CN202490790U - Battery sorting tray - Google Patents

Battery sorting tray Download PDFInfo

- Publication number

- CN202490790U CN202490790U CN2012200645474U CN201220064547U CN202490790U CN 202490790 U CN202490790 U CN 202490790U CN 2012200645474 U CN2012200645474 U CN 2012200645474U CN 201220064547 U CN201220064547 U CN 201220064547U CN 202490790 U CN202490790 U CN 202490790U

- Authority

- CN

- China

- Prior art keywords

- battery

- sorting

- tray

- utility

- model

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000011810 insulating material Substances 0.000 claims description 4

- 229910052751 metal Inorganic materials 0.000 claims description 3

- 239000002184 metal Substances 0.000 claims description 3

- 238000000034 method Methods 0.000 description 4

- WHXSMMKQMYFTQS-UHFFFAOYSA-N Lithium Chemical compound [Li] WHXSMMKQMYFTQS-UHFFFAOYSA-N 0.000 description 2

- 229910052744 lithium Inorganic materials 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 238000012360 testing method Methods 0.000 description 2

- 239000003990 capacitor Substances 0.000 description 1

- 238000004806 packaging method and process Methods 0.000 description 1

Images

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/10—Energy storage using batteries

Landscapes

- Discharge Of Articles From Conveyors (AREA)

Abstract

本实用新型公开了一种无需开发新的电池托盘,而采用现有的18650电池的承载托盘就能完成对小型圆形电池进行承载的电池分选托块,包括圆柱形本体,该本体直径为18mm,长度为65mm;所述本体的顶沿轴向向内开设有凹槽,该凹槽为小型圆形电池放置区。采用本实用新型结构的电池分选托块,将小型圆形电池放置在小型圆形电池放置区内,再将电池分选托块放置在现有的18650电池的承载托盘并配合配套的专用分选机进行分选,提高了专用机分选的可操作性以及分选准确性,无需重新开发新的承载托盘,节省了成本。

The utility model discloses a battery sorting support block capable of carrying small round batteries without developing a new battery tray, and adopting the existing 18650 battery carrying tray, which includes a cylindrical body with a diameter of 18mm, length 65mm; the top of the body is axially inwardly provided with a groove, which is a small circular battery placement area. Using the battery sorting bracket of the utility model, the small round battery is placed in the small round battery placement area, and then the battery sorting bracket is placed on the existing 18650 battery carrying tray and matched with the matching special sorting tray. Sorting by machine selection improves the operability and accuracy of special-purpose machine sorting, and saves costs without the need to redevelop new carrying trays.

Description

技术领域 technical field

本实用新型涉及一种电池生产工艺设备,尤其是一种电池分选托块。The utility model relates to a battery production process equipment, in particular to a battery sorting support block.

背景技术 Background technique

18650型锂电是电子产品中比较常用的锂电池,常在笔记本电脑的电池中作为电芯使用。其型号定义为18650型,即指电池的直径为18mm,长度为65mm,圆柱体型的电池。The 18650 type lithium battery is a lithium battery commonly used in electronic products, and is often used as a battery cell in a laptop battery. Its model is defined as type 18650, which refers to a cylindrical battery with a diameter of 18mm and a length of 65mm.

目前,在生产类似电容器式小型圆形电池的过程中,电池在测试后,需要根据预先设定参数要求对电池进行档次分选,合格电池包装装箱。主要操作流程如下:测试→分选→包装→发货。由于小型圆形电池尺寸特殊,比18650电池尺寸要小,因此无法使用现有的18650电池的承载托盘并配合配套的专用分选机进行分选,而采用手动分选则无法保证100%的准确性。如果根据需要设计出一款适合小型圆形电池的电池托盘测试工装,则需要投入更多的成本。At present, in the process of producing small round batteries similar to capacitors, after the batteries are tested, the batteries need to be sorted according to the preset parameters, and the qualified batteries are packaged and packed. The main operation process is as follows: testing→sorting→packaging→delivery. Due to the special size of the small round battery, which is smaller than the size of the 18650 battery, it is impossible to use the existing 18650 battery carrying tray and cooperate with the matching special sorting machine for sorting, and manual sorting cannot guarantee 100% accuracy sex. If a battery tray test tool suitable for small circular batteries is designed according to needs, more costs need to be invested.

实用新型内容 Utility model content

本实用新型要解决的技术问题是提供一种无需开发新的电池托盘,而采用现有的18650电池的承载托盘就能完成对小型圆形电池进行承载的电池分选托块。The technical problem to be solved by the utility model is to provide a battery sorting support block that can carry small round batteries by using the existing 18650 battery carrying tray without developing a new battery tray.

为解决上述问题,本实用新型的一种电池分选托块,包括圆柱形本体,该本体直径为18mm,长度为65mm;所述本体的顶沿轴向向内开设有凹槽,该凹槽为小型圆形电池放置区。In order to solve the above problems, a battery sorting bracket of the utility model includes a cylindrical body with a diameter of 18mm and a length of 65mm; the top of the body is provided with a groove inward along the axial direction, and the groove It is a small circular battery placement area.

所述本体的底端沿轴向向内开设有凹槽,该凹槽内部填充有金属块。A groove is opened axially inwardly at the bottom end of the body, and the inside of the groove is filled with metal blocks.

所述本体为绝缘材料制成。The body is made of insulating material.

采用本实用新型结构的电池分选托块,将小型圆形电池放置在小型圆形电池放置区内,再将电池分选托块放置在现有的18650电池的承载托盘并配合配套的专用分选机进行分选,提高了专用机分选的可操作性以及分选准确性,无需重新开发新的承载托盘,节省了成本。本实用新型结构简单,方便制造,能够有效地提高了工作效率。Using the battery sorting bracket of the utility model, the small round battery is placed in the small round battery placement area, and then the battery sorting bracket is placed on the existing 18650 battery carrying tray and matched with the matching special sorting tray. Sorting by machine selection improves the operability and accuracy of special-purpose machine sorting, and saves costs without the need to redevelop new carrying trays. The utility model has simple structure, is convenient to manufacture, and can effectively improve work efficiency.

附图说明 Description of drawings

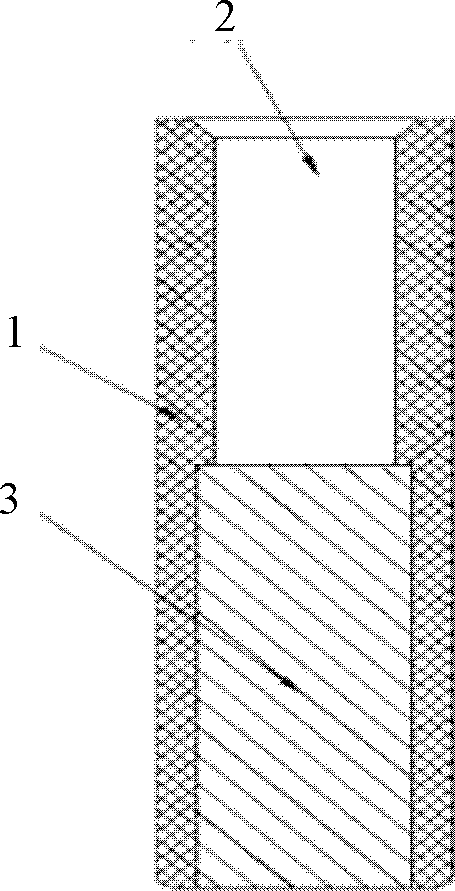

图1为本实用新型电池分选托块的结构示意图。Fig. 1 is a schematic structural view of the battery sorting bracket of the present invention.

具体实施方式 Detailed ways

为了使本技术领域的人员更好地理解本实用新型技术方案,下面结合附图和实施方式对本实用新型作进一步的详细说明。In order to enable those skilled in the art to better understand the technical solution of the utility model, the utility model will be further described in detail below in conjunction with the accompanying drawings and embodiments.

如图1所示,本实用新型的一种电池分选托块,包括圆柱形本体1,该本体1直径为18mm,长度为65mm;所述本体1的顶沿轴向向内开设有凹槽,该凹槽为小型圆形电池放置区2。As shown in Figure 1, a battery sorting tray of the present utility model includes a

所述本体1的底端沿轴向向内开设有凹槽,该凹槽内部填充有金属块3。The bottom end of the

所述本体1为绝缘材料制成。The

采用本实用新型结构的电池分选托块,将小型圆形电池放置在小型圆形电池放置区内,再将电池分选托块放置在现有的18650电池的承载托盘并配合配套的专用分选机进行分选。本实用新型工装整体采用绝缘材料,避免小电池放入及接触过程中产生短路隐患,在靠近顶端1/2处采取凹槽设计,用于放置小电池。由于原来的托盘尺寸是为圆柱型电池设计,小电池因无法稳固定位而无法放入,造成后续无法正常使用配套的分选机进行机器分选。使用本实用新型结构的电池分选托块,小电池通过中间载体可以顺利实现在托盘中的准确定位及拿取,即可以正常使用后续配套的分选机进行机器分选。相关作业全部通过设备完成,保证最终分选档次的100%准确性。为加强工装的重量及在托盘中的稳定性,在托块底端开槽填入铁块增加重量。Using the battery sorting bracket of the utility model, the small round battery is placed in the small round battery placement area, and then the battery sorting bracket is placed on the existing 18650 battery carrying tray and matched with the matching special sorting tray. Sorting machine for sorting. The tooling of the utility model adopts insulating materials as a whole to avoid short-circuit hidden dangers in the process of placing and contacting small batteries, and adopts a groove design near the

Claims (3)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012200645474U CN202490790U (en) | 2012-02-23 | 2012-02-23 | Battery sorting tray |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012200645474U CN202490790U (en) | 2012-02-23 | 2012-02-23 | Battery sorting tray |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN202490790U true CN202490790U (en) | 2012-10-17 |

Family

ID=46997034

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2012200645474U Expired - Lifetime CN202490790U (en) | 2012-02-23 | 2012-02-23 | Battery sorting tray |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN202490790U (en) |

-

2012

- 2012-02-23 CN CN2012200645474U patent/CN202490790U/en not_active Expired - Lifetime

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN103779609B (en) | A kind of electric vehicle lithium battery production device and production method thereof | |

| CN202490790U (en) | Battery sorting tray | |

| CN203158835U (en) | Automatic blanking mechanism for button cell box | |

| CN204726770U (en) | A kind of cigarette filling device of manual cigarette case | |

| CN103851320A (en) | Triangular frame convenient to accommodate | |

| CN204171231U (en) | A kind of sensor inner core side pin looper device | |

| CN203740193U (en) | Folding and placing machine for single-layered thin-wall inner support of tin box | |

| CN203772192U (en) | Apparatus for measuring depth of elongated blind hole part | |

| CN203806295U (en) | Lithium ion battery large-roll pole piece carrying tool | |

| CN204855331U (en) | Lithium ion batteries cathode materials compacted density test fixture | |

| CN205471062U (en) | Get pond frock of discharging in packing carton fast | |

| CN203193107U (en) | New electronic plastic terminal assembly equipment | |

| CN206528688U (en) | Screw packing device | |

| CN202814317U (en) | Piston rod double-flat symmetry simple detection tool | |

| CN205539397U (en) | Laminate polymer battery detecting box tray | |

| CN204124415U (en) | A kind of micro-injecting magnetic part packing device | |

| CN202631569U (en) | Upper mold with regulating device of electric testing jig | |

| CN203910922U (en) | Rotary lithium cell gasket placement device | |

| CN104773593A (en) | Adhesive tape holder | |

| CN206340567U (en) | A kind of bogey for cell piece finished product go-on-go | |

| CN203287093U (en) | Electronic scale | |

| CN203124953U (en) | Fixing device of energy storage seal welding machine feeding box | |

| CN201877472U (en) | Battery aluminium-plastic film with doubling sink mark | |

| CN203246726U (en) | Fast cigarette quantifying device | |

| CN201816789U (en) | Charging device for tubular ointment packing can |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CX01 | Expiry of patent term |

Granted publication date: 20121017 |

|

| CX01 | Expiry of patent term |