CN202490585U - Novel manure high-efficiency mixer - Google Patents

Novel manure high-efficiency mixer Download PDFInfo

- Publication number

- CN202490585U CN202490585U CN2012201312577U CN201220131257U CN202490585U CN 202490585 U CN202490585 U CN 202490585U CN 2012201312577 U CN2012201312577 U CN 2012201312577U CN 201220131257 U CN201220131257 U CN 201220131257U CN 202490585 U CN202490585 U CN 202490585U

- Authority

- CN

- China

- Prior art keywords

- manure

- bucket

- utility

- model

- rotating shaft

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 210000003608 fece Anatomy 0.000 title claims abstract description 36

- 239000010871 livestock manure Substances 0.000 title claims abstract description 26

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims abstract description 10

- 238000003756 stirring Methods 0.000 abstract description 16

- 238000009413 insulation Methods 0.000 abstract description 4

- 238000003306 harvesting Methods 0.000 abstract description 2

- 238000000034 method Methods 0.000 description 4

- 238000005516 engineering process Methods 0.000 description 2

- 230000002550 fecal effect Effects 0.000 description 2

- 238000004321 preservation Methods 0.000 description 2

- 230000007812 deficiency Effects 0.000 description 1

- 230000001934 delay Effects 0.000 description 1

- 239000003337 fertilizer Substances 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

Images

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02A—TECHNOLOGIES FOR ADAPTATION TO CLIMATE CHANGE

- Y02A40/00—Adaptation technologies in agriculture, forestry, livestock or agroalimentary production

- Y02A40/10—Adaptation technologies in agriculture, forestry, livestock or agroalimentary production in agriculture

- Y02A40/20—Fertilizers of biological origin, e.g. guano or fertilizers made from animal corpses

Landscapes

- Fertilizers (AREA)

- Mixers Of The Rotary Stirring Type (AREA)

Abstract

本实用新型提供一种新型粪肥高效搅拌机,其结构中转动轴的一端穿插入粪桶内部,插入粪桶内部的搅拌杆外侧固定有搅拌杆,转动轴的另一端通过皮带轮机构与电动机连接;粪桶的外侧设置有保温外壳,进水口、排水口插入粪桶与保温外壳之间;出口设置在粪桶的下端。本实用新型的一种新型粪肥高效搅拌机和现有技术相比,能够有效降低工作人员的劳动强度,还可以将粪肥搅拌均匀,稳定农作物的收成;而且可以在低温天气提高粪桶内的温度,进行粪肥的搅拌工作,避免耽误农业操作,本实用新型还具有设计合理、结构简单、易于加工、使用方便等特点,因而,具有很好的使用价值。

The utility model provides a new high-efficiency mixer for manure. In its structure, one end of the rotating shaft is inserted into the inside of the dung bucket, and a stirring rod is fixed on the outside of the stirring rod inserted into the inside of the dung bucket. The other end of the rotating shaft is connected with the motor through a belt pulley mechanism; The outer side of the bucket is provided with a thermal insulation shell, and the water inlet and the water outlet are inserted between the feces bucket and the thermal insulation shell; the outlet is set at the lower end of the feces bucket. Compared with the prior art, a new manure high-efficiency mixer of the utility model can effectively reduce the labor intensity of the staff, and can also stir the manure evenly to stabilize the harvest of crops; The manure can be stirred to avoid delaying agricultural operations. The utility model also has the characteristics of reasonable design, simple structure, easy processing, and convenient use, so it has good use value.

Description

1、技术领域 1. Technical field

本实用新型具体地说是一种新型粪肥高效搅拌机。The utility model is specifically a novel manure high-efficiency mixer.

2、背景技术 2. Background technology

在施肥的时候,粪肥的搅拌均匀是一项必不可少的工序,它直接影响肥料的质量稳定性。普通的方法通常是人工手持长杆等工具,将其插入粪肥中,然后手动搅拌,由于粪肥散发着浓烈的臭味,会呛得人喘不过气来,而且搅拌过程中粪肥会溅到人身上。此种方法不仅增大了工作人员的劳动强度,对人的身体健康也造成了一定的影响。而且在温度特别低的时候,现有技术也无法进行搅拌工作,容易耽误农业操作。When fertilizing, uniform mixing of manure is an essential process, which directly affects the quality and stability of fertilizer. The common method is to manually hold tools such as long poles, insert them into the manure, and then manually stir them. Because the manure emits a strong odor, it will make people breathless, and the manure will splash on people during the stirring process. . This kind method has not only increased the labor intensity of staff, also caused certain influence to people's health. Moreover, when the temperature is particularly low, the prior art cannot carry out stirring work, which easily delays agricultural operations.

3、发明内容 3. Contents of the invention

本实用新型的目的是克服现有技术中存在的不足,提供一种可以在低温情况下操作的新型粪肥高效搅拌机。The purpose of the utility model is to overcome the deficiencies in the prior art, and provide a new high-efficiency manure mixer that can be operated at low temperature.

本实用新型的技术方案是按以下方式实现的,其结构由皮带轮机构、电动机、转动轴、进水口、出口、搅拌杆、粪桶、保温外壳和排水口构成,转动轴的一端穿插入粪桶内部,插入粪桶内部的搅拌杆外侧固定有搅拌杆,转动轴的另一端通过皮带轮机构与电动机连接;粪桶的外侧设置有保温外壳,进水口、排水口插入粪桶与保温外壳之间;出口设置在粪桶的下端。The technical scheme of the utility model is realized in the following manner, its structure is composed of a belt pulley mechanism, a motor, a rotating shaft, a water inlet, an outlet, a stirring rod, a feces bucket, a heat preservation shell and a drain outlet, and one end of the rotating shaft is inserted into the feces bucket Inside, a stirring rod is fixed on the outer side of the stirring rod inserted into the excrement bucket, and the other end of the rotating shaft is connected to the motor through a pulley mechanism; an insulating shell is arranged on the outside of the fecal bucket, and the water inlet and outlet are inserted between the fecal bucket and the insulating shell; The outlet is arranged at the lower end of the manure bucket.

上述设置在转动轴外侧的搅拌杆为单螺旋排列。The stirring rods arranged outside the rotating shaft are arranged in a single helix.

本实用新型的优点是:The utility model has the advantages of:

本实用新型的一种新型粪肥高效搅拌机和现有技术相比,能够有效降低工作人员的劳动强度,还可以将粪肥搅拌均匀,稳定农作物的收成;而且可以在低温天气提高粪桶内的温度,进行粪肥的搅拌工作,避免耽误农业操作,本实用新型还具有设计合理、结构简单、易于加工、使用方便等特点,因而,具有很好的使用价值。Compared with the prior art, a new manure high-efficiency mixer of the utility model can effectively reduce the labor intensity of the staff, and can also stir the manure evenly to stabilize the harvest of crops; The manure can be stirred to avoid delaying agricultural operations. The utility model also has the characteristics of reasonable design, simple structure, easy processing, and convenient use, so it has good use value.

4、附图说明 4. Description of drawings

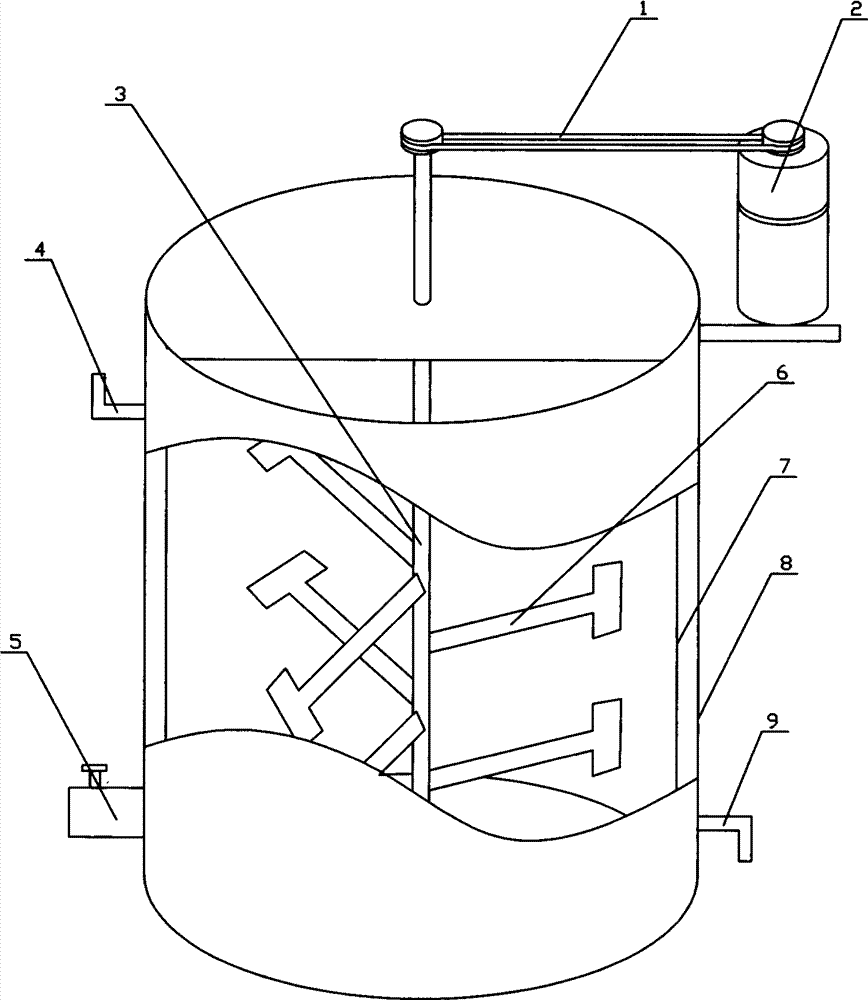

图1为一种新型粪肥高效搅拌机的结构示意图;Fig. 1 is the structural representation of a kind of novel manure efficient mixer;

附图中的标记分别表示;The marks in the accompanying drawings indicate respectively;

1、皮带轮机构;2、电动机;3、转动轴;4、进水口;5、出口;6、搅拌杆;7、粪桶;8、保温外壳;9、排水口。1. Pulley mechanism; 2. Motor; 3. Rotating shaft; 4. Water inlet; 5. Outlet; 6. Stirring rod;

5、具体实施方式 5. Specific implementation

下面结合附图对本实用新型的一种新型粪肥高效搅拌机作以下详细说明。A kind of novel manure high-efficiency mixer of the present utility model is described in detail below in conjunction with accompanying drawing.

如图1所示,本实用新型的一种新型粪肥高效搅拌机其结构由皮带轮机构1、电动机2、转动轴3、进水口4、出口5、搅拌杆6、粪桶7、保温外壳8和排水口9构成,转动轴3的一端穿插入粪桶7内部,插入粪桶内部的搅拌杆外侧固定有搅拌杆6,转动轴3的另一端通过皮带轮机构1与电动机2连接;粪桶7的外侧设置有保温外壳8,进水口4、排水口9插入粪桶7与保温外壳8之间;出口5设置在粪桶7的下端。As shown in Figure 1, the structure of a new type of high-efficiency manure mixer of the present invention consists of a pulley mechanism 1, a

设置在转动轴3外侧的搅拌杆6为单螺旋排列。The stirring rods 6 arranged outside the rotating shaft 3 are arranged in a single helix.

本实用新型的一种新型粪肥高效搅拌机其加工制作非常简单方便,按照说明书附图所示即可加工。The processing and manufacture of a novel high-efficiency manure mixer of the utility model is very simple and convenient, and can be processed as shown in the accompanying drawings.

除说明书所述的技术特征外,均为本专业技术人员的已知技术。Except for the technical features described in the instructions, all are known technologies by those skilled in the art.

Claims (2)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012201312577U CN202490585U (en) | 2012-03-31 | 2012-03-31 | Novel manure high-efficiency mixer |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012201312577U CN202490585U (en) | 2012-03-31 | 2012-03-31 | Novel manure high-efficiency mixer |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN202490585U true CN202490585U (en) | 2012-10-17 |

Family

ID=46996829

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2012201312577U Expired - Fee Related CN202490585U (en) | 2012-03-31 | 2012-03-31 | Novel manure high-efficiency mixer |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN202490585U (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108658402A (en) * | 2018-05-21 | 2018-10-16 | 台州创投环保科技有限公司 | A kind of animal excretion processing unit to economize on resources |

| CN117136699A (en) * | 2023-09-13 | 2023-12-01 | 黄三角智能农机装备产业研究院 | High-efficiency full-volume liquid manure drip irrigation system |

-

2012

- 2012-03-31 CN CN2012201312577U patent/CN202490585U/en not_active Expired - Fee Related

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108658402A (en) * | 2018-05-21 | 2018-10-16 | 台州创投环保科技有限公司 | A kind of animal excretion processing unit to economize on resources |

| CN117136699A (en) * | 2023-09-13 | 2023-12-01 | 黄三角智能农机装备产业研究院 | High-efficiency full-volume liquid manure drip irrigation system |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN202490585U (en) | Novel manure high-efficiency mixer | |

| CN111704331A (en) | An environmentally friendly livestock and poultry manure treatment device | |

| CN206061946U (en) | A kind of pesticide stirs flusher | |

| CN204607825U (en) | Recycling system after a kind of cow dung reprocessing | |

| CN106907917A (en) | A kind of coiled dryer for animal harmless treatment | |

| CN206279098U (en) | A kind of agricultural fertilizer material installation for fermenting | |

| CN201704324U (en) | High concentration material automatic feeding and discharging and alpine region solar temperature rising biogas device | |

| CN103626540B (en) | A kind of Organic fertilizer fermentation machine | |

| CN211972286U (en) | A kind of agricultural organic waste fermentation device | |

| CN207113422U (en) | A kind of intelligent pig manure dewaterer | |

| CN207478503U (en) | A biological fertilizer mixing device | |

| CN214115383U (en) | a composting reactor | |

| CN204837728U (en) | Automatic change material mixing arrangement | |

| CN203761824U (en) | Portable corn nitrogen fertilizer dressing device | |

| CN212246793U (en) | Fertilizer apparatus for producing | |

| CN202942834U (en) | Proportioning device of decolorizing agent for coal ash coagulation | |

| CN204409486U (en) | Agriculture and animal husbandry organic waste produces feed device | |

| CN206828418U (en) | A kind of multipurpose compost agitating device | |

| CN205323613U (en) | Unloading formula mixer for building quick | |

| CN216513582U (en) | Agricultural is collection device for organic fertilizer | |

| CN206760041U (en) | A kind of efficient fertilizing equipment | |

| CN211706475U (en) | An organic fertilizer mixing device | |

| CN205760747U (en) | Yellow cake agitating device | |

| CN204352782U (en) | Water soluble fertilizer liquid storage tank agitator | |

| CN214482251U (en) | Agricultural mechanized fertilizer injection unit |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C17 | Cessation of patent right | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20121017 Termination date: 20130331 |