CN1080787C - Washing machine - Google Patents

Washing machine Download PDFInfo

- Publication number

- CN1080787C CN1080787C CN96112450A CN96112450A CN1080787C CN 1080787 C CN1080787 C CN 1080787C CN 96112450 A CN96112450 A CN 96112450A CN 96112450 A CN96112450 A CN 96112450A CN 1080787 C CN1080787 C CN 1080787C

- Authority

- CN

- China

- Prior art keywords

- cleaning

- water

- cleaning cylinder

- washing machine

- discharge

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F39/00—Details of washing machines not specific to a single type of machines covered by groups D06F9/00 - D06F27/00

- D06F39/08—Liquid supply or discharge arrangements

- D06F39/083—Liquid discharge or recirculation arrangements

- D06F39/085—Arrangements or adaptations of pumps

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F39/00—Details of washing machines not specific to a single type of machines covered by groups D06F9/00 - D06F27/00

- D06F39/02—Devices for adding soap or other washing agents

- D06F39/028—Arrangements for selectively supplying water to detergent compartments

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F39/00—Details of washing machines not specific to a single type of machines covered by groups D06F9/00 - D06F27/00

- D06F39/08—Liquid supply or discharge arrangements

- D06F39/083—Liquid discharge or recirculation arrangements

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F39/00—Details of washing machines not specific to a single type of machines covered by groups D06F9/00 - D06F27/00

- D06F39/10—Filtering arrangements

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Detail Structures Of Washing Machines And Dryers (AREA)

Abstract

The present invention provides a washing machine, wherein feed circulation water from a delivery port at one position on the bottom of a spinning tub to a plurality of delivery ports on the upper part of the spinning tub for quickly dissolving a detergent and increasing a washing effect, and apply various functions including the arrest of lint or a waterfall type shower, regarding a washing machine formed to have a structure for circulating water from the periphery of a pulsator housing part formed on the inner bottom of the spinning tub. This washing machine has a circulation function of introducing washing liquid to an upper part within a spinning tub 11 through the pumping operation of the rear vane 16 of a pulsator 10 associated with the operation of a pulsator 10 disposed on the inner bottom of the spinning tub 11. Furthermore, a water delivery port 15 is formed so as to have one end communicated to a pulsator housing part 12 including the rear vane 16 of the pulsator 10, and the other end of the delivery port 15 is communicated to the ends of a plurality of water discharge passages 24 at one side. The ends of the water discharge passages 24 at the other side are respectively introduced to upper positions within the spinning tub 11.

Description

The periphery that the present invention relates to a kind of rotation wing installation portion that forms from the washing machine inside bottom makes the washing machine of recirculated water circulation.

The structure of existing this washing machine as shown in Figure 10 and Figure 11.Below, this structure is described.

As shown in the figure, cleaning cylinder 1 forms recess 2 in a part in interior week, and this recess 2 links to each other with the fan-shaped outlet 4 of rotation wing installation portion 3.Setting-in and is discharged cover 5 and water inlet cover 6 on this recess 2, form with cleaning cylinder 1 in the passage 7 that separates.Above water inlet cover 6, discharge portion 8 is being set, the filter 9 that is used to reclaim the end of a thread removably is being installed on this discharge portion 8.

Such structure is mainly used in twin tube washing machine etc., and it arrives hydraulic pressure in the passage 7 by the revolving force of the rotation wing 10, then by filter 9 water filling in cleaning cylinder 1, makes the cleaning fluid circulation.

As shown in figure 11, cleaning cylinder 1 forms square, and the circulating device of above-mentioned cleaning fluid is arranged on the bight of cleaning cylinder 1.This is the passage 7 that rouses the outside because of forming easily in the bight, and the gap of washing machine body and cleaning cylinder 1 is bigger in corner positions, guarantees passage 7 easily.

In this existing structure, owing to be to form, so the shape easy deformation of cleaning cylinder 1 is arranged, particularly the problem of big distortion takes place under the warm water condition easily during running from the sidewall of cleaning cylinder 1 recess 2 of bottom to the inside.In addition, even using same cleaning cylinder 1 and constituting under the occasion of the product that does not have filter 9 the sort of specifications, also need to discharge cover 5 and water inlet cover 6, the structure that difficult formation can reduce cost.

For filter 9 is set more than 2 places, when a plurality of discharge portion 8 is set on cleaning cylinder 1 top, must recess 2, outlet 4 be set in other parts, discharges cover 5 and water inlet cover 6 etc.For this reason, not only make the structure complicated of cleaning cylinder 1, and intensity weakens also, have the problem that makes recess 2 expansions, water cover 6 into etc. is come off because of effects such as hydraulic pressure.

In order to improve the cleansing power of washing machine, need make cleaning agent produce cleaning action rapidly, for this reason, not only need mechanical force, and need make water and cleaning agent circulation, be discharged in the cleaning cylinder 1 from the top, with its rapid dissolving.So, wish to be provided with a plurality of discharge portions 8 to increase quantity of circulating water, cleaning agent is dissolved rapidly.In addition, must reclaim the end of a thread of generation when cleaning effectively to prevent attached on the clothing that cleans, so the recovering mechanism of forced cyclic type must be arranged.For this reason, must form a plurality of discharge portions 8 on the top of cleaning cylinder 1, and preferably can form simple, cheap structure.

The present invention makes in order to address the above problem, its objective is provides a kind of washing machine, it can be from the discharge oral area at 1 position of the cleaning cylinder bottom a plurality of discharge portion delivery cycle water to cleaning cylinder top, can dissolve cleaning agent fast, can improve cleaning performance, and can have additional functions such as the end of a thread of capture or waterfall shape spray.

In washing machine of the present invention, be provided with the discharge oral area that an end is communicated with pump chamber, this pump chamber comprises the intra vane that rotates the wing, and the other end of above-mentioned discharge oral area is communicated with a plurality of discharge water channels, with lead respectively upper portion in the above-mentioned cleaning cylinder of these other ends of discharging water channels.

Like this, can dissolve cleaning agent fast, can improve cleaning performance, and can have additional functions such as the end of a thread of capture or waterfall shape spray from the discharge oral area at 1 position of cleaning cylinder bottom a plurality of discharge portion delivery cycle water to cleaning cylinder top.

The washing machine that claim 1 of the present invention is put down in writing has and utilizes pumping action with the lead circulatory function of cleaning cylinder internal upper part of cleaning fluid, this pumping action is to be formed by the intra vane of the above-mentioned rotation wing along with the action of the rotation wing that is arranged on the cleaning cylinder inside bottom, because above-mentioned washing machine is provided with the discharge oral area that an end is communicated with the pump chamber of the intra vane that comprises the above-mentioned rotation wing, this other end of discharging oral area is communicated with, with lead respectively top in the above-mentioned cleaning cylinder of other ends of these discharge water channels with a plurality of discharge water channels.Thereby, can be from the discharge oral area at 1 position of cleaning cylinder bottom a plurality of discharge portion delivery cycle water to cleaning cylinder top, thus cleaning fluid is circulated in cleaning cylinder from cleaning cylinder top, cleaning agent can be dissolved fast, cleaning performance can be improved; Can shorten scavenging period by quick removal dirt; By fully being dissolved, cleaning agent can prevent that the cleaning agent composition from remaining on the clothing of cleaning.Can also have additional functions such as the end of a thread of capture or waterfall shape spray.

The invention that claim 2 is put down in writing is owing to require will discharge the outside that oral area exports to cleaning cylinder on the 1 invention basis of being put down in writing at aforesaid right.So consider from the angle of metal pattern, discharge oral area and change between the inaccessible structure at the structure that connects outlet and the wall that forms about 2mm and with it easily, can at random select the number of discharge water channel according to the outlet number that connects.In addition, can also not have the product of circulatory function with identical cleaning cylinder exploitation, thereby improve investment results.

The invention that claim 3 is put down in writing owing to require at aforesaid right on the invention bases of 1 or 2 records, with direct in a plurality of discharge water channels of the upper portion in the cleaning cylinder at least one the end with spray the nozzle of in cleaning cylinder, sprinkling water on shape ground and be communicated with.Thereby, becoming the spray shape to spill down from nozzle from the discharge oral area of cleaning cylinder bottom water that discharge, that circulate through discharging water channel, its result, can when cleaning, cleaning fluid be spilt to the clothing that cleans with the spray shape, can improve cleaning performance, and can when cleaning, clear water be spilt to the clothing that cleans with the spray shape, improve washing (-)off properties.

The invention that claim 4 is put down in writing owing to require at aforesaid right on 1 or 2 the invention basis, is communicated with at least one the end in a plurality of discharge water channels of the upper portion in the guiding cleaning cylinder with the water filling port that is configured in the cleaning cylinder upper portion.Thereby oral area discharges by cleaning cylinder bottom is discharged, and carries, comprises the water of cleaning agent and inject with the spray shape from water filling port through discharging water channel, its result, can dissolve cleaning agent fast, can improve cleaning performance, and can shorten scavenging period by quick removal dirt.

The invention that claim 5 is put down in writing, owing to require at aforesaid right on the invention basis of 4 records, the cleaning agent box is set and is arranged to make the water of discharging just to enter in the cleaning cylinder through this cleaning agent box from water filling port, thereby discharge oral area from cleaning cylinder bottom and flow through heat-clearing method agent box through discharging water that water channel circulates and that discharge from water filling port by making, cleaning agent in the cleaning agent box is dissolved fast, can improve cleaning performance, and can prevent that the cleaning agent composition from remaining on the clothing of cleaning by cleaning agent is fully dissolved.

The invention that claim 6 is put down in writing, owing to require on the 4 invention bases of being put down in writing cotton linters filter to be set at aforesaid right, and be arranged to make the water of discharging just to enter in the cleaning cylinder through behind this cotton linters filter from water filling port.Thereby, discharge oral area from cleaning cylinder bottom by making, through the current of discharging that water channel circulates and discharging from water filling port through cotton linters filter, can capture the water be included in discharge and be the end of a thread in cleaning fluid or the clear water, prevent the end of a thread attached on the clothing that cleans, and can take off cotton linters filter, remove the end of a thread that traps easily.

To being simply described as follows of accompanying drawing:

Fig. 1 is the profile of the washing machine of the present invention the 1st embodiment.

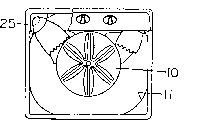

Fig. 2 be the 1st embodiment washing machine cut vertical view after the part.

Fig. 3 is the major part amplification profile of the washing machine of the 1st embodiment.

Fig. 4 is the major part decomposition diagram of the washing machine of the 1st embodiment.

Fig. 5 is the amplification plan view after the washing machine of the 1st embodiment cuts a part.

Fig. 6 is the major part vertical view of the washing machine of the present invention the 2nd embodiment.

Fig. 7 is the major part profile of the washing machine of the present invention the 2nd embodiment.

Fig. 8 is the major part profile of the washing machine of the present invention the 3rd embodiment.

Fig. 9 is the major part profile of the washing machine of the present invention the 4th embodiment.

Figure 10 is the major part decomposition diagram of existing washing machine.

Figure 11 is the major part vertical view of existing washing machine.

Below, with reference to accompanying drawing embodiments of the invention are described.The member identical with the example of prior art all adopts same numeral and saves explanation.

Embodiment 1

As Fig. 1~shown in Figure 4, be provided with rotation wing installation portion 12 in the inside bottom of cleaning cylinder 11, on this rotation wing installation portion 12, be provided with the rotation wing 10 free to rotately.The space that rotation wing installation portion 12 is configured for guaranteeing to be drawn into by the rotation of the rotation wing 10 water of the rotation wing 10 bottoms forms pump chamber.On rotation wing installation portion 12 outer peripheral edges parts, form fan-shaped recess 13.Setting-in and is discharged cover 14 on this recess 13, makes in recess 13 and the cleaning cylinder 11 to separate.Fore-end at this recess 13 is provided with discharge oral area 15, will discharge oral area 15 and export to outside the cleaning cylinder 11.

The rotation wing 10 is provided with intra vane 16 overleaf, makes its rotation by motor 17 by belt 18, belt pulley 19 and reduction gearing 20.On cleaning cylinder 11 tops and bight a plurality of pipes 21 are set accordingly, drain hose 22 is connected with discharge oral area 15 with branched pipe 23.On branched pipe 23, connect a plurality of discharge water channels 24, will discharge oral area 15 and be communicated with, at setting-in on the pipe 21 and be used for cleaning fluid to spray the nozzle 25 of shape under in cleaning cylinder 11, spilling with pipe 21.

As shown in Figure 5, the rib 12a from scallop section 13 to rotation wing installation portion 12 is being set on rotation wing installation portion 12, this rib 12a is divided into 2 parts towards the center of the rotation wing 10.This rib 12a is used for guaranteeing the effective discharging performance on the left rotation and right rotation direction of the rotation wing 10.

The following describes the action of washing machine with said structure.Put into cleaning cylinder 11, water is added to predetermined water level when making motor 17 rotations then when the clothing that desire is cleaned, make 10 rotations of the rotation wing by belt 18, belt pulley 19, reduction gearing 20.Rotation along with the rotation wing 10, the pumping action that is formed by the intra vane 16 that is arranged on the rotation wing 10 back sides makes the cleaning fluids that rotate in the wing installation portion 12 discharge by recess 13 and from discharging oral area 15, cleaning fluid is spilled in the cleaning cylinder 11 from 25 one-tenth sprays of a plurality of nozzles shape ground by discharge water channel 24, pipe 21 then.

Like this, circulate in cleaning cylinder 11 from cleaning cylinder 11 tops,, cleaning agent is dissolved rapidly, and can improve cleaning performance with the watering of spray shape by making cleaning fluid.Again owing to removing dirt rapidly, so can shorten scavenging period.Owing to cleaning agent is fully dissolved, remain on the clothing of cleaning so can prevent the cleaning agent composition.

Owing to from a plurality of nozzles 25, to cleaning cylinder 11 in, sprinkle water, when cleaning, on the clothing of cleaning, spill cleaning fluid, thereby can improve scourability to spray shape with the spray shape.In addition, when cleaning, can spill clear water to the clothing that cleans, thereby can improve washing (-)off properties with the spray shape.

Owing to will discharge the outside that oral area 15 is directed to cleaning cylinder 11, so consider from the angle of metal pattern, discharge oral area 15 and change between the inaccessible structure at the structure that runs through outlet and the wall that forms about 2mm and with it easily, can at random select the number of discharge water channel 24 according to the number of the outlet that connects.In addition, can also not have the product of circulatory function with identical cleaning cylinder exploitation, thereby can improve investment results.

In the above-described embodiments,, also 1 nozzle 25 can only be set, in addition, nozzle 25 and following water filling port can be set also though be provided with a plurality of nozzles 25 on the top of cleaning cylinder 11.

Embodiment 2

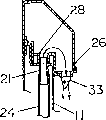

As shown in Figure 6 and Figure 7, water filling port 26 is configured on the recirculated water receiving portion 27, and recirculated water receiving portion 27 is arranged on the upper portion of cleaning cylinder 11.Be provided with connecting portion 28 on recirculated water receiving portion 27, this connecting portion 28 is communicated with pipe 21, and pipe 21 with discharge water channel 24 and be communicated with, thereby can with from the recirculated water in discharge water road 24 from 26 one-tenth waterfall shapes of water filling port be injected in the cleaning cylinder 11.

Water inlet receiving portion 29 is to be used for the water from water channel is fed in the cleaning cylinder 11, and it is intake in cleaning cylinder 11 from water inlet 30.Though be recirculated water receiving portion 27 and water inlet receiving portion 29 to be kept apart, also can water filling port 26 and water inlet 30 be formed 1 here without this dividing plate 31 with dividing plate 31.Other structure is identical with the foregoing description 1.

The following describes the action of washing machine with said structure.When the clothing that desire is cleaned is put in the cleaning cylinder 11 and begun to intake, intake by water inlet 30 by water inlet receiving portion 29.When intaking predetermined water level and when motor 17 is rotated, the rotation wing 10 is rotated by belt 18, belt pulley 19 and reduction gearing 20.The pumping action that forms along with intra vane 16 of the rotation of this rotation wing 10 by being arranged on the rotation wing 10 back sides, cleaning fluid in the rotation wing installation portion 12 is discharged by recess 13 and from discharging oral area 15, and by discharging water channel 24, pipe 21 from 26 one-tenth waterfall shape ground water fillings in cleaning cylinder 11 of water filling port.

Like this, in cleaning cylinder 11, circulate, become waterfall shape ground water filling from the top of cleaning cylinder 11, can dissolve cleaning agent fast, thereby can improve cleaning performance by making cleaning fluid.By quick removal dirt, can shorten scavenging period.Owing to cleaning agent is fully dissolved, remain on the clothing of cleaning so can prevent the cleaning agent composition.

Though be that 1 water filling port 26 is set in the above-described embodiments, also can and discharge water channel 24 a plurality of water filling ports 26 are set according to a plurality of pipes 21.

Embodiment 3

As shown in Figure 8, cleaning agent box 32 can be mounted to with freely dismantling and cleaning agent can be left in wherein, and the water of discharging from water filling port 26 just enters in the cleaning cylinder 11 through behind this cleaning agent box 32.

The following describes the action of washing machine with said structure.When the clothing that desire is cleaned is put into cleaning cylinder 11 in, cleaning agent put into cleaning agent box 32 in, the predetermined water level of intaking and when motor 17 is rotated, make by belt 18, belt pulley 19, reduction gearing 20 and rotate the wing 10 rotations.The pumping action that forms along with the rotation of this rotation wing 10, by the intra vane 16 that is arranged on the rotation wing 10 back sides, cleaning fluids in the rotation wing installation portion 12 are discharged by recess 13 and from discharging oral area 15, and by discharge water channel 24, pipe 21 from water filling port 26 through cleaning agent boxes 32 and water filling in cleaning cylinder 11.

Therefore, can dissolve the cleaning agent in the cleaning agent box 32 apace, can improve cleaning performance, and can prevent that the cleaning agent composition from residuing on the clothing of cleaning by cleaning agent is fully dissolved.

Embodiment 4

As shown in Figure 9, cotton linters filter 33 can be mounted to with freely dismantling the water of discharging from water filling port 26 just enters in the cleaning cylinder 11 through this cotton linters filter 33.Other structure is identical with the foregoing description 2.

The following describes the action of washing machine with said structure.When the clothing that desire is cleaned is put into cleaning cylinder 11 in, the water level of the regulation of intaking and when motor 17 is rotated, make 10 rotations of the rotation wing by belt 18, belt pulley 19, reduction gearing 20.The pumping action that forms along with intra vane 16 of the rotation of this rotation wing 10 by being arranged on the rotation wing 10 back sides, cleaning fluids in the rotation wing installation portion 12 are discharged by recess 13 and from discharging oral area 15, and by discharging water channel 24, pipe 21 from water filling port 26 through cotton linters filters 33 and water filling in cleaning cylinder 11.

Therefore, can capture the end of a thread that is included in cleaning fluid or the clear water, prevent the end of a thread attached on the clothing that cleans, and cotton linters filter can be taken off, remove easily the end of a thread that traps by cotton linters filter 33.

The washing machine of record has and utilizes pumping action with the lead circulatory function of cleaning cylinder internal upper part of cleaning fluid in the aforesaid claim 1 of the present invention, this pumping action is to be formed by the intra vane of the above-mentioned rotation wing along with the rotation wing action that is arranged on the cleaning cylinder inside bottom, because above-mentioned washing machine is provided with the discharge oral area that an end is communicated with the pump chamber of the intra vane that comprises the above-mentioned rotation wing, this other end of discharging oral area is communicated with a plurality of discharge water channels, with the other end of these discharge waters lead respectively in the above-mentioned cleaning cylinder the top.Thereby, can be from the discharge oral area at 1 position of cleaning cylinder bottom a plurality of discharge portion delivery cycle water to cleaning cylinder top, thus cleaning fluid is circulated in cleaning cylinder from cleaning cylinder top, can dissolve cleaning agent fast, can improve cleaning performance; Can shorten scavenging period by quick removal dirt; By fully being dissolved, cleaning agent can prevent that the cleaning agent composition from remaining on the clothing of cleaning.In addition, can also have additional functions such as the end of a thread of recovery or one-tenth waterfall shape spray.

The invention of record in the claim 2, because will discharge oral area exports to the cleaning cylinder outside, so consider from the angle of metal pattern, discharging oral area changes between the inaccessible structure at the structure that connects outlet and the wall of the about 2mm of formation and with it easily, can be according to the at random selected number of discharging water channel of the outlet number that connects, can also not have the product of circulatory function with identical cleaning cylinder exploitation in addition, thereby investment results are provided.

The invention of record in the claim 3, since will direct in a plurality of discharge water channels of the upper portion in the cleaning cylinder at least one the end with spray the nozzle of in cleaning cylinder, sprinkling water on shape ground and be communicated with, thereby, by the discharge oral area of cleaning cylinder bottom is discharged, through discharging water that water channel circulates, becoming the spray shape to spill down from nozzle, can when cleaning, cleaning fluid be spilt to the clothing that cleans with spray quinoline shape, can improve cleaning performance, and can when cleaning, clear water be spilt to the clothing that cleans with the spray shape, improve washing (-)off properties.

The invention of record in the claim 4, the end of at least one in a plurality of discharge water channels of the upper portion owing to will lead in the cleaning cylinder is communicated with the water filling port that is configured in the cleaning cylinder upper portion, so, process that oral area is discharged by discharging from the cleaning cylinder bottom discharged water channel water that carry, that comprise cleaning agent and injected with waterfall shape from water filling port, can dissolve cleaning agent fast, can improve cleaning performance, and can shorten scavenging period by quick removal dirt.

The invention of record in the claim 5, because the cleaning agent box is set, and be arranged to make the water of discharging just to enter in the cleaning cylinder cleaning agent box through this cleaning agent box from water filling port, so flow through the cleaning agent box through discharging water that water channel circulates and that discharge from water filling port by making from the discharge oral area of cleaning cylinder bottom, cleaning agent in the cleaning agent box is dissolved fast, can improve cleaning performance, can prevent that by cleaning agent is fully dissolved the cleaning agent composition from remaining on the clothing of cleaning.

Invention according to record in the claim 6, owing to cotton linters filter is set and is arranged to cotton linters filter make the water of discharging just to enter in the cleaning cylinder through behind this cotton linters filter from water filling port, so by making from the discharge oral area of cleaning cylinder bottom, the current that circulate through discharging water channel and discharge from water filling port are through cotton linters filter, can capture the water be included in discharge and be the end of a thread in cleaning fluid or the clear water, prevent that the end of a thread is attached on the clothing that cleans; And can take off cotton linters filter, remove the end of a thread trap easily.

Claims (6)

1. washing machine, it has and utilizes pumping action with the lead circulatory function of the upper portion in the cleaning cylinder of cleaning fluid, this pumping action is to be formed by the intra vane of the above-mentioned rotation wing along with the action of the rotation wing that is arranged on the cleaning cylinder inside bottom, it is characterized in that: be provided with the discharge oral area that an end is communicated with the pump chamber of the intra vane that comprises the above-mentioned rotation wing, this other end of discharging oral area is communicated with, with lead respectively upper portion in the above-mentioned cleaning cylinder of other ends of these discharge water channels with a plurality of discharge water channels.

2. washing machine as claimed in claim 1 is characterized in that: derive to the outside of cleaning cylinder discharging oral area.

3. washing machine as claimed in claim 1 or 2 is characterized in that: the end of at least one in a plurality of discharge water channels of the upper portion in the guiding cleaning cylinder is communicated with nozzle, and this nozzle is used for sprinkling water in cleaning cylinder with the spray shape.

4. washing machine as claimed in claim 1 or 2 is characterized in that: at least one the end in a plurality of discharge water channels of the upper portion of guiding in the cleaning cylinder is communicated with the water filling port of the upper portion that is configured in cleaning cylinder.

5. washing machine as claimed in claim 4 is characterized in that: be provided with the cleaning agent box, the water of discharging from water filling port is entered in the cleaning cylinder through this cleaning agent box.

6. washing machine as claimed in claim 4 is characterized in that: be provided with cotton linters filter, the water of discharging from water filling port is entered in the cleaning cylinder through this cotton linters filter.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP8121293A JPH09299684A (en) | 1996-05-16 | 1996-05-16 | Washing machine |

| JP121293/96 | 1996-05-16 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN1165885A CN1165885A (en) | 1997-11-26 |

| CN1080787C true CN1080787C (en) | 2002-03-13 |

Family

ID=14807679

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN96112450A Expired - Fee Related CN1080787C (en) | 1996-05-16 | 1996-10-17 | Washing machine |

Country Status (6)

| Country | Link |

|---|---|

| JP (1) | JPH09299684A (en) |

| KR (1) | KR100446879B1 (en) |

| CN (1) | CN1080787C (en) |

| IN (1) | IN191871B (en) |

| MY (1) | MY135117A (en) |

| TW (1) | TW417702U (en) |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4877346B2 (en) * | 2009-03-25 | 2012-02-15 | パナソニック株式会社 | Washing machine |

| JP5397093B2 (en) * | 2009-08-27 | 2014-01-22 | パナソニック株式会社 | Drum washing machine |

| CN102482834B (en) * | 2009-08-27 | 2014-12-17 | 松下电器产业株式会社 | Drum type washing machine |

| JP5299174B2 (en) * | 2009-08-27 | 2013-09-25 | パナソニック株式会社 | Drum washing machine |

| JP5397092B2 (en) * | 2009-08-27 | 2014-01-22 | パナソニック株式会社 | Drum washing machine |

| EP2392720A1 (en) * | 2010-06-04 | 2011-12-07 | Electrolux Home Products Corporation N.V. | Washing water recirculation tub arrangement |

| US9777418B2 (en) | 2013-08-05 | 2017-10-03 | Whirlpool Corporation | Laundry treating appliance laundry mover with liquid diverter |

| CN105887408B (en) * | 2016-05-19 | 2019-05-21 | 无锡小天鹅股份有限公司 | Washing machine and its control method |

| CN105839338A (en) * | 2016-05-19 | 2016-08-10 | 无锡小天鹅股份有限公司 | Pulsator washing machine as well as control method and control device thereof |

| CN107354660B (en) * | 2017-08-01 | 2022-02-01 | 青岛海尔洗衣机有限公司 | Pulsator washing machine and control method |

| CN107354678A (en) * | 2017-08-11 | 2017-11-17 | 青岛海尔洗衣机有限公司 | The channel structure and washing machine of washing machine |

| CN111350056B (en) * | 2018-12-20 | 2023-01-13 | 青岛海尔洗衣机有限公司 | Washing machine's filter equipment and washing machine |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0033114A2 (en) * | 1980-01-28 | 1981-08-05 | BASF Aktiengesellschaft | Fungicidal substituted thioureas, preparation thereof and use thereof as fungicides; compositions containing them |

| GB2287961A (en) * | 1994-04-01 | 1995-10-04 | Zanussi Elettrodomestici | Clothes washing machine with improved water recovery tank |

| US5560060A (en) * | 1995-01-10 | 1996-10-01 | General Electric Company | System and method for adjusting the operating cycle of a cleaning appliance |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3060787B2 (en) * | 1993-08-02 | 2000-07-10 | 松下電器産業株式会社 | Automatic washing machine |

-

1996

- 1996-05-16 JP JP8121293A patent/JPH09299684A/en active Pending

- 1996-09-13 IN IN1636CA1996 patent/IN191871B/en unknown

- 1996-09-20 MY MYPI96003896A patent/MY135117A/en unknown

- 1996-09-20 TW TW089201000U patent/TW417702U/en not_active IP Right Cessation

- 1996-10-02 KR KR1019960043673A patent/KR100446879B1/en not_active IP Right Cessation

- 1996-10-17 CN CN96112450A patent/CN1080787C/en not_active Expired - Fee Related

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0033114A2 (en) * | 1980-01-28 | 1981-08-05 | BASF Aktiengesellschaft | Fungicidal substituted thioureas, preparation thereof and use thereof as fungicides; compositions containing them |

| GB2287961A (en) * | 1994-04-01 | 1995-10-04 | Zanussi Elettrodomestici | Clothes washing machine with improved water recovery tank |

| US5560060A (en) * | 1995-01-10 | 1996-10-01 | General Electric Company | System and method for adjusting the operating cycle of a cleaning appliance |

Also Published As

| Publication number | Publication date |

|---|---|

| TW417702U (en) | 2001-01-01 |

| IN191871B (en) | 2004-01-10 |

| KR100446879B1 (en) | 2004-11-08 |

| KR970075088A (en) | 1997-12-10 |

| CN1165885A (en) | 1997-11-26 |

| MY135117A (en) | 2008-02-29 |

| JPH09299684A (en) | 1997-11-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN1080787C (en) | Washing machine | |

| CN1239773C (en) | Washing machine | |

| CN1176632C (en) | Water filter for dish-washing machine | |

| CN1203803C (en) | Dishwasher | |

| CN1132283A (en) | Filter installed in water-flowing path washing machine | |

| CN212345157U (en) | Crayfish cleaning equipment | |

| CN110548714A (en) | automatic change chinese-medicinal material belt cleaning device | |

| CN220000672U (en) | High-pressure spray cleaning machine for rough roller | |

| CN110787516A (en) | Rotary drum filter | |

| CN1137587A (en) | Washing machine having detachable washing bucket | |

| CN211079613U (en) | High-efficient cloth wool washing device | |

| CN210445603U (en) | Peanut belt cleaning device | |

| CN217797623U (en) | Treatment tank for cleaning stainless steel welding wires | |

| CN217773365U (en) | Pretreatment device for purified water | |

| CN1086212C (en) | Washing machine | |

| CN216857505U (en) | Cleaning device of tapping machine | |

| CN113578856B (en) | Cleaning device is used in production of mechanical equipment spare part | |

| CN214441212U (en) | Traditional chinese medicine cleaning and drying machine | |

| CN215075357U (en) | A belt cleaning device for hickory chick | |

| CN221601625U (en) | Benzene washing tower circulation cleaning device | |

| CN213435884U (en) | Chain belt cleaning device | |

| CN214211476U (en) | Water circulation treatment system for fish tofu packaging | |

| CN218797701U (en) | Hydraulic motor rotor belt cleaning device | |

| CN217411654U (en) | Talc ore dressing ore raw material belt cleaning device | |

| CN221816886U (en) | Cleaning machine with filtering structure |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C17 | Cessation of patent right | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20020313 Termination date: 20131017 |