CN202494532U - System for calibrating surface temperature of metal plate - Google Patents

System for calibrating surface temperature of metal plate Download PDFInfo

- Publication number

- CN202494532U CN202494532U CN2012201363121U CN201220136312U CN202494532U CN 202494532 U CN202494532 U CN 202494532U CN 2012201363121 U CN2012201363121 U CN 2012201363121U CN 201220136312 U CN201220136312 U CN 201220136312U CN 202494532 U CN202494532 U CN 202494532U

- Authority

- CN

- China

- Prior art keywords

- metal plate

- temperature

- constant temperature

- thermostatic bath

- tested

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 229910052751 metal Inorganic materials 0.000 title claims abstract description 143

- 239000002184 metal Substances 0.000 title claims abstract description 143

- 238000010438 heat treatment Methods 0.000 claims abstract description 42

- 239000000463 material Substances 0.000 claims description 21

- 238000005259 measurement Methods 0.000 claims description 19

- 239000000567 combustion gas Substances 0.000 claims description 13

- 239000000126 substance Substances 0.000 claims description 7

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 6

- 150000003839 salts Chemical class 0.000 claims description 5

- 239000012774 insulation material Substances 0.000 claims description 4

- 239000004576 sand Substances 0.000 claims description 4

- 238000007789 sealing Methods 0.000 claims description 4

- 239000000346 nonvolatile oil Substances 0.000 claims description 3

- 238000001931 thermography Methods 0.000 description 28

- 238000000034 method Methods 0.000 description 10

- 238000005485 electric heating Methods 0.000 description 9

- 230000003647 oxidation Effects 0.000 description 5

- 238000007254 oxidation reaction Methods 0.000 description 5

- WCUXLLCKKVVCTQ-UHFFFAOYSA-M Potassium chloride Chemical compound [Cl-].[K+] WCUXLLCKKVVCTQ-UHFFFAOYSA-M 0.000 description 4

- FAPWRFPIFSIZLT-UHFFFAOYSA-M Sodium chloride Chemical compound [Na+].[Cl-] FAPWRFPIFSIZLT-UHFFFAOYSA-M 0.000 description 4

- 230000005540 biological transmission Effects 0.000 description 4

- 238000009529 body temperature measurement Methods 0.000 description 4

- FGIUAXJPYTZDNR-UHFFFAOYSA-N potassium nitrate Chemical compound [K+].[O-][N+]([O-])=O FGIUAXJPYTZDNR-UHFFFAOYSA-N 0.000 description 4

- VWDWKYIASSYTQR-UHFFFAOYSA-N sodium nitrate Chemical compound [Na+].[O-][N+]([O-])=O VWDWKYIASSYTQR-UHFFFAOYSA-N 0.000 description 4

- 238000010301 surface-oxidation reaction Methods 0.000 description 4

- 229910000838 Al alloy Inorganic materials 0.000 description 3

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 3

- 229910000831 Steel Inorganic materials 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 239000000047 product Substances 0.000 description 3

- 239000000523 sample Substances 0.000 description 3

- 239000010959 steel Substances 0.000 description 3

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- 239000000956 alloy Substances 0.000 description 2

- WDIHJSXYQDMJHN-UHFFFAOYSA-L barium chloride Chemical compound [Cl-].[Cl-].[Ba+2] WDIHJSXYQDMJHN-UHFFFAOYSA-L 0.000 description 2

- 229910001626 barium chloride Inorganic materials 0.000 description 2

- 239000004020 conductor Substances 0.000 description 2

- 238000005516 engineering process Methods 0.000 description 2

- 238000009434 installation Methods 0.000 description 2

- 238000012544 monitoring process Methods 0.000 description 2

- 231100000252 nontoxic Toxicity 0.000 description 2

- 230000003000 nontoxic effect Effects 0.000 description 2

- 239000003921 oil Substances 0.000 description 2

- 235000011164 potassium chloride Nutrition 0.000 description 2

- 239000001103 potassium chloride Substances 0.000 description 2

- 235000010333 potassium nitrate Nutrition 0.000 description 2

- 239000004323 potassium nitrate Substances 0.000 description 2

- 238000012545 processing Methods 0.000 description 2

- 230000005855 radiation Effects 0.000 description 2

- 239000011780 sodium chloride Substances 0.000 description 2

- 235000010344 sodium nitrate Nutrition 0.000 description 2

- 239000004317 sodium nitrate Substances 0.000 description 2

- 230000008646 thermal stress Effects 0.000 description 2

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 1

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 1

- 229910002651 NO3 Inorganic materials 0.000 description 1

- NHNBFGGVMKEFGY-UHFFFAOYSA-N Nitrate Chemical compound [O-][N+]([O-])=O NHNBFGGVMKEFGY-UHFFFAOYSA-N 0.000 description 1

- 238000012356 Product development Methods 0.000 description 1

- 239000004411 aluminium Substances 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 238000010009 beating Methods 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 229910052802 copper Inorganic materials 0.000 description 1

- 239000010949 copper Substances 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 229910001873 dinitrogen Inorganic materials 0.000 description 1

- 238000007599 discharging Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 238000002474 experimental method Methods 0.000 description 1

- 239000012467 final product Substances 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 238000003331 infrared imaging Methods 0.000 description 1

- 238000009413 insulation Methods 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 238000002372 labelling Methods 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 239000011159 matrix material Substances 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 229910052757 nitrogen Inorganic materials 0.000 description 1

- 230000003287 optical effect Effects 0.000 description 1

- 231100000614 poison Toxicity 0.000 description 1

- 230000007096 poisonous effect Effects 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

- 238000011160 research Methods 0.000 description 1

- 238000005070 sampling Methods 0.000 description 1

- 238000007669 thermal treatment Methods 0.000 description 1

- 230000005619 thermoelectricity Effects 0.000 description 1

- 238000004861 thermometry Methods 0.000 description 1

- 230000001052 transient effect Effects 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

Images

Landscapes

- Radiation Pyrometers (AREA)

Abstract

The utility model relates to a system for calibrating surface temperature of a metal plate. The system is composed of a constant temperature bath device and a temperature measuring device. The constant temperature bath device comprises a constant temperature bath box, wherein the constant temperature bath box is composed of a base plate and a wall surface, the wall surface is composed of a wall of a constant temperature bath box body and a wall of a measured metal plate, constant temperature bath medium is arranged inside the constant temperature bath box, and the constant temperature bath box also comprises heating elements which heat the constant temperature bath medium. The temperature measuring device comprises a non-contact temperature measurer and a directly contact temperature sensitive element, wherein the directly contact temperature sensitive element is arranged in the constant temperature bath box and installed on the internal side of the measured metal plate, and the non-contact temperature measurer is installed on the external side of the measured metal plate. The system in the utility model is simple in structure, convenient in usage, and accurate and reliable in measuring results.

Description

Technical field

The utility model relates to strip heat treatment technics field, cold rolled metal; Relate in particular in the Technology for Heating Processing of metal plate and belt; Be used to demarcate the device of bright and clean non-oxidation metal plate surface temperature; This device can be applicable to the cold rolled metal heat-treatment production line, and uses the experimentize field of research and product development of smooth finish surface metal plate.

Background technology

Along with the demand of each industry to high quality of products constantly increases, the metal plate process of thermal treatment requires also more and more stricter.In heat treatment process; In order to obtain the metal plate product of certain mechanical property and excellent surface characteristic; Need metal plate be heated accurately or is cooled to special process temperature spot (or temperature range in), with the mechanical property that ensures metal plate or surface quality in the desired scope of product.Therefore, we need guarantee the accuracy of the metal plate surface temperature that instrument records.

In continuity is produced unit, because material in continuous motion, can't carry out contact type measurement to the metal plate surface temperature, so the non-contact measurement mode,, main on-line measurement means have just been become like infrared imaging etc.

Yet non-contact measurement receives the interference of several factors; Receive the influence of the surperficial emissivity of testee, environment temperature, atmospheric temperature, atmospheric attenuation rate, solar radiation etc. like the thermometric accuracy of thermal infrared imager; Wherein the influence of emissivity is the most outstanding, and the result who directly measures is often inaccurate.Therefore; We need with the metering system of contact, demarcate the temperature range that contactlesss temperature instrument needs accurately to measure earlier under off-line state; Promptly directly measure the temperature on one group of measured matter surface through the contact temperature instrument; As reference value, calculate the actual transmission rate of this material surface, thus the accuracy when guaranteeing the same metallics surface temperature of this noncontact instrument measurement.

The emissivity of material surface not only depends on the inwardness of material; Also depend on physical state, smooth degree of material surface etc. simultaneously; These factors make that the measurement of emissivity is very complicated; And the accurate accuracy that directly influences the infrared measurement of temperature data of emissivity numerical value has become a major subjects in the infrared thermal imagery thermometry so how to confirm the emissivity on testee surface.

The utility model content

The utility model technical matters to be solved provides a kind of simple in structure, easy to use, and thermometric accurately and reliably metal plate surface temperature calibration system can be provided for bright and clean metal plate.

The technical scheme that the utility model adopted is: a kind of metal plate surface temperature calibration system; It is made up of thermostatic bath device and temperature measuring equipment; Described thermostatic bath device comprises the constant temperature bath cabinet, and described constant temperature bath cabinet is made up of base plate and wall, and described wall is formed by constant temperature bath cabinet body wall face with by the wall that tested metal plate is done; Described constant temperature bath cabinet is built-in with the thermostatic bath medium, and described constant temperature bath cabinet also includes the heating element that the thermostatic bath medium is heated; Described temperature measuring equipment comprises the contactless temperature measurer and the thermal sensing element of direct contact type, and the thermal sensing element of described direct contact type places in the constant temperature bath cabinet, and is installed on the medial surface of tested metal plate; Described contactless temperature measurer is installed in the outside of tested metal plate.

Press such scheme, described thermostatic bath device also includes the stirrer that the thermostatic bath medium is stirred; Described temperature measuring equipment also comprises the thermostatic bath medium temperature element that is used to monitor the thermostatic bath medium temperature.

Press such scheme, described constant temperature bath cabinet also includes the lid of band vent port.

Press such scheme, the thermal sensing element of described direct contact type has more than 4 or 4, is evenly distributed on the tested metal plate medial surface; Described contactless temperature measurer has more than one or one.

Press such scheme, be coated with insulation material on the described constant temperature bath cabinet body wall face.

Press such scheme, the material of described constant temperature bath cabinet body wall face or chemical constitution the same with the material of tested metal plate near.

Press such scheme, the medial surface of described tested metal plate is provided with the mounting hole of the thermal sensing element of direct contact type, and the thermal sensing element of direct contact type directly inserts in the mounting hole.

Press such scheme, described heating element is combustion gas heating element and/or electrical heating elements; Described thermostatic bath medium is water, nonvolatile oil, fine sand, non-volatile salt or lead.

Press such scheme, the outside of described tested metal plate is installed on the measurement black box of band observation port, measures black box and is installed on the tested metal plate through the sealing of sheet metal packoff, and described contactless temperature measurer is installed in to be measured on the black box.

Press such scheme,,, be provided with the tinsel of diameter below 1mm along horizontal and vertical direction near tested metal plate place measuring black box inside.

The beneficial effect of the utility model is: 1, simple in structure, easy to use.2, adopt a plurality of temperature thermocouples or temperature detecting resistance and the direct contact thermography of metal plate, temperature-measuring results accurately and reliably.3, the temperature range that can demarcate is wide, does not take place on the metal plate surface under the situation of physics or chemical change, can demarcate the temperature spot in the 0-1500 ℃ of scope.4, easy maintenance, good economy performance.

Description of drawings

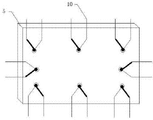

Fig. 1 is the structural representation of an embodiment of the utility model.

Fig. 2 is the distribution schematic diagram of tested metal plate temperature element on tested metal plate medial surface.

Fig. 3 is the scheme of installation of tested metal plate temperature element on thick tested metal plate cross section.

Fig. 4 is many infrared thermography appearance and the structural representation of measuring black box.

Fig. 5 is that separate unit infrared thermography appearance carries out thermometric structural representation to tested metal plate.

Among the figure: 1. measure black box; 2. infrared thermography appearance observation port; 3. porous media material; 4. infrared thermography appearance; 5. tested metal plate; 6. thermostatic bath medium; 7. heating element; 8. constant temperature bath cabinet; 9. thermostatic bath medium temperature element; 10. tested metal plate temperature element; 11. stirrer; 12. mounting hole; 13. sheet metal packoff; 14. tinsel; 15. observation port blind plate; 16. observation port.

Embodiment

Further specify the embodiment of the utility model below in conjunction with accompanying drawing.

Referring to Fig. 1, Fig. 2, Fig. 3, Fig. 4 and Fig. 5; A kind of metal plate surface temperature calibration system; It is made up of thermostatic bath device and temperature measuring equipment; Described thermostatic bath device comprises constant temperature bath cabinet 8, and described constant temperature bath cabinet 8 is made up of base plate and wall, and described wall is formed by constant temperature bath cabinet body wall face with by the wall that tested metal plate 5 is done; Described constant temperature bath cabinet 8 is built-in with thermostatic bath medium 6, and described constant temperature bath cabinet 8 also includes the heating element 7 that thermostatic bath medium 6 is heated; Described temperature measuring equipment comprises the contactless temperature measurer and the thermal sensing element of direct contact type, and the thermal sensing element of described direct contact type places in the constant temperature bath cabinet 8, and is installed on the medial surface of tested metal plate 5; Described contactless temperature measurer is installed in the outside of tested metal plate 5; Described thermostatic bath device also includes the stirrer 11 that thermostatic bath medium 6 is stirred, and is even with the temperature that guarantees thermostatic bath medium 6; Described temperature measuring equipment also comprises the thermostatic bath medium temperature element 9 that is used to monitor thermostatic bath medium 6 temperature.

In the present embodiment; Described thermostatic bath medium 6 is a kind of in water, nonvolatile oil, fine sand, non-volatile salt or the lead, generally: 0-100 ℃ of bath temperature scope, 100-260 ℃ of oil bath temperature scope; 400-600 ℃ of sand-bath temperature, 350-1740 ℃ of lead bath temperature.The salt temperature scope is relevant with the slaine of employing, the useful sodium chloride of normally used slaine, potassium chloride, barium chloride, sodium nitrate, potassium nitrate etc.Nitrate at high temperature decomposes easily, and maximum temperature all is no more than 580 ℃, and wherein the sodium nitrate maximum operating temperature is no more than 380 ℃, and the maximum operating temperature of potassium nitrate is no more than 400 ℃; And the villaumite chemical property is comparatively stable, and the working temperature of sodium chloride is 850 ~ 1100 ℃, and potassium chloride is 800 ~ 1000 ℃, and barium chloride is 750 ~ 1350 ℃.Therefore, the temperature range that the utility model can be demarcated is wide, does not take place on the metal plate surface under the situation of physics or chemical change, can demarcate the temperature spot in the 0-1500 ℃ of scope.

In order to guarantee the temperature constant of thermostatic bath medium 6, need on constant temperature bath cabinet body wall face, coat insulation material.Accurate for the temperature of guaranteeing thermostatic bath medium 6, the thermostatic bath medium temperature element 9 that thermostatic bath medium 6 is carried out temperature monitoring is temperature element.When thermostatic bath medium 6 is volatile media or poisonous medium, should on constant temperature bath cabinet 8, establishes the lid of band vent port, and the gas of discharging is carried out outdoor waste discharge or other safe handling.When if thermostatic bath medium 6 is selected water, husky or nontoxic non-volatility oily for use, can constant temperature bath cabinet 8 be made the form of open-top.

Consider that constant temperature bath cabinet 8 needs consistent with the swell increment of tested metal plate 5 when adding thermal expansion; To reduce the thermal stress of thermal deformation and material; Therefore the material with tested metal plate 5 is the same as far as possible for the material of described constant temperature bath cabinet body wall face, and perhaps chemical constitution is near (for this alloy materials such as steel, aluminium alloys).

In the present embodiment, described tested metal plate temperature element 10 can adopt temperature thermocouple or temperature detecting resistance, and described tested metal plate temperature element 10 has a plurality of, is installed on the surface of tested metal plate 5 near constant temperature bath cabinet 8 inboards.The quantity of temperature element 10 or temperature detecting resistance is relevant with the area of tested metal plate 5, but its quantity preferably is no less than 4, is evenly distributed on tested metal plate 5 medial surfaces.When the thickness of tested metal plate 5 is big; Because the cross-wise direction thermal resistance is bigger; Tend to produce the temperature difference of can not ignore on two surfaces; Therefore need be on tested metal plate, radially (thickness direction) gets out the mounting hole 12 of installing tested metal plate temperature element 10 (thermoelectricity is thermal resistance occasionally), and the probe of the tested metal plate temperature element 10 of measuring tested metal plate temperature is directly inserted in the mounting hole 12.To guarantee that generally tested metal plate 5 inside and outside temperature difference are not more than the measuring accuracy of tested metal plate temperature element 10.

In the present embodiment, described contactless temperature measurer is an infrared thermography appearance 4, and described infrared thermography appearance 4 has more than one or one.Accurate in order to guarantee infrared thermography appearance 4 thermometrics, install the measurement black box of processing by porous media material 31 usually in the outside of tested metal plate 5, measure black box 1 and be installed on the tested metal plate 5 through 13 sealings of sheet metal packoff.Infrared thermography appearance 4 is installed on the observation port 16 of measuring black box 1.Because the field range of infrared thermography appearance 4 is limited; A measuring instrument possibly can't cover the surf zone of whole tested metal plate 5; Therefore on measurement black box 1, drive a plurality of observation ports 16, set up many infrared thermography appearance 4 and measure simultaneously, referring to Fig. 4.When an infrared thermography appearance 4 is only arranged, can take the mode of Fig. 5, when measuring at every turn; With the temporary transient no observation port 16 of observation port blind plate 15 sealings, to avoid space outerpace thermal imaging is impacted, then under same stable measurement state earlier; Measure with same infrared thermography appearance 4 gradation, more each thermal imaging photo is spliced, for the convenience of stitching image; Need on metal plate 5 or thermal imaging photo, make marks; But common mark can't projection on the infrared thermal imaging photo, therefore need press close to tested metal plate 5 places measuring black box 1 inside; Along the horizontal and vertical several thin tinsels 14 (generally selecting the finer wire of diameter below 1mm for use) of pulling on; Because the temperature of tinsel 14 is lower than the temperature of tested metal plate 5, one elongated dark-coloured lines can on infrared photograph, be formed, as the mark line of photomosaic.

In the present embodiment, when thermostatic bath medium 6 is an electric conductor, then heating element 7 adopts electrical heating elements, when adopting Electric heating, should use pottery or quartzy insulating sleeve.When heating-up temperature is lower than 400 ℃, required heating power is less, when the combustion gas heating is difficult to accurately control, adopts Electric heating, so that control heating power preferably; When heating-up temperature was higher than 1000 ℃, the material tolerance degree of the electric heating body of Electric heating reduced greatly, and the combustion gas heating has better efficient, therefore adopted the combustion gas type of heating, and promptly heating element 7 is the combustion gas heating element; When heating-up temperature was 400-1000 ℃, Electric heating and combustion gas type of heating all could.

For the emissivity that guarantees tested metal plate 5 surfaces can not have greatly changed along with the metal plate surface state, so the utility model only limits to the metal plate of smooth finish surface.Consider tested metal plate 5 surface oxidation problem at high temperature, when carrying out temperature calibration, can not take place in the temperature range of obvious surface oxidation as far as possible, perhaps this system is placed and carry out temperature calibration in the closed container that is full of reducing atmosphere.The metal plate of oxidation is surperficial or have the metal plate of coated layer surperficial, because emissivity is relevant with surface oxidation/coated layer, the value that records is unreliable, so not in the utility model scope.

The utility model adopts the constant temperature thermal source of water/oil/salt/sand/lead bath as metal plate; The curve of demarcating as required; Make the metal plate overall uniform be heated to specific temperature spot, under specified temp point, with the measured temperature value of the dull and stereotyped temperature thermocouple of direct contacting metal or temperature detecting resistance as standard value; Measured value to contactless infrared thermography instrument is calibrated, thereby the temperature survey that guarantees metal plate is accurate, reliable.

In the utility model, using the purpose of measuring black box is to reduce the interference of external environment to the infrared thermography apparatus measuring value, makes measuring process stable, guarantees measurement reliability.The infrared ray of measuring black box and being in the environment impacts measurement; Therefore with the casing that covers up between tested metal plate and the infrared thermography appearance, cabinet wall selects for use slin emissivity near 1 material (the emissivity value is getting final product more than 0.8) as far as possible.

The method of the metal plate surface temperature being demarcated with the utility model metal plate surface temperature calibration system; Specifically: with the thermostatic bath medium as heating source; Heat the one side of tested metal plate, and the temperature that a plurality of direct contact type thermal sensing elements (like thermopair, thermal resistance) are measured metal plate is installed at this face; Other one side at tested metal plate is then measured the metal plate surface temperature with contactless temperature measuring device.Because the temperature-measurement principle of infrared measurement of temperature instrument is based on Shi Difen-Boltzmann's law, the emittance of the black matrix that it provides and the relation of its temperature are W=ε * σ * T

4In the formula, Boltzmann constant σ=5.67 * 10

-8W/m2.K

4T is the absolute temperature of testee, and unit is K; ε is the testee slin emissivity.The infrared thermography instrument relies on optical element that infrared ray is focused on the infrared eye, and converts electric signal to through the infrared energy that detector receives, thereby confirms the temperature height of testee.This metal plate temperature is demarcated and just is being based on this theory; Under the environmental baseline of setting; With the metal plate of known temperature, proofread and correct non-contact type temperature measurement instrument (being generally the infrared thermography appearance), obtain the true emissivity on this metal plate surface; Thereby guarantee when measuring the metal of surface state of the same race, can draw surface temperature accurately and reliably, to satisfy the measuring accuracy requirement of experiment or online production with sampling instrument.

With the method that the utility model metal plate surface temperature calibration system is demarcated the metal plate surface temperature, concrete steps comprise:

The first step is confirmed temperature range and the thermostatic bath medium demarcated.At first interval according to the temperature of charge of producing unit or experimental study, confirm the metal plate temperature range that need measure.Because when the temperature survey of infrared emanation principle is carried out on the metal plate surface; Its emissivity should be stablized as far as possible; Accurate as far as possible to guarantee the temperature that measures; Therefore carrying out timing signal, must guarantee that obvious oxidation (like pure iron, steel, copper) does not take place the metal planar surface, perhaps complete oxidation (like aluminium and aluminium alloy) under demarcation normal temperature state before.If need the temperature range span of measurement big; Can cause metal plate that this process of surface oxidation takes place under air+hot environment; Then need be in the temperature range of oxidation take place, whole metal plate surface temperature calibration system placed in the confined space that is full of protective atmosphere (like pure nitrogen gas or nitrogen and hydrogen gas mixture) measure.

Constant temperature bath cabinet 8 directly with the wall of tested metal plate 5 as it, makes the temperature of tested metal plate 5 as far as possible near the temperature of thermostatic bath medium 6 when making.Consider that the constant temperature bath cabinet needs consistent with the swell increment of metal plate when adding thermal expansion; To reduce the thermal stress of thermal deformation and material; Therefore the material with tested metal plate is the same as far as possible for the material of constant temperature bath cabinet body wall face, and perhaps chemical constitution is near (for this alloy materials such as steel, aluminium alloys).Other walls of constant temperature bath cabinet 8 (constant temperature bath cabinet body wall face) all should coat insulation material, and vent port should be established in the top.When if thermostatic bath medium 6 is selected water, husky or nontoxic non-volatility oily for use, can directly constant temperature bath cabinet 8 be made the form of open-top.

In second step, the thermostatic bath medium is heated to the temperature value that needs demarcation.Calibration range according to confirming in the first step whenever selects a calibration point at a distance from 20 ~ 50 ℃; Not high for accuracy requirement, and need the temperature range of demarcation bigger, can be a bit at a distance from 100 ℃ of choosings.The interval of calibration point should be greater than 4 ~ 5 times of infrared measurement instrument measuring error.

Should carry out gradually to high temperature from low temperature during heating, and be heated in the process of element 7 heating, keep the operate as normal of stirrer 11, so that the temperature of whole thermostatic bath medium is even as far as possible at thermostatic bath medium 6.Need consider the thermal inertia of whole constant temperature bath cabinet 8 and thermostatic bath medium 6 during intensification, so heating rate≤1 ℃/minute.

Heating element 7 adopts combustion gas heating element or electrical heating elements.If the thermostatic bath medium is an electric conductor, then adopt the electrical heating elements heating, when adopting Electric heating, should use the insulation of pottery or quartzy insulating sleeve.When heating-up temperature was lower than 400 ℃, required heating power was less, and the combustion gas heating is difficult to accurate control, then adopts Electric heating, so that control heating power preferably; When heating-up temperature was higher than 1000 ℃, the material tolerance degree of the electric heating body of Electric heating reduced greatly, and the combustion gas heating has better efficient, therefore adopted the combustion gas type of heating, promptly adopted the combustion gas heating element to heat; When heating-up temperature was 400-1000 ℃, electrical heating method mode and combustion gas type of heating all could.

After thermostatic bath medium 6 is heated to design temperature point, keep the temperature constant of 30min at least, and the reading of continuous monitoring thermostatic bath medium temperature element 9 is beated in 30min.When the reading amplitude of beating is not higher than the measuring accuracy of thermostatic bath medium temperature element 9, can think thermostatic bath medium 6 temperature complete stability get off, can prepare to carry out metal plate temperature survey and demarcation.

The 3rd step, the temperature survey of metal plate.Tested metal plate 5 has a plurality of tested metal plate temperature elements 10 near constant temperature bath cabinet 8 inboard mounted on surface.The quantity of tested metal plate temperature element 10 is relevant with the area of tested metal plate 5, but its quantity is no less than 4, is evenly distributed on tested metal plate 5 surfaces.When the thickness of tested metal plate 5 is big; Because the cross-wise direction thermal resistance is bigger; Tend to produce the temperature difference of can not ignore on two surfaces; Therefore need to get out the probe mounting hole 12 of installing tested metal plate temperature element 10, the tested metal plate temperature element 10 of measuring tested metal plate 5 temperature is directly inserted in the mounting hole 12 along the thickness direction of tested metal plate 5.To guarantee that generally tested metal plate 5 temperature difference are not more than the temperature measurement accuracy of tested metal plate temperature element 10.

During measurement, earlier tested metal plate 5 is divided into several regions, region quantity is no less than 4, and relevant with the quantity of the temperature element 10 that is provided with, and generally the probe of the tested metal plate temperature element 10 of each zone installation is positioned at this regional center.Can't see the mark line of drawing on the tested metal plate 5 in the thermal imagery photo that the temperature-measuring element of infrared principles is taken; Therefore can be in measuring black box 1 near the position adjustment notch of tested metal plate 5 with fine wire 14; Because tinsel 14 is starkly lower than the temperature of tested metal plate 5; Can dark projection be arranged in the thermal imaging of infrared thermography appearance 4, play the effect of mark measured zone.Before measuring beginning, earlier through looking into the initial transmissions rate ε of the tested metal plate that the physical parameter table tries to achieve

0, each zone uses tested metal plate temperature element 10 to carry out the direct temperature measurement then, and uses 4 pairs of these zones of infrared thermography appearance to carry out temperature survey simultaneously, writes down two kinds of instrument measured value separately.Successively, the temperature of All Ranges is all measured.

The 4th step, the demarcation of certain temperature spot of infrared thermography appearance 4.To certain measured zone, suppose that the metal plate temperature of using temperature element 10 to record is T

1, use initial transmissions rate value ε

0The zone leveling temperature that the infrared thermography appearance 4 that is provided with records is T

0, the emissivity after the calibration is ε

1So according to Boltzmann's radiation law, ε

1* T

1 4=ε

0* T

0 4

Therefore ε is arranged

1=ε

0* (T

0/ T

1)

4

Thereby we obtain the emissivity value ε that this zone is accurately measured through the supplied infrared thermography appearance behind the temperature calibration

1(or and functional relationship of temperature) (annotated: ε

1Be the actual transmission rate of tested metal plate).

Because each regional temperature deviation, and the deviation of apparatus measures need all so be measured, demarcate, then with the emissivity behind each region labeling each measured zone

1Ask weighted mean value (weight, can directly be averaged for this regional area percentage) after rejecting significantly bad value when the All Ranges area is identical.

In the 5th step, whole temperature range is carried out temperature calibration one by one.Interval according to the determined temperature calibration of the first step, repeated for second step to the 4th step, measure metal plate 5 temperature variant slin emissivity ε in the whole temperature range

1, then the slin emissivity of this demarcation temperature province is carried out mathematical regression, obtain tested metal plate 5 temperature variant slin emissivity ε in the whole temperature range

1(the true emissivity relevant) with the surface working state

,The infrared measurement of temperature instrument that this emissivity can be used for similar model on the continuously acting production lines to the temperature survey of similar metalliferous material (annotate: the infrared thermometer of different manufacturers or model has difference on eyeglass, infrared ray sensing element, signal conversion module, and therefore the emissivity value that records of the method through the utility model can not be used with).

Claims (10)

1. metal plate surface temperature calibration system; It is characterized in that: it is made up of thermostatic bath device and temperature measuring equipment; Described thermostatic bath device comprises the constant temperature bath cabinet, and described constant temperature bath cabinet is made up of base plate and wall, and described wall is formed by constant temperature bath cabinet body wall face with by the wall that tested metal plate is done; Described constant temperature bath cabinet is built-in with the thermostatic bath medium, and described constant temperature bath cabinet also includes the heating element that the thermostatic bath medium is heated; Described temperature measuring equipment comprises the contactless temperature measurer and the thermal sensing element of direct contact type, and the thermal sensing element of described direct contact type places in the constant temperature bath cabinet, and is installed on the medial surface of tested metal plate; Described contactless temperature measurer is installed in the outside of tested metal plate.

2. metal plate surface temperature calibration system as claimed in claim 1 is characterized in that: described thermostatic bath device also includes the stirrer that the thermostatic bath medium is stirred; Described temperature measuring equipment also comprises the thermostatic bath medium temperature element that is used to monitor the thermostatic bath medium temperature.

3. according to claim 1 or claim 2 metal plate surface temperature calibration system, it is characterized in that: described constant temperature bath cabinet also includes the lid of band vent port.

4. metal plate surface temperature calibration system as claimed in claim 1, it is characterized in that: the thermal sensing element of described direct contact type has more than 4 or 4, is evenly distributed on the tested metal plate medial surface; Described contactless temperature measurer has more than one or one.

5. metal plate surface temperature calibration system as claimed in claim 1 is characterized in that: be coated with insulation material on the described constant temperature bath cabinet body wall face.

6. like claim 1 or 5 described metal plate surface temperature calibration systems, it is characterized in that: the material of described constant temperature bath cabinet body wall face or chemical constitution the same with the material of tested metal plate near.

7. metal plate surface temperature calibration system as claimed in claim 1, it is characterized in that: the medial surface of described tested metal plate is provided with the mounting hole of the thermal sensing element of direct contact type, and the thermal sensing element of direct contact type directly inserts in the mounting hole.

8. metal plate surface temperature calibration system as claimed in claim 1 is characterized in that: described heating element is combustion gas heating element and/or electrical heating elements; Described thermostatic bath medium is water, nonvolatile oil, fine sand, non-volatile salt or lead.

9. metal plate surface temperature calibration system as claimed in claim 1; It is characterized in that: the outside of described tested metal plate is installed on the measurement black box of band observation port; Measure black box and be installed on the tested metal plate through the sealing of sheet metal packoff, described contactless temperature measurer is installed in to be measured on the black box.

10. metal plate surface temperature calibration system as claimed in claim 9 is characterized in that: measuring black box inside, near tested metal plate place, be provided with the tinsel of diameter below 1mm along horizontal and vertical direction.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012201363121U CN202494532U (en) | 2012-03-31 | 2012-03-31 | System for calibrating surface temperature of metal plate |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012201363121U CN202494532U (en) | 2012-03-31 | 2012-03-31 | System for calibrating surface temperature of metal plate |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN202494532U true CN202494532U (en) | 2012-10-17 |

Family

ID=47000757

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2012201363121U Expired - Fee Related CN202494532U (en) | 2012-03-31 | 2012-03-31 | System for calibrating surface temperature of metal plate |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN202494532U (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102620835A (en) * | 2012-03-31 | 2012-08-01 | 中冶南方(武汉)威仕工业炉有限公司 | System for calibrating surface temperature of metal flat plate |

-

2012

- 2012-03-31 CN CN2012201363121U patent/CN202494532U/en not_active Expired - Fee Related

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102620835A (en) * | 2012-03-31 | 2012-08-01 | 中冶南方(武汉)威仕工业炉有限公司 | System for calibrating surface temperature of metal flat plate |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN102620836B (en) | Method for calibrating surface temperature of metal flat plate | |

| US20160334284A1 (en) | System and method for calibrating and characterising instruments for temperature measurement by telemetry | |

| CN113483900B (en) | Measurement method of infrared radiation aluminum alloy plate temperature field based on blackbody point online calibration | |

| CN102620835A (en) | System for calibrating surface temperature of metal flat plate | |

| CN105758208B (en) | High-temperature heat treatment non-contact temperature uniformity detection system and its detection method | |

| CN111272289A (en) | Real-time calibration device for thermal infrared imager | |

| CN107543634B (en) | Striped formula radiant heat flux measuring device based on fexible film thermoelectric pile | |

| CN102621180B (en) | Method for testing energy-saving performance of doors and windows | |

| CN202494532U (en) | System for calibrating surface temperature of metal plate | |

| Förster et al. | A novel surface-integrated spray-on thermocouple for heat transfer measurements | |

| Piasecka et al. | Comparison of two methods for contactless surface temperature measurement | |

| Lanc et al. | The determination of the emissivity of aluminum alloy AW 6082 using infrared thermography | |

| CN208125220U (en) | One kind being used for heat accumulating type closed calcium carbide furnace thermal imaging apparatus for measuring charge level | |

| CN103267773B (en) | Double-ring thermal protection transient radiation heatflowmeter and measuring method | |

| CN202421094U (en) | Nontransparent material normal spectral emissivity measurement device | |

| CN108534906A (en) | A kind of multiple spot temperature and humidity test instrument and its application method | |

| Selivanova et al. | An intelligent data-measuring system for determining the thermal properties of materials and products | |

| CN101819067A (en) | Infrared microscopy specimen and establishment of standard data base thereof | |

| CN209342253U (en) | A kind of temperature monitoring device | |

| CN202631115U (en) | Thermal infrared temperature measurement signal processing system | |

| CN219015495U (en) | Temperature measuring furnace roller for measuring temperature of steel plate in annealing furnace | |

| CN113465755A (en) | Indirect test method for steady-state radiation temperature | |

| CN204479213U (en) | Thermocouple detection device | |

| Belen’kii et al. | Determination of the precision characteristics of contact and contactless methods of monitoring the temperature of a surface | |

| CN120538707A (en) | Post-processing multi-purpose measurement sensor and measurement method based on calibration integral equation method |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C17 | Cessation of patent right | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20121017 Termination date: 20140331 |