CN212958261U - Sealing structure of casement window - Google Patents

Sealing structure of casement window Download PDFInfo

- Publication number

- CN212958261U CN212958261U CN202021452801.9U CN202021452801U CN212958261U CN 212958261 U CN212958261 U CN 212958261U CN 202021452801 U CN202021452801 U CN 202021452801U CN 212958261 U CN212958261 U CN 212958261U

- Authority

- CN

- China

- Prior art keywords

- strip

- sash

- preset

- sealing

- connecting piece

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Specific Sealing Or Ventilating Devices For Doors And Windows (AREA)

Abstract

The specifications of the duckbill sealant strip on the market at present have a large size suitable for larger profiles and a small size suitable for smaller profiles, wherein the existing large-size duckbill sealant strip has a structural defect, so that the durability and the sealing property are not good enough. For solving the current problem, the utility model provides a seal structure of flat-open window, including window frame and casement, wherein, a connecting elements has been preset to the window frame, connecting elements is fixed to be inlayed and is equipped with a first joint strip, through the durability of joint strip is reinforceed to first joint strip's structure.

Description

Technical Field

The utility model belongs to the technical field of building door and window's technique and specifically relates to a seal structure of flat-open window is related to.

Background

In order to enable a casement window to have better sound insulation performance, particularly the sound insulation performance of the casement window with hollow glass, a common duckbilled sealing rubber strip in the prior art has the specification suitable for a large size of a large section bar and the specification suitable for a small size of a small section bar in the current market, wherein the existing large-size duckbilled sealing rubber strip has the defects in structure, so that the durability and the sealing performance are not good enough; in addition, present duckbilled joint strip often installs with on the casement, makes duckbilled joint strip easily age to reducing the leakproofness.

SUMMERY OF THE UTILITY MODEL

To the not enough of prior art, the utility model aims to provide a seal structure of flat-open window.

In order to achieve the above object, the present invention provides a sealing structure for a casement window, comprising a window frame and a window sash, wherein the window frame is preset with a connecting assembly, the connecting assembly is composed of a connecting piece inner profile and a connecting piece outer profile which are fixedly connected by embedding two first heat insulating strips, and the connecting assembly is fixedly embedded with a first sealing rubber strip; a long platform is preset on one side, close to the connecting assembly, of the first sealing rubber strip, and two symmetrically-arranged buckles are integrally formed on two sides of the long platform, wherein the two buckles are respectively embedded in the connecting piece inner profile and the connecting piece outer profile; a bevel edge and a short platform are preset on one side, close to the window sash, of the first sealing rubber strip, wherein a pressing buckle is formed at one end of the bevel edge and abuts against the inner section of the connecting piece; a triangular pressing end is preset on the short platform; a plurality of reinforcing ribs with different lengths are preset in the first sealing rubber strip; the sash is preset with a sash inner profile and a sash outer profile which are fixedly connected through embedding a second heat insulation strip and a third heat insulation strip, wherein the third heat insulation strip is arranged on one side far away from the connecting component, the second heat insulation strip is arranged on one side close to the connecting component, and a blocking strip is integrally formed on one side of the second heat insulation strip close to the connecting component; when the window sash is closed, the barrier strip is in sealing fit with the triangular pressing end.

Furthermore, sealing grooves are preset in the outer sash edge section and the inner connecting piece section; and a second sealing rubber strip is fixedly embedded in each sealing groove.

Further, when the window sash is closed, the connecting piece inner section is attached to the sash edge inner section through the second sealing rubber strip, and the sash edge outer section is attached to the connecting piece outer section through the second sealing rubber strip.

The utility model has the advantages that: the durability of the adhesive tape is strengthened through the structure of the first sealing adhesive tape, wherein the triangular structure of the triangular pressing end enables the triangular pressing end to be more stable when the triangular pressing end abuts against the barrier strip, and the formed sealing performance is better; in addition, the first sealing rubber strip is installed on the window frame, so that the aging of the first sealing rubber strip is slowed down.

Drawings

Fig. 1 is a schematic view of a sealing structure of the casement window.

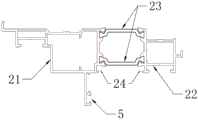

Fig. 2 is a schematic view of the connection assembly.

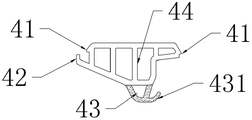

Fig. 3 is a schematic view of the first joint strip.

Fig. 4 is a schematic view of the sash.

The window frame comprises a window frame 1, a connecting assembly 2, a connecting assembly 21, a connecting assembly inner section bar 22, a connecting assembly outer section bar 23, a first heat insulation strip 24, a groove 3, a window sash 31, a sash inner section bar 32, a sash outer section bar 33, a second heat insulation strip 34, a third heat insulation strip 35, a barrier strip 4, a first sealing rubber strip 41, a buckle 42, a press buckle 43, a triangular press end 43, a 431-duckbilled press head 44, a reinforcing rib 5, a sealing groove 6 and a second sealing rubber strip.

Detailed Description

In order to facilitate understanding of the present invention, the present invention will be described more fully hereinafter with reference to the accompanying drawings. The preferred embodiments of the present invention are shown in the drawings. The invention may, however, be embodied in many different forms and should not be construed as limited to the embodiments set forth herein. These embodiments are provided so that this disclosure will be thorough and complete.

Referring to fig. 1, 2 or 3, the sealing structure of a casement window comprises a window frame 1 and a window sash 3, wherein the window frame 1 is provided with a connecting assembly 2 in advance to be hinged with the window sash 3. The connecting component 2 is composed of a connecting component inner section 21 and a connecting component outer section 22, wherein the connecting component inner section 21 and the connecting component outer section 22 are fixedly connected through two first heat insulation strips 23 which are embedded and symmetrically distributed up and down, and a groove 24 is preset on both the outer edge of the connecting component inner section 21 and the outer edge of the connecting component outer section 22. A first sealing rubber strip 4 is arranged on one side, close to the window sash 3, of the connecting assembly 2, a long platform is preset on one side, close to the connecting assembly 2, of the first sealing rubber strip 4, two symmetrically-distributed buckles 41 are integrally formed on two sides of the long platform, and the two buckles 41 are fixedly embedded in the two grooves 24 respectively, so that the first sealing rubber strip 4 is fixedly connected with the connecting assembly 2; a bevel edge and a short platform are preset on one side of the first sealing rubber strip 4 close to the window sash 3, wherein a pressing buckle 42 is formed at one end of the bevel edge, and the pressing buckle 42 is pressed against the connecting piece inner section bar 21, so that the buckle 41 is more stably embedded in the groove 24; a triangular pressing end 43 is preset on the short platform, the triangular pressing end 43 is triangular to enable the structure to be stable, and a triangular side line is formed by extending to form a duckbilled pressing head 431 in an arc shape; three reinforcing ribs 44 with different lengths are preset inside the first sealing rubber strip 4, wherein the length of the reinforcing rib 44 positioned at the middle is the longest.

Referring to fig. 1, 2 or 4, a sash inner profile 31 and a sash outer profile 32 are preset on the window sash 3, the sash inner profile 31 and the sash outer profile 32 are fixedly connected by a second heat insulation strip 33 and a third heat insulation strip 34 which are embedded and distributed up and down, wherein the third heat insulation strip 34 is arranged on one side far away from the connecting assembly 2, the second heat insulation strip 33 is arranged on one side close to the connecting assembly 2, and a blocking strip 35 is integrally formed on one side of the second heat insulation strip 33 close to the connecting assembly 2. The fan-edge outer section 32 and the connecting piece inner section 21 are integrally formed with a sealing groove 5, and two second sealing rubber strips 6 are fixedly embedded in the two sealing grooves 5 respectively.

When the window sash 3 is closed, the connecting piece inner section 21 is sealed and attached to the sash edge inner section 31 through the second sealing rubber strip 6; the outer sash edge profile 32 is tightly attached to the outer connecting piece profile 22 through the second sealing rubber strip 6; the barrier strip 35 with duckbilled pressure head 431 supports each other and presses and sealed laminating, makes casement 3 with be formed with two sealed chambeies between coupling assembling 2, realize good sealed effect.

The above-described embodiments are merely preferred embodiments of the present invention, which are not intended to limit the present invention in any way. Those skilled in the art can make many changes, modifications, and equivalents of the embodiments of the invention without departing from the scope of the invention. Therefore, the content of the technical scheme of the utility model, according to the equivalent change made by the idea of the utility model, should be covered in the protection scope of the utility model.

Claims (3)

1. The utility model provides a sealing structure of flat-open window, includes window frame (1) and casement (3), its characterized in that: a connecting component (2) is preset on the window frame (1), the connecting component (2) consists of a connecting piece inner profile (21) and a connecting piece outer profile (22) which are fixedly connected through embedding two first heat insulation strips (23), and a first sealing rubber strip (4) is fixedly embedded in the connecting component (2); a long platform is preset on one side, close to the connecting component (2), of the first sealing rubber strip (4), two symmetrically-arranged buckles (41) are integrally formed on two sides of the long platform, and the two buckles (41) are respectively embedded in the connecting piece inner profile (21) and the connecting piece outer profile (22); one side of the first sealing rubber strip (4) close to the window sash (3) is preset with a bevel edge and a short platform, wherein one end of the bevel edge is formed with a press buckle (42), and the press buckle (42) is pressed against the connecting piece inner section bar (21); a triangular pressing end (43) is preset on the short platform; a plurality of reinforcing ribs (44) with different lengths are preset in the first sealing rubber strip (4); a sash inner section (31) and a sash outer section (32) which are fixedly connected through embedding a second heat insulation strip (33) and a third heat insulation strip (34) are preset on the sash (3), wherein the third heat insulation strip (34) is arranged on one side far away from the connecting component (2), the second heat insulation strip (33) is arranged on one side close to the connecting component (2), and a blocking strip (35) is integrally formed on one side, close to the connecting component (2), of the second heat insulation strip (33); when the window sash (3) is closed, the barrier strip (35) is in sealing fit with the triangular pressing end (43).

2. A sealing structure of a casement window according to claim 1, wherein: the sealing grooves (5) are preset in the fan-edge outer section (32) and the connecting piece inner section (21); and a second sealing rubber strip (6) is fixedly embedded in each sealing groove (5).

3. A sealing structure of a casement window according to claim 2, wherein: when the window sash (3) is closed, the connecting piece inner section bar (21) is attached to the sash edge inner section bar (31) through the second sealing rubber strip (6), and the sash edge outer section bar (32) is attached to the connecting piece outer section bar (22) through the second sealing rubber strip (6).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202021452801.9U CN212958261U (en) | 2020-07-22 | 2020-07-22 | Sealing structure of casement window |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202021452801.9U CN212958261U (en) | 2020-07-22 | 2020-07-22 | Sealing structure of casement window |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN212958261U true CN212958261U (en) | 2021-04-13 |

Family

ID=75394843

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202021452801.9U Active CN212958261U (en) | 2020-07-22 | 2020-07-22 | Sealing structure of casement window |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN212958261U (en) |

-

2020

- 2020-07-22 CN CN202021452801.9U patent/CN212958261U/en active Active

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US11808079B2 (en) | Inner frame for door or window, skylight comprising the same and manufacturing method thereof | |

| CN212958261U (en) | Sealing structure of casement window | |

| CN108999523B (en) | Flush-open window sash embedded structure | |

| CN204002366U (en) | A kind of doors and windows sealing rubber strip supports assembly | |

| CN212507922U (en) | Chinese aluminum door and window with invisible gauze | |

| CN209799731U (en) | Wood-aluminum composite window | |

| CN211623101U (en) | Flat-open aluminum alloy door and window with built-in screen window | |

| CN210948237U (en) | Inward casement window combined with corner window | |

| CN209799732U (en) | Bridge cut-off aluminium door and window | |

| CN218912714U (en) | External thermal insulation flat-pushing window | |

| CN220395509U (en) | Steel-aluminum combined sealing folding door | |

| KR101929921B1 (en) | A windbreak assembly for a sliding door | |

| CN221823643U (en) | Passive aluminum-wood composite window system provided with hidden frame window sashes | |

| CN215632476U (en) | Inward opening door | |

| CN221823635U (en) | High-performance aluminum alloy passive window system | |

| CN114135208B (en) | Non-destructive detachable sealing structure of frameless ground spring door and sealing frame in same | |

| CN221462180U (en) | Single window | |

| CN215804241U (en) | Clearance seal structure and aluminum alloy door and window | |

| CN211818952U (en) | Aluminum alloy casement window with high waterproof and heat-insulating properties | |

| CN208203043U (en) | A kind of combined type PVC window sealing strip | |

| CN210422330U (en) | Three-sealing high-performance outward casement window | |

| CN213359908U (en) | Water blocking frame for system window | |

| CN219431658U (en) | Window structure of integrative flat-open of thermal-insulated window screening | |

| CN219887875U (en) | Reinforced steel beam heat insulation structure of fire-resistant window | |

| CN214835946U (en) | Energy-saving sealed waterproof window |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |