CN114441210A - Working platform of intelligent quality inspection equipment for comprehensive performance of electric cylinder - Google Patents

Working platform of intelligent quality inspection equipment for comprehensive performance of electric cylinder Download PDFInfo

- Publication number

- CN114441210A CN114441210A CN202210207421.6A CN202210207421A CN114441210A CN 114441210 A CN114441210 A CN 114441210A CN 202210207421 A CN202210207421 A CN 202210207421A CN 114441210 A CN114441210 A CN 114441210A

- Authority

- CN

- China

- Prior art keywords

- working platform

- base

- electric cylinder

- sliding

- telescopic rod

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01M—TESTING STATIC OR DYNAMIC BALANCE OF MACHINES OR STRUCTURES; TESTING OF STRUCTURES OR APPARATUS, NOT OTHERWISE PROVIDED FOR

- G01M99/00—Subject matter not provided for in other groups of this subclass

- G01M99/008—Subject matter not provided for in other groups of this subclass by doing functionality tests

Abstract

The invention provides a working platform of intelligent quality inspection equipment for comprehensive performance of an electric cylinder, which comprises the following steps: the system comprises an electric cylinder comprehensive performance intelligent quality inspection device and a dynamic test working platform; electric jar comprehensive properties intelligence quality inspection equipment includes: a front baffle and a rear baffle are fixed on two sides of the short edge of the guide rail base, a grating ruler is fixed on the long edge of the guide rail base, and sliding teeth are arranged on the grating ruler in a sliding manner; a sliding table which is in sliding connection with the guide rail base is arranged between the front baffle and the rear baffle; the surface of the sliding table is provided with a fixed block and a sliding block which is connected with the mounting groove in a sliding manner, and the force sensor is clamped and fixed between the fixed block and the sliding block; an electric cylinder is coaxially and fixedly arranged between the mounting groove and the notch of the opening groove block, and the sliding table is adjusted to test the data of the electric cylinder; the dynamic test working platform comprises: the base, it has telescopic link sliding bottom to slide between the base both sides limit, and this equipment can carry out the detection of multinomial data to the electric jar fast to can simulate the detection data when the electric jar practical application rocks the state.

Description

Technical Field

The invention relates to the technical field of design of electric cylinder detection equipment, in particular to intelligent quality inspection equipment for comprehensive performance of an electric cylinder and a dynamic test working platform thereof.

Background

Because the electric cylinder is when the load detection, inside motor speed can take place irregular change, leads to the inside motor of electric cylinder to take place the shake in the in-process of being surveyed, and this kind of condition will make the precision of final testing result not high.

According to on-site research, the quality inspection link of most of the current electric cylinder production enterprises before the delivery of the electric cylinder selects manual inspection, in the face of a large number of electric cylinder products, the manual quality inspection mostly adopts a sampling inspection mode to carry out delivery quality inspection, measurement tools such as a universal meter, a tension meter, a vernier caliper, a noise detector and the like are used for detecting eight indexes of current, voltage, thrust, tension, static load, stroke, noise and Hall signals of the electric cylinder, the whole manual inspection flow is complex and tedious, and the quality inspection can be finished according to the standard by an operator with more than three years of working experience. The existing electric cylinder quality inspection equipment in the market at present is divided into hydraulic and pneumatic quality inspection equipment, and the electric cylinder running speed that these two types of quality inspection equipment are bulky and can't deal with real-time change, and ultimate detection precision is not high to current electric cylinder quality inspection equipment can't accomplish the automated inspection under the simulation dynamic environment, and efficiency also has great promotion.

Disclosure of Invention

The invention aims to provide intelligent quality inspection equipment for comprehensive performance of an electric cylinder and a dynamic test working platform thereof, which are used for solving the problem of low efficiency of the traditional electric cylinder quality inspection scheme and are provided with the working platform for performance detection of the electric cylinder under the dynamic condition.

In order to achieve the purpose, the invention is realized by adopting the following technical scheme: an electric jar comprehensive properties intelligence quality testing equipment work platform: the system comprises an electric cylinder comprehensive performance intelligent quality inspection device and a dynamic test working platform;

electric jar comprehensive properties intelligence quality testing equipment includes: a front baffle and a rear baffle are fixed on two sides of the short edge of the guide rail base, a grating ruler is fixed on the long edge of the guide rail base, and sliding teeth are arranged on the grating ruler in a sliding manner;

a sliding table which is in sliding connection with the guide rail base is arranged between the front baffle and the rear baffle;

the surface of the sliding table is provided with a fixed block and a sliding block which is connected with the mounting groove in a sliding manner, and the force sensor is clamped and fixed between the fixed block and the sliding block;

an electric cylinder is coaxially and fixedly installed between the installation groove and the notch of the opening groove block, and the sliding table is adjusted to test the data of the electric cylinder;

the dynamic test working platform comprises: the device comprises a dynamic test working platform base, a telescopic rod sliding base and a dynamic test working platform, wherein the telescopic rod sliding base is arranged between two side edges of the dynamic test working platform base in a sliding mode;

an electric appliance control cabinet is fixed on one side edge of the dynamic test working platform table board, a plurality of groups of control units are arranged in the electric appliance control cabinet, and the sliding table, the dynamic test working platform table board and the electric appliance control cabinet are adjusted to enable the dynamic test electric cylinder data.

The guide rail base surface is equipped with two tracks, the slip table bottom is equipped with the track groove, and the slip table internal screw wears to be equipped with first lead screw, and first lead screw one end switching is connected servo motor output shaft in preceding baffle, the other end.

And a bearing seat is arranged between the output shaft of the servo motor and the end head of the first lead screw and is connected with the end head of the first lead screw and the output shaft of the servo motor.

A stop block is fixedly inserted into the stop block fixing pin on the sliding block; and an electric cylinder fixing bolt is inserted into the groove of the open groove block so as to fix the electric cylinder.

The dynamic test working platform base is hinged to the dynamic test working platform table surface through a side rotating shaft bolt parallel to the telescopic rod sliding base.

A telescopic mechanism is arranged between the dynamic test working platform table surface and the telescopic rod sliding base; the two ends of the telescopic mechanism are correspondingly hinged with the dynamic test working platform table surface and the telescopic rod sliding base.

Telescopic machanism includes telescopic link sliding bottom, telescopic link sliding bottom goes up the connecting bolt and articulates there are right telescopic link base, left telescopic link base, and it has right telescopic link, left telescopic link to correspond the activity grafting in right telescopic link base, the left telescopic link base, right telescopic link, left telescopic link connecting bolt hinge in dynamic test work platform mesa.

A second lead screw penetrates through the middle of the sliding base in a spiral mode, two ends of the second lead screw are perpendicularly connected to two sides of the base of the dynamic testing working platform in a switching mode, and one end of the second lead screw is connected with an output shaft of the motor.

The side vertical surface of the electric appliance control cabinet is sequentially provided with a touch screen, a high-speed counting module, a programmable controller, an analog quantity conversion module, a voltage sensor and a current sensor from top to bottom;

the electric cylinder is respectively and electrically connected with a voltage sensor and a current sensor, the force measuring sensor, the voltage sensor and the current sensor are respectively and electrically connected with an analog quantity conversion module, the grating ruler is electrically connected with a high-speed counting module, and the analog quantity conversion module, the touch screen and the high-speed counting module are respectively and electrically connected with a programmable controller and an electric appliance control cabinet.

The dynamic test working platform is characterized in that the bottom of the base of the dynamic test working platform is further fixedly provided with an integral base, the lower end of the integral base is fixedly provided with 6 support columns, and the lower ends of the support columns are provided with rollers.

According to the technical scheme, the invention has the beneficial effects that:

1. according to the device, the PLC is used for adjusting the rotating speed of the servo motor to change the running speed of the sliding table, a real-time adjustable stepless load is provided for the electric cylinder in the detection process, and the accuracy of the final detection numerical value is ensured. The detection of the eight indexes of current, voltage, thrust, tension, static load, stroke, noise and Hall signals can be completed only by one reciprocating stroke of the electric cylinder product on a detection station, compared with the traditional manual quality inspection of the electric cylinder, the time for detecting one electric cylinder product is shortened from 270s to 50s, and the detection efficiency is greatly improved.

2. The dynamic test working platform is arranged in the device, the conventional detection equipment can only statically detect the electric cylinder, each part of the dynamic test working platform is linked to realize performance detection of the electric cylinder under a dynamic environment, the shaking state of the electric cylinder in actual application can be simulated in a quality inspection process, a built-in high-speed counting module, an analog quantity conversion module, a force measuring sensor, a voltage sensor and a current sensor are arranged in the whole device, and the elements are matched with one another to enable the whole control scheme to be intelligent and efficient.

Drawings

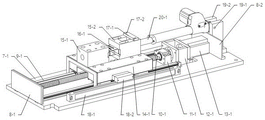

FIG. 1 is a perspective view of an intelligent quality inspection device for comprehensive performance of an electric cylinder and a dynamic test working platform thereof.

FIG. 2 is a front view of the intelligent quality inspection equipment for comprehensive performance of electric cylinder and its dynamic testing platform.

FIG. 3 is a single-station three-dimensional structure diagram of the intelligent quality inspection equipment for comprehensive performance of the electric cylinder.

Fig. 4 is an exploded view of the dynamic test platform of the present invention.

Wherein: 1-1, dynamically testing the table top of a working platform; 1-2, dynamically testing a working platform base; 1-3, an integral base; 2. a roller; 3-1, an electric appliance control cabinet; 3-2, a touch screen; 3-3, a high-speed counting module; 3-4, a programmable controller; 3-5, an analog quantity conversion module; 3-6, a voltage sensor; 3-7, a current sensor; 3-8, a motor; 4. connecting a bolt; 4-5, a rotating shaft bolt; 5-1, a right telescopic rod base; 5-2, a left telescopic rod base; 5-3, a left telescopic rod; 5-4, a right telescopic rod; 6-1, a telescopic rod sliding base; 6-2, a second lead screw; 7-1, a guide rail base; 8-1, a front baffle; 8-2, a rear baffle; 9-1, guide rails; 10-1, a first lead screw; 11-1 bearing seat; 12-1, a servo motor fixing seat; 13-1, a servo motor; 14-1, a sliding table; 15-1, fixing blocks; 15-2, sliding blocks; 16-1, a force sensor; 17-1, a stop block; 17-2, a stop block fixing pin; 18-1, a grating ruler; 18-2, a sliding rule; 19-1, fixing a bolt by an electric cylinder; 19-2, open slots; 20-1 and a bolt.

Detailed Description

In order to make the technical means, the creation characteristics, the achievement purposes and the effects of the invention easy to understand, the invention is further described with the specific embodiments.

It should be noted that in the description of the present invention, the terms "front", "rear", "left", "right", "upper", "lower", "inner", "outer", and the like indicate orientations or positional relationships based on the orientations or positional relationships shown in the drawings, and are only for convenience of describing the present invention but do not require that the present invention must be constructed and operated in a specific orientation, and thus, should not be construed as limiting the present invention. As used in the description of the present invention, the terms "front," "back," "left," "right," "up," "down" and "in" refer to directions in the drawings, and the terms "inner" and "outer" refer to directions toward and away from, respectively, the geometric center of a particular component.

Referring to the attached drawings 1-4, the invention discloses an electric cylinder comprehensive performance intelligent quality inspection equipment working platform, which comprises two parts, namely electric cylinder comprehensive performance intelligent quality inspection equipment and a dynamic test working platform; wherein electric jar comprehensive properties intelligence quality inspection equipment includes: a front baffle 8-1 and a rear baffle 8-2 are fixed on two sides of the short side of the guide rail base 7-1, a grating ruler 18-1 is fixed on the long side of the guide rail base 7-1, and a sliding tooth 18-2 slides on the grating ruler 18-1;

a sliding table 14-1 which is connected with the guide rail base 7-1 in a sliding way is arranged between the front baffle 8-1 and the rear baffle 8-2;

a fixed block 15-1 is arranged on the surface of the sliding table 14-1 and is connected with a sliding block 15-2 with a mounting groove in a sliding manner, and a force measuring sensor 16-1 is clamped and fixed between the fixed block 15-1 and the sliding block 15-2; an electric cylinder 20-1 is coaxially and fixedly arranged between the mounting groove and the opening groove block 19-2, and the sliding table 14-1 is adjusted to test the data of the electric cylinder 20-1;

wherein dynamic test work platform includes: the testing device comprises a dynamic testing working platform base 1-2, a telescopic rod sliding base 6-1 is arranged between two side edges of the dynamic testing working platform base 1-2 in a sliding mode, the dynamic testing working platform base 1-2 is connected with a dynamic testing working platform table-board 1-1 through an opening and closing hinge, and a plurality of groups of electric cylinder comprehensive performance intelligent quality testing equipment are fixedly installed on the side, opposite to the telescopic rod sliding base 6-1, of the dynamic testing working platform table-board 1-1;

an electric appliance control cabinet 3-1 is fixed on one side edge of the dynamic test working platform table-board 1-1, a plurality of groups of control elements are arranged in the electric appliance control cabinet 3-1, and the sliding table 14-1 and the dynamic test working platform table-board 1-1 are adjusted to be matched with the electric appliance control cabinet 3-1 so as to dynamically test the data of the electric cylinder 20-1.

The device is manufactured to get rid of the fact that a traditional electric cylinder testing device can only statically detect the performance of the electric cylinder, the dynamic testing working platform can automatically adjust the state of the intelligent quality inspection device for the comprehensive performance of the electric cylinder to realize dynamic detection, the process can simulate the automatic detection state of the electric cylinder 20-1 in a dynamic environment, the detection of eight indexes of current, voltage, thrust, tension, static load, stroke, noise and Hall signals can be completed by the electric cylinder 20-1 product on a detection station through only one reciprocating stroke, the detection time of the electric cylinder is greatly shortened at a quick detection speed, the detection efficiency is improved, and meanwhile, the detection accuracy of the electric cylinder can be improved through dynamic monitoring.

For further understanding of the present apparatus, the apparatus will be described in detail with reference to the electric cylinder 20-1.

Referring to fig. 3, two tracks 9-1 are arranged on the surface of a guide rail base 7-1, a track groove is arranged at the bottom of a sliding table 14-1, the sliding table 14-1 can freely slide along the tracks 9-1, a first lead screw 10-1 is spirally arranged in the sliding table 14-1 in a penetrating manner, one end of the first lead screw 10-1 is connected to a front baffle 8-1, the other end of the first lead screw is connected with an output shaft of a servo motor 13-1, a bearing seat 11-1 is arranged between the output shaft of the servo motor 13-1 and the end of the first lead screw 10-1, the bearing seat 11-1 is connected with the end of the first lead screw 10-1 and the output shaft of the servo motor 13-1, and the bearing seat is arranged to facilitate later maintenance of the connection part of the device; in the figure, a stop block 17-1 is fixedly inserted into a stop block fixing pin 17-2 on the sliding block 17-1, an electric cylinder fixing bolt 19-1 is inserted into a notch of the opening groove block 19-2, and the electric cylinder fixing bolt 19-1 penetrates through the electric cylinder 20-1 to be fixed.

In FIG. 4, a concrete structure of the dynamic testing platform can be seen, a rotating shaft pin 4-5 is arranged on the side of the dynamic testing platform base 1-2 parallel to the telescopic rod sliding base 6-1, the rotating shaft pin 4-5 is inserted into the dynamic testing platform base 1-2 and the dynamic testing platform table-board 1-1, so that the two are rotatably connected, in addition, a telescopic mechanism is arranged between the dynamic testing platform table-board 1-1 and the telescopic rod sliding base 6-1, the telescopic mechanism comprises a telescopic rod sliding base 6-1, the connecting pin 4 on the telescopic rod sliding base 6-1 is hinged with a right telescopic rod base 5-1, a left telescopic rod base 5-2, a right telescopic rod base 5-1 and a left telescopic rod base 5-2, a right telescopic rod 5-4 and a right telescopic rod are correspondingly and movably inserted into the right telescopic rod base 5-2, The left telescopic rod 5-3, the right telescopic rod 5-4 and the left telescopic rod 5-3 are hinged to the dynamic test working platform table-board 1-1 through a connecting bolt 4, a second lead screw 6-2 penetrates through the middle of the telescopic rod sliding base 6-1 in a spiral mode, two ends of the second lead screw 6-2 are vertically connected to two sides of the dynamic test working platform base 1-2 in a switching mode, one end of the second lead screw 6-2 is connected with an output shaft of a motor 3-8, the motor 3-8 is started to control the fan-shaped movement of the dynamic test working platform table-board 1, and dynamic monitoring of the device is achieved.

Wherein the side elevation of the electrical appliance control cabinet 3-1 is sequentially provided with a touch screen 3-2, a high-speed counting module 3-3, a programmable controller 3-4, an analog quantity conversion module 3-5, a voltage sensor 3-6 and a current sensor 3-7 from top to bottom, the specific connection modes of the control units are that an electric cylinder 20-1 is respectively and electrically connected with the voltage sensor 3-6 and the current sensor 3-7, a force measurement sensor 16-1, the voltage sensor 3-6 and the current sensor 3-7 are respectively and electrically connected with the analog quantity conversion module 3-5, a grating ruler 18-1 is electrically connected with the high-speed counting module 3-3, the analog quantity conversion module 3-5, the touch screen 3-2 and the high-speed counting module 3-3 are respectively and electrically connected with the programmable controller 3-4, and an electric appliance control cabinet 3-1.

In order to facilitate the transfer of equipment, the bottom of the base 1-2 of the dynamic test working platform is also fixedly provided with an integral base 1-3, the lower end of the integral base 1-3 is also fixedly provided with 6 support columns, and the lower ends of the support columns are provided with rollers 2.

The device is used in the concrete work: an electric cylinder 20-1 to be tested is placed on an open slot on the right side of a bottom plate of the intelligent quality inspection equipment for comprehensive performance of the electric cylinder, the electric cylinder is fixed by using an electric cylinder fixing bolt 19-1, a start button is pressed down, the electric cylinder 20-1 is pushed out, meanwhile, a control module of various sensors including a servo motor 13-1 sends a real-time numerical value of the electric cylinder 20-1 to a PLC (programmable logic controller), the rotating speed of the servo motor 20-1 is controlled after calculation and analysis, real-time adjustable stepless load is provided for the electric cylinder 20-1 to ensure that the electric cylinder keeps a stable load in the operation process, when the electric cylinder is pushed out to a limit position, the servo motor 20-1 rotates reversely to apply a reverse force to the electric cylinder to perform static load test, after the test is finished, the electric cylinder retracts, the servo motor 20-1 drives a sliding table 14-1 to continue to provide the real-time adjustable stepless load for the electric cylinder to ensure that the electric cylinder keeps the stable load in the retraction process, after retraction, the guide rail base 7-1 is provided with a grating ruler 18-1, a sliding ruler 18-2 and a detectable stroke, and detection is finished by eight indexes of current, voltage, thrust, pull, static load, stroke, noise and Hall signals of the electric cylinder.

The invention provides a dynamic test working platform in order to simulate the shaking state of an electric cylinder in practical application. By driving a rear end motor 3-8 of a base 1-2 of the dynamic testing working platform, a lead screw 6-2 drives a telescopic rod sliding base 6-1 to move, a left telescopic rod 5-3 and a right telescopic rod 5-4 start to extend out, when the telescopic rod sliding base 6-1 and the telescopic rods reach extreme positions, the motor 3-8 stops rotating, the rotation angle of the working platform is 90 degrees at the moment, then the telescopic rod sliding base 6-1 and the telescopic rods 5-3 and 5-4 run reversely, and the dynamic working state of the electric cylinder under the actual application environment is simulated by the circulation.

It will be appreciated by those skilled in the art that the invention may be embodied in other specific forms without departing from the spirit or essential characteristics thereof. The embodiments disclosed above are therefore to be considered in all respects as illustrative and not restrictive. All changes which come within the scope of or equivalence to the invention are intended to be embraced therein.

Claims (10)

1. Electric jar comprehensive properties intelligence quality testing equipment work platform, characterized by: the device comprises an electric cylinder comprehensive performance intelligent quality inspection device and a dynamic test working platform;

electric jar comprehensive properties intelligence quality testing equipment includes: a front baffle (8-1) and a rear baffle (8-2) are fixed on two sides of the short side of the guide rail base (7-1), a grating ruler (18-1) is fixed on the long side of the guide rail base (7-1), and a sliding tooth (18-2) slides on the grating ruler (18-1);

a sliding table (14-1) which is in sliding connection with the guide rail base (7-1) is arranged between the front baffle (8-1) and the rear baffle (8-2);

a fixed block (15-1) and a sliding block (15-2) with a mounting groove are arranged on the surface of the sliding table (14-1), and the force-measuring sensor (16-1) is clamped and fixed between the fixed block (15-1) and the sliding block (15-2);

an electric cylinder (20-1) is coaxially and fixedly arranged between the mounting groove and the notch of the opening groove block (19-2), and the sliding table (14-1) is adjusted to test the data of the electric cylinder (20-1);

the dynamic test working platform comprises: the device comprises a base (1-2), a telescopic rod sliding base (6-1) is arranged between two side edges of the base (1-2) in a sliding mode, the base (1-2) is connected with a dynamic test working platform table-board (1-1) in an opening-closing hinge mode, and a plurality of groups of electric cylinder comprehensive performance intelligent quality inspection equipment are fixedly installed on the side, opposite to the telescopic rod sliding base (6-1), of the dynamic test working platform table-board (1-1);

an electric appliance control cabinet (3-1) is fixed on one side edge of the dynamic test working platform table-board (1-1), a plurality of groups of control units are arranged in the electric appliance control cabinet (3-1), and the sliding table (14-1) and the dynamic test working platform table-board (1-1) are adjusted and matched with the electric appliance control cabinet (3-1) so as to dynamically test data of the electric cylinder (20-1).

2. The working platform of the electric cylinder comprehensive performance intelligent quality inspection equipment as claimed in claim 1, wherein the working platform comprises: the guide rail device is characterized in that two rails (9-1) are arranged on the surface of the guide rail base (7-1), a rail groove is formed in the bottom of the sliding table (14-1), a first lead screw (10-1) penetrates through the inner spiral of the sliding table (14-1), one end of the first lead screw (10-1) is connected to the front baffle (8-1), and the other end of the first lead screw is connected with an output shaft of a servo motor (13-1).

3. The working platform of the electric cylinder comprehensive performance intelligent quality inspection equipment as claimed in claim 2, wherein: a bearing seat (11-1) is arranged between the output shaft of the servo motor (13-1) and the end of the first lead screw (10-1), and the bearing seat (11-1) is connected with the end of the first lead screw (10-1) and the output shaft of the servo motor (13-1).

4. The electric cylinder comprehensive performance intelligent quality inspection equipment working platform according to claim 3, which is characterized in that: a stop block (17-1) is fixedly inserted into the stop block fixing pin (17-2) on the sliding block (17-1); an electric cylinder fixing bolt (19-1) is inserted in the notch of the opening groove block (19-2) so as to fix the electric cylinder (20-1).

5. The working platform of the intelligent quality inspection equipment for the comprehensive performance of the electric cylinder as claimed in claim 4, wherein: the dynamic test working platform base (1-2) is hinged with the dynamic test working platform table-board (1-1) through a side rotating shaft bolt (4-5) parallel to the telescopic rod sliding base (6-1).

6. The electric cylinder comprehensive performance intelligent quality inspection equipment working platform according to claim 5, which is characterized in that: a telescopic mechanism is arranged between the dynamic test working platform table surface (1-1) and the telescopic rod sliding base (6-1); the two ends of the telescopic mechanism are correspondingly hinged with the dynamic test working platform surface (1-1) and the telescopic rod sliding base (6-1).

7. The electric cylinder comprehensive performance intelligent quality inspection equipment working platform according to claim 6, which is characterized in that: the telescopic mechanism comprises a telescopic rod sliding base (6-1), a right telescopic rod base (5-1) and a left telescopic rod base (5-2) are hinged to a connecting bolt (4) on the telescopic rod sliding base (6-1), a right telescopic rod (5-4) and a left telescopic rod (5-3) are correspondingly and movably inserted in the right telescopic rod base (5-1) and the left telescopic rod base (5-2), and the connecting bolt (4) of the right telescopic rod (5-4) and the left telescopic rod (5-3) is hinged to the dynamic test working platform surface (1-1).

8. The electric cylinder comprehensive performance intelligent quality inspection equipment working platform according to claim 7, which is characterized in that: a second lead screw (6-2) is spirally arranged in the middle of the sliding base (6-1) in a penetrating mode, two ends of the second lead screw (6-2) are perpendicularly connected to two sides of the base (1-2) in a rotating mode, and one end of the second lead screw (6-2) is connected with an output shaft of a motor (3-8).

9. The electric cylinder comprehensive performance intelligent quality inspection equipment working platform according to claim 8, characterized in that: the side vertical surface of the electric appliance control cabinet (3-1) is sequentially provided with a touch screen (3-2), a high-speed counting module (3-3), a programmable controller (3-4), an analog quantity conversion module (3-5), a voltage sensor (3-6) and a current sensor (3-7) from top to bottom;

the electric cylinder (20-1) is respectively and electrically connected with a voltage sensor (3-6) and a current sensor (3-7), the force measuring sensor (16-1), the voltage sensor (3-6) and the current sensor (3-7) are respectively and electrically connected with an analog quantity conversion module (3-5), the grating ruler (18-1) is electrically connected with a high-speed counting module (3-3), and the analog quantity conversion module (3-5), the touch screen (3-2) and the high-speed counting module (3-3) are respectively and electrically connected with a programmable controller (3-4) and an electric appliance control cabinet (3-1).

10. The working platform of the electric cylinder comprehensive performance intelligent quality inspection equipment according to any one of claims 1 to 9, which is characterized in that: the bottom of the base (1-2) is also fixed with an integral base (1-3), the lower end of the integral base (1-3) is fixed with 6 supporting columns, and the lower ends of the supporting columns are provided with rollers (2).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210207421.6A CN114441210A (en) | 2022-03-04 | 2022-03-04 | Working platform of intelligent quality inspection equipment for comprehensive performance of electric cylinder |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210207421.6A CN114441210A (en) | 2022-03-04 | 2022-03-04 | Working platform of intelligent quality inspection equipment for comprehensive performance of electric cylinder |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN114441210A true CN114441210A (en) | 2022-05-06 |

Family

ID=81358653

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210207421.6A Pending CN114441210A (en) | 2022-03-04 | 2022-03-04 | Working platform of intelligent quality inspection equipment for comprehensive performance of electric cylinder |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN114441210A (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115096633A (en) * | 2022-08-23 | 2022-09-23 | 江苏万泰电机有限公司 | Sliding table type electric cylinder detection device |

| CN117169563A (en) * | 2023-11-02 | 2023-12-05 | 江苏轩铭智能装备有限公司 | Regulator cubicle terminal strip debugging device |

-

2022

- 2022-03-04 CN CN202210207421.6A patent/CN114441210A/en active Pending

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115096633A (en) * | 2022-08-23 | 2022-09-23 | 江苏万泰电机有限公司 | Sliding table type electric cylinder detection device |

| CN117169563A (en) * | 2023-11-02 | 2023-12-05 | 江苏轩铭智能装备有限公司 | Regulator cubicle terminal strip debugging device |

| CN117169563B (en) * | 2023-11-02 | 2024-01-26 | 江苏轩铭智能装备有限公司 | Regulator cubicle terminal strip debugging device |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN114441210A (en) | Working platform of intelligent quality inspection equipment for comprehensive performance of electric cylinder | |

| CN216846939U (en) | Working platform of intelligent quality inspection equipment for comprehensive performance of electric cylinder | |

| CN108318363B (en) | Detection device and detection method for wear of bottom pivot mushroom head | |

| CN211121940U (en) | Automatic detection device for sliding force of sliding block | |

| CN110132584A (en) | A kind of data acquisition device and method of ball screw assembly, life prediction | |

| CN207197657U (en) | Corner machine is repaiied in automatic loading | |

| CN207019890U (en) | A kind of seat chair back durability test machine | |

| CN111220910A (en) | Permanent magnet motor magnetic block installation direction automatic checkout device | |

| CN109839312B (en) | Device for calibrating static rigidity of mooring cable in air | |

| CN206684273U (en) | A kind of electromechanical monitoring device | |

| CN215768094U (en) | Shield constructs machine cutter abrasion testing machine | |

| CN209689660U (en) | A kind of Multifunction Sensor performance detection machine | |

| CN210834912U (en) | Vicat instrument | |

| CN108982097B (en) | Mechanism transmission efficiency testing device for teaching experiment | |

| CN209706708U (en) | A kind of efficient mistake proofing detection device of axis class outer diameter | |

| CN203745005U (en) | Measuring instrument | |

| CN218383068U (en) | Electrostatic field distribution measuring device | |

| CN111157387A (en) | Roller type friction and wear testing machine and method | |

| CN205940978U (en) | Displacement right angle deviator and cam measurement laboratory bench | |

| CN220104367U (en) | Intelligent metering calibration device of dynamometer | |

| CN207147680U (en) | A kind of motor propulsion test device | |

| CN219736190U (en) | Automobile engine bearing cap height detection device | |

| CN218181046U (en) | Comprehensive test bed for alternating current motor | |

| CN213239459U (en) | Loading test bed for agricultural machinery complete machine engine | |

| CN214842995U (en) | Displacement sensor detection device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |