CN212635834U - High-efficient sponge horizontal cutting machine - Google Patents

High-efficient sponge horizontal cutting machine Download PDFInfo

- Publication number

- CN212635834U CN212635834U CN202021518629.2U CN202021518629U CN212635834U CN 212635834 U CN212635834 U CN 212635834U CN 202021518629 U CN202021518629 U CN 202021518629U CN 212635834 U CN212635834 U CN 212635834U

- Authority

- CN

- China

- Prior art keywords

- seat

- shaped mounting

- cutting machine

- mounting seat

- fixed

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Abstract

The utility model belongs to the technical field of sponge production facility technique and specifically relates to a high-efficient sponge horizontal cutting machine, which comprises a fixed base, the fixed first L shape mount pad that is equipped with of fixing base, the fixed guide post that is equipped with of first L shape mount pad symmetry, two guide post sliding connection is equipped with second L shape mount pad, second L shape mount pad threaded connection is equipped with the screw thread lead screw, the fixed removal seat that is equipped with of second L shape mount pad, it is fixed to be equipped with four gyro wheels to remove the seat, the spout all rotates the connection and is equipped with the screw thread post, the equal threaded connection of screw thread post is equipped with the movable block, one side of fixing base is equipped with annular transport assembly. The utility model discloses on the basis of ordinary horizontal cutting machine, set up regulation, reciprocal and rotary device, improved cutting efficiency, space utilization and application scope, have wide market prospect, be fit for promoting.

Description

Technical Field

The utility model relates to a sponge production facility technical field especially relates to a high-efficient sponge horizontal cutting machine.

Background

The sponge is generally required to be foamed and cut to form, the sponge extruded by a sponge horizontal continuous foaming machine is generally in a square column shape, and the sponge is required to be subjected to processes of longitudinal cutting treatment, horizontal cutting and the like. However, generally use sponge horizontal cutting machine in the market, most can only one-way cutting, and cutting efficiency is low, simultaneously, when carrying out the cutting to longer sponge, often need use large-scale cutting machine, reduced space utilization, current horizontal cutting machine can't adjust the cutting width according to the volume of sponge, and application scope is narrower, to above not enough, we have put forward a high-efficient sponge horizontal cutting machine, replaces the horizontal cutting machine of old-fashioned, satisfies people's life demand.

SUMMERY OF THE UTILITY MODEL

The utility model aims at solving the shortcomings of low cutting efficiency, low space utilization rate and narrow application range in the prior art and providing a high-efficient sponge horizontal cutting machine.

In order to achieve the above purpose, the utility model adopts the following technical scheme:

a high-efficiency sponge horizontal cutting machine is designed, and comprises a fixed seat, wherein a first L-shaped mounting seat is fixedly arranged in the middle of the upper surface of the fixed seat, guide posts are symmetrically and fixedly arranged on one side of the first L-shaped mounting seat, two guide posts are slidably connected with a second L-shaped mounting seat, the second L-shaped mounting seat is in threaded connection with a threaded lead screw, one end of the threaded lead screw penetrates through the first L-shaped mounting seat and is rotatably connected with the first L-shaped mounting seat and is fixedly provided with a motor, the motor is fixedly connected with the first L-shaped mounting seat, a moving seat is fixedly arranged on one side of the second L-shaped mounting seat, four rollers are fixedly arranged on the lower surface of the moving seat, the first L-shaped mounting seat and the second L-shaped mounting seat are respectively provided with a sliding groove, the inner wall of the sliding groove is rotatably connected with a threaded post, one end of the two threaded posts respectively penetrates through the fixed seat and the moving seat and, the two stepping motors are respectively and fixedly connected with the fixed seat and the movable seat, moving blocks are connected to the surface of the threaded column in a threaded mode, a reciprocating cutting assembly is fixedly arranged between the two moving blocks, and an annular conveying assembly is arranged on one side of the fixed seat.

Preferably, the reciprocating cutting assembly comprises two fixed plates, the fixed plates are respectively fixedly connected with a moving block, the fixed plates are symmetrically and slidably connected with push rods, one ends of the push rods are respectively and fixedly provided with a limiting block, four ends of the push rods, far away from the limiting block, are symmetrically and fixedly provided with mounting plates, two mounting plates are provided with cutting tools through bolt fixing, one side of the moving block is fixedly provided with a mounting table, the mounting table is fixedly provided with a driving motor, an output shaft of the driving motor penetrates through the mounting table and is fixedly provided with a turntable, one side of the lower surface of the turntable is rotatably connected with a transmission column, the transmission column is sleeved with a limiting rod, and two ends of the limiting rod are respectively and fixedly connected with.

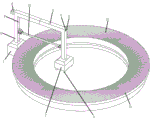

Preferably, the annular conveying assembly comprises an annular base, the upper surface of the annular base is rotatably connected with an annular conveying table, the annular conveying table is fixedly provided with a worm wheel, one side of the worm wheel is in toothed connection with a turbine sleeve, the turbine sleeve is fixedly provided with a speed regulating motor, and the speed regulating motor is fixedly connected with the annular base.

Preferably, a plurality of anti-slip grooves are formed in the upper surface of the annular conveying table at equal angles.

Preferably, the cutting tool comprises a plurality of cutting knives of different lengths.

The utility model provides a pair of high-efficient sponge horizontal cutting machine, beneficial effect lies in: the utility model discloses a first L shape mount pad, the guide post, second L shape mount pad, the screw lead screw, including a motor, an end cap, a controller, and a cover plate, remove the seat, mutually support between gyro wheel and the reciprocal cutting assembly, can adjust according to the width of waiting to cut the sponge, convenient and fast, application scope is wider, through setting up reciprocal cutting assembly, can improve the cutting effect of sponge, through setting up annular conveying assembly, area has been reduced, can place the sponge of a plurality of area cutting on the annular is carried the bench when having improved space utilization, carry out continuous cutting, the cutting efficiency has been improved.

Drawings

Fig. 1 is a front view of a high-efficiency sponge horizontal cutting machine provided by the utility model;

fig. 2 is a sectional view of a high-efficiency sponge horizontal cutting machine provided by the utility model;

fig. 3 is a view of the reciprocating cutting assembly of the high-efficiency sponge horizontal cutting machine provided by the utility model.

In the figure: the cutting machine comprises a fixed seat 1, a first L-shaped mounting seat 2, a guide post 3, a second L-shaped mounting seat 4, a threaded screw rod 5, a motor 6, a moving seat 7, a roller 8, a sliding groove 9, a threaded post 10, a stepping motor 11, a reciprocating cutting assembly 12, an annular conveying assembly 13, an anti-skidding groove 14, a moving block 15, a fixing plate 1201, a push rod 1202, a limiting block 1203, a mounting plate 1204, a cutting tool 1205, a mounting table 1206, a driving motor 1207, a turntable 1208, a transmission post 1209, a limiting rod 1210, an annular base 1301, an annular conveying table 1302, a worm wheel 1303, a turbine sleeve 1304 and a speed regulating motor 1305.

Detailed Description

The technical solutions in the embodiments of the present invention will be described clearly and completely with reference to the accompanying drawings in the embodiments of the present invention, and it is obvious that the described embodiments are only some embodiments of the present invention, not all embodiments.

Referring to fig. 1-3, a high-efficiency sponge horizontal cutting machine comprises a fixed seat 1, a first L-shaped mounting seat 2 is fixedly arranged in the middle of the upper surface of the fixed seat 1, guide posts 3 are symmetrically and fixedly arranged on one side of the first L-shaped mounting seat 2, two guide posts 3 are slidably connected with a second L-shaped mounting seat 4, a threaded lead screw 5 is connected with the second L-shaped mounting seat 4 in a threaded manner, one end of the threaded lead screw 5 penetrates through the first L-shaped mounting seat 2 to be rotatably connected with the first L-shaped mounting seat 2 and is fixedly provided with a motor 6, the motor 6 is fixedly connected with the first L-shaped mounting seat 2, one side of the second L-shaped mounting seat 4 is fixedly provided with a movable seat 7, the lower surface of the movable seat 7 is fixedly provided with four rollers 8, the first L-shaped mounting seat 2 and the second L-shaped mounting seat 4 are both provided with a chute 9, the inner wall of the chute 9 is both rotatably connected with threaded posts 10, one ends of the two threaded posts 10 respectively penetrate through the fixed, two step motor 11 respectively with fixing base 1 and removal seat 7 fixed connection, the equal threaded connection in surface of screw thread post 10 is equipped with movable block 15, is fixed between two movable blocks 15 to be equipped with reciprocal cutting assembly 12, and one side of fixing base 1 is equipped with annular conveyor assembly 13.

Referring to fig. 1-3, a high-efficiency horizontal sponge cutting machine, a reciprocating cutting assembly 12 includes two fixed plates 1201, the fixed plates 1201 are respectively fixedly connected to a moving block 15, the fixed plates 1201 are symmetrically and slidably connected to push rods 1202, a limit block 1203 is fixedly arranged at one end of each push rod 1202, mounting plates 1204 are symmetrically and fixedly arranged at one ends of the four push rods 1202 far away from the limit block 1203, cutting tools 1205 are fixedly arranged on the two mounting plates 1204 through bolts, a mounting table 1206 is fixedly arranged at one side of the moving block 15, a driving motor 1207 is fixedly arranged on the mounting table 1206, an output shaft of the driving motor 1207 penetrates through the mounting table 1206 and is fixedly provided with a rotating disc 1208, a transmission column 1209 is rotatably connected to one side of the lower surface of the rotating disc 1208, a limit rod 1210 is sleeved on the transmission column 1209, two ends of the limit rod 1210 are respectively fixedly connected to the limit block 1203, an annular, annular delivery platform 1302 is fixed to be equipped with worm wheel 1303, and one side toothing of worm wheel 1303 is equipped with turbine sleeve 1304, and turbine sleeve 1304 is fixed to be equipped with buncher 1305, buncher 1305 and annular base 1301 fixed connection, and the upper surface of annular delivery platform 1302 is isometric to be equipped with a plurality of antiskid groove 14, and cutting tool 1205 includes the cutting knife of a plurality of different length.

The utility model provides a high-efficient sponge horizontal cutting machine, when using, the staff makes screw lead screw 5 begin to rotate through controller control motor 6 according to the sponge width of waiting to cut, second L shape mount pad 4 promotes removal seat 7 with it under the cooperation of gyro wheel 8 and begins to move, until moving to appointed position, then pass through bolt fastening to mounting panel 1204 with cutting tool 1205 that the length is fit for, then place a plurality of sponges of waiting to cut on the upper surface of annular delivery platform 1302, control step motor 11 through the controller and begin work and make screw lead screw 5 begin to rotate, movable block 15 drives reciprocal cutting assembly 12 with it and moves to suitable position, then control governing motor 1305 and begin work, make annular delivery platform 1302 drive a plurality of sponges and rotate under the transmission of turbine sleeve 1304 and worm gear 1303, driving motor 1207 begins to work simultaneously makes carousel 1208 drive transmission post 1209 and begin to rotate, under the cooperation of the limiting rod 1210, the push rod 1202 drives the mounting plate 1204 and the cutting tool 1205 to reciprocate to perform cutting operation, and when the annular conveying table 1302 rotates for a circle, the stepping motor 11 starts to operate again, so that the cutting tool 1205 moves downwards to the next cutting point to cut the sponge.

The above, only be the concrete implementation of the preferred embodiment of the present invention, but the protection scope of the present invention is not limited thereto, and any person skilled in the art is in the technical scope of the present invention, according to the technical solution of the present invention and the utility model, the concept of which is equivalent to replace or change, should be covered within the protection scope of the present invention.

Claims (5)

1. A high-efficiency sponge horizontal cutting machine comprises a fixed seat (1) and is characterized in that a first L-shaped mounting seat (2) is fixedly arranged in the middle of the upper surface of the fixed seat (1), guide posts (3) are symmetrically and fixedly arranged on one side of the first L-shaped mounting seat (2), two guide posts (3) are slidably connected with a second L-shaped mounting seat (4), a threaded lead screw (5) is connected with the second L-shaped mounting seat (4) in a threaded manner, one end of the threaded lead screw (5) penetrates through the first L-shaped mounting seat (2) to be rotatably connected with the first L-shaped mounting seat (2) and is fixedly provided with a motor (6), the motor (6) is fixedly connected with the first L-shaped mounting seat (2), a moving seat (7) is fixedly arranged on one side of the second L-shaped mounting seat (4), and four idler wheels (8) are fixedly arranged on the lower surface of the moving seat (7), the cutting machine is characterized in that the first L-shaped mounting seat (2) and the second L-shaped mounting seat (4) are both provided with a sliding groove (9), the inner wall of the sliding groove (9) is connected with a threaded column (10) in a rotating mode, one end of the threaded column (10) penetrates through the fixing seat (1) and the moving seat (7) respectively and is fixedly provided with a stepping motor (11), the stepping motor (11) is fixedly connected with the fixing seat (1) and the moving seat (7) respectively, the surface of the threaded column (10) is connected with a moving block (15) in a threaded mode, a reciprocating cutting assembly (12) is fixedly arranged between the moving blocks (15), and an annular conveying assembly (13) is arranged on one side of the fixing seat (1).

2. The high-efficiency horizontal sponge cutting machine as claimed in claim 1, wherein the reciprocating cutting assembly (12) comprises two fixed plates (1201), the fixed plates (1201) are respectively fixedly connected with a moving block (15), the fixed plates (1201) are symmetrically and slidably connected with push rods (1202), one ends of the push rods (1202) are respectively and fixedly provided with a limit block (1203), one ends of the four push rods (1202) far away from the limit block (1203) are symmetrically and fixedly provided with mounting plates (1204), the two mounting plates (1204) are fixedly provided with cutting tools (1205) through bolts, one side of the moving block (15) is fixedly provided with a mounting table (1206), the mounting table (1206) is fixedly provided with a driving motor (1207), an output shaft of the driving motor (1207) penetrates through the mounting table (1206) and is fixedly provided with a rotating disc (1208), one side of the lower surface of the rotating disc (1208) is rotatably connected with a transmission column (1209), the transmission column (1209) is sleeved with a limiting rod (1210), and two ends of the limiting rod (1210) are fixedly connected with the limiting block (1203) respectively.

3. The high-efficiency horizontal sponge cutting machine as claimed in claim 1, wherein the annular conveying assembly (13) comprises an annular base (1301), an annular conveying table (1302) is rotatably connected to the upper surface of the annular base (1301), a worm wheel (1303) is fixedly arranged on the annular conveying table (1302), a turbine sleeve (1304) is meshed with one side of the worm wheel (1303), a speed regulating motor (1305) is fixedly arranged on the turbine sleeve (1304), and the speed regulating motor (1305) is fixedly connected with the annular base (1301).

4. A high efficiency horizontal sponge cutting machine as claimed in claim 3 wherein said annular conveying table (1302) is provided with a plurality of anti-slip grooves (14) on its upper surface at equal angles.

5. A high efficiency horizontal sponge cutting machine as claimed in claim 2 wherein said cutter (1205) comprises a plurality of cutters of different lengths.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202021518629.2U CN212635834U (en) | 2020-07-28 | 2020-07-28 | High-efficient sponge horizontal cutting machine |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202021518629.2U CN212635834U (en) | 2020-07-28 | 2020-07-28 | High-efficient sponge horizontal cutting machine |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN212635834U true CN212635834U (en) | 2021-03-02 |

Family

ID=74764269

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202021518629.2U Active CN212635834U (en) | 2020-07-28 | 2020-07-28 | High-efficient sponge horizontal cutting machine |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN212635834U (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113858615A (en) * | 2021-09-23 | 2021-12-31 | 江苏恒达医疗管理服务有限公司 | Three-dimensional laser deposition forming 3D printing equipment and printing method thereof |

-

2020

- 2020-07-28 CN CN202021518629.2U patent/CN212635834U/en active Active

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113858615A (en) * | 2021-09-23 | 2021-12-31 | 江苏恒达医疗管理服务有限公司 | Three-dimensional laser deposition forming 3D printing equipment and printing method thereof |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN203636088U (en) | Saw cutting machine tool for aluminum plastic profile door and window | |

| CN211491852U (en) | External wall insulation board cutting system | |

| CN212635834U (en) | High-efficient sponge horizontal cutting machine | |

| CN211353195U (en) | Hedge trimmer for landscaping | |

| CN201693232U (en) | Plate simple stripping machine used for steel structure engineering profile | |

| CN211413834U (en) | Pendulum plate shearing machine | |

| CN211279218U (en) | Efficient cutting machine for ceramic plates | |

| CN202241620U (en) | Cutting machine | |

| CN1165409C (en) | Foamed-material cutter capable of being lifted | |

| CN203726609U (en) | Automatic cutting machine of foam cement heat preserving plate | |

| CN206652922U (en) | A kind of reinforcing bar automatic cutting equipment | |

| CN213381896U (en) | Foam horizontal cutting machine | |

| CN203045809U (en) | Annular cross knife specially-shaped sponge cutting machine | |

| CN213647656U (en) | Multi-blade rhizome herbal medicine cutting device | |

| CN213260336U (en) | Cutting device for concrete waste reprocessing | |

| CN201520016U (en) | Small-circle-saw-blade machine tool for processing ultrathin stone | |

| CN201428457Y (en) | Diamond string bead wire cutting machine | |

| CN210081839U (en) | Plastic tubing cutting device is used in processing of car wiring harness | |

| CN201189683Y (en) | Cutting-sawing device with two U shaped ends | |

| CN211022122U (en) | Automatic fruit peeler | |

| CN2712589Y (en) | Stone sawing and cutting machine with multi-tools | |

| CN202028672U (en) | Rotary handpiece for numerical control crosscut shears | |

| CN217290210U (en) | Continuous cutting device for processing reinforcing steel bars | |

| CN206825709U (en) | Silicon single crystal rod electric cutting device based on diamond wire roller | |

| CN203471886U (en) | Multifunctional edge sawing linking machine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |