Alloy melting stove liquation is got the flat hood-opening device of the horizontal saliva of soup mouth

Technical field

The utility model relates to a kind of hood-opening device of alloy melt vessel, and a kind of specifically alloy melting stove liquation is got the flat hood-opening device of the horizontal saliva of soup mouth.

Background technology

The liquation of present aluminium alloy melting furnace is got the soup mouth and is in normally open usually, and high temperature aluminum liquid directly contacts with air, and heat loss is bigger, and getting the soup mouth is the topmost part of aluminium alloy melting furnace hydrothermal solution thermal loss.Therefore how effectively to reduce or reduce and get soup mouth heat loss, for energy-conservation one of the direct important function that plays.Get soup flap like what design was opened up and down, it is bigger to take up room, and opening process air resistance ratios is bigger; Driving the surrounding air motion easily, is not very desirable, opposite for the insulation of getting the soup mouth; As will get soup flap and be designed to the horizontally openable form, it is smaller not only to take up room, and air drag is smaller during horizontally openable; Air flows little, and it is just smaller to take away heat, so the level mode of uncapping has superiority to getting the insulation of soup mouth.

Summary of the invention

The purpose of the utility model provides a kind of alloy melting stove liquation and gets the flat hood-opening device of the horizontal saliva of soup mouth, is set to horizontal direction through hood-opening device and opens, and reduces the open circumferential air and flows, and the heat that reduces the alloy liquation runs off.

For realizing above-mentioned purpose; The utility model provides a kind of alloy melting stove liquation and get the flat hood-opening device of the horizontal saliva of soup mouth; Comprise and get the soup flap, be used to control said connection rod set of getting the horizontal movement of soup flap; Said alloy melting stove liquation is got the flat hood-opening device of the horizontal saliva of soup mouth and is also comprised a fixed support, and said connection rod set is connected in said fixed support.

Above-mentioned alloy melting stove liquation is got the flat hood-opening device of the horizontal saliva of soup mouth, and said alloy melting stove liquation is got the flat hood-opening device of the horizontal saliva of soup mouth and comprised that also one is used to control the cylinder of said connection rod set motion.

Above-mentioned alloy melting stove liquation is got the flat hood-opening device of the horizontal saliva of soup mouth, and said cylinder is fixed in a cylinder support.

Above-mentioned alloy melting stove liquation is got the flat hood-opening device of the horizontal saliva of soup mouth, and said connection rod set comprises five connecting rods, i.e. first connecting rod, second connecting rod, third connecting rod, the 4th connecting rod and the 5th connecting rod.

Above-mentioned alloy melting stove liquation is got the flat hood-opening device of the horizontal saliva of soup mouth; One end of said second connecting rod is connected in the middle part of said first connecting rod; The other end of said second connecting rod is connected to said third connecting rod and said the 4th connecting rod, and said the 4th connecting rod is connected in said the 5th connecting rod.

Above-mentioned alloy melting stove liquation is got the flat hood-opening device of the horizontal saliva of soup mouth, and said alloy melting stove liquation is got the flat hood-opening device of the horizontal saliva of soup mouth and comprised that also one is used to get the soup ladle of soup.

The utility model alloy melting stove liquation is got the flat hood-opening device of the horizontal saliva of soup mouth, is set to horizontal direction through hood-opening device and opens, and has reduced the open circumferential air and has flowed, and the heat that has reduced the alloy liquation runs off.In order to realize that getting the soup flap gets horizontal movement, at first limit the movement locus of bell, make it according to fixing movement locus motion, in order to realize getting the reciprocating motion of soup flap, adopt cylinder to move back and forth and realize that getting the soup flap must move back and forth.Cylinder moves back and forth by solenoid control, links with getting soup equipment soup ladle simultaneously, realizes the production automation.

Description of drawings

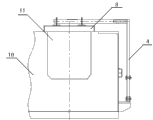

Fig. 1 is the utility model structural representation;

Fig. 2 is the utility model cross-sectional view.

The drawing reference numeral explanation:

1-cylinder support 2-the 2nd connecting rod 3-fixed support 4-connection rod set 5-the 3rd connecting rod 6-the 4th connecting rod 7-the 5th connecting rod 8-the 1st connecting rod 9 is got the soup flap 10-body of heater 11-mouthful 12-cylinder that ladles.

The specific embodiment

Below in conjunction with accompanying drawing the utility model is done further explain.

Please refer to Fig. 1 and Fig. 2, Fig. 1 is the utility model structural representation, and Fig. 2 is the utility model cross-sectional view.A kind of alloy melting stove liquation is got the flat hood-opening device of the horizontal saliva of soup mouth; Comprise and get soup flap 9, be used to control the connection rod set 4 of getting 9 horizontal movements of soup flap; The alloy melting stove liquation of the utility model is got the flat hood-opening device of the horizontal saliva of soup mouth and is also comprised a fixed support 3; Connection rod set 4 lower ends are connected in fixed support 3, and the upper end is fixed in and is got soup flap 9 tops.

Further, connection rod set 4 comprises five connecting rods, i.e. first connecting rod 8, second connecting rod 2, third connecting rod 5, the 4th connecting rod 6 and the 5th connecting rod 7.One end of second connecting rod 2 is connected in the middle part of first connecting rod 8, and the other end of second connecting rod 2 is connected to third connecting rod 5 and the 4th connecting rod 6, the four connecting rods 6 are connected in the 5th connecting rod 7.

Further, alloy melting stove liquation is got the flat hood-opening device of the horizontal saliva of soup mouth and is comprised that also one is used for the cylinder 1 of control link group 4 motions.This cylinder 1 is fixed in a cylinder support 1.

Further, alloy melting stove liquation is got the flat hood-opening device of the horizontal saliva of soup mouth and is comprised that also one is used to get the soup ladle of soup.

Getting soup flap 9 can symmetry make, about each fan, get above the first connecting rod 8 that soup flap 9 is connected to connection rod set 4, this gets the movement locus of soup flap 9 by first connecting rod control, other connecting rods of connection rod set 4 are realized transmission of power.Cylinder 12 is power resources.The original state bell is in the closed position, i.e. D among the figure

1The position, connection rod set 4 fixed hinge point A

1, A

2The position is motionless, and each moves connection rod set 4 hinge point and be in B respectively

1, C

1, E

1After bell was opened, cylinder 12 at first moved, hinge point E

1Ascending motion is to E

2, corresponding B

1Around A

1Move to B

2, C

1Around A

2Move to C

2Soup flap 9 is got by D in the position

1Around A

2Move to D

2The position.During the cylinder counter motion, get the soup flap and close, simultaneously A

2Select to be in and get on the soup mouth opening and closing center, have substrate hold-down function to getting the Tang Kou plane after getting 9 opening and closing of soup flap, realize that getting the soup flap must seal.

In order to satisfy the automation of production process, cylinder is by solenoid control, and with get soup device soup ladle action interlock, lid is opened when realizing getting soup, gets the automation of cover closing after the soup.

Those skilled in the art will recognize that; The above-mentioned specific embodiment is exemplary; Be in order better to make those skilled in the art can understand this patent; Can not be interpreted as it is restriction to this patent protection domain, so long as according to spirit that this patent discloses done anyly be equal to change or modify, all fall into the scope of this patent protection.