Disclosure of Invention

The technical problem to be solved by the invention is to provide an embedded heat dissipation device for a server room, which overcomes the problems.

The invention is realized by the following technical scheme.

An embedded heat dissipation device for a server room comprises a working box and an annular air suction cavity which is positioned in the working box and is provided with an upward opening, wherein an annular filter plate capable of filtering air entering the annular air suction cavity is fixedly arranged in the annular air suction cavity, a first cavity which is positioned at the lower side of the annular air suction cavity and is communicated with the annular air suction cavity is fixedly arranged in the working box, a first rotating shaft is arranged on the inner wall of the upper side of the first cavity in a rotating manner, a first gear, a second gear and an air suction fan blade are sequentially and fixedly arranged on the first rotating shaft from top to bottom, the air suction fan blade rotates to suck outside air into the room through the annular air suction cavity, a differential rotation device capable of rotating the first rotating shaft at two different rotating speeds is fixedly arranged in the working box, a second cavity which is positioned at the right side of the first cavity is fixedly arranged in the working box, and a piston is slidably arranged in the second cavity, the lower end face of the working box is fixedly provided with a heat conducting rod which is located on the lower side of the second cavity and extends upwards into the second cavity, the heat conducting rod is located on the lower side of the piston, the second cavity on the lower side of the piston is filled with thermosensitive gas, the heat conducting rod can transmit the temperature in a machine room in real time, a first sliding groove which is located on the left side of the second cavity and communicated with the second cavity is fixedly arranged in the working box, a first circular sliding block is arranged in the first sliding groove in a sliding mode, the left end face of the first circular sliding block is connected with the left cavity wall of the first sliding groove through a first compression spring, an alarm device capable of giving an alarm is fixedly arranged in the working box, and when the piston slides upwards to abut against the inner wall on the upper side of the second cavity, the alarm device starts an alarm.

Further, the differential rotation device comprises a third cavity which is positioned at the right side of the first cavity and communicated with the first cavity, a second chute which is positioned at the upper side of the third cavity and communicated with the third cavity is fixedly arranged in the working box, the right cavity wall of the second chute is fixedly provided with an electromagnet, the electromagnet is in electrical signal connection with the first circular slider, when the first circular slider stops being extruded, the electromagnet is electrified, a magnetic slider which is positioned at the left side of the electromagnet is arranged in the second chute in a sliding manner, the left end surface of the magnetic slider is connected with the left cavity wall of the second chute through a first tension spring, the lower end surface of the magnetic slider is fixedly provided with a motor which is positioned in the third cavity, the lower end surface of the motor is rotatably provided with a motor shaft, a key groove with a downward opening is arranged in the motor shaft, and a third gear which is engaged with the first gear is fixedly arranged on the motor shaft, a third sliding groove which is positioned on the upper side of the second sliding groove and communicated with the second sliding groove is fixedly arranged in the working box, a second round sliding block which is partially positioned in the second sliding groove is arranged in the third sliding groove in a sliding mode, the upper end face of the second round sliding block is connected with the inner wall of the upper side of the third sliding groove through a second compression spring, and when the third gear is meshed with the first gear, the rotating speed of the first rotating shaft is slower.

Furthermore, a fourth cavity is fixedly arranged in the working box and is positioned on the left side of the first cavity and communicated with the first cavity, a fourth chute is fixedly arranged in the working box and is positioned on the upper side of the fourth cavity and is communicated with the fourth cavity, a first sliding block is arranged in the fourth chute in a sliding manner, the left end face of the first sliding block is connected with the left cavity wall of the fourth chute through the fourth chute, the left end face of the first sliding block is connected with the upper end face of the second circular sliding block through a first pull rope, a fourth rotating shaft is arranged on the lower end face of the first sliding block in a rotating manner, a belt pulley is fixedly arranged on the fourth rotating shaft, a motor shaft is connected with the fourth rotating shaft through the belt pulley in a transmission manner, a fourth gear is fixedly arranged on the left side of the second gear on the fourth rotating shaft, when the first pull rope is loosened, the first sliding block slides rightwards to abut against the right cavity wall of the fourth chute, the fourth gear with the meshing of second gear, thereby make first pivot rotates with faster rotational speed, set firmly in the work box be located fourth cavity downside the left condenser of first cavity, work as when the electro-magnet circular telegram, the condenser starts the cooling of discharge air conditioning.

Furthermore, a fifth cavity which is located on the right side of the second cavity and is provided with a downward opening is fixedly arranged in the working box, dry powder for fire extinguishing is filled in the fifth cavity, a fifth chute which is located on the rear side of the fifth cavity and is communicated with the fifth cavity is fixedly arranged in the working box, a sealing plate which can seal the lower opening of the fifth cavity is arranged in the fifth chute in a sliding manner, the rear end face of the sealing plate is connected with the rear cavity wall of the fifth chute through a third compression spring, a sixth chute which is located on the lower side of the third cavity and is communicated with the third cavity is fixedly arranged in the working box, a second sliding block is arranged in the sixth chute in a sliding manner, the left end face of the second sliding block is connected with the left chute wall of the sixth chute through a second extension spring, a second rotating shaft which is located in the third cavity is rotatably arranged on the upper end face of the second sliding block, and a winding wheel is fixedly arranged on the second rotating shaft, the wire winding wheel is connected with the rear end face of the closing plate through a second pull rope, a first bevel gear located on the upper side of the wire winding wheel is fixedly arranged on the second rotating shaft, and when the wire winding wheel rotates, the closing plate is pulled backwards to open the lower opening of the fifth cavity, so that dry powder in the fifth cavity falls down to prevent ignition.

Further, the alarm device comprises a sixth cavity located on the right side of the third cavity, a third rotating shaft extending leftwards into the third cavity is rotatably arranged on the right cavity wall of the sixth cavity, a second bevel gear and a third bevel gear which are located in the third cavity are fixedly arranged on the third rotating shaft from right to left in sequence, a fifth gear which is located in the sixth cavity is fixedly arranged on the third rotating shaft, a rack which is located behind the fifth gear and meshed with the fifth gear is slidably arranged on the inner wall on the rear side of the sixth cavity, the upper end face of the rack is connected with the inner wall on the upper side of the sixth cavity through a third stretching spring, the upper end face of the rack is connected with the right end face of the second slider through a third pull rope, an alarm capable of alarming is fixedly arranged on the inner wall on the lower side of the sixth cavity, and when the rack is abutted against the alarm, the alarm gives an alarm, the third pull rope pulls the second sliding block to slide rightwards to abut against the right cavity wall of the sixth sliding groove, and the first bevel gear is meshed with the second bevel gear.

Furthermore, a T-shaped cavity with an upward opening is formed in the piston, a T-shaped rotating shaft extending upwards into the third cavity is arranged in the T-shaped cavity in a rotating mode, a fourth bevel gear located in the third cavity is fixedly arranged on the T-shaped rotating shaft, when the piston slides upwards to abut against the inner wall of the upper side of the second cavity, the T-shaped rotating shaft is clamped into the key groove, and the fourth bevel gear is meshed with the third bevel gear.

The invention has the beneficial effects that: the invention relates to a heat dissipation device capable of adjusting the rotating speed of heat dissipation fan blades in a machine room, wherein when a heat conduction rod monitors that the temperature in the machine room rises to a certain value, an air suction fan blade is switched to a high rotating speed mode to accelerate heat dissipation of the machine room, a condenser of the heat dissipation device can start heat dissipation of the machine room, and when the temperature rises to a threshold value, an alarm device of the heat dissipation device can be connected into an alarm system to prompt relevant personnel and spray dry powder in the heat dissipation device, so that serious loss caused by fire disasters is prevented.

Detailed Description

The present invention will be further described with reference to the following description and examples, which include but are not limited to the following examples.

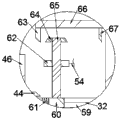

As shown in fig. 1-4, an embedded heat dissipation device for a server room comprises a working box 10 and an annular air suction cavity 21 located in the working box 10 and having an upward opening, wherein an annular filter plate 22 is fixedly disposed in the annular air suction cavity 21 and capable of filtering air entering the annular air suction cavity 21, a first cavity 20 is fixedly disposed in the working box 10 and located at the lower side of the annular air suction cavity 21 and communicated with the annular air suction cavity 21, a first rotating shaft 23 is rotatably disposed on the inner wall of the upper side of the first cavity 20, a first gear 51, a second gear 50 and an air suction fan blade 49 are sequentially and fixedly disposed on the first rotating shaft 23 from top to bottom, the air suction fan blade 49 rotates to suck outside air into the room through the annular air suction cavity 21, and a differential rotation device 71 is fixedly disposed in the working box 10 and capable of rotating the first rotating shaft 23 at two different rotation speeds, a second cavity 43 located on the right side of the first cavity 20 is fixedly arranged in the working box 10, a piston 39 is arranged in the second cavity 43 in a sliding manner, a heat conducting rod 41 located on the lower side of the second cavity 43 and extending upwards into the second cavity 43 is fixedly arranged on the lower end face of the working box 10, the heat conducting rod 41 is located on the lower side of the piston 39, the second cavity 43 on the lower side of the piston 39 is filled with heat-sensitive gas, the heat conducting rod 41 can transmit the temperature in the machine room in real time, a first sliding chute 58 located on the left side of the second cavity 43 and communicated with the second cavity 43 is fixedly arranged in the working box 10, a first circular sliding block 56 is arranged in the first sliding chute 58 in a sliding manner, the left end face of the first circular sliding block 56 is connected with the left cavity wall of the first sliding chute 58 through a first compression spring 57, and an alarm device 72 capable of giving an alarm is fixedly arranged in the working box 10, when the piston 39 slides upwards into abutment with the inner wall of the upper side of the second cavity 43, the alarm device 72 activates an alarm.

Advantageously, the differential rotation device 71 includes a third cavity 68 located at the right side of the first cavity 20 and communicated with the first cavity 20, a second chute 26 located at the upper side of the third cavity 68 and communicated with the third cavity 68 is fixedly installed in the work box 10, an electromagnet 31 is fixedly installed on the right chamber wall of the second chute 26, the electromagnet 31 is electrically connected with the first circular slider 56, when the first circular slider 56 stops being squeezed, the electromagnet 31 is energized, a magnetic slider 25 located at the left side of the electromagnet 31 is slidably installed in the second chute 26, the left end surface of the magnetic slider 25 is connected with the left chamber wall of the second chute 26 through a first tension spring 24, a motor 48 located in the third cavity 68 is fixedly installed on the lower end surface of the magnetic slider 25, a motor shaft 69 is rotatably installed on the lower end surface of the motor 48, a key slot 45 with a downward opening is installed in the motor shaft 69, a third gear 47 engaged with the first gear 51 is fixedly arranged on the motor shaft 69, a third chute 28 located at the upper side of the second chute 26 and communicated with the second chute 26 is fixedly arranged in the working box 10, a second circular sliding block 30 partially located in the second chute 26 is slidably arranged in the third chute 28, the upper end surface of the second circular sliding block 30 is connected with the inner wall of the upper side of the third chute 28 through a second compression spring 29, and when the third gear 47 is engaged with the first gear 51, the rotating speed of the first rotating shaft 23 is slower.

Beneficially, a fourth cavity 12 located at the left side of the first cavity 20 and communicated with the first cavity 20 is fixedly arranged in the working box 10, a fourth sliding chute 19 located at the upper side of the fourth cavity 12 and communicated with the fourth cavity 12 is fixedly arranged in the working box 10, a first sliding block 18 is slidably arranged in the fourth sliding chute 19, the left end surface of the first sliding block 18 is connected with the left cavity wall of the fourth sliding chute 19 through the fourth sliding chute 19, the left end surface of the first sliding block 18 is connected with the upper end surface of the second circular sliding block 30 through a first pull rope 16, a fourth rotating shaft 14 is rotatably arranged on the lower end surface of the first sliding block 18, a belt pulley 15 is fixedly arranged on the fourth rotating shaft 14, the motor shaft 69 is in transmission connection with the fourth rotating shaft 14 through the belt pulley 15, a fourth gear 13 is fixedly arranged on the fourth rotating shaft 14 and located at the left side of the second gear, when first stay cord 16 relaxs, first slider 18 slide right extremely with the wall butt of the fourth spout 19 right side, fourth gear 13 with the meshing of second gear 50 makes first pivot 23 rotates with faster rotational speed, work box 10 internal stability is equipped with and is located fourth cavity 12 downside the left condenser 11 of first cavity 20, works as when electro-magnet 31 circular telegram, condenser 11 starts the cooling of discharge air conditioning.

Beneficially, a fifth cavity 38 located at the right side of the second cavity 43 and opening downward is fixedly arranged in the working box 10, dry powder for fire extinguishing is filled in the fifth cavity 38, a fifth chute 52 located at the rear side of the fifth cavity 38 and communicating with the fifth cavity 38 is fixedly arranged in the working box 10, a closing plate 40 capable of closing the lower opening of the fifth cavity 38 is slidably arranged in the fifth chute 52, the rear end face of the closing plate 40 is connected with the rear cavity wall of the fifth chute 52 through a third compression spring 53, a sixth chute 59 located at the lower side of the third cavity 68 and communicating with the third cavity 68 is fixedly arranged in the working box 10, a second sliding block 60 is slidably arranged in the sixth chute 59, the left end face of the second sliding block 60 is connected with the left cavity wall of the sixth chute 59 through a second extension spring 61, the upper end face of the second sliding block 60 is rotatably provided with a second rotating shaft 65 located in the third cavity 68, a winding wheel 62 is fixedly arranged on the second rotating shaft 65, the winding wheel 62 is connected with the rear end face of the closing plate 40 through a second pull rope 54, a first bevel gear 64 positioned on the upper side of the winding wheel 62 is fixedly arranged on the second rotating shaft 65, when the winding wheel 62 rotates, the closing plate 40 is pulled backwards, the lower opening of the fifth cavity 38 is opened, and therefore dry powder in the fifth cavity 38 falls down to prevent fire.

Advantageously, the alarm device 72 includes a sixth cavity 34 located on the right side of the third cavity 68, the right cavity wall of the sixth cavity 34 is rotatably provided with a third rotating shaft 66 extending leftward into the third cavity 68, the third rotating shaft 66 is fixedly provided with a second bevel gear 67 and a third bevel gear 63 located in the third cavity 68 in sequence from right to left, the third rotating shaft 66 is fixedly provided with a fifth gear 36 located in the sixth cavity 34, the inner wall of the rear side of the sixth cavity 34 is slidably provided with a rack 35 located behind the fifth gear 36 and engaged with the fifth gear 36, the upper end surface of the rack 35 is connected with the inner wall of the upper side of the sixth cavity 34 through a third tension spring 33, the upper end surface of the rack 35 is connected with the right end surface of the second slider 60 through a third pull rope 32, the inner wall of the lower side of the sixth cavity 34 is fixedly provided with an alarm 37 capable of alarming, when the rack 35 abuts against the alarm 37, the alarm 37 gives an alarm, the third pull rope 32 pulls the second slide block 60 to slide rightwards to abut against the right cavity wall of the sixth sliding chute 59, and the first bevel gear 64 is meshed with the second bevel gear 67.

Advantageously, an upward-opening T-shaped cavity 55 is formed in the piston 39, a T-shaped rotating shaft 46 extending upward into the third cavity 68 is rotatably arranged in the T-shaped cavity 55, a fourth bevel gear 44 located in the third cavity 68 is fixedly arranged on the T-shaped rotating shaft 46, when the piston 39 slides upward to abut against the inner wall of the upper side of the second cavity 43, the T-shaped rotating shaft 46 is clamped into the key groove 45, and the fourth bevel gear 44 is meshed with the third bevel gear 63.

Sequence of mechanical actions of the whole device:

the initial state of the invention is as follows: the first extension spring 24 is in a relaxed state, the electromagnet 31 is not energized, the third gear 47 is meshed with the first gear 51, the second circular slider 30 is partially positioned in the second sliding groove 26, the second compression spring 29 is in a relaxed state, the first pull rope 16 is in a strained state, the fourth compression spring 17 is in a compressed state, the fourth gear 13 is not meshed with the second gear 50, the condenser 11 is not started, the fourth extension spring 42 is in a relaxed state, the first compression spring 57 is in a compressed state, the first circular slider 56 is positioned in the first sliding groove 58, the fourth bevel gear 44 is not meshed with the third bevel gear 63, the first bevel gear 64 is not meshed with the second bevel gear 67, the third extension spring 33 is in a relaxed state, the third pull rope 32 is in a relaxed state, the second extension spring 61 is in a relaxed state, the second pull rope 54 is not strained, the third compression spring 53 is in a relaxed state, and the closing plate 40 closes the lower opening of the fifth cavity 38;

1. the motor 48 is started to drive the motor shaft 69 to rotate, the motor shaft 69 rotates to drive the third gear 47 to rotate, the third gear 47 is meshed with the first gear 51, the third gear 47 rotates to drive the first gear 51 to rotate, the first gear 51 rotates to drive the first rotating shaft 23 to rotate, the first rotating shaft 23 rotates to drive the air suction fan blade 49 to rotate, the air suction fan blade 49 rotates to suck outside air into the annular air suction cavity 21, the outside air is filtered by the annular filter plate 22 and then blown out through the first cavity 20, and heat dissipation and cooling are carried out on the server room;

2. the heat conducting rod 41 monitors the temperature in the server room in real time, transmits the temperature in the server room to the second cavity 43, so that the heat-sensitive gas in the second cavity 43 expands, and if the heat conducting rod 41 monitors the temperature rise in the server room, the expansion of the gas in the second cavity 43 pushes the piston 39 to slide upward, the piston 39 slides upward stretching the fourth tension spring 42, when the piston 39 slides upward to stop pressing the first circular slider 56, the first compression spring 57 is reset to eject the first circular slider 56, when the first circular slider 56 is ejected, the electromagnet 31 is electrified to adsorb the magnetic slider 25 and slide rightwards, the magnetic slider 25 slides rightwards to drive the motor 48 to slide rightwards, the motor 48 slides rightwards to drive the motor shaft 69 to slide rightwards, and the motor shaft 69 slides rightwards to drive the third gear 47 to slide rightwards, so that the third gear 47 is disengaged from the first gear 51;

3. when the electromagnet 31 is electrified, the condenser 11 is started to cool and radiate the machine room;

4. when the magnetic slider 25 slides rightwards to abut against the electromagnet 31, the second circular slider 30 is extruded to slide upwards into the third sliding groove 28, the first pull rope 16 is loosened while the second compression spring 29 is extruded, the first pull rope 16 is loosened to reset the fourth compression spring 17, the fourth compression spring 17 is reset to slide the first slider 18 rightwards, the first slider 18 slides rightwards to drive the fourth rotating shaft 14 to slide rightwards, the fourth rotating shaft 14 slides rightwards to drive the fourth gear 13 to slide rightwards, when the first slider 18 abuts against the right cavity wall of the fourth sliding groove 19 rightwards, the fourth gear 13 is meshed with the second gear 50, as the motor shaft 69 is in transmission connection with the fourth rotating shaft 14 through the belt pulley 15, the motor shaft 69 rotates to drive the fourth rotating shaft 14 to rotate, the fourth rotating shaft 14 rotates to drive the fourth gear 13 to rotate, the fourth gear 13 rotates to drive the second gear 50 to rotate, the second gear 50 rotates to drive the first rotating shaft 23 to rotate at a faster rotating speed, the first rotating shaft 23 rotates to drive the suction fan blade 49 to rotate, and the suction fan blade 49 rotates to increase the air volume entering the annular suction cavity 21, so that the accelerated heat dissipation is performed in the machine room;

5. if the temperature in the machine room continues to rise, when the piston 39 slides upwards to abut against the upper cavity wall of the second cavity 43, the T-shaped rotating shaft 46 is clamped in the key groove 45, the piston 39 slides upwards to drive the T-shaped rotating shaft 46 to slide upwards, the T-shaped rotating shaft 46 slides upwards to drive the fourth bevel gear 44 to slide upwards, the fourth bevel gear 44 is meshed with the third bevel gear 63, the motor shaft 69 rotates to drive the T-shaped rotating shaft 46 to rotate, the T-shaped rotating shaft 46 rotates to drive the fourth bevel gear 44 to rotate, the fourth bevel gear 44 rotates to drive the third bevel gear 63 to rotate, the third bevel gear 63 rotates to drive the third rotating shaft 66 to rotate, the third rotating shaft 66 rotates to drive the fifth gear 36 to rotate, as the fifth gear 36 is meshed with the upper tooth surface of the rack 35, the fifth gear 36 rotates to drive the rack 35 to slide downwards, the rack 35 slides downwards to tighten the third rope 32, the third rope 32 is tightened to pull the second, the second sliding block 60 slides rightwards to drive the second rotating shaft 65 to slide rightwards, and when the rack 35 slides downwards to abut against the alarm 37, the alarm 37 sends an electric signal to give an alarm;

6. when the rack 35 abuts against the alarm 37, the second slider 60 abuts against the right cavity wall of the sixth chute 59, the first bevel gear 64 is meshed with the second bevel gear 67, the third rotating shaft 66 rotates to drive the second bevel gear 67 to rotate, the second bevel gear 67 rotates to drive the first bevel gear 64 to rotate, the first bevel gear 64 rotates to drive the second rotating shaft 65 to rotate, the second rotating shaft 65 rotates to drive the winding wheel 62 to rotate, the winding wheel 62 rotates to tension the second pull rope 54, the second pull rope 54 is tensioned to enable the closing plate 40 to slide backwards, the lower opening of the fifth cavity 38 is opened, dry powder in the fifth cavity 38 falls into the machine room, and fire caused by overhigh temperature in the machine room is prevented from causing serious loss;

7. after the use is finished, the invention restores the initial position and continues to radiate the heat of the machine room.

The above embodiments are merely illustrative of the technical ideas and features of the present invention, and the purpose thereof is to enable those skilled in the art to understand the contents of the present invention and implement the present invention, and not to limit the protection scope of the present invention. All equivalent changes and modifications made according to the spirit of the present invention should be covered within the protection scope of the present invention.