CN210519820U - Procypris rabaudi farming systems - Google Patents

Procypris rabaudi farming systems Download PDFInfo

- Publication number

- CN210519820U CN210519820U CN201921561545.4U CN201921561545U CN210519820U CN 210519820 U CN210519820 U CN 210519820U CN 201921561545 U CN201921561545 U CN 201921561545U CN 210519820 U CN210519820 U CN 210519820U

- Authority

- CN

- China

- Prior art keywords

- pond

- feed

- water

- fry

- hatching

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 241001489464 Procypris rabaudi Species 0.000 title claims abstract description 31

- 238000009313 farming Methods 0.000 title claims abstract description 10

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims abstract description 103

- 230000012447 hatching Effects 0.000 claims abstract description 43

- 241000251468 Actinopterygii Species 0.000 claims abstract description 18

- 235000011837 pasties Nutrition 0.000 claims abstract description 17

- 235000015097 nutrients Nutrition 0.000 claims abstract description 16

- 238000004659 sterilization and disinfection Methods 0.000 claims abstract description 16

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 claims abstract description 15

- 229910052760 oxygen Inorganic materials 0.000 claims abstract description 15

- 239000001301 oxygen Substances 0.000 claims abstract description 15

- 238000003860 storage Methods 0.000 claims abstract description 15

- 238000002156 mixing Methods 0.000 claims abstract description 14

- 238000000746 purification Methods 0.000 claims abstract description 13

- 241000252233 Cyprinus carpio Species 0.000 claims abstract description 9

- 238000006213 oxygenation reaction Methods 0.000 claims abstract description 7

- 230000001502 supplementing effect Effects 0.000 claims abstract description 7

- 238000003756 stirring Methods 0.000 claims description 32

- 238000009395 breeding Methods 0.000 claims description 17

- 230000001488 breeding effect Effects 0.000 claims description 17

- 238000010438 heat treatment Methods 0.000 claims description 13

- 239000010865 sewage Substances 0.000 claims description 13

- 238000005086 pumping Methods 0.000 claims description 11

- 239000004576 sand Substances 0.000 claims description 7

- 241000252231 Cyprinus Species 0.000 claims description 6

- 239000004575 stone Substances 0.000 claims description 6

- 235000013305 food Nutrition 0.000 claims description 4

- 230000003247 decreasing effect Effects 0.000 claims description 3

- 238000001914 filtration Methods 0.000 claims description 3

- 230000000384 rearing effect Effects 0.000 claims description 2

- 241001671870 Carpiodes Species 0.000 claims 4

- 239000000243 solution Substances 0.000 claims 3

- 238000005273 aeration Methods 0.000 claims 2

- 239000012527 feed solution Substances 0.000 claims 1

- 239000011435 rock Substances 0.000 abstract description 9

- 235000019621 digestibility Nutrition 0.000 abstract description 4

- 235000019629 palatability Nutrition 0.000 abstract description 4

- 230000002349 favourable effect Effects 0.000 abstract description 2

- 238000007599 discharging Methods 0.000 description 5

- 239000002245 particle Substances 0.000 description 3

- 241001489469 Procypris Species 0.000 description 2

- 239000004568 cement Substances 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 239000010794 food waste Substances 0.000 description 2

- 230000008676 import Effects 0.000 description 2

- 239000007788 liquid Substances 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- 235000021049 nutrient content Nutrition 0.000 description 2

- 230000001706 oxygenating effect Effects 0.000 description 2

- 239000008188 pellet Substances 0.000 description 2

- 208000027418 Wounds and injury Diseases 0.000 description 1

- 238000007664 blowing Methods 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000012258 culturing Methods 0.000 description 1

- 230000006378 damage Effects 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 208000014674 injury Diseases 0.000 description 1

- 241000894007 species Species 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

Images

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02A—TECHNOLOGIES FOR ADAPTATION TO CLIMATE CHANGE

- Y02A40/00—Adaptation technologies in agriculture, forestry, livestock or agroalimentary production

- Y02A40/80—Adaptation technologies in agriculture, forestry, livestock or agroalimentary production in fisheries management

- Y02A40/81—Aquaculture, e.g. of fish

Landscapes

- Farming Of Fish And Shellfish (AREA)

Abstract

A Cyprinus Carpio culture system comprises an indoor spawn hatching part, an outdoor fry culture part and a fish feeding device; the indoor spawn hatching part comprises a water storage disinfection pond, a procypris rabaudi hatching pond and an oxygen supplementing device which are positioned indoors; the water inlet of the water storage disinfection tank is communicated with a water source; the fry outdoor culture part comprises an outdoor water quality purification pond, a fry culture pond, an oxygenation mechanism and a pollution discharge mechanism; the fish feeding device is positioned on one side of the fry culture pond and comprises a feed crushing mechanism, a conveying auger and a pasty feed mixing mechanism. The utility model discloses a farming systems provides the growth environment that quality of water is good, dissolved oxygen is abundant, safe and reliable for the hatching of former carp roe of rock and fry, mixes the feed after smashing and mixes with the nutrient solution and synthesizes to be pasty, increases feed surface area and improves the palatability, is favorable to the fry feed to improve the digestibility, better absorbs fodder nutrient composition.

Description

Technical Field

The utility model relates to a fish culture field, concretely relates to former carp farming systems of rock.

Background

Cyprinus carpioides is a fish belonging to Cyprinus of Cyprinaceae, and is a specific species in China. In the upstream fishery of the Yangtze river, the economic value is higher, and the method is suitable for intensive culture of ponds and reservoirs. The existing procypris rabaudi hatching pond is often unable to guarantee dissolved oxygen, and directly fills oxygen in the pond body and easily causes the influence to roe. The existing procypris rabaudi fry culture pond is usually carried out in a square cement pond, procypris rabaudi fries just enter the culture pond, move quickly in a new environment and easily collide with the wall of the cement pond to cause fry injury, so that economic loss is brought to farmers. The fry just enter the culture pond, and food waste is easily caused by feeding pellet feed, so that the surface area of the feed can be increased, the palatability can be improved, the fry can be favorably eaten, the digestibility can be improved, and the nutrient content of the feed can be better absorbed.

SUMMERY OF THE UTILITY MODEL

The utility model aims at providing a former carp farming systems of rock to above-mentioned defect exactly.

A Cyprinus Carpio culture system comprises an indoor spawn hatching part, an outdoor fry culture part and a fish feeding device;

the indoor roe hatching part comprises an indoor water storage disinfection tank, an indoor procypris rabaudi hatching tank and an indoor oxygen supplementing device; the water inlet of the water storage disinfection tank is communicated with a water source; the rock protocarp hatching pond is separated from the water storage disinfection pond through a pond wall, the oxygen charging device is arranged on the pond wall, a net cage is arranged in the rock protocarp hatching pond, a fish egg hatching frame is arranged in the net cage, a water temperature heating device is arranged at the bottom of the rock protocarp hatching pond, a water pumping pipeline and a second water pumping pump are arranged on one side of the rock protocarp hatching pond, and the water pumping pipeline extends into the bottom of the rock protocarp hatching pond; the oxygenating device comprises a shell, a water inlet pipe, an air inlet pipe and a water outlet pipe, wherein the water inlet pipe and the air inlet pipe are arranged on the upper portion of the shell, the water outlet pipe is arranged at the bottom of the shell, the air inlet pipe is connected with a plurality of spiral pipes which are vertically arranged downwards, a plurality of air outlet holes are uniformly formed in the pipe walls of the spiral pipes, a first cuboid sponge block is sleeved outside each spiral pipe, the bottom of each first sponge block is abutted against the bottom of the shell, the water inlet pipe is communicated to a water storage disinfection pond through a first water suction pump and a pipeline, the water outlet pipe is communicated to the interior of a rock original carp hatching pond, and the air inlet pipe;

the fry outdoor culture part comprises an outdoor water quality purification pond, a fry culture pond, an oxygenation mechanism and a pollution discharge mechanism; the upper part of the water quality purification pool is provided with a drainage pipeline connected with the water outlet of the first water pump, a sand and stone filter layer is arranged in the water quality purification pool, and the bottom of the water quality purification pool is provided with a purification pool water outlet with a filter screen; the fry breeding pond is positioned below the water quality purifying pond, a water outlet of the purifying pond is communicated to the upper part of the fry breeding pond through a pipeline, the bottom of the fry breeding pond is obliquely arranged, a drain outlet is formed in the lowest part of the bottom of the fry breeding pond, a cylindrical first anti-collision net is fixedly connected to the side wall of the fry breeding pond, a circular second anti-collision net is sewn to the bottom of the first anti-collision net, and the diameter of the lower part of the first anti-collision net is smaller than that of the upper part of the first anti-collision net; the oxygenation mechanism consists of a second air blower, a blast pipeline and an inflation assembly arranged at the bottom of the fry culture pond, the inflation assembly comprises a plurality of circular pipes with diameters decreasing in sequence and a connecting pipe for communicating the circular pipes, the end part of the connecting pipe is communicated with the blast pipeline, a plurality of air outlet holes are uniformly formed in the upper walls of the circular pipes, and second sponge blocks for covering the air outlet holes are adhered to the air outlet holes; the blowdown mechanism comprises a blowdown pipeline arranged at the bottom of the fry culture pond and connected with a blowdown port and a blowdown pump connected with the blowdown pipeline;

the fish feeding device is positioned on one side of the fry culture pond and comprises a feed crushing mechanism, a conveying auger and a pasty feed mixing mechanism; the feed crushing mechanism comprises a feed crushing box body, a rotary cutting blade arranged inside the feed crushing box body, a feed inlet arranged at the top of the feed crushing box body, a feed outlet arranged at the bottom of the feed crushing box body and a filtering sieve plate positioned above the feed outlet, wherein the rotary cutting blade is driven to rotate by a driving motor arranged outside the feed crushing box body, the filtering sieve plate is in a V-shaped structure, and the feed outlet is communicated with the feed end of the conveying auger; pasty feed mixing mechanism includes the agitator tank jar body, sets up at the agitator motor at agitator tank jar body top, is located the agitator tank jar internal portion and by the rotatory stirring rake subassembly of agitator motor drive, the stirring rake subassembly includes the (mixing) shaft and sets up at the first stirring rake at (mixing) shaft middle part and set up the second stirring rake in the (mixing) shaft lower part, the length of first stirring rake is two-thirds of second stirring rake length, agitator tank jar body upper portion be equipped with carry the crushing fodder import that the output of auger is connected, agitator tank jar body upper portion still is equipped with feed nutrient solution feed inlet, agitator tank jar body bottom is equipped with the export of pasty fodder, the export of pasty fodder passes through the pipeline and is connected with the fish food delivery pump to go into the fry breeding pond with the pump of pasty fodder.

The number of the spiral pipes is four.

The water temperature heating device is a resistance heating pipe or a heating coil.

The gauze density of the net cage in the procypris rabaudi hatching pond is 4-8 meshes.

The thickness of the sand and stone filter layer is 60-80 mm.

The upper part of the fry culture pond is also provided with an overflow port.

The cross section of the fry culture pond is square.

The number of the plurality of circular tubes is 3.

The upper part of the feed inlet of the feed crushing box body is provided with a hinged cover plate.

The feed inlet of the feed nutrient solution is connected with a feed delivery pump and a feed liquid barrel for containing the feed nutrient solution through a pipeline.

The utility model has the advantages that: the method provides a safe and reliable growth environment with good water quality and rich dissolved oxygen for hatching the spawns and fries of the Procypris rabaudi; the feed is mixed with nutrient solution after being crushed into paste, so that the surface area of the feed is increased, the palatability is improved, the feed is favorable for fry to eat, the digestibility is improved, and the nutrient components of the feed are better absorbed.

Drawings

Fig. 1 is a schematic structural diagram of the present invention.

FIG. 2 is a schematic view showing the structure of an hatching part in an egg chamber.

Fig. 3 is a schematic structural view of the oxygen supply device.

Fig. 4 is a schematic structural view of the spiral tube and the first sponge block.

Fig. 5 is a schematic structural view of the fry outdoor rearing part.

FIG. 6 is a schematic view of the construction of the inflation assembly.

Fig. 7 is a schematic structural diagram of the air outlet and the second sponge block.

Fig. 8 is a schematic structural view of the fish feeding device.

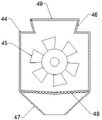

Fig. 9 is a schematic structural view of the feed crushing mechanism.

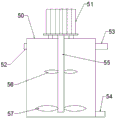

Fig. 10 is a schematic structural view of a mash feed mixing mechanism.

Detailed Description

As shown in the attached drawing, the procypris rabaudi culture system comprises an indoor spawn hatching part, an outdoor fry culture part and a fish feeding device;

the indoor spawn hatching part comprises an indoor water storage disinfection tank 1, an indoor procypris rabaudi hatching tank 2 and an indoor oxygen supplementing device 3; the water inlet of the water storage disinfection tank 1 is communicated with a water source; the procypris rabaudi hatching pond 2 is separated from the water storage disinfection pond 1 through a pond wall, the oxygen charging device 3 is arranged on the pond wall, a net cage 4 is arranged in the procypris rabaudi hatching pond 2, a fish egg hatching frame is arranged in the net cage 4, a water temperature heating device 5 is arranged at the bottom of the procypris rabaudi hatching pond 2, a water pumping pipeline 6 and a second water pumping pump 7 are arranged on one side of the procypris rabaudi hatching pond 2, and the water pumping pipeline 6 extends into the bottom of the procypris rabaudi hatching pond 2; the oxygenating device 3 comprises a shell 7, a water inlet pipe 8 and an air inlet pipe 9 which are arranged on the upper portion of the shell 7, and a water outlet pipe 10 which is arranged at the bottom of the shell 7, wherein the top of the shell 7 is also provided with an air outlet 11, the air inlet pipe 9 is connected with a plurality of spiral pipes 12 which are vertically arranged downwards, a plurality of air outlet holes are uniformly formed in the pipe walls of the spiral pipes 12, a cuboid-shaped first sponge block 13 is sleeved outside the spiral pipes 12, the bottom of the first sponge block 13 is abutted against the bottom of the shell 7, the water inlet pipe 8 is communicated to a water storage disinfection pond 1 through a first water suction pump 14 and a pipeline, the water outlet pipe 10 is communicated to a rock carp hatching pond 2, and the air inlet pipe 9 is;

the fry outdoor culture part comprises an outdoor water quality purification pool 21, a fry culture pool 22, an oxygenation mechanism and a pollution discharge mechanism; a drainage pipeline 39 connected with the water outlet of the first water pump 14 is arranged at the upper part of the water quality purification tank 21, a sand and stone filter layer 24 is arranged in the water quality purification tank 21, and a purification tank water outlet 25 with a filter screen is arranged at the bottom of the water quality purification tank 21; the fry breeding pond 22 is positioned below the water quality purifying pond 21, a water outlet 25 of the purifying pond is communicated to the upper part of the fry breeding pond 22 through a pipeline, the bottom of the fry breeding pond 22 is obliquely arranged, a drain outlet 26 is arranged at the lowest part of the bottom of the fry breeding pond 22, a cylindrical first anti-collision net 27 is fixedly connected to the side wall of the fry breeding pond 22, a circular second anti-collision net 28 is sewn to the bottom of the first anti-collision net 27, and the diameter of the lower part of the first anti-collision net 27 is smaller than that of the upper part of the first anti-collision net 27; the oxygenation mechanism consists of a second air blower 29, a blast pipeline 30 and an inflation assembly arranged at the bottom of the fry culture pond 22, the inflation assembly comprises a plurality of round pipes 31 with diameters decreasing gradually in sequence and a connecting pipe 32 for communicating the round pipes 31, the end part of the connecting pipe 32 is communicated with the blast pipeline 30, a plurality of air outlets 36 are uniformly arranged on the upper walls of the round pipes 31, and second sponge blocks 37 for covering the air outlets 36 are adhered on the air outlets 36; the sewage discharging mechanism comprises a sewage discharging pipeline 33 which is arranged at the bottom of the fry culturing pond 22 and connected with the sewage discharging port 26 and a sewage discharging pump 34 which is connected with the sewage discharging pipeline 33;

the fish feeding device is positioned on one side of the fry culture pond 22 and comprises a feed crushing mechanism 41, a conveying auger 42 and a pasty feed mixing mechanism 43; the feed crushing mechanism 41 comprises a feed crushing box body 44, a rotary cutting blade 45 arranged inside the feed crushing box body 44, a feed inlet 46 arranged at the top of the feed crushing box body 44, a feed outlet 47 arranged at the bottom of the feed crushing box body 44 and a filter sieve plate 48 positioned above the feed outlet 47, wherein the rotary cutting blade 45 is driven to rotate by a driving motor arranged outside the feed crushing box body 44, the filter sieve plate 48 is in a V-shaped structure, and the feed outlet 47 is communicated with the feed end of the conveying auger 42; pasty feed mixing mechanism 43 includes the agitator tank jar body 50, set up agitator motor 51 at agitator tank jar body 50 top, be located agitator tank jar body 50 inside and by agitator motor 51 drive rotatory stirring rake subassembly, the stirring rake subassembly includes (mixing) shaft 55 and sets up at the first stirring rake 56 in (mixing) shaft 55 middle part and set up the second stirring rake 57 in (mixing) shaft 55 lower part, the length of first stirring rake 56 is two-thirds of second stirring rake 57 length, agitator tank jar body 50 upper portion be equipped with carry the crushing fodder import 52 that auger 42's output is connected, agitator tank jar body 50 upper portion still is equipped with feed nutrient solution feed inlet 53, agitator tank jar body 50 bottom is equipped with pasty feed outlet 54, pasty feed outlet 54 is connected with the fish food delivery pump through the pipeline to with pasty feed pump in fry culture pond 22.

The number of the plurality of spiral tubes 12 is four.

The water temperature heating device 5 is a resistance heating pipe or a heating coil.

The gauze density of the net box 4 in the procypris rabaudi hatching pond 2 is 4-8 meshes.

The thickness of the sand and stone filter layer 24 is 60-80 mm.

The upper part of the fry culture pond 22 is also provided with an overflow port 35.

The cross section of the fry culture pond 22 is square.

The number of the plurality of circular tubes 31 is 3.

The upper part of the feed inlet 46 of the feed crushing box body 44 is provided with a hinged cover plate 49.

The feed nutrient solution feed port 53 is connected with a feed delivery pump and a feed liquid barrel for containing feed nutrient solution through pipelines.

The working principle is as follows: firstly, a water source (preferably river water or lake water and underground water) is introduced into a water storage disinfection pond 1, the water is pumped into an oxygen supplementing device 3 through a first water pump 14 after disinfection, then an air blower 15 is started to oxygenate the shell 7 through an air inlet pipe 9 and a spiral pipe 12, air enters a first sponge block 13 after passing through the spiral pipe 12 and is dispersed into finer bubbles, the bubbles are dissolved into water and then are discharged into a procypris hatching pond 2 through a water outlet pipe 10, a water temperature heating device 5 is started to ensure that the water temperature in the procypris hatching. The first water pump 14 pumps the pond water in the procypris rabaudi hatching pond 2 into the water quality purification pond 21, the pond water enters the fry culture pond 22 after being filtered by the sand and stone filter layer 24, then the second air blower 29 is started to oxygenate the pond water in the fry culture pond 22 through the air blowing pipeline 30 and the air inflation component arranged at the bottom of the fry culture pond 22, the dirt at the bottom of the fry culture pond 22 is periodically pumped away through the sewage discharge pipeline 33 and the sewage discharge pump 34 to keep the water quality of the pond water in the fry culture pond 22, and a safe growth environment with good water quality and rich dissolved oxygen is provided for the growth of procypris rabaudi fries. Regularly throwing feed particles into a feed crushing box body 44 from a feed inlet 46, closing a cover plate 49, starting a driving motor to drive a rotary cutting blade 45 to rotate, enabling the crushed feed particles to leak from a filter sieve plate 48 and enter a conveying auger 42, conveying the crushed feed particles into a stirring tank body 50 through the conveying auger 42, inputting feed nutrient solution from a feed nutrient solution inlet 53, starting a stirring motor 51 to drive a stirring paddle component to mix the feed into paste, and finally pumping the paste feed into a fry culture pond 22 through a pipeline and a fish food conveying pump. The fry just enters the culture pond, and pellet feed is fed to easily cause food waste, and after the device is used, the feed is mixed with nutrient solution to form paste after being crushed, so that the surface area of the feed is increased, the palatability is improved, the fry can eat the feed to improve the digestibility, and the nutrient content of the feed can be better absorbed.

Claims (10)

1. A Cyprinus Carpio culture system is characterized by comprising an indoor spawn hatching part, an outdoor fry culture part and a fish feeding device;

the indoor spawn hatching part comprises an indoor water storage and disinfection tank (1), a procypris rabaudi hatching tank (2) and an oxygen supplementing device (3); the water inlet of the water storage disinfection tank (1) is communicated with a water source; the procypris rabaudi hatching pond (2) is separated from the water storage disinfection pond (1) through a pond wall, the oxygen supplementing device (3) is arranged on the pond wall, a net cage (4) is arranged in the procypris rabaudi hatching pond (2), a fish egg hatching frame is arranged in the net cage (4), a water temperature heating device (5) is arranged at the bottom of the procypris rabaudi hatching pond (2), a water pumping pipeline (6) and a second water pumping pump (7) are arranged on one side of the procypris rabaudi hatching pond (2), and the water pumping pipeline (6) extends into the bottom of the procypris rabaudi hatching pond (2); the oxygen supplementing device (3) comprises a shell, a water inlet pipe (8) and an air inlet pipe (9) which are arranged on the upper portion of the shell, and a water outlet pipe (10) which is arranged at the bottom of the shell, wherein an air outlet (11) is further formed in the top of the shell, the air inlet pipe (9) is connected with a plurality of spiral pipes (12) which are vertically arranged downwards, a plurality of air outlet holes are uniformly formed in the pipe walls of the spiral pipes (12), a first cuboid sponge block (13) is sleeved outside the spiral pipes (12), the bottom of the first sponge block (13) is abutted to the bottom of the shell, the water inlet pipe (8) is communicated to the water storage disinfection pond (1) through a first water suction pump (14) and a pipeline, the water outlet pipe (10) is communicated to the interior of the original rock carp hatching pond (2), and the air inlet pipe (9;

the fry outdoor culture part comprises an outdoor water quality purification pool (21), a fry culture pool (22), an oxygenation mechanism and a pollution discharge mechanism; a drainage pipeline (39) connected with the water outlet of the first water pump (14) is arranged at the upper part of the water quality purifying pool (21), a sand filtering layer (24) is arranged in the water quality purifying pool (21), and a purifying pool water outlet (25) with a filter screen is arranged at the bottom of the water quality purifying pool (21); the fry breeding pond (22) is located below the water quality purifying pond (21), a water outlet (25) of the purifying pond is communicated to the upper portion of the fry breeding pond (22) through a pipeline, the bottom of the fry breeding pond (22) is obliquely arranged, a sewage discharge outlet (26) is formed in the lowest position of the bottom of the fry breeding pond (22), a cylindrical first anti-collision net (27) is fixedly connected to the side wall of the fry breeding pond (22), a circular second anti-collision net (28) is sewn to the bottom of the first anti-collision net (27), and the diameter of the lower portion of the first anti-collision net (27) is smaller than that of the upper portion of the first anti-collision net; the oxygenation mechanism consists of a second air blower (29), a blast pipeline (30) and an aeration component arranged at the bottom of the fry culture pond (22), the aeration component comprises a plurality of round pipes (31) with successively decreasing diameters and a connecting pipe (32) for communicating the round pipes (31), the end part of the connecting pipe (32) is communicated with the blast pipeline (30), a plurality of air outlet holes (36) are uniformly formed in the upper walls of the round pipes (31), and a second sponge block (37) for covering the air outlet holes (36) is adhered to the air outlet holes; the sewage discharge mechanism comprises a sewage discharge pipeline (33) which is arranged at the bottom of the fry culture pond (22) and connected with the sewage discharge port (26) and a sewage discharge pump (34) which is connected with the sewage discharge pipeline (33);

the fish feeding device is positioned on one side of the fry culture pond (22) and comprises a feed crushing mechanism (41), a conveying auger (42) and a pasty feed mixing mechanism (43); the feed crushing mechanism (41) comprises a feed crushing box body (44), a rotary cutting blade (45) arranged inside the feed crushing box body (44), a feed inlet (46) arranged at the top of the feed crushing box body (44), a feed outlet (47) arranged at the bottom of the feed crushing box body (44) and a filter sieve plate (48) positioned above the feed outlet (47), wherein the rotary cutting blade (45) is driven to rotate by a driving motor arranged outside the feed crushing box body (44), the filter sieve plate (48) is of a V-shaped structure, and the feed outlet (47) is communicated with the feed end of the conveying auger (42); the pasty feed mixing mechanism (43) comprises a stirring tank body (50), a stirring motor (51) arranged at the top of the stirring tank body (50), and a stirring paddle component which is positioned inside the stirring tank body (50) and driven to rotate by the stirring motor (51), wherein the stirring paddle component comprises a stirring shaft (55), a first stirring paddle (56) arranged in the middle of the stirring shaft (55) and a second stirring paddle (57) arranged at the lower part of the stirring shaft (55), the length of the first stirring paddle (56) is two thirds of the length of the second stirring paddle (57), a crushed feed inlet (52) connected with the output end of the conveying auger (42) is arranged at the upper part of the stirring tank body (50), a feed nutrient solution feed inlet (53) is also arranged at the upper part of the stirring tank body (50), a pasty feed outlet (54) is arranged at the bottom of the stirring tank body (50), and the pasty feed outlet (54) is connected with a fish food conveying pump through a pipeline, thereby pumping the pasty feed into the fry rearing pond (22).

2. A Cyprinus carpiod farming system according to claim 1, wherein the number of the plurality of spiral tubes (12) is four.

3. A Cyprinus carpiod breeding system according to claim 1, wherein the water temperature heating means (5) is a resistance heating pipe or a heating coil.

4. The procypris rabaudi culture system according to claim 1, wherein the net mesh density of the net cage (4) in the procypris rabaudi hatching pond (2) is 4-8 meshes.

5. A Cyprinus carpiod farming system according to claim 1, characterised in that the sand and stone filter layer (24) has a thickness of 60-80 mm.

6. The procypris rabaudi culture system according to claim 1, wherein an overflow port (35) is further formed in the upper portion of the fry culture pond (22).

7. A Cyprinus carpiod farming system according to claim 1, wherein the fry farming pond (22) is square in cross-section.

8. A crap carp culture system according to claim 1, wherein said plurality of circular tubes (31) is 3 in number.

9. A Cyprinus Carpio farming system according to claim 1, wherein the feed inlet (46) of the feed crushing tank (44) is provided at its upper part with a hinged cover plate (49).

10. The cultivating system for the procypris rabaudi as claimed in claim 1, wherein the feed nutrient solution inlet (53) is connected with a feed delivery pump and a feed solution barrel for containing feed nutrient solution through pipelines.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201921561545.4U CN210519820U (en) | 2019-09-19 | 2019-09-19 | Procypris rabaudi farming systems |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201921561545.4U CN210519820U (en) | 2019-09-19 | 2019-09-19 | Procypris rabaudi farming systems |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN210519820U true CN210519820U (en) | 2020-05-15 |

Family

ID=70605964

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201921561545.4U Expired - Fee Related CN210519820U (en) | 2019-09-19 | 2019-09-19 | Procypris rabaudi farming systems |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN210519820U (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112544544A (en) * | 2020-12-10 | 2021-03-26 | 棠香铁山(重庆)智慧农业科技有限公司 | Anti-season crayfish breeding system and control method |

-

2019

- 2019-09-19 CN CN201921561545.4U patent/CN210519820U/en not_active Expired - Fee Related

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112544544A (en) * | 2020-12-10 | 2021-03-26 | 棠香铁山(重庆)智慧农业科技有限公司 | Anti-season crayfish breeding system and control method |

| CN112544544B (en) * | 2020-12-10 | 2023-05-16 | 棠香铁山(重庆)智慧农业科技有限公司 | Out-of-season crayfish culture system and control method |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN205258262U (en) | Pasture excrement and urine processing apparatus | |

| CN109548720A (en) | The compound shrimp ecosystem cultivated based on heterotopic biological floc sedimentation and nitrified in situ | |

| CN211129429U (en) | Aquaculture feeder | |

| CN210519820U (en) | Procypris rabaudi farming systems | |

| CN208402934U (en) | A kind of waste water recycling system based in simulation natural flows environment fishpond | |

| CN210610702U (en) | Former carp hatching seedling growing system of rock | |

| CN113261526A (en) | Uniformly-spraying feeding equipment for aquatic product cultivation and method thereof | |

| CN211298114U (en) | A cellular-type culture pond for fry is bred | |

| CN113100161A (en) | Inflatable oxygen increasing device for regulating and controlling livestock and poultry aquaculture environment and method thereof | |

| CN215798751U (en) | Device is put in with high-efficient of organic matter to water microorganism breeds | |

| CN109220954B (en) | Energy-saving and environment-friendly aquatic manure collecting device | |

| CN209105954U (en) | A kind of energy-efficient fish culture apparatus | |

| CN113415903A (en) | Efficient organic matter throwing device for water microorganism propagation and throwing method thereof | |

| CN210645995U (en) | A mixing arrangement for producing microbial preparation for aquaculture | |

| CN112021190A (en) | Automatic water adding and feeding equipment for livestock breeding | |

| CN218126396U (en) | Cold water fish fry period breeding pollution discharge device | |

| CN202143406U (en) | Liquid oxygen applying and beneficiating device for industrialized culture | |

| CN220831467U (en) | Aquatic product culture pond | |

| CN209660187U (en) | A kind of floating frame charging device | |

| CN220044593U (en) | Fish breeding device with sewage treatment and cyclic utilization | |

| CN111466327A (en) | Ecological breeding device based on thing networking | |

| CN108812515A (en) | Based on pollution discharge mechanism can high-efficient dirt exhausting fish farming system | |

| CN210519831U (en) | Fish food feeding device for procypris rabaudi fries | |

| CN205865636U (en) | Naked spot fish breed aquatics pond | |

| CN210519844U (en) | Outdoor culture system for procypris rabaudi fry |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20200515 Termination date: 20200919 |

|

| CF01 | Termination of patent right due to non-payment of annual fee |