CN202491175U - Back pressure roll and brush roll leveling system for scrubbing machine - Google Patents

Back pressure roll and brush roll leveling system for scrubbing machine Download PDFInfo

- Publication number

- CN202491175U CN202491175U CN2012201097636U CN201220109763U CN202491175U CN 202491175 U CN202491175 U CN 202491175U CN 2012201097636 U CN2012201097636 U CN 2012201097636U CN 201220109763 U CN201220109763 U CN 201220109763U CN 202491175 U CN202491175 U CN 202491175U

- Authority

- CN

- China

- Prior art keywords

- brush

- control device

- brushing

- roller

- frequency converter

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000005201 scrubbing Methods 0.000 title 1

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 claims abstract description 10

- 230000006837 decompression Effects 0.000 claims abstract description 6

- 229910052759 nickel Inorganic materials 0.000 claims abstract description 5

- 238000006243 chemical reaction Methods 0.000 claims description 7

- 229910000831 Steel Inorganic materials 0.000 claims description 6

- 239000010959 steel Substances 0.000 claims description 6

- 239000004576 sand Substances 0.000 claims 3

- 229910003460 diamond Inorganic materials 0.000 claims 1

- 239000010432 diamond Substances 0.000 claims 1

- 239000000428 dust Substances 0.000 claims 1

- 230000001680 brushing effect Effects 0.000 abstract description 51

- 238000000034 method Methods 0.000 abstract description 15

- 229910052593 corundum Inorganic materials 0.000 abstract description 4

- 239000010431 corundum Substances 0.000 abstract description 4

- 238000013459 approach Methods 0.000 abstract description 3

- 238000005498 polishing Methods 0.000 abstract 1

- 229910001651 emery Inorganic materials 0.000 description 9

- 230000000694 effects Effects 0.000 description 5

- 238000004519 manufacturing process Methods 0.000 description 4

- 239000000463 material Substances 0.000 description 2

- 230000001133 acceleration Effects 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 230000007812 deficiency Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 229910010271 silicon carbide Inorganic materials 0.000 description 1

- 238000009966 trimming Methods 0.000 description 1

Images

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P70/00—Climate change mitigation technologies in the production process for final industrial or consumer products

- Y02P70/10—Greenhouse gas [GHG] capture, material saving, heat recovery or other energy efficient measures, e.g. motor control, characterised by manufacturing processes, e.g. for rolling metal or metal working

Landscapes

- Finish Polishing, Edge Sharpening, And Grinding By Specific Grinding Devices (AREA)

Abstract

本实用新型公开了一种整刷精度高、整刷效果稳定、整刷方式简单且整刷效率高的背压辊。同时,还提供了一种磨板机整刷系统及方法。磨板机整刷系统包括变频器、PLC控制装置、伺服控制装置、磨刷加减压执行装置,所述PLC控制装置用于提取所述变频器实时输出的电流并发送脉冲指令给所述伺服控制装置,所述伺服控制装置用于接收所述PLC控制装置发出的脉冲指令,并通过所述磨刷加减压执行装置的动作控制刷辊向背压辊靠近并接触,所述磨刷加减压执行装置受控于所述伺服控制装置而完成刷辊的加减压动作,所述变频器用于驱动带动所述刷辊转动的转动电机,所述背压辊包括圆形滚柱、从内向外依次设置在所述圆形滚柱外表面的镍层和金刚砂层。

The utility model discloses a back pressure roller with high brushing precision, stable brushing effect, simple brushing method and high brushing efficiency. At the same time, it also provides a system and method for polishing a grinding machine. The complete brushing system of the plate grinding machine includes a frequency converter, a PLC control device, a servo control device, and a grinding brush adding and decompressing actuator. The PLC control device is used to extract the real-time output current of the frequency converter and send pulse commands to the servo The control device, the servo control device is used to receive the pulse command sent by the PLC control device, and control the brush roller to approach and contact the back pressure roller through the action of the grinding brush addition and decompression actuator, and the grinding brush addition and subtraction The pressure actuator is controlled by the servo control device to complete the pressure and pressure action of the brush roller. The frequency converter is used to drive the rotating motor that drives the brush roller to rotate. The back pressure roller includes circular rollers, A nickel layer and a corundum layer are sequentially arranged on the outer surface of the circular roller.

Description

技术领域 technical field

本实用新型涉及一种背压辊及磨板机整刷系统。 The utility model relates to a back pressure roller and a complete brushing system of a grinding machine.

背景技术 Background technique

磨板机的刷辊在工作一段时间后,刷辊会不太平整,这时需要通过背压辊对刷辊进行整平,以往的方式是用用整刷板输入到刷辊下面,进行整刷,整刷板是使用高硬度的钢板制作的并在钢板上镀有金刚砂,通常工艺要求整刷板平整度<0.2mm,即使这样高的精度要求仍然无法满足某些工艺的需求,而厚度仅有2mm并且面积如此大的一张钢板在存放和使用过程中不可避免的会产生轻微的弯曲或变形,这是长时间困扰线路板行业磨板工艺的一个瓶颈,而且在加工时间长的情况下,需要反复停机和开机,这样操作不太方便,而且也浪费时间。 After the brush roller of the grinding machine has been working for a period of time, the brush roller will not be very smooth. At this time, the brush roller needs to be leveled by the back pressure roller. The previous method is to input the whole brush plate under the brush roller for trimming Brush, the whole brush plate is made of high-hardness steel plate and coated with emery on the steel plate. Usually the process requires the flatness of the whole brush plate to be <0.2mm. Even such a high precision requirement still cannot meet the needs of some processes, and the thickness A steel plate with only 2mm and such a large area will inevitably be slightly bent or deformed during storage and use. This is a bottleneck that has plagued the grinding process of the circuit board industry for a long time. In this case, it is necessary to stop and start repeatedly, which is inconvenient to operate and wastes time.

综上所述,现有技术存在着整刷精度低、整刷效果不稳定、整刷方式繁琐、整刷效率低的缺陷。 To sum up, the prior art has the defects of low precision of brushing, unstable effect of brushing, cumbersome brushing methods and low efficiency of brushing.

实用新型内容 Utility model content

本实用新型所要解决的技术问题是克服现有技术的不足,提供一种整刷精度高、整刷效果稳定、整刷方式简单且整刷效率高的背压辊。同时,还提供了一种磨板机整刷系统。 The technical problem to be solved by the utility model is to overcome the deficiencies of the prior art and provide a back pressure roller with high brushing precision, stable brushing effect, simple brushing method and high brushing efficiency. At the same time, a complete brushing system for a grinding machine is also provided.

本实用新型一种背压辊所采用的技术方案是:所述背压辊包括圆形滚柱、设置在所述圆形滚柱外表面上的金刚砂层。 The technical scheme adopted by a back pressure roller of the utility model is: the back pressure roller includes a circular roller and a carborundum layer arranged on the outer surface of the circular roller.

所述圆形滚柱为无缝钢管,所述圆形滚柱与所述金刚砂层之间设置有镍层,所述金刚砂层为400目金刚砂。 The circular roller is a seamless steel pipe, a nickel layer is arranged between the circular roller and the corundum layer, and the corundum layer is 400 mesh corundum.

本实用新型一种磨板机整刷系统所采用的技术方案是:所述磨板机整刷系统包括变频器、PLC控制装置、伺服控制装置、磨刷加减压执行装置,所述PLC控制装置用于提取所述变频器实时输出的电流并发送脉冲指令给所述伺服控制装置,所述伺服控制装置用于接收所述PLC控制装置发出的脉冲指令,并通过所述磨刷加减压执行装置的动作控制刷辊向所述背压辊靠近并接触,所述磨刷加减压执行装置受控于所述伺服控制装置而完成刷辊的加减压动作,所述变频器用于驱动带动所述刷辊转动的转动电机。 The technical scheme adopted by the whole brushing system of the grinding machine of the utility model is: the whole brushing system of the grinding machine includes a frequency converter, a PLC control device, a servo control device, a grinding brush adding and decompressing execution device, and the PLC control The device is used to extract the real-time output current of the frequency converter and send the pulse command to the servo control device, and the servo control device is used to receive the pulse command sent by the PLC control device, and increase and reduce pressure through the grinding brush The action of the executive device controls the brush roller to approach and contact the back pressure roller. The actuator for adding and decompressing the grinding brush is controlled by the servo control device to complete the action of increasing and reducing the pressure of the brush roller. The frequency converter is used to drive A rotating motor that drives the brush roller to rotate.

进一步的,所述PLC控制装置包括模/数转换装置、脉冲输出装置,所述模/数转换装置用于提取所述变频器实时输出电流并发送信号给所述脉冲输出装置,所述脉冲输出装置发送脉冲指令给所述伺服控制装置,所述伺服控制装置包括伺服驱动器和伺服电机,所述伺服驱动器用于接收所述PLC控制器发出的脉冲指令,并控制所述伺服电机进行动力输出,使所述磨刷加减压执行装置进行动作。 Further, the PLC control device includes an analog/digital conversion device and a pulse output device, and the analog/digital conversion device is used to extract the real-time output current of the frequency converter and send a signal to the pulse output device, and the pulse output The device sends a pulse command to the servo control device, the servo control device includes a servo driver and a servo motor, the servo driver is used to receive the pulse command sent by the PLC controller, and control the servo motor to perform power output, Make the brush increasing and decreasing pressure implementing device operate.

本实用新型的有益效果是:由于本实用新型所述背压辊包括圆形滚柱、设置在所述圆形滚柱外表面的金刚砂层,即所述背压辊是由磨床精磨而成的圆柱形,外表面镀有所述金刚砂,与现有技术相比,强度远高于整刷板,无需考虑整刷板变形问题,而且辊即使在旋转状态都可以保证跳动小于0.02 mm,而外圆的同轴度也可以保证在0.02 mm以内,相比于传统的整刷板镀金刚砂综合表面平整度从0.2mm提升到了0.02mm,提升了一个等级,整刷效果有了质的提升,这就用一种看似简单的方法巧妙的解决了传统整刷板不能达到的整刷效果,而且,传统的整刷板整刷需要员工停机并手动开启整刷板程序,并放入整刷板才能完成整刷功能,整刷1次再到投料生产所需时间约10分钟。而本实用新型所述背压辊自动整刷可以无需人为操作设备,所有的功能可以全部由程序控制自动完成,整刷1次再到投料生产所需时间约2分钟,所以整刷精度高、整刷效果稳定、整刷方式简单且整刷效率高。 The beneficial effects of the utility model are: since the back pressure roller of the utility model includes a circular roller and an emery layer arranged on the outer surface of the circular roller, that is, the back pressure roller is finely ground by a grinder Compared with the existing technology, the strength is much higher than that of the whole brush plate, and there is no need to consider the deformation of the whole brush plate, and the roller can ensure that the runout is less than 0.02 mm even in the rotating state. The coaxiality of the outer circle can also be guaranteed to be within 0.02 mm. Compared with the traditional whole brush plate, the comprehensive surface flatness of emery plated with emery has been improved from 0.2mm to 0.02mm, which is a level up, and the whole brush effect has been qualitatively improved. This uses a seemingly simple method to ingeniously solve the complete brush effect that the traditional full brush board cannot achieve. Moreover, the traditional full brush board requires employees to stop the machine and manually start the whole brush program, and put in the whole brush The board can complete the whole brushing function, and it takes about 10 minutes for the whole brush to be fed into production. However, the automatic brushing of the back pressure roller in the utility model does not require human operation equipment, and all functions can be automatically completed by program control. It takes about 2 minutes for the brushing once to feed and produce, so the accuracy of the brushing is high, The whole brushing effect is stable, the whole brushing method is simple and the whole brushing efficiency is high.

附图说明 Description of drawings

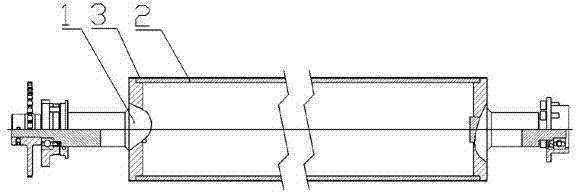

图1是本实用新型背压辊的结构示意图; Fig. 1 is the structural representation of the back pressure roller of the utility model;

图2是本实用新型磨板机整刷系统的原理框图; Fig. 2 is the principle block diagram of the whole brushing system of the grinding plate machine of the present invention;

图3是本实用新型整刷方法的流程图。 Fig. 3 is a flow chart of the whole brushing method of the present invention.

具体实施方式 Detailed ways

如图1所示,本实用新型背压辊包括圆形滚柱1、从内向外依次设置在所述圆形滚柱1外表面的镍层2和金刚砂层3,即所述背压辊可以是由磨床精磨而成的圆柱形滚筒,外表面镀有所述金刚砂,又或者从节省材料的角度考虑,采用无缝钢管,此时则必须在所述圆形滚柱1与所述金刚砂层3之间设置镍层2,防止所述圆形滚柱1生锈,与现有技术相比,所述圆形滚柱1强度远高于整刷板,无需考虑整刷板变形问题,而且所述背压辊即使在旋转状态都可以保证跳动小于0.02 mm,而外圆的同轴度也可以保证在0.02 mm以内,相比于传统的整刷板镀金刚砂综合表面平整度从0.2mm提升到了0.02mm,提升了一个等级,整刷效果有了质的提升,这就用一种看似简单的方法巧妙的解决了传统整刷板不能达到的整刷效果,而且,传统的整刷板整刷需要员工停机并手动开启整刷板程序,并放入整刷板才能完成整刷功能,整刷1次再到投料生产所需时间约10分钟。而本实用新型所述背压辊自动整刷可以无需人为操作设备,所有的功能可以全部由程序控制自动完成,整刷1次再到投料生产所需时间约2分钟,所以整刷精度高、整刷效果稳定、整刷方式简单且整刷效率高,而所述金刚砂层3选用的是400#金刚砂,这是因为,型号太小,则整刷的效果难以保证,而若采用的型号太大,则会导致磨刷时刮上线路板。 As shown in Figure 1, the back pressure roller of the utility model comprises a circular roller 1, a nickel layer 2 and an emery layer 3 arranged on the outer surface of the circular roller 1 from the inside to the outside, that is, the back pressure roller can It is a cylindrical roller finely ground by a grinder, and the outer surface is coated with the emery, or from the perspective of material saving, a seamless steel pipe is used. At this time, the circular roller 1 and the emery must be connected. A nickel layer 2 is arranged between the layers 3 to prevent the round roller 1 from rusting. Compared with the prior art, the strength of the round roller 1 is much higher than that of the whole brush plate, and there is no need to consider the deformation of the whole brush plate. Moreover, even if the back pressure roller is in the rotating state, the runout can be guaranteed to be less than 0.02 mm, and the coaxiality of the outer circle can also be guaranteed to be within 0.02 mm. It has been raised to 0.02mm, which is a level up, and the overall brushing effect has been qualitatively improved. This uses a seemingly simple method to ingeniously solve the overall brushing effect that the traditional full brushing board cannot achieve. Moreover, the traditional full brushing The complete brushing of the board requires employees to stop and manually start the whole brushing program, and put in the whole brushing board to complete the whole brushing function. It takes about 10 minutes for the whole brushing once to feed the production. However, the automatic brushing of the back pressure roller in the utility model does not require human operation equipment, and all functions can be automatically completed by program control. It takes about 2 minutes for the brushing once to feed and produce, so the accuracy of the brushing is high, The effect of the whole brush is stable, the way of the whole brush is simple and the efficiency of the whole brush is high, and what the emery layer 3 selects is 400# emery, this is because the model is too small, then the effect of the whole brush is difficult to guarantee, and if the model adopted is too large If it is too large, it will cause the circuit board to be scraped when brushing.

如图2所示,本实用新型还公开了一种磨板机整刷系统,所述整刷系统包括变频器4、PLC控制装置5、伺服控制装置6、磨刷加减压执行装置7,所述PLC控制装置5用于提取所述变频器4实时输出的电流并发送脉冲指令给所述伺服控制装置6,所述伺服控制装置6用于接收所述PLC控制器5发出的脉冲指令,并控制所述磨刷加减压执行装置7动作,使刷辊向所述背压辊靠近并接触,所述磨刷加减压执行装置7受控于所述伺服控制装置6而完成刷辊的加减压动作,即所述刷辊与所述背压辊接触后之间的压力,所述变频器4用于驱动使所述刷辊转动的转动电机,其中,所述PLC控制装置5包括模/数转换装置8、脉冲输出装置9,所述模/数转换装置8用于提取所述变频器4实时输出电流并发送信号给所述脉冲输出装置9,所述脉冲输出装置9发送脉冲指令给所述伺服控制装置6,所述伺服控制装置6包括伺服驱动器10和伺服电机11,所述伺服驱动器10用于接收所述PLC控制装置5发出的脉冲指令,并控制所述伺服电机11进行动力输出,使所述磨刷加减压执行装置7进行动作。

As shown in Fig. 2, the utility model also discloses a complete brushing system of a grinding machine, the complete brushing system includes a

如图3所示,所述的整刷方法的是按以下步骤实现的: As shown in Figure 3, described whole brushing method is to realize according to the following steps:

(一)、 当生产物料投入数量达到了设定值时,设备在所述PLC控制装置5的控制下进入自动整刷程序;

(1) When the input quantity of production materials reaches the set value, the equipment enters the automatic brushing program under the control of the

(二)、 所述伺服电机11在所述PLC控制装置5和所述伺服驱动器10的组合控制下高速加压到距离所述背压辊2mm后切换为缓慢加压,当所述刷辊触碰到所述背压辊后,所述伺服电机11对所述刷辊的继续加压使得所述变频器4所驱动的转动电机负载增大,同时所述模/数转换装置8对磨刷负载电流进行实时读取;

(2) The

(三)、 当所述PLC控制装置5提取到的所述变频器4负载电流大于0.3A(设定的电流值)时,此时开始对整刷时间计时(整刷时间事先由操作员工设定好初始参数,通常无需改变),所述脉冲输出装置9发送脉冲指令给所述伺服驱动器10,而所述伺服驱动器10命令所述伺服电机11减压,即通过所述磨刷加减压控制装置7使所述刷辊,稍微抬起,反之则加压(所述变频器4负载电流小于0.3A);

(3) When the load current of the

(四)、 当整刷时间到达设定值后,所述PLC控制装置5命令所述伺服电机11将所述刷辊高速提起,脱离所述背压辊,此时自动整刷结束,所述PLC控制装置5将程序自动切换为正常生产模式。

(4) When the brushing time reaches the set value, the

需要特别指出的是,整刷过程中所述伺服控制装置根据初始设定的所述变频器负载电流为目标值进行加减压控制的程序使用了多段速装置的控制和PID装置的控制,多段速控制使得电流距离设定值偏差较大时则用较高速调压,偏差较小时采用较低速调压(总共将调压速度根据实时电流偏差分为了4档),而PID控制又使得磨刷能够根据实时负载电流用更短的时间达到设定电流值,总之,4段速调压控制和PID控制模式的引入使得设备达到设定值的调节时间大为缩短,进一步的提高了整刷精度和整刷效率。 It should be pointed out that during the whole brushing process, the servo control device uses the control of the multi-stage speed device and the control of the PID device to control the acceleration and deceleration according to the initially set load current of the inverter as the target value. The speed control makes the voltage regulation at a higher speed when the deviation between the current and the set value is large, and the voltage regulation at a lower speed when the deviation is small (the voltage regulation speed is divided into 4 levels according to the real-time current deviation), and the PID control makes the grinding The brush can reach the set current value in a shorter time according to the real-time load current. In short, the introduction of the 4-stage speed voltage regulation control and PID control mode greatly shortens the adjustment time for the equipment to reach the set value, and further improves the overall brush. Accuracy and overall brushing efficiency.

Claims (4)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012201097636U CN202491175U (en) | 2012-03-22 | 2012-03-22 | Back pressure roll and brush roll leveling system for scrubbing machine |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012201097636U CN202491175U (en) | 2012-03-22 | 2012-03-22 | Back pressure roll and brush roll leveling system for scrubbing machine |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN202491175U true CN202491175U (en) | 2012-10-17 |

Family

ID=46997417

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2012201097636U Expired - Fee Related CN202491175U (en) | 2012-03-22 | 2012-03-22 | Back pressure roll and brush roll leveling system for scrubbing machine |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN202491175U (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102601736A (en) * | 2012-03-22 | 2012-07-25 | 珠海镇东有限公司 | Back pressure roller, leveling brush system and leveling brush method for plate polishing machine |

-

2012

- 2012-03-22 CN CN2012201097636U patent/CN202491175U/en not_active Expired - Fee Related

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102601736A (en) * | 2012-03-22 | 2012-07-25 | 珠海镇东有限公司 | Back pressure roller, leveling brush system and leveling brush method for plate polishing machine |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN105568278B (en) | Method and device of the automatic tabletting with placing pressed powder in laser cladding process | |

| CN208575707U (en) | An electric grinding device | |

| CN110936283A (en) | Novel dustless burnishing machine of high-efficient environmental protection | |

| CN202491175U (en) | Back pressure roll and brush roll leveling system for scrubbing machine | |

| CN201998057U (en) | Intelligent feed amount control device of edging heads of edging machine | |

| CN201427274Y (en) | multistage variable-speed milling and grinding machine | |

| CN106002528B (en) | A kind of online burr based on high voltage ceramic capacitor ceramic dielectric chip removes machine | |

| CN204277812U (en) | A kind of swinging abrasive cut-off wheel shaping machine set of built-in press waxing | |

| CN205291626U (en) | A jar has high -efficient rapid prototyping device who supplies powder and retrieve function | |

| CN113510547A (en) | Mechanical grinding device that building decorative panel used | |

| CN201833486U (en) | Flattening and thickness-fixing machine | |

| CN201690987U (en) | tea rolling machine | |

| CN201911252U (en) | Tea kneading machine | |

| CN201537837U (en) | Electric Drive Device for Grinding Moving Mechanism of Surface Grinder | |

| CN203227627U (en) | Ultrasonic cleaning device applied to filter element of polyester industry | |

| CN109571717B (en) | Precise pressing control method of ceramic brick press | |

| CN204397597U (en) | A kind of Novel grinder | |

| CN102601736A (en) | Back pressure roller, leveling brush system and leveling brush method for plate polishing machine | |

| CN203648414U (en) | Automatic sintering medium spraying device | |

| CN206749102U (en) | A turntable hot pressing device | |

| CN201324704Y (en) | Precision coating device for dry-process polyurethane coating line | |

| CN206937013U (en) | A kind of sectional material polishing machine and system | |

| CN222627285U (en) | Waxing device for brick production | |

| CN220741898U (en) | Brake block production make-up machine | |

| CN205870823U (en) | Automatic elimination equipment of high -voltage ceramic capacitor porcelain medium rod chip burr |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20121017 Termination date: 20160322 |

|

| CF01 | Termination of patent right due to non-payment of annual fee |