CN203560895U - Coal-saving device for coal-fired boiler - Google Patents

Coal-saving device for coal-fired boiler Download PDFInfo

- Publication number

- CN203560895U CN203560895U CN201320509118.8U CN201320509118U CN203560895U CN 203560895 U CN203560895 U CN 203560895U CN 201320509118 U CN201320509118 U CN 201320509118U CN 203560895 U CN203560895 U CN 203560895U

- Authority

- CN

- China

- Prior art keywords

- coal

- slag

- elevator

- saving device

- boiler

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Abstract

The utility model relates to the field of slag processing technology in a boiler system and especially relates to a coal-saving device for coal-fired boiler. The coal-saving device comprises a fluidized bed, slag falling pipes, an accidental discharging pipe, an elevator and a small reverting bed. The accidental discharging pipe is welded with a deslagging pipe. The deslagging pipe is connected with a feeding port of the elevator. A discharging port of the elevator is connected with a reverting leg of the small reverting bed. The coal-saving device for the coal-fired boiler has following beneficial effects: uncombusted slag particles in the boiler are recycled so that coal combustion amount of the coal-fired boiler is reduced and the utilization rate of coal combustion is enhanced.

Description

Technical field

The utility model relates to steam generator system field, relates in particular to a kind of coal-burning boiler coal-saving device.

Background technology

Boiler is a kind of by the burning of fuel, the chemical energy in fuel is converted into the device of heat energy.The fuel using has: coal, heavy oil, liquefied gas etc.Along with deepening continuously of energy-conserving and environment-protective, an enterprise will stand firm in market economy, must make great efforts to reduce costs, and improves the ability of enterprise participation competition.The enterprise of present many application coal-burning boilers, all reaches the object of saving coal by minimizing area of heat-supply service, shortening heating time, and has often ignored the coal waste of boiler in running.

Because coal in China kind mixes, often coal burning caloricity can not match with the coal-fired kind of boiler design, lower than designing requirement, do not reach desirable combustion conditions, therefore the thermal efficiency is on the low side, and the coal-fired fugitive constituent having is higher, catches fire rapidly, during burning, there is longer flame, burn comparatively stable, but coking capacity is strong, easily forms closely knit jelly, in addition, the coal that ash fusion point is low, the ash content after burning is easily formed piece, also can make the ventilation condition of fire grate worsen, impact burning, causes the increase of unburned coal amount in slag.Having comparatively general phenomenon is at present that boiler load factor is on the low side, and furnace load decreases, and burning of coal is incomplete, and boiler slag carbon content raises.

Burning of coal will be experienced the low temperature when lighting to the aflame high temperature chilling process to will after-flame time again, for what meet productive life, use vapour needs, must maintain the high temperature in burner hearth, this just need to increase air blast and air inducing amount, improve boiler operatiopn speed, make the coal moment in burner hearth remain on the high-temp combustion stage, cause burning of coal incomplete, in slag, occur unburnt slag granules.

Summary of the invention

the technical problem solving

It is insufficient that the utility model mainly solves current boiler combustion, the problem that contains a large amount of unburnt slag granules in slag.

technical scheme

For solving the problems of the technologies described above, the concrete solution that the utility model provides is:

A kind of coal-burning boiler coal-saving device, comprises fluid bed, slag dropping tube, accident slag-discharge pipe, elevator, returning charge lectulum, described accident slag-discharge pipe is welded with scum pipe, and described scum pipe connects the feeding port of elevator, and the returning charge leg of the feed opening of described elevator and returning charge lectulum is connected.From scum pipe slag out, by elevator, enter returning charge leg, finally enter burner hearth and carry out second-time burning.

By above technical scheme, can reclaim unburnt slag particle in slag, accomplish the abundant recycling of fuel.

beneficial effect

By reclaiming unburnt slag particle in slag, reduced the Coal-fired capacity of coal-burning boiler, improve coal-fired utilization rate.

Accompanying drawing explanation

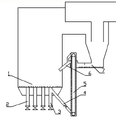

Accompanying drawing 1, structural representation of the present utility model;

Mark in figure: 1, fluid bed 2, slag dropping tube 3, accident slag-discharge pipe 4, scum pipe 5, elevator 6, returning charge leg 7, returning charge lectulum.

The specific embodiment

Below in conjunction with drawings and Examples, the utility model is further described

With reference to Fig. 1, a kind of coal-burning boiler coal-saving device, by fluid bed, slag dropping tube, accident slag-discharge pipe, elevator, returning charge lectulum composition, on described accident slag-discharge pipe, be welded with scum pipe, scum pipe connects the feeding port of elevator, and the returning charge leg of the feed opening of elevator and returning charge lectulum is connected.From scum pipe slag out, by elevator, enter returning charge leg, finally by returning charge leg, enter burner hearth and carry out second-time burning.

In running, a part of slag is discharged from slag dropping tube, and a part of slag returns to burner hearth by elevator.The utility model can reclaim unburnt slag particle in slag, accomplishes the abundant recycling of fuel.

Claims (1)

1. a coal-burning boiler coal-saving device, comprise fluid bed, slag dropping tube, accident slag-discharge pipe, elevator, returning charge lectulum, is characterized in that: described accident slag-discharge pipe is welded with scum pipe, described scum pipe connects the feeding port of elevator, and the returning charge leg of the feed opening of described elevator and returning charge lectulum is connected.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201320509118.8U CN203560895U (en) | 2013-08-21 | 2013-08-21 | Coal-saving device for coal-fired boiler |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201320509118.8U CN203560895U (en) | 2013-08-21 | 2013-08-21 | Coal-saving device for coal-fired boiler |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN203560895U true CN203560895U (en) | 2014-04-23 |

Family

ID=50510614

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201320509118.8U Expired - Fee Related CN203560895U (en) | 2013-08-21 | 2013-08-21 | Coal-saving device for coal-fired boiler |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN203560895U (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108592012A (en) * | 2018-04-13 | 2018-09-28 | 云南农业大学 | A kind of biomass combustion furnace of high effect cleaning |

-

2013

- 2013-08-21 CN CN201320509118.8U patent/CN203560895U/en not_active Expired - Fee Related

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108592012A (en) * | 2018-04-13 | 2018-09-28 | 云南农业大学 | A kind of biomass combustion furnace of high effect cleaning |

| CN108592012B (en) * | 2018-04-13 | 2019-10-22 | 云南农业大学 | A kind of biomass combustion furnace of high effect cleaning |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN101776271B (en) | Fluidized bed incinerating device and process suitable for treatment of waste with low heating value | |

| CN201688552U (en) | Assembled water tube boiler by burning biomass | |

| CN101586799B (en) | Moderate temperature moderate voltage steam boiler capable of burning down the blast furnace gas | |

| CN102022716A (en) | Vertical waste incineration boiler | |

| CN202382230U (en) | Fluid bed furnace | |

| CN105202575B (en) | Coal dust or broken coal burning produce the method and device of high temperature hyperoxia torch ignition | |

| CN110486717A (en) | It is a kind of to mix the CFB boiler system for burning waste gas and waste liquid | |

| CN207019075U (en) | A kind of circulating fluid bed garbage furnace | |

| CN203560895U (en) | Coal-saving device for coal-fired boiler | |

| CN107575859A (en) | The oxygenation start-up burner and its ignition smooth combustion method of a kind of coal burning boiler of power station | |

| CN202938289U (en) | Fuel-saving ignition device of circulating fluidized bed boiler | |

| CN203628629U (en) | Coal saving device for coal burning boiler | |

| CN204042840U (en) | Scoot burning boiler | |

| CN107166383A (en) | A kind of oxygen-enriched few-oil ignition system of boiler | |

| CN202382251U (en) | Novel waste incineration boiler | |

| CN203489257U (en) | Circulating fluidized bed boiler with coal gangue with low heating value as fuel | |

| CN203431878U (en) | Novel pure-combustion garbage fluidized bed incinerator | |

| CN209511994U (en) | A kind of non helping hand spontaneous combustion heat accumulating type biological particles combustion furnace | |

| CN203731661U (en) | Automatic feeding biomass boiler | |

| CN206944145U (en) | A kind of oxygen-enriched few-oil ignition system of boiler | |

| CN202546779U (en) | Pi-shaped garbage incineration boiler | |

| CN201903063U (en) | Vertical refuse incinerator | |

| CN203364119U (en) | Novel biomass incineration boiler | |

| CN207035493U (en) | A kind of burning biomass particle heat conduction oil boiler furnace apparatus | |

| CN201487941U (en) | Stable combusting device of coal-water slurry boiler |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20140423 Termination date: 20160821 |

|

| CF01 | Termination of patent right due to non-payment of annual fee |