CN112109396A - Novel waterproof chemical fiber gauze - Google Patents

Novel waterproof chemical fiber gauze Download PDFInfo

- Publication number

- CN112109396A CN112109396A CN202011114265.6A CN202011114265A CN112109396A CN 112109396 A CN112109396 A CN 112109396A CN 202011114265 A CN202011114265 A CN 202011114265A CN 112109396 A CN112109396 A CN 112109396A

- Authority

- CN

- China

- Prior art keywords

- layer

- base material

- gauze

- chemical fiber

- waterproof

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 239000000835 fiber Substances 0.000 title claims abstract description 31

- 239000000126 substance Substances 0.000 title claims abstract description 26

- 239000010410 layer Substances 0.000 claims abstract description 122

- 239000000463 material Substances 0.000 claims abstract description 44

- 239000011241 protective layer Substances 0.000 claims abstract description 19

- 238000004026 adhesive bonding Methods 0.000 claims description 10

- 239000003795 chemical substances by application Substances 0.000 claims description 10

- 239000004744 fabric Substances 0.000 claims description 10

- 239000004698 Polyethylene Substances 0.000 claims description 7

- 230000000844 anti-bacterial effect Effects 0.000 claims description 4

- 235000017166 Bambusa arundinacea Nutrition 0.000 claims description 3

- 235000017491 Bambusa tulda Nutrition 0.000 claims description 3

- 235000015334 Phyllostachys viridis Nutrition 0.000 claims description 3

- 239000004745 nonwoven fabric Substances 0.000 claims description 3

- -1 polyethylene Polymers 0.000 claims description 3

- 241001330002 Bambuseae Species 0.000 claims description 2

- 239000011425 bamboo Substances 0.000 claims description 2

- 239000011248 coating agent Substances 0.000 claims description 2

- 238000000576 coating method Methods 0.000 claims description 2

- 229920000573 polyethylene Polymers 0.000 claims description 2

- 229920000642 polymer Polymers 0.000 claims description 2

- 238000010030 laminating Methods 0.000 claims 4

- 241000233866 Fungi Species 0.000 claims 2

- 239000004743 Polypropylene Substances 0.000 claims 2

- 229920001155 polypropylene Polymers 0.000 claims 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Chemical compound O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 abstract description 27

- 239000012790 adhesive layer Substances 0.000 abstract description 16

- 239000012466 permeate Substances 0.000 abstract description 7

- 230000009471 action Effects 0.000 abstract description 3

- 230000000694 effects Effects 0.000 description 5

- 239000002245 particle Substances 0.000 description 4

- 230000003385 bacteriostatic effect Effects 0.000 description 3

- 230000002706 hydrostatic effect Effects 0.000 description 3

- 238000000034 method Methods 0.000 description 3

- 238000012986 modification Methods 0.000 description 3

- 230000004048 modification Effects 0.000 description 3

- 230000008569 process Effects 0.000 description 3

- 230000001954 sterilising effect Effects 0.000 description 3

- 239000004753 textile Substances 0.000 description 3

- 238000005253 cladding Methods 0.000 description 2

- 150000001875 compounds Chemical class 0.000 description 2

- 239000000047 product Substances 0.000 description 2

- 238000004659 sterilization and disinfection Methods 0.000 description 2

- 241000209128 Bambusa Species 0.000 description 1

- 229920003043 Cellulose fiber Polymers 0.000 description 1

- 229920002101 Chitin Polymers 0.000 description 1

- 229920000742 Cotton Polymers 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 238000009833 condensation Methods 0.000 description 1

- 230000005494 condensation Effects 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000002474 experimental method Methods 0.000 description 1

- 239000012528 membrane Substances 0.000 description 1

- 230000035699 permeability Effects 0.000 description 1

- 239000002994 raw material Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/02—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/12—Layered products comprising a layer of synthetic resin next to a fibrous or filamentary layer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/32—Layered products comprising a layer of synthetic resin comprising polyolefins

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B29/00—Layered products comprising a layer of paper or cardboard

- B32B29/02—Layered products comprising a layer of paper or cardboard next to a fibrous or filamentary layer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B29/00—Layered products comprising a layer of paper or cardboard

- B32B29/06—Layered products comprising a layer of paper or cardboard specially treated, e.g. surfaced, parchmentised

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B33/00—Layered products characterised by particular properties or particular surface features, e.g. particular surface coatings; Layered products designed for particular purposes not covered by another single class

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/02—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer

- B32B5/022—Non-woven fabric

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/22—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed

- B32B5/24—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed one layer being a fibrous or filamentary layer

- B32B5/26—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed one layer being a fibrous or filamentary layer another layer next to it also being fibrous or filamentary

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B7/00—Layered products characterised by the relation between layers; Layered products characterised by the relative orientation of features between layers, or by the relative values of a measurable parameter between layers, i.e. products comprising layers having different physical, chemical or physicochemical properties; Layered products characterised by the interconnection of layers

- B32B7/04—Interconnection of layers

- B32B7/06—Interconnection of layers permitting easy separation

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B7/00—Layered products characterised by the relation between layers; Layered products characterised by the relative orientation of features between layers, or by the relative values of a measurable parameter between layers, i.e. products comprising layers having different physical, chemical or physicochemical properties; Layered products characterised by the interconnection of layers

- B32B7/04—Interconnection of layers

- B32B7/12—Interconnection of layers using interposed adhesives or interposed materials with bonding properties

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/54—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties by welding together the fibres, e.g. by partially melting or dissolving

- D04H1/542—Adhesive fibres

- D04H1/544—Olefin series

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H3/00—Non-woven fabrics formed wholly or mainly of yarns or like filamentary material of substantial length

- D04H3/005—Synthetic yarns or filaments

- D04H3/007—Addition polymers

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H3/00—Non-woven fabrics formed wholly or mainly of yarns or like filamentary material of substantial length

- D04H3/08—Non-woven fabrics formed wholly or mainly of yarns or like filamentary material of substantial length characterised by the method of strengthening or consolidating

- D04H3/14—Non-woven fabrics formed wholly or mainly of yarns or like filamentary material of substantial length characterised by the method of strengthening or consolidating with bonds between thermoplastic yarns or filaments produced by welding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/02—Synthetic macromolecular fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/02—Synthetic macromolecular fibres

- B32B2262/0253—Polyolefin fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/06—Vegetal fibres

- B32B2262/062—Cellulose fibres, e.g. cotton

- B32B2262/065—Lignocellulosic fibres, e.g. jute, sisal, hemp, flax, bamboo

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/70—Other properties

- B32B2307/724—Permeability to gases, adsorption

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/70—Other properties

- B32B2307/726—Permeability to liquids, absorption

- B32B2307/7265—Non-permeable

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Respiratory Apparatuses And Protective Means (AREA)

- Laminated Bodies (AREA)

- Materials For Medical Uses (AREA)

Abstract

The invention discloses a novel waterproof chemical fiber gauze, which belongs to the technical field of chemical fiber gauze and comprises a base material layer, wherein a waterproof breathable layer is attached inside the base material layer, two protective layers are attached inside the base material layer, the protective layers are respectively attached to two sides of the surface of the waterproof breathable layer, an adhesive layer is coated on one side of the top of the surface of the base material layer, an anti-sticking layer is adhered on the surface of the adhesive layer, the base material layer can be adhered with a dressing layer through the adhesive layer, the waterproof breathable layer is made of a PE high-molecular breathable film, water vapor can smoothly permeate to the other side of the waterproof breathable layer according to the capillary motion principle, when the water vapor is condensed into water drops, water molecules cannot smoothly separate from the water drops and permeate to the other side due to the action of the surface tension of the water drops, so that the waterproof breathable layer has the waterproof breathable, can play the purpose of protecting the waterproof breathable layer.

Description

Technical Field

The invention relates to the technical field of chemical fiber gauze, in particular to novel waterproof chemical fiber gauze.

Background

The gauze is a textile product with sparse warp and weft, belongs to the cloth class, and is characterized by being sparse and having obvious grids, and the chemical fiber gauze is the gauze prepared by taking chemical fiber cloth as a raw material, has higher strength and durability compared with the traditional pure cotton gauze, and is very wide in application.

Patent No. CN 202409604U discloses a medical gauze, which uses chitin fiber with antibacterial and bacteriostatic effects in the gauze, so that the prepared gauze has antibacterial and bacteriostatic effects, can effectively prevent secondary pollution caused in storage and use processes, and improves the safety of product use.

The gauze has the following defects that 1, the traditional gauze is single in functionality, only has a simple shielding protection effect and does not have waterproof property, and when water is attached to the outside of the gauze in the actual use process, water can stretch into the gauze to influence the use of the gauze; 2. traditional gauze can only the cladding wound, need use bandage or other fasteners to tie up gauze in order fixed when fixed, and it is troublesome to use, and the gauze cooperates the dressing to use together usually, and gauze and dressing be the components of a whole that can function independently structure, easily take place the dislocation skew condition after the cladding, for this reason, we propose a novel waterproof chemical fiber gauze.

Disclosure of Invention

The invention provides novel waterproof chemical fiber gauze, aiming at improving the waterproof performance of the gauze and facilitating the adhesion of the gauze.

The specific technical scheme provided by the invention is as follows:

the novel waterproof chemical fiber gauze provided by the invention comprises a base material layer, wherein a waterproof breathable layer is attached to the inside of the base material layer, two protective layers are attached to the inside of the base material layer, the protective layers are respectively attached to two sides of the surface of the waterproof breathable layer, an adhesive layer is coated on one side of the top of the surface of the base material layer, an anti-sticking layer is adhered to the surface of the adhesive layer, a dressing layer can be adhered to the base material layer through the adhesive layer, a sterilization layer is attached to one side of the surface of the base material layer, and a dust-free paper layer is attached to one side of the surface of.

Optionally, the base material layer is made of chemical fiber cloth.

Optionally, the waterproof breathable layer is made of PE high-molecular breathable films, and the protective layer is made of PP spunbonded non-woven fabrics.

Optionally, the anti-sticking layer is made of release paper.

Optionally, the material of the sterilization layer is natural bamboo fiber.

The invention has the following beneficial effects:

1. the waterproof breathable layer and the protective layer are arranged inside the base material layer, the protective layer is attached to two sides of the waterproof breathable layer, the base material layer is made of chemical fiber cloth, the fabric is a fiber textile made of a high molecular compound, compared with the traditional fabric, the waterproof breathable layer is firm and durable, the waterproof breathable layer is made of a PE high molecular breathable film, water particles are very fine in a water vapor state, according to the principle of capillary motion, the other side of the waterproof breathable layer can be smoothly permeated, so that a vapor permeation phenomenon occurs, when water vapor is condensed into water drops, the particles become large, water molecules cannot smoothly separate from the water drops to permeate the other side due to the action of surface tension of the water drops, namely, the water permeation is prevented, the waterproof breathable layer has the waterproof and breathable characteristics, the waterproof performance is not influenced, the protective layer is made of PP spunbonded non-woven fabric, and the purpose of protecting the waterproof breathable layer can be achieved, simultaneously, the pulling force and the hydrostatic pressure can be enhanced.

2. The surface coating on the bed material layer has gluing agent layer, the surface of gluing agent layer is attached with antiseized layer, antiseized layer material is for releasing type paper, the effect that does not adhere has, when the gauze is normally used, directly use, when needs fix, can tear antiseized layer on bed material layer surface, make gluing agent layer expose, the stickness through gluing agent layer can be directly attached gauze in suitable position, need not to use bandage etc. to carry out extra fixing, the use convenience of gauze has been improved, when needs simultaneously, can be directly be in the same place with dressing layer is fixed through gluing agent layer and bed material layer, make gauze and dressing fixed, avoid dressing and gauze to take place the condition of skew dislocation in the use.

Drawings

In order to more clearly illustrate the technical solutions in the embodiments of the present invention, the drawings needed to be used in the description of the embodiments will be briefly introduced below, and it is obvious that the drawings in the following description are only some embodiments of the present invention, and it is obvious for those skilled in the art to obtain other drawings based on these drawings without creative efforts.

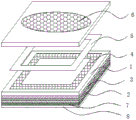

Fig. 1 is a schematic view of an overall structure of a novel waterproof chemical fiber gauze according to an embodiment of the present invention;

fig. 2 is a schematic diagram of an internal structure of a base material layer of the novel waterproof chemical fiber gauze according to the embodiment of the present invention.

In the figure: 1. a base material layer; 2. a waterproof breathable layer; 3. a protective layer; 4. an adhesive layer; 5. an anti-sticking layer; 6. a dressing layer; 7. a degerming layer; 8. a dust-free paper layer.

Detailed Description

In order to make the objects, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail with reference to the accompanying drawings, and it is apparent that the described embodiments are only a part of the embodiments of the present invention, not all of the embodiments. All other embodiments, which can be derived by a person skilled in the art from the embodiments given herein without making any creative effort, shall fall within the protection scope of the present invention.

The novel waterproof chemical fiber gauze according to the embodiment of the invention will be described in detail with reference to fig. 1-2.

Referring to fig. 1 and 2, the novel waterproof chemical fiber gauze provided by the embodiment of the invention comprises a base material layer 1, a waterproof breathable layer 2 is attached to the inside of the base material layer 1, two protective layers 3 are attached to the inside of the base material layer 1, the protective layers 3 are respectively attached to two sides of the surface of the waterproof breathable layer 2, an adhesive layer 4 is coated on one side of the top of the surface of the base material layer 1, an anti-sticking layer 5 is adhered to the surface of the adhesive layer 4, a dressing layer 6 can be adhered to the base material layer 1 through the adhesive layer 4, a degerming layer 7 is attached to one side of the surface of the base material layer 1, and a dust-free paper layer 8 is attached to one side of the surface of the degerming layer.

The example, waterproof ventilative layer 2 material is PE polymer ventilated membrane, the aqueous vapor is according to capillary motion's principle, can permeate waterproof ventilative layer 2 opposite side smoothly, after the steam condensation becomes the drop of water, because the effect of drop of water surface tension, the hydrone just can not break away from the drop of water smoothly and permeate the opposite side, make waterproof ventilative layer 2 have waterproof ventilative characteristic, protective layer 3 material is PP spunbonded nonwoven, can play the purpose of protecting waterproof ventilative layer 2, can strengthen pulling force and hydrostatic pressure simultaneously, when needs fix, can tear antiseized layer 5 on basic material layer 1 surface, make gluing agent layer 4 expose, the stickness through gluing agent layer 4 can be directly attached gauze in suitable position, need not to use the bandage etc. to additionally fix, the convenience in use of gauze has been improved.

When the waterproof breathable fabric is used, the waterproof breathable layer 2 and the protective layer 3 are arranged inside the base material layer 1, the protective layer 3 is attached to two sides of the waterproof breathable layer 2, the base material layer 1 is made of chemical fiber cloth and is a fiber textile made of high-molecular compounds, compared with the traditional fabric, the waterproof breathable layer 2 is firm and durable, the waterproof breathable layer 2 is made of a PE (polyethylene) high-molecular breathable film, water particles are very fine in the water vapor state, the waterproof breathable layer 2 can smoothly permeate to the other side of the waterproof breathable layer according to the principle of capillary motion, so that the vapor permeation phenomenon occurs, after water vapor is condensed into water drops, the particles are enlarged, water molecules cannot smoothly separate from the water drops to permeate to the other side due to the action of the surface tension of the water drops, the water permeation is prevented, the waterproof breathable layer 2 has the waterproof and breathable characteristics, the waterproof breathable layer is waterproof and does not influence the air permeability, the waterproof breathable layer can be protected, meanwhile, the tensile force and the hydrostatic pressure can be enhanced, the adhesive layer 4 is coated on the surface of the base material layer 1, the anti-sticking layer 5 is attached to the surface of the adhesive layer 4, the anti-sticking layer 5 is made of release paper and has an anti-sticking effect, when the gauze is normally used, the gauze is directly used, when the gauze needs to be fixed, the anti-sticking layer 5 on the surface of the base material layer 1 can be torn off, the adhesive layer 4 is exposed, the gauze can be directly attached to a proper position through the viscosity of the adhesive layer 4, additional fixation through bandages and the like is not needed, the use convenience of the gauze is improved, meanwhile, when needed, the dressing layer 6 can be directly fixed with the base material layer 1 through the adhesive layer 4, the gauze and dressing are fixed, the situation that the dressing and the gauze are offset and dislocated in the using process is avoided, and the sterilizing, cellulose fiber extracted from naturally growing bamboos has natural antibacterial and bacteriostatic characteristics, the degerming effect can be improved, and the dust-free paper layer 8 can play a role in protecting and isolating the whole gauze.

The invention relates to a novel waterproof chemical fiber gauze, which comprises a base material layer 1, a waterproof breathable layer 2, a protective layer 3, an adhesive layer 4, an anti-sticking layer 5, a dressing layer 6, a degerming layer 7 and a dust-free paper layer 8, wherein the components are all universal standard components or components known by technical staff in the field, and the structure and the principle of the novel waterproof chemical fiber gauze can be known by technical manuals or conventional experimental methods.

It will be apparent to those skilled in the art that various modifications and variations can be made in the embodiments of the present invention without departing from the spirit or scope of the embodiments of the invention. Thus, if such modifications and variations of the embodiments of the present invention fall within the scope of the claims of the present invention and their equivalents, the present invention is also intended to encompass such modifications and variations.

Claims (5)

1. The utility model provides a novel waterproof chemical fiber gauze, includes base material layer (1), its characterized in that, base material layer (1) inside laminating has waterproof ventilative layer (2), base material layer (1) inside laminating has protective layer (3) and protective layer (3) to be two, protective layer (3) attach respectively in waterproof ventilative layer (2) surface both sides, base material layer (1) surface top one side coating has gluing agent layer (4), gluing agent layer (4) surface adhesion has antiseized layer (5), base material layer (1) can bond through gluing agent layer (4) has dressing layer (6), the laminating of base material layer (1) surface one side has except that fungus layer (7), except that fungus layer (7) surface one side laminating has dustless ply (8).

2. The novel waterproof chemical fiber gauze as claimed in claim 1, wherein the base material layer (1) is made of chemical fiber cloth.

3. The novel waterproof chemical fiber gauze as claimed in claim 1, wherein the waterproof breathable layer (2) is made of a PE (polyethylene) polymer breathable film, and the protective layer (3) is made of a PP (polypropylene) spun-bonded non-woven fabric.

4. The novel waterproof chemical fiber gauze as claimed in claim 1, wherein the anti-sticking layer (5) is made of release paper.

5. The novel waterproof chemical fiber gauze as claimed in claim 1, wherein the material of the antibacterial layer (7) is natural bamboo fiber.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202011114265.6A CN112109396A (en) | 2020-10-19 | 2020-10-19 | Novel waterproof chemical fiber gauze |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202011114265.6A CN112109396A (en) | 2020-10-19 | 2020-10-19 | Novel waterproof chemical fiber gauze |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN112109396A true CN112109396A (en) | 2020-12-22 |

Family

ID=73794818

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202011114265.6A Withdrawn CN112109396A (en) | 2020-10-19 | 2020-10-19 | Novel waterproof chemical fiber gauze |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN112109396A (en) |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20130116645A1 (en) * | 2011-11-07 | 2013-05-09 | Tyco Healthcare Group Lp | Absorbent Foam Tape And Related Methods Thereof |

| CN205181614U (en) * | 2015-12-02 | 2016-04-27 | 南阳市汇博生物技术有限公司 | Dressing of compound biological activity fibre |

| CN209751378U (en) * | 2019-01-15 | 2019-12-10 | 上海华舟压敏胶制品有限公司 | Paste comfortable medical pressure-sensitive adhesive dressing |

| CN110613552A (en) * | 2019-10-30 | 2019-12-27 | 江阴市医疗器械有限公司 | Medical dressing formed by compounding |

| CN211251577U (en) * | 2019-11-25 | 2020-08-14 | 吴江康欣医用辅料有限公司 | Non-woven fabric dressing with high elasticity |

| CN211610346U (en) * | 2020-01-20 | 2020-10-02 | 南昌益民医用卫生材料有限公司 | Medical gauze dressing |

| CN213861084U (en) * | 2020-10-19 | 2021-08-03 | 常熟市庄盛特种化纤有限公司 | Novel waterproof chemical fiber gauze |

-

2020

- 2020-10-19 CN CN202011114265.6A patent/CN112109396A/en not_active Withdrawn

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20130116645A1 (en) * | 2011-11-07 | 2013-05-09 | Tyco Healthcare Group Lp | Absorbent Foam Tape And Related Methods Thereof |

| CN205181614U (en) * | 2015-12-02 | 2016-04-27 | 南阳市汇博生物技术有限公司 | Dressing of compound biological activity fibre |

| CN209751378U (en) * | 2019-01-15 | 2019-12-10 | 上海华舟压敏胶制品有限公司 | Paste comfortable medical pressure-sensitive adhesive dressing |

| CN110613552A (en) * | 2019-10-30 | 2019-12-27 | 江阴市医疗器械有限公司 | Medical dressing formed by compounding |

| CN211251577U (en) * | 2019-11-25 | 2020-08-14 | 吴江康欣医用辅料有限公司 | Non-woven fabric dressing with high elasticity |

| CN211610346U (en) * | 2020-01-20 | 2020-10-02 | 南昌益民医用卫生材料有限公司 | Medical gauze dressing |

| CN213861084U (en) * | 2020-10-19 | 2021-08-03 | 常熟市庄盛特种化纤有限公司 | Novel waterproof chemical fiber gauze |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| RU2763479C2 (en) | Stretchable bandages | |

| US8598052B2 (en) | Highly air-permeable and water-resistance sheet, a highly air-permeable and water-resistance sheet composite and an absorbent article, and a method for manufacturing a highly air-permeable and water-resistance sheet and a method for manufacturing a highly air-permeable and water-resistance sheet composite | |

| CN213861084U (en) | Novel waterproof chemical fiber gauze | |

| CN101433484A (en) | Seaweed fiber medical dressing | |

| CN104224446A (en) | Alginate adhesive bandage and manufacturing method of alginate adhesive bandage | |

| CN112078203A (en) | Mask with three layers of different-shaped structures and preparation method thereof | |

| CN112109396A (en) | Novel waterproof chemical fiber gauze | |

| CN211023523U (en) | Degradable sanitary napkin with organic cotton core | |

| CN206383590U (en) | A kind of antibacterial water proof nonwoven cloth | |

| JPH0833673A (en) | Tacky adhesive film for first-and adhesive plaster and first-aid adhesive plaster using the same film | |

| CN109091309B (en) | Paper diaper with grid-type absorption main body and preparation method thereof | |

| CN210617518U (en) | High-water-absorption composite non-woven fabric | |

| CN205947925U (en) | High ventilative absorption articles for use of high water -resistant | |

| CN213098766U (en) | Traditional Chinese medicine hemostatic gauze piece | |

| CN212949587U (en) | Three-layer mask with anisotropic structure | |

| JP5095402B2 (en) | Absorption article | |

| CN215229295U (en) | Degradable sanitary towel with alginate fiber core | |

| JP6633832B2 (en) | Manufacturing method of nanofiber sheet member | |

| CN207724985U (en) | A kind of hot wind brightens super soft multiple hydrophilic nonwoven fabrics | |

| CN207672228U (en) | A kind of double-deck spunlace non-woven cloth of sanitary napkin | |

| CN216417535U (en) | Strong-air-feeling antibacterial sanitary towel | |

| CN219148209U (en) | Degradable bamboo fiber band-aid | |

| CN214071889U (en) | Washable plane mask convenient for replacing filter disc | |

| CN219903672U (en) | High-strength composite antibacterial breathable film structure | |

| CN215943938U (en) | High-elasticity composite non-woven fabric |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| WW01 | Invention patent application withdrawn after publication | ||

| WW01 | Invention patent application withdrawn after publication |

Application publication date: 20201222 |