CN107849703B - 带涂层的滑动元件 - Google Patents

带涂层的滑动元件 Download PDFInfo

- Publication number

- CN107849703B CN107849703B CN201680035774.5A CN201680035774A CN107849703B CN 107849703 B CN107849703 B CN 107849703B CN 201680035774 A CN201680035774 A CN 201680035774A CN 107849703 B CN107849703 B CN 107849703B

- Authority

- CN

- China

- Prior art keywords

- coating

- chromium

- sliding

- primer layer

- primer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/06—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the coating material

- C23C14/0641—Nitrides

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/22—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the process of coating

- C23C14/24—Vacuum evaporation

- C23C14/28—Vacuum evaporation by wave energy or particle radiation

- C23C14/30—Vacuum evaporation by wave energy or particle radiation by electron bombardment

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/22—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the process of coating

- C23C14/34—Sputtering

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/06—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the deposition of metallic material

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/22—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the deposition of inorganic material, other than metallic material

- C23C16/26—Deposition of carbon only

- C23C16/27—Diamond only

- C23C16/276—Diamond only using plasma jets

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/22—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the deposition of inorganic material, other than metallic material

- C23C16/30—Deposition of compounds, mixtures or solid solutions, e.g. borides, carbides, nitrides

- C23C16/32—Carbides

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/22—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the deposition of inorganic material, other than metallic material

- C23C16/30—Deposition of compounds, mixtures or solid solutions, e.g. borides, carbides, nitrides

- C23C16/34—Nitrides

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/56—After-treatment

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C28/00—Coating for obtaining at least two superposed coatings either by methods not provided for in a single one of groups C23C2/00 - C23C26/00 or by combinations of methods provided for in subclasses C23C and C25C or C25D

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C28/00—Coating for obtaining at least two superposed coatings either by methods not provided for in a single one of groups C23C2/00 - C23C26/00 or by combinations of methods provided for in subclasses C23C and C25C or C25D

- C23C28/04—Coating for obtaining at least two superposed coatings either by methods not provided for in a single one of groups C23C2/00 - C23C26/00 or by combinations of methods provided for in subclasses C23C and C25C or C25D only coatings of inorganic non-metallic material

- C23C28/044—Coating for obtaining at least two superposed coatings either by methods not provided for in a single one of groups C23C2/00 - C23C26/00 or by combinations of methods provided for in subclasses C23C and C25C or C25D only coatings of inorganic non-metallic material coatings specially adapted for cutting tools or wear applications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C28/00—Coating for obtaining at least two superposed coatings either by methods not provided for in a single one of groups C23C2/00 - C23C26/00 or by combinations of methods provided for in subclasses C23C and C25C or C25D

- C23C28/30—Coatings combining at least one metallic layer and at least one inorganic non-metallic layer

- C23C28/34—Coatings combining at least one metallic layer and at least one inorganic non-metallic layer including at least one inorganic non-metallic material layer, e.g. metal carbide, nitride, boride, silicide layer and their mixtures, enamels, phosphates and sulphates

- C23C28/347—Coatings combining at least one metallic layer and at least one inorganic non-metallic layer including at least one inorganic non-metallic material layer, e.g. metal carbide, nitride, boride, silicide layer and their mixtures, enamels, phosphates and sulphates with layers adapted for cutting tools or wear applications

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25D—PROCESSES FOR THE ELECTROLYTIC OR ELECTROPHORETIC PRODUCTION OF COATINGS; ELECTROFORMING; APPARATUS THEREFOR

- C25D15/00—Electrolytic or electrophoretic production of coatings containing embedded materials, e.g. particles, whiskers, wires

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25D—PROCESSES FOR THE ELECTROLYTIC OR ELECTROPHORETIC PRODUCTION OF COATINGS; ELECTROFORMING; APPARATUS THEREFOR

- C25D3/00—Electroplating: Baths therefor

- C25D3/02—Electroplating: Baths therefor from solutions

- C25D3/04—Electroplating: Baths therefor from solutions of chromium

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25D—PROCESSES FOR THE ELECTROLYTIC OR ELECTROPHORETIC PRODUCTION OF COATINGS; ELECTROFORMING; APPARATUS THEREFOR

- C25D7/00—Electroplating characterised by the article coated

- C25D7/10—Bearings

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25D—PROCESSES FOR THE ELECTROLYTIC OR ELECTROPHORETIC PRODUCTION OF COATINGS; ELECTROFORMING; APPARATUS THEREFOR

- C25D9/00—Electrolytic coating other than with metals

- C25D9/04—Electrolytic coating other than with metals with inorganic materials

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16J—PISTONS; CYLINDERS; SEALINGS

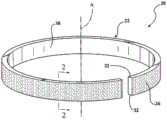

- F16J9/00—Piston-rings, e.g. non-metallic piston-rings, seats therefor; Ring sealings of similar construction

- F16J9/26—Piston-rings, e.g. non-metallic piston-rings, seats therefor; Ring sealings of similar construction characterised by the use of particular materials

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16J—PISTONS; CYLINDERS; SEALINGS

- F16J9/00—Piston-rings, e.g. non-metallic piston-rings, seats therefor; Ring sealings of similar construction

- F16J9/28—Piston-rings, e.g. non-metallic piston-rings, seats therefor; Ring sealings of similar construction of non-metals

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25D—PROCESSES FOR THE ELECTROLYTIC OR ELECTROPHORETIC PRODUCTION OF COATINGS; ELECTROFORMING; APPARATUS THEREFOR

- C25D5/00—Electroplating characterised by the process; Pretreatment or after-treatment of workpieces

- C25D5/10—Electroplating with more than one layer of the same or of different metals

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25D—PROCESSES FOR THE ELECTROLYTIC OR ELECTROPHORETIC PRODUCTION OF COATINGS; ELECTROFORMING; APPARATUS THEREFOR

- C25D5/00—Electroplating characterised by the process; Pretreatment or after-treatment of workpieces

- C25D5/60—Electroplating characterised by the structure or texture of the layers

- C25D5/605—Surface topography of the layers, e.g. rough, dendritic or nodular layers

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25D—PROCESSES FOR THE ELECTROLYTIC OR ELECTROPHORETIC PRODUCTION OF COATINGS; ELECTROFORMING; APPARATUS THEREFOR

- C25D5/00—Electroplating characterised by the process; Pretreatment or after-treatment of workpieces

- C25D5/60—Electroplating characterised by the structure or texture of the layers

- C25D5/605—Surface topography of the layers, e.g. rough, dendritic or nodular layers

- C25D5/611—Smooth layers

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25D—PROCESSES FOR THE ELECTROLYTIC OR ELECTROPHORETIC PRODUCTION OF COATINGS; ELECTROFORMING; APPARATUS THEREFOR

- C25D5/00—Electroplating characterised by the process; Pretreatment or after-treatment of workpieces

- C25D5/60—Electroplating characterised by the structure or texture of the layers

- C25D5/625—Discontinuous layers, e.g. microcracked layers

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Inorganic Chemistry (AREA)

- Electrochemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Toxicology (AREA)

- Health & Medical Sciences (AREA)

- Physics & Mathematics (AREA)

- Plasma & Fusion (AREA)

- Pistons, Piston Rings, And Cylinders (AREA)

- Coating By Spraying Or Casting (AREA)

- Physical Vapour Deposition (AREA)

- Chemical Vapour Deposition (AREA)

- Other Surface Treatments For Metallic Materials (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US14/693,194 US9551419B2 (en) | 2015-04-22 | 2015-04-22 | Coated sliding element |

| US14/693,194 | 2015-04-22 | ||

| PCT/US2016/028227 WO2016172071A1 (en) | 2015-04-22 | 2016-04-19 | Coated sliding element |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN107849703A CN107849703A (zh) | 2018-03-27 |

| CN107849703B true CN107849703B (zh) | 2021-10-15 |

Family

ID=56015083

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201680035774.5A Active CN107849703B (zh) | 2015-04-22 | 2016-04-19 | 带涂层的滑动元件 |

Country Status (7)

| Country | Link |

|---|---|

| US (2) | US9551419B2 (enExample) |

| EP (1) | EP3286353B1 (enExample) |

| JP (1) | JP2018513278A (enExample) |

| KR (1) | KR20170140278A (enExample) |

| CN (1) | CN107849703B (enExample) |

| BR (1) | BR112017022769A2 (enExample) |

| WO (1) | WO2016172071A1 (enExample) |

Families Citing this family (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3096046B1 (en) * | 2015-05-22 | 2019-04-03 | Goodrich Actuation Systems SAS | Abradable seal |

| US20170030211A1 (en) * | 2015-07-28 | 2017-02-02 | General Electric Company | Seals with a conformable coating for turbomachinery |

| US9945481B2 (en) * | 2016-07-07 | 2018-04-17 | Federal-Mogul Llc | Polymer coating in cracked piston ring coating |

| CN108070833B (zh) * | 2016-11-17 | 2019-12-13 | 宁波江丰电子材料股份有限公司 | 聚焦环及其工作方法 |

| US10323747B2 (en) * | 2017-03-28 | 2019-06-18 | Mahle International Gmbh | Piston ring and method for manufacturing a piston ring |

| US10563764B2 (en) | 2017-05-26 | 2020-02-18 | Mahle International Gmbh | Coated steel piston ring |

| CN108070816A (zh) * | 2017-11-29 | 2018-05-25 | 马鞍山市恒特重工科技有限公司 | 一种提升铣刨机刀头耐磨性能的方法 |

| DE102017221606A1 (de) | 2017-11-30 | 2019-06-06 | Federal-Mogul Burscheid Gmbh | Kolbenring |

| US11255432B2 (en) * | 2019-04-05 | 2022-02-22 | Raytheon Technologies Corporation | Low friction, wear resistant piston seal |

| JP2022530796A (ja) * | 2019-04-29 | 2022-07-01 | ベルンドルフ イノベーションズ ウント テクノロジー ゲゼルシャフト ミット ベシュレンクテル ハフツング | ベルト本体を備えたエンドレスベルトを製造する方法 |

| CN111364086B (zh) * | 2020-04-20 | 2021-07-27 | 安徽士必达液压器材有限公司 | 石油钻杆内孔壁纳米金属陶瓷电沉积镀层及其制备方法 |

| CN111455316A (zh) * | 2020-06-03 | 2020-07-28 | 中国科学院兰州化学物理研究所 | 利用磁控溅射技术制备Mo-S-C-N自组装纳米多层薄膜的方法 |

| GB2614640B (en) * | 2020-09-09 | 2025-05-07 | Waukesha Bearings Corp | Composite structures for reciprocating gas compressor systems |

| CN112376017A (zh) * | 2020-11-13 | 2021-02-19 | 西安工业大学 | 一种具有耐磨涂层的纺织钢领及其制备方法 |

| CN113005488A (zh) * | 2020-12-30 | 2021-06-22 | 比尔安达(上海)润滑材料有限公司 | 一种高硬度和低摩擦系数的二硫化钨掺杂复合涂层的制备方法 |

| US20220364643A1 (en) * | 2021-05-12 | 2022-11-17 | Tenneco Inc. | Coated piston ring for an internal combustion engine |

| CN115094368B (zh) * | 2022-06-30 | 2024-02-09 | 安徽聚力石油钻采设备科技有限公司 | 一种免喷涂柱塞的制备方法 |

| US12522922B2 (en) * | 2023-06-13 | 2026-01-13 | Rtx Corporation | Coating system and substrate with coating system |

| JP7634799B1 (ja) * | 2024-09-30 | 2025-02-21 | 株式会社リケン | 摺動部材の製造方法、摺動部材、及びピストンリング |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2003064463A (ja) * | 2001-06-15 | 2003-03-05 | Nippon Piston Ring Co Ltd | 摺動部材の耐摩耗性溶射皮膜 |

| JP5453533B2 (ja) * | 2010-07-09 | 2014-03-26 | 大同メタル工業株式会社 | 摺動部材 |

Family Cites Families (31)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3806139A (en) | 1972-03-30 | 1974-04-23 | Nippon Piston Ring Co Ltd | Piston ring |

| JPS5823256A (ja) | 1981-08-05 | 1983-02-10 | Toyota Motor Corp | ピストンリング |

| JPS62233458A (ja) | 1986-03-31 | 1987-10-13 | Riken Corp | ピストンリング |

| JP2681967B2 (ja) | 1988-02-12 | 1997-11-26 | トヨタ自動車株式会社 | ピストン−ピストンリングアッセンブリ |

| JPH0763266A (ja) | 1993-08-25 | 1995-03-07 | Nippon Piston Ring Co Ltd | ピストンリング |

| JP3070815B2 (ja) * | 1993-09-03 | 2000-07-31 | トヨタ自動車株式会社 | すべり軸受構造 |

| US5490445A (en) | 1994-03-14 | 1996-02-13 | Ford Motor Company | Ultra low device volume piston system |

| US5598763A (en) | 1994-03-14 | 1997-02-04 | Ford Motor Company | Flutter free piston ring assembly |

| US5392692A (en) | 1994-03-14 | 1995-02-28 | Ford Motor Company | Antiblow-by piston and seal construction for high temperature applications |

| US5430938A (en) | 1994-03-14 | 1995-07-11 | Ford Motor Company | Method of making and using a piston ring assembly |

| DE19614105B4 (de) | 1996-04-10 | 2005-08-25 | Federal-Mogul Wiesbaden Gmbh & Co. Kg | Gleitschichtmaterial für Verbundlager, Schichtverbundwerkstoff und Stoßdämpferstangenführungselement |

| WO1999043963A1 (en) | 1998-02-24 | 1999-09-02 | Taiho Kogyo Co., Ltd. | Sliding bearing for internal combustion engine |

| DE60332705D1 (de) * | 2002-01-18 | 2010-07-08 | Riken Kk | Kolbenring mit spritzbeschichtung |

| JP2007107589A (ja) | 2005-10-12 | 2007-04-26 | Daido Metal Co Ltd | すべり軸受 |

| WO2007099968A1 (ja) | 2006-02-28 | 2007-09-07 | Nippon Piston Ring Co., Ltd. | ピストンリング |

| DE112007002854T5 (de) | 2006-11-24 | 2009-10-29 | Kabushiki Kaisha Riken | Kolbenring |

| US20120114971A1 (en) * | 2007-01-05 | 2012-05-10 | Gerd Andler | Wear resistant lead free alloy sliding element method of making |

| JP2008286375A (ja) * | 2007-05-21 | 2008-11-27 | Ntn Corp | 摺動部材用組成物および転がり軸受 |

| DE102008038636B4 (de) | 2007-08-24 | 2012-10-25 | Nippon Piston Ring Co., Ltd. | Kolbenring |

| US20100319647A1 (en) * | 2007-11-30 | 2010-12-23 | Nippon Piston Ring Co., Ltd. | Combination structure of piston ring and cylinder liner for internal combustion engine |

| DE102008055194A1 (de) * | 2008-12-30 | 2010-07-08 | Federal-Mogul Wiesbaden Gmbh | Gleitelement |

| DE102009046281B3 (de) * | 2009-11-02 | 2010-11-25 | Federal-Mogul Burscheid Gmbh | Gleitelement, insbesondere Kolbenring, und Kombination eines Gleitelements mit einem Laufpartner |

| EP2511575B1 (en) | 2009-12-08 | 2016-08-24 | Kabushiki Kaisha Riken | Piston ring and piston device |

| US8906130B2 (en) * | 2010-04-19 | 2014-12-09 | Praxair S.T. Technology, Inc. | Coatings and powders, methods of making same, and uses thereof |

| DE102010062114B4 (de) * | 2010-11-29 | 2014-12-11 | Federal-Mogul Burscheid Gmbh | Gleitelement, insbesondere Kolbenring, mit einer Beschichtung |

| JP2012202522A (ja) * | 2011-03-28 | 2012-10-22 | Tpr Co Ltd | ピストンリング |

| EP2771594B1 (en) * | 2011-10-27 | 2019-05-29 | Tenneco Inc. | Piston assembly including a polymer coating with hard particles applied to sliding surfaces |

| MX359796B (es) | 2011-10-31 | 2018-10-10 | Kk Riken | Junta de pistón. |

| JP6312189B2 (ja) * | 2012-03-30 | 2018-04-18 | 住友電工焼結合金株式会社 | 摺動部材、及び摺動部材の製造方法 |

| WO2014054286A1 (ja) * | 2012-10-02 | 2014-04-10 | 株式会社リケン | ピストンリング |

| DE102012020756A1 (de) | 2012-10-23 | 2014-04-24 | Mahle International Gmbh | Bauteil mit einer Beschichtung und Verfahren zu seiner Herstellung |

-

2015

- 2015-04-22 US US14/693,194 patent/US9551419B2/en active Active

-

2016

- 2016-04-19 BR BR112017022769A patent/BR112017022769A2/pt not_active Application Discontinuation

- 2016-04-19 EP EP16723566.2A patent/EP3286353B1/en active Active

- 2016-04-19 KR KR1020177032945A patent/KR20170140278A/ko not_active Withdrawn

- 2016-04-19 JP JP2017555567A patent/JP2018513278A/ja active Pending

- 2016-04-19 CN CN201680035774.5A patent/CN107849703B/zh active Active

- 2016-04-19 WO PCT/US2016/028227 patent/WO2016172071A1/en not_active Ceased

-

2017

- 2017-01-23 US US15/412,551 patent/US9816613B2/en active Active

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2003064463A (ja) * | 2001-06-15 | 2003-03-05 | Nippon Piston Ring Co Ltd | 摺動部材の耐摩耗性溶射皮膜 |

| JP5453533B2 (ja) * | 2010-07-09 | 2014-03-26 | 大同メタル工業株式会社 | 摺動部材 |

Also Published As

| Publication number | Publication date |

|---|---|

| US20170130841A1 (en) | 2017-05-11 |

| US20160312891A1 (en) | 2016-10-27 |

| US9551419B2 (en) | 2017-01-24 |

| JP2018513278A (ja) | 2018-05-24 |

| KR20170140278A (ko) | 2017-12-20 |

| CN107849703A (zh) | 2018-03-27 |

| EP3286353B1 (en) | 2019-06-19 |

| WO2016172071A1 (en) | 2016-10-27 |

| BR112017022769A2 (pt) | 2018-07-10 |

| US9816613B2 (en) | 2017-11-14 |

| EP3286353A1 (en) | 2018-02-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN107849703B (zh) | 带涂层的滑动元件 | |

| JP5030439B2 (ja) | 摺動部材 | |

| JP5452734B2 (ja) | コーティングを有するスライド要素、特に、ピストンリング、およびスライド要素を製造するプロセス | |

| EP3657000B1 (en) | Cast iron cylinder liner, and internal combustion engine | |

| CN1103878C (zh) | 带有涂层的滚动元件轴承 | |

| RU2649490C2 (ru) | Скользящий элемент, в частности поршневое кольцо, с покрытием | |

| EP1837534A2 (en) | Titanium spherical plain bearing with liner and treated surface | |

| KR102849689B1 (ko) | 마찰 방지 래커, 이러한 마찰 방지 래커를 갖는 슬라이딩 요소 및 그 이용 | |

| KR20120042769A (ko) | 코팅을 구비한 활주 요소, 특히 피스톤 링 | |

| KR20130048719A (ko) | 슬라이딩 부재, 특히 피스톤 링, 및 슬라이딩 부재의 코팅 방법 | |

| CN102272468A (zh) | 滑动元件 | |

| CN110678675B (zh) | 活塞环及制造方法 | |

| KR20210008872A (ko) | 내마모성 피막, 내마모성 부재, 내마모성 피막의 제조 방법 및 슬라이딩 기구 | |

| CN112204279A (zh) | 轴密封装置 | |

| US9945481B2 (en) | Polymer coating in cracked piston ring coating | |

| Tyagi et al. | Effect of temperature on the sliding wear behavior of HVOF sprayed Al2O3 composite coating | |

| CN112128222B (zh) | 金属元件表面上的接触层和具有这种接触层的铰链 | |

| US20140137831A1 (en) | Cylinder Bore Coating System | |

| JP5376668B2 (ja) | ピストンリング | |

| JP5981013B1 (ja) | 内燃機関用ピストンリング | |

| US20230193950A1 (en) | Plain bearing, notably for aerospace applications, having improved wear resistance | |

| CN118911864A (zh) | 活塞环覆层 | |

| WO2023013264A1 (ja) | オイルリング |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| TR01 | Transfer of patent right | ||

| TR01 | Transfer of patent right |

Effective date of registration: 20240328 Address after: michigan Patentee after: Tenneco Co.,Ltd. Country or region after: U.S.A. Address before: 27300 West Eleven Mile Highway South Field, Michigan, USA Patentee before: FEDERAL-MOGUL Corp. Country or region before: U.S.A. |