WO2023036404A1 - Taste balancing botanical compounds - Google Patents

Taste balancing botanical compounds Download PDFInfo

- Publication number

- WO2023036404A1 WO2023036404A1 PCT/EP2021/074604 EP2021074604W WO2023036404A1 WO 2023036404 A1 WO2023036404 A1 WO 2023036404A1 EP 2021074604 W EP2021074604 W EP 2021074604W WO 2023036404 A1 WO2023036404 A1 WO 2023036404A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- compound

- mixture

- madecassoside

- terminoloside

- total weight

- Prior art date

Links

- 150000001875 compounds Chemical class 0.000 title claims abstract description 86

- 235000019640 taste Nutrition 0.000 title description 5

- 239000000203 mixture Substances 0.000 claims abstract description 100

- 238000000034 method Methods 0.000 claims abstract description 15

- 235000019605 sweet taste sensations Nutrition 0.000 claims abstract description 15

- 238000004519 manufacturing process Methods 0.000 claims abstract description 13

- 235000013305 food Nutrition 0.000 claims abstract description 8

- 239000008194 pharmaceutical composition Substances 0.000 claims abstract description 5

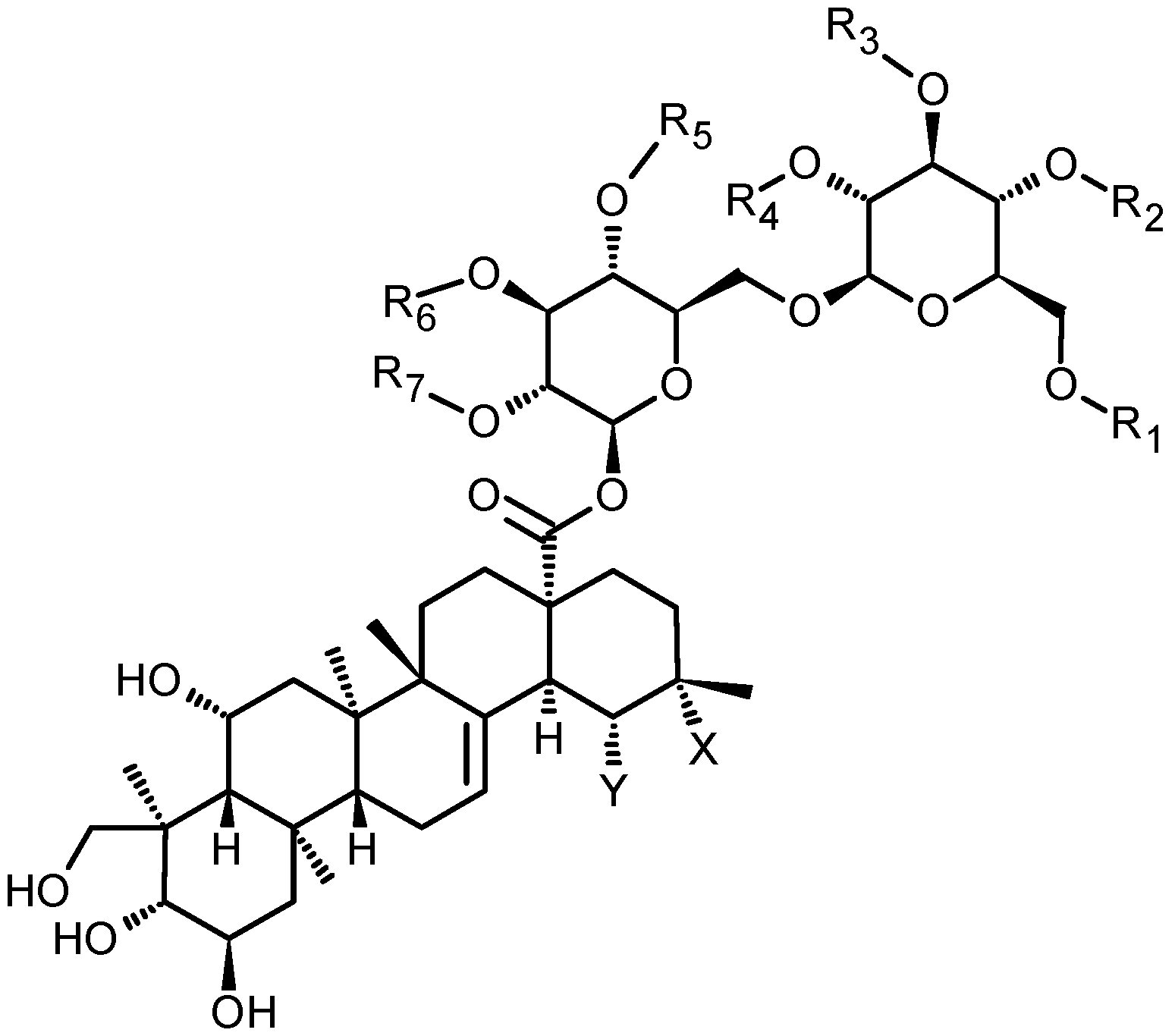

- NNWMHSNRRWMMBI-PJISEHJASA-N Asiaticoside B Chemical compound O[C@@H]1[C@H](O)[C@@H](O)[C@H](C)O[C@H]1O[C@@H]1[C@@H](CO)O[C@@H](OC[C@@H]2[C@H]([C@H](O)[C@@H](O)[C@H](OC(=O)[C@@]34[C@@H](CC(C)(C)CC3)C=3[C@@]([C@]5(C)C[C@@H](O)[C@H]6[C@](C)(CO)[C@@H](O)[C@H](O)C[C@]6(C)[C@H]5CC=3)(C)CC4)O2)O)[C@H](O)[C@H]1O NNWMHSNRRWMMBI-PJISEHJASA-N 0.000 claims description 54

- BNMGUJRJUUDLHW-HCZMHFOYSA-N Madecassoside Chemical compound O([C@@H]1[C@@H](CO)O[C@H]([C@@H]([C@H]1O)O)OC[C@H]1O[C@H]([C@@H]([C@@H](O)[C@@H]1O)O)OC(=O)[C@]12CC[C@H]([C@@H]([C@H]1C=1[C@@]([C@@]3(C[C@@H](O)[C@H]4[C@](C)(CO)[C@@H](O)[C@H](O)C[C@]4(C)[C@H]3CC=1)C)(C)CC2)C)C)[C@@H]1O[C@@H](C)[C@H](O)[C@@H](O)[C@H]1O BNMGUJRJUUDLHW-HCZMHFOYSA-N 0.000 claims description 52

- QCYLIQBVLZBPNK-UHFFFAOYSA-N asiaticoside A Natural products O1C(C(=O)C(C)C)=CC(C)C(C2(C(OC(C)=O)CC34C5)C)C1CC2(C)C3CCC(C1(C)C)C45CCC1OC1OCC(O)C(O)C1O QCYLIQBVLZBPNK-UHFFFAOYSA-N 0.000 claims description 48

- BNMGUJRJUUDLHW-HLUHVYOBSA-N Madecassoside Natural products C[C@@H]1CC[C@@]2(CC[C@]3(C)C(=CC[C@@H]4[C@@]5(C)C[C@@H](O)[C@H](O)[C@@](C)(CO)[C@@H]5[C@H](O)C[C@@]34C)[C@@H]2[C@H]1C)C(=O)O[C@@H]6O[C@H](CO[C@@H]7O[C@H](CO)[C@@H](O[C@@H]8O[C@H](C)[C@H](O)[C@@H](O)[C@H]8O)[C@H](O)[C@H]7O)[C@@H](O)[C@H](O)[C@H]6O BNMGUJRJUUDLHW-HLUHVYOBSA-N 0.000 claims description 44

- 229940090813 madecassoside Drugs 0.000 claims description 44

- 150000001720 carbohydrates Chemical class 0.000 claims description 31

- 239000000178 monomer Substances 0.000 claims description 23

- 150000003839 salts Chemical class 0.000 claims description 23

- 229930006000 Sucrose Natural products 0.000 claims description 21

- CZMRCDWAGMRECN-UGDNZRGBSA-N Sucrose Chemical compound O[C@H]1[C@H](O)[C@@H](CO)O[C@@]1(CO)O[C@@H]1[C@H](O)[C@@H](O)[C@H](O)[C@@H](CO)O1 CZMRCDWAGMRECN-UGDNZRGBSA-N 0.000 claims description 21

- 229960004793 sucrose Drugs 0.000 claims description 21

- WQZGKKKJIJFFOK-GASJEMHNSA-N Glucose Natural products OC[C@H]1OC(O)[C@H](O)[C@@H](O)[C@@H]1O WQZGKKKJIJFFOK-GASJEMHNSA-N 0.000 claims description 20

- SHZGCJCMOBCMKK-UHFFFAOYSA-N D-mannomethylose Natural products CC1OC(O)C(O)C(O)C1O SHZGCJCMOBCMKK-UHFFFAOYSA-N 0.000 claims description 18

- PNNNRSAQSRJVSB-UHFFFAOYSA-N L-rhamnose Natural products CC(O)C(O)C(O)C(O)C=O PNNNRSAQSRJVSB-UHFFFAOYSA-N 0.000 claims description 18

- 235000013681 dietary sucrose Nutrition 0.000 claims description 17

- 108700023372 Glycosyltransferases Proteins 0.000 claims description 16

- 102000051366 Glycosyltransferases Human genes 0.000 claims description 16

- SHZGCJCMOBCMKK-JFNONXLTSA-N L-rhamnopyranose Chemical compound C[C@@H]1OC(O)[C@H](O)[C@H](O)[C@H]1O SHZGCJCMOBCMKK-JFNONXLTSA-N 0.000 claims description 16

- SRBFZHDQGSBBOR-UHFFFAOYSA-N beta-D-Pyranose-Lyxose Natural products OC1COC(O)C(O)C1O SRBFZHDQGSBBOR-UHFFFAOYSA-N 0.000 claims description 16

- 239000008103 glucose Substances 0.000 claims description 15

- PYMYPHUHKUWMLA-UHFFFAOYSA-N arabinose Natural products OCC(O)C(O)C(O)C=O PYMYPHUHKUWMLA-UHFFFAOYSA-N 0.000 claims description 14

- SRBFZHDQGSBBOR-IOVATXLUSA-N D-xylopyranose Chemical compound O[C@@H]1COC(O)[C@H](O)[C@H]1O SRBFZHDQGSBBOR-IOVATXLUSA-N 0.000 claims description 13

- WQZGKKKJIJFFOK-VFUOTHLCSA-N beta-D-glucose Chemical compound OC[C@H]1O[C@@H](O)[C@H](O)[C@@H](O)[C@@H]1O WQZGKKKJIJFFOK-VFUOTHLCSA-N 0.000 claims description 12

- 244000146462 Centella asiatica Species 0.000 claims description 9

- RFSUNEUAIZKAJO-ARQDHWQXSA-N Fructose Chemical compound OC[C@H]1O[C@](O)(CO)[C@@H](O)[C@@H]1O RFSUNEUAIZKAJO-ARQDHWQXSA-N 0.000 claims description 9

- 239000005913 Maltodextrin Substances 0.000 claims description 9

- 229920002774 Maltodextrin Polymers 0.000 claims description 9

- 229910052739 hydrogen Inorganic materials 0.000 claims description 9

- 229940035034 maltodextrin Drugs 0.000 claims description 9

- 239000000419 plant extract Substances 0.000 claims description 9

- 239000000126 substance Substances 0.000 claims description 9

- 235000004032 Centella asiatica Nutrition 0.000 claims description 8

- 239000005715 Fructose Substances 0.000 claims description 8

- 229930091371 Fructose Natural products 0.000 claims description 8

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 claims description 8

- 239000001257 hydrogen Substances 0.000 claims description 8

- 238000011534 incubation Methods 0.000 claims description 8

- 108010055629 Glucosyltransferases Proteins 0.000 claims description 7

- 102000000340 Glucosyltransferases Human genes 0.000 claims description 7

- 108010042194 dextransucrase Proteins 0.000 claims description 7

- IAJILQKETJEXLJ-UHFFFAOYSA-N Galacturonsaeure Natural products O=CC(O)C(O)C(O)C(O)C(O)=O IAJILQKETJEXLJ-UHFFFAOYSA-N 0.000 claims description 6

- IAJILQKETJEXLJ-QTBDOELSSA-N aldehydo-D-glucuronic acid Chemical compound O=C[C@H](O)[C@@H](O)[C@H](O)[C@H](O)C(O)=O IAJILQKETJEXLJ-QTBDOELSSA-N 0.000 claims description 6

- WQZGKKKJIJFFOK-PHYPRBDBSA-N alpha-D-galactose Chemical compound OC[C@H]1O[C@H](O)[C@H](O)[C@@H](O)[C@H]1O WQZGKKKJIJFFOK-PHYPRBDBSA-N 0.000 claims description 6

- SHZGCJCMOBCMKK-DVKNGEFBSA-N alpha-D-quinovopyranose Chemical compound C[C@H]1O[C@H](O)[C@H](O)[C@@H](O)[C@@H]1O SHZGCJCMOBCMKK-DVKNGEFBSA-N 0.000 claims description 6

- 108010048202 alternansucrase Proteins 0.000 claims description 6

- PYMYPHUHKUWMLA-WDCZJNDASA-N arabinose Chemical compound OC[C@@H](O)[C@@H](O)[C@H](O)C=O PYMYPHUHKUWMLA-WDCZJNDASA-N 0.000 claims description 6

- 238000001035 drying Methods 0.000 claims description 6

- 238000004108 freeze drying Methods 0.000 claims description 6

- 229930182830 galactose Natural products 0.000 claims description 6

- 229940097043 glucuronic acid Drugs 0.000 claims description 6

- HSCJRCZFDFQWRP-JZMIEXBBSA-N UDP-alpha-D-glucose Chemical compound O[C@@H]1[C@@H](O)[C@H](O)[C@@H](CO)O[C@@H]1OP(O)(=O)OP(O)(=O)OC[C@@H]1[C@@H](O)[C@@H](O)[C@H](N2C(NC(=O)C=C2)=O)O1 HSCJRCZFDFQWRP-JZMIEXBBSA-N 0.000 claims description 5

- HSCJRCZFDFQWRP-UHFFFAOYSA-N Uridindiphosphoglukose Natural products OC1C(O)C(O)C(CO)OC1OP(O)(=O)OP(O)(=O)OCC1C(O)C(O)C(N2C(NC(=O)C=C2)=O)O1 HSCJRCZFDFQWRP-UHFFFAOYSA-N 0.000 claims description 5

- 238000002156 mixing Methods 0.000 claims description 5

- OWEGMIWEEQEYGQ-UHFFFAOYSA-N 100676-05-9 Natural products OC1C(O)C(O)C(CO)OC1OCC1C(O)C(O)C(O)C(OC2C(OC(O)C(O)C2O)CO)O1 OWEGMIWEEQEYGQ-UHFFFAOYSA-N 0.000 claims description 4

- GUBGYTABKSRVRQ-XLOQQCSPSA-N Alpha-Lactose Chemical compound O[C@@H]1[C@@H](O)[C@@H](O)[C@@H](CO)O[C@H]1O[C@@H]1[C@@H](CO)O[C@H](O)[C@H](O)[C@H]1O GUBGYTABKSRVRQ-XLOQQCSPSA-N 0.000 claims description 4

- 108010025880 Cyclomaltodextrin glucanotransferase Proteins 0.000 claims description 4

- GUBGYTABKSRVRQ-QKKXKWKRSA-N Lactose Natural products OC[C@H]1O[C@@H](O[C@H]2[C@H](O)[C@@H](O)C(O)O[C@@H]2CO)[C@H](O)[C@@H](O)[C@H]1O GUBGYTABKSRVRQ-QKKXKWKRSA-N 0.000 claims description 4

- GUBGYTABKSRVRQ-PICCSMPSSA-N Maltose Natural products O[C@@H]1[C@@H](O)[C@H](O)[C@@H](CO)O[C@@H]1O[C@@H]1[C@@H](CO)OC(O)[C@H](O)[C@H]1O GUBGYTABKSRVRQ-PICCSMPSSA-N 0.000 claims description 4

- 229920002472 Starch Polymers 0.000 claims description 4

- GUBGYTABKSRVRQ-QUYVBRFLSA-N beta-maltose Chemical compound OC[C@H]1O[C@H](O[C@H]2[C@H](O)[C@@H](O)[C@H](O)O[C@@H]2CO)[C@H](O)[C@@H](O)[C@@H]1O GUBGYTABKSRVRQ-QUYVBRFLSA-N 0.000 claims description 4

- 239000008101 lactose Substances 0.000 claims description 4

- 239000008107 starch Substances 0.000 claims description 4

- 235000019698 starch Nutrition 0.000 claims description 4

- 239000005720 sucrose Substances 0.000 claims description 4

- 229920000858 Cyclodextrin Polymers 0.000 claims description 3

- HFHDHCJBZVLPGP-UHFFFAOYSA-N schardinger α-dextrin Chemical compound O1C(C(C2O)O)C(CO)OC2OC(C(C2O)O)C(CO)OC2OC(C(C2O)O)C(CO)OC2OC(C(O)C2O)C(CO)OC2OC(C(C2O)O)C(CO)OC2OC2C(O)C(O)C1OC2CO HFHDHCJBZVLPGP-UHFFFAOYSA-N 0.000 claims description 3

- 229920001503 Glucan Polymers 0.000 claims description 2

- 101710172282 Oleandomycin glycosyltransferase Proteins 0.000 claims description 2

- 238000001694 spray drying Methods 0.000 claims description 2

- IGVKWAAPMVVTFX-BUHFOSPRSA-N (e)-octadec-5-en-7,9-diynoic acid Chemical compound CCCCCCCCC#CC#C\C=C\CCCC(O)=O IGVKWAAPMVVTFX-BUHFOSPRSA-N 0.000 claims 1

- GVOISEJVFFIGQE-YCZSINBZSA-N n-[(1r,2s,5r)-5-[methyl(propan-2-yl)amino]-2-[(3s)-2-oxo-3-[[6-(trifluoromethyl)quinazolin-4-yl]amino]pyrrolidin-1-yl]cyclohexyl]acetamide Chemical compound CC(=O)N[C@@H]1C[C@H](N(C)C(C)C)CC[C@@H]1N1C(=O)[C@@H](NC=2C3=CC(=CC=C3N=CN=2)C(F)(F)F)CC1 GVOISEJVFFIGQE-YCZSINBZSA-N 0.000 claims 1

- -1 a-glucosidase Proteins 0.000 description 20

- 235000013361 beverage Nutrition 0.000 description 16

- 239000000047 product Substances 0.000 description 16

- 235000002639 sodium chloride Nutrition 0.000 description 16

- 150000002772 monosaccharides Chemical class 0.000 description 13

- 239000000284 extract Substances 0.000 description 11

- 235000003599 food sweetener Nutrition 0.000 description 11

- 235000000346 sugar Nutrition 0.000 description 11

- 239000003765 sweetening agent Substances 0.000 description 11

- IDQVFXZQPGAVAM-GGVBUJAJSA-N (4as,6ar,6as,6br,8r,8ar,9r,10r,11r,12ar,14bs)-8,10,11-trihydroxy-9-(hydroxymethyl)-2,2,6a,6b,9,12a-hexamethyl-1,3,4,5,6,6a,7,8,8a,10,11,12,13,14b-tetradecahydropicene-4a-carboxylic acid Chemical compound C1[C@@H](O)[C@H](O)[C@@](C)(CO)[C@@H]2[C@H](O)C[C@@]3(C)[C@]4(C)CC[C@@]5(C(O)=O)CCC(C)(C)C[C@H]5C4=CC[C@@H]3[C@]21C IDQVFXZQPGAVAM-GGVBUJAJSA-N 0.000 description 9

- 235000013399 edible fruits Nutrition 0.000 description 9

- PRAUVHZJPXOEIF-AOLYGAPISA-N madecassic acid Chemical compound C1[C@@H](O)[C@H](O)[C@@](C)(CO)[C@@H]2[C@H](O)C[C@@]3(C)[C@]4(C)CC[C@@]5(C(O)=O)CC[C@@H](C)[C@H](C)[C@H]5C4=CC[C@@H]3[C@]21C PRAUVHZJPXOEIF-AOLYGAPISA-N 0.000 description 9

- 238000012360 testing method Methods 0.000 description 9

- IDQVFXZQPGAVAM-UHFFFAOYSA-N (2alpha,3beta,6beta)-2,3,6,23-Tetrahydroxy-12-oleanen-28-oic acid Natural products C1C(O)C(O)C(C)(CO)C2C(O)CC3(C)C4(C)CCC5(C(O)=O)CCC(C)(C)CC5C4=CCC3C21C IDQVFXZQPGAVAM-UHFFFAOYSA-N 0.000 description 8

- 210000004027 cell Anatomy 0.000 description 8

- 229940011656 madecassic acid Drugs 0.000 description 8

- BUWCHLVSSFQLPN-UHFFFAOYSA-N madecassic acid Natural products CC1CCC2(CCC3(C)C(=CCC4C5(C)CC(O)C(O)C(C)(C5CCC34C)C(=O)O)C2C1C)C(=O)OC6OC(COC7OC(CO)C(OC8OC(C)C(O)C(O)C8O)C(O)C7O)C(O)C(O)C6O BUWCHLVSSFQLPN-UHFFFAOYSA-N 0.000 description 8

- 235000014633 carbohydrates Nutrition 0.000 description 7

- 239000000243 solution Substances 0.000 description 7

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Chemical compound O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 7

- GWCRPYGYVRXVLI-UHFFFAOYSA-N 2-ethyl-4-hydroxy-5-methyl-3(2H)-furanone Chemical compound CCC1OC(C)=C(O)C1=O GWCRPYGYVRXVLI-UHFFFAOYSA-N 0.000 description 6

- 241000588724 Escherichia coli Species 0.000 description 6

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 6

- 229930193140 Neomycin Natural products 0.000 description 6

- 125000002496 methyl group Chemical group [H]C([H])([H])* 0.000 description 6

- 229960004927 neomycin Drugs 0.000 description 6

- 229920000642 polymer Polymers 0.000 description 6

- 229930182478 glucoside Natural products 0.000 description 5

- 150000008131 glucosides Chemical class 0.000 description 5

- 150000004676 glycans Chemical class 0.000 description 5

- 150000002482 oligosaccharides Polymers 0.000 description 5

- 229920001282 polysaccharide Polymers 0.000 description 5

- 239000005017 polysaccharide Substances 0.000 description 5

- 230000009466 transformation Effects 0.000 description 5

- 150000004043 trisaccharides Chemical class 0.000 description 5

- 235000013311 vegetables Nutrition 0.000 description 5

- WRMNZCZEMHIOCP-UHFFFAOYSA-N 2-phenylethanol Chemical compound OCCC1=CC=CC=C1 WRMNZCZEMHIOCP-UHFFFAOYSA-N 0.000 description 4

- GLZPCOQZEFWAFX-UHFFFAOYSA-N Geraniol Chemical compound CC(C)=CCCC(C)=CCO GLZPCOQZEFWAFX-UHFFFAOYSA-N 0.000 description 4

- WYQVAPGDARQUBT-FGWHUCSPSA-N Madecassol Chemical compound O([C@@H]1[C@@H](CO)O[C@H]([C@@H]([C@H]1O)O)OC[C@H]1O[C@H]([C@@H]([C@@H](O)[C@@H]1O)O)OC(=O)[C@]12CC[C@H]([C@@H]([C@H]1C=1[C@@]([C@@]3(CC[C@H]4[C@](C)(CO)[C@@H](O)[C@H](O)C[C@]4(C)[C@H]3CC=1)C)(C)CC2)C)C)[C@@H]1O[C@@H](C)[C@H](O)[C@@H](O)[C@H]1O WYQVAPGDARQUBT-FGWHUCSPSA-N 0.000 description 4

- 239000007983 Tris buffer Substances 0.000 description 4

- 229940022757 asiaticoside Drugs 0.000 description 4

- WYQVAPGDARQUBT-XCWYDTOWSA-N asiaticoside Natural products O=C(O[C@H]1[C@H](O)[C@@H](O)[C@H](O)[C@@H](CO[C@H]2[C@H](O)[C@H](O)[C@H](O[C@H]3[C@H](O)[C@H](O)[C@@H](O)[C@H](C)O3)[C@@H](CO)O2)O1)[C@@]12[C@@H]([C@@H](C)[C@H](C)CC1)C=1[C@](C)([C@@]3(C)[C@@H]([C@@]4(C)[C@H]([C@@](CO)(C)[C@@H](O)[C@H](O)C4)CC3)CC=1)CC2 WYQVAPGDARQUBT-XCWYDTOWSA-N 0.000 description 4

- XUPYJHCZDLZNFP-UHFFFAOYSA-N butyl butanoate Chemical compound CCCCOC(=O)CCC XUPYJHCZDLZNFP-UHFFFAOYSA-N 0.000 description 4

- 238000006243 chemical reaction Methods 0.000 description 4

- 239000008367 deionised water Substances 0.000 description 4

- 229940079919 digestives enzyme preparation Drugs 0.000 description 4

- 238000009472 formulation Methods 0.000 description 4

- IFYYFLINQYPWGJ-UHFFFAOYSA-N gamma-decalactone Chemical compound CCCCCCC1CCC(=O)O1 IFYYFLINQYPWGJ-UHFFFAOYSA-N 0.000 description 4

- 239000002609 medium Substances 0.000 description 4

- KVWWIYGFBYDJQC-UHFFFAOYSA-N methyl dihydrojasmonate Chemical compound CCCCCC1C(CC(=O)OC)CCC1=O KVWWIYGFBYDJQC-UHFFFAOYSA-N 0.000 description 4

- 239000008188 pellet Substances 0.000 description 4

- 238000000746 purification Methods 0.000 description 4

- UNYNVICDCJHOPO-UHFFFAOYSA-N sotolone Chemical compound CC1OC(=O)C(O)=C1C UNYNVICDCJHOPO-UHFFFAOYSA-N 0.000 description 4

- LENZDBCJOHFCAS-UHFFFAOYSA-N tris Chemical compound OCC(N)(CO)CO LENZDBCJOHFCAS-UHFFFAOYSA-N 0.000 description 4

- PHXATPHONSXBIL-UHFFFAOYSA-N xi-gamma-Undecalactone Chemical compound CCCCCCCC1CCC(=O)O1 PHXATPHONSXBIL-UHFFFAOYSA-N 0.000 description 4

- PSQYTAPXSHCGMF-BQYQJAHWSA-N β-ionone Chemical compound CC(=O)\C=C\C1=C(C)CCCC1(C)C PSQYTAPXSHCGMF-BQYQJAHWSA-N 0.000 description 4

- XPCTZQVDEJYUGT-UHFFFAOYSA-N 3-hydroxy-2-methyl-4-pyrone Chemical compound CC=1OC=CC(=O)C=1O XPCTZQVDEJYUGT-UHFFFAOYSA-N 0.000 description 3

- INAXVXBDKKUCGI-UHFFFAOYSA-N 4-hydroxy-2,5-dimethylfuran-3-one Chemical compound CC1OC(C)=C(O)C1=O INAXVXBDKKUCGI-UHFFFAOYSA-N 0.000 description 3

- WEVYAHXRMPXWCK-UHFFFAOYSA-N Acetonitrile Chemical compound CC#N WEVYAHXRMPXWCK-UHFFFAOYSA-N 0.000 description 3

- 241000194108 Bacillus licheniformis Species 0.000 description 3

- 244000299461 Theobroma cacao Species 0.000 description 3

- 150000001299 aldehydes Chemical class 0.000 description 3

- JXSVIVRDWWRQRT-UYDOISQJSA-N asiatic acid Chemical compound C1[C@@H](O)[C@H](O)[C@@](C)(CO)[C@@H]2CC[C@@]3(C)[C@]4(C)CC[C@@]5(C(O)=O)CC[C@@H](C)[C@H](C)[C@H]5C4=CC[C@@H]3[C@]21C JXSVIVRDWWRQRT-UYDOISQJSA-N 0.000 description 3

- 229940011658 asiatic acid Drugs 0.000 description 3

- LBGFKBYMNRAMFC-PYSQTNCISA-N asiatic acid Natural products C[C@@H]1CC[C@@]2(CC[C@]3(C)C(=CC[C@@H]4[C@@]5(C)C[C@@H](O)[C@H](O)[C@@](C)(CO)[C@@H]5CC[C@@]34C)[C@]2(C)[C@H]1C)C(=O)O LBGFKBYMNRAMFC-PYSQTNCISA-N 0.000 description 3

- 230000036983 biotransformation Effects 0.000 description 3

- 239000013592 cell lysate Substances 0.000 description 3

- 230000006037 cell lysis Effects 0.000 description 3

- 238000005119 centrifugation Methods 0.000 description 3

- 235000013601 eggs Nutrition 0.000 description 3

- 230000002255 enzymatic effect Effects 0.000 description 3

- CLXOLTFMHAXJST-UHFFFAOYSA-N esculentic acid Natural products C12CC=C3C4CC(C)(C(O)=O)CCC4(C(O)=O)CCC3(C)C1(C)CCC1C2(C)CCC(O)C1(CO)C CLXOLTFMHAXJST-UHFFFAOYSA-N 0.000 description 3

- 239000012634 fragment Substances 0.000 description 3

- HIGQPQRQIQDZMP-UHFFFAOYSA-N geranil acetate Natural products CC(C)=CCCC(C)=CCOC(C)=O HIGQPQRQIQDZMP-UHFFFAOYSA-N 0.000 description 3

- HIGQPQRQIQDZMP-DHZHZOJOSA-N geranyl acetate Chemical compound CC(C)=CCC\C(C)=C\COC(C)=O HIGQPQRQIQDZMP-DHZHZOJOSA-N 0.000 description 3

- 238000006206 glycosylation reaction Methods 0.000 description 3

- 238000004255 ion exchange chromatography Methods 0.000 description 3

- BPHPUYQFMNQIOC-NXRLNHOXSA-N isopropyl beta-D-thiogalactopyranoside Chemical compound CC(C)S[C@@H]1O[C@H](CO)[C@H](O)[C@H](O)[C@H]1O BPHPUYQFMNQIOC-NXRLNHOXSA-N 0.000 description 3

- SATCULPHIDQDRE-UHFFFAOYSA-N piperonal Chemical compound O=CC1=CC=C2OCOC2=C1 SATCULPHIDQDRE-UHFFFAOYSA-N 0.000 description 3

- 238000002360 preparation method Methods 0.000 description 3

- 239000007787 solid Substances 0.000 description 3

- 235000014347 soups Nutrition 0.000 description 3

- 150000008163 sugars Chemical class 0.000 description 3

- 150000003648 triterpenes Chemical class 0.000 description 3

- 238000002604 ultrasonography Methods 0.000 description 3

- SFEOKXHPFMOVRM-UHFFFAOYSA-N (+)-(S)-gamma-ionone Natural products CC(=O)C=CC1C(=C)CCCC1(C)C SFEOKXHPFMOVRM-UHFFFAOYSA-N 0.000 description 2

- WQZGKKKJIJFFOK-SVZMEOIVSA-N (+)-Galactose Chemical compound OC[C@H]1OC(O)[C@H](O)[C@@H](O)[C@H]1O WQZGKKKJIJFFOK-SVZMEOIVSA-N 0.000 description 2

- MBDOYVRWFFCFHM-SNAWJCMRSA-N (2E)-hexenal Chemical compound CCC\C=C\C=O MBDOYVRWFFCFHM-SNAWJCMRSA-N 0.000 description 2

- JZQKTMZYLHNFPL-BLHCBFLLSA-N (2E,4E)-deca-2,4-dienal Chemical compound CCCCC\C=C\C=C\C=O JZQKTMZYLHNFPL-BLHCBFLLSA-N 0.000 description 2

- ZHHYXNZJDGDGPJ-BSWSSELBSA-N (2e,4e)-nona-2,4-dienal Chemical compound CCCC\C=C\C=C\C=O ZHHYXNZJDGDGPJ-BSWSSELBSA-N 0.000 description 2

- BSAIUMLZVGUGKX-BQYQJAHWSA-N (E)-non-2-enal Chemical compound CCCCCC\C=C\C=O BSAIUMLZVGUGKX-BQYQJAHWSA-N 0.000 description 2

- LVBXEMGDVWVTGY-VOTSOKGWSA-N (E)-oct-2-enal Chemical compound CCCCC\C=C\C=O LVBXEMGDVWVTGY-VOTSOKGWSA-N 0.000 description 2

- AROCNZZBLCAOPH-UHFFFAOYSA-N 1-methyl-4-prop-2-enoxybenzene Chemical compound CC1=CC=C(OCC=C)C=C1 AROCNZZBLCAOPH-UHFFFAOYSA-N 0.000 description 2

- JLIDVCMBCGBIEY-UHFFFAOYSA-N 1-penten-3-one Chemical compound CCC(=O)C=C JLIDVCMBCGBIEY-UHFFFAOYSA-N 0.000 description 2

- NCPWFIVLKCFWSP-BSWSSELBSA-N 2,4-Nonadien-1-ol Chemical compound CCCC\C=C\C=C\CO NCPWFIVLKCFWSP-BSWSSELBSA-N 0.000 description 2

- FZOZFDAMVVEZSJ-UHFFFAOYSA-N 2-Acetyl-4,5-dihydrothiazole Chemical compound CC(=O)C1=NCCS1 FZOZFDAMVVEZSJ-UHFFFAOYSA-N 0.000 description 2

- JZBCTZLGKSYRSF-UHFFFAOYSA-N 2-Ethyl-3,5-dimethylpyrazine Chemical compound CCC1=NC=C(C)N=C1C JZBCTZLGKSYRSF-UHFFFAOYSA-N 0.000 description 2

- LNIMMWYNSBZESE-UHFFFAOYSA-N 2-Ethyl-3-methylpyrazine, 9CI Chemical compound CCC1=NC=CN=C1C LNIMMWYNSBZESE-UHFFFAOYSA-N 0.000 description 2

- DBZAKQWXICEWNW-UHFFFAOYSA-N 2-acetylpyrazine Chemical compound CC(=O)C1=CN=CC=N1 DBZAKQWXICEWNW-UHFFFAOYSA-N 0.000 description 2

- WHMWOHBXYIZFPF-UHFFFAOYSA-N 2-ethyl-3,(5 or 6)-dimethylpyrazine Chemical compound CCC1=NC(C)=CN=C1C WHMWOHBXYIZFPF-UHFFFAOYSA-N 0.000 description 2

- HCFAJYNVAYBARA-UHFFFAOYSA-N 4-heptanone Chemical compound CCCC(=O)CCC HCFAJYNVAYBARA-UHFFFAOYSA-N 0.000 description 2

- QJYOEDXNPLUUAR-UHFFFAOYSA-N 4-hydroxy-2-methyl-5-ethyl-3-oxo-2H-furan Natural products CCC1=C(O)C(=O)C(C)O1 QJYOEDXNPLUUAR-UHFFFAOYSA-N 0.000 description 2

- JOOXCMJARBKPKM-UHFFFAOYSA-N 4-oxopentanoic acid Chemical compound CC(=O)CCC(O)=O JOOXCMJARBKPKM-UHFFFAOYSA-N 0.000 description 2

- OALYTRUKMRCXNH-UHFFFAOYSA-N 5-pentyloxolan-2-one Chemical compound CCCCCC1CCC(=O)O1 OALYTRUKMRCXNH-UHFFFAOYSA-N 0.000 description 2

- GHBSPIPJMLAMEP-UHFFFAOYSA-N 6-pentyloxan-2-one Chemical compound CCCCCC1CCCC(=O)O1 GHBSPIPJMLAMEP-UHFFFAOYSA-N 0.000 description 2

- CSCPPACGZOOCGX-UHFFFAOYSA-N Acetone Natural products CC(C)=O CSCPPACGZOOCGX-UHFFFAOYSA-N 0.000 description 2

- KWOLFJPFCHCOCG-UHFFFAOYSA-N Acetophenone Chemical compound CC(=O)C1=CC=CC=C1 KWOLFJPFCHCOCG-UHFFFAOYSA-N 0.000 description 2

- SCCDQYPEOIRVGX-UHFFFAOYSA-N Acetyleugenol Chemical compound COC1=CC(CC=C)=CC=C1OC(C)=O SCCDQYPEOIRVGX-UHFFFAOYSA-N 0.000 description 2

- 244000223760 Cinnamomum zeylanicum Species 0.000 description 2

- 102000002322 Egg Proteins Human genes 0.000 description 2

- 108010000912 Egg Proteins Proteins 0.000 description 2

- 241000196324 Embryophyta Species 0.000 description 2

- UNXHWFMMPAWVPI-UHFFFAOYSA-N Erythritol Natural products OCC(O)C(O)CO UNXHWFMMPAWVPI-UHFFFAOYSA-N 0.000 description 2

- 241001646716 Escherichia coli K-12 Species 0.000 description 2

- WEEGYLXZBRQIMU-UHFFFAOYSA-N Eucalyptol Chemical compound C1CC2CCC1(C)OC2(C)C WEEGYLXZBRQIMU-UHFFFAOYSA-N 0.000 description 2

- 239000001329 FEMA 3811 Substances 0.000 description 2

- DHMQDGOQFOQNFH-UHFFFAOYSA-N Glycine Chemical compound NCC(O)=O DHMQDGOQFOQNFH-UHFFFAOYSA-N 0.000 description 2

- 239000006391 Luria-Bertani Medium Substances 0.000 description 2

- PBILBHLAPJTJOT-CQSZACIVSA-N Phyllodulcin Chemical compound C1=C(O)C(OC)=CC=C1[C@@H]1OC(=O)C2=C(O)C=CC=C2C1 PBILBHLAPJTJOT-CQSZACIVSA-N 0.000 description 2

- NBBJYMSMWIIQGU-UHFFFAOYSA-N Propionic aldehyde Chemical compound CCC=O NBBJYMSMWIIQGU-UHFFFAOYSA-N 0.000 description 2

- FAPWRFPIFSIZLT-UHFFFAOYSA-M Sodium chloride Chemical compound [Na+].[Cl-] FAPWRFPIFSIZLT-UHFFFAOYSA-M 0.000 description 2

- 108010073771 Soybean Proteins Proteins 0.000 description 2

- 241000186988 Streptomyces antibioticus Species 0.000 description 2

- MOYAFQVGZZPNRA-UHFFFAOYSA-N Terpinolene Chemical compound CC(C)=C1CCC(C)=CC1 MOYAFQVGZZPNRA-UHFFFAOYSA-N 0.000 description 2

- 244000269722 Thea sinensis Species 0.000 description 2

- 244000185386 Thladiantha grosvenorii Species 0.000 description 2

- 235000011171 Thladiantha grosvenorii Nutrition 0.000 description 2

- 239000005862 Whey Substances 0.000 description 2

- 102000007544 Whey Proteins Human genes 0.000 description 2

- 108010046377 Whey Proteins Proteins 0.000 description 2

- PYMYPHUHKUWMLA-LMVFSUKVSA-N aldehydo-D-ribose Chemical compound OC[C@@H](O)[C@@H](O)[C@@H](O)C=O PYMYPHUHKUWMLA-LMVFSUKVSA-N 0.000 description 2

- PNNNRSAQSRJVSB-BXKVDMCESA-N aldehydo-L-rhamnose Chemical compound C[C@H](O)[C@H](O)[C@@H](O)[C@@H](O)C=O PNNNRSAQSRJVSB-BXKVDMCESA-N 0.000 description 2

- 229940024606 amino acid Drugs 0.000 description 2

- HUMNYLRZRPPJDN-UHFFFAOYSA-N benzaldehyde Chemical compound O=CC1=CC=CC=C1 HUMNYLRZRPPJDN-UHFFFAOYSA-N 0.000 description 2

- IOJUPLGTWVMSFF-UHFFFAOYSA-N benzothiazole Chemical compound C1=CC=C2SC=NC2=C1 IOJUPLGTWVMSFF-UHFFFAOYSA-N 0.000 description 2

- QUKGYYKBILRGFE-UHFFFAOYSA-N benzyl acetate Chemical compound CC(=O)OCC1=CC=CC=C1 QUKGYYKBILRGFE-UHFFFAOYSA-N 0.000 description 2

- SESFRYSPDFLNCH-UHFFFAOYSA-N benzyl benzoate Chemical compound C=1C=CC=CC=1C(=O)OCC1=CC=CC=C1 SESFRYSPDFLNCH-UHFFFAOYSA-N 0.000 description 2

- 239000000872 buffer Substances 0.000 description 2

- 235000015155 buttermilk Nutrition 0.000 description 2

- CRPUJAZIXJMDBK-UHFFFAOYSA-N camphene Chemical compound C1CC2C(=C)C(C)(C)C1C2 CRPUJAZIXJMDBK-UHFFFAOYSA-N 0.000 description 2

- ULDHMXUKGWMISQ-UHFFFAOYSA-N carvone Chemical compound CC(=C)C1CC=C(C)C(=O)C1 ULDHMXUKGWMISQ-UHFFFAOYSA-N 0.000 description 2

- 235000019219 chocolate Nutrition 0.000 description 2

- 238000004587 chromatography analysis Methods 0.000 description 2

- 229960005233 cineole Drugs 0.000 description 2

- 235000017803 cinnamon Nutrition 0.000 description 2

- NEHNMFOYXAPHSD-UHFFFAOYSA-N citronellal Chemical compound O=CCC(C)CCC=C(C)C NEHNMFOYXAPHSD-UHFFFAOYSA-N 0.000 description 2

- QMVPMAAFGQKVCJ-UHFFFAOYSA-N citronellol Chemical compound OCCC(C)CCC=C(C)C QMVPMAAFGQKVCJ-UHFFFAOYSA-N 0.000 description 2

- JOZKFWLRHCDGJA-UHFFFAOYSA-N citronellol acetate Chemical compound CC(=O)OCCC(C)CCC=C(C)C JOZKFWLRHCDGJA-UHFFFAOYSA-N 0.000 description 2

- 235000009508 confectionery Nutrition 0.000 description 2

- 239000002537 cosmetic Substances 0.000 description 2

- ZYGHJZDHTFUPRJ-UHFFFAOYSA-N coumarin Chemical compound C1=CC=C2OC(=O)C=CC2=C1 ZYGHJZDHTFUPRJ-UHFFFAOYSA-N 0.000 description 2

- 239000012043 crude product Substances 0.000 description 2

- 235000013365 dairy product Nutrition 0.000 description 2

- UDGKKUWYNITJRX-UHFFFAOYSA-N davidigenin Chemical compound C1=CC(O)=CC=C1CCC(=O)C1=CC=C(O)C=C1O UDGKKUWYNITJRX-UHFFFAOYSA-N 0.000 description 2

- 229910021641 deionized water Inorganic materials 0.000 description 2

- 238000001514 detection method Methods 0.000 description 2

- POULHZVOKOAJMA-UHFFFAOYSA-N dodecanoic acid Chemical compound CCCCCCCCCCCC(O)=O POULHZVOKOAJMA-UHFFFAOYSA-N 0.000 description 2

- 239000000839 emulsion Substances 0.000 description 2

- LZCLXQDLBQLTDK-UHFFFAOYSA-N ethyl 2-hydroxypropanoate Chemical compound CCOC(=O)C(C)O LZCLXQDLBQLTDK-UHFFFAOYSA-N 0.000 description 2

- 125000001495 ethyl group Chemical group [H]C([H])([H])C([H])([H])* 0.000 description 2

- TVQGDYNRXLTQAP-UHFFFAOYSA-N ethyl heptanoate Chemical compound CCCCCCC(=O)OCC TVQGDYNRXLTQAP-UHFFFAOYSA-N 0.000 description 2

- SHZIWNPUGXLXDT-UHFFFAOYSA-N ethyl hexanoate Chemical compound CCCCCC(=O)OCC SHZIWNPUGXLXDT-UHFFFAOYSA-N 0.000 description 2

- WDAXFOBOLVPGLV-UHFFFAOYSA-N ethyl isobutyrate Chemical compound CCOC(=O)C(C)C WDAXFOBOLVPGLV-UHFFFAOYSA-N 0.000 description 2

- FKRCODPIKNYEAC-UHFFFAOYSA-N ethyl propionate Chemical compound CCOC(=O)CC FKRCODPIKNYEAC-UHFFFAOYSA-N 0.000 description 2

- RRAFCDWBNXTKKO-UHFFFAOYSA-N eugenol Chemical compound COC1=CC(CC=C)=CC=C1O RRAFCDWBNXTKKO-UHFFFAOYSA-N 0.000 description 2

- 238000001704 evaporation Methods 0.000 description 2

- 230000008020 evaporation Effects 0.000 description 2

- 235000011389 fruit/vegetable juice Nutrition 0.000 description 2

- IFYYFLINQYPWGJ-VIFPVBQESA-N gamma-Decalactone Natural products CCCCCC[C@H]1CCC(=O)O1 IFYYFLINQYPWGJ-VIFPVBQESA-N 0.000 description 2

- PHXATPHONSXBIL-JTQLQIEISA-N gamma-Undecalactone Natural products CCCCCCC[C@H]1CCC(=O)O1 PHXATPHONSXBIL-JTQLQIEISA-N 0.000 description 2

- 229940020436 gamma-undecalactone Drugs 0.000 description 2

- 230000013595 glycosylation Effects 0.000 description 2

- LPLVUJXQOOQHMX-QWBHMCJMSA-N glycyrrhizinic acid Chemical compound O([C@@H]1[C@@H](O)[C@H](O)[C@H](O[C@@H]1O[C@@H]1C([C@H]2[C@]([C@@H]3[C@@]([C@@]4(CC[C@@]5(C)CC[C@@](C)(C[C@H]5C4=CC3=O)C(O)=O)C)(C)CC2)(C)CC1)(C)C)C(O)=O)[C@@H]1O[C@H](C(O)=O)[C@@H](O)[C@H](O)[C@H]1O LPLVUJXQOOQHMX-QWBHMCJMSA-N 0.000 description 2

- CATSNJVOTSVZJV-UHFFFAOYSA-N heptan-2-one Chemical compound CCCCCC(C)=O CATSNJVOTSVZJV-UHFFFAOYSA-N 0.000 description 2

- NGAZZOYFWWSOGK-UHFFFAOYSA-N heptan-3-one Chemical compound CCCCC(=O)CC NGAZZOYFWWSOGK-UHFFFAOYSA-N 0.000 description 2

- IPCSVZSSVZVIGE-UHFFFAOYSA-N hexadecanoic acid Chemical compound CCCCCCCCCCCCCCCC(O)=O IPCSVZSSVZVIGE-UHFFFAOYSA-N 0.000 description 2

- FUZZWVXGSFPDMH-UHFFFAOYSA-N hexanoic acid Chemical compound CCCCCC(O)=O FUZZWVXGSFPDMH-UHFFFAOYSA-N 0.000 description 2

- MLFHJEHSLIIPHL-UHFFFAOYSA-N isoamyl acetate Chemical compound CC(C)CCOC(C)=O MLFHJEHSLIIPHL-UHFFFAOYSA-N 0.000 description 2

- PQLMXFQTAMDXIZ-UHFFFAOYSA-N isoamyl butyrate Chemical compound CCCC(=O)OCCC(C)C PQLMXFQTAMDXIZ-UHFFFAOYSA-N 0.000 description 2

- PHTQWCKDNZKARW-UHFFFAOYSA-N isoamylol Chemical compound CC(C)CCO PHTQWCKDNZKARW-UHFFFAOYSA-N 0.000 description 2

- RGFNRWTWDWVHDD-UHFFFAOYSA-N isobutyl butyrate Chemical compound CCCC(=O)OCC(C)C RGFNRWTWDWVHDD-UHFFFAOYSA-N 0.000 description 2

- NTOPKICPEQUPPH-UHFFFAOYSA-N isopropyl methoxy pyrazine Chemical compound COC1=NC=CN=C1C(C)C NTOPKICPEQUPPH-UHFFFAOYSA-N 0.000 description 2

- ZYTMANIQRDEHIO-KXUCPTDWSA-N isopulegol Chemical compound C[C@@H]1CC[C@@H](C(C)=C)[C@H](O)C1 ZYTMANIQRDEHIO-KXUCPTDWSA-N 0.000 description 2

- CDOSHBSSFJOMGT-UHFFFAOYSA-N linalool Chemical compound CC(C)=CCCC(C)(O)C=C CDOSHBSSFJOMGT-UHFFFAOYSA-N 0.000 description 2

- UWKAYLJWKGQEPM-LBPRGKRZSA-N linalyl acetate Chemical compound CC(C)=CCC[C@](C)(C=C)OC(C)=O UWKAYLJWKGQEPM-LBPRGKRZSA-N 0.000 description 2

- 235000013622 meat product Nutrition 0.000 description 2

- HEBKCHPVOIAQTA-UHFFFAOYSA-N meso ribitol Natural products OCC(O)C(O)C(O)CO HEBKCHPVOIAQTA-UHFFFAOYSA-N 0.000 description 2

- BDAGIHXWWSANSR-UHFFFAOYSA-N methanoic acid Natural products OC=O BDAGIHXWWSANSR-UHFFFAOYSA-N 0.000 description 2

- VAMXMNNIEUEQDV-UHFFFAOYSA-N methyl anthranilate Chemical compound COC(=O)C1=CC=CC=C1N VAMXMNNIEUEQDV-UHFFFAOYSA-N 0.000 description 2

- 229930189775 mogroside Natural products 0.000 description 2

- ITVGXXMINPYUHD-CUVHLRMHSA-N neohesperidin dihydrochalcone Chemical compound C1=C(O)C(OC)=CC=C1CCC(=O)C(C(=C1)O)=C(O)C=C1O[C@H]1[C@H](O[C@H]2[C@@H]([C@H](O)[C@@H](O)[C@H](C)O2)O)[C@@H](O)[C@H](O)[C@@H](CO)O1 ITVGXXMINPYUHD-CUVHLRMHSA-N 0.000 description 2

- 229940089953 neohesperidin dihydrochalcone Drugs 0.000 description 2

- 235000010434 neohesperidine DC Nutrition 0.000 description 2

- 235000019520 non-alcoholic beverage Nutrition 0.000 description 2

- SJWFXCIHNDVPSH-UHFFFAOYSA-N octan-2-ol Chemical compound CCCCCCC(C)O SJWFXCIHNDVPSH-UHFFFAOYSA-N 0.000 description 2

- NMRPBPVERJPACX-UHFFFAOYSA-N octan-3-ol Chemical compound CCCCCC(O)CC NMRPBPVERJPACX-UHFFFAOYSA-N 0.000 description 2

- YLYBTZIQSIBWLI-UHFFFAOYSA-N octyl acetate Chemical compound CCCCCCCCOC(C)=O YLYBTZIQSIBWLI-UHFFFAOYSA-N 0.000 description 2

- VWMVAQHMFFZQGD-UHFFFAOYSA-N p-Hydroxybenzyl acetone Natural products CC(=O)CC1=CC=C(O)C=C1 VWMVAQHMFFZQGD-UHFFFAOYSA-N 0.000 description 2

- JYVLIDXNZAXMDK-UHFFFAOYSA-N pentan-2-ol Chemical compound CCCC(C)O JYVLIDXNZAXMDK-UHFFFAOYSA-N 0.000 description 2

- MDHYEMXUFSJLGV-UHFFFAOYSA-N phenethyl acetate Chemical compound CC(=O)OCCC1=CC=CC=C1 MDHYEMXUFSJLGV-UHFFFAOYSA-N 0.000 description 2

- DTUQWGWMVIHBKE-UHFFFAOYSA-N phenylacetaldehyde Chemical compound O=CCC1=CC=CC=C1 DTUQWGWMVIHBKE-UHFFFAOYSA-N 0.000 description 2

- 229940067107 phenylethyl alcohol Drugs 0.000 description 2

- VGEREEWJJVICBM-UHFFFAOYSA-N phloretin Chemical compound C1=CC(O)=CC=C1CCC(=O)C1=C(O)C=C(O)C=C1O VGEREEWJJVICBM-UHFFFAOYSA-N 0.000 description 2

- 229920005990 polystyrene resin Polymers 0.000 description 2

- 239000000843 powder Substances 0.000 description 2

- HUAZGNHGCJGYNP-UHFFFAOYSA-N propyl butyrate Chemical compound CCCOC(=O)CCC HUAZGNHGCJGYNP-UHFFFAOYSA-N 0.000 description 2

- 235000018102 proteins Nutrition 0.000 description 2

- 102000004169 proteins and genes Human genes 0.000 description 2

- 108090000623 proteins and genes Proteins 0.000 description 2

- 239000012264 purified product Substances 0.000 description 2

- NJGBTKGETPDVIK-UHFFFAOYSA-N raspberry ketone Chemical compound CC(=O)CCC1=CC=C(O)C=C1 NJGBTKGETPDVIK-UHFFFAOYSA-N 0.000 description 2

- 239000011541 reaction mixture Substances 0.000 description 2

- 235000015067 sauces Nutrition 0.000 description 2

- 235000013580 sausages Nutrition 0.000 description 2

- 235000011888 snacks Nutrition 0.000 description 2

- 239000001509 sodium citrate Substances 0.000 description 2

- NLJMYIDDQXHKNR-UHFFFAOYSA-K sodium citrate Chemical compound O.O.[Na+].[Na+].[Na+].[O-]C(=O)CC(O)(CC([O-])=O)C([O-])=O NLJMYIDDQXHKNR-UHFFFAOYSA-K 0.000 description 2

- VWDWKYIASSYTQR-UHFFFAOYSA-N sodium nitrate Chemical compound [Na+].[O-][N+]([O-])=O VWDWKYIASSYTQR-UHFFFAOYSA-N 0.000 description 2

- 229940001941 soy protein Drugs 0.000 description 2

- 235000013599 spices Nutrition 0.000 description 2

- DSAJORLEPQBKDA-AWEZNQCLSA-N sterubin Chemical compound C1([C@@H]2CC(=O)C3=C(O)C=C(C=C3O2)OC)=CC=C(O)C(O)=C1 DSAJORLEPQBKDA-AWEZNQCLSA-N 0.000 description 2

- DSAJORLEPQBKDA-UHFFFAOYSA-N sterubin Natural products O1C2=CC(OC)=CC(O)=C2C(=O)CC1C1=CC=C(O)C(O)=C1 DSAJORLEPQBKDA-UHFFFAOYSA-N 0.000 description 2

- 235000019202 steviosides Nutrition 0.000 description 2

- 125000001424 substituent group Chemical group 0.000 description 2

- 239000003826 tablet Substances 0.000 description 2

- 235000013616 tea Nutrition 0.000 description 2

- MGSRCZKZVOBKFT-UHFFFAOYSA-N thymol Chemical compound CC(C)C1=CC=C(C)C=C1O MGSRCZKZVOBKFT-UHFFFAOYSA-N 0.000 description 2

- 235000019583 umami taste Nutrition 0.000 description 2

- NQPDZGIKBAWPEJ-UHFFFAOYSA-N valeric acid Chemical compound CCCCC(O)=O NQPDZGIKBAWPEJ-UHFFFAOYSA-N 0.000 description 2

- MWOOGOJBHIARFG-UHFFFAOYSA-N vanillin Chemical compound COC1=CC(C=O)=CC=C1O MWOOGOJBHIARFG-UHFFFAOYSA-N 0.000 description 2

- 239000003643 water by type Substances 0.000 description 2

- NPNUFJAVOOONJE-ZIAGYGMSSA-N β-(E)-Caryophyllene Chemical compound C1CC(C)=CCCC(=C)[C@H]2CC(C)(C)[C@@H]21 NPNUFJAVOOONJE-ZIAGYGMSSA-N 0.000 description 2

- HDTRYLNUVZCQOY-UHFFFAOYSA-N α-D-glucopyranosyl-α-D-glucopyranoside Natural products OC1C(O)C(O)C(CO)OC1OC1C(O)C(O)C(O)C(CO)O1 HDTRYLNUVZCQOY-UHFFFAOYSA-N 0.000 description 1

- NOOLISFMXDJSKH-UTLUCORTSA-N (+)-Neomenthol Chemical compound CC(C)[C@@H]1CC[C@@H](C)C[C@@H]1O NOOLISFMXDJSKH-UTLUCORTSA-N 0.000 description 1

- MHXCIKYXNYCMHY-AUSJPIAWSA-N (+)-lariciresinol Chemical compound C1=C(O)C(OC)=CC(C[C@@H]2[C@@H]([C@H](OC2)C=2C=C(OC)C(O)=CC=2)CO)=C1 MHXCIKYXNYCMHY-AUSJPIAWSA-N 0.000 description 1

- YGWKXXYGDYYFJU-SSDOTTSWSA-N (+)-menthofuran Chemical compound C1[C@H](C)CCC2=C1OC=C2C YGWKXXYGDYYFJU-SSDOTTSWSA-N 0.000 description 1

- WTOYNNBCKUYIKC-JMSVASOKSA-N (+)-nootkatone Chemical compound C1C[C@@H](C(C)=C)C[C@@]2(C)[C@H](C)CC(=O)C=C21 WTOYNNBCKUYIKC-JMSVASOKSA-N 0.000 description 1

- NZGWDASTMWDZIW-MRVPVSSYSA-N (+)-pulegone Chemical compound C[C@@H]1CCC(=C(C)C)C(=O)C1 NZGWDASTMWDZIW-MRVPVSSYSA-N 0.000 description 1

- QEBNYNLSCGVZOH-NFAWXSAZSA-N (+)-valencene Chemical compound C1C[C@@H](C(C)=C)C[C@@]2(C)[C@H](C)CCC=C21 QEBNYNLSCGVZOH-NFAWXSAZSA-N 0.000 description 1

- MATGKVZWFZHCLI-LSDHHAIUSA-N (-)-matairesinol Chemical compound C1=C(O)C(OC)=CC(C[C@@H]2[C@H](C(=O)OC2)CC=2C=C(OC)C(O)=CC=2)=C1 MATGKVZWFZHCLI-LSDHHAIUSA-N 0.000 description 1

- GEWDNTWNSAZUDX-WQMVXFAESA-N (-)-methyl jasmonate Chemical compound CC\C=C/C[C@@H]1[C@@H](CC(=O)OC)CCC1=O GEWDNTWNSAZUDX-WQMVXFAESA-N 0.000 description 1

- RMLYXMMBIZLGAQ-UHFFFAOYSA-N (-)-monatin Natural products C1=CC=C2C(CC(O)(CC(N)C(O)=O)C(O)=O)=CNC2=C1 RMLYXMMBIZLGAQ-UHFFFAOYSA-N 0.000 description 1

- 239000001871 (1R,2R,5S)-5-methyl-2-prop-1-en-2-ylcyclohexan-1-ol Substances 0.000 description 1

- NIONDZDPPYHYKY-SNAWJCMRSA-N (2E)-hexenoic acid Chemical compound CCC\C=C\C(O)=O NIONDZDPPYHYKY-SNAWJCMRSA-N 0.000 description 1

- AMXYRHBJZOVHOL-UHFFFAOYSA-N (2E,6E)-2,6-Nonadien-1-ol Natural products CCC=CCCC=CCO AMXYRHBJZOVHOL-UHFFFAOYSA-N 0.000 description 1

- 239000001890 (2R)-8,8,8a-trimethyl-2-prop-1-en-2-yl-1,2,3,4,6,7-hexahydronaphthalene Substances 0.000 description 1

- AMXYRHBJZOVHOL-DYWGDJMRSA-N (2e,6e)-nona-2,6-dien-1-ol Chemical compound CC\C=C\CC\C=C\CO AMXYRHBJZOVHOL-DYWGDJMRSA-N 0.000 description 1

- VYPONAGZHAJHGT-ZBJFTSOASA-N (2r)-2-[(z)-pent-2-enyl]-2,3-dihydropyran-6-one Chemical compound CC\C=C/C[C@@H]1CC=CC(=O)O1 VYPONAGZHAJHGT-ZBJFTSOASA-N 0.000 description 1

- NEDIAPMWNCQWNW-SECBINFHSA-N (2r)-2-pentyl-2,3-dihydropyran-6-one Chemical compound CCCCC[C@@H]1CC=CC(=O)O1 NEDIAPMWNCQWNW-SECBINFHSA-N 0.000 description 1

- SDOFMBGMRVAJNF-KVTDHHQDSA-N (2r,3r,4r,5r)-6-aminohexane-1,2,3,4,5-pentol Chemical compound NC[C@@H](O)[C@@H](O)[C@H](O)[C@H](O)CO SDOFMBGMRVAJNF-KVTDHHQDSA-N 0.000 description 1

- RMLYXMMBIZLGAQ-HZMBPMFUSA-N (2s,4s)-4-amino-2-hydroxy-2-(1h-indol-3-ylmethyl)pentanedioic acid Chemical compound C1=CC=C2C(C[C@](O)(C[C@H](N)C(O)=O)C(O)=O)=CNC2=C1 RMLYXMMBIZLGAQ-HZMBPMFUSA-N 0.000 description 1

- 239000001490 (3R)-3,7-dimethylocta-1,6-dien-3-ol Substances 0.000 description 1

- 239000001082 (3R)-3-sulfanylpentan-2-one Substances 0.000 description 1

- NUFKRGBSZPCGQB-FLBSXDLDSA-N (3s)-3-amino-4-oxo-4-[[(2r)-1-oxo-1-[(2,2,4,4-tetramethylthietan-3-yl)amino]propan-2-yl]amino]butanoic acid;pentahydrate Chemical compound O.O.O.O.O.OC(=O)C[C@H](N)C(=O)N[C@H](C)C(=O)NC1C(C)(C)SC1(C)C.OC(=O)C[C@H](N)C(=O)N[C@H](C)C(=O)NC1C(C)(C)SC1(C)C NUFKRGBSZPCGQB-FLBSXDLDSA-N 0.000 description 1

- 229940098795 (3z)- 3-hexenyl acetate Drugs 0.000 description 1

- VUDZSIYXZUYWSC-DBRKOABJSA-N (4r)-1-[(2r,4r,5r)-3,3-difluoro-4-hydroxy-5-(hydroxymethyl)oxolan-2-yl]-4-hydroxy-1,3-diazinan-2-one Chemical compound FC1(F)[C@H](O)[C@@H](CO)O[C@H]1N1C(=O)N[C@H](O)CC1 VUDZSIYXZUYWSC-DBRKOABJSA-N 0.000 description 1

- 239000001730 (5R)-5-butyloxolan-2-one Substances 0.000 description 1

- 239000001745 (6R)-3,6-dimethyl-4,5,6,7-tetrahydro-1-benzofuran Substances 0.000 description 1

- ZWTDXYUDJYDHJR-UHFFFAOYSA-N (E)-1-(2,4-dihydroxyphenyl)-3-(2,4-dihydroxyphenyl)-2-propen-1-one Natural products OC1=CC(O)=CC=C1C=CC(=O)C1=CC=C(O)C=C1O ZWTDXYUDJYDHJR-UHFFFAOYSA-N 0.000 description 1

- YDXQPTHHAPCTPP-AATRIKPKSA-N (E)-3-Octen-1-ol Chemical compound CCCC\C=C\CCO YDXQPTHHAPCTPP-AATRIKPKSA-N 0.000 description 1

- NDFKTBCGKNOHPJ-AATRIKPKSA-N (E)-hept-2-enal Chemical compound CCCC\C=C\C=O NDFKTBCGKNOHPJ-AATRIKPKSA-N 0.000 description 1

- QMVPMAAFGQKVCJ-SNVBAGLBSA-N (R)-(+)-citronellol Natural products OCC[C@H](C)CCC=C(C)C QMVPMAAFGQKVCJ-SNVBAGLBSA-N 0.000 description 1

- CDOSHBSSFJOMGT-JTQLQIEISA-N (R)-linalool Natural products CC(C)=CCC[C@@](C)(O)C=C CDOSHBSSFJOMGT-JTQLQIEISA-N 0.000 description 1

- MIEKOFWWHVOKQX-UHFFFAOYSA-N (S)-2-(4-Methoxyphenoxy)propanoic acid Chemical class COC1=CC=C(OC(C)C(O)=O)C=C1 MIEKOFWWHVOKQX-UHFFFAOYSA-N 0.000 description 1

- VIQXICKUKPVFRK-UHFFFAOYSA-N (S)-3-Methylthiohexyl acetate Chemical compound CCCC(SC)CCOC(C)=O VIQXICKUKPVFRK-UHFFFAOYSA-N 0.000 description 1

- WMBOCUXXNSOQHM-FLIBITNWSA-N (Z)-3-butylidenephthalide Chemical compound C1=CC=C2C(=C/CCC)/OC(=O)C2=C1 WMBOCUXXNSOQHM-FLIBITNWSA-N 0.000 description 1

- UFLHIIWVXFIJGU-ARJAWSKDSA-N (Z)-hex-3-en-1-ol Chemical compound CC\C=C/CCO UFLHIIWVXFIJGU-ARJAWSKDSA-N 0.000 description 1

- RLWJIETUBNSFMD-VMPITWQZSA-N (e)-n-[2-(1,3-benzodioxol-5-yl)ethyl]-3-(3,4-dimethoxyphenyl)prop-2-enamide Chemical compound C1=C(OC)C(OC)=CC=C1\C=C\C(=O)NCCC1=CC=C(OCO2)C2=C1 RLWJIETUBNSFMD-VMPITWQZSA-N 0.000 description 1

- VVGOCOMZRGWHPI-ARJAWSKDSA-N (z)-4-heptenal Chemical compound CC\C=C/CCC=O VVGOCOMZRGWHPI-ARJAWSKDSA-N 0.000 description 1

- YGFGZTXGYTUXBA-UHFFFAOYSA-N (±)-2,6-dimethyl-5-heptenal Chemical compound O=CC(C)CCC=C(C)C YGFGZTXGYTUXBA-UHFFFAOYSA-N 0.000 description 1

- HNAGHMKIPMKKBB-UHFFFAOYSA-N 1-benzylpyrrolidine-3-carboxamide Chemical compound C1C(C(=O)N)CCN1CC1=CC=CC=C1 HNAGHMKIPMKKBB-UHFFFAOYSA-N 0.000 description 1

- PZNPLUBHRSSFHT-RRHRGVEJSA-N 1-hexadecanoyl-2-octadecanoyl-sn-glycero-3-phosphocholine Chemical compound CCCCCCCCCCCCCCCCCC(=O)O[C@@H](COP([O-])(=O)OCC[N+](C)(C)C)COC(=O)CCCCCCCCCCCCCCC PZNPLUBHRSSFHT-RRHRGVEJSA-N 0.000 description 1

- 239000001169 1-methyl-4-propan-2-ylcyclohexa-1,4-diene Substances 0.000 description 1

- OQWNKUAZQSLNSR-UHFFFAOYSA-N 12-methyltridecanal Chemical compound CC(C)CCCCCCCCCCC=O OQWNKUAZQSLNSR-UHFFFAOYSA-N 0.000 description 1

- AEQDJSLRWYMAQI-UHFFFAOYSA-N 2,3,9,10-tetramethoxy-6,8,13,13a-tetrahydro-5H-isoquinolino[2,1-b]isoquinoline Chemical compound C1CN2CC(C(=C(OC)C=C3)OC)=C3CC2C2=C1C=C(OC)C(OC)=C2 AEQDJSLRWYMAQI-UHFFFAOYSA-N 0.000 description 1

- PSINWXIDJYEXLO-UHFFFAOYSA-N 2,3-Diethyl-5-methylpyrazine Chemical compound CCC1=NC=C(C)N=C1CC PSINWXIDJYEXLO-UHFFFAOYSA-N 0.000 description 1

- BAMPVSWRQZNDQC-UHFFFAOYSA-N 2,4,5-trimethylthiazole Chemical compound CC1=NC(C)=C(C)S1 BAMPVSWRQZNDQC-UHFFFAOYSA-N 0.000 description 1

- ZHHYXNZJDGDGPJ-UHFFFAOYSA-N 2,4-Nonadienal Natural products CCCCC=CC=CC=O ZHHYXNZJDGDGPJ-UHFFFAOYSA-N 0.000 description 1

- DBBHCZMXKBCICL-UHFFFAOYSA-N 2,5-dimethylfuran-3-thiol Chemical compound CC1=CC(S)=C(C)O1 DBBHCZMXKBCICL-UHFFFAOYSA-N 0.000 description 1

- 239000001278 2-(5-ethenyl-5-methyloxolan-2-yl)propan-2-ol Substances 0.000 description 1

- MOMFXATYAINJML-UHFFFAOYSA-N 2-Acetylthiazole Chemical compound CC(=O)C1=NC=CS1 MOMFXATYAINJML-UHFFFAOYSA-N 0.000 description 1

- OXQGTIUCKGYOAA-UHFFFAOYSA-N 2-Ethylbutanoic acid Chemical compound CCC(CC)C(O)=O OXQGTIUCKGYOAA-UHFFFAOYSA-N 0.000 description 1

- RUYNUXHHUVUINQ-UHFFFAOYSA-N 2-Methyl-3-furanthiol Chemical compound CC=1OC=CC=1S RUYNUXHHUVUINQ-UHFFFAOYSA-N 0.000 description 1

- HSDXVAOHEOSTFZ-UHFFFAOYSA-N 2-Pentylpyridine Chemical compound CCCCCC1=CC=CC=N1 HSDXVAOHEOSTFZ-UHFFFAOYSA-N 0.000 description 1

- RCSBILYQLVXLJG-UHFFFAOYSA-N 2-Propenyl hexanoate Chemical compound CCCCCC(=O)OCC=C RCSBILYQLVXLJG-UHFFFAOYSA-N 0.000 description 1

- QMIBAVZANYVPEF-UHFFFAOYSA-N 2-[[(benzhydrylamino)-(3,5-dichloroanilino)methylidene]amino]acetic acid Chemical compound C=1C=CC=CC=1C(C=1C=CC=CC=1)N=C(NCC(=O)O)NC1=CC(Cl)=CC(Cl)=C1 QMIBAVZANYVPEF-UHFFFAOYSA-N 0.000 description 1

- DQBQWWSFRPLIAX-UHFFFAOYSA-N 2-acetyl-1-pyrroline Chemical compound CC(=O)C1=NCCC1 DQBQWWSFRPLIAX-UHFFFAOYSA-N 0.000 description 1

- SVONRAPFKPVNKG-UHFFFAOYSA-N 2-ethoxyethyl acetate Chemical compound CCOCCOC(C)=O SVONRAPFKPVNKG-UHFFFAOYSA-N 0.000 description 1

- 239000001363 2-ethyl-3,5-dimethylpyrazine Substances 0.000 description 1

- KXYCNEIORCQEFU-UHFFFAOYSA-N 2-ethyl-4-(hydroxymethyl)furan-3-one Chemical compound CCC1OC=C(CO)C1=O KXYCNEIORCQEFU-UHFFFAOYSA-N 0.000 description 1

- 239000001487 2-ethyl-4-hydroxy-5-methylfuran-3-one Substances 0.000 description 1

- ABFVFIZSXKRBRL-UHFFFAOYSA-N 2-hydroxy-2-phenyl-3h-chromen-4-one Chemical class C1C(=O)C2=CC=CC=C2OC1(O)C1=CC=CC=C1 ABFVFIZSXKRBRL-UHFFFAOYSA-N 0.000 description 1

- CFAKWWQIUFSQFU-UHFFFAOYSA-N 2-hydroxy-3-methylcyclopent-2-en-1-one Chemical compound CC1=C(O)C(=O)CC1 CFAKWWQIUFSQFU-UHFFFAOYSA-N 0.000 description 1

- OFLXNHNYPQPQKW-UHFFFAOYSA-N 2-isopropyl-4-methylthiazole Chemical compound CC(C)C1=NC(C)=CS1 OFLXNHNYPQPQKW-UHFFFAOYSA-N 0.000 description 1

- OQVAOEIMSKZGAL-UHFFFAOYSA-N 2-methyl-3-methylsulfanylfuran Chemical compound CSC=1C=COC=1C OQVAOEIMSKZGAL-UHFFFAOYSA-N 0.000 description 1

- XHIUFYZDQBSEMF-UHFFFAOYSA-N 2-methylbutyl acetate Chemical compound CCC(C)COC(C)=O XHIUFYZDQBSEMF-UHFFFAOYSA-N 0.000 description 1

- WLAMNBDJUVNPJU-UHFFFAOYSA-N 2-methylbutyric acid Chemical compound CCC(C)C(O)=O WLAMNBDJUVNPJU-UHFFFAOYSA-N 0.000 description 1

- VMUXSMXIQBNMGZ-UHFFFAOYSA-N 3,4-dihydrocoumarin Chemical compound C1=CC=C2OC(=O)CCC2=C1 VMUXSMXIQBNMGZ-UHFFFAOYSA-N 0.000 description 1

- SLAOFBPSPQHAJS-UHFFFAOYSA-N 3-(4-hydroxycyclohexa-2,4-dien-1-yl)-1-phenylprop-2-en-1-one Chemical class C1=CC(O)=CCC1C=CC(=O)C1=CC=CC=C1 SLAOFBPSPQHAJS-UHFFFAOYSA-N 0.000 description 1

- SZECUQRKLXRGSJ-UHFFFAOYSA-N 3-Mercapto-2-pentanone Chemical compound CCC(S)C(C)=O SZECUQRKLXRGSJ-UHFFFAOYSA-N 0.000 description 1

- NMRPBPVERJPACX-QMMMGPOBSA-N 3-Octanol Natural products CCCCC[C@@H](O)CC NMRPBPVERJPACX-QMMMGPOBSA-N 0.000 description 1

- STZUZYMKSMSTOU-UHFFFAOYSA-N 3-Octyl acetate Chemical compound CCCCCC(CC)OC(C)=O STZUZYMKSMSTOU-UHFFFAOYSA-N 0.000 description 1

- RLPQPHISCURSNX-UHFFFAOYSA-N 3-ethylfuran-2-ol Chemical compound CCC=1C=COC=1O RLPQPHISCURSNX-UHFFFAOYSA-N 0.000 description 1

- CLUWOWRTHNNBBU-UHFFFAOYSA-N 3-methylthiopropanal Chemical compound CSCCC=O CLUWOWRTHNNBBU-UHFFFAOYSA-N 0.000 description 1

- PBILBHLAPJTJOT-UHFFFAOYSA-N 3S-phyllodulcin Natural products C1=C(O)C(OC)=CC=C1C1OC(=O)C2=C(O)C=CC=C2C1 PBILBHLAPJTJOT-UHFFFAOYSA-N 0.000 description 1

- OSWFIVFLDKOXQC-UHFFFAOYSA-N 4-(3-methoxyphenyl)aniline Chemical compound COC1=CC=CC(C=2C=CC(N)=CC=2)=C1 OSWFIVFLDKOXQC-UHFFFAOYSA-N 0.000 description 1

- CYDQOEWLBCCFJZ-UHFFFAOYSA-N 4-(4-fluorophenyl)oxane-4-carboxylic acid Chemical compound C=1C=C(F)C=CC=1C1(C(=O)O)CCOCC1 CYDQOEWLBCCFJZ-UHFFFAOYSA-N 0.000 description 1

- HFNGYHHRRMSKEU-UHFFFAOYSA-N 4-Methoxybenzyl acetate Chemical compound COC1=CC=C(COC(C)=O)C=C1 HFNGYHHRRMSKEU-UHFFFAOYSA-N 0.000 description 1

- XPDORSROGAZEGY-UHFFFAOYSA-N 4-Methoxybenzyl formate Chemical compound COC1=CC=C(COC=O)C=C1 XPDORSROGAZEGY-UHFFFAOYSA-N 0.000 description 1

- OSFGNTLIOUHOKN-UHFFFAOYSA-N 4-[benzyl(methyl)sulfamoyl]benzoic acid Chemical compound C=1C=C(C(O)=O)C=CC=1S(=O)(=O)N(C)CC1=CC=CC=C1 OSFGNTLIOUHOKN-UHFFFAOYSA-N 0.000 description 1

- QCVGEOXPDFCNHA-UHFFFAOYSA-N 5,5-dimethyl-2,4-dioxo-1,3-oxazolidine-3-carboxamide Chemical compound CC1(C)OC(=O)N(C(N)=O)C1=O QCVGEOXPDFCNHA-UHFFFAOYSA-N 0.000 description 1

- BKAWJIRCKVUVED-UHFFFAOYSA-N 5-(2-hydroxyethyl)-4-methylthiazole Chemical compound CC=1N=CSC=1CCO BKAWJIRCKVUVED-UHFFFAOYSA-N 0.000 description 1

- DALUCNUGMDNXET-UHFFFAOYSA-N 5-Ethyl-2,4-dimethylthiazole Chemical compound CCC=1SC(C)=NC=1C DALUCNUGMDNXET-UHFFFAOYSA-N 0.000 description 1

- IUFQZPBIRYFPFD-UHFFFAOYSA-N 5-ethyl-3-hydroxy-4-methyl-2(5H)-furanone Chemical compound CCC1OC(=O)C(O)=C1C IUFQZPBIRYFPFD-UHFFFAOYSA-N 0.000 description 1

- OUDFNZMQXZILJD-UHFFFAOYSA-N 5-methyl-2-furaldehyde Chemical compound CC1=CC=C(C=O)O1 OUDFNZMQXZILJD-UHFFFAOYSA-N 0.000 description 1

- JGVWYJDASSSGEK-UHFFFAOYSA-N 5-methyl-2-propan-2-ylidenecyclohexan-1-ol Chemical compound CC1CCC(=C(C)C)C(O)C1 JGVWYJDASSSGEK-UHFFFAOYSA-N 0.000 description 1

- YZRXRLLRSPQHDK-UHFFFAOYSA-N 6-Hexyltetrahydro-2H-pyran-2-one Chemical compound CCCCCCC1CCCC(=O)O1 YZRXRLLRSPQHDK-UHFFFAOYSA-N 0.000 description 1

- PVXPPJIGRGXGCY-DJHAAKORSA-N 6-O-alpha-D-glucopyranosyl-alpha-D-fructofuranose Chemical compound O[C@@H]1[C@@H](O)[C@H](O)[C@@H](CO)O[C@@H]1OC[C@@H]1[C@@H](O)[C@H](O)[C@](O)(CO)O1 PVXPPJIGRGXGCY-DJHAAKORSA-N 0.000 description 1

- 239000001606 7-[(2S,3R,4S,5S,6R)-4,5-dihydroxy-6-(hydroxymethyl)-3-[(2S,3R,4R,5R,6S)-3,4,5-trihydroxy-6-methyloxan-2-yl]oxyoxan-2-yl]oxy-5-hydroxy-2-(4-hydroxyphenyl)chroman-4-one Substances 0.000 description 1

- LDIOUQIXNSSOGU-UHFFFAOYSA-N 8-(3-pentylamino)-2-methyl-3-(2-chloro-4-methoxyphenyl)-6,7-dihydro-5h-cyclopenta[d]pyrazolo[1,5-a]pyrimidine Chemical compound CC1=NN2C(NC(CC)CC)=C3CCCC3=NC2=C1C1=CC=C(OC)C=C1Cl LDIOUQIXNSSOGU-UHFFFAOYSA-N 0.000 description 1

- HBAQYPYDRFILMT-UHFFFAOYSA-N 8-[3-(1-cyclopropylpyrazol-4-yl)-1H-pyrazolo[4,3-d]pyrimidin-5-yl]-3-methyl-3,8-diazabicyclo[3.2.1]octan-2-one Chemical class C1(CC1)N1N=CC(=C1)C1=NNC2=C1N=C(N=C2)N1C2C(N(CC1CC2)C)=O HBAQYPYDRFILMT-UHFFFAOYSA-N 0.000 description 1

- NVEQFIOZRFFVFW-UHFFFAOYSA-N 9-epi-beta-caryophyllene oxide Natural products C=C1CCC2OC2(C)CCC2C(C)(C)CC21 NVEQFIOZRFFVFW-UHFFFAOYSA-N 0.000 description 1

- WBZFUFAFFUEMEI-UHFFFAOYSA-M Acesulfame k Chemical compound [K+].CC1=CC(=O)[N-]S(=O)(=O)O1 WBZFUFAFFUEMEI-UHFFFAOYSA-M 0.000 description 1

- ROWKJAVDOGWPAT-UHFFFAOYSA-N Acetoin Chemical compound CC(O)C(C)=O ROWKJAVDOGWPAT-UHFFFAOYSA-N 0.000 description 1

- 239000004377 Alitame Substances 0.000 description 1

- 244000105624 Arachis hypogaea Species 0.000 description 1

- 108010011485 Aspartame Proteins 0.000 description 1

- 241000228215 Aspergillus aculeatus Species 0.000 description 1

- 241000228245 Aspergillus niger Species 0.000 description 1

- 240000006439 Aspergillus oryzae Species 0.000 description 1

- 241000228257 Aspergillus sp. Species 0.000 description 1

- 241000193752 Bacillus circulans Species 0.000 description 1

- 235000014469 Bacillus subtilis Nutrition 0.000 description 1

- 241000894006 Bacteria Species 0.000 description 1

- FERIUCNNQQJTOY-UHFFFAOYSA-M Butyrate Chemical compound CCCC([O-])=O FERIUCNNQQJTOY-UHFFFAOYSA-M 0.000 description 1

- FERIUCNNQQJTOY-UHFFFAOYSA-N Butyric acid Natural products CCCC(O)=O FERIUCNNQQJTOY-UHFFFAOYSA-N 0.000 description 1

- OYPRJOBELJOOCE-UHFFFAOYSA-N Calcium Chemical compound [Ca] OYPRJOBELJOOCE-UHFFFAOYSA-N 0.000 description 1

- 239000005973 Carvone Substances 0.000 description 1

- 102000005575 Cellulases Human genes 0.000 description 1

- 108010084185 Cellulases Proteins 0.000 description 1

- JSQCMNXZFPMWES-WRBXKWMASA-N Centellasaponin B Natural products O=C(O[C@H]1[C@H](O)[C@@H](O)[C@H](O)[C@@H](CO[C@H]2[C@H](O)[C@@H](O)[C@H](O)[C@@H](CO)O2)O1)[C@@]12[C@@H]([C@@H](C)[C@H](C)CC1)C=1[C@](C)([C@@]3(C)[C@@H]([C@]4(C)[C@@H]([C@H](O)C3)[C@@](CO)(C)[C@@H](O)[C@H](O)C4)CC=1)CC2 JSQCMNXZFPMWES-WRBXKWMASA-N 0.000 description 1

- JSQCMNXZFPMWES-UHFFFAOYSA-N Centellasaponin B Chemical compound C1CC(C2(CC(O)C3C(C)(CO)C(O)C(O)CC3(C)C2CC=2)C)(C)C=2C2C(C)C(C)CCC21C(=O)OC(C(C(O)C1O)O)OC1COC1OC(CO)C(O)C(O)C1O JSQCMNXZFPMWES-UHFFFAOYSA-N 0.000 description 1

- NPBVQXIMTZKSBA-UHFFFAOYSA-N Chavibetol Natural products COC1=CC=C(CC=C)C=C1O NPBVQXIMTZKSBA-UHFFFAOYSA-N 0.000 description 1

- WTEVQBCEXWBHNA-UHFFFAOYSA-N Citral Natural products CC(C)=CCCC(C)=CC=O WTEVQBCEXWBHNA-UHFFFAOYSA-N 0.000 description 1

- JOZKFWLRHCDGJA-LLVKDONJSA-N Citronellyl acetate Natural products CC(=O)OCC[C@H](C)CCC=C(C)C JOZKFWLRHCDGJA-LLVKDONJSA-N 0.000 description 1

- 240000000560 Citrus x paradisi Species 0.000 description 1

- 108091026890 Coding region Proteins 0.000 description 1

- UDIPTWFVPPPURJ-UHFFFAOYSA-M Cyclamate Chemical compound [Na+].[O-]S(=O)(=O)NC1CCCCC1 UDIPTWFVPPPURJ-UHFFFAOYSA-M 0.000 description 1

- YYLLIJHXUHJATK-UHFFFAOYSA-N Cyclohexyl acetate Chemical compound CC(=O)OC1CCCCC1 YYLLIJHXUHJATK-UHFFFAOYSA-N 0.000 description 1

- DCXYFEDJOCDNAF-UWTATZPHSA-N D-Asparagine Chemical compound OC(=O)[C@H](N)CC(N)=O DCXYFEDJOCDNAF-UWTATZPHSA-N 0.000 description 1

- RFSUNEUAIZKAJO-VRPWFDPXSA-N D-Fructose Natural products OC[C@H]1OC(O)(CO)[C@@H](O)[C@@H]1O RFSUNEUAIZKAJO-VRPWFDPXSA-N 0.000 description 1

- FBPFZTCFMRRESA-FSIIMWSLSA-N D-Glucitol Natural products OC[C@H](O)[C@H](O)[C@@H](O)[C@H](O)CO FBPFZTCFMRRESA-FSIIMWSLSA-N 0.000 description 1

- FBPFZTCFMRRESA-KVTDHHQDSA-N D-Mannitol Chemical compound OC[C@@H](O)[C@@H](O)[C@H](O)[C@H](O)CO FBPFZTCFMRRESA-KVTDHHQDSA-N 0.000 description 1

- LKDRXBCSQODPBY-JDJSBBGDSA-N D-allulose Chemical compound OCC1(O)OC[C@@H](O)[C@@H](O)[C@H]1O LKDRXBCSQODPBY-JDJSBBGDSA-N 0.000 description 1

- HEBKCHPVOIAQTA-QWWZWVQMSA-N D-arabinitol Chemical compound OC[C@@H](O)C(O)[C@H](O)CO HEBKCHPVOIAQTA-QWWZWVQMSA-N 0.000 description 1

- 229930182846 D-asparagine Natural products 0.000 description 1

- FBPFZTCFMRRESA-JGWLITMVSA-N D-glucitol Chemical compound OC[C@H](O)[C@@H](O)[C@H](O)[C@H](O)CO FBPFZTCFMRRESA-JGWLITMVSA-N 0.000 description 1

- MNQZXJOMYWMBOU-VKHMYHEASA-N D-glyceraldehyde Chemical compound OC[C@@H](O)C=O MNQZXJOMYWMBOU-VKHMYHEASA-N 0.000 description 1

- ROHFNLRQFUQHCH-RXMQYKEDSA-N D-leucine Chemical compound CC(C)C[C@@H](N)C(O)=O ROHFNLRQFUQHCH-RXMQYKEDSA-N 0.000 description 1

- 229930182819 D-leucine Natural products 0.000 description 1

- COLNVLDHVKWLRT-MRVPVSSYSA-N D-phenylalanine Chemical compound OC(=O)[C@H](N)CC1=CC=CC=C1 COLNVLDHVKWLRT-MRVPVSSYSA-N 0.000 description 1

- 229930182832 D-phenylalanine Natural products 0.000 description 1

- SRBFZHDQGSBBOR-SOOFDHNKSA-N D-ribopyranose Chemical compound O[C@@H]1COC(O)[C@H](O)[C@@H]1O SRBFZHDQGSBBOR-SOOFDHNKSA-N 0.000 description 1

- LKDRXBCSQODPBY-IANNHFEVSA-N D-sorbose Chemical compound OCC1(O)OC[C@@H](O)[C@H](O)[C@H]1O LKDRXBCSQODPBY-IANNHFEVSA-N 0.000 description 1

- LKDRXBCSQODPBY-OEXCPVAWSA-N D-tagatose Chemical compound OCC1(O)OC[C@@H](O)[C@H](O)[C@@H]1O LKDRXBCSQODPBY-OEXCPVAWSA-N 0.000 description 1

- UNXHWFMMPAWVPI-QWWZWVQMSA-N D-threitol Chemical compound OC[C@@H](O)[C@H](O)CO UNXHWFMMPAWVPI-QWWZWVQMSA-N 0.000 description 1

- AYFVYJQAPQTCCC-STHAYSLISA-N D-threonine Chemical compound C[C@H](O)[C@@H](N)C(O)=O AYFVYJQAPQTCCC-STHAYSLISA-N 0.000 description 1

- 229930182822 D-threonine Natural products 0.000 description 1

- 229930182827 D-tryptophan Natural products 0.000 description 1

- QIVBCDIJIAJPQS-SECBINFHSA-N D-tryptophane Chemical compound C1=CC=C2C(C[C@@H](N)C(O)=O)=CNC2=C1 QIVBCDIJIAJPQS-SECBINFHSA-N 0.000 description 1

- NOOLISFMXDJSKH-UHFFFAOYSA-N DL-menthol Natural products CC(C)C1CCC(C)CC1O NOOLISFMXDJSKH-UHFFFAOYSA-N 0.000 description 1

- 206010013911 Dysgeusia Diseases 0.000 description 1

- 239000004278 EU approved seasoning Substances 0.000 description 1

- DWONJCNDULPHLV-HOTGVXAUSA-N Enterodiol Chemical compound C([C@@H](CO)[C@H](CO)CC=1C=C(O)C=CC=1)C1=CC=CC(O)=C1 DWONJCNDULPHLV-HOTGVXAUSA-N 0.000 description 1

- AOJXPBNHAJMETF-UHFFFAOYSA-N Enterodiol Natural products OCC(Cc1ccc(O)cc1)C(CO)Cc2ccc(O)cc2 AOJXPBNHAJMETF-UHFFFAOYSA-N 0.000 description 1

- 239000004386 Erythritol Substances 0.000 description 1

- ZFDIRQKJPRINOQ-HWKANZROSA-N Ethyl crotonate Chemical compound CCOC(=O)\C=C\C ZFDIRQKJPRINOQ-HWKANZROSA-N 0.000 description 1

- YIKYNHJUKRTCJL-UHFFFAOYSA-N Ethyl maltol Chemical compound CCC=1OC=CC(=O)C=1O YIKYNHJUKRTCJL-UHFFFAOYSA-N 0.000 description 1

- WEEGYLXZBRQIMU-WAAGHKOSSA-N Eucalyptol Chemical compound C1C[C@H]2CC[C@]1(C)OC2(C)C WEEGYLXZBRQIMU-WAAGHKOSSA-N 0.000 description 1

- 239000005770 Eugenol Substances 0.000 description 1

- 239000005792 Geraniol Substances 0.000 description 1

- GLZPCOQZEFWAFX-YFHOEESVSA-N Geraniol Natural products CC(C)=CCC\C(C)=C/CO GLZPCOQZEFWAFX-YFHOEESVSA-N 0.000 description 1

- 239000004471 Glycine Substances 0.000 description 1

- 235000010469 Glycine max Nutrition 0.000 description 1

- 244000068988 Glycine max Species 0.000 description 1

- 244000303040 Glycyrrhiza glabra Species 0.000 description 1

- 235000006200 Glycyrrhiza glabra Nutrition 0.000 description 1

- 239000004378 Glycyrrhizin Substances 0.000 description 1

- HYQNKKAJVPMBDR-HIFRSBDPSA-N Hernandulcin Chemical compound CC(C)=CCC[C@](C)(O)[C@@H]1CCC(C)=CC1=O HYQNKKAJVPMBDR-HIFRSBDPSA-N 0.000 description 1

- HYQNKKAJVPMBDR-UHFFFAOYSA-N Hernandulcin Natural products CC(C)=CCCC(C)(O)C1CCC(C)=CC1=O HYQNKKAJVPMBDR-UHFFFAOYSA-N 0.000 description 1

- 244000267823 Hydrangea macrophylla Species 0.000 description 1

- 235000014486 Hydrangea macrophylla Nutrition 0.000 description 1

- DGAQECJNVWCQMB-PUAWFVPOSA-M Ilexoside XXIX Chemical compound C[C@@H]1CC[C@@]2(CC[C@@]3(C(=CC[C@H]4[C@]3(CC[C@@H]5[C@@]4(CC[C@@H](C5(C)C)OS(=O)(=O)[O-])C)C)[C@@H]2[C@]1(C)O)C)C(=O)O[C@H]6[C@@H]([C@H]([C@@H]([C@H](O6)CO)O)O)O.[Na+] DGAQECJNVWCQMB-PUAWFVPOSA-M 0.000 description 1

- 206010022489 Insulin Resistance Diseases 0.000 description 1

- XINCECQTMHSORG-UHFFFAOYSA-N Isoamyl isovalerate Chemical compound CC(C)CCOC(=O)CC(C)C XINCECQTMHSORG-UHFFFAOYSA-N 0.000 description 1

- AMIMRNSIRUDHCM-UHFFFAOYSA-N Isopropylaldehyde Chemical compound CC(C)C=O AMIMRNSIRUDHCM-UHFFFAOYSA-N 0.000 description 1

- 241001138401 Kluyveromyces lactis Species 0.000 description 1

- 241000170280 Kluyveromyces sp. Species 0.000 description 1

- ONIBWKKTOPOVIA-BYPYZUCNSA-N L-Proline Chemical compound OC(=O)[C@@H]1CCCN1 ONIBWKKTOPOVIA-BYPYZUCNSA-N 0.000 description 1

- 229930182821 L-proline Natural products 0.000 description 1

- SRBFZHDQGSBBOR-OWMBCFKOSA-N L-ribopyranose Chemical compound O[C@H]1COC(O)[C@@H](O)[C@H]1O SRBFZHDQGSBBOR-OWMBCFKOSA-N 0.000 description 1

- 241000186604 Lactobacillus reuteri Species 0.000 description 1

- YVRYZXAHRGGELT-UHFFFAOYSA-N Lariciresinol Natural products C1=C2OCOC2=CC(C2C(C)C3(OC)C=C(CC=C)C(=O)CC3(O2)OC)=C1 YVRYZXAHRGGELT-UHFFFAOYSA-N 0.000 description 1

- 239000005639 Lauric acid Substances 0.000 description 1

- BRHDDEIRQPDPMG-UHFFFAOYSA-N Linalyl oxide Chemical compound CC(C)(O)C1CCC(C)(C=C)O1 BRHDDEIRQPDPMG-UHFFFAOYSA-N 0.000 description 1

- 244000292467 Lippia dulcis Species 0.000 description 1

- 235000000144 Lippia dulcis Nutrition 0.000 description 1

- FYYHWMGAXLPEAU-UHFFFAOYSA-N Magnesium Chemical compound [Mg] FYYHWMGAXLPEAU-UHFFFAOYSA-N 0.000 description 1

- HYMLWHLQFGRFIY-UHFFFAOYSA-N Maltol Natural products CC1OC=CC(=O)C1=O HYMLWHLQFGRFIY-UHFFFAOYSA-N 0.000 description 1

- 244000070406 Malus silvestris Species 0.000 description 1

- 229930195725 Mannitol Natural products 0.000 description 1

- MZSGWZGPESCJAN-MOBFUUNNSA-N Melitric acid A Natural products O([C@@H](C(=O)O)Cc1cc(O)c(O)cc1)C(=O)/C=C/c1cc(O)c(O/C(/C(=O)O)=C/c2cc(O)c(O)cc2)cc1 MZSGWZGPESCJAN-MOBFUUNNSA-N 0.000 description 1

- YGWKXXYGDYYFJU-UHFFFAOYSA-N Menthofuran Natural products C1C(C)CCC2=C1OC=C2C YGWKXXYGDYYFJU-UHFFFAOYSA-N 0.000 description 1

- OKKJLVBELUTLKV-UHFFFAOYSA-N Methanol Chemical group OC OKKJLVBELUTLKV-UHFFFAOYSA-N 0.000 description 1

- KVWWIYGFBYDJQC-GHMZBOCLSA-N Methyl dihydrojasmonate Chemical compound CCCCC[C@@H]1[C@@H](CC(=O)OC)CCC1=O KVWWIYGFBYDJQC-GHMZBOCLSA-N 0.000 description 1

- OSWPMRLSEDHDFF-UHFFFAOYSA-N Methyl salicylate Natural products COC(=O)C1=CC=CC=C1O OSWPMRLSEDHDFF-UHFFFAOYSA-N 0.000 description 1

- KWKVAGQCDSHWFK-VNKDHWASSA-N Methyl sorbate Chemical compound COC(=O)\C=C\C=C\C KWKVAGQCDSHWFK-VNKDHWASSA-N 0.000 description 1

- 102000014171 Milk Proteins Human genes 0.000 description 1

- 108010011756 Milk Proteins Proteins 0.000 description 1

- 101710084933 Miraculin Proteins 0.000 description 1

- 235000009815 Momordica Nutrition 0.000 description 1

- 241000218984 Momordica Species 0.000 description 1

- 108050004114 Monellin Proteins 0.000 description 1

- 241000594464 Mycetia Species 0.000 description 1

- OZNUPWACHHUIKC-JXMROGBWSA-N N-[2-(3,4-Dimethoxyphenyl)ethyl]-3,4-dimethoxycinnamic acid amide Chemical compound C1=C(OC)C(OC)=CC=C1CCNC(=O)\C=C\C1=CC=C(OC)C(OC)=C1 OZNUPWACHHUIKC-JXMROGBWSA-N 0.000 description 1

- YQHMWTPYORBCMF-UHFFFAOYSA-N Naringenin chalcone Natural products C1=CC(O)=CC=C1C=CC(=O)C1=C(O)C=C(O)C=C1O YQHMWTPYORBCMF-UHFFFAOYSA-N 0.000 description 1

- 239000004384 Neotame Substances 0.000 description 1

- GLZPCOQZEFWAFX-JXMROGBWSA-N Nerol Natural products CC(C)=CCC\C(C)=C\CO GLZPCOQZEFWAFX-JXMROGBWSA-N 0.000 description 1

- CKMNPXWFAZLBNK-QOFYEYOWSA-N OC[C@H]1O[C@@H]2O[C@@H]3[C@@H](CO)O[C@H](O[C@@H]4[C@@H](CO)O[C@H](O[C@@H]5[C@@H](CO)O[C@H](O[C@H]1[C@H](O)[C@H]2O)[C@H](O)[C@H]5O)[C@H](O)[C@H]4O)[C@H](O)[C@H]3O Chemical compound OC[C@H]1O[C@@H]2O[C@@H]3[C@@H](CO)O[C@H](O[C@@H]4[C@@H](CO)O[C@H](O[C@@H]5[C@@H](CO)O[C@H](O[C@H]1[C@H](O)[C@H]2O)[C@H](O)[C@H]5O)[C@H](O)[C@H]4O)[C@H](O)[C@H]3O CKMNPXWFAZLBNK-QOFYEYOWSA-N 0.000 description 1

- 208000008589 Obesity Diseases 0.000 description 1

- RZPAKFUAFGMUPI-UHFFFAOYSA-N Oleandomycin Natural products O1C(C)C(O)C(OC)CC1OC1C(C)C(=O)OC(C)C(C)C(O)C(C)C(=O)C2(OC2)CC(C)C(OC2C(C(CC(C)O2)N(C)C)O)C1C RZPAKFUAFGMUPI-UHFFFAOYSA-N 0.000 description 1

- 239000004104 Oleandomycin Substances 0.000 description 1

- 240000007594 Oryza sativa Species 0.000 description 1

- 235000007164 Oryza sativa Nutrition 0.000 description 1

- 206010033307 Overweight Diseases 0.000 description 1

- 235000021314 Palmitic acid Nutrition 0.000 description 1

- 241000985535 Penicillium decumbens Species 0.000 description 1

- 101000865553 Pentadiplandra brazzeana Defensin-like protein Proteins 0.000 description 1

- LQKRYVGRPXFFAV-UHFFFAOYSA-N Phenylmethylglycidic ester Chemical compound CCOC(=O)C1OC1(C)C1=CC=CC=C1 LQKRYVGRPXFFAV-UHFFFAOYSA-N 0.000 description 1

- 240000004760 Pimpinella anisum Species 0.000 description 1

- 235000012550 Pimpinella anisum Nutrition 0.000 description 1

- ZLMJMSJWJFRBEC-UHFFFAOYSA-N Potassium Chemical compound [K] ZLMJMSJWJFRBEC-UHFFFAOYSA-N 0.000 description 1

- PXRCIOIWVGAZEP-UHFFFAOYSA-N Primaeres Camphenhydrat Natural products C1CC2C(O)(C)C(C)(C)C1C2 PXRCIOIWVGAZEP-UHFFFAOYSA-N 0.000 description 1

- UVMRYBDEERADNV-UHFFFAOYSA-N Pseudoeugenol Natural products COC1=CC(C(C)=C)=CC=C1O UVMRYBDEERADNV-UHFFFAOYSA-N 0.000 description 1

- 241000220324 Pyrus Species 0.000 description 1

- MUPFEKGTMRGPLJ-RMMQSMQOSA-N Raffinose Natural products O(C[C@H]1[C@@H](O)[C@H](O)[C@@H](O)[C@@H](O[C@@]2(CO)[C@H](O)[C@@H](O)[C@@H](CO)O2)O1)[C@@H]1[C@H](O)[C@@H](O)[C@@H](O)[C@@H](CO)O1 MUPFEKGTMRGPLJ-RMMQSMQOSA-N 0.000 description 1

- OZNUPWACHHUIKC-UHFFFAOYSA-N Rubemamine Natural products C1=C(OC)C(OC)=CC=C1CCNC(=O)C=CC1=CC=C(OC)C(OC)=C1 OZNUPWACHHUIKC-UHFFFAOYSA-N 0.000 description 1

- RLWJIETUBNSFMD-UHFFFAOYSA-N Rubescenamine Natural products C1=C(OC)C(OC)=CC=C1C=CC(=O)NCCC1=CC=C(OCO2)C2=C1 RLWJIETUBNSFMD-UHFFFAOYSA-N 0.000 description 1

- 241001092459 Rubus Species 0.000 description 1

- GRLJIIJNZJVMGP-UHFFFAOYSA-N S-Methyl butanethioate Chemical compound CCCC(=O)SC GRLJIIJNZJVMGP-UHFFFAOYSA-N 0.000 description 1

- WINXNKPZLFISPD-UHFFFAOYSA-M Saccharin sodium Chemical compound [Na+].C1=CC=C2C(=O)[N-]S(=O)(=O)C2=C1 WINXNKPZLFISPD-UHFFFAOYSA-M 0.000 description 1

- VMHLLURERBWHNL-UHFFFAOYSA-M Sodium acetate Chemical compound [Na+].CC([O-])=O VMHLLURERBWHNL-UHFFFAOYSA-M 0.000 description 1

- 240000003768 Solanum lycopersicum Species 0.000 description 1

- 235000002560 Solanum lycopersicum Nutrition 0.000 description 1

- 244000061456 Solanum tuberosum Species 0.000 description 1

- 235000002595 Solanum tuberosum Nutrition 0.000 description 1

- 244000228451 Stevia rebaudiana Species 0.000 description 1

- 235000006092 Stevia rebaudiana Nutrition 0.000 description 1

- UEDUENGHJMELGK-HYDKPPNVSA-N Stevioside Chemical compound O([C@@H]1[C@@H](O)[C@H](O)[C@@H](CO)O[C@H]1O[C@]12C(=C)C[C@@]3(C1)CC[C@@H]1[C@@](C)(CCC[C@]1([C@@H]3CC2)C)C(=O)O[C@H]1[C@@H]([C@@H](O)[C@H](O)[C@@H](CO)O1)O)[C@@H]1O[C@H](CO)[C@@H](O)[C@H](O)[C@H]1O UEDUENGHJMELGK-HYDKPPNVSA-N 0.000 description 1

- 239000004376 Sucralose Substances 0.000 description 1

- 235000009470 Theobroma cacao Nutrition 0.000 description 1

- 241001141092 Thermomicrobia Species 0.000 description 1

- 239000005844 Thymol Substances 0.000 description 1

- HDTRYLNUVZCQOY-WSWWMNSNSA-N Trehalose Natural products O[C@@H]1[C@@H](O)[C@@H](O)[C@@H](CO)O[C@@H]1O[C@@H]1[C@H](O)[C@@H](O)[C@@H](O)[C@@H](CO)O1 HDTRYLNUVZCQOY-WSWWMNSNSA-N 0.000 description 1

- VYPONAGZHAJHGT-UHFFFAOYSA-N Tuberolactone Natural products CCC=CCC1CC=CC(=O)O1 VYPONAGZHAJHGT-UHFFFAOYSA-N 0.000 description 1

- MUPFEKGTMRGPLJ-UHFFFAOYSA-N UNPD196149 Natural products OC1C(O)C(CO)OC1(CO)OC1C(O)C(O)C(O)C(COC2C(C(O)C(O)C(CO)O2)O)O1 MUPFEKGTMRGPLJ-UHFFFAOYSA-N 0.000 description 1

- TVXBFESIOXBWNM-UHFFFAOYSA-N Xylitol Natural products OCCC(O)C(O)C(O)CCO TVXBFESIOXBWNM-UHFFFAOYSA-N 0.000 description 1

- NIONDZDPPYHYKY-UHFFFAOYSA-N Z-hexenoic acid Natural products CCCC=CC(O)=O NIONDZDPPYHYKY-UHFFFAOYSA-N 0.000 description 1

- 240000008042 Zea mays Species 0.000 description 1

- 235000016383 Zea mays subsp huehuetenangensis Nutrition 0.000 description 1

- 235000002017 Zea mays subsp mays Nutrition 0.000 description 1

- HRHOWZHRCRZVCU-WAYWQWQTSA-N [(z)-hex-2-enyl] acetate Chemical compound CCC\C=C/COC(C)=O HRHOWZHRCRZVCU-WAYWQWQTSA-N 0.000 description 1

- 239000002253 acid Substances 0.000 description 1

- 239000000443 aerosol Substances 0.000 description 1

- 235000013334 alcoholic beverage Nutrition 0.000 description 1

- 230000001476 alcoholic effect Effects 0.000 description 1

- GZCGUPFRVQAUEE-KVTDHHQDSA-N aldehydo-D-mannose Chemical compound OC[C@@H](O)[C@@H](O)[C@H](O)[C@H](O)C=O GZCGUPFRVQAUEE-KVTDHHQDSA-N 0.000 description 1

- 235000019409 alitame Nutrition 0.000 description 1

- 108010009985 alitame Proteins 0.000 description 1

- HDTRYLNUVZCQOY-LIZSDCNHSA-N alpha,alpha-trehalose Chemical compound O[C@@H]1[C@@H](O)[C@H](O)[C@@H](CO)O[C@@H]1O[C@@H]1[C@H](O)[C@@H](O)[C@H](O)[C@@H](CO)O1 HDTRYLNUVZCQOY-LIZSDCNHSA-N 0.000 description 1

- FAMPSKZZVDUYOS-UHFFFAOYSA-N alpha-Caryophyllene Natural products CC1=CCC(C)(C)C=CCC(C)=CCC1 FAMPSKZZVDUYOS-UHFFFAOYSA-N 0.000 description 1

- XCPQUQHBVVXMRQ-UHFFFAOYSA-N alpha-Fenchene Natural products C1CC2C(=C)CC1C2(C)C XCPQUQHBVVXMRQ-UHFFFAOYSA-N 0.000 description 1

- UZFLPKAIBPNNCA-BQYQJAHWSA-N alpha-ionone Chemical compound CC(=O)\C=C\C1C(C)=CCCC1(C)C UZFLPKAIBPNNCA-BQYQJAHWSA-N 0.000 description 1

- UZFLPKAIBPNNCA-UHFFFAOYSA-N alpha-ionone Natural products CC(=O)C=CC1C(C)=CCCC1(C)C UZFLPKAIBPNNCA-UHFFFAOYSA-N 0.000 description 1

- QUMXDOLUJCHOAY-UHFFFAOYSA-N alpha-methylbenzyl acetate Natural products CC(=O)OC(C)C1=CC=CC=C1 QUMXDOLUJCHOAY-UHFFFAOYSA-N 0.000 description 1

- WUOACPNHFRMFPN-UHFFFAOYSA-N alpha-terpineol Chemical compound CC1=CCC(C(C)(C)O)CC1 WUOACPNHFRMFPN-UHFFFAOYSA-N 0.000 description 1

- 150000001413 amino acids Chemical class 0.000 description 1

- 235000021016 apples Nutrition 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- 239000000605 aspartame Substances 0.000 description 1

- 235000010357 aspartame Nutrition 0.000 description 1

- IAOZJIPTCAWIRG-QWRGUYRKSA-N aspartame Chemical compound OC(=O)C[C@H](N)C(=O)N[C@H](C(=O)OC)CC1=CC=CC=C1 IAOZJIPTCAWIRG-QWRGUYRKSA-N 0.000 description 1

- 229960003438 aspartame Drugs 0.000 description 1

- 235000015173 baked goods and baking mixes Nutrition 0.000 description 1

- 235000013527 bean curd Nutrition 0.000 description 1

- 235000013405 beer Nutrition 0.000 description 1

- 229940007550 benzyl acetate Drugs 0.000 description 1

- 229960002903 benzyl benzoate Drugs 0.000 description 1

- NOPLRNXKHZRXHT-YFVJMOTDSA-N beta-Sinensal Chemical compound O=CC(/C)=C/CCC(/C)=C/CCC(=C)C=C NOPLRNXKHZRXHT-YFVJMOTDSA-N 0.000 description 1

- NPNUFJAVOOONJE-UHFFFAOYSA-N beta-cariophyllene Natural products C1CC(C)=CCCC(=C)C2CC(C)(C)C21 NPNUFJAVOOONJE-UHFFFAOYSA-N 0.000 description 1

- JGQFVRIQXUFPAH-UHFFFAOYSA-N beta-citronellol Natural products OCCC(C)CCCC(C)=C JGQFVRIQXUFPAH-UHFFFAOYSA-N 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- OHDFENKFSKIFBJ-UHFFFAOYSA-N bis(2-methyl-3-furyl)disulfide Chemical compound O1C=CC(SSC2=C(OC=C2)C)=C1C OHDFENKFSKIFBJ-UHFFFAOYSA-N 0.000 description 1

- 235000015895 biscuits Nutrition 0.000 description 1

- 235000019658 bitter taste Nutrition 0.000 description 1

- 239000008280 blood Substances 0.000 description 1

- 210000004369 blood Anatomy 0.000 description 1

- 235000013532 brandy Nutrition 0.000 description 1

- 235000008429 bread Nutrition 0.000 description 1

- 235000015496 breakfast cereal Nutrition 0.000 description 1

- OBNCKNCVKJNDBV-UHFFFAOYSA-N butanoic acid ethyl ester Natural products CCCC(=O)OCC OBNCKNCVKJNDBV-UHFFFAOYSA-N 0.000 description 1

- 235000014121 butter Nutrition 0.000 description 1

- RPRPDTXKGSIXMD-UHFFFAOYSA-N butyl hexanoate Chemical compound CCCCCC(=O)OCCCC RPRPDTXKGSIXMD-UHFFFAOYSA-N 0.000 description 1

- ZTQSAGDEMFDKMZ-UHFFFAOYSA-N butyric aldehyde Natural products CCCC=O ZTQSAGDEMFDKMZ-UHFFFAOYSA-N 0.000 description 1

- 239000011575 calcium Substances 0.000 description 1

- 229910052791 calcium Inorganic materials 0.000 description 1

- 229930006739 camphene Natural products 0.000 description 1

- ZYPYEBYNXWUCEA-UHFFFAOYSA-N camphenilone Natural products C1CC2C(=O)C(C)(C)C1C2 ZYPYEBYNXWUCEA-UHFFFAOYSA-N 0.000 description 1

- 239000002775 capsule Substances 0.000 description 1

- 235000013736 caramel Nutrition 0.000 description 1

- NPNUFJAVOOONJE-UONOGXRCSA-N caryophyllene Natural products C1CC(C)=CCCC(=C)[C@@H]2CC(C)(C)[C@@H]21 NPNUFJAVOOONJE-UONOGXRCSA-N 0.000 description 1

- 229940117948 caryophyllene Drugs 0.000 description 1

- 238000004113 cell culture Methods 0.000 description 1

- 235000013351 cheese Nutrition 0.000 description 1

- 229940112822 chewing gum Drugs 0.000 description 1

- 235000015218 chewing gum Nutrition 0.000 description 1

- 235000010675 chips/crisps Nutrition 0.000 description 1

- 238000013375 chromatographic separation Methods 0.000 description 1

- 229930007050 cineol Natural products 0.000 description 1

- CCRCUPLGCSFEDV-UHFFFAOYSA-N cinnamic acid methyl ester Natural products COC(=O)C=CC1=CC=CC=C1 CCRCUPLGCSFEDV-UHFFFAOYSA-N 0.000 description 1

- WJSDHUCWMSHDCR-VMPITWQZSA-N cinnamyl acetate Natural products CC(=O)OC\C=C\C1=CC=CC=C1 WJSDHUCWMSHDCR-VMPITWQZSA-N 0.000 description 1

- NPFVOOAXDOBMCE-PLNGDYQASA-N cis-3-Hexenyl acetate Natural products CC\C=C/CCOC(C)=O NPFVOOAXDOBMCE-PLNGDYQASA-N 0.000 description 1

- RRGOKSYVAZDNKR-ARJAWSKDSA-M cis-3-hexenylacetate Chemical compound CC\C=C/CCCC([O-])=O RRGOKSYVAZDNKR-ARJAWSKDSA-M 0.000 description 1

- NNWHUJCUHAELCL-UHFFFAOYSA-N cis-Methyl isoeugenol Natural products COC1=CC=C(C=CC)C=C1OC NNWHUJCUHAELCL-UHFFFAOYSA-N 0.000 description 1

- NNWHUJCUHAELCL-PLNGDYQASA-N cis-isomethyleugenol Chemical compound COC1=CC=C(\C=C/C)C=C1OC NNWHUJCUHAELCL-PLNGDYQASA-N 0.000 description 1

- 229940043350 citral Drugs 0.000 description 1

- 229930003633 citronellal Natural products 0.000 description 1

- 235000000983 citronellal Nutrition 0.000 description 1

- 235000000484 citronellol Nutrition 0.000 description 1

- 235000016213 coffee Nutrition 0.000 description 1

- 235000013353 coffee beverage Nutrition 0.000 description 1

- 239000012141 concentrate Substances 0.000 description 1

- 235000008504 concentrate Nutrition 0.000 description 1

- 108010010165 curculin Proteins 0.000 description 1

- 239000000625 cyclamic acid and its Na and Ca salt Substances 0.000 description 1

- 125000000422 delta-lactone group Chemical group 0.000 description 1

- FYTRVXSHONWYNE-UHFFFAOYSA-N delta-octanolide Chemical compound CCCC1CCCC(=O)O1 FYTRVXSHONWYNE-UHFFFAOYSA-N 0.000 description 1

- SQIFACVGCPWBQZ-UHFFFAOYSA-N delta-terpineol Natural products CC(C)(O)C1CCC(=C)CC1 SQIFACVGCPWBQZ-UHFFFAOYSA-N 0.000 description 1

- 208000002925 dental caries Diseases 0.000 description 1

- 210000003298 dental enamel Anatomy 0.000 description 1

- 230000037123 dental health Effects 0.000 description 1

- 206010012601 diabetes mellitus Diseases 0.000 description 1

- 235000005911 diet Nutrition 0.000 description 1

- 230000000378 dietary effect Effects 0.000 description 1

- DMSHWWDRAYHEBS-UHFFFAOYSA-N dihydrocoumarin Natural products C1CC(=O)OC2=C1C=C(OC)C(OC)=C2 DMSHWWDRAYHEBS-UHFFFAOYSA-N 0.000 description 1

- 235000021186 dishes Nutrition 0.000 description 1

- 239000006185 dispersion Substances 0.000 description 1

- WTOYNNBCKUYIKC-UHFFFAOYSA-N dl-nootkatone Natural products C1CC(C(C)=C)CC2(C)C(C)CC(=O)C=C21 WTOYNNBCKUYIKC-UHFFFAOYSA-N 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 235000014103 egg white Nutrition 0.000 description 1

- 210000000969 egg white Anatomy 0.000 description 1

- 210000002969 egg yolk Anatomy 0.000 description 1

- 235000013345 egg yolk Nutrition 0.000 description 1

- SBHXYTNGIZCORC-ZDUSSCGKSA-N eriodictyol Chemical compound C1([C@@H]2CC(=O)C3=C(O)C=C(C=C3O2)O)=CC=C(O)C(O)=C1 SBHXYTNGIZCORC-ZDUSSCGKSA-N 0.000 description 1

- TUJPOVKMHCLXEL-UHFFFAOYSA-N eriodictyol Natural products C1C(=O)C2=CC(O)=CC(O)=C2OC1C1=CC=C(O)C(O)=C1 TUJPOVKMHCLXEL-UHFFFAOYSA-N 0.000 description 1

- 235000011797 eriodictyol Nutrition 0.000 description 1

- SBHXYTNGIZCORC-UHFFFAOYSA-N eriodyctiol Natural products O1C2=CC(O)=CC(O)=C2C(=O)CC1C1=CC=C(O)C(O)=C1 SBHXYTNGIZCORC-UHFFFAOYSA-N 0.000 description 1

- 235000019414 erythritol Nutrition 0.000 description 1

- 229940009714 erythritol Drugs 0.000 description 1

- UNXHWFMMPAWVPI-ZXZARUISSA-N erythritol Chemical compound OC[C@H](O)[C@H](O)CO UNXHWFMMPAWVPI-ZXZARUISSA-N 0.000 description 1

- OPCRGEVPIBLWAY-QNRZBPGKSA-N ethyl (2E,4Z)-deca-2,4-dienoate Chemical compound CCCCC\C=C/C=C/C(=O)OCC OPCRGEVPIBLWAY-QNRZBPGKSA-N 0.000 description 1

- RGXWDWUGBIJHDO-UHFFFAOYSA-N ethyl decanoate Chemical compound CCCCCCCCCC(=O)OCC RGXWDWUGBIJHDO-UHFFFAOYSA-N 0.000 description 1

- PPXUHEORWJQRHJ-UHFFFAOYSA-N ethyl isovalerate Chemical compound CCOC(=O)CC(C)C PPXUHEORWJQRHJ-UHFFFAOYSA-N 0.000 description 1

- 229940116333 ethyl lactate Drugs 0.000 description 1

- 229940093503 ethyl maltol Drugs 0.000 description 1

- BTCQMCOBMIXUCG-UHFFFAOYSA-N ethyl vanillin isobutyrate Chemical compound CCOC1=CC(C=O)=CC=C1OC(=O)C(C)C BTCQMCOBMIXUCG-UHFFFAOYSA-N 0.000 description 1

- 229960002217 eugenol Drugs 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 235000019197 fats Nutrition 0.000 description 1

- 235000011194 food seasoning agent Nutrition 0.000 description 1

- 235000019253 formic acid Nutrition 0.000 description 1

- 235000021433 fructose syrup Nutrition 0.000 description 1

- 235000015203 fruit juice Nutrition 0.000 description 1

- 235000012055 fruits and vegetables Nutrition 0.000 description 1

- FBPFZTCFMRRESA-GUCUJZIJSA-N galactitol Chemical compound OC[C@H](O)[C@@H](O)[C@@H](O)[C@H](O)CO FBPFZTCFMRRESA-GUCUJZIJSA-N 0.000 description 1

- OALYTRUKMRCXNH-QMMMGPOBSA-N gamma-Nonalactone Natural products CCCCC[C@H]1CCC(=O)O1 OALYTRUKMRCXNH-QMMMGPOBSA-N 0.000 description 1

- 125000000457 gamma-lactone group Chemical group 0.000 description 1

- IPBFYZQJXZJBFQ-UHFFFAOYSA-N gamma-octalactone Chemical compound CCCCC1CCC(=O)O1 IPBFYZQJXZJBFQ-UHFFFAOYSA-N 0.000 description 1

- WTEVQBCEXWBHNA-JXMROGBWSA-N geranial Chemical compound CC(C)=CCC\C(C)=C\C=O WTEVQBCEXWBHNA-JXMROGBWSA-N 0.000 description 1

- 229940113087 geraniol Drugs 0.000 description 1

- 229930182470 glycoside Natural products 0.000 description 1

- 150000002338 glycosides Chemical class 0.000 description 1

- LPLVUJXQOOQHMX-UHFFFAOYSA-N glycyrrhetinic acid glycoside Natural products C1CC(C2C(C3(CCC4(C)CCC(C)(CC4C3=CC2=O)C(O)=O)C)(C)CC2)(C)C2C(C)(C)C1OC1OC(C(O)=O)C(O)C(O)C1OC1OC(C(O)=O)C(O)C(O)C1O LPLVUJXQOOQHMX-UHFFFAOYSA-N 0.000 description 1

- 229960004949 glycyrrhizic acid Drugs 0.000 description 1

- UYRUBYNTXSDKQT-UHFFFAOYSA-N glycyrrhizic acid Natural products CC1(C)C(CCC2(C)C1CCC3(C)C2C(=O)C=C4C5CC(C)(CCC5(C)CCC34C)C(=O)O)OC6OC(C(O)C(O)C6OC7OC(O)C(O)C(O)C7C(=O)O)C(=O)O UYRUBYNTXSDKQT-UHFFFAOYSA-N 0.000 description 1

- 235000019410 glycyrrhizin Nutrition 0.000 description 1

- 235000011868 grain product Nutrition 0.000 description 1

- 235000014168 granola/muesli bars Nutrition 0.000 description 1

- 239000008187 granular material Substances 0.000 description 1

- 235000011617 hard cheese Nutrition 0.000 description 1

- 230000036541 health Effects 0.000 description 1

- 230000005802 health problem Effects 0.000 description 1

- NDFKTBCGKNOHPJ-UHFFFAOYSA-N hex-2-enal Natural products CCCCC=CC=O NDFKTBCGKNOHPJ-UHFFFAOYSA-N 0.000 description 1

- UFLHIIWVXFIJGU-UHFFFAOYSA-N hex-3-en-1-ol Natural products CCC=CCCO UFLHIIWVXFIJGU-UHFFFAOYSA-N 0.000 description 1

- VLKZOEOYAKHREP-UHFFFAOYSA-N hexane Substances CCCCCC VLKZOEOYAKHREP-UHFFFAOYSA-N 0.000 description 1

- 238000004128 high performance liquid chromatography Methods 0.000 description 1

- 238000004896 high resolution mass spectrometry Methods 0.000 description 1

- FTODBIPDTXRIGS-ZDUSSCGKSA-N homoeriodictyol Chemical compound C1=C(O)C(OC)=CC([C@H]2OC3=CC(O)=CC(O)=C3C(=O)C2)=C1 FTODBIPDTXRIGS-ZDUSSCGKSA-N 0.000 description 1

- FTODBIPDTXRIGS-UHFFFAOYSA-N homoeriodictyol Natural products C1=C(O)C(OC)=CC(C2OC3=CC(O)=CC(O)=C3C(=O)C2)=C1 FTODBIPDTXRIGS-UHFFFAOYSA-N 0.000 description 1

- 235000015243 ice cream Nutrition 0.000 description 1

- 235000021539 instant coffee Nutrition 0.000 description 1

- 235000014109 instant soup Nutrition 0.000 description 1

- 235000020344 instant tea Nutrition 0.000 description 1

- PANBRUWVURLWGY-UHFFFAOYSA-N intreleven aldehyde Natural products CCCCCCCCC=CC=O PANBRUWVURLWGY-UHFFFAOYSA-N 0.000 description 1

- 229960004903 invert sugar Drugs 0.000 description 1

- 229940117955 isoamyl acetate Drugs 0.000 description 1

- 229940094941 isoamyl butyrate Drugs 0.000 description 1

- KQNPFQTWMSNSAP-UHFFFAOYSA-N isobutyric acid Chemical compound CC(C)C(O)=O KQNPFQTWMSNSAP-UHFFFAOYSA-N 0.000 description 1

- JSLCOZYBKYHZNL-UHFFFAOYSA-N isobutyric acid butyl ester Natural products CCCCOC(=O)C(C)C JSLCOZYBKYHZNL-UHFFFAOYSA-N 0.000 description 1

- 229940095045 isopulegol Drugs 0.000 description 1

- 235000015141 kefir Nutrition 0.000 description 1

- 235000008960 ketchup Nutrition 0.000 description 1

- 239000000832 lactitol Substances 0.000 description 1

- 235000010448 lactitol Nutrition 0.000 description 1