CN1778611A - Footplate of gangway and railway car - Google Patents

Footplate of gangway and railway car Download PDFInfo

- Publication number

- CN1778611A CN1778611A CNA2005100921869A CN200510092186A CN1778611A CN 1778611 A CN1778611 A CN 1778611A CN A2005100921869 A CNA2005100921869 A CN A2005100921869A CN 200510092186 A CN200510092186 A CN 200510092186A CN 1778611 A CN1778611 A CN 1778611A

- Authority

- CN

- China

- Prior art keywords

- railway vehicle

- aforementioned

- attachment strap

- vehicle

- extrudate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B61—RAILWAYS

- B61D—BODY DETAILS OR KINDS OF RAILWAY VEHICLES

- B61D17/00—Construction details of vehicle bodies

- B61D17/04—Construction details of vehicle bodies with bodies of metal; with composite, e.g. metal and wood body structures

- B61D17/20—Communication passages between coaches; Adaptation of coach ends therefor

Landscapes

- Engineering & Computer Science (AREA)

- Life Sciences & Earth Sciences (AREA)

- Wood Science & Technology (AREA)

- Mechanical Engineering (AREA)

- Train Traffic Observation, Control, And Security (AREA)

- Vibration Prevention Devices (AREA)

- Bridges Or Land Bridges (AREA)

- Platform Screen Doors And Railroad Systems (AREA)

- Current-Collector Devices For Electrically Propelled Vehicles (AREA)

Abstract

The invention discloses a thin and high quality approach slab which can inhibit voice which is generated by the approach slab, extrudate (110) is arrayed in parallel along the width direction of railway vehicle, and is connected through a tube (80), the upper surface of the extrude is used as a walking surface, adjacent extrudates (110) are connected through liner bushings (90), two ends of the tube (80) which take splayed shape are extended on a bottom bracket through extension springs (50,50), an antiskid component (120) is adhered on the upper surface of the extrudate (110), and the bottom of the extudate is contacted with the upper surface of the bottom bracket through a sliding component (70). When relative displacement is generated between vehicle bodies at the time that a railway vehicle passes through curved line, the approach slab (10) can be easily slid. Therefore, when one side of railway vehicle is rocked, each extrudate (110, 110) is gradually rotated along the width direction of the railway vehicle, and walk of passengers and the like is led to carry out successfully.

Description

Technical field

The present invention relates to the attachment strap on the perforation road that is provided with on a kind of connecting portion of the railway vehicle that constitutes marshalling connecting railway vehicle.

Background technology

Constitute connecting railway vehicle on the car end of each railway vehicle of marshalling, be provided with and connect the road so that the passenger can move easily and safely.

Generally, patent documentation described as follows 1 is described, connects route such as lower part and constitutes: be connected with the end of the length direction of railway vehicle, and the attachment strap overlapping with the opposing party's attachment strap; Be connected with the end of the length direction of railway vehicle, and cover the wrinkle protective case on perforation road of end of the length direction of railway vehicle.

Yet this structure can't be said and the present railway vehicle fit of seeking to improve the vehicle overall appearance.

And following patent documentation 2 can think to realize that this improves purpose attractive in appearance.Attachment strap is placed in the end of the railway vehicle of adjacency.There is rotor bottom surface at attachment strap, and thus, a side railway vehicle moves by aforementioned rotor broad ways with respect to the opposing party's vehicle broad ways displacement the time.

In this document the wrinkle protective case is not put down in writing.

Attachment strap by patent documentation 2 can obtain the big perforation road of Width size.

Patent documentation 1: real public clear 50-43848 communique

Patent documentation 2: specially permit communique No. 3060367

Generally, numerous the travelling frequently with in the vehicle in Japan with regard to existing situation, can't say that it connects the road and is considering very thoroughly aspect design and the mechanism.Thus, for the space, guest room that the design-calculated high quality constantly develops, connecting the road has the tendency of keeping original form.

Particularly, the plate of the end that is arranged on railway vehicle in opposite directions of the attachment strap of patent documentation 1 constitutes with the degree that overlaps, so vibration when travelling owing to railway vehicle and the reasons such as displacement between car body have the situation that is produced noise by attachment strap.

And, in patent documentation 2, solved the problem points of above-mentioned attachment strap.But, attachment strap shown here be configured in relative car body along its Width displacement the time, have the structure that attachment strap can be deformed into parallelogram, owing to be equipped with the rotor (wheel) that supports these attachment straps structures, so attachment strap single-piece thickness is bigger.So, go for above the floor of car body and the railway vehicle in the Europe that the distance between above the adaptor union is bigger, but because the high about 200mm of the railway vehicle in the adaptor union aspect ratio Europe of railway vehicle in Japan, so above the floor of car body and the distance between above the adaptor union not enough, be suitable for difficulty.

Summary of the invention

The purpose of this invention is to provide a kind of in order to make the whole high quality in the perforation road that comprises attachment strap, low noise, the smaller attachment strap of its thickness.

Above-mentioned purpose realizes by following formation, attachment strap is provided on the perforation road of the connecting portion between the railway vehicle, for can moving, passenger etc. is positioned on the floor on this perforation road, a plurality of flat boards of this attachment strap and length direction configured in parallel railway vehicle are connected by the link along the Width of railway vehicle, and aforementioned a plurality of plates can be that the center vertically rotates with aforementioned link.

Description of drawings

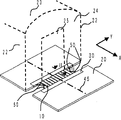

Fig. 1 is the oblique drawing at the junction surface of vehicle and vehicle.

Fig. 2 is the II-II line section drawing of Fig. 1.

Fig. 3 is the exploded perspective view of attachment strap 10.

Fig. 4 is the planar view of connecting portion of the extrudate 110,110 of attachment strap 10.

Fig. 5 is the decomposition view that connects the pipe 80 of extrudate 110.

Fig. 6 is an oblique drawing of seeing the extrudate 110 of attachment strap 10 from bottom surface side.

Fig. 7 is the right side view of Fig. 6.

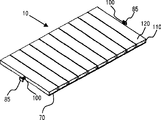

Fig. 8 is the oblique drawing of finishing of attachment strap 10.

Fig. 9 is the oblique drawing of the movement of the attachment strap 10 when showing the vehicle rocking vibration of adjacency.

Among the figure: 10-attachment strap, 20-underframe, 30-lid, the line of centers of 45-vehicle lengthwise direction, 50-extension spring, 70-slide unit, 80-pipe, 85-end panel, 90-lining, 100-coil spring, 110-extrudate, 111-protuberance, 120-slip-proofing device.

The specific embodiment

Below by Fig. 1 to Fig. 9 one embodiment of the invention are illustrated.

At first, in Fig. 1, show the situation that attachment strap 10 disposes on railway vehicle.Attachment strap 10 is positioned at the position of each underframe 20 of the railway vehicle of crossing over adjacency.The car end of underframe 20 (face work side) has the otch (degree of depth and width) 21 (Fig. 2, Fig. 9) that can take in attachment strap 10 according to the mode that the 10 ladder differences from underframe (above the floor) to attachment strap diminish.The width of otch 21 (width of the Width of car body) is bigger than the width of attachment strap 10.The height of the depth ratio attachment strap of otch 21 is more bigger.And, be placed on attachment strap 10 on the underframe 20 after, load to cover the lid 30 of otch 21, and be fixed on the underframe 20.Thus, constitute underframe 20 from a side to the continuous plane of the opposing party's underframe (above the floor).Gapped S in lid 30 bottom surface and between above the attachment strap 10.On the Width (Y direction) of the length direction (directions X) of vehicle and vehicle, be flat above the attachment strap 10.

In Fig. 1, underframe 20 covers by side structure 22, top structure body 23, the car end structure body 24 of railway vehicle.The mouth 25 that connects the road is arranged on car end structure body 24.Though diagram does not cover by the wrinkle protective case between vehicle and the vehicle.X represents the length direction of vehicle, and Y represents the Width of vehicle.

In Fig. 2, show the relation of underframe 20, attachment strap 10, otch 21, lid 30.The Width of underframe is under the situation of level, on attachment strap 10 and the lid 30 below between gapped S.Gap S is about 25mm.And, the ramp (slope) 32 on the plane of the front end of connection cover 30 smoothly and attachment strap 10 is set at lid 30 front end.

In from Fig. 1 to Fig. 9, attachment strap 10 by its length direction towards formations such as a plurality of extrudates (being also referred to as flat board) 110 of length over ends of body direction, pipe (pipe) (Connection Element) 80 that broad ways connects this extrudate and extension springs 50.Extrudate 110 is the extrudate of aluminum alloy.Extrudate 110 is that top and bottom are flat along the section bar of directions X extruding.Section bar 110 is a hollow.Pipe 80 uses hollow tubular in order to make light weight, but is that solid axle is also passable.Pipe 80 connects the central part of the length direction of extrudate 110.By a plurality of extrudates 110, the floor that formation occupant etc. can easily move.Gap between the vehicle that connects near the length of extrudate 110 is big.The length of section bar 110 is about about 700mm.

In Fig. 3, offer hole 111 in the two sides of extrudate, and the tube portion of lining 90,90 is connected in each hole 111,111.Pipe connects this lining 90.Lining 90 is resinous.Between the end panel 85 of the convex shoulder of the lining 90 of the extrudate 110 of the end that connects Width and the shaft end of pipe 80, dispose coil spring 100.Coil spring 100 is positioned at the both ends of pipe.

The end panel 85 of an axial end of pipe 80 is welded on the pipe 80.The end panel 85 of the other end and pipe 80 are for dividing other parts.Make coil spring 100 connect the pipe 80 that is welded with end panel 85, another distolateral distolateral perforation lining 90 of pipe 80 from a plurality of extrudates 110.After connecting the extrudate 110 (lining 90) of the other end, configuration coil spring 110, and at the end anchor portion plate 85 of managing 80.In the screw thread 81 of pipe 80 end, be screwed into the threaded portion of end panel 85 and fixing.

As shown in Figure 4, the convex shoulder by lining 90,90 contacts between the extrudate 110 of adjacency.

As shown in Figure 3, Figure 4, push down extrudate 110 by coil spring 100.That is, by 100 pairs of extrudate pressurizations of coil spring.

As shown in Figure 2, on extrudate 110, paste slip-proofing device 120.The top recessed amount that is equivalent to the thickness of slip-proofing device 120 of extrudate 110.On the end of the aforementioned Width of recess, protuberance 115 (Fig. 7) is arranged.Paste slip-proofing device 120 along this protuberance 115, carry out sticking operation easily.

In Fig. 5, an example of the assemble method of character display tube 80 and end panel 85.In a pipe side's of 80 end welding end panel 85.And, cut out external screw thread in advance in pipe the opposing party's of 80 end, conclude with the negative thread of end panel 85.In order to prevent the coming off of end panel 85, use spring cotter (in Fig. 5,87 holes for spring cotter used) etc. prevent from rotate thereafter.

Fig. 7 is the oblique drawing after the assembling as mentioned above.

As shown in Figure 1, last, by the hole of extension spring 50 connection end panel 85 and the hook that on the otch 21 of underframe 20, is provided with (not diagram).The position of aforementioned hook is positioned at position than pipe 80 axle head along the bigger position of aforementioned Width.The vertical dimension position of aforementioned hook is when underframe 20 broad ways levels, identical with pipe 80 position reality.Thus, the Width of pipe 80 2 extension spring 50 along continuous straight runs by being Eight characters shape stretches.Thus, though relative the opposing party's of railway vehicle of a side railway vehicle along its Width displacement, the center of the Width of attachment strap 10 also remain on railway vehicle Width center 45 near.

And as Fig. 6 and shown in Figure 7, (position of sliding mutually with the otch 21 of vehicle end) pastes slide unit 70 in the bottom surface of each section bar 110.Slide unit 70 is resins that lubricity is arranged.Slide unit 70 is fixing at a plurality of screw rods of the underrun of section bar 110 (bolt) (not diagram).When slide unit 70 produces relative displacement between the car body of vehicle when the curve etc., attachment strap 10 can easily be slided.

As Fig. 6 and shown in Figure 7, the following slide unit 70 of extrudate 110 be along aforementioned Width downward direction protrude circular-arc.This be along aforementioned Width downward direction protrude circular-arc, but also can be along the length direction downward direction of extrudate protrude circular-arc.

In Fig. 9, be presented under the situation of railway vehicle generation rocking vibration of adjacency, while attachment strap 10 forms the state that curved surface is followed underframe 20.So-called rocking vibration is the on every side vibration of rotation of car body around the center shaft 45 of the length direction of car body.The vehicle on the right side of Fig. 9 (underframe 20) does not wave, the broad ways level, and the vehicle in the left side of Fig. 9 (underframe 20) waves.The vehicle (underframe 20) in left side is with respect to the vehicle (underframe 20) on right side, and its upper end side rises.Plane for the side's (right side) of the vehicle of adjacency underframe 20 produces on the opposing party's (left side) underframe 20 in the angle of oscillation, and each section bar 110 that constitutes attachment strap 10 is that vertically rotate at the center with the pipe 80 that limits these section bars 110.And, between the section bar 110 of adjacency, produce minute angle.Its result, because the underframe 20,20 of attachment strap 10 about connecting with curved surface, so walking easily such as passenger is moved.

As shown in Figure 9, the underframe 20 of adjacency produces under the situation of angle of inclination, and slide unit 70 moves in the time of underframe 20 bevelleds with the line that underframe 20 joins.At this moment, if the shape at the position that slide unit 70 and underframe 20 are joined is circular-arc shaping in advance, it is moved smoothly.

Technical scope of the present invention is not to be defined in literal of putting down in writing in the claim or the literal of putting down in writing in summary of the invention, comprises those skilled in the art's scope of displacement easily yet.

Claims (7)

1. an attachment strap is provided on the perforation road of the connecting portion between the railway vehicle, and can move for passenger etc. and be positioned on the floor on this perforation road, it is characterized in that,

A plurality of flat boards of this attachment strap and length direction configured in parallel railway vehicle are connected by the link along the Width of railway vehicle,

Aforementioned a plurality of plate can be the center rotation with aforementioned link.

2. attachment strap according to claim 1 is characterized in that,

Aforementioned a plurality of plate with railway vehicle end position contacting on, parts are equipped with lubricity.

3. attachment strap according to claim 1 is characterized in that,

Aforementioned a plurality of plate with railway vehicle end position contacting on, parts are equipped with lubricity, the face that aforementioned parts and end vehicle with lubricity contacts is circular-arc.

4. attachment strap according to claim 1 is characterized in that,

By the coil spring of retractility is arranged, connect the Width end of aforementioned link and the Width end of aforementioned railway vehicle.

5. a railway vehicle is characterized in that,

Have on the perforation road of the connecting portion that is provided between the railway vehicle, and can move for passenger etc. and be arranged on attachment strap on the floor on this perforation road,

A plurality of flat boards of this attachment strap and length direction configured in parallel railway vehicle connect by the link along the Width of railway vehicle,

Aforementioned a plurality of plate can be the center rotation with aforementioned link.

6. railway vehicle according to claim 5 is characterized in that,

Aforementioned a plurality of plate is fixed with the parts with lubricity at the position that contacts with the railway vehicle end,

The face that aforementioned parts and end vehicle with lubricity contacts is circular-arc.

7. railway vehicle according to claim 5 is characterized in that,

The end of the aforementioned Width of aforementioned link is connected by coil spring with the Width end of aforementioned railway vehicle.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004337333 | 2004-11-22 | ||

| JP2004337333A JP4417821B2 (en) | 2004-11-22 | 2004-11-22 | Railway vehicle with a through-passage |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN1778611A true CN1778611A (en) | 2006-05-31 |

Family

ID=35985209

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNA2005100921869A Pending CN1778611A (en) | 2004-11-22 | 2005-08-24 | Footplate of gangway and railway car |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US20060107865A1 (en) |

| EP (1) | EP1659045A1 (en) |

| JP (1) | JP4417821B2 (en) |

| KR (1) | KR100737493B1 (en) |

| CN (1) | CN1778611A (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101654109B (en) * | 2008-08-22 | 2012-08-08 | 许布奈有限公司 | Bridge for a communication passage between two articulated vehicles, e.g. of a tramway |

| CN112744243A (en) * | 2019-10-31 | 2021-05-04 | 比亚迪股份有限公司 | Rail vehicle |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ES2319084B1 (en) * | 2008-10-20 | 2010-03-16 | Thyssenkrupp Elevator Innovation | TRANSVERSAL LONGITUDINAL BOARD. |

| KR101034039B1 (en) * | 2009-12-23 | 2011-05-11 | 한국과학기술원 | Magnetic field shielding device for non-contact electromagnetic inductive charging electric vehicle |

| CN104254471A (en) * | 2011-12-13 | 2014-12-31 | 易构国际有限责任公司 | Gangway floor for a gangway between a first car of a multi-car vehicle and a second car of said vehicle |

| AT13451U1 (en) * | 2012-09-12 | 2013-12-15 | Ultimate Europ Transp Equipment Gmbh | Bridge between two articulated vehicle parts |

| GB2598541B (en) * | 2020-07-16 | 2022-12-07 | Bombardier Transp Gmbh | Rail vehicle provided with an end wall, a doorway and footplate catchers |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE539581C (en) * | 1930-08-08 | 1931-11-30 | Philipp Kremer Dr Ing | Transition platform for cars with movable bars |

| BE460037A (en) * | 1939-06-29 | |||

| JPS5043848Y2 (en) | 1972-05-27 | 1975-12-15 | ||

| ATE9445T1 (en) * | 1980-07-16 | 1984-10-15 | Hans Ferri | FILTER UNIT. |

| DE3806702A1 (en) * | 1988-03-02 | 1989-09-14 | Huebner Gummi & Kunststoff | LINKED BRIDGE AS PART OF A SEPARABLE CAR TRANSITION |

| EP0441069A1 (en) * | 1990-02-05 | 1991-08-14 | Caoutchouc Manufacture Et Plastiques Societe Anonyme | Ductile floor for the passage of heavy road vehicles between railway transport vehicles or road transport vehicles |

| US5845584A (en) * | 1994-02-04 | 1998-12-08 | Standard Car Truck Company | Rail car bridge plate |

| EP0669243B1 (en) | 1994-02-25 | 1997-08-06 | HÜBNER Gummi- und Kunststoff GmbH | Diagonal movable bridge elements for an intercommunication passage between two vehicles |

| FR2724620B1 (en) * | 1994-09-16 | 1997-01-10 | Lohr Ind | DEFORMABLE GATEWAY BETWEEN TWO LOADING PLANS CARRIED BY SUCCESSIVE CHASSIS ESPECIALLY RAIL |

| US5771812A (en) * | 1995-07-06 | 1998-06-30 | Hubner Gummi-Und Kunststoff Gmbh | Articulated gangway |

| WO2000027656A1 (en) * | 1998-11-05 | 2000-05-18 | Hübner Gummi- Und Kunststoff Gmbh | Connecting device between two vehicle parts of an articulated vehicle that are interconnected in an articulated manner |

-

2004

- 2004-11-22 JP JP2004337333A patent/JP4417821B2/en not_active Expired - Fee Related

-

2005

- 2005-08-23 KR KR1020050077130A patent/KR100737493B1/en not_active IP Right Cessation

- 2005-08-24 CN CNA2005100921869A patent/CN1778611A/en active Pending

- 2005-08-24 US US11/209,738 patent/US20060107865A1/en not_active Abandoned

- 2005-08-25 EP EP05255222A patent/EP1659045A1/en not_active Withdrawn

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101654109B (en) * | 2008-08-22 | 2012-08-08 | 许布奈有限公司 | Bridge for a communication passage between two articulated vehicles, e.g. of a tramway |

| CN112744243A (en) * | 2019-10-31 | 2021-05-04 | 比亚迪股份有限公司 | Rail vehicle |

Also Published As

| Publication number | Publication date |

|---|---|

| JP4417821B2 (en) | 2010-02-17 |

| JP2006143043A (en) | 2006-06-08 |

| US20060107865A1 (en) | 2006-05-25 |

| KR20060056844A (en) | 2006-05-25 |

| KR100737493B1 (en) | 2007-07-09 |

| EP1659045A1 (en) | 2006-05-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN1778611A (en) | Footplate of gangway and railway car | |

| CN1289339C (en) | Mounting structure of bumper beam | |

| CN1094103C (en) | System for guiding road vehicle axle along at least one rail on ground | |

| CN1342578A (en) | Endless-track type building machinery vehicle frame structure | |

| CN1480366A (en) | Steel rail vehicle | |

| CN1843819A (en) | Car body structure | |

| CN1265986C (en) | Inner rear-view mirror | |

| CN100349778C (en) | Rear fender and related support structure for a motorcycle, and motorcycle including same | |

| JP2013067461A (en) | Passenger conveyor | |

| US6834911B2 (en) | Mobile work machine comprising accessible platforms | |

| CN1044591C (en) | Guide structure for lift | |

| CA2455957A1 (en) | Counterbalanced deck for railroad freight car | |

| CN101581156A (en) | Monolayer slope multiplication parking method and slop parking planker | |

| CN1104374C (en) | Escalator apparatus | |

| CN205091134U (en) | Car of riding instead of walk climbing testboard | |

| CN2543940Y (en) | High altitude work platform | |

| CN1097388A (en) | the back handle assembly of two-wheeled motorcycle | |

| CN104144829A (en) | Method-system of parking a vehicle using only front road course and placement of the rear of the vehicle in a final parking position by an auxiliary mechanism | |

| CN2625228Y (en) | Air transport and excursion vehicle | |

| CN1238241C (en) | Escalator for negotiating curves | |

| CN108482392B (en) | Escape device for air-iron system and air-iron system | |

| CN1939794A (en) | Assembling structure of car body front portion | |

| CN1174911C (en) | Escalator | |

| CN1181347A (en) | Automatic staircase with wheelchair stairs and its operation method | |

| CN1324196C (en) | Adjustable road surface expandable seam apparatus and mounting method thereof |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C02 | Deemed withdrawal of patent application after publication (patent law 2001) | ||

| WD01 | Invention patent application deemed withdrawn after publication |