CN107546552B - Plug connector and combination thereof - Google Patents

Plug connector and combination thereof Download PDFInfo

- Publication number

- CN107546552B CN107546552B CN201610482281.8A CN201610482281A CN107546552B CN 107546552 B CN107546552 B CN 107546552B CN 201610482281 A CN201610482281 A CN 201610482281A CN 107546552 B CN107546552 B CN 107546552B

- Authority

- CN

- China

- Prior art keywords

- protruding

- lock catch

- locking

- plug connector

- button

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 230000013011 mating Effects 0.000 claims description 29

- 238000001514 detection method Methods 0.000 claims description 28

- 210000001503 joint Anatomy 0.000 claims description 16

- 238000003825 pressing Methods 0.000 claims description 11

- 239000012212 insulator Substances 0.000 claims description 8

- 238000009413 insulation Methods 0.000 claims description 3

- 230000005489 elastic deformation Effects 0.000 claims 1

- 230000009286 beneficial effect Effects 0.000 abstract description 2

- 239000002184 metal Substances 0.000 description 4

- 238000000034 method Methods 0.000 description 3

- 230000000994 depressogenic effect Effects 0.000 description 2

- 230000000149 penetrating effect Effects 0.000 description 2

- 229910001220 stainless steel Inorganic materials 0.000 description 2

- 239000010935 stainless steel Substances 0.000 description 2

- 238000010276 construction Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 238000003032 molecular docking Methods 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

- 239000004065 semiconductor Substances 0.000 description 1

Images

Landscapes

- Details Of Connecting Devices For Male And Female Coupling (AREA)

Abstract

The invention discloses a plug connector and a combination thereof, the plug connector comprises a plug connector and a socket connector, the plug connector comprises a first insulating body, a locking part and an insulating shell, the socket connector comprises a shell, the locking part comprises a locking arm which can be pressed and rebounded, the locking arm is provided with a protruding part protruding out of the first insulating body and a locking part, a button is arranged at the position of the insulating shell corresponding to the protruding part, a limiting groove is arranged at the position of the shell corresponding to the locking part, the locking part is limited in the limiting groove during inserting and matching, the button can be pressed to drive the locking arm to elastically deform so that the locking part is separated from the limiting of the limiting groove, and the inserting or disconnecting of the electric connector combination can be divided into a plurality of stages by the matching of the locking part, the button and the limiting groove, thereby being beneficial to avoiding instant discharge of a power terminal and improving the safety of the.

Description

[ technical field ] A method for producing a semiconductor device

The present invention relates to a plug connector and a combination thereof, and more particularly, to a plug connector and a combination thereof which are safe during plugging.

[ background of the invention ]

The prior art refers to an electrical connector assembly disclosed in the chinese utility model No. CN204144588U, the connector comprises a first connector and a second connector which are matched with each other, wherein the first connector comprises a first insulating body and a first terminal which is fixedly held on the first insulating body, the second connector comprises a second insulating body and a second terminal which is fixedly held on the second insulating body, the first terminal and the second terminal respectively comprise five terminals, the five terminals are respectively a detection terminal positioned in the middle and power supply terminals positioned at two sides of the detection terminal, in the butt joint direction, the five first terminals are arranged in parallel, the five second terminals are also arranged in parallel, when the first connector and the second connector are plugged in and pulled out, the first and second power terminals and the first and second detecting terminals are simultaneously connected or disconnected, the instant discharge of the power supply terminal can be caused, potential safety hazards exist, and the service life of the electric connector is influenced.

Therefore, there is a need to provide a new plug connector and a combination thereof to overcome the above-mentioned drawbacks.

[ summary of the invention ]

The invention aims to provide a plug connector and a combination thereof, wherein the process of plugging and disconnecting the plug connector has a plurality of stages, so that the instant discharge of a power terminal can be avoided, and the safety of the electric connector is improved.

The purpose of the invention is realized by the following technical scheme one: a plug connector comprises a first insulating body, a first terminal fixedly held on the first insulating body, a locking piece fixed on the first insulating body and an insulating shell assembled outside the first insulating body, wherein the locking piece comprises a locking arm capable of being pressed and rebounded, the locking arm is provided with a protruding part protruding out of the first insulating body, the insulating shell corresponds to the position of the protruding part and is provided with a button capable of pressing the protruding part, the locking arm is provided with a locking part protruding in the same direction as the protruding part, and the button can be pressed to further drive the protruding part to further drive the locking arm to elastically deform in the protruding direction so as to enable the locking part to deviate in the protruding direction.

Furthermore, the first insulating body comprises a pair of first bearing parts extending along a butt joint direction and a second bearing part located between the two first bearing parts, the lock catch arm comprises a pair of first lock catch arms extending along the butt joint direction and arranged above the second bearing part, and the first lock catch arm is provided with a first protruding part protruding out of the second bearing part and a first locking part protruding in the same direction as the first protruding part.

