CN106404264B - Counter-force type roller braking inspection bench-based bench internal resistance measuring device and method - Google Patents

Counter-force type roller braking inspection bench-based bench internal resistance measuring device and method Download PDFInfo

- Publication number

- CN106404264B CN106404264B CN201610860543.XA CN201610860543A CN106404264B CN 106404264 B CN106404264 B CN 106404264B CN 201610860543 A CN201610860543 A CN 201610860543A CN 106404264 B CN106404264 B CN 106404264B

- Authority

- CN

- China

- Prior art keywords

- force

- counter

- internal resistance

- rack

- braking

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01L—MEASURING FORCE, STRESS, TORQUE, WORK, MECHANICAL POWER, MECHANICAL EFFICIENCY, OR FLUID PRESSURE

- G01L5/00—Apparatus for, or methods of, measuring force, work, mechanical power, or torque, specially adapted for specific purposes

- G01L5/28—Apparatus for, or methods of, measuring force, work, mechanical power, or torque, specially adapted for specific purposes for testing brakes

Abstract

The invention relates to a device and a method for measuring the internal resistance of a rack based on a counter-force type roller braking inspection bench. The device mainly comprises a force application and measurement device (A),The device comprises a fixing device (B), a counter-force roller braking inspection table (C) and a tire suspension device (D). The measuring device and the measuring method can be applied to calibration of the rack, loads are applied to the tire suspension device (D) by adjusting the force application and force measurement device (A), so that wheel loads in the actual detection process of an automobile are simulated, the internal resistance values of the rack under different wheel loads are obtained, and the incidence relation between the internal resistance values of the rack and the axle load is established. For different vehicle types, determining corresponding internal resistance F of the rack according to different shaft loadsxAnd error compensation is carried out on the braking force, and the detection accuracy is improved. The device can be widely applied to automobile detection, test and scientific research institutions.

Description

Technical Field

The invention relates to an automobile detection device and method, in particular to a device and method for measuring the internal resistance of a rack based on a counter-force type roller brake inspection bench.

Background

The braking performance of the automobile is directly related to the driving safety of the automobile, the braking performance is necessarily detected by a common braking test bed, and currently, most braking detection equipment used in a domestic vehicle performance detection station is a counter-force type roller braking test bed. The test principle is as follows: the tested wheel is arranged between the driving roller and the driven roller, and the third roller is pressed down to enable the approach switch to be conducted. The motor is started through the time delay circuit, the wheel is driven to rotate at a low speed through the speed reducer, the chain transmission, the driving roller and the driven roller, and a driver steps on the brake pedal after the rotating speed of the wheel is stable. The friction torque of the wheel brake is transmitted to the roller through the tire and becomes the force of the tire to the roller. At the same time, the roller has a reaction force to the tangential direction of the periphery of the tire to overcome the friction torque of the brake and maintain the wheel to continue rotating. Because of the existence of acting force, the reducer shell and the force measuring lever swing towards the opposite direction of the rotation of the roller together, the force or displacement of the force measuring lever is converted into an electric signal proportional to the magnitude of the braking force through a sensor, and the detected braking force is output by an indicating device or a printer after the electric signal is collected and processed by a computer.

At present, in the process that the counter force of an automobile is detected on a roller test bed, a driving motor can drive other rotating parts of a roller group and the test bed to move together, and in the moving process, energy loss can exist in friction between the rotating parts, including friction loss generated between a tire and a roller and friction loss generated between transmission systems inside the test bed. Wherein, the friction loss generated in the test bed is the internal resistance of the bench. The brake force of the automobile detected in the detection process also comprises the resistance of the part, so that the detection result has errors. Therefore, the internal resistance of the counter-force type roller brake test bed is determined and calibrated before the counter-force type roller brake test bed is put into use, so that the detection result is more accurate. The sliding method is usually adopted to determine the internal resistance of the rack, and the value of the internal resistance of the rack obtained by using the law of conservation of kinetic energy in the sliding method is usually a fixed value, and the internal resistance of the rack is related to the axle load of an automobile and the running speed of the automobile during detection, so the sliding method has larger error.

Disclosure of Invention

The invention aims to solve the problem that the braking force result is inaccurate due to inaccurate internal resistance of a rack in the detection process of a reaction type roller braking test bed of the conventional automobile with different axial loads. A device and a method for measuring the internal resistance of a rack based on a reaction type roller braking test bed are provided. By measuring the values of the rack internal resistance under different shaft loads, the incidence relation between the rack internal resistance of the counter-force type roller braking test bed and the automobile shaft load is determined, and error compensation is performed on the braking force result, so that the detection result is more accurate.

In order to solve the technical problems, the invention is realized by adopting the following technical scheme:

a counter-force type roller braking inspection bench-based bench internal resistance measuring device mainly comprises a force application and force measuring device A, a fixing device B, a counter-force type roller braking inspection bench C and a tire suspension device D, wherein the tire suspension device D is connected with the force application and force measuring device A through a hinge, the force application and force measuring device A is fixedly connected onto the fixing device B through bolts, and the fixing device B is fixedly connected onto a bench of the counter-force type roller braking inspection bench C through bolts; in application of force and power measuring device A, application of force handle 1 passes through the key-type connection with lead screw 2, and lead screw 2 adopts screw-thread fit with base member 3, and lead screw 2 and connecting piece I5 carry out the transmission of power through slider 4, and slider 4 is connected with base member 3 through guide block 7 to carry out longitudinal movement on base member 3 along guide block 7, force sensor 6 is connected with slider 4 through connecting piece I5.

In the fixing device B, a connecting plate 14 is connected with a base body 3 in the force application and measurement device A through a bolt, a lead screw 15 and a lead screw 17 are identical in structure and are connected through a connecting sleeve 16, the lead screw 17 is connected with a bottom plate 20 through a hinge, and the bottom plate 20 is fixed on a rack of a counter-force type roller braking inspection table C through a bolt.

A method for measuring the internal resistance of a rack based on a counter-force roller brake inspection bench is characterized in that a force application and force measurement device A is adjusted by rotating a force application handle 1, and a load is applied to a tire suspension device D, so that the axle load of an automobile is simulated;

in the process that the counter-force roller braking test bed roller group drives the tire to rotate, the value of the force sensor 6 instrument is read to obtain the simulated axle load, and the internal resistance value F of the bed frame is measured in real time according to the counter-force roller braking test bed data acquisition systemxAnd establishing the incidence relation between the shaft load and the internal resistance of the rack.

Compared with the prior art, the invention has the beneficial effects that:

1. the internal resistance of the bench is calibrated before the counter-force type roller braking test bench detects the braking force at present, the obtained calibration value is a fixed value, and the internal resistance of the bench can change due to different shaft loads in the actual detection process.

2. The rack internal resistance measuring device based on the counter-force type roller braking test bed has the advantages of simple structure, convenience in operation, small occupied space, low cost and high detection precision, different axle loads can be accurately simulated by adjusting the force application device, the real vehicle is not required for calibration, and the rack internal resistance values of automobiles with different axle loads in the detection process can be determined by only adopting the device in the calibration process.

Drawings

The invention is further described with reference to the accompanying drawings in which:

FIG. 1 shows a shaft of a bench internal resistance measuring device based on a reaction type roller braking test bed

Measuring a projection drawing;

FIG. 2a shows the table frame internal resistance measuring device based on the counter-force type roller braking test table of the present invention

An axonometric projection of the force application and force measurement device;

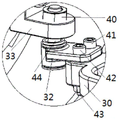

FIG. 2b is an enlarged view of a portion of FIG. 2 a;

FIG. 3 shows the table frame internal resistance measuring device based on the counter-force type roller braking test table of the invention

The fixing device is used for measuring a projection diagram;

FIG. 4 is a diagram of a device for measuring the internal resistance of a rack based on a counter-force type roller braking test bed according to the invention

A simplified model schematic diagram of a counter-force type roller braking inspection bench;

FIG. 5a shows the device for measuring the internal resistance of the rack based on the counter-force roller braking test bed according to the present invention

An axonometric projection of the tire suspension device;

FIG. 5b is a partial enlarged view of FIG. 5 a;

FIG. 6 is a diagram of a device for measuring the internal resistance of a rack based on a counter-force type roller braking test bed according to the invention

Schematic diagram of data acquisition system.

In the figure: A. force application and force measurement device, B fixing device, C reaction force type roller brake inspection bench simplified model, D tire suspension device, 1 force application handle, 2 lead screw I, 3 base body, 4 slide block, 5 connecting piece I, 6 force sensor, 7 guide block, 8 connecting piece II, 9 supporting frame, 10 hinge, 11 lower connecting piece, 12 upper connecting piece, 13 connecting pin, 14 connecting plate, 15 lead screw II, 16 connecting sleeve, 17 lead screw III, 18 fastening bolt, 19 bolt hole, 20 bottom plate, 21 frame, 22 chain, 23 driven roller, 24 third roller, 25 driving roller, 26 piston rod, 27 damping spring, 28 supporting seat ring, 29 damper, 30 lower swing arm, 31 fastening bolt, 32 ball head seat, 33 universal steering joint, 34 brake disc, 35 tire, 36. the brake caliper comprises a brake caliper, 37 parts of a ball head seat, 38 parts of the ball head seat, 39 parts of an upper swing arm, 40 parts of a fastening nut, 41 parts of a fastening bolt I, 42 parts of a fastening bolt II, 43 parts of a fastening nut, 44 parts of a ball pin, 45 parts of an analog quantity signal amplification wiring board, 46 parts of an analog quantity acquisition card, 47 parts of an industrial personal computer.

Detailed Description

The invention is described in detail below with reference to the attached drawing figures:

the invention provides a device and a method for measuring the internal resistance of a rack based on a reaction type roller braking inspection bench, which can improve the accuracy of vehicle braking performance detection. The research on the vehicle braking performance has high social value and wide social significance, has good promotion effect on the safe operation, riding comfort and stability of the vehicle, and also has good social benefit and economic benefit.

Referring to fig. 1, the device for measuring the internal resistance of the rack based on the counter-force type roller braking inspection table of the invention comprises: the device comprises a force application and force measurement device A, a fixing device B, a counter force type roller braking inspection table C and a tire suspension device D. The tire suspension device D is connected with the force application and force measurement device A through a hinge, the force application and force measurement device A is fixed on the fixing device B through bolt connection, and the fixing device B is fixed on the counter-force roller braking inspection table C through bolt connection.

Referring to fig. 2, the force application and measurement device a of the device for measuring the internal resistance of the rack based on the counter-force type roller brake test bench according to the present invention includes: the device comprises a force application handle 1, a lead screw 2, a base body 3, a sliding block 4, a connecting piece 5, a force sensor 6, a guide block 7, a connecting piece 8, a supporting frame 9, a hinge 10, a lower connecting piece 11, an upper connecting piece 12 and a connecting pin 13. The force application handle 1 is connected with the lead screw 2 through a key, and the lead screw 2 is in threaded fit with the base body 3. The connecting piece 5 and the connecting piece 8 have the same structure, the force sensor 6 is connected with the sliding block 4 through the connecting piece 5, the specification of the force sensor 6 is an S-shaped pull pressure sensor, and the magnitude of each applied force can be directly measured through a measuring instrument of the S-shaped standard pull pressure sensor. The screw 2 and the connecting piece 5 are force-transmitting via a slide 4, which is connected to the base body via a guide block 7, which is moved on the base body in the longitudinal direction of the guide block. The force application handle 1 is rotated to drive the screw rod 2 to move, so that the sliding block 4 generates displacement, force is transmitted to the force sensor 6 through the connecting piece 5, and the force application size can be measured.

Referring to fig. 3, the fixing device B of the device for measuring the internal resistance of the rack based on the counter-force type roller brake test bench according to the present invention includes: the connecting plate 14, the lead screw 15, the connecting sleeve 16, the lead screw 17, the fastening bolt 18, the bolt hole 19 and the bottom plate 20. The connecting plate 14 is connected with the base body 3 in the force application and measurement device A through a bolt, and the lead screw 15 and the lead screw 17 are connected through a connecting sleeve 16 in the same structure. The distance between the spindle 15 and the spindle 17 can be shortened or increased by rotating the connecting sleeve 16, so that the angle of application and force measurement can be changed. The screw rod 15 is connected with the connecting plate 14 through a hinge, and the bottom plate 20 is fixed on a rack of the counter-force type roller braking inspection table C through bolts. The fixing device B is mainly used for reinforcing the suspension tire model D and the counter-force type roller braking inspection bench C and preventing deviation in the aspect of mechanical matching in the calibration process.

Referring to fig. 4, a counter-force type roller brake test table C in the device for measuring the rack internal resistance based on the counter-force type roller brake test table according to the present invention is a counter-force type roller brake test table manufactured by the capital development corporation, and has a model number of FZ-10C. The simplified model of the counter-force type roller braking inspection bench mainly comprises the following steps: a frame 21, a chain wheel 22, a driven roller 23, a third roller 24 and a driving roller 25. The driven roller 23 and the driving roller 25 are fixed to the frame by bearings and connected by a sprocket 22.

Referring to fig. 5, the tire suspension apparatus D of the apparatus for measuring the internal resistance of the rack based on the counter-force type drum brake test stand according to the present invention includes: the brake device comprises a piston rod 26, a damping spring 27, a support race 28, a damper 29, a lower swing arm 30, a fastening bolt 31, a ball socket 32, a universal steering joint 33, a brake disc 34, a tire 35, a brake caliper 36, a ball socket 37, a ball socket 38, an upper swing arm 39, a fastening nut 40, a fastening nut 41, a fastening bolt 42, a fastening bolt 43 and a ball pin 44.

Wherein the piston rod 26, the damping spring 27, the supporting seat 28 and the damper 29 form a damping system, the top of the piston rod 26 is a cylinder with the height of 40mm, the wall thickness of 5mm and the inner diameter of 30mm, the cylinder is coaxially matched with the connecting piece 8 in the force application and measurement device A, when pressure is applied, the pressure acts on the lower swing arm 30 through the piston rod 26, and the real wheel weight of the automobile is really simulated. The shock absorber 29 is hinged with the lower swing arm 30, the inner ends of the lower swing arm 30 and the upper swing arm 39 are hinged with the base body 3 in the force application and measurement device A, and the outer ends of the lower swing arm 30 and the upper swing arm 39 are respectively connected with the universal steering knuckle 33 through the ball stud 44. The lower swing arm 30 and the ball seat 32 are fixedly connected through a fastening bolt I41 and a fastening bolt II 42, the ball seat 32 and the universal steering joint 33 are connected through a ball pin 44, and the connection mode of the upper swing arm 39 is the same as that of the lower swing arm 30.

Referring to fig. 6, the schematic diagram of the data acquisition system in the bench internal resistance measuring device based on the counter-force roller braking test bed according to the present invention includes: an analog signal amplifying wiring board 45, an analog acquisition card 46 and an industrial personal computer 47. The analog quantity signals of the left and right internal resistances of the rack are amplified through the amplifying wiring board 45, then the processed signals are collected through the analog quantity acquisition card 46, and finally the corresponding internal resistance values of the rack are obtained in the industrial personal computer 46.

The working principle of the experimental device of the invention is as follows:

aiming at automobiles with different axle weights, corresponding axle loads are applied by adjusting the force application and force measurement device A, and then the force is transmitted to the tire suspension device D through the connecting device to simulate the axle weight in the actual detection process of the automobile. The length of the screw rod can be adjusted by adjusting the connecting sleeve between the two screw rods in the fixing device B, and the tire in the tire suspension device D is vertically contacted with the roller group of the counter-force type roller braking inspection bench C by adjusting the angle of the screw rod.

The method for measuring the internal resistance of the rack based on the counter-force type roller braking test bed comprises the following steps:

before the counter-force type roller braking test bed is put into use, the internal resistance of the test bed needs to be calibrated, the obtained calibration value is a fixed value, in the actual detection process, the internal resistance of the bed can change due to different shaft loads, the measurement device for the internal resistance of the bed built by the invention can calibrate the internal resistance of the bed under different shaft loads, and error compensation is carried out on the braking force result, so that the detected braking force value is more accurate.

The method for measuring the internal resistance of the rack comprises the following specific steps:

(1) fixing and assembling the force adjusting and measuring device A, the fixing device B, the counter-force type roller braking inspection table C and the tire suspension device D according to the connection relation shown in the figure 1, ensuring that the surface of a tire is vertically contacted with the surface of a roller group of the braking inspection table, zeroing the force sensor 6, adjusting the force applying handle 1 in the force applying and measuring device A, and enabling the stress of the force sensor 6 to be zero;

(2) rotating the force application handle 1, reading the readings of the force sensor 6, gradually increasing the unit amount of the shaft load, starting the driving motor to drive the roller set and the tire to rotate, and obtaining the value of the blocking force through the data acquisition system, namely the value of the internal resistance of the rack (marked as F) under the shaft loadx)。

And acquiring data of the internal resistance and the axle load of the rack, fitting the acquired data by adopting a least square method, and determining the incidence relation between the internal resistance of the rack and the axle load of the vehicle. The internal resistance value F of the rack of the vehicle with different axle loads in the detection process can be obtained through the incidence relationxIf the braking force value measured during the detection process is F, (F-F)x) In order to remove the actual braking force of the internal resistance of the rack, error compensation can be carried out on the braking force result, so that the detection result is more accurate.

Claims (2)

1. The utility model provides a rack internal resistance measuring device based on counter-force formula cylinder braking checkout stand, mainly comprises application of force and power measuring device (A), fixing device (B), counter-force formula cylinder braking checkout stand (C) and tire suspension device (D), its characterized in that:

the tire suspension device (D) is connected with the force application and force measurement device (A) through a hinge, the force application and force measurement device (A) is fixedly connected onto the fixing device (B) through a bolt, and the fixing device (B) is fixedly connected onto a rack of the counter-force roller braking inspection bench (C) through a bolt; in the force application and force measurement device (A), a force application handle (1) is connected with a lead screw I (2) through a key, the lead screw I (2) is in threaded fit with a base body (3), the lead screw I (2) and a connecting piece I (5) transmit force through a sliding block (4), the sliding block (4) is connected with the base body (3) through a guide block (7) and moves longitudinally on the base body (3) along the guide block (7), and a force sensor (6) is connected with the sliding block (4) through the connecting piece I (5);

the tire suspension device (D) is hinged with the base body (3) in the force application and force measurement device (A) through the inner ends of the upper swing arm (39) and the lower swing arm (30), a piston rod (26), a damping spring (27), a support seat ring (28) and a damper (29) in the tire suspension device (D) form a damping system, the damper (29) is hinged with the lower swing arm (30), and when pressure is applied, the pressure acts on the lower swing arm (30) through the piston rod (26), so that the real wheel weight of an automobile is truly simulated;

in the fixing device (B), the connecting plate (14) is connected with the base body (3) in the force application and force measurement device (A) through bolts, the lead screw II (15) and the lead screw III (17) are identical in structure and are connected through a connecting sleeve (16), the lead screw III (17) is connected with the bottom plate (20) through a hinge, and the bottom plate (20) is fixed on a rack of a counter-force type roller braking inspection table (C) through bolts.

2. The measurement method of the rack internal resistance measurement device based on the counter-force type roller brake inspection bench is characterized in that:

the force application and force measurement device (A) is adjusted by rotating the force application handle (1), and load is applied to the tire suspension device (D), so that the axle load of the automobile is simulated;

and in the process that the counter-force roller braking test bed roller group drives the tire to rotate, the value of the instrument of the force sensor (6) is read to obtain the simulated axle load, the internal resistance value of the rack is measured in real time according to the counter-force roller braking test bed data acquisition system, and the incidence relation between the axle load and the internal resistance of the rack is established.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201610860543.XA CN106404264B (en) | 2016-09-29 | 2016-09-29 | Counter-force type roller braking inspection bench-based bench internal resistance measuring device and method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201610860543.XA CN106404264B (en) | 2016-09-29 | 2016-09-29 | Counter-force type roller braking inspection bench-based bench internal resistance measuring device and method |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN106404264A CN106404264A (en) | 2017-02-15 |

| CN106404264B true CN106404264B (en) | 2022-07-05 |

Family

ID=58015735

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201610860543.XA Active CN106404264B (en) | 2016-09-29 | 2016-09-29 | Counter-force type roller braking inspection bench-based bench internal resistance measuring device and method |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN106404264B (en) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109738117B (en) * | 2019-02-01 | 2023-08-15 | 广东省计量科学研究院(华南国家计量测试中心) | Dynamic detection device for roller counter-force type braking inspection bench |

| CN110595800A (en) * | 2019-09-20 | 2019-12-20 | 葛在 | Device and method for testing braking performance of automobile |

| CN112945584B (en) * | 2021-03-22 | 2023-03-28 | 东风汽车集团股份有限公司 | Tire impact resistance testing device |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2009135498A1 (en) * | 2008-05-06 | 2009-11-12 | Gm Global Technology Operations, Inc. | Digital controller for an automotive steering test rig |

| CN201673013U (en) * | 2010-04-28 | 2010-12-15 | 吉林大学 | Dynamic calibration device of roller reaction type brake tester |

| CN102768117B (en) * | 2012-07-03 | 2015-04-15 | 浙江江兴汽车检测设备有限公司 | Portable dynamic wheel type calibrator for roller opposite force type automobile brake inspection bench |

| CN202836987U (en) * | 2012-09-24 | 2013-03-27 | 中国人民解放军总后勤部军事交通运输研究所 | Single-axis counter-force type dual-roller detection test platform of trailer inertial braking system |

| CN104502014B (en) * | 2014-12-16 | 2016-08-17 | 吉林大学 | Braking-force detecting device that automobile axle load based on stand adjusts automatically and method |

| CN206161222U (en) * | 2016-09-29 | 2017-05-10 | 吉林大学 | Rack internal resistance measuring device based on counter -force type cylinder brake test bench |

-

2016

- 2016-09-29 CN CN201610860543.XA patent/CN106404264B/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| CN106404264A (en) | 2017-02-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN103389205B (en) | A kind of device detecting combination property under ball screw assembly, stress state | |

| CN107907331B (en) | Wheel hub bearing rigidity testing machine | |

| CN201364215Y (en) | Friction moment measuring device of bearing under different axial loads and rotating speed | |

| CN106404264B (en) | Counter-force type roller braking inspection bench-based bench internal resistance measuring device and method | |

| CN106769021A (en) | A kind of industrial robot power unit reliability test bench | |

| CN208860265U (en) | Bearing disk detecting tool | |

| CN205426517U (en) | Lathe main shaft comprehensive properties detection / monitoring testing system | |

| CN101972948A (en) | Test device for thermal error of machine tool spindle under simulated work load condition | |

| CN106680117A (en) | Novel sheet metal torsion testing machine | |

| CN201331403Y (en) | Moment rigidity tester for hub bearing unit | |

| CN106124199A (en) | Precision speed reduction device static properties test device and method of testing thereof | |

| CN205879528U (en) | Precision speed reducer static performance testing arrangement | |

| CN105444949A (en) | Moment-of-inertia test bench based on torque sensor | |

| CN107576299A (en) | Detection means for ball screw assembly, | |

| CN104390772A (en) | Device and method for testing static and dynamic variable friction of telescopic mechanism | |

| CN201885839U (en) | Precise ball-screw pair friction mechanism research experiment table | |

| CN206161222U (en) | Rack internal resistance measuring device based on counter -force type cylinder brake test bench | |

| CN201364135Y (en) | Detection device for negative clearance of non-driving wheel hub bearing unit | |

| CN108709683A (en) | The flexible torque sensor dynamic test platform in module oriented approach joint | |

| CN205538241U (en) | Portable rigidity test rack | |

| CN205580746U (en) | Stopper test bench device | |

| CN106940253A (en) | Automobile hub bearing friction torque detection means | |

| CN207751464U (en) | A kind of detection device for ball screw assembly, | |

| CN205679403U (en) | Shock absorber static friction force test device in high precision | |

| CN113567023B (en) | Method for measuring friction torque of rolling bearing |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |