CN1440887A - wheel frame with sensor - Google Patents

wheel frame with sensor Download PDFInfo

- Publication number

- CN1440887A CN1440887A CN 02106799 CN02106799A CN1440887A CN 1440887 A CN1440887 A CN 1440887A CN 02106799 CN02106799 CN 02106799 CN 02106799 A CN02106799 A CN 02106799A CN 1440887 A CN1440887 A CN 1440887A

- Authority

- CN

- China

- Prior art keywords

- sensor

- wheel frame

- base

- tire

- frame

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000009434 installation Methods 0.000 abstract 1

- 238000000034 method Methods 0.000 description 6

- 238000003466 welding Methods 0.000 description 3

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- 230000002301 combined effect Effects 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 238000012544 monitoring process Methods 0.000 description 2

- 230000001133 acceleration Effects 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- 239000013536 elastomeric material Substances 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 230000003137 locomotive effect Effects 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- NHDHVHZZCFYRSB-UHFFFAOYSA-N pyriproxyfen Chemical compound C=1C=CC=NC=1OC(C)COC(C=C1)=CC=C1OC1=CC=CC=C1 NHDHVHZZCFYRSB-UHFFFAOYSA-N 0.000 description 1

Images

Landscapes

- Measuring Fluid Pressure (AREA)

Abstract

本发明涉及一种具有传感器的轮框,用以安装于一轮胎中,其包括:一轮框部分,具有一阀杆;一底座,固定于该轮框部分上,定位与该阀杆相对;以及一传感器,嵌入并加装于该底座中,用以感应该轮胎的状态,并以射频讯号发送。

The present invention relates to a wheel frame with a sensor for installation in a tire, comprising: a wheel frame part with a valve stem; a base fixed on the wheel frame part and positioned opposite to the valve stem; and a sensor embedded in and installed in the base for sensing the state of the tire and sending it as a radio frequency signal.

Description

Technical field

The present invention relates to a kind of air-inflation tyre with sensor device, particularly a kind of air-inflation tyre, it has sensor device, firmly is fixed on the wheel frame, and is interchangeable.

Background technology

Existing many devices can be in order to inspect for motor vehicle airtyred pressure in the existing technology, give the US Patent the 4th of Shumway such as on September 13rd, 1977,048, No. 614 " warning device that tire pressure is low excessively (Low Tire Pressure Warning Device) " wherein discloses a kind of tire pressure warning system that is used for Pneumatic vehicle tire.This tire pressure warning system is installed on the wheel frame of vehicle tyre, and have a bootable radio transmitter, power resources, a switch and diaphragm element, when the pressure of this tire is lower than predetermined pressure, can start this radio transmitter, with the warning driver.Aforesaid warning device only can give a warning to low excessively tire pressure, and its member is quite complicated, and is not suitable for modern vehicle.

Give people's such as Gabelmann US Patent the 5th on December 1st, 1998,844, No. 131 " the tire pressure sensor device (Tire Pressure SensorApparatus For A Pneumatic Tire Vehicle) that is used for Pneumatic vehicle tire ", wherein disclose a kind of pressure sensor device, this sensor device comprises a shell, have at least two base components, on the wheel rim platform that is placed in vehicle, and support this shell adjustably, and form stationary state with the combined action of tire valve rod.

Moreover, give the US Patent the 6th of Straub on May 2nd, 2000,055, in No. 855 " the wheel additional device of tire pressure sensor (Tire Pressure Sensor WheelAttachment Apparatus) ", disclose a kind of equipment in order on the wheel frame that is fixed in a wheel of vehicle, wherein this equipment has a pressure sensor, and threaded fastener, this pressure sensor can be fixed on the wheel frame of vehicle by this threaded fastener and a tire valve rod.

Moreover, the applicant has proposed to mention in No. 089117036 application case " airtyred tire pressure monitoring method and device thereof " on August 22nd, 2000, this device has a sensor module, be installed in the air-inflation tyre respectively, in order to respond to the state of this tire, and the tire condition that will respond to sends with RF signal, in view of the above in order to monitor out this tire condition.Again, the applicant has proposed to disclose a kind of state sensor of Pneumatic vehicle tire, in order to be mounted in the Pneumatic vehicle tire in No. 089118096 application case " state sensor of Pneumatic vehicle tire " on September 2nd, 2000.This two patent is all incorporated this paper into and is thought reference.

In the aforementioned techniques, generally the valve rod by this tire is installed on state sensor on the wheel rim platform of tire.Yet, be installed in the stem side of this tire when this sensor after, this balancing of tyre will coorespondingly be affected.Moreover aforesaid sensor is owing to fixed with the member of screw thread, so all might get loose in use, and makes the running that this sensor can't be correct.

Therefore, as previously mentioned, aforesaid sensor can not be fixed on the wheel frame of wheel well, just needs to provide a kind of frame of taking turns to have well secured sensor, so that detect the state in this vehicle at any time.

Summary of the invention

Main purpose of the present invention provides a kind of wheel frame with sensor, and wherein this sensor can firmly be fixed on the wheel frame of vehicle, and with a receiving device interaction so that monitor this vehicle operation state.

Secondary objective of the present invention provides a kind of wheel frame with sensor, wherein be fixed in this to this sensor-robust and take turns on the frame, and this sensor can be taken turns on the frame by this and is unloaded.

For reaching above-mentioned purpose, the wheel frame with sensor of the present invention, in order to be installed in the tire, it comprises: a wheel rim part has a valve rod; One base is fixed on this wheel rim part, locatees relative with this valve rod; And a sensor, embed and be installed in this base, in order to responding to the state of this tire, and send with radio-frequency (RF) signal.

According to another viewpoint of the present invention, this this base with wheel frame of sensor has two stay hooks in addition, in order to fasten this sensor.This base has bifoldable plate in addition, in order to unload this sensor.

According to another viewpoint again of the present invention, this wheel frame with sensor has a upper cover part in addition, in order to this base combined action firmly to fix this sensor.This upper cover part has a recess, and when this upper cover part and this base combined action, this recess can further prop up this sensor, firmly to fix this sensor.

Described before combining, because this wheel rim part has sensor device, this vehicle-state can be sent in this vehicle by radio-frequency (RF) signal, and the driver of this vehicle is just understood the state of this vehicle tyre in view of the above, and then avoided contingent emergency situation.Moreover, be placed in to this sensor-robust this and take turns on the frame, take turns the valve rod opposite position of frame with this, so this sensor does not have the possibility that comes off, and can promote this balancing of tyre.Again, this sensor also can unload easily, so that with changing or keep in repair this sensor.

Description of drawings

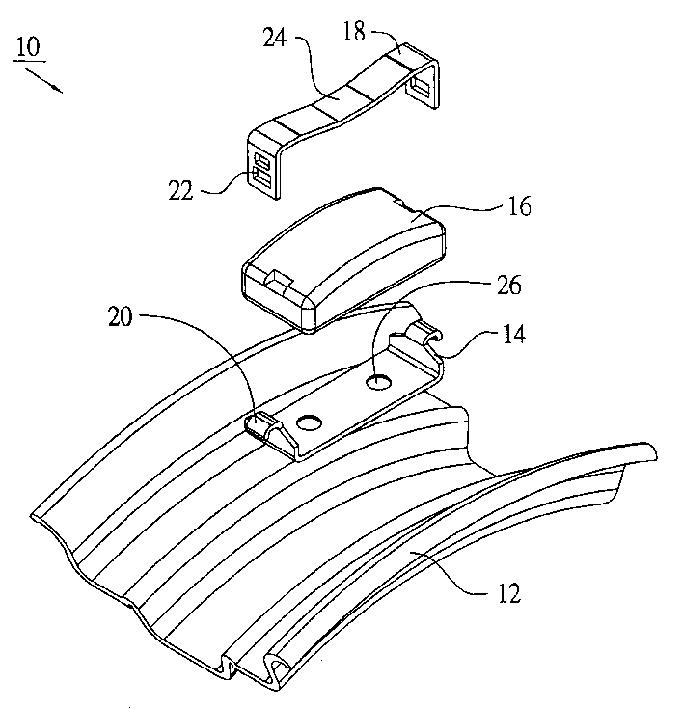

Fig. 1 has the expansion drawing of the wheel frame of sensor for first embodiment of the invention;

Fig. 2 has the block diagram of the wheel frame of sensor for this of Fig. 1;

Fig. 3 has the expansion drawing of the wheel frame of sensor for second embodiment of the invention;

Fig. 4 has the block diagram of the wheel frame of sensor for this of Fig. 3.Nomenclature among the figure

10 have the wheel frame of sensor

12 wheel rim parts, 14 bases

16 sensors, 18 upper cover parts

22 perforates of 20 stay hooks

24 recesses, 26 contacts

50 have the wheel frame of sensor

52 wheel rim parts, 54 bases

56 sensors, 58 bolts

60 recesses, 62 stay hooks

64 openings, 66 tapped bore

68 flaps

The specific embodiment

Now please refer to Fig. 1 and Fig. 2, wherein show the wheel frame 10 with sensor of first embodiment of the invention, this takes turns frame 10 forms a vehicle in order to install a rubber tread additional inflation wheel.This wheel frame 10 with sensor comprises a wheel rim part 12, a base 14, a sensor 16 and upper cover part 18.

This base 14 can such as welding, spot welding, rivet, screw thread, firmly be connected with this wheel rim part 12 by any fixed form.As shown in the figure, this base 14 is fixedly attached on this wheel rim part 12 by spot welding by two contacts 26.The position of this base 14 is with respect to the valve rod (not shown) of this wheel rim part 12, in view of the above to promote the balance that this takes turns frame 10.

This sensor 16 is placed in this base 14, and is fixed by this upper cover part 18.The size of this sensor 16 is equivalent to the size of this base 14 substantially, so that this sensor 16 can firmly embed in this base 14.This base 14 has two stay hooks 20, can with perforate 22 combineds action of this upper cover part 18, to fasten this upper cover part 18.Under the preferable situation, this upper cover part 18 has a recess 24, and by the elastomeric material manufacturing, such as springs, this upper cover part 18 can closely be pushed down this sensor 16 in view of the above, and further firmly fixes this sensor 16.Moreover, when desiring to unload this sensor 16, can just can make this perforate 22 break away from this stay hook 20, and unload this sensor 16 with this upper cover part 18 further to pressing down.

Being skillful in present technique person can understand, and this base 14 also can to take turns frame integrally formed with this.That is to say that this is taken turns frame 12 and itself has a groove, in order to embed this sensor 16.This take turns 12 of frames have two stay hooks 20 in order to these upper cover part 18 combineds action, so to fix this sensor 16.Perhaps, this is taken turns frame 12 and is not had any recess, and this sensor 16 only firmly is buckled in this by this upper cover part 18 and takes turns frame 12.

This sensor 16 has a sensor-specific integrated circuit ASIC (SensorApplication-Specific Integrated Circuit), and radio frequency (Radio Frequency; FR) forwarder, this sensor 16 can be responded to the state of this tire, and such as the data of pressure, temperature and the acceleration/accel of tire, and the tire state that will respond to sends with radio frequency (RF) signal.This sensor 16 is found in No. 089117036 application case " airtyred tire pressure monitoring method and device thereof " that the applicant was proposed on August 22nd, 2000, and this patent application case is incorporated this specification sheets in this and thought reference.

Be skillful in present technique person and can understand this sensor 16 and can be any shape, the profile of graphic this sensor 16 only provides as an example, so that explanation, but not in order to limit.Again, when the profile of this sensor 16 was other shape, this base 14 and upper cover part 18 can have corresponding profile.

Now please refer to Fig. 3 and Fig. 4, wherein show the wheel frame 50 with sensor of the second embodiment of the present invention, this takes turns frame 50, and to take turns frame 10 similar with this substantially, and wherein similar elements indicates similar sign.This wheel frame 50 with sensor comprises a wheel rim part 52, a base 54 and a sensor 56.

This base 54 is connected on two tapped bore 66 of this wheel rim part 52 by two bolts 58.This sensor 56 is placed in this base 54, and the size of this sensor 56 is equivalent to the size of this base 54 substantially.This base 54 has two stay hooks 62, can hook the recess 60 of this sensor 56, thereby fixes this sensor 56.Under the preferable situation, this base 54 has bifoldable plate (flap) 68, and this flap 68 all has an opening 64.Therefore, when desiring to unload this sensor 56, can insert in this opening 64, take out this sensor 56 so that break this base 54 into two with one's hands by a lever (not shown).

Being skillful in present technique person can understand, and this wheel rim part is the wheel frame of a locomotive tire, yet this wheel rim part also can be the wheel frame of a motor tire.Again, this is taken turns frame and can be iron frame or the aluminum wheel frame of taking turns.

As previously mentioned, this wheel rim part has sensor device, this vehicle-state can be sent in this vehicle by radio-frequency (RF) signal, and the driver of this vehicle is just understood the state of this vehicle tyre in view of the above, and avoids contingent emergency situation.Moreover, be placed in to this sensor-robust this and take turns on the frame, take turns the valve rod opposite position of frame with this, so this sensor does not have the possibility that comes off, and can promote this balancing of tyre.Again, this sensor also can unload easily, so that with changing or keep in repair this sensor.

Though the present invention discloses with aforementioned preferred embodiment, so it is not in order to limiting the present invention, anyly has the knack of this operator, without departing from the spirit and scope of the present invention, and when doing various changes and modification.Therefore protection scope of the present invention is when being as the criterion with claims.

Claims (13)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN 02106799 CN1231367C (en) | 2002-02-28 | 2002-02-28 | Wheel rim with sensor |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN 02106799 CN1231367C (en) | 2002-02-28 | 2002-02-28 | Wheel rim with sensor |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN1440887A true CN1440887A (en) | 2003-09-10 |

| CN1231367C CN1231367C (en) | 2005-12-14 |

Family

ID=27768510

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN 02106799 Expired - Fee Related CN1231367C (en) | 2002-02-28 | 2002-02-28 | Wheel rim with sensor |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN1231367C (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN100584646C (en) * | 2004-08-21 | 2010-01-27 | 三星Techwin株式会社 | Vehicle tire with RFID tag |

| CN101465043B (en) * | 2007-12-20 | 2011-07-20 | 财团法人工业技术研究院 | Screw, bolt and detection system thereof |

| CN102183323B (en) * | 2007-12-20 | 2012-09-05 | 财团法人工业技术研究院 | Fixed component inspection system |

| CN103183876A (en) * | 2011-12-27 | 2013-07-03 | 青岛博玉特橡塑制品有限公司 | Dielectric rubber body for packaging sensor and radio-communication system taking dielectric rubber body as carrier |

-

2002

- 2002-02-28 CN CN 02106799 patent/CN1231367C/en not_active Expired - Fee Related

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN100584646C (en) * | 2004-08-21 | 2010-01-27 | 三星Techwin株式会社 | Vehicle tire with RFID tag |

| CN101465043B (en) * | 2007-12-20 | 2011-07-20 | 财团法人工业技术研究院 | Screw, bolt and detection system thereof |

| CN102183323B (en) * | 2007-12-20 | 2012-09-05 | 财团法人工业技术研究院 | Fixed component inspection system |

| CN103183876A (en) * | 2011-12-27 | 2013-07-03 | 青岛博玉特橡塑制品有限公司 | Dielectric rubber body for packaging sensor and radio-communication system taking dielectric rubber body as carrier |

| CN103183876B (en) * | 2011-12-27 | 2015-07-15 | 青岛博玉特橡塑制品有限公司 | Dielectric rubber body for packaging sensor and radio-communication system taking dielectric rubber body as carrier |

Also Published As

| Publication number | Publication date |

|---|---|

| CN1231367C (en) | 2005-12-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| TW515764B (en) | Wheel rim having sensor | |

| EP1978345B1 (en) | Method for estimating magnitude of force acting on rolling tire | |

| US20110203710A1 (en) | Automatic tire pressure control and monitoring system and method | |

| JP4241587B2 (en) | Wheel state monitoring device and wheel state monitoring method | |

| JP6272225B2 (en) | tire | |

| US10688837B2 (en) | Tire-mounted sensor and sensor device used for same | |

| US10946861B2 (en) | Hydroplaning determination device | |

| CN111655529A (en) | Instrument cluster monitoring system | |

| CN1683196A (en) | Vehicle and method for controlling brake system indicators | |

| CN1982738A (en) | Brake lining wear sensor between lining block | |

| JP2003205715A (en) | Tire state sensor | |

| CN1761584A (en) | Installation structure for electronic component for tire | |

| CN1440887A (en) | wheel frame with sensor | |

| CN2826556Y (en) | External tire-pressure monitoring transmitter | |

| JP2022553819A (en) | Sensor assembly and system for monitoring dynamic objects | |

| JP2009035242A (en) | Patch for fixing detection device, tire, and detection device fixing method | |

| US20090207009A1 (en) | Method and Device for Monitoring Pressure of Vehicle Tires | |

| CN106427420A (en) | Tire safety system with monitoring and emergency functions | |

| US20020113693A1 (en) | Low-pressure testing device for an automobile tire | |

| CN223735996U (en) | Installation component of air bag generator | |

| CN1234550C (en) | tire condition sensor | |

| CN103692869A (en) | External TMPS (Tire Pressure Monitor System) sensor with lengthened air nozzle and inflating function | |

| EP3400156B1 (en) | A spring brake chamber | |

| KR20030087258A (en) | Alarm apparatus for booster fail | |

| KR100646464B1 (en) | Tire air pressure monitoring device to store air pressure warnings |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C19 | Lapse of patent right due to non-payment of the annual fee | ||

| CF01 | Termination of patent right due to non-payment of annual fee |