hanging rings are symmetrically welded on the left side and the right side of the upper end face of the stainless steel fine filter screen basket 41, a lifting seat is welded on the right side of the upper end face of the stainless steel coarse filter screen plate 49 and used for lifting and disassembling the stainless steel fine filter screen basket 41, a clamping groove is formed in the middle of the left end face of the collection box body 1 and matched with a hanging seat 48 of a slag storage box body 43, the clamping groove is convenient for fixing the hanging seat 48, so as to conveniently install and position the slag storage box body 43, the sliding cavity facilitates the impurities blocked by the upper end surface of the stainless steel coarse filter screen plate 49 to slide into the slag storage box body 43 under the influence of self gravity.

The working principle is as follows: when in use, the sewage inlet pipe 3 is firstly connected with an external sewage discharge outlet, then the quick sewage discharge valve 44 is connected with an external sludge pool inlet through a pipeline, then the gate valve 47 is connected with an external sewage treatment equipment inlet through a pipeline, when sewage flows into the collection box body 1 from the sewage inlet pipe 3, the sewage is guided by the guide plate 42 to fall in the middle position of the stainless steel coarse filter screen plate 49 for rough filtration, large granular impurities which are insoluble in water in the sewage are blocked, the sewage then falls to the left side inside the collection box body 1 for sedimentation, the blocked large granular impurities slide to the left side along the inclined stainless steel coarse filter screen plate 49 under the action of gravity, pass through the sliding chamber to the slag storage box body 43 for temporary placement, when the water level of the sewage at the left side inside the collection box body 1 is higher than the height of the through chamber 451 on the blocking plate, the sewage passes through the through chamber 451 and flows to the stainless steel fine filter screen basket 41 to the right side for secondary filtration, the small particle impurities which are insoluble in water in the sewage are blocked, then the sewage flows into the gate valve 47 through the water outlet pipe 46, and the treated sewage can be discharged into the external sewage treatment equipment by opening the gate valve 47.

When the impurities in the slag storage box body 43 are accumulated to a certain height, the slag storage box body 43 can be detached to be cleaned by lifting the slag storage box body 43 to the upper side by hand, then the slag storage box body 43 is hung and fixed on the left end face of the collection box body 1 through the hanging seat 48, when the sludge accumulated on the left side in the collection box body 1 needs to be cleaned, the accumulated sludge can be discharged to an external sludge pool by only opening the quick drain valve 44, when the stainless steel coarse filter screen plate 49 and the stainless steel fine filter screen basket 41 need to be cleaned, the box cover plate 2 is firstly lifted and opened by the lifting handle 21, and then the hanging ring and the lifting seat are lifted by an external hook, so that the stainless steel coarse filter screen plate 49 and the stainless steel fine filter screen basket 41 can be lifted and cleaned from the collection box body 1.

The basic principles and the main features of the invention and the advantages of the invention have been shown and described above, it will be evident to those skilled in the art that the invention is not limited to the details of the foregoing illustrative embodiments, but that the invention may be embodied in other specific forms without departing from the spirit or essential characteristics of the invention. The present embodiments are therefore to be considered in all respects as illustrative and not restrictive, the scope of the invention being indicated by the appended claims rather than by the foregoing description, and all changes which come within the meaning and range of equivalency of the claims are therefore intended to be embraced therein. Any reference sign in a claim should not be construed as limiting the claim concerned.

Furthermore, it should be understood that although the present description refers to embodiments, not every embodiment may contain only a single embodiment, and such description is for clarity only, and those skilled in the art should integrate the description, and the embodiments may be combined as appropriate to form other embodiments understood by those skilled in the art.

Finally, it should be noted that: the above embodiments are only used to illustrate the technical solution of the present invention, and not to limit the same; while the invention has been described in detail and with reference to the foregoing embodiments, it will be understood by those skilled in the art that: the technical solutions described in the foregoing embodiments may still be modified, or some or all of the technical features may be equivalently replaced; and the modifications or the substitutions do not make the essence of the corresponding technical solutions depart from the scope of the technical solutions of the embodiments of the present invention.

Claims (9)

1. A sewage collecting device for rural sewage treatment is characterized by comprising a collecting box body,

the sewage collecting device is characterized in that a sewage inlet pipe is arranged on the left end face of the collecting box body, a pretreatment mechanism is arranged in the collecting box body and comprises a barrier plate, a fine filter screen basket, a coarse filter screen plate, a slag storage box body, a water outlet pipe and a gate valve, the barrier plate is arranged on the left side in the collecting box body, the coarse filter screen plate is arranged on the left side of the upper end face of the barrier plate, a sliding cavity is formed in the upper side of the left end face of the collecting box body and communicated with the slag storage box body, and the slag storage box body is arranged on the left end face of the collecting box; a fine filter screen basket is arranged on the right side in the collection box body on the right side of the barrier plate;

a water outlet pipe is arranged on the lower side of the right end face of the collecting box body, and a gate valve is installed at the right end of the water outlet pipe.

2. The sewage collecting device for rural sewage treatment as claimed in claim 1, wherein a box cover plate is clamped on an upper end face of the collecting box body, and a lifting handle is arranged in the middle of the upper end face of the box cover plate.

3. The sewage collecting device for rural sewage treatment as defined in claim 1, wherein hanging rings are symmetrically arranged on the left and right sides of the upper end surface of the fine filter screen basket, and a lifting seat is arranged on the right side of the upper end surface of the coarse filter screen plate.

4. The sewage collecting device for rural sewage treatment according to claim 1, wherein a guide plate is arranged on the left side of the inner wall of the collecting box body.

5. The sewage collecting device for rural sewage treatment as claimed in claim 1, wherein a drain pipe is arranged at the lower side of the left end face of the collecting box body, and a quick drain valve is arranged on the left end face of the drain pipe.

6. The sewage collecting device for rural sewage treatment as claimed in claim 1, wherein the front and rear end surfaces of the blocking plate are connected with the front and rear sides of the inner wall of the collecting box body, and the upper side of the inside of the blocking plate is provided with a through cavity.

7. The rural sewage treatment wastewater collection device of claim 1, wherein the coarse screen plate is arranged obliquely.

8. The sewage collecting device for rural sewage treatment as defined in claim 1, wherein said slag storage box is fitted on the left end surface of said collecting box, a hanging seat is welded under the right end surface of said slag storage box, a clamping groove is provided in the middle of the left end surface of said collecting box, and said clamping groove is matched with said hanging seat.

9. The sewage collecting device for rural sewage treatment according to claim 1, wherein the coarse filter screen plate is a stainless steel coarse filter screen plate, and the fine filter screen basket is a stainless steel fine filter screen basket.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202021832388.9U CN213132288U (en) | 2020-08-28 | 2020-08-28 | Rural sewage is sewage collection device for sewage treatment |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202021832388.9U CN213132288U (en) | 2020-08-28 | 2020-08-28 | Rural sewage is sewage collection device for sewage treatment |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN213132288U true CN213132288U (en) | 2021-05-07 |

Family

ID=75742760

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202021832388.9U Active CN213132288U (en) | 2020-08-28 | 2020-08-28 | Rural sewage is sewage collection device for sewage treatment |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN213132288U (en) |

-

2020

- 2020-08-28 CN CN202021832388.9U patent/CN213132288U/en active Active

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN214571260U (en) | Environmental engineering sewage recovery unit | |

| CN213132288U (en) | Rural sewage is sewage collection device for sewage treatment | |

| CN210845553U (en) | Self-service effluent treatment plant for carwash | |

| CN201390659Y (en) | Oil collecting and removal device | |

| CN208229479U (en) | A kind of sewage treatment scum collector | |

| CN213101010U (en) | Ore dressing waste water filters and uses filter residue collection device | |

| CN207418459U (en) | The net filter of micropore flocculation reaction deposition | |

| CN209456193U (en) | One kind being used for powder sewage-treatment plant | |

| CN208667316U (en) | A kind of sewage disposal device | |

| CN207525854U (en) | Roofing, ground rainwater cleaning system | |

| CN208700636U (en) | A kind of unpowered oil removal settling tank | |

| CN207845358U (en) | A kind of full-automatic separation of solid and liquid sewage disposal system | |

| CN207776055U (en) | Buried roofing, ground rainwater reuse purification system | |

| CN111635023A (en) | Large-traffic continuous discharge sewage treatment system | |

| CN219149521U (en) | Sewage treatment mud discharging device | |

| CN207418354U (en) | Flocculation reaction deposition separator | |

| CN215365232U (en) | Sewage circulation treatment facility for hydraulic engineering | |

| CN208829531U (en) | Reversed flocculating concentration apparatus | |

| CN204841190U (en) | Rain water treatment facilities | |

| CN219823708U (en) | Electroplating sewage filtering box | |

| CN207436240U (en) | Roofing, ground rainwater purification pre-processing system | |

| CN218221482U (en) | Integration sand sedimentation tank with prescreening function | |

| CN212740981U (en) | High-efficient sewage treatment device is used in city | |

| CN213725277U (en) | Large-particle impurity filtering device for sewage treatment | |

| CN209348184U (en) | A kind of inclined-plate clarifying basin based on active iron medicament |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |