CN202492386U - Gas circuit control circuit for distilled water treatment - Google Patents

Gas circuit control circuit for distilled water treatment Download PDFInfo

- Publication number

- CN202492386U CN202492386U CN2012201256454U CN201220125645U CN202492386U CN 202492386 U CN202492386 U CN 202492386U CN 2012201256454 U CN2012201256454 U CN 2012201256454U CN 201220125645 U CN201220125645 U CN 201220125645U CN 202492386 U CN202492386 U CN 202492386U

- Authority

- CN

- China

- Prior art keywords

- water

- valve

- solenoid valve

- air

- ppm

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Chemical compound O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 title claims abstract description 112

- 239000012153 distilled water Substances 0.000 title abstract 4

- 239000002826 coolant Substances 0.000 claims description 17

- 230000005540 biological transmission Effects 0.000 abstract description 4

- 239000002994 raw material Substances 0.000 abstract 6

- 230000001105 regulatory effect Effects 0.000 abstract 5

- 239000000498 cooling water Substances 0.000 abstract 3

- 230000000694 effects Effects 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 230000009286 beneficial effect Effects 0.000 description 1

- 230000007812 deficiency Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

Images

Landscapes

- Fluid-Driven Valves (AREA)

Abstract

The utility model discloses a gas circuit control circuit for distilled water treatment, the output end of compressed air is connected with the input end of a pressure regulating filter, the control end of the pressure regulating filter is connected with a pressure controller, the output end of the pressure regulating filter is respectively connected with the control ends of a cooling water electromagnetic valve, a raw material water 1 pneumatic electromagnetic valve, a raw material water 2 pneumatic electromagnetic valve, an I-effect concentrated water lower discharge electromagnetic valve and a distilled water switching electromagnetic valve, the output end of the pressure regulating filter is also connected with the control end of an industrial steam regulating valve, the output ends of the cooling water solenoid valve, the raw material water 1 pneumatic solenoid valve, the raw material water 2 pneumatic solenoid valve, the I-effect concentrated water lower discharge solenoid valve and the distilled water switching solenoid valve are respectively connected with the control ends of the cooling water solenoid valve, the raw material water 1 pneumatic diaphragm valve, the raw material water 2 pneumatic diaphragm valve, the I-effect concentrated water lower discharge pneumatic valve and the two-position three-way valve. The utility model discloses an automatic control replaces artifical manual control, carries out unified control to each gas transmission line, ensures that gas transmission line pressure is unanimous.

Description

Technical field

The utility model relates to a kind of zero(ppm) water processing and uses the gas circuit pilot circuit.

Background technology

Zero(ppm) water is meant with the pure water of distillating method preparation, can be divided into one or many zero(ppm) water, has been widely used in medical treatment, scientific research, the productive life at present.Existing zero(ppm) water is handled very in disorder with gas circuit, and operator must learn the position of every gas circuit by heart, and annexation; Relatively independent between each gas circuit, can not guarantee that the pressure between each gas circuit is in full accord, simultaneously a plurality of valves are carried out when needs check, open, close, during operation such as modification; Need hurry back and forth in a plurality of places, can't guarantee in time to execute all operations, be easy to occur to leak close, open more, phenomenons such as mistake is looked into, under-enumeration; Not only wasted a large amount of gas; And cause manifold pressure excessive easily, and bad phenomenon such as pipe expansion, blast, the loss that causes is inestimable.

The utility model content

The purpose of the utility model promptly is to overcome the deficiency of prior art, provides a kind of zero(ppm) water to handle and uses the gas circuit pilot circuit, and it is in disorder to have solved traditional zero(ppm) water treating processes gas circuit, can not unify control, can not guarantee problems such as gas circuit internal pressure unanimity.

The purpose of the utility model realizes through following technical scheme: zero(ppm) water is handled and use the gas circuit pilot circuit, and it comprises that pressure regulation strainer, pressure controller, water coolant air-operated solenoid valve, raw water 1 air-operated solenoid valve, raw water 2 air-operated solenoid valves, I imitate the dense SV, zero(ppm) water switching solenoid valve, water coolant pneumavalve, raw water 1 pneumatic diaphragm valve, raw water 2 pneumatic diaphragm valves, I arranged under water and imitate dense underwater exhaust and move valve, two position three-way valve, industrial steam variable valve;

Compressed-air actuated output terminal is connected with the input terminus of pressure regulation strainer; The control end of pressure regulation strainer is connected with pressure controller; The output terminal of pressure regulation strainer is imitated the dense control end of arranging SV, zero(ppm) water switching solenoid valve under water with water coolant air-operated solenoid valve, raw water 1 air-operated solenoid valve, raw water 2 air-operated solenoid valves, I respectively and is connected; The output terminal of pressure regulation strainer also is connected with the control end of industrial steam variable valve; Industrial steam variable valve and outside industrial steam pipe connection; The water coolant air-operated solenoid valve is connected with the externally cooled waterpipe through the water coolant pneumavalve; Raw water 1 air-operated solenoid valve is through raw water 1 pneumatic diaphragm valve and external feed water 1 pipe connection, and raw water 2 air-operated solenoid valves are through raw water 2 pneumatic diaphragm valves and external feed water 2 pipe connection, and I is imitated the dense SV of arranging under water and imitated dense underwater exhaust through I and move valve and be connected with the dense discharge pipe under water of outside I effect; The zero(ppm) water switching solenoid valve is through two position three-way valve and outside zero(ppm) water pipe connection, and the circuit between described compressed-air actuated output terminal and the pressure regulation strainer is provided with the hand valve.

Zero(ppm) water is handled and is used the gas circuit pilot circuit, and it also comprises one or more subsequent use SVs, and the control end of described subsequent use SV is connected with the output terminal of pressure regulation strainer.

The beneficial effect of the utility model is: the utility model provides a kind of zero(ppm) water to handle and uses the gas circuit pilot circuit; Adopt control automatically to replace conventional artificial manually to control; Each gas transmission circuit is unified automatic control, has not only saved manpower, and can guarantee in time to realize to the checking of valve, open, close, operation such as modification; And, realize the pressure of gas transmission circuit is controlled through pressure controller.

Description of drawings

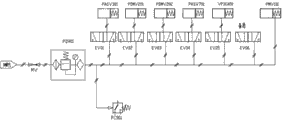

Fig. 1 is that the circuit of the utility model is formed synoptic diagram;

Among the figure, PD901-pressure regulation strainer, PC901-pressure controller; EV01-water coolant air-operated solenoid valve, EV02-raw water 1 air-operated solenoid valve, EV03-raw water 2 air-operated solenoid valves; The EV04-I is imitated the dense SV of arranging, EV05-zero(ppm) water switching solenoid valve, PASV301-water coolant pneumavalve under water; PDMV201-raw water 1 pneumatic diaphragm valve, PDMV202-raw water 2 pneumatic diaphragm valves, the PASV701-I is imitated the moving valve of dense underwater exhaust; The VP3G401-two position three-way valve, PMV101-industrial steam variable valve, MV-hand valve.

Embodiment

Below in conjunction with accompanying drawing the utility model is done further description, but the protection domain of the utility model is not limited to the following stated.

As shown in Figure 1; Zero(ppm) water is handled and use the gas circuit pilot circuit, and it comprises that pressure regulation strainer PD901, pressure controller PC901, water coolant air-operated solenoid valve EV01, raw water 1 air-operated solenoid valve EV02, raw water 2 air-operated solenoid valve EV03, I imitate the dense SV EV04, zero(ppm) water switching solenoid valve EV05, water coolant pneumavalve PASV301, raw water 1 pneumatic diaphragm valve PDMV201, raw water 2 pneumatic diaphragm valve PDMV202, I of arranging under water and imitate dense underwater exhaust and move valve PASV701, two position three-way valve VP3G401, industrial steam variable valve PMV101;

Compressed-air actuated output terminal is connected with the input terminus of pressure regulation strainer PD901; Circuit between described compressed-air actuated output terminal and the pressure regulation strainer PD901 is provided with hand valve MV; The control end of pressure regulation strainer PD901 is connected with pressure controller PC901; The output terminal of pressure regulation strainer PD901 is imitated the dense control end of arranging SV EV04, zero(ppm) water switching solenoid valve EV05 under water with water coolant air-operated solenoid valve EV01, raw water 1 air-operated solenoid valve EV02, raw water 2 air-operated solenoid valve EV03, I respectively and is connected; The output terminal of pressure regulation strainer PD901 also is connected with the control end of industrial steam variable valve PMV101; Industrial steam variable valve PMV101 and outside industrial steam pipe connection; Water coolant air-operated solenoid valve EV01 is connected with the externally cooled waterpipe through water coolant pneumavalve PASV301; Raw water 1 air-operated solenoid valve EV02 is through raw water 1 pneumatic diaphragm valve PDMV201 and external feed water 1 pipe connection; Raw water 2 air-operated solenoid valve EV03 are through raw water 2 pneumatic diaphragm valve PDMV202 and external feed water 2 pipe connection, and I is imitated the dense SV EV04 that arranges under water and imitated the moving valve PASV701 of dense underwater exhaust through I and be connected with the dense discharge pipe under water of outside I effect, and zero(ppm) water switching solenoid valve EV05 passes through two position three-way valve VP3G401 and outside zero(ppm) water pipe connection.

Zero(ppm) water is handled and is used the gas circuit pilot circuit, and it also comprises one or more subsequent use SVs, and the control end of described subsequent use SV is connected with the output terminal of pressure regulation strainer PD901.

Claims (3)

1. zero(ppm) water is handled and use the gas circuit pilot circuit, it is characterized in that: it comprises that pressure regulation strainer, pressure controller, water coolant air-operated solenoid valve, raw water 1 air-operated solenoid valve, raw water 2 air-operated solenoid valves, I imitate the dense SV, zero(ppm) water switching solenoid valve, water coolant pneumavalve, raw water 1 pneumatic diaphragm valve, raw water 2 pneumatic diaphragm valves, I arranged under water and imitate dense underwater exhaust and move valve, two position three-way valve, industrial steam variable valve;

Compressed-air actuated output terminal is connected with the input terminus of pressure regulation strainer; The control end of pressure regulation strainer is connected with pressure controller; The output terminal of pressure regulation strainer is imitated the dense control end of arranging SV, zero(ppm) water switching solenoid valve under water with water coolant air-operated solenoid valve, raw water 1 air-operated solenoid valve, raw water 2 air-operated solenoid valves, I respectively and is connected; The output terminal of pressure regulation strainer also is connected with the control end of industrial steam variable valve; Industrial steam variable valve and outside industrial steam pipe connection; The water coolant air-operated solenoid valve is connected with the externally cooled waterpipe through the water coolant pneumavalve, and raw water 1 air-operated solenoid valve is through raw water 1 pneumatic diaphragm valve and external feed water 1 pipe connection, and raw water 2 air-operated solenoid valves are through raw water 2 pneumatic diaphragm valves and external feed water 2 pipe connection; I is imitated the dense SV of arranging under water and is imitated the moving valve of dense underwater exhaust through I and imitate dense discharge pipe under water with outside I and be connected, and the zero(ppm) water switching solenoid valve passes through two position three-way valve and outside zero(ppm) water pipe connection.

2. zero(ppm) water according to claim 1 is handled and is used the gas circuit pilot circuit, and it is characterized in that: it also comprises one or more subsequent use SVs, and the control end of described subsequent use SV is connected with the output terminal of pressure regulation strainer.

3. zero(ppm) water according to claim 1 is handled and is used the gas circuit pilot circuit, and it is characterized in that: the circuit between described compressed-air actuated output terminal and the pressure regulation strainer is provided with the hand valve.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012201256454U CN202492386U (en) | 2012-03-29 | 2012-03-29 | Gas circuit control circuit for distilled water treatment |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012201256454U CN202492386U (en) | 2012-03-29 | 2012-03-29 | Gas circuit control circuit for distilled water treatment |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN202492386U true CN202492386U (en) | 2012-10-17 |

Family

ID=46998622

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2012201256454U Expired - Lifetime CN202492386U (en) | 2012-03-29 | 2012-03-29 | Gas circuit control circuit for distilled water treatment |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN202492386U (en) |

-

2012

- 2012-03-29 CN CN2012201256454U patent/CN202492386U/en not_active Expired - Lifetime

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN202493900U (en) | Pressure flow regulation device | |

| CN104196777A (en) | Programmable integrated control system capable of controlling inlet and outlet oil ways independently | |

| CN202348624U (en) | Single-action pneumatic anti-surge adjusting valve | |

| CN205187852U (en) | Vehicle -mounted oxygenerator | |

| CN102635587A (en) | Gas supply control structure of cylinder | |

| CN105041624A (en) | Analysis method for energy-saving potential of air compressor system | |

| CN202492386U (en) | Gas circuit control circuit for distilled water treatment | |

| CN201907219U (en) | Air pressure control system of mechanical press | |

| CN206111743U (en) | Hydraulic pressure fastener and hydraulic pressure fastener's control system | |

| CN103407976A (en) | Nitrogen making machine | |

| CN201919350U (en) | Hydraulic system for rice machine | |

| CN104675772B (en) | Load sensitive control hydraulic system | |

| CN203702742U (en) | Circulation oil device in pressure swing adsorption technique | |

| CN202597307U (en) | Air cylinder air supply control structure | |

| CN203161699U (en) | Pressure swing adsorption oil hydraulic system | |

| CN205745445U (en) | A kind of bidirectional hydraulic control reversal valve | |

| CN214734536U (en) | Low-cost high-efficient nitrogen purification supercharging equipment of peak staggering power consumption | |

| CN202934716U (en) | Pneumatic control system for knife board lifting of transverse cutting machine | |

| CN203653138U (en) | Hydraulic mechanism for endless rope winch | |

| CN210180848U (en) | Automatic pressurization fatigue test system | |

| CN203549380U (en) | Metal powder hierarchy system nitrogen recycling device | |

| CN203516242U (en) | Hydraulic circuit device with two throttling valves | |

| CN205256709U (en) | A filling equipment for fertile production of liquid | |

| CN202100944U (en) | Switching system with piston type low-pressure nitrogen compressor providing instrument air | |

| CN206647243U (en) | The pneumatic medicine system of pulsating |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CX01 | Expiry of patent term | ||

| CX01 | Expiry of patent term |

Granted publication date: 20121017 |