Furthermore, the button comprises a first button which is arranged at a position corresponding to the first protruding part and can be pressed along the protruding direction of the first protruding part, and the first button can be contacted with the first protruding part and further drives the first locking arm to elastically deform along the protruding direction by pressing the first button, so that the first locking part deviates along the protruding direction.

Furthermore, the lock catch part comprises a pair of second lock catch arms extending in the same direction as the first lock catch arms, the two second lock catch arms are respectively fixed on the outer sides of the two first bearing parts, the second lock catch arms extend to form second locking parts, the extending direction of the second locking parts is perpendicular to the extending direction of the first locking parts, the second lock catch arms are provided with second protruding parts extending in the same direction as the second locking parts, the buttons comprise second buttons which are arranged corresponding to the positions of the second protruding parts and can be pressed along the extending direction of the second protruding parts, and the second buttons can be pressed to contact with the second protruding parts and further drive the second lock catch arms to elastically deform so that the second locking parts can deviate along the extending direction.

Furthermore, the first terminal includes a first detection terminal, the first detection terminal is provided with a first detection portion, a protruding portion protruding out of the first insulation body is arranged behind the first detection portion, the protruding portion is located between the pair of latch arms, and pressing the button can enable the button to be in contact with the protruding portion and further drive the first detection portion to elastically deform.

The purpose of the invention is also realized by the following technical scheme II: a plug connector combination is defined with a butt joint direction and comprises a plug connector and a socket connector which can be matched in a plug-in mode, wherein the plug connector comprises a first insulating body, a first terminal fixedly held on the first insulating body, a locking piece fixed on the first insulating body and an insulating shell assembled on the outer side of the first insulating body, the socket connector comprises a second insulating body, a second terminal fixedly held on the second insulating body and a shell body covered on the outer side of the second insulating body, the locking piece comprises a locking arm capable of rebounding under pressure, the locking arm is provided with a protruding portion protruding out of the first insulating body and a locking portion protruding out in the same direction with the protruding portion, a button capable of pressing the protruding portion is arranged at the position, corresponding to the protruding portion, of the insulating shell body, and a limiting groove is arranged at the position, corresponding to the locking portion, of the shell body, when the electric connector combination is in inserting matching, the clamping lock part is limited in the limiting groove, the button is pressed to realize the contact of the button and the protruding part and further drive the lock catch arm to elastically deform along the protruding direction, so that the clamping lock part is separated from the limiting groove for limiting.

Furthermore, first insulator includes a pair of edge first supporting part that the butt joint direction extends and is located second supporting part between two first supporting parts, the hasp arm includes along the butt joint direction extends and locates a pair of first hasp arm of second supporting part top, first hasp arm is equipped with protruding first protruding portion that stretches out second supporting part and with the protruding first latch portion that stretches out of first protruding portion syntropy, institute the spacing groove is including corresponding first spacing groove that first latch portion set up.

Furthermore, the button comprises a first button which is arranged at a position corresponding to the first protruding part and can be pressed along the protruding direction of the first protruding part, and the first button can be contacted with the first protruding part and further drives the first locking arm to elastically deform along the protruding direction by pressing the first button, so that the first locking part is separated from the limit of the first limit groove.

Further, the lock catch part comprises a pair of second lock catch arms extending in the same direction as the first lock catch arms, the two second lock catch arms are respectively fixed on the outer sides of the two first bearing parts, the second lock catch arms extend to form second locking parts, the shell is provided with second limiting grooves corresponding to the second locking parts, the second lock catch arms are provided with second protruding parts extending in the same direction as the second locking parts, the buttons comprise second buttons which are arranged in positions corresponding to the second protruding parts and can be pressed in the extending direction of the second protruding parts, and the second buttons can be pressed to contact with the second protruding parts and further drive the second lock catch arms to elastically deform so that the second locking parts are separated from the limiting positions of the second limiting grooves.

Furthermore, the first terminal includes a first detecting terminal and a first power terminal, the second terminal includes a second detecting terminal and a second power terminal respectively butted with the first detecting terminal and the first power terminal, the length of the second limiting groove is greater than the length of the first limiting groove, when the mated plug connector is pulled out from the socket connector, the first button is pressed to drive the boss and the first protrusion to be pressed down, so that the first detecting part and the second detecting part are disconnected and the first latch part is separated from the limit of the first limiting groove, at this time, the first power terminal and the second power terminal are still connected and the second latch part is still limited in the second limiting groove, further, the plug connector is moved to the edge of the second limiting groove along the second limiting groove to the position far away from the socket connector, and finally, after the second button is pressed, the second clamping lock part is pressed to deviate so as to be separated from the limit of the second limit groove, and at the moment, the plug connector can be completely pulled out of the socket connector along the butting direction.

Compared with the prior art, the invention has the following beneficial effects: the plug connector and the combination thereof have the advantages that the matching of the locking piece and the button can divide the plugging or the disconnection of the electric connector combination into a plurality of stages, namely, the detection terminal is in butt joint or disconnection with the power terminal in different time sequences, the instant discharge of the power terminal is avoided, the safety index and the service life of the electric connector are improved, and in addition, the design of controlling the opening and the closing of the detection terminal by the first button further increases the safety of the electric connector and is convenient to operate.

[ description of the drawings ]

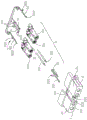

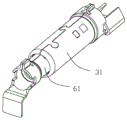

Fig. 1 is a perspective view of a plug connector of the present invention.

Fig. 2 is an exploded perspective view of the plug connector shown in fig. 1.

Figure 3 is an exploded perspective view of the plug connector of figure 2 from another angle.

Fig. 4 is a partially exploded perspective view of the plug connector of the present invention.

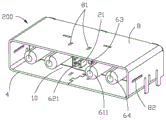

Fig. 5 is a perspective view of the receptacle connector of the present invention.

Fig. 6 is an exploded perspective view of the receptacle connector shown in fig. 5.

Fig. 7 is an exploded perspective view of the receptacle connector of fig. 6 from another angle.

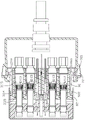

Figure 8 is a perspective view of a plug connector assembly of the present invention.

Fig. 9 is a perspective view of the plug connector assembly of fig. 8 at another angle.

Fig. 10 is a perspective view showing a mated state of the plug connector assembly of the present invention.

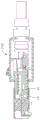

Figure 11 is a cross-sectional view of the plug connector assembly of the present invention taken along line a-a of figure 10.

Figure 12 is a cross-sectional view of the plug connector assembly of the present invention taken along line B-B of figure 10.

Fig. 13 is a perspective view showing another mated state of the plug connector assembly of the present invention.

Figure 14 is a cross-sectional view of the plug connector assembly of the present invention taken along line C-C of figure 13.

Figure 15 is a cross-sectional view of the plug connector assembly of the present invention taken along line D-D of figure 13.

Fig. 16 is a cross-sectional view of the plug connector combination of fig. 14 shown with the first button depressed.

Figure 17 is a cross-sectional view of the plug connector combination of figure 12 shown with the second button depressed.

Fig. 18 is an exploded perspective view of the first terminal and a perspective view of the second terminal of the plug connector assembly of the present invention.

Fig. 19 is a perspective view of the plug connector assembly of the present invention with the first and second terminals mated.

[ description of main reference symbols ]

| A first |

1 | |

51 |

| |

10 | |

52 |

| |

100 | Supporting |

521 |

| |

1000 | Second |

522 |

| First insulating body | 2 | A |

53 |

| |

200 | Third coordination moiety | 54 |

| A first bearing |

21 | |

6 |

| Second bearing |

22 | Second |

61 |

| Accommodating |

211 | |

611 |

| |

221 | Second detecting |

62 |

| Inserting |

222 | The second detecting |

621 |

| |

23 | |

63 |

| First |

231 | Second butt |

631 |

| First terminal | 3 | |

64 |

| First |

31 | |

641 |

| |

311 | |

7 |

| |

3111 | |

71 |

| Clamping |

3112 | |

72 |

| |

3113 | |

8 |

| |

3114 | |

81 |

| Limiting |

3115 | |

82 |

| First detecting |

32 | Second coordination moiety | 83 |

| A first detecting part | 321 | A |

84 |

| Raised |

322 | |

9 |

| |

33 | First latch arm | 91 |

| A first butt |

331 | First protruding |

911 |

| |

34 | |

912 |

| |

341 | |

92 |

| Second butt |

4 | |

921 |

| Second |

5 | |

922 |

The following detailed description will further illustrate the invention in conjunction with the above-described figures.

[ detailed description ] embodiments

Hereinafter, embodiments of the plug connector and the combination thereof according to the present invention will be described with reference to fig. 1 to 19.

Referring to fig. 1 to 9, the present invention discloses a plug connector assembly 1000 including a plug connector 100 and a receptacle connector 200 mated with each other. The mating direction is defined as the plugging direction of the plug connector 100 and the receptacle connector 200.

As shown in fig. 1 to 7, the plug connector 100 is provided with a first mating face 1 located at the front end in the mating direction and includes a first insulating body 2, a first terminal 3 held on the first insulating body 2, a latch 9 fixed on the first insulating body 2, and an insulating housing 7 covering the first insulating body 2, wherein the insulating housing 7 is provided with a button; the receptacle connector 200 has a second mating surface 4 and includes a second insulative housing 5, a second terminal 6 fixed to the second insulative housing 5, and a housing 8 covering the second insulative housing 5, wherein a mating space 10 is formed between the housing 8 and the second terminal 6, and in this embodiment, the housing 8 is made of stainless steel. The first mating surface 1 and the second mating surface 4 are the first mating surfaces to mate with the plug connector 100 and the receptacle connector 200 respectively, the first terminal 3 comprises a first power terminal 31 and a first detection terminal 32, the second terminal 6 comprises a second power terminal 61 and a second detection terminal 62 respectively matched with the first power terminal 31 and the first detection terminal 32, the first and second power terminals 31 and 61 are respectively provided with first and second contact portions 311 and 611 extending in the mating direction and mating with each other, the first and second detection terminals 32, 62 are respectively provided with a first and second detection portions 321, 621 which are in contact with each other to achieve a detection function, the first contact portion 311 is closer to the first contact surface 1 than the first detecting portion 321, the second contact portion 611 is closer to the second contact surface 4 than the second detecting portion 621.

Referring to fig. 4, the first insulating body 2 includes a pair of first bearing portions 21 extending along the mating direction and a second bearing portion 22 located between the two first bearing portions 21, the two first bearing portions 21 are closer to the first mating surface 1 than the second bearing portion 22, and further a recess 23 (see fig. 1) is formed at a front end of the second bearing portion 22, each first bearing portion 21 has a receiving groove 211 penetrating through the front end thereof, the second bearing portion 22 has a groove 221 penetrating through the front end thereof and communicating with the recess 23, and a slot 222 (see fig. 3) located at one side of the groove 221 and communicating with the groove 221. The first contact portions 311 are respectively received in the receiving slots 211, the first detecting portion 321 is received in the slot 222 and protrudes into the groove 23, that is, the first power terminal 31 is disposed on the first carrying portion 21, and the first detecting terminal 32 is disposed on the second carrying portion 22.

Referring to fig. 6 and 11, the second insulating housing 5 includes a plurality of slots 51 and a protrusion 52 protruding forward, the second contact portions 611 respectively protrude forward out of the slots 51, when the plug connector 100 and the receptacle connector 200 are mated, the protrusion 52 is received in the recess 23 of the plug connector 100, the front end of the protrusion 25 is provided with a pair of supporting portions 521 protruding forward and received in the recess 23, and the second detecting portion 621 is held between the two supporting portions 521 for the forward or reverse contact of the first detecting portion 321 to achieve the detecting function.

The first terminal 3 includes a pair of first signal terminals 33, the second terminal 6 includes a pair of second signal terminals 63 which are matched with the first signal terminals 33 to transmit signals, the recess 23 is provided with a pair of first signal terminal slots 231 which are positioned outside the recess 23 and are used for receiving the first signal terminals 32, the boss 52 is provided with a pair of second signal terminal slots 522 which are positioned outside the two supporting portions 521 and are used for receiving the second signal terminals 63, the first and second signal terminals 33 and 63 are respectively provided with first and second butting portions 331 and 631 which are received in the first and second signal terminal slots 321 and 522, referring to fig. 16, the first butting portion 331 is closer to the first butting face 1 than the first contact portion 311, the second detecting portion 621 is closer to the second butting face 4 than the second butting portion 631, when the plug connector 100 is butted with the socket connector 200, the first and second signal terminals 33 and 63 are contacted earlier than the first and second detection terminals 32 and 62 and later than the first and second power supply terminals 31 and 61.

The first terminal 3 further includes a pair of first ground terminals 34, the second terminal 6 further includes a pair of second ground terminals 64, and the first and second ground terminals 34 and 64 are respectively provided with first and second ground portions 341 and 641. In this embodiment, in the mating direction, the first grounding portion 341 is closer to the first mating surface 1 than the first contact portion 311, and the second grounding portion 641 is flush with the second contact portion 611, so that the first and second grounding terminals 34 and 64 are the earliest to be in contact with each other in all the terminals during mating.

As shown in fig. 8 to 9, the first terminal 3 and the second terminal 6 each include seven terminals that can be butted against each other, and the seven terminals of the first terminal 3 are respectively a first detection terminal 32 located in the middle, a pair of first signal terminals 33 located at both sides of the first detection terminal 32, a pair of first power terminals 31 located outside the first signal terminals 33, and a pair of first ground terminals 34 located at the outermost side; the arrangement of each of the second terminals 6 corresponds to the arrangement of the first terminals 3.

As shown in fig. 18 and 19, the first contact portion 311 of the first power terminal 31 includes a sleeve 3111 and an annular elastic clamping element 3112 disposed in the sleeve 3111, the clamping element 3112 includes a plurality of elastic sheets 3113 extending along the butting direction and arranged in a circle, and the elastic sheets 3113 are provided with butting points 3114 protruding along the circle center direction of the circle. Referring to fig. 12, the sleeve 3111 includes a stopper 3115 protruding inward therefrom, and the clamping member 3112 is positioned on the stopper 3115 in the mating direction. When the plug connector 100 is mated with the receptacle connector 200, the second contact portion 611 is inserted into the clamping member 3112, and the mating contact 3114 and the second contact portion 611 are in multi-point contact to conduct current in multiple paths, so that the plug connector assembly 1000 has less temperature rise while transmitting large current.

Referring to fig. 11 and 13, the first detecting terminal 32 is provided with a protruding portion 322 protruding out of the second supporting portion 22 at the rear of the first detecting portion 321, the button includes a first button 71 disposed at a position corresponding to the protruding portion 322 and capable of being pressed along the extending direction of the protruding portion 322, and pressing the first button 71 can make the first button 71 contact with the protruding portion 322 and further drive the first detecting portion 321 to elastically deform along the direction perpendicular to the mating direction, so as to disconnect the electrical connection between the first detecting terminal 32 and the second detecting terminal 62.

As shown in fig. 1 to 7, the latch 9 fixed on the first insulating body 2 includes a latch arm that can be pressed and rebounded, in this embodiment, the latch arm includes a pair of first latch arms 91 extending along the mating direction and disposed above the second bearing portion 22, the protrusion 322 is located between the pair of first latch arms 91, and the first latch arm 91 is provided with a first protrusion 911 protruding out of the second bearing portion 22 and extending in the same direction as the protrusion 322, and a first latching portion 912 protruding in the same direction as the first protrusion 911. In this way, the position of the first protrusion 911 is also set corresponding to the first button 71, and the first button 71 can press the first protrusion 911. The position of the housing 8 corresponding to the first latching portion 912 is provided with a first limiting groove 81 extending in the same direction as the first latching arm 91, when the plug connector assembly 1000 is plugged and mated, the first latching portion 912 is limited in the first limiting groove 81, and pressing the first button 71 can realize that the first button is contacted with the protruding portion 322 and simultaneously contacted with the first protruding portion 911 and further drives the first latching arm 91 to elastically deform along the direction deviating from the protruding direction, so that the first latching portion 912 deviates along the protruding direction, and the first latching portion 912 is separated from the limiting of the first limiting groove 81.

As shown in fig. 2 to 4, the locking member includes a pair of second locking arms 92 extending in the same direction as the first locking arms 91, the two second locking arms 92 are respectively fixed at the outer sides of the two first bearing portions 21, the second locking arms 92 extend to form second locking portions 922, the housing 8 is provided with second limiting grooves 82 parallel to the first limiting grooves 81 corresponding to the second locking portions 922, when the plug connector assembly 1000 is plugged and mated, the second locking portions 922 are limited by the second limiting grooves 82, in this embodiment, the extending direction of the second locking portions 922 is perpendicular to the extending direction of the first locking portions 912, and in the mating direction, the length of the second limiting grooves 82 is greater than the length of the first limiting grooves 81.

The second latch arm 92 is provided with a second protrusion 921 extending in the same direction as the second latch 922, and the button on the insulating housing 7 further includes a second button 72 provided at a position corresponding to the second protrusion 921 and capable of being pressed in the extending direction of the second protrusion 921. Referring to fig. 12, 16 and 17, when the plug connector assembly 1000 is mated, the second latching portion 922 is retained in the second retaining groove 82, and pressing the second button 72 can make the second button 72 contact with the second protrusion 921 and further drive the second latch arm 92 to elastically deform, so that the second latching portion 922 is shifted along the extending direction to be separated from the retaining of the second retaining groove 82.

Referring to fig. 10-17, different mating processes of the plug connector 100 and the receptacle connector 200 are illustrated, and the mating process is described in detail below. Fig. 10 to 12 show a fully mated state of the plug connector assembly 1000, in which the first and second locking portions 912 and 922 are respectively limited in the first and second limiting grooves 81 and 82; referring to fig. 12 and 13, when mating plug connector 100 is removed from receptacle connector 200, first button 71 is pressed, the protrusion 322 and the first protrusion 911 are simultaneously driven by the first button 71 to be pressed down, and at this time, the first detecting portion 321 is disconnected from the second detecting portion 621 while the first and second power terminals 31, 61 are still electrically contacted, the first locking portion 912 is disengaged from the first limiting groove 81, and at this time, the second locking portion 922 is still limited by the second limiting groove 82, since the length of the second position-limiting groove 82 is greater than the length of the first position-limiting groove 81, the plug connector 100 can be further moved along the extending direction of the second position-limiting groove 82 (i.e., the mating direction) toward a position away from the receptacle connector 200 to a position where the second position-limiting groove 82 is close to the edge of the second mating surface 4 (the state shown in fig. 14); as shown in fig. 14 to 17, when the second button 72 is pressed, the second latching portion 922 is pressed and deflected to be disengaged from the position of the second position-limiting groove 82, and at this time, the plug connector 100 can be completely pulled out of the receptacle connector 200 along the mating direction, and the first and second power terminals 31 and 61 are disconnected. The arrangement can ensure that the first and second detection terminals 32 and 62 are electrically disconnected with the first and second power terminals 31 and 61 at different time sequences, thereby avoiding instant discharge of the power terminals, and improving the safety index and the service life of the electric connector.

Referring to fig. 1 to 3, the plug connector 100 is provided with a metal housing 11 covering the first and second bearing portions 21 and 22, in this embodiment, the metal housing 11 is made of stainless steel so as to provide a good strength support for the plug connector 100; in addition, the metal housing 11 and the housing 8 have a guiding function when the plug connector 100 is mated with the receptacle connector 200. The insulating housing 7 is of a two-piece construction, i.e. it can be fixed to the outside of the metal housing 11 by means of a butt-joint assembly.

Referring to fig. 5 to 7, the second insulating body 5 is provided with a first positioning portion 53 and a third positioning portion 54 which are recessed inwards, and the first and third positioning portions 53 and 54 are respectively located at two opposite sides of the second insulating body 5; the housing 8 includes a second positioning portion 83 and a fourth positioning portion 84 recessed in the same direction as the first and third positioning portions 53 and 54, respectively, the first and second positioning portions 53 and 83 can be assembled and fixed relatively, and the second and third positioning portions 54 and 84 can be assembled and fixed relatively, so that the second insulating body 5 can be assembled and fixed in the housing 8.

The above description is only a part of the embodiments of the present invention, and not all embodiments, and any equivalent variations of the technical solutions of the present invention, which are made by those skilled in the art through reading the present specification, are covered by the claims of the present invention.

Claims (10)

1. A plug connector for mating with a receptacle connector, the plug connector comprising a first insulating body, a first terminal held by the first insulating body, a latch fixed on the first insulating body, and an insulating housing assembled outside the first insulating body, the first terminal comprising a first detecting terminal and a first power terminal connected to the receptacle connector, the plug connector comprising: the lock catch part comprises a plurality of lock catch arms capable of being pressed to rebound, the lock catch arms are provided with protruding protrusions extending out of the first insulating body, the insulating shell corresponds to the positions of the protrusions and is provided with buttons capable of pressing the protrusions, the lock catch arms are provided with locking parts protruding in the same direction as the protrusions, the buttons can be pressed to further drive the protrusions to further drive the lock catch arms to elastically deform along the direction deviating from the protruding direction, so that the locking parts deviate along the protruding direction, the lock catch arms comprise first lock catch arms and second lock catch arms extending in the same direction, the locking parts of the first lock catch arms and the second lock catch arms are respectively a first locking part and a second locking part, the first locking part protrudes along a first direction, the second locking part protrudes along a second direction perpendicular to the first direction, and the buttons comprise first locking part, second locking part, and second locking part corresponding to the first locking part and the second locking part respectively, When the first button is pressed, the first latching portion is deviated along the first direction, the first detection terminal is disconnected with the socket connector, the first power supply terminal is still connected with the socket connector, and when the second button is pressed, the second latching portion is deviated along the second direction.

2. The plug connector of claim 1, wherein: the first insulating body comprises a pair of first bearing parts extending along a butt joint direction and a second bearing part located between the first bearing parts, the lock catch arm comprises a pair of first lock catch arms extending along the butt joint direction and arranged above the second bearing part, and the first lock catch arm is provided with a first protruding part protruding out of the second bearing part and a first locking part protruding in the same direction as the first protruding part.

3. The plug connector of claim 2, wherein: the first button is arranged corresponding to the position of the first protruding portion and can be pressed in the first direction, and when the first button is pressed, the first button can be in contact with the first protruding portion and further drives the first locking arm to elastically deform along the first direction, so that the first locking portion is enabled to deviate along the first direction.

4. The plug connector of claim 3, wherein: the lock catch piece comprises a pair of second lock catch arms integrally arranged with the first lock catch arms, the pair of second lock catch arms are respectively fixed on the outer sides of the pair of first bearing parts, the second lock catch arms are provided with second protruding parts extending in the same direction as the second locking parts, the second button corresponds to the second protruding parts and can be pressed in the second direction, and the second button can be pressed to contact with the second protruding parts and further drive the second lock catch arms to elastically deform so that the second locking parts can deviate in the second direction.

5. The plug connector of claim 1, wherein: the first detection terminal is provided with a first detection part, a protruding part protruding out of the first insulation body is arranged behind the first detection part, the protruding part is located near the lock catch arm, and the button can be contacted with the protruding part and further drives the first detection part to generate elastic deformation by pressing the button.

6. A plug connector assembly defining a mating direction, comprising a plug connector and a receptacle connector which are mated with each other, wherein the plug connector comprises a first insulator, a first terminal held by the first insulator, a latch fixed to the first insulator, and an insulative housing assembled outside the first insulator, the receptacle connector comprises a second insulator, a second terminal held by the second insulator, and a housing covering the second insulator, the first terminal comprises a first detecting terminal and a first power terminal, the second terminal comprises a second detecting terminal and a second power terminal respectively mated with the first detecting terminal and the first power terminal, the plug connector assembly further comprises a first detecting terminal and a second power terminal, and the receptacle connector comprises: the lock catch part comprises a plurality of lock catch arms which can be pressed and rebounded, the lock catch arms are provided with protruding parts protruding out of the first insulating body and locking parts protruding in the same direction with the protruding parts, buttons capable of pressing the protruding parts are arranged at positions, corresponding to the protruding parts, of the insulating shell, the buttons can be pressed to enable the buttons to be in contact with the protruding parts and further drive the lock catch arms to elastically deform along the protruding direction, the lock catch arms comprise first lock catch arms and second lock catch arms extending in the same direction, the locking parts of the first lock catch arms and the second lock catch arms are respectively a first locking part and a second locking part, the first locking part protrudes along a first direction, the second locking part protrudes along a second direction perpendicular to the first direction, and the buttons comprise first buttons and second buttons respectively corresponding to the first lock catch arms and the second lock catch arms, the shell is provided with a first limiting groove and a second limiting groove corresponding to the positions of the first clamping lock part and the second clamping lock part respectively, when the plug connector assembly is spliced and paired, the first clamping lock part and the second clamping lock part are limited in the first limiting groove and the second limiting groove, when the first button is pressed, the first clamping lock part is deviated along the first direction, so that the first clamping lock part is separated from the limitation of the first limiting groove, the first and second detection terminals are disconnected and the first and second power terminals are still connected, and when the second button is pressed, the second clamping lock part is deviated along the second direction, so that the second clamping lock part is separated from the limitation of the second limiting groove.

7. The plug connector combination of claim 6, wherein: the first insulating body comprises a pair of first bearing parts extending along the butt joint direction and a second bearing part located between the first bearing parts, the lock catch arm comprises a pair of first lock catch arms extending along the butt joint direction and arranged above the second bearing part, and the first lock catch arm is provided with a first protruding part protruding out of the second bearing part and a first locking part protruding in the same direction as the first protruding part.

8. The plug connector combination of claim 7, wherein: the first button is arranged corresponding to the position of the first protruding portion and can be pressed in the first direction, and when the first button is pressed, the first button can be contacted with the first protruding portion and further drives the first locking arm to elastically deform along the first direction, so that the first locking portion is separated from the limiting position of the first limiting groove.

9. The plug connector combination of claim 8, wherein: the lock catch piece comprises a pair of second lock catch arms, the second lock catch arms are respectively fixed on the outer sides of the first bearing parts, the second lock catch arms are provided with second protruding parts extending in the same direction as the second locking parts, the second button is arranged corresponding to the second protruding parts and can be pressed in the second direction, and the second button can be pressed to be in contact with the second protruding parts and further drive the second lock catch arms to elastically deform, so that the second locking parts are separated from the limiting positions of the second limiting grooves.

10. The plug connector combination of claim 9, wherein: the first detection terminal is provided with a bulge part which protrudes out of the first insulation body, the length of the second limit groove is larger than that of the first limit groove, when the matched plug connector is pulled out of the socket connector, the first button is pressed to drive the bulge part and the first protrusion part to be pressed downwards so that the first detection part and the second detection part are disconnected and the first latch part is separated from the limit of the first limit groove, at the moment, the first power terminal and the second power terminal are still connected and the second latch part is still limited in the second limit groove, the plug connector is further moved to the position far away from the socket connector along the second limit groove to the edge of the second limit groove, and finally, the second latch part is pressed to deviate so as to be separated from the limit of the second limit groove after the second button is pressed, the plug connector can now be pulled completely out of the receptacle connector in the mating direction.

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201610482281.8A CN107546552B (en) | 2016-06-28 | 2016-06-28 | Plug connector and combination thereof |

| TW105123396A TWI701875B (en) | 2016-06-28 | 2016-07-25 | Plug connector and assembly thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201610482281.8A CN107546552B (en) | 2016-06-28 | 2016-06-28 | Plug connector and combination thereof |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN107546552A CN107546552A (en) | 2018-01-05 |

| CN107546552B true CN107546552B (en) | 2020-11-17 |

Family

ID=60962210

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201610482281.8A Active CN107546552B (en) | 2016-06-28 | 2016-06-28 | Plug connector and combination thereof |

Country Status (2)

| Country | Link |

|---|---|

| CN (1) | CN107546552B (en) |

| TW (1) | TWI701875B (en) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108243595B (en) * | 2018-03-13 | 2024-05-10 | 西安麦格米特电气有限公司 | Power module and plug frame assembly |

| CN111313193B (en) * | 2020-03-11 | 2025-06-10 | 安费诺电子装配(厦门)有限公司 | Vehicle-mounted line terminal connector and vehicle-mounted storage structure |

| CN113629444A (en) * | 2020-05-09 | 2021-11-09 | 富士康(昆山)电脑接插件有限公司 | Electrical connector |

| CN113823933B (en) * | 2021-10-11 | 2022-07-29 | 湖南捷联通新能源科技有限公司 | Interference-proof movable connector capable of providing multiple insurance for signal |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN2405334Y (en) * | 1999-11-11 | 2000-11-08 | 富士康(昆山)电脑接插件有限公司 | Wire/cable connector |

| CN101232136A (en) * | 2007-01-23 | 2008-07-30 | 富士康(昆山)电脑接插件有限公司 | electrical connector |

| CN201438577U (en) * | 2009-07-13 | 2010-04-14 | 富士康(昆山)电脑接插件有限公司 | Cable connector |

| CN201708380U (en) * | 2010-05-12 | 2011-01-12 | 富士康(昆山)电脑接插件有限公司 | Cable connector |

| CN102738622A (en) * | 2011-04-12 | 2012-10-17 | 广濑电机株式会社 | Electric connector for circuit substrate |

| CN102904108A (en) * | 2011-07-24 | 2013-01-30 | 富士康(昆山)电脑接插件有限公司 | Electrical connectors and combinations thereof |

| JP2015076163A (en) * | 2013-10-07 | 2015-04-20 | 株式会社七星科学研究所 | Power cable connector |

| CN104823337A (en) * | 2012-11-08 | 2015-08-05 | Ls电线有限公司 | Connector and connection device for high-voltage power supply having the same |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1619760B1 (en) * | 2003-01-16 | 2007-09-19 | Sumitomo Wiring Systems, Ltd. | A jig and a method for withdrawing a terminal in a connector |

| TWM311148U (en) * | 2006-09-08 | 2007-05-01 | Cheng Uei Prec Ind Co Ltd | Plug connector |

| CN204230477U (en) * | 2014-10-29 | 2015-03-25 | 安费诺-泰姆斯(常州)通讯设备有限公司 | Orthoscopic electric connector |

-

2016

- 2016-06-28 CN CN201610482281.8A patent/CN107546552B/en active Active

- 2016-07-25 TW TW105123396A patent/TWI701875B/en active

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN2405334Y (en) * | 1999-11-11 | 2000-11-08 | 富士康(昆山)电脑接插件有限公司 | Wire/cable connector |

| CN101232136A (en) * | 2007-01-23 | 2008-07-30 | 富士康(昆山)电脑接插件有限公司 | electrical connector |

| CN201438577U (en) * | 2009-07-13 | 2010-04-14 | 富士康(昆山)电脑接插件有限公司 | Cable connector |

| CN201708380U (en) * | 2010-05-12 | 2011-01-12 | 富士康(昆山)电脑接插件有限公司 | Cable connector |

| CN102738622A (en) * | 2011-04-12 | 2012-10-17 | 广濑电机株式会社 | Electric connector for circuit substrate |

| CN102904108A (en) * | 2011-07-24 | 2013-01-30 | 富士康(昆山)电脑接插件有限公司 | Electrical connectors and combinations thereof |

| CN104823337A (en) * | 2012-11-08 | 2015-08-05 | Ls电线有限公司 | Connector and connection device for high-voltage power supply having the same |

| JP2015076163A (en) * | 2013-10-07 | 2015-04-20 | 株式会社七星科学研究所 | Power cable connector |

Also Published As

| Publication number | Publication date |

|---|---|

| TW201817095A (en) | 2018-05-01 |

| CN107546552A (en) | 2018-01-05 |

| TWI701875B (en) | 2020-08-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN107546552B (en) | Plug connector and combination thereof | |

| JP2013247110A (en) | Electric connector | |

| EP2606537B1 (en) | Connector device and connector assembly for vehicle electrical power supply or transmission in a vehicle | |

| CN209860272U (en) | Electric connector combination | |

| US20140051274A1 (en) | Electrical connector | |

| CN213753127U (en) | Electrical connection device | |

| CN212412327U (en) | Electric connector and electric connector assembly | |

| CN107546511B (en) | Electric connector and combination thereof | |

| CN210007015U (en) | Electrical connector | |

| CN204966790U (en) | Electric connector | |

| US20110256782A1 (en) | Electrical connector having movable central contact | |

| TW201907628A (en) | Electrical Connector And Electrical Connector Assembly Having The Same | |

| CN213692407U (en) | Plug connector and electric connector assembly with same | |

| CN215343224U (en) | Quick connector | |

| CN210668776U (en) | Electrical connector | |

| CN223079426U (en) | Electric connector | |

| CN201741951U (en) | Electric connector | |

| WO2009153671A2 (en) | Hdmi with detect pin | |

| CN105932475A (en) | Radio-frequency connector assembly and radio-frequency connector and adaptive radio-frequency connector thereof | |

| CN223743950U (en) | Sockets and connectors | |

| CN222673372U (en) | Bidirectional conduction connector socket and bidirectional conduction connector assembly | |

| CN222508050U (en) | Electric connector set and elastic terminal thereof | |

| CN212935026U (en) | Cable connector and connector assembly | |

| CN106560957B (en) | Power connector adapter and assembling method thereof | |

| CN217589560U (en) | Power supply connector |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| TA01 | Transfer of patent application right | ||

| TA01 | Transfer of patent application right |

Effective date of registration: 20190411 Address after: No. 4401 Shangdu Road, Baisha Town, Zhongmou County, Zhengzhou City, Henan Province Applicant after: Fu Ding Precision Industrial (Zhengzhou) Co., Ltd. Address before: 215316 No. 999 North Gate Road, Yushan, Kunshan, Suzhou, Jiangsu Applicant before: Fushikang (Kunshan) Computer Connectors Co., Ltd. Applicant before: Accurate Science and Technology Co., Ltd. risen by letter |

|

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |