CN113530066A - Preassembled fixing piece seam-remaining type assembled ceiling and installation mode - Google Patents

Preassembled fixing piece seam-remaining type assembled ceiling and installation mode Download PDFInfo

- Publication number

- CN113530066A CN113530066A CN202110936984.4A CN202110936984A CN113530066A CN 113530066 A CN113530066 A CN 113530066A CN 202110936984 A CN202110936984 A CN 202110936984A CN 113530066 A CN113530066 A CN 113530066A

- Authority

- CN

- China

- Prior art keywords

- keel

- buckling

- inverted

- fixing piece

- fixture

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B9/00—Ceilings; Construction of ceilings, e.g. false ceilings; Ceiling construction with regard to insulation

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B9/00—Ceilings; Construction of ceilings, e.g. false ceilings; Ceiling construction with regard to insulation

- E04B9/06—Ceilings; Construction of ceilings, e.g. false ceilings; Ceiling construction with regard to insulation characterised by constructional features of the supporting construction, e.g. cross section or material of framework members

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B9/00—Ceilings; Construction of ceilings, e.g. false ceilings; Ceiling construction with regard to insulation

- E04B9/06—Ceilings; Construction of ceilings, e.g. false ceilings; Ceiling construction with regard to insulation characterised by constructional features of the supporting construction, e.g. cross section or material of framework members

- E04B9/12—Connections between non-parallel members of the supporting construction

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B9/00—Ceilings; Construction of ceilings, e.g. false ceilings; Ceiling construction with regard to insulation

- E04B9/18—Means for suspending the supporting construction

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B9/00—Ceilings; Construction of ceilings, e.g. false ceilings; Ceiling construction with regard to insulation

- E04B9/22—Connection of slabs, panels, sheets or the like to the supporting construction

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B9/00—Ceilings; Construction of ceilings, e.g. false ceilings; Ceiling construction with regard to insulation

- E04B9/22—Connection of slabs, panels, sheets or the like to the supporting construction

- E04B9/28—Connection of slabs, panels, sheets or the like to the supporting construction with the slabs, panels, sheets or the like having grooves engaging with horizontal flanges of the supporting construction or accessory means connected thereto

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04G—SCAFFOLDING; FORMS; SHUTTERING; BUILDING IMPLEMENTS OR AIDS, OR THEIR USE; HANDLING BUILDING MATERIALS ON THE SITE; REPAIRING, BREAKING-UP OR OTHER WORK ON EXISTING BUILDINGS

- E04G21/00—Preparing, conveying, or working-up building materials or building elements in situ; Other devices or measures for constructional work

- E04G21/14—Conveying or assembling building elements

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Mechanical Engineering (AREA)

- Finishing Walls (AREA)

Abstract

The invention relates to the field of architectural decoration, in particular to a preassembled fixing piece seam-remaining type fabricated ceiling which comprises a keel component, a fixing piece and a veneer, wherein the keel component comprises an inverted A keel and an inner buckling keel with a pendant, a first buckling part used for buckling with the inverted A keel is arranged above the inner buckling keel with the pendant, and a second buckling part used for buckling with the fixing piece is arranged below the inner buckling keel with the pendant; the mounting below is provided with the recess that is used for the gomphosis decorative board, and the outside limit is provided with and is used for the joint groove with second buckling portion adaptation, and the decorative board is close to its edge and is provided with the limit of bending, and the limit of bending is embedded inside the recess and fixed with it, is provided with a piece of seam limit of piecing together between the edge of the limit of bending and decorative board. The invention adopts the integral structure as a card insertion design, improves the installation efficiency of the integral suspended ceiling, overcomes the technical problem that the assembled suspended ceiling is not detachable, and simultaneously improves the integral attractiveness and safety of the suspended ceiling.

Description

Technical Field

The invention relates to the field of architectural decoration, in particular to a preassembled fixture seam-retaining type assembled ceiling and an installation mode.

Background

With the promotion of factory production and modularized installation in the field of architectural decoration, the application of the light-weight high-strength aluminum honeycomb panel in indoor decoration is wider and wider. The aluminum honeycomb panel is a plate for suspended ceilings, which is formed by compounding a double-sided aluminum skin and an aluminum honeycomb core at a high temperature. In recent years, due to the excellent performance, the aluminum honeycomb plate suspended ceiling is more and more favored by owners, so that the decoration cases of the aluminum honeycomb plate suspended ceiling are more and more. However, most of fabricated suspended ceilings in the market adopt the forms of exposed lines and combined frames for single-block installation, so that the structure is single, the aesthetic property is poor, and meanwhile, no good solution is provided for the edge part of the suspended ceiling and the abutted seam of the veneer.

For example, a hook type suspended ceiling mounting structure with the application number of CN202010434202.2 comprises a screw rod, a hanging piece, a transverse line, a vertical line, a binding line, a suspended ceiling plate and a filling plate, wherein a plurality of transverse lines and vertical lines are respectively arranged below a wall top through a plurality of hanging pieces and the screw rod, the transverse lines are arranged at intervals along the transverse direction, the vertical lines are arranged at intervals along the longitudinal direction, a ceiling board is arranged between two adjacent transverse lines or vertical lines, the edge folding line is arranged around the wall, an edge folding ceiling board is arranged between the edge folding line and the adjacent transverse line or vertical line, the ceiling board is arranged on the hook supporting legs of the transverse lines through clamping hooks at two ends, a filling plate is arranged between the ceiling board and the first limit baffle frame, establish the furred ceiling on receiving the limit line and hold the bracket, the spacing fender frame of third, install the infill panel between receiving limit furred ceiling board and the spacing fender frame of third. The ceiling mounting structure has the advantages of simpler installation and firm installation, but the problem cannot be solved.

Disclosure of Invention

The invention provides a preassembled fixture seam-remaining assembled ceiling and an installation method thereof, aiming at overcoming the defects that the construction is single and the aesthetic property is poor due to the fact that most assembled ceilings in the prior art are installed in a single-block mode in a form of exposed lines and combined frames, and the processing on the edges of the ceilings and the abutted seams of decorative panels is not in place.

In order to achieve the purpose, the invention is realized by the following technical scheme:

a preassembled fixture gap-retaining assembled suspended ceiling comprises a keel assembly, a fixture arranged below the keel assembly and a veneer fixedly connected with the fixture,

the keel component comprises an inverted A keel and an inner-buckled keel with a pendant, wherein the inverted A keel is fixedly connected with a wall body through the pendant, a first buckling part used for buckling with the inverted A keel is arranged above the inner-buckled keel with the pendant, and a second buckling part used for buckling with a fixing part is arranged below the inner-buckled keel with the pendant;

the fixing piece is formed by combining a U-shaped fixing piece A and a U-shaped fixing piece B side by side, grooves for embedding the veneer are formed below the U-shaped fixing piece A and the U-shaped fixing piece B, and clamping grooves matched with the second buckling parts are formed in the outer side edges of the U-shaped fixing piece A and the U-shaped fixing piece B respectively;

the decorative panel is provided with a bending edge near the edge, the bending edge is embedded in the groove and fixed with the groove, and a splicing edge is arranged between the bending edge and the edge of the decorative panel.

The inverted A keel, the self-pendant inner buckling keel, the U-shaped fixing piece A, U type fixing piece B, the veneer and other members in the invention are all designed in a card insertion mode, so that the mounting efficiency of the suspended ceiling can be improved in the mounting process, and the technical problem that the assembled suspended ceiling is not detachable is solved.

Meanwhile, the assembly type ceiling abandons the installation method of the traditional ceiling in the form of a bright line and a combined frame, and the design of a large veneer is adopted, and because the veneer is provided with a bending edge, the veneer can be embedded with a groove in a fixing piece and then is fixed in a gluing or screw connection mode, so that the technical blank that the assembly type ceiling cannot be designed into a large plate is solved. Meanwhile, due to the design of the edge joint, the edge joint can cover the fixing piece when the two decorative panels are connected, so that the effect of a hidden process joint can be achieved in the splicing process, and the problems of uneven panel surface, non-uniform remained joint, non-attractive appearance of the whole body and the like after installation are solved.

Preferably, the inverted-a keel is hollow and inverted-a-shaped, the width of the lower end of the inverted-a keel is smaller than that of the upper end of the inverted-a keel, and the top of the inverted-a keel is composed of two bending edges bending towards the inside of the inverted-a keel, so that a fastening groove matched with the first fastening part is formed at the top of the inverted-a keel.

Preferably, the hanging part comprises a V-shaped hook matched with the inverted A keel in shape, the top of one side of the V-shaped hook is provided with a bending section, and the bending section is provided with a hanging rod connected with a wall body through a bolt.

The inverted A keel and the V-shaped hook are matched in shape, and when the V-shaped hook is fixed on the top of a wall through the hanging rod, the inverted A keel can be inserted into the V-shaped groove of the V-shaped hook, so that the purpose of inserting the V-shaped hook is achieved, the purposes of quick installation and quick adjustment and disassembly are achieved, and the installation efficiency in the installation process is effectively improved.

Preferably, the first buckling part at the upper end of the self-pendant inner buckling keel is formed by combining two obliquely arranged L-shaped clamping claws, the second buckling part at the lower end of the self-pendant inner buckling keel is in a shape like a Chinese character 'ji', and the middle parts of the left side and the right side of the self-pendant inner buckling keel are bent towards the inside of the self-pendant inner buckling keel to form the clamping part.

The first buckling part at the upper end of the inner buckling keel with the pendant is composed of two L-shaped clamping claws, when the inverted A keel is required to be buckled with the first buckling part, the inner buckling keel with the pendant is only required to be pushed upwards, so that the bottom of the inverted A keel is embedded in a gap between the two L-shaped clamping claws of the first buckling part, the L-shaped clamping claws are continuously pushed upwards along with the inner buckling keel with the pendant to be opened, and the L-shaped clamping claws can be buckled in the buckling grooves at the top of the inverted A keel after being pushed to the top end.

Preferably, the opening directions of the first engaging portion and the second engaging portion are perpendicular to each other.

Preferably, the cross section of the U-shaped fixing piece A is in a shape like a Chinese character ji, the left side and the right side of the U-shaped fixing piece A are the same in height, a first concave edge is arranged in the middle of one side, and a clamping edge is outwards arranged at the bottom of the other side.

Preferably, the cross section of the U-shaped fixing piece B is also in a shape like a Chinese character ji, the height of one side edge of the U-shaped fixing piece B is lower than that of the other side edge, the lower side edge of the U-shaped fixing piece B is matched with the clamping edge, the U-shaped fixing piece A and the U-shaped fixing piece B are equal in height, and a second concave edge is arranged in the middle of the other side edge of the U-shaped fixing piece B.

The fixing piece is formed by combining a U-shaped fixing piece A and a U-shaped fixing piece B, wherein the U-shaped fixing piece A and the U-shaped fixing piece B are in a shape like a Chinese character 'ji', one of two sides is a straight side, and the other side is provided with an inner concave side. Because the bottom of the straight flange of U type mounting A still outwards is provided with a joint limit, consequently U type mounting B's straight flange can be in cooperation in-process support and lean on above the joint limit, and this kind of cooperation mode can guarantee that U type mounting A and U type mounting B combination can promote greatly in the stability when fixed with the second buckling parts, prevents that U type mounting A and U type mounting B from following second buckling parts below roll-off.

In addition, U type mounting A/B sets up when furred ceiling limit portion, can improve the intensity at furred ceiling edge, has reduced the loss rate of panel.

Preferably, the width of the clamping edge is twice the width of the splicing edge.

According to the ceiling suspended ceiling, the width of the clamping edge is set to be twice of the width of the splicing edge, so that after the U-shaped fixing piece A and the U-shaped fixing piece B are respectively clamped with one veneer, the two splicing edges can just completely cover the clamping edge, the clamping edge is prevented from being exposed on the premise that the gap between the veneers is reduced as much as possible, and the attractiveness of the whole ceiling is greatly improved.

Preferably, the veneer comprises a high plate, a level-lowering plate and a low plate, wherein the high plate is fixedly connected with the fixing piece, one end of the level-lowering plate is connected with the fixing piece, and the other end of the level-lowering plate is connected with the low plate through an angle iron and a bolt.

A mounting method of a preassembled fixture seam-retaining type assembled ceiling comprises the following steps:

s.1, preparing materials, namely snapping lines on the top surface of a wall;

s.2, fixedly connecting the hanging piece with the wall body through an expansion bolt, and then fixing the inverted A keel on the hanging piece;

s.3, pushing the self-pendant inner-buckling keel upwards to enable the first buckling part and the inverted A keel to be clamped mutually, and enabling all the self-pendant inner-buckling keels to be fixed on the inverted A keel;

s.4, fixedly embedding the bent edges of the high-level board in the veneer into grooves of the U-shaped fixing piece A and the U-shaped fixing piece B respectively, and then sequentially clamping the assembled high-level board, the U-shaped fixing piece A and the U-shaped fixing piece B into a second buckling part of the inner buckling keel with the hanging pieces to complete the installation of the high-level board;

and S.5, sequentially installing the falling-level plate and the low-level plate, and fixedly connecting the falling-level plate and the low-level plate through angle iron, so that the installation of the whole falling-level ceiling is completed.

Therefore, the invention has the following beneficial effects:

(1) the invention adopts the veneer design of the large plate, and fills the technical blank that the assembled ceiling can not be designed into the large plate;

(2) the hidden seam design is adopted at the seam of the veneer, so that the integral attractiveness and safety of the suspended ceiling are improved;

(3) the integral structure is designed in a clamping manner, so that the mounting efficiency of the integral suspended ceiling is improved, and the technical problem that the assembled suspended ceiling is not detachable is solved;

(4) when the U-shaped fixing piece A/B is arranged at the edge of the suspended ceiling, the strength of the edge of the veneer can be enhanced, the loss rate of the plate is reduced, and the problems of the scheme of processing the edge and splicing the two veneers of the conventional fabricated aluminum honeycomb suspended ceiling are solved;

(5) the factory prefabricated U-shaped fixing piece is connected with the plate to form a standardized module, so that the requirement of assembled modularized standardized installation is met;

(7) the problems of uneven board surface, non-uniform remained seams, non-attractive integral appearance and the like after installation are solved.

Drawings

FIG. 1 is a schematic diagram of a structure of the present invention.

Fig. 2 is a schematic structural view of another angle of the present invention.

Fig. 3 is a top view of the present invention.

Fig. 4 is a side view of the present invention.

Fig. 5 is an enlarged view of the invention at a in fig. 1.

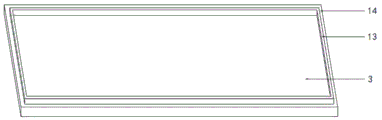

Fig. 6 is a schematic structural view of the veneer of the present invention.

Figure 7 is a schematic structural view of the inverted a keel of the invention.

Figure 8 is a front view of the inverted a keel of the invention.

FIG. 9 is a schematic view of the structure of the hanger of the present invention.

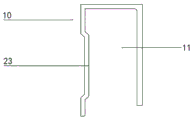

Fig. 10 is a schematic structural view of the inner buckle keel with the hanging piece of the invention.

Figure 11 is a side view of the self-contained pendant inside-buckling keel of the present invention.

Fig. 12 is a front view of the self-contained pendant inside-buckling keel of the present invention.

Fig. 13 is a schematic structural view of the U-shaped fastener a of the present invention.

Figure 14 is a front view of the U-shaped fastener a of the present invention.

Fig. 15 is a schematic structural view of the U-shaped fastener B of the present invention.

Figure 16 is a front view of the U-shaped fastener B of the present invention.

Wherein: the keel assembly comprises a keel assembly 1, a fixing piece 2, a veneer 3, an inverted A keel 4, an inner buckling keel 5 with a hanging piece, a hanging piece 6, a first buckling part 7, a second buckling part 8, a U-shaped fixing piece A9, a U-shaped fixing piece B10, a groove 11, a clamping groove 12, a bending edge 13, a splicing edge 14, a bending edge 15, a buckling groove 16, a V-shaped hook 17, a hanging rod 18, a bending section 19, a clamping part 20, a first inner concave edge 21, a clamping edge 22, a second inner concave edge 23, a high-level plate 24, a falling-level plate 25, a low-level plate 26, angle iron 27 and an L-shaped clamping claw 28.

Detailed Description

The invention is further described with reference to the drawings and the specific embodiments. Those skilled in the art will be able to implement the invention based on these teachings. Moreover, the embodiments of the present invention described in the following description are generally only some embodiments of the present invention, and not all embodiments. Therefore, all other embodiments obtained by a person of ordinary skill in the art based on the embodiments of the present invention without any creative effort shall fall within the protection scope of the present invention.

Example 1

Referring to fig. 1-16, a preassembled fixture seam-retaining type fabricated suspended ceiling comprises a keel assembly 1, a fixture 2 arranged below the keel assembly 1 and a veneer 3 fixedly connected with the fixture 2.

Fossil fragments subassembly 1 is including falling A fossil fragments 4 and detaining fossil fragments 5 in taking the pendant certainly, wherein:

the inverted A keel 4 is strip-shaped, the cross section of the inverted A keel is hollow inverted A-shaped with the width of the lower end smaller than that of the upper end, and the top of the inverted A keel is composed of two bending edges 15 bending towards the inner cavity of the inverted A keel, so that a buckling groove 16 matched with the first buckling part 7 is formed at the top of the inverted A keel 4.

In addition, the inverted A keel 4 can be fixedly connected with a wall body through the hanging piece 6, the hanging piece 6 comprises a V-shaped hook 17 of which the shape is matched with that of the inverted A keel 4, the top of one side of the V-shaped hook 17 is provided with a bending section 19, and the bending section 19 is provided with a hanging rod 18 connected with the wall body through a bolt. When the V-shaped hook 17 is fixed on the wall top through the hanging rod 18, the inverted A keel 4 can be inserted into the V-shaped groove of the V-shaped hook 17, the purpose of card insertion is realized, the purposes of quick installation and quick adjustment and disassembly of the inverted A keel 4 are realized, and the installation efficiency in the installation process is effectively improved.

The self-provided pendant inner-buckled keel 5 is also long-strip-shaped, a first buckling part 7 formed by combining two obliquely-arranged L-shaped clamping jaws 28 is arranged above the self-provided pendant inner-buckled keel 5, when the inverted A keel 4 is required to be buckled with the first buckling part 7, the self-provided pendant inner-buckled keel 5 is only required to be upwards pushed, the bottom of the inverted A keel 4 is embedded between two L-shaped clamping jaws 19 of the first buckling part 7, when the self-provided pendant inner-buckled keel 5 continues to be upwards pushed, the L-shaped clamping jaws 19 can be opened, and after the top end is pushed, the L-shaped clamping jaws 19 can be buckled in the buckling groove 16 at the top of the inverted A keel 4 in a returning mode.

A second buckling part 8 which is buckled with the fixing part 2 in a shape like a Chinese character 'ji' is arranged below the inner buckling keel 5 with the pendant, and the middle parts of the left side and the right side of the second buckling part 8 are bent towards the inside of the second buckling part, so that a clamping part 20 for clamping the fixing part 2 is formed.

In addition, the opening direction of the second buckling part 8 of the buckling part is perpendicular to the opening direction of the first buckling part 7, so that when the hanging piece inner-buckled keel 5 is fixed with the inverted A keel 4, the hanging piece inner-buckled keel 5 is perpendicular to the inverted A keel 4, and the fixing part 2 is perpendicular to the hanging piece inner-buckled keel 5.

The fixing member 2 is formed by combining a U-shaped fixing member A9 and a U-shaped fixing member B10 side by side, a groove 11 for embedding the veneer 3 is formed below the two, and a clamping groove 12 for matching with the second buckling part 8 is formed on the outer side edge of each of the U-shaped fixing member A9 and the U-shaped fixing member B10. Therefore, when the U-shaped fastener A9 and the U-shaped fastener B10 are combined to form the fastener 2, the clamping portion 20 of the second engaging portion 8 in the shape of the "ziji" can be just engaged with the engaging groove 12, thereby fixing the fastener 2.

To describe the structure of the U-shaped fastener A9 and the U-shaped fastener B10 more closely, the present embodiment further describes both below:

the section of the U-shaped fixing piece A9 is in a shape of a Chinese character ji, the left side and the right side of the U-shaped fixing piece A9 are the same in height, a first concave edge 21 is arranged in the middle of one side, the other side is a straight edge, and a clamping edge 22 is outwards arranged at the bottom of the straight edge.

The cross section of the U-shaped fixing piece B10 is also in a shape like a Chinese character 'ji', the height of one side edge is lower than that of the other side edge, the lower side edge is a straight edge which can be matched with the clamping edge 22, so that the U-shaped fixing piece A9 and the U-shaped fixing piece B10 are leveled, and the middle part of the other side edge is provided with a second concave edge 23.

Therefore, when the two straight sides of the U-shaped fastener A9 and the U-shaped fastener B10 are attached to each other, the two sides of the combined fastener 2 are respectively provided with a first concave side 21 and a second concave side 23, and the outer portions of the first concave side and the second concave side can be clamped and fixed with the bending portion of the second buckling portion 8. The bending edge 13 of the veneer 3 can be inserted into the area between the first concave edge 21, the second concave edge 23 and the straight edge, and the veneer can be fixed by gluing and screw connection. Because the bottom of the straight edge of the U-shaped fixing piece A is also outwards provided with a clamping edge 22, the straight edge of the U-shaped fixing piece B10 can abut against the clamping edge 22 in the matching process, and the matching mode can ensure that the stability of the combination of the U-shaped fixing piece A9 and the U-shaped fixing piece B10 when the combination is fixed with the second buckling part 8 can be greatly improved, so that the U-shaped fixing piece A9 and the U-shaped fixing piece B10 can be prevented from sliding out of the lower part of the second buckling part 8. In addition, U type mounting A/B not only can be used for connecting decorative board 3 as the connecting piece, when setting both of it at the limit portion of furred ceiling, can improve the intensity at the decorative board edge, has reduced the loss rate of panel.

The veneer 3 comprises a high plate 24, a falling plate 25 and a low plate 26, wherein the high plate 24 is fixedly connected with the fixing member 2, one end of the falling plate 25 is connected with the fixing member 2, and the other end is connected with the low plate 26 through an angle iron 27 by a bolt.

Whether the high plate 24, the falling plate 25 or the low plate 26 is provided with a bending edge 13 near the edge thereof, the bending edge 13 can be embedded inside the groove 11 and fixed with the groove by gluing or nailing. In addition, be provided with a piece of seam limit 14 between the edge of bending limit 13 and decorative board 3, the width on this piece of seam limit 14 is the half of joint limit 22 width, consequently after U type mounting A9 and U type mounting B10 joint has a decorative board 3 respectively, two piece of seam limits 14 can cover joint limit 22 completely just, thereby can be under the prerequisite that reduces the gap between the decorative board 3 as far as, the outer hourglass on joint limit 22 has been prevented, make the aesthetic property of whole furred ceiling promote greatly.

Example 2

A method of installing the preassembled fixture slotted assembly ceiling of embodiment 1, comprising the steps of:

s.1, preparing materials, namely snapping lines on the top surface of a wall;

s.2, fixedly connecting the hanging piece 6 with a wall body through an expansion bolt, fixing the inverted A keel 4 on the hanging piece 6, and then installing base layer components such as wood plastic lines and the like;

s.3, pushing the self-pendant inner buckling keel 5 upwards to enable the first buckling part 7 and the inverted A keel 4 to be clamped mutually, and enabling all the self-pendant inner buckling keels 5 to be fixed on the inverted A keel 4;

s.4, fixedly embedding the bent edges 13 of the high-level plate 24 in the veneer 3 into the grooves 11 of the U-shaped fixing piece A9 and the U-shaped fixing piece B10 respectively, fixing the high-level plate 24, the U-shaped fixing piece A9 and the U-shaped fixing piece B10 in an adhesive or nailing manner, and sequentially clamping the assembled high-level plate 24, the U-shaped fixing piece A9 and the U-shaped fixing piece B10 into the second buckling part 8 of the inner buckling keel 5 with the hanging pieces to complete the installation of the high-level plate 24;

and S.5, sequentially installing the falling plate 25 and the low plate 26, and fixedly connecting the falling plate and the low plate through angle iron 27, thereby completing the installation of the whole falling ceiling.

Claims (10)

1. A preassembled fixture seam-remaining assembled suspended ceiling comprises a keel assembly (1), a fixture (2) arranged below the keel assembly (1) and a veneer (3) fixedly connected with the fixture (2), and is characterized in that,

the keel component (1) comprises an inverted A keel (4) and a self-provided hanging piece inner-buckled keel (5), wherein the inverted A keel (4) is fixedly connected with a wall body through a hanging piece (6), a first buckling part (7) used for being buckled with the inverted A keel (4) is arranged above the self-provided hanging piece inner-buckled keel (5), and a second buckling part (8) used for being buckled with the fixing piece (2) is arranged below the self-provided hanging piece inner-buckled keel (5);

the fixing piece (2) is formed by combining a U-shaped fixing piece A (9) and a U-shaped fixing piece B (10) side by side, grooves (11) for embedding the veneer (3) are formed below the U-shaped fixing piece A and the U-shaped fixing piece B (10), and clamping grooves (12) which are matched with the second buckling parts (8) are formed in the outer side edges of the U-shaped fixing piece A (9) and the U-shaped fixing piece B (10) respectively;

the decorative panel (3) is provided with a bending edge (13) close to the edge of the decorative panel, the bending edge (13) is embedded in the groove (11) and fixed with the groove, and a splicing seam edge (14) is arranged between the bending edge (13) and the edge of the decorative panel (3).

2. The preassembled fixture slit assembled ceiling as claimed in claim 1, characterized in that the inverted-a keel (4) is hollow and has an inverted-a shape, the width of the lower end of the inverted-a keel is smaller than that of the upper end of the inverted-a keel, and the top of the inverted-a keel (4) is formed by two bending edges (15) bending toward the inside of the inverted-a keel, so that a fastening groove (16) matching with the first fastening part (7) is formed at the top of the inverted-a keel (4).

3. The preassembled fixture seam-retaining assembled ceiling as claimed in claim 1 or 2, characterized in that the hanger (6) comprises a V-shaped hook (17) with a shape matched with the inverted a keel (4), a bent section (19) is arranged at the top of one edge of the V-shaped hook (17), and the bent section (19) is provided with a hanging rod (18) for connecting with a wall body through a bolt connection.

4. The preassembled fixture seam-retaining type assembled suspended ceiling of claim 1, wherein the first buckling part (7) at the upper end of the self-hanging inner buckling keel (5) is formed by combining two obliquely arranged L-shaped clamping jaws (28), the second buckling part (8) at the lower end of the self-hanging inner buckling keel (5) is in a shape like a Chinese character 'ji', and the middle parts of the left side and the right side of the self-hanging inner buckling keel are bent inwards to form the clamping part (20).

5. A preassembled fixture stay seam type suspended ceiling as set forth in claim 1 or 4, characterized in that the opening directions of the first fastening part (7) and the second fastening part (8) are perpendicular to each other.

6. The preassembled fixture slit type assembled suspended ceiling as claimed in claim 1, wherein the U-shaped fixture a (9) has a cross section in a shape of a Chinese character ji, the left and right sides of the U-shaped fixture a have the same height, a first concave side (21) is arranged in the middle of one side, and a clamping side (22) is arranged outwards at the bottom of the other side.

7. A preassembled fixture slotted assembly ceiling as set forth in claim 6, characterized in that the U-shaped fixture B (10) is also in a cross section of a shape like a Chinese character 'ji', one side of which has a height lower than that of the other side, the lower side of which is matched with the clamping edge (22) so that the U-shaped fixture A (9) is flush with the U-shaped fixture B (10), and the middle of the other side is provided with a second concave edge (23).

8. A pre-assembled fixed stay-on-slot false ceiling according to claim 6 or 7, characterised in that the width of the snap-on edge (22) is twice the width of the patchwork edge (14).

9. The preassembled fixture slit-type assembled ceiling as claimed in claim 1, characterized in that the veneer (3) comprises a high plate (24), a stepped plate (25) and a low plate (26), wherein the high plate (24) is fixedly connected with the fixture (2), one end of the stepped plate (25) is connected with the fixture (2), and the other end is bolted with the low plate (26) through an angle iron (27).

10. A method of installing a preassembled fixture, slot-type suspended ceiling as set forth in any of claims 1 to 9, comprising the steps of:

s.1, preparing materials, namely snapping lines on the top surface of a wall;

s.2, fixedly connecting the hanging piece (6) with a wall body through an expansion bolt, and then fixing the inverted A keel (4) on the hanging piece (6);

s.3, pushing the self-pendant inner-buckling keel (5) upwards to enable the first buckling part (7) and the inverted A keel (4) to be clamped with each other, and enabling all the self-pendant inner-buckling keels (5) to be fixed on the inverted A keel (4);

s.4, respectively fixedly embedding the bent edges (13) of the high-level plate (24) in the veneer (3) into the grooves (11) of the U-shaped fixing piece A (9) and the U-shaped fixing piece B (10), and then sequentially clamping the assembled high-level plate (24), the U-shaped fixing piece A (9) and the U-shaped fixing piece B (10) into the second buckling part (8) of the inner buckling keel (5) with the hanging piece to complete the installation of the high-level plate (24);

s.5, sequentially installing the falling plate (25) and the low plate (26), and fixedly connecting the falling plate and the low plate through angle iron (27), thereby completing the installation of the whole falling ceiling.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202110936984.4A CN113530066A (en) | 2021-08-16 | 2021-08-16 | Preassembled fixing piece seam-remaining type assembled ceiling and installation mode |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202110936984.4A CN113530066A (en) | 2021-08-16 | 2021-08-16 | Preassembled fixing piece seam-remaining type assembled ceiling and installation mode |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN113530066A true CN113530066A (en) | 2021-10-22 |

Family

ID=78091124

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202110936984.4A Pending CN113530066A (en) | 2021-08-16 | 2021-08-16 | Preassembled fixing piece seam-remaining type assembled ceiling and installation mode |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN113530066A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN114197727A (en) * | 2021-11-25 | 2022-03-18 | 浙江亚厦装饰股份有限公司 | Low-floor-height assembled ceiling structure and mounting method |

-

2021

- 2021-08-16 CN CN202110936984.4A patent/CN113530066A/en active Pending

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN114197727A (en) * | 2021-11-25 | 2022-03-18 | 浙江亚厦装饰股份有限公司 | Low-floor-height assembled ceiling structure and mounting method |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN205444781U (en) | Pendant and pendant combination | |

| CN215888840U (en) | Preassembled fixing piece seam-remaining type assembled ceiling | |

| CN113530066A (en) | Preassembled fixing piece seam-remaining type assembled ceiling and installation mode | |

| CN205421813U (en) | Panel buckle is system of hanging futilely | |

| CN113585592A (en) | Assembled large-plate full-clamping type ceiling and installation method thereof | |

| CN113585597B (en) | Stable structure back-off type assembled suspended ceiling and installation mode | |

| CN214275627U (en) | Lamp slot mounting structure | |

| CN215888825U (en) | High-order decorative board hoisting structure | |

| CN215888874U (en) | Keel connecting structure of full-clamping insertion type ceiling | |

| CN215888829U (en) | Assembled large-plate full-clamping type ceiling | |

| CN215888828U (en) | High-level veneer flush joint mounting structure | |

| CN113293912B (en) | Assembled suspended ceiling edge folding structure and installation method | |

| CN215829761U (en) | Edge folding structure of assembled suspended ceiling | |

| CN102900317B (en) | Unit row window of hidden framing curtain wall | |

| CN210439536U (en) | Herringbone overlapping suspended ceiling | |

| CN211548522U (en) | Connecting structure with decorative surface for decorative panel | |

| CN211523662U (en) | Glass curtain wall assembly structure with randomly adjusted angle | |

| CN112815278A (en) | Lamp slot mounting structure and mounting method thereof | |

| CN215889227U (en) | Connecting device suitable for wall top closing up | |

| CN113585590B (en) | High-position veneer butt-joint mounting structure and mounting method thereof | |

| CN113585588A (en) | High-position veneer hoisting structure and installation method thereof | |

| CN108930375A (en) | A kind of facing panel assembly and its assemble method | |

| CN113585604A (en) | Keel connecting structure of full-clamping insertion type suspended ceiling and mounting method thereof | |

| CN214302408U (en) | Ceiling corner fitting of assembly type wall body mounting structure | |

| CN220504247U (en) | Curtain wall construction with cambered surface molding aluminum plate and vertical sunshade ornamental strip |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |