CN101316919A - Porous solid lubricant, bearing, and constant velocity universal joint - Google Patents

Porous solid lubricant, bearing, and constant velocity universal joint Download PDFInfo

- Publication number

- CN101316919A CN101316919A CNA2006800447201A CN200680044720A CN101316919A CN 101316919 A CN101316919 A CN 101316919A CN A2006800447201 A CNA2006800447201 A CN A2006800447201A CN 200680044720 A CN200680044720 A CN 200680044720A CN 101316919 A CN101316919 A CN 101316919A

- Authority

- CN

- China

- Prior art keywords

- solid lubricant

- porous solid

- mixture

- foaming

- composition

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Landscapes

- Lubricants (AREA)

Abstract

The present invention provides a solid lubricant which is improved in the ability to retain a lubricating oil therein and in which the amount of the lubricating oil oozing out due to a deformation caused by external force can be reduced to a minimum necessary amount; and a bearing or constant velocity universal joint containing the lubricant enclosed therein. The porous solid lubricant comprises a lubricating component comprising a lubricating oil and a resin component as essential components, wherein the resin component is a solid matter having porosity imparted thereto by foaming and the lubricating component is occluded in the resin. Since the lubricating component is occluded in the resin in a foamed state, the resin, which is flexible, deforms upon reception of an external force, e.g., compression, expansion, flexing, or torsion, to ooze out the lubricating component. Thus, the lubricating component is gradually released from spaces among the molecules of the resin. The amount of the lubricating oil which can be retained is larger than that of the lubricating oil held by mere infiltration into the pores. With the lubricant, the bearing can have a long life, can be operated even at a high revolution, and can be produced at low cost. Furthermore, the constant velocity universal joint can have a long life and be reduced in damage to the boot made of rubber.

Description

Technical field

The present invention relates to and to the porous solid lubricant of the sliding part of mechanism or rotating part supplying lubricating oil and to use its bearing and constant velocity joint.

Background technology

Usually, be to make with lubricator in the sliding part of most machinery of representative or rotating part etc. with automobile or industrial machinery.Lubricant roughly is divided into liquid lubricant and solid lubricant, thereby but having of also knowing lubricating oil is increased and makes its lubricating grease or keep liquid lubricant can prevent the solid lubricant that it disperses or trickles with automorph property.

For example, known having mixes extrahigh-molecular weight polyolefins or urethane resin and solidifying agent thereof in lubricating oil or lubricating grease, and keeps liquid lubricated composition to make the solid lubricant (patent documentation 1,2,3) of its rerum natura of slowly oozing out the intermolecular of resin.

In addition, having of knowing makes the polyurethane elastomer (patent documentation 4) of the self lubricity that reacts as the polyvalent alcohol of urethane raw and vulcabond in lubricated composition in the presence of lubricant.

Such solid lubricant is bearing enclosed and under the solidified situation, lubricating oil slowly oozes out, if use it, then do not need to be used for the maintenance of make-up oil, in washy harsh environment for use or act on and multiplely in the environment etc. of strong mass force wave the long-term effect that helps bearing life yet.

Yet, if such solid lubricant is used in the position that external stresses such as the compression of constant velocity joint or bending apply repeatedly with high frequency, then for it according to compression or crooked and be out of shape, need very large power, or very large stress puts on solid lubricant, thereby keeps its part also to need physical strength.

But the required intensity or the filling ratio of solid lubricant of bearing or constant velocity joint etc. be not easy to realize simultaneously usually, promptly is difficult to keep the high lubricant of physical strength with high fill-ratio, may hinder the long lifetime of bearing etc. sometimes.

Therefore, even also seek to keep with high fill-ratio the solid lubricant of the high lubricant of physical strength at the position that external stresses such as compression or bending take place repeatedly with high frequency.

Know to make lubricating oil depth foaming and form in the softish resin that is communicated with pore, and in this pore, keep the oil-containing solid lubricant of lubricating oil also to be filled in the inside of bearing or constant velocity joint and the technology (patent documentation 5) used.

Patent documentation 1: the spy opens flat 6-41569 communique

Patent documentation 2: the spy opens flat 6-172770 communique

Patent documentation 3: the spy opens the 2000-319681 communique

Patent documentation 4: the spy opens flat 11-286601 communique

Patent documentation 5; Te Kaiping 9-42297 communique

But, in above-mentioned conventional art, solid lubricant in the lubricating oil infiltration softish resin has the softish deformability corresponding to external force, can also follow compression or crooked, but the lubricating oil confining force is little, under the situation that the high-speed condition with bearing etc. uses, also may lubricating oil extract out rapidly and exhausted.

Such oil-containing solid lubricant can use in the lubricated or enclosed space at short notice, but if use in the long lubricated part of needs or at open space, then cause the lubricating oil undersupply, or if oily confining force is little, then remaining lubricating oil is emitted repeatedly and is absorbed from pore, causes constantly flowing in the space.

If exterior members such as the lubricating oil that oozes out from such solid lubricant and rubber contact superfluously, then also lubricating oil or its additive chemistry corrosion or its starting material of deterioration sometimes.

In addition, in the operation of making such solid lubricant,, need a large amount of manufacturing processes, if also be difficult to satisfy the requirement of cost degradation like this in order to make the infiltration of lubricating oil or lubricating grease reliably.In addition, not only at industrial favourable economic aspect, but also the satisfied load at environment of needs reduces, the requirement of the degree of freedom of design.

Also have, in the rolling bearing of having filled, have following defective based on the solid lubricant of above-mentioned conventional art, that is: the life-span short, burn-back easily in high speed rotating also has, because heat release is big, therefore, as the resinous principle fusion of mother metal, causes and can not use.In addition, in filling the full load method of solid lubricant very close to each otherly, there are the following problems, that is: with described solid lubricant in bearing in the solidified postcooling process, solid lubricant shrinks, and therefore, self is adsorbed on rolling body lubricant, it is big that rotary torque becomes easily, causes the problem of easy heat release.

In the operation of making such solid lubricant, in order to make the infiltration of lubricating oil or lubricating grease reliably, need a large amount of manufacturing processes, also cause being difficult to satisfy the requirement of cost degradation thus.

In addition, if attaching is touched outside the rubber systems such as protective sleeve that remaining lubricating oil is installed with covering axle and foreign steamer ground, then lubricate corrosion or deterioration rubber such as oil additives sometimes in constant velocity joint.

And then, in order to make the infiltration of lubricating oil or lubricating grease reliably, need a large amount of operations, therefore, when making constant velocity joint, have problems with low cost.

Summary of the invention

The objective of the invention is to address the above problem, the described confining force that can improve the solid lubricant that keeps lubricating oil is provided, and, the lubricants capacity that the distortion that causes owing to external force is oozed out can be suppressed at necessary minimal porous solid lubricant.

Also have, the object of the present invention is to provide and to address the above problem and to make manufacturing process fairly simple, can satisfy the solid lubricant that bearing or constant velocity joint etc. make the requirement of the cost degradation in the manufacturing process of device with lubricator.

And then, the objective of the invention is to also to provide the lubricity of the solid lubricant that keeps lubricating oil superior, long lifetime and can moving with high speed rotating, and, can make manufacturing process fairly simple, the porous solid lubricant of requirement that can satisfy cost degradation is bearing enclosed.

In addition; the object of the invention is also to provide the lubricating oil confining force that improves solid lubricant; the distortion that external force is caused and the lubricants capacity that oozes out is suppressed at necessary inferior limit; efficient is used lubricating oil well; the constant velocity joint that the damage of long lifetime and rubber system protective sleeve is also few; in addition, the manufacturing process of this constant speed universal joint is further simple, helps the reduction of production cost.

In order to address the above problem, in the present invention, a kind of porous solid lubricant, it is characterized in that, with the lubricated composition that contains lubricating oil and resinous principle is must composition, and described resinous principle is to foam and by the solids of porous, and in the inner occlusion of resin described lubricated composition is arranged.

" occlusion " of described in the present invention " occlusion " and academic term equivalent in meaning is meant that liquid (liquid lubricant etc.) is contained in the meaning in the solid resin under the situation that does not become compound.

In the present invention, therefore the state with the resinous principle foaming will lubricate the composition occlusion in resin,, can utilize the flexibility of resin, for example, the distortion that external force such as compression, expansion, bending, distortion cause, lubricated composition is oozed out, emit to the outside from the intermolecular of resin.At this moment, the lubricants capacity that oozes out waits the degree that changes corresponding to the recoverable deformation of external force size by selecting resinous principle, thereby can be made as necessary inferior limit.

Also have, preferably the resinous principle that has foamed be foaming for the continuous pore rate at the resinous principle 50% or more, why be only to ooze out the effect of appropriate amount fully because have by being out of shape the lubricated composition that makes in the pore.

In addition, surface-area increases the resinous principle with rubber-like elasticity that is made of resin or rubber by foaming, can also remain in the pore the remaining lubricating oil that oozes out once more temporarily, thereby the lubricants capacity that oozes out is stable, in addition, and by the lubricated composition of occlusion in resin, and, in the infiltration pore, thereby compare with the state of non-foaming, the maintenance dose of lubricating oil is more.

In addition, porous solid lubricant of the present invention is compared with non-foam, and the energy that needs when crooked is very little, can keep lubricating oil with high-density, simultaneously, can carry out the softish distortion.In addition, having the foaming part in a large number is porous part, therefore, also favourable aspect lightweight.

In order to obtain playing the porous solid lubricant of such effect, the expansion ratio of preferred resin composition is 1.1~200 times, and in addition, resinous principle is a urethane resin, and this is because make corresponding to the elasticity or the occlusion of external force size reliable.

Have in the porous solid lubricant of invention of resinous principle of rubber-like elasticity in use, preferred porous solid lubricant is to make the mixture foaming that contains lubricated composition, have liquid rubber, solidifying agent and the whipping agent of hydroxyl at intramolecularly, solidify and form, under the sort of situation, in described mixture, all with respect to mixture, described lubricated composition is 1 weight %~80 weight %, and described liquid rubber is 5 weight %~80 weight %.

Said mixture is at filling mixt around the slide unit or in being shaped with mould and make this mixture foam, solidify and form.

Manufacture method as the porous solid lubricant that uses liquid rubber, be preferably as follows operation and be necessary operation, that is: the composition that will contain lubricated composition, has liquid rubber, solidifying agent and a whipping agent of hydroxyl at intramolecularly mixes, and obtains the mixed processes of mixture; In the foaming of described mixture, solidify finish before, with described mixture be filled in slide unit around or be shaped with the filling work procedure in the mould; The described mixture of described filling is foamed, solidified foaming, curing process.

In addition, using as resinous principle under the situation of urethane resin, preferred porous solid lubricant is to make the mixture that contains lubricated composition, has urethane prepolymer, solidifying agent and a whipping agent of isocyanate group at intramolecularly foam, solidify and form, and the cooperation ratio of described lubricated composition all is 1 weight %~90 weight % with respect to described mixture.Contain the use level of the mixture of lubricated composition, urethane prepolymer, solidifying agent and whipping agent by control, can change the density of porous solid lubricant.

In these cases, and then the preferred consolidation agent is the aromatic series polyamino compound, and described whipping agent is a water.

Use in the invention of urethane resins at these, preferably mixture is filled in sliding part or rotating part around or be shaped with Mo Nei and foam and solidify and form.

If lubricated composition remains in foaming, the solidified solid state component, then can carry out distortion freely to external stress, especially can improve flexibility.As this lubricated composition, mainly be present in the solid state component, for example,, lubricated composition is slowly emitted at necessary position by external factor such as compression, bending, distortion, expansions.

In addition, the manufacture method of such porous solid lubricant preferably includes: the composition that will contain lubricated composition, has urethane prepolymer, solidifying agent and a whipping agent of isocyanate group at intramolecularly mixes, and obtains the mixed processes of mixture; In the foaming of described mixture, solidify finish before, with described mixture be filled in slide unit or rotating part around or be shaped with the filling work procedure in the mould; The described mixture of described filling is foamed, solidified foaming, curing process.

If like this, foaming, the cured article that then can directly make the maintenance lubricant are porous solid lubricant, do not need post-treatment such as cutting or back infiltration, and its result enhances productivity, and can cheaply make.

In addition, in the present invention,, form porous solid lubricant is enclosed in the bearing that inclosure that bearing inside forms has porous solid lubricant for the long lifetime that solves bearing and the problem of high speed rotating.

In addition; in the present invention; can between foreign steamer and interior wheel, keep in the constant velocity joint that lubricant forms efficient to use lubricating oil well; and form the few constant velocity joint of damage of long lifetime and rubber system protective sleeve; therefore, the porous solid lubricant that forms described predetermined component remains in the constant velocity joint that forms between foreign steamer and the interior wheel.

The distortion of the resin that the lubricating oil that contains with the state of occlusion in the solid resin can not cause owing to external force and oozing out sharp; thereby can efficient lubricating oil is oozed out and use; therefore; lubricants capacity is that necessary inferior limit gets final product, and forms the few constant velocity joint of damage of long lifetime and rubber system protective sleeve.

In addition, in the manufacturing process of solid lubricant, may not need the operation of infiltrating, therefore, the manufacturing process of constant velocity joint correspondingly becomes simply, thereby can reduce production costs.

In order to form such constant velocity joint, preferably the expansion ratio with the resinous principle of solid lubricant is made as 1.1~200 times, and in addition, resinous principle is a urethane resin, and this is because in order to obtain elasticity or the occlusion corresponding to the external force size reliably.

The present invention comprises resinous principle and lubricated composition, described resinous principle with the foaming state with described lubricated composition occlusion in resin, therefore, has the described confining force that can improve the solid lubricant that keeps lubricating oil, and, the lubricants capacity that the distortion that causes owing to external force is oozed out can be formed necessary minimal advantage.

Promptly, the porous solid lubricant of the present invention that lubricated composition mainly exists with solid state component improves flexibility according to the mode that can carry out the distortion freely of external stress, for example, can will lubricate composition by external factor such as compression, bending, distortion, expansions slowly emits at necessary position.

In addition, also having can fairly simpleization manufacturing process, satisfies the advantage of the requirement of cost degradation.

And then, use liquid rubber, around the slide unit or be shaped, make its foaming, solidify the porous solid lubricant that forms and do not need post-treatment such as cutting with filling mixt in the mould, it is superior to lubricate the composition confining force.

In addition, in this case, with mixed processes, filling work procedure, foaming, curing process serves as that the manufacture method of porous solid lubricant that must operation can directly be made foaming, the cured article that keeps lubricant, therefore, has post-treatment such as not needing cutting or back infiltration, enhance productivity, can the cheap advantage of making.

Inclosure has the bearing of porous solid lubricant to compare with the maintenance dose that only keeps by the infiltration in the pore, the maintenance dose of the lubricated composition in the porous solid lubricant is more, when operation, from porous solid lubricant, around rolling body, slowly emit lubricating oil, therefore, can move with high speed rotating, can play the contribution effect the long lifetime.

In addition, by enclosing porous solid lubricant, can have lubricant near the rolling surface of bearing, compare with grease lubrication, to the easier supply of lubricant of rolling surface, in addition, porous solid lubricant is also brought into play at the effect from the sealing element of the intrusion of the dirt of outside, moisture etc.In addition, solid lubricant has a large amount of porous parts, therefore, also helps the lightweight aspect of bearing.And then, need after the assembling of bearing, not enclose lubricant, therefore, can improve its production efficiency, can cheaply make bearing.

In addition; the invention of constant velocity joint has: form the lubricant confining force that improves solidifying agent; to form necessary inferior limit owing to the lubricants capacity that the distortion that external force causes is oozed out; the constant velocity joint that the damage of long lifetime and rubber system protective sleeve is few; in addition; form and more to oversimplify manufacturing process, also help the advantage of constant velocity joint of the reduction of production cost.

Also have, have also that form can fairly simpleization manufacturing process, satisfy the advantage of constant velocity joint of the requirement of cost degradation.

Description of drawings

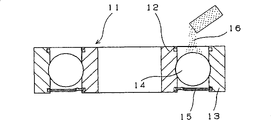

Fig. 1 is the synoptic diagram of inclosure example in the deep groove ball bearing (no sealing element) of expression first embodiment.

Fig. 2 is the synoptic diagram of inclosure example in the deep groove ball bearing (having sealing element) of expression second embodiment.

Fig. 3 is the synoptic diagram of inclosure example in the thrust ball bearing (no sealing element) of expression the 3rd embodiment.

Fig. 4 is the synoptic diagram of the use of the cylinder anchor clamps in expression the 3rd embodiment.

Fig. 5 is a sectional view of enclosing the 4th embodiment in the deep trouth ball bearing.

Fig. 6 is the sectional view of the constant velocity joint of the 5th embodiment.

Fig. 7 is the sectional view of the constant velocity joint of the 6th embodiment.

Fig. 8 is the sectional view of the constant velocity joint of the 7th embodiment.

Among the figure: 1,11-deep groove ball bearing; 2,12,22, wheel in the 32-; 3,13,23,33-foreign steamer; 4,14,24,34-ball (rolling body), 5-iron plate; 6,16,26-porous solid lubricant mixture of ingredients; The 7-bearing outside diameter; 15,35-sealing element; The 21-thrust ball bearing; The 25-mould; 27-cylinder anchor clamps; The 28-porous solid lubricant; 31-deep trouth ball bearing; The 36-retainer; The 37-porous solid lubricant; Wheel in the 41-; The 42-foreign steamer; The 44-groove; The 45-rolling body; The 46-retainer; The 47-axle; The 48-protective sleeve; The 49-elastic resin that foams; 50, the banded fastening piece of 51-; 52,52a, 52b-solid lubricant.

Embodiment

At first, the embodiment to the porous solid lubricant in first aspect~the 5th aspect describes.

As the resinous principle that constitutes porous solid lubricant of the present invention, in resin (plastics) or rubber etc., can adopt elastomerics or plastomer any or both are as hotchpotch (ア ロ イ) or copolymerization composition.

Under the situation of rubber, can adopt natural rubber, polyisoprene rubber, divinyl rubber, styrene butadiene ribber, neoprene, isoprene-isobutylene rubber, paracril, ethylene-propylene rubber(EPR), silicon rubber, polyurethane elastomer, the various rubber such as (Network ロ ロ ス Le Off オ Application go system) that contain viton chlorine sulphur rubber.

In addition, under the situation of plastics, can enumerate polyethylene, polypropylene, polystyrene, polychlorostyrene ethene, polyacetal, polymeric amide 4,6 (PA4,6), polyamide 6,6 (PA6,6), polyamide 6 T (PA6T), polymeric amide 9T general-purpose plastics or engineering plastics such as (PA9T).

In addition, be not limited to above-mentioned plastics etc., can also use polyurethane formed bodies such as soft urethane molding, hard urethane molding, semi-rigid molding or polyurethane elastomer etc.

In addition, can also make urethane is that caking agent, cyanoacrylate are that caking agent, epoxide resin adhesive, polyvinyl acetate (PVA) are that caking agent, polyimide are that various caking agents such as caking agent foam and solidify and use.

In solid state component, can add pigment or various additives such as antioxidant, metal passivator, antistatic agent, incombustible agent, mould inhibitor or filler etc. as required.

The porous solid lubricant of embodiment with lubricated composition and resinous principle as must composition, can be according to compression, crooked, centrifugal force and the external stresses such as expansion of bubble of following the temperature rising to outside supplying lubricating oil.

The preferred hole continuously of bubble that produces during in the utilization foaming and by porous, it will lubricate composition according to external stress and directly supply with to the outside from the surface of resin via continuous hole.Under the situation of separate wells, the total amount of the lubricating oil in the solid state component is taken in bubble temporarily, sometimes where necessary can not be to outside supplying lubricating oil fully.

Also have, in the present invention, the resinous principle of preferred foaming is the resinous principle that the continuous pore rate foams in the mode more than 50%.If the continuous pore rate is less than prescribed value, then the lubricating oil of resinous principle (solid state component) is taken into the ratio increase in separated foam temporarily, in case of necessity can not be in the majority to the situation that the outside is supplied with, and therefore not preferred.

The continuous air bubbles rate of Tiao Jieing is can be by following technology variable of calculating in the present invention.

(1) at first, the porous solid lubricant of foamed solidification is cut into the size that is fit to measure weight, it is made as A, measure its weight, and, calculate the lubricated composition weight of A and the resinous principle weight of A by the add-on of forming.

(2) then, use sherwood oil, the A that measures above-mentioned weight is carried out Soxhlet cleaned 3 hours as solvent, then, be placed on 80 ℃ thermostatic bath 2 hours, the complete drying organic solvent, obtain B, and measure its (lubricated composition that is taken in resinous principle+separated foam) weight B.

(3) by the value of the weight of the resinous principle weight of lubricated composition weight A, the A of the A that obtains, B, by calculate the continuous air bubbles rate with following formula.

Continuous air bubbles rate (%)={ the lubricated composition weight of 1-(the resinous principle weight of B-A)/A } * 100

According to above-mentioned formula as can be known, because in 3 hours Soxhlet cleaning, the lubricated composition that is taken in the discontinuous separated foam is not discharged to the outside, therefore, can calculate the continuous air bubbles rate by aforesaid operations.

In order not only in such continuous air bubbles, to keep lubricated composition, and promptly constitute also occlusion in resin intermolecular etc., preferably adopt the response type method of impregnation that foamable reaction and curing reaction are carried out simultaneously in resin inside.If like this, then the lubricant high-density can be filled in resin inside, can omit the back infiltration operation that makes the lubricant infiltration and replenish then.

With respect to this, only by the foaming solid bodies that is shaped in advance, make lubricant infiltration back method of impregnation wherein, can not make the liquid lubricant infiltration resin inside of sufficient amount, therefore, do not have sufficient lubricant confining force, lubricating oil is emitted at short notice, causes undersupply under the situation of life-time service sometimes.Therefore, infiltration operation in back preferably adopts as the householder method of response type method of impregnation.

The response type method of impregnation preferably uses commercially available tensio-active agents such as silicone-based surfactant, and each raw molecule is disperseed equably.In addition, can be according to the kind and the addition of surfactant, control surface tension force, the character (successive type or self) of the bubble that control produces or the size of bubble.

As tensio-active agent, can enumerate negatively charged ion and be tensio-active agent, nonionic and be tensio-active agent, positively charged ion and be tensio-active agent, amphoterics, silicone-based tensio-active agent, fluorine is tensio-active agent etc.

The preferred 1 weight % of the ratio~95 weight % of the lubricating oil in the lubricated composition (under will lubricating the situation that becomes to be divided into 100 weight %), and then preferred 5~80 weight parts.Under the situation of the ratio of lubricating oil less than 1 weight %, be difficult to the abundant supplying lubricating oil in necessary position.In addition, under the situation of a large amount of cooperation that surpasses 95 weight %, even at low temperatures, lubricating grease does not solidify yet, and keeps liquid, can not bring into play the solid lubricant functions peculiar sometimes.

As the lubricating oil that uses among the present invention, so long as do not dissolve the foaming solid state component that forms foam, just can not select kind and use, but for example be used alone or as a mixture lubricating oil, lubricating grease, wax etc. also can.

As the lubricating oil that uses among the present invention, can enumerate alkane (パ ラ Off イ Application) and be or cycloalkanes (Na Off テ Application) is that mineral oil, ester are that synthetic oil, ether are synthetic oil, hydrocarbon system synthetic oil, GTL base oil, fluorocarbon oil, the normally used lubricating oil of silicone wet goods or their mixing oil.

At resin material and lubricating oil because chemical similarity such as polarity and do not dissolve, under the dispersive situation,, make easy physical mixed can prevent the segregation of lubricant by using the close lubricating oil of viscosity.

As the thickening material of the lubricating grease that uses in the present invention, can enumerate urea based compounds such as soap classes such as lithium soap, lithium compound soap, calcium soap soap compound soap, aluminium soap, aluminium compound soap, two urea compounds, poly-urea compounds, but not limit especially.

As urea is thickening material, for example, can enumerate two urea compounds, poly-urea compounds, but not limit especially.

Two urea compounds for example can be obtained by the reaction of vulcabond and monoamine.As vulcabond, can enumerate phenylene diisocyanate, diphenyl diisocyanate, phenyl diisocyanate, diphenylmethanediisocyanate, octadecyl vulcabond, decane vulcabond, hexane diisocyanate etc., as monoamine, can enumerate octylame, amino dodecane, cetylamine, stearylamine, oleyl amine, aniline, para-totuidine, hexahydroaniline etc.

Poly-urea compounds is for example obtained by the reaction of vulcabond and monoamine, diamines.As vulcabond, monoamine, can use the identical material of material that uses in the generation with two urea compounds, as diamines, can enumerate quadrol, propylene diamine, butanediamine, hexanediamine, octamethylenediamine, phenylenediamine, tolylene diamine, xylidene(s) etc.

As grease base plinth oil, can use the base oil identical with described lubricating oil.

In addition, as the wax that is used in lubricating grease, can be that wax, fatty acid amide are that wax, ketoamine class, hydrogen solidify any of wet goods for hydrocarbon system synthetic wax, polyethylene wax, aliphatic ester.As the oil component that is used in these waxes, can use the oil component identical with described lubricating oil.

In above-mentioned lubricated composition, also can and then contain molybdenumdisulphide, solid lubricants such as graphite, friction modifiers such as organic-molybdenum, amine, lipid acid, oiliness improvers such as lipid, amine system, the antioxidant of phenol system etc., petroleum sulfonate, the dinonylnaphthalene sulfonic acid ester, rust-preventive agent such as sorbitan ester, sulphur system, the extreme pressure additive of sulphur-phosphorus system etc., organic zinc, the wearing and tearing of phosphorus system etc. prevent agent, benzotriazole, metal passivators such as Sodium Nitrite, polymethacrylate, various additives such as viscosity index rising agent such as polystyrene.

As the method that makes the solid state component foaming, can adopt known foaming method, for example, can enumerate the organic solvent heating that boiling points such as water, acetone, hexane is lower, make the physical method of its gasification or blast from the outside rare gas elementes such as air or nitrogen the mechanical foaming method, use and to utilize temperature or photolysis, the method for the decomposition-type foaming agent of generation nitrogen etc. etc. as azobis isobutyronitrile (AIBN) or azo dicarboximide (ADCA) etc.s.In addition, have as raw material under the situation of reactive high isocyanate group, the chemical foaming that the carbonic acid gas that uses the chemical reaction by itself and water molecules to produce causes also can.

In order to use the foaming of following such reaction, preferably use catalyzer as required, for example, use tertiary amine series catalysts or organo-metallic catalyst etc.

As the tertiary amine series catalysts, can enumerate monoamine, two amines, three amines, cyclic amine, alcamines, ether amine, imdazole derivatives, sour block amine catalyst etc.

In addition, as organo-metallic catalyst, can enumerate stannous octoate (ス Na オ Network エ one ト), dibutyltin diacetate, dibutyl tin laurate, mercaptan dibutyl tin, thiocarboxylic acid dibutyl tin, toxilic acid dibutyl tin, two mercaptan dioctyl tins, thiocarboxylic acid dioctyl tin, phenylmercuric propionate salt, octene lead plumbate etc.In addition, for the purpose of balance of conditioned reaction etc., can mix that these are multiple and use.

The expansion ratio of foaming lubricant is 1.1~200 times, preferred 1~less than 100 times.Why be because expansion ratio less than 1.1 situation under, cause bubble volume little sometimes, can not allowable strain when applying external stress, thereby or solids appropriate situation such as indeformable really up to the mark.In addition, when surpassing 200 times, when surpassing 100 times, be difficult to obtain standing the intensity of external stress, in use cause breakage or destruction sometimes according to purposes.

Solid lubricant can flow in the mould and be shaped, and in addition, also can solidify under normal pressure and then then is processed as the purpose shape by block or grinding etc.

Then, the porous solid lubricant of the invention of the 6th aspect~the 9th aspect and the embodiment of manufacture method thereof are described.

Viewpoint from thermotolerance, flexibility, cost-effectivenes, it is good that the solid state component that uses in the porous solid lubricant of the present invention uses urethane resin, as its raw material, it is good using compound that contains two above isocyanate group and the liquid rubber that contains two above hydroxyls.

The liquid rubber that has hydroxyl at intramolecularly can be enumerated C-terminal liquid polybutadiene, the liquid polyisobutylene of C-terminal, C-terminal polyolefin polyvalent alcohol.At this moment, preferred hydroxyl value is 45~120mg KOH/g.If it is insufficient that hydroxyl value less than 45mg KOH/g, then foams, solidifies, if hydroxyl value greater than 120mg KOH/g, is then lost the elastic force of porous solid lubricant sometimes.In addition, with isocyanate group or epoxy group(ing) etc. with the liquid rubber of a part of modification of the terminal hydroxyl of these liquid rubbers as long as end contains hydroxyl, also can use.For the purpose of the rerum natura of the foam made of control etc., mix and use that these compounds are two or more also can.

The molecular structure of above-mentioned liquid rubber is similar to the lubricated composition of chain methane series described later or naphthene series mineral oil formation, therefore, be considered to superior with the chemical affinity of the molecule that constitutes lubricated composition, liquid rubber molecule and lubricated component molecules twine by more weak interaction.Therefore, a large amount of lubricated compositions is infiltrated in the liquid rubber molecule, can bring into play high lubricated composition retentivity.By it being given strong power such as heat or centrifugal force, destroy the interaction of liquid rubber and lubricated composition, can slowly emit lubricated composition.

As the solidifying agent that uses among the present invention, so long as with the functional end-group of liquid rubber be hydroxyl reaction, prolong molecular chain, or crosslinked, just do not limit especially.As preferred solidifying agent, can enumerate the polymeric polyisocyanate class.The polymeric polyisocyanate class can be reacted with water described later, produces gas, and is therefore especially preferred.

As the polymeric polyisocyanate class, can enumerate aromatic series, aliphatics or alicyclic polymeric isocyanate class.

As the aromatic poly-isocyanate class, can enumerate toluene support vulcabond (below, be recited as TDI), polymer of the tripolymer of TDI, diphenylmethanediisocyanate (below, be recited as MDI), MDI, naphthalene diisocyanate (NDI), phenylene diisocyanate, diphenylene vulcabond etc.

As the aliphatic polymeric isocyanate class, can enumerate 18 methylene diisocyanates, decamethylene vulcabond, hexamethylene diisocyanate, 2,2,4-trimethyl hexamethylene diisocyanate, xylylene vulcabond etc.

As the alicyclic polymeric isocyanate class, can enumerate isophorone diisocyanate, dicyclohexyl methane diisocyanate etc.

In addition, can also use the affixture of polyvalent alcohols such as above-mentioned polymeric polyisocyanate class and TriMethylolPropane(TMP).

In addition, under the situation that the terminal isocyanate modification urethane prepolymer solidifying agent that uses uses, can access the urethane that more is rich in elastic force in as the Thermocurable urethane.

At high temperature carry out functional end-group with liquid rubber and be under the situation of reaction of hydroxyl, can use block agent such as utilizing phenols, lactams, alcohols, oximes blocked isocyanate of isocyanate group block etc.

Have the liquid rubber of terminal hydroxyl and have isocyanate group solidifying agent the cooperation ratio by hydroxyl (OH) and isocyanate group (equivalence ratio NCO) is the scope of (OH/NCO)=1/ (0.9~1.7) preferably, especially consider under the situation of foaminess and elastic force the scope of preferred (OH/NCO)=1/ (1.0~1.5).

Can be used in lubricated composition of the present invention so long as do not dissolve the solid state component that forms foam, just can not select kind and use.As lubricated composition, for example, can be used alone or as a mixture lubricating oil, lubricating grease, wax etc.

As lubricating oil, can use the identical lubricating oil of lubricating oil that uses in the invention with described first aspect~fourth aspect, also can use lubricating grease and other additives.

Also have, in lubricating oil, preferably with the superior chain methane series of the intermiscibility of liquid rubber or naphthene series mineral oil, hydrocarbon system synthetic oil, GTL base oil.

Whipping agent is so long as can make liquid rubber just foam, solidify can to use.Can enumerate the reaction of (a) and isocyanate compound and the chemical foaming agents such as water, (b) that produce carbon dioxide carries out decomposition by heat treated or rayed as whipping agent, azo isobutyronitrile (AIBN), Cellmic C 121 decomposition-type foaming agents such as (ADCA), (c) that produces nitrogen etc. adds the lower organic solvent of boiling points such as hot acetone, hexane and the pneumatogen, (d) that produce blast the mechanical foaming agent of rare gas element such as nitrogen or air from the outside.

In the present invention, use isocyanate compound, therefore, preferably produce the water of carbon dioxide with the isocyanate compound reaction as solidifying agent.

The porous solid lubricant that obtains about making the mixture that contains lubricated composition, liquid rubber, solidifying agent and whipping agent foam, solidify, the cooperation ratio of lubricated composition all is 1 weight %~80 weight % with respect to mixture, preferred 30 weight %~80 weight %.If lubricated composition is less than 1 weight %, then lubricated wet goods feed rate is few, can not bring into play the function as porous solid lubricant, if during greater than 80 weight %, is difficult to solidify.

The cooperation ratio of above-mentioned liquid rubber all is 5 weight %~80 weight % with respect to mixture, preferred 15 weight %~80 weight %.Do not solidify less than 5 weight % the time, therefore, do not have the function as porous solid lubricant, greater than 80 weight % the time, the supply of lubricant is few, does not have the function as porous solid lubricant.

The cooperation ratio of above-mentioned solidifying agent determines that according to the use level and the expansion ratio of liquid rubber the cooperation ratio of above-mentioned whipping agent is according to determining with the relation of expansion ratio described later.That is, curing dose (ratio) is determined by the hydroxyl equivalent of liquid rubber and the normal relation of water.

In the present invention, preferred 1.1 times~200 times of the expansion ratio of porous solid lubricant, more preferably 1.1 times~100 times, and then preferred 1.1 times~10 times.Expansion ratio less than 1.1 times situation under, bubble volume diminishes, can not allowable strain when having applied external stress.In addition, under situation, be difficult to obtain standing the intensity of external stress according to purposes greater than described regulation multiplying power.

In addition, in order to promote the curing speed of porous solid lubricant, can use tertiary amine series catalysts or organo-metallic catalyst etc.As the tertiary amine series catalysts that uses, can enumerate monoamine, two amines, three amines, cyclic amine, alcamines, ether amine etc.In addition, as organo-metallic catalyst, can enumerate stannous octoate (ス Na オ Network エ one ト), dibutyltin diacetate, dibutyl tin laurate, mercaptan dibutyl tin, thiocarboxylic acid dibutyl tin, toxilic acid dibutyl tin, two mercaptan dioctyl tins, thiocarboxylic acid dioctyl tin etc.In addition, for the purpose of balance of conditioned reaction etc., mix that these are multiple and use.

In the present invention, in porous solid lubricant, except pigment or antistatic agent, incombustible agent, mould inhibitor or filler etc., can also add described various additive as required.

In the present invention, in order to realize the high-density fillingization of lubricated composition and the high strength of material property simultaneously, the preferred response type method of impregnation that in the presence of the lubricated composition of lubricated wet goods, carries out foamable reaction and curing reaction simultaneously that uses.This is considered to lubricant and infiltrates equably and be formed in the bubble of foam in the foam formation stage, and lubricated composition occlusion realizes the high-density fillingization of lubricant and the high strength of material property thus simultaneously in the solid state component of foamed solidification.

With respect to this, make foam in advance, make in the lubricant infiltration back method of impregnation wherein, there is not sufficient lubricant confining force, lubricating oil is emitted at short notice, causes the lubricant undersupply under the situation of life-time service sometimes.

The manufacture method of porous solid lubricant of the present invention comprises: the composition that will contain lubricated composition, has liquid rubber, solidifying agent and a whipping agent of hydroxyl at intramolecularly mixes and obtains the mixed processes of mixture; In the foaming of said mixture, solidify finish before, with said mixture be filled in slide unit around or be shaped with the filling work procedure in the mould; Make said mixture foaming, solidified foaming, the curing process of above-mentioned filling.

In above-mentioned mixed processes, the method for mixes liquid rubber, solidifying agent, lubricated composition and whipping agent does not limit especially, for example, can use normally used stirrers such as Henschel mixer, ribbon mixer, stirring mixer to mix.

Mixture utilizes solidifying agent to solidify rapidly, therefore, preferably will drop in the stirrer except other compositions of solidifying agent, drops into solidifying agent at last.

In above-mentioned filling work procedure, will contain the mixture of liquid rubber, solidifying agent, lubricated composition and whipping agent in the foaming of mixture, solidify be filled in before finishing slide unit around or be shaped with in the mould.Carry out simultaneously with by be filled in slide unit around or the curing reaction that causes as the foaming of the liquid rubber of whipping agent and the liquid rubber in the mixture and solidifying agent of the carbonic acid gas that generates of the chemical reaction with isocyanic ester in the mixture in the mould and water of being shaped, the foaming, the cured article that have the shape of packing space in formation around the slide unit or in the molding die are foam.The foam that should lubricate the composition infiltration is a porous solid lubricant of the present invention.

In above-mentioned manufacture method, preferably use commercially available tensio-active agents such as silicone-based surfactant, each raw molecule is disperseed equably.In addition, kind control surface tension force that can be by this surfactant is controlled to be continuous air bubbles or separated foam with the kind of the bubble that generates.As such tensio-active agent, can enumerate negatively charged ion and be tensio-active agent, nonionic and be tensio-active agent, positively charged ion and be tensio-active agent, amphoterics, silicone-based tensio-active agent, fluorine is tensio-active agent etc.

In addition, in above-mentioned manufacture method, as mechanical material with slide unit, bearing, universal joint, ball-screw, line slideway or sphere sleeve pipe etc. are arranged, can be after filling contains the mixture of lubricated composition, liquid rubber, solidifying agent, whipping agent around the slide unit in these mechanical materials, make its foaming, curing, directly make and enclose the mechanical material that the foaming lubricant is arranged.

In addition, in above-mentioned manufacture method, can not use mechanical part with molding die or slide unit (below, be recited as molding die etc.) and be shaped.In this case, need be by blocking or grinding etc. is the purpose shape with foamed solidification thing post-treatment.In addition, do not using under the situation of molding die etc., in foaming, cured article, be difficult to keep lubricated composition, therefore, under the insufficient situation of amounts of lubrication, after post-treatment is the purpose shape, infiltrating after need making lubricant.In addition, even infiltrate behind the lubricant in the solidified foam, the lubricant retentivity is also compared reduction with the method for using molding die etc., or takes place that lubricant leaks easily easily wait appropriate situation when the processing of foam.

Therefore, in the present invention, from the quality aspect, operation aspect, cost aspect, the preferred method that mixture is filled in molding die etc. that adopts.

In the porous solid lubricant of making like this, the distortion of the foam that the lubricated composition that contains with its state of infiltrating can not cause owing to external force and sharply oozing out, thus can efficient lubricated composition is oozed out and use.Its result, it is that necessary inferior limit gets final product that lubricant becomes component, and can be in the long-term lubricity that keeps.

Then, the porous solid lubricant of the invention of the tenth~the 13 aspect and the embodiment of manufacture method thereof are described.

This porous solid lubricant is to make urethane prepolymer foaming, curing and the solids of porous, and is the porous solid lubricant that has lubricated composition to form in the inner occlusion of resin.

The urethane prepolymer that uses in the invention of the tenth~the 13 aspect is the urethane prepolymer that has isocyanate group at intramolecularly, and this isocyanate group also can be by other substituting group blocks.Urethane prepolymer obtains by organic polymeric polyisocyanate and active hydrogen radical reaction.

As organic polymeric polyisocyanate, comprise aforesaid aromatic diisocyanate, aliphatics or alicyclic and polyisocyanate compounds.Though a part repeats, and is listed below.

Aromatic diisocyanate for example can enumerate diphenylmethanediisocyanate (below, be recited as MDI), 2,4-toluene support vulcabond, 2,6-toluene support vulcabond and composition thereof (below, be recited as TDI), 1,5-naphthalene diisocyanate, 1,3-phenylene diisocyanate, 1,4-phenylene diisocyanate.

Aliphatics or alicyclic diisocyanate for example can enumerate 1, the 6-hexamethylene diisocyanate (below, be recited as HDI), 1,12-dodecane vulcabond, 1,3-tetramethylene vulcabond, 1, the 3-cyclohexyl diisocyanate, 1, the 4-cyclohexyl diisocyanate, different propane vulcabond, 2,4-hexahydrotoluene vulcabond, 2,6-hexahydrotoluene vulcabond, 1,3-hexahydrobenzene group diisocyanate, 1,4-hexahydrobenzene group diisocyanate, 2,4 '-perhydro diphenylmethanediisocyanate, 4,4 '-perhydro diphenylmethanediisocyanate.

As polyisocyanate compounds, can enumerate 4,4 ', 4 "-triphenylmethane triisocyanate, 4,6,4 '-phenylbenzene triisocyanate, 2,4,4 '-diphenyl ether triisocyanate, polymethylene polyphenyl base polymeric polyisocyanate.In addition, can enumerate the polyisocyanate compounds that the part of these isocyanic ester is modified as biuret, allophanate, carbodiimide, oxazoline ketone, acid amides, imide etc.

As described compound, can enumerate low molecular polylol, polyethers is that polyvalent alcohol, polyester are that polyvalent alcohol, Viscotrol C are polyvalent alcohol etc. with active hydrogen base.These can use separately or as two or more mixtures.As low molecular polylol, can enumerate the divalence polyvalent alcohol, for example, ethylene glycol, Diethylene Glycol, propylene glycol, 1,4-butyleneglycol, 1,6-hexylene glycol, neopentyl glycol, hydrogenation dihydroxyphenyl propane etc., the above polyvalent alcohol (3~8 valency polyvalent alcohol) of trivalent, for example, glycerine, TriMethylolPropane(TMP), hexanetriol, tetramethylolmethane, Sorbitol Powder, sucrose etc.

As polyethers is polyvalent alcohol, (carbonatoms is 2~4 a epoxy alkane, for example can to enumerate the epoxy alkane of above-mentioned low molecular polylol, oxyethane, propylene oxide, butylene oxide ring) ring-opening polymerization polymer of affixture and epoxy alkane, specifically, comprise polyoxyethylene glycol, polypropylene glycol, polytetramethylene ether diol.

As polyester is polyvalent alcohol, can enumerate polyester polyol, polycaprolactone polyol and polyester ether polylol etc.Polyester polyol is by carboxylic acid (the saturated or unsaturated carboxylic acid of aliphatics, for example, hexanodioic acid, nonane diacid, laurostearic acid, toxilic acid, fumaric acid, methylene-succinic acid, dimerization linolenic acid and or aromatic carboxylic acid, for example, phthalandione, m-phthalic acid) and the polycondensation of polyvalent alcohol (above-mentioned low molecular polylol and/or polyether glycol) obtain.

Polycaprolactone polyol is by in the presence of catalyzer such as organometallic compound, metal-chelating compounds, fatty acid metal acylate, makes the polymerization starter of glycols or three alcohols and 6-caprolactone, Alpha-Methyl-6-caprolactone, ε-methyl-6-caprolactone etc. carry out addition polymerization and obtains.Polyester ether polylol by having carboxyl and/or OH base endways polyester and epoxy alkane for example, addition reaction such as oxyethane, propylene oxide and obtaining.As Viscotrol C is polyvalent alcohol, can enumerate the transesterify or the esterification polyol of Viscotrol C and Viscotrol C or Castor Oil Fatty Acid and above-mentioned low molecular polylol, polyether glycol, polyester polyol.

(content NCO) is more than the 2 weight % to the urethane prepolymer preferred isocyanate base that uses among the present invention.(NCO) content then is difficult to realize simultaneously foaminess and elastic force less than 2 weight % as if isocyanate group.

As the solidifying agent that uses among the present invention, can separately or share with 3,3-two chloro-4,4 '-tetramethyl triaminotriphenyl methane NH2 (below, be recited as MOCA) or 4,4 '-diamino-3,3 '-diethyl-5,5 '-dimethyl diphenylmethane is the aromatic series polyamine of representative, with 1,4-butyleneglycol or TriMethylolPropane(TMP) are that low molecular polylol, polyether glycol, the Viscotrol C of representative is that polyvalent alcohol, polyester are polyvalent alcohol etc.Wherein, the aromatic series polyamine has advantage from cost, and is therefore preferred.

Have the urethane prepolymer of isocyanate group and have terminal hydroxyl or the cooperation ratio of the solidifying agent of terminal amino group by hydroxyl (OH) or amido (NH

2) and isocyanate group (equivalence ratio NCO) preferred (OH or NH

2/ NCO)=1/ scope of (0.9~1.7) is if consider foaminess and elastic force, then preferred (OH or NH especially

2/ NCO)=1/ scope of (1.0~1.5).

In addition, can in solid state component, use additive as required.As additive, can enumerate with the hindered phenol is antioxidant, stiffeners (carbon black, hard charcoal, colloid silica etc.), inorganic filler (lime carbonate, barium sulfate, talcum, clay, ground silica etc.), ageing inhibitor, incombustible agent, metal passivator, antistatic agent, mould inhibitor or the filler and the tinting material etc. of representative.

Can be used in lubricated composition of the present invention so long as do not dissolve the solid state component that forms foam, just can not select kind and use.As lubricated composition, can separately or mix aforesaid lubricating oil, lubricating grease, wax etc. and use.

Can be used in whipping agent of the present invention so long as make the urethane prepolymer foaming as described above, just can use, especially owing to using the urethane prepolymer that has isocyanate group at intramolecularly, therefore preferred and isocyanate compound reacts and the water of generation carbon dioxide.

Porous solid lubricant of the present invention obtains by making the mixture foaming, the curing that contain above-mentioned lubricated composition, urethane prepolymer, solidifying agent and whipping agent.

The cooperation ratio of above-mentioned lubricated composition all is 1~90 weight % with respect to mixture, preferred 5~80 weight %.If lubricated composition is less than 1 weight %, then lubricated wet goods feed rate is few, can not bring into play the function as porous solid lubricant, does not solidify greater than 90 weight % the time.

The above-mentioned cooperation ratio that has the urethane prepolymer of isocyanate group at intramolecularly all is 8~98 weight % with respect to mixture, preferred 20~80 weight %.Do not solidify during less than 8 weight %, therefore, can not bring into play the function as porous solid lubricant, during greater than 98 weight %, the supply of lubricating oil is few, does not have the function as porous solid lubricant.

The cooperation ratio of above-mentioned solidifying agent determines that according to the use level and the expansion ratio of urethane prepolymer the cooperation ratio of above-mentioned whipping agent is according to determining with the relation of expansion ratio described later.That is, curing dose (ratio) is determined by the hydroxyl equivalent of the urethane prepolymer that has isocyanate group at intramolecularly and the relation of water equivalent.

In the present invention, preferred 1.1 times~100 times of the expansion ratio of porous solid lubricant, more preferably 1.1 times~10 times.Expansion ratio less than 1.1 times situation under, bubble volume diminishes, can not allowable strain when having applied external stress.In addition, under greater than 100 times situation, be difficult to obtain standing the intensity of external stress.

In addition, follow in use under the situation of foaming of such reaction, preferably use catalyzer as required, use for example tertiary amine series catalysts or organo-metallic catalyst etc. as described above.

In the present invention, from realizing the high-density fillingization of lubricated composition and the high strength of material property simultaneously, preferably use the response type method of impregnation that foamable reaction and curing reaction are carried out simultaneously.

The manufacture method of porous solid lubricant of the present invention comprises: the composition that will contain lubricated composition, has urethane prepolymer, solidifying agent and a whipping agent of isocyanate group at intramolecularly mixes and obtains the mixed processes of mixture; In the foaming of said mixture, solidify finish before, with said mixture be filled in slide unit around or be shaped with the filling work procedure in the mould; Make said mixture foaming, solidified foaming, the curing process of above-mentioned filling.

Based on Fig. 1~Fig. 5, the embodiment that porous solid lubricant is bearing enclosed is described.

At first, as shown in Figure 5, bearing 31 comprises: interior wheel 32, and the foreign steamer 33 of interior wheel 32 concentric arrangement, wherein be clipped in a plurality of rolling bodys 34 between foreign steamer, keep these a plurality of rolling bodys 34 retainer 36, be fixed in the sealing element 35 of foreign steamer 33 etc.

Based on Fig. 1~Fig. 3, the example to the inclosure method of the porous solid lubricant of such bearing is described.

Fig. 1 represents the inclosure example in the deep groove ball bearing (no sealing element), as shown in Figure 1, the iron plate 5 bigger than bearing outside diameter 7 or and its similar anchor clamps on place and take turns 2 in having, foreign steamer 3, be clipped in the bearing 1 of the rolling body 4 between inside and outside the wheel, porous solid lubricant mixture of ingredients 6 before well-stirred foaming is faced flows in the space that is surrounded by interior wheel 2, foreign steamer 3, iron plate 5, makes its foaming, curing.

In this case, make mixture 6 flow in the bearings 1 after, and then on bearing 1 upper cap, also can than bearing outside diameter 7 big iron plate 5 or anchor clamps similar with it.Under the situation that covers iron plate or anchor clamps, the filling ratio of the porous solid lubricant during the raising bearing is interior.After foaming, the curing of mixture 6 finish, unload iron plate 5 or anchor clamps similar with it, it is bearing enclosed to obtain porous solid lubricant.

Fig. 2 represents the inclosure example in the deep groove ball bearing (no sealing element), wheel 12, foreign steamer 13 in will having, be clipped in rolling body 14 between foreign steamer and the bearing 11 that only is assemblied in one-sided sealing element 15 leave standstill according to the mode that sealing element 15 is positioned at downside.

Also have, make well-stirred foaming face preceding porous solid lubricant mixture of ingredients 16 and flow into bearings 11, make its foaming, curing.In this case, with Fig. 1 in the same manner, for the filling ratio of the porous solid lubricant in improving in the bearing, make mixture 16 flow in the bearings 11 after, and then iron plate or with it the similar anchor clamps bigger than bearing outside diameter also can on bearing 11 upper caps.The sealing element of upside is as the substitute of the anchor clamps that are used to improve filling ratio, in foaming process assembling also can, be assemblied in bearing 11 after also can foaming, solidify end.

Fig. 3 represents the inclosure example in the thrust ball bearing, and Fig. 4 is the synoptic diagram of expression by the use of the cylinder anchor clamps of Fig. 3.

As shown in Figures 3 and 4, prepare to accommodate the mould 25 of thrust ball bearing 21, the bearing 21 that has interior wheel 22, foreign steamer 23 and be clipped in the rolling body 24 between interior foreign steamer is set.Porous solid lubricant mixture of ingredients 26 before well-stirred foaming is faced flows into the bearing 21 from the internal side diameter of bearing 21, will insert inside diameter with the cylinder anchor clamps 27 of internal diameter same diameter, makes mixture 26 foaming, solidifies.In mixture 26 foaming, solidify and after becoming porous solid lubricant 28, take apart a die 25 and cylinder anchor clamps 27, it is bearing enclosed to obtain porous solid lubricant.

In addition, also can use injection moulding machine etc. in the inclosure of the lubricant in bearing.In this case, bearing is assemblied in mould, in spiral (screw) blended porous solid lubricant composition from nozzle bearing enclosed in.

Like this, as shown in Figure 5, around the rolling body 34 of bearing 31, enclose above-mentioned porous solid lubricant 37.

As described above the porous solid lubricant of Zhi Zaoing bearing enclosed in, the distortion of the foam that the lubricated composition that the state with the infiltration porous solid in lubricated contains can not cause owing to external force and sharply oozing out can make and lubricate into component efficiency and ooze out well at the slip all-moving surface and use.Its result, the component that lubricates into of this bearing is that necessary inferior limit gets final product, long lifetime and also can move with high speed rotating.

Based on following accompanying drawing, the working of an invention mode relevant with constant velocity joint described.

As shown in Figure 6, the constant velocity joint of the 5th embodiment is ball permanent joint (BJ as described below; Ball fixed joint), that is: on the inner peripheral surface of the periphery of interior wheel 41 and foreign steamer 42, be provided with to arranged opposite a plurality of grooves 43,44 that extend vertically, keep spherical rolling body 45 with retainer (retainer) 46, it is rotated in these paired grooves 43,44 is directed freely, thus, by the groove 43,44 of rolling body 45 axially on move allow in each the change of intersecting angle of wheel 41 and foreign steamer 42, and can be via rolling body 45 with revolving force from inwardly wheel 41 and foreign steamer 42 transmission of each groove 43,44.

In the constant velocity joint of such structure; solid lubricant 52 is filled according to the mode of the integral body of wheel 41, rolling body 45, retainer 46 in covering in inside at foreign steamer 42; on the other hand; assemble the snake abdomen protective sleeve 48 of rubber system according to mode across the periphery of the axle 47 of the maintenance of the periphery of foreign steamer 42 and interior wheel 41, airtight with banded fastening piece (so-called protective sleeve band (boot band)) 50,51 fastening protective sleeves 48.

Protective sleeve 48 is made of the rubber material; can adopt to stand the material that possesses stopping property to dust in the atmosphere or water, resistance to tearing, oil-proofness, thermotolerance, wearability etc. of use; for example, neoprene or thermoplastic polyester elastomer (eastern レ デ

ユパ Application corporate system: Ha イ ト レ Le) etc.In addition, adding softening agent, softening agent, lubricant, antioxidant, stiffeners etc. also can.

Porous solid lubricant in as the plastics of resinous principle or rubber etc., can adopt any or both of elastomerics or plastomer as mentioned above as hotchpotch (ア ロ イ) or copolymerization composition.

In addition, adopt lubricated composition or foaming method get final product as described above,, so long as do not dissolve the solids of formation foam, just can not select kind and use as lubricating oil, but for example be used alone or as a mixture lubricating oil, lubricating grease, wax etc. also can.

Solid lubricant flow into the mould internal shaping also can, in addition, after also can under normal pressure, solidifying, by blocking or post-treatment such as grinding is the shape of purpose.In addition, to the inside of the foreign steamer of constant velocity joint, normally between wheel and the foreign steamer foam filled and be cured reaction also can, can assemble protective sleeve then and make constant velocity joint.

Except described the 5th embodiment, porous solid lubricant also can be enclosed in the constant velocity joint of various known forms.For example, as fixed-type constant-velocity universal joint, the ball permanent joint that in the 5th embodiment, illustrates (abbreviating BJ sometimes as), can also enumerate no undercut coupling ball joint (undercut free joint) (abbreviating UJ sometimes as).Such BJ or the nodule number of UJ have 6 or 8 s' situation.

Enclose under the situation of BJ or UJ at the solid lubricant that will foam, only fill the position that needs lubricant, therefore, can play the contribution effect to cost degradation, lightweight, and, because the operating angle that uses is big, therefore, be compressed easily, bending, to the easier supply of lubricant of sliding part.

In addition, as the portable constant velocity joint that slides, can enumerate double offset joint (doubleoffset joint) (abbreviating DOJ sometimes as), T-joint (triple joint) (abbreviating TJ sometimes as), cross groove joint (cross groove joint) (abbreviating LJ sometimes as) etc.

Be described in detail as follows with reference to accompanying drawing, as shown in Figure 7, the double offset joint (DOJ) of the 6th embodiment the internal surface of foreign steamer 53 and spherical in the outside surface of wheel 54 dispose with equal angles vertically and be formed with 6 or 8 rail grooves 55 around axle, 56, will be at this rail groove 55,56 6 or 58 supportings of 8 ball 57 usefulness retainers that group is gone into, the peripheral shape of this retainer 58 is become sphere, and also form the sphere that mates with the periphery of interior wheel the interior week of retainer 58, the felling axe 59 that connects rotation, around the interior wheel shaft 60 that axis rotates, it is rotated in it with interlock via ball 17 constant speed.

When felling axe 59 and interior wheel shaft 60 had the rotation of intersecting angle ground, the ball 57 that moves along rail groove 55 was retained as rail groove 55,56 in and does not float in the other direction along groove, thereby is difficult to along groove direction rolling movement, mainly move by sliding come and go mobile.

The solid lubricant 52a that wants portion's filling-foam to the inside of such DOJ.

As shown in Figure 8, the T-joint of the 7th embodiment (TJ) comprising: the T-shaped axial region 63 that has three pin axles 62 around the front end of wheel shaft 61; At one end be provided with the joint axial region 65 of the cylindrical portion 64 that this T-shaped axial region 63 can insert.

TJ has three rail grooves 66 that extend vertically at the inner peripheral surface of cylindrical portion 64, can chimeric rotatably roller means (so-called spherical roller) on three pin axles 62, the mode that is formed the pair of sidewalls face guiding of rail groove 66 according to the roller 67 of this roller means is gone into the cylindrical portion 64 of joint axial region 65 with 63 groups of T-shaped axial regions, the solid lubricant 52b of foaming is filled in wants in the portion.

Such TJ or described DOJ need the moving area that slides in the axial direction, and therefore, grease-enclosed amount (lubricant inclosure spatial volume) is more than fixed joint such as described BJ.

Yet the solid lubricant 52 of foaming only can be filled necessary position, therefore, encloses under the situation of DOJ or TJ at solid lubricant that will foaming, and the contribution effect that cost degradation and lightweight are played further becomes big.

Embodiment 1

Below, the use raw material summary column used in embodiment and the comparative example is exhausted as follows, the composition and the measurement result of solid lubricant is illustrated in the table 1.

(a) urethane prepolymer (ダ イ セ Le chemical industry system: プ ラ Network セ Le EP-1130)

(b) amine is solidifying agent (イ Ha ラ ケ ミ カ Le corporate system: イ Ha ラ キ

ユア ミ Application MT)

(c) water (ion exchanged water)

(d) silicone-based surfactant (eastern レ ダ ウ corporate system: SRX298)

(e) urea is lubricating grease (Nippon Oil(Nippon Mitsubishi Oil) corporate system パ イ ロ ノ Star Network ユ ニ バ one サ Le N6C)

(f) isocyanic ester (Japanese polyurethane corporate system: コ ロ ネ one ト T80)

(g) polyether glycol (Asahi Glass's corporate system: プ レ ミ ノ one Le SX4004)

(h) amine series catalysts (eastern ソ one corporate system: TOYOCAT DB2)

(i) lubricating oil (Nippon Oil(Nippon Mitsubishi Oil) corporate system: one PVC Application 100)

[embodiment 1,2]

Press the one-tenth component (composition) shown in the table 1 and in urethane prepolymer, add silicone-based surfactant and urea lubricating grease, under 120 ℃, stir well.To wherein adding amine is solidifying agent, after the stirring, adds the water as whipping agent, places 1 hour in being set at 120 ℃ thermostatic bath, makes its curing, and the solid lubrication body obtains foaming.

[embodiment 3]

Press the one-tenth component (composition) shown in the table 1 in polyether glycol, add silicone-based surfactant, mineral oil, amine series catalysts, as the water of whipping agent, 90 ℃ of heating and stirring well down.To wherein adding isocyanic ester, stir well, confirm foamable reaction after, in being set at 90 ℃ thermostatic bath, placed 15 minutes, obtained foaming solid lubrication body.

[comparative example 1]

Press the one-tenth component (composition) shown in the table 1, obtain non-foaming lubricant with the manufacture method identical with the foregoing description 1.

[comparative example 2]

In the composition shown in the table 1 (composition), except the mineral oil composition, with the synthetic foam of the method identical with embodiment 2.Oil is infiltrated from behind, form back infiltration type foaming lubricant.

[reference example 1]

In the composition shown in the table 1 (composition), except the composition of silicone-based surfactant, by the method identical with embodiment 3, synthetic foam forms the continuous air bubbles rate less than 50% solid lubricant.

For the solid lubricant that obtains, measure expansion ratio and resilience elasticity, the separating of oil projects of centrifugal force, what comprehensive judgement was used could.Also have, the elastic measuring method of resilience carries out according to JISK6400-3.

Centrifugal force is separating of oil to be illustrated in the oily decrement with respect to oily loading level of rotation after 1 hour under rotor radius 75mm, rotating speed 1500rpm/ minute the condition.In addition, the continuous air bubbles rate is calculated according to the measuring method that has used above-mentioned formula.

[table 1]

As can be known clear and definite from the result shown in the table 1, the embodiment 1 of foam compares with the comparative example 1 of non-foam, even under identical kinergety (under the mass force), elastic deformation amount's also bigger (the resilience Young's modulus is little), the character of product having shape-following-up compression set is also stronger.Hence one can see that, and the foaming solid lubricant of embodiment is also stood use in the driving space that external stresses such as out of use compression in the past apply.

In addition, even under the situation of the foamex of same composition, only by back infiltration operation keep mineral oil comparative example 2 solid lubricant with mineral oil with foaming the time embodiment 1 of occlusion compare, the separating of oil amount under the identical centrifugal force is also many.Hence one can see that, and by the lubricant infiltration of response type, the abundant occlusion of lubricating oil can be made the solid lubricant with slow release performance in the resin solid state component.

In addition, from these embodiment and comparative example as can be known, by the response type that carries out simultaneously with foaming, the lubricating oil occlusion is in the inside of resin, thereby with only compare by lubricating oil infiltration foamed resin products being made have lubricated oil condition in the bubble, the oily confining force that occlusion causes is higher.

And then, the continuous air bubbles rate less than 50% reference example in, compare with embodiment 3, the few this point of separating of oil amount under centrifugal force is poor, if but take all factors into consideration resilience Young's modulus and other, then stand use within the scope of the invention.

[the inventive embodiment 4~embodiment 7 of the use liquid rubber of the 6th aspect~the 9th aspect and comparative example 3~comparative example 4]

To press the cooperation mixed shown in the table 1 except the compounding ingredient of isocyanic ester, add isocyanic ester at last, obtain mixture rapidly, this mixture 20.6g will be filled in the teflon resin container made (diameter 100mm * height 150mm).After through several seconds, the beginning foamable reaction was placed several hours at normal temperatures, made its curing, obtained test piece.In this test piece, correctly measure about about 1g, utilize the oil of centrifuge separator slowly to emit test (rotor radius 9.9mm, rotating speed 850rpm).At this, estimate by calculate the lubricant weight rate with following formula.

Lubricant weight before lubricant weight rate (%)=100 * (lubricant weight before the test-test back lubricant weight)/test.

(%) is more little for the weight rate of calculating, and oily discharging amount is few more, we can say that the lubricant confining force is big.In the present invention, be more than 0.5% with weight rate and 10% following average evaluation is that the lubricant confining force is superior.

[table 2]

1), cooperates with the back infiltration for foam

As can be known clear and definite from the result of table 2, in comparative example 3~comparative example 4, the release performance of lubricating oil is too much, and is once extracted out under centrifugal action, therefore, can not expect its long lifetime.With respect to this, in embodiment 4~7, utilize centrifugal force slowly to emit lubricant, therefore, can provide lubricated with the MIN oil mass of necessity.

[inventive embodiment 8~12 of the use urethane prepolymer of the tenth~the 13 aspect and comparative example 5]

In 80 ℃ tetrafluoroethylene system beakers (diameter 60mm * height 150mm), mix compounding ingredient except solidifying agent, amine catalyst and whipping agent well in the cooperation ratio shown in the table 1.Then, will drop in the beaker, stir well at 120 ℃ of following dissolved MOCA.Then, drop into amine catalyst and whipping agent and stir.After several seconds, the beginning foamable reaction was placed 30 minutes down at 100 ℃, made its curing, obtained test piece.Use visual or opticmicroscope, observe this test piece.To be evaluated as superior porous solid lubricant at the foam of the elastic caoutchouc shape of the shape that oil oozes out when pressing that press...withes one's finger, " zero " mark will be recorded in the table 1 in the lump.Be not cured in the comparative example 1.

In addition, for the test piece that obtains being investigated the slow release performance of lubricant, it is provided in lubricating oil shown below slowly emits in the test, the result is recorded in the table 3 in the lump.

<lubricating oil is slowly emitted test 〉

In the centrifuge separator of rotor radius 75mm, drop into test piece, with rotating speed 1500rpm rotation 1 hour, the lubricant weight rate before and after the determination test.At this, the lubricant weight rate is by calculating and estimate with following formula.

Lubricant weight before lubricant weight rate (%)=100 * (lubricant weight before the test-test back lubricant weight)/test

(%) is more little for the weight rate of calculating, and oily discharging amount is few more, we can say that the lubricant confining force is big.

[table 3]

1) caprolactone is a urethane prepolymer

2) ether is urethane prepolymer

3) ester is a urethane prepolymer

As shown in Table 3, it in embodiment 8~12 foam of the elastic caoutchouc shape of the shape that oil oozes out when press...withing one's finger pressure, confirm superior porous solid lubricant, but in comparative example 5, foam, but a part is not solidified, not as porous solid lubricant performance function.With respect to this, in embodiment 8~12, applied under the state of centrifugal force, not extract out immediately from foam, lubricant is emitted lentamente.

[embodiment 13]

In the cooperation ratio shown in the embodiment 1 of table 1, in as the urethane prepolymer of resinous principle, add silicone-based surfactant and urea lubricating grease, under 120 ℃, stir well.To wherein adding amine is solidifying agent, after the stirring, adds the water as whipping agent, after filling in the internal space of spot contact bearing 6204, places 1 hour in being set at 120 ℃ thermostatic bath, and it is solidified, and obtains the bearing enclosed test piece of porous solid lubricant.For the test piece that obtains, implement bearing long duration test shown below, measure the bearing life time, the result is recorded in the table 1 in the lump.