WO2022019029A1 - Device and method for manufacturing reconstituted tobacco sheet - Google Patents

Device and method for manufacturing reconstituted tobacco sheet Download PDFInfo

- Publication number

- WO2022019029A1 WO2022019029A1 PCT/JP2021/023577 JP2021023577W WO2022019029A1 WO 2022019029 A1 WO2022019029 A1 WO 2022019029A1 JP 2021023577 W JP2021023577 W JP 2021023577W WO 2022019029 A1 WO2022019029 A1 WO 2022019029A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- tobacco sheet

- reconstructed tobacco

- reconstructed

- die

- drum

- Prior art date

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24B—MANUFACTURE OR PREPARATION OF TOBACCO FOR SMOKING OR CHEWING; TOBACCO; SNUFF

- A24B3/00—Preparing tobacco in the factory

- A24B3/14—Forming reconstituted tobacco products, e.g. wrapper materials, sheets, imitation leaves, rods, cakes; Forms of such products

Definitions

- the present invention relates to a reconstructed tobacco sheet manufacturing apparatus and a manufacturing method.

- a rolling method, a cast (slurry) method, and a papermaking method are known as a method for manufacturing a reconstructed tobacco sheet. These production methods are selected according to the amount of water contained in the reconstituted tobacco raw material. In addition, each of these manufacturing methods is realized by different reconstructed tobacco sheet manufacturing devices.

- the rolling method is known to be particularly suitable for reconstituted tobacco raw materials containing 50% by volume or less of water.

- the kneaded product of the reconstituted tobacco raw material is rolled and molded by a rotary roller, the thickness is adjusted, and then the kneaded product is dried by a dryer provided separately.

- the cast (slurry) method is known to be particularly suitable for reconstituted tobacco raw materials containing 50% by volume or more of water.

- the fluid of the reconstituted tobacco raw material is continuously spread on a rotary drum or belt conveyor, leveled to a desired thickness with a member called a blade, and then the rotary drum or It is peeled off from the belt conveyor and dried by a separately provided dryer (see, for example, Patent Document 1).

- the papermaking method is known to be particularly suitable for reconstituted tobacco raw materials containing 80% by volume or more of water.

- the fluid of the reconstituted tobacco raw material is continuously spread on a liquid permeable belt conveyor, and after the water is removed by a squeezing roller and the desired thickness is obtained, a separately provided drying is performed. It is dried by the machine.

- An object of the present invention is to provide a reconstructed tobacco sheet manufacturing apparatus and a manufacturing method capable of obtaining a reconstructed tobacco sheet having a uniform thickness by a simple manufacturing process regardless of the amount of water contained in the reconstructed tobacco raw material. To provide.

- a reconstructed tobacco sheet manufacturing apparatus includes a die for discharging the reconstructed tobacco raw material and an extruder for pumping the reconstructed tobacco raw material to the die by rotating a screw rotatably arranged inside.

- the die has a housing, a supply port formed in the housing and supplied with the reconstituted tobacco raw material, and a discharge port formed on one side of the housing to discharge the reconstituted tobacco raw material. According to this, it is possible to obtain a reconstructed tobacco sheet having a uniform thickness by a simple manufacturing process regardless of the amount of water contained in the reconstituted tobacco raw material.

- the extruder is a twin-screw extruder having a pair of screws arranged in parallel with each other and rotating in opposite directions. According to this, even when the viscosity of the reconstituted tobacco raw material is very high, it is possible to knead efficiently. Further, according to this, it is possible to improve the sheet formability at the time of extruding the reconstructed tobacco raw material.

- the first or second embodiment further includes a degassing mechanism for degassing the reconstituted tobacco raw material supplied to the extruder. According to this, it is possible to obtain a reconstructed tobacco sheet having high density, homogeneity, and high strength.

- a method for producing a reconstructed tobacco sheet is provided.

- the method for manufacturing this reconstructed tobacco sheet is a process of pumping the reconstructed tobacco raw material to the supply port of the die by rotating a screw provided in the extruder, and molding the reconstructed tobacco raw material into a sheet from the discharge port of the die. And discharge. According to this, regardless of the amount of water contained in the reconstituted tobacco raw material, it is possible to obtain a reconstituted tobacco sheet having a uniform thickness and being cut by a simple manufacturing process.

- FIG. 7 It is sectional drawing in the arrow view VIII-VIII shown in FIG. 7. It is a top view which shows the manufacturing apparatus of the reconstructed tobacco sheet which concerns on 3rd Embodiment of this invention. It is a top view which shows the manufacturing apparatus of the reconstructed tobacco sheet which concerns on 4th Embodiment of this invention. It is a side view which shows the manufacturing apparatus of the reconstructed tobacco sheet which concerns on 6th Embodiment of this invention. It is a side view which looked at the die of the reconstructed tobacco sheet manufacturing apparatus which concerns on 7th Embodiment of this invention from the discharge port side. It is a side view which looked at the die of the reconstructed tobacco sheet manufacturing apparatus which concerns on 8th Embodiment of this invention from the discharge port side.

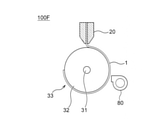

- FIG. 1 is a side view showing a reconstructed tobacco sheet manufacturing apparatus according to the first embodiment of the present invention.

- the reconstructed tobacco sheet manufacturing apparatus 100 includes an extruder 10, a die 20, a drum dryer (main drum) 30, a scraper 40, and rollers 51 and 52.

- the drum dryer 30 has a shaft 31 and a drum body 32.

- the extruder 10 pumps the reconstituted tobacco raw material supplied from a tank or the like (not shown) to the die 20.

- the die 20 discharges the reconstituted tobacco raw material supplied from the extruder 10, whereby the reconstituted tobacco raw material is formed on the drum body 32 of the drum dryer 30 as the reconstructed tobacco sheet 1.

- the drum dryer 30 dries and conveys the reconstructed tobacco sheet 1 formed on the drum main body 32.

- the scraper 40 peels the reconstructed tobacco sheet 1 dried by the drum dryer 30 from the drum body 32.

- the rollers 51 and 52 guide the transport of the reconstructed tobacco sheet 1 peeled off by the scraper 40.

- the reconstituted tobacco raw material is at least one substance selected from polysaccharides (starch, dextrin, etc.) and water or alcohol (ethanol, propylene glycol, etc.) or at least self-selected as a medium of any liquid.

- the reconstituted tobacco raw material is not limited to the above, and may contain other substances.

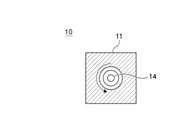

- FIG. 2 is a block diagram showing an extruder of the reconstructed tobacco sheet manufacturing apparatus according to the first embodiment of the present invention.

- FIG. 3 is a cross-sectional view taken along the line III-III shown in FIG.

- the extruder 10 is rotatably arranged in the housing 11, the supply port 12 formed at one end of the housing 11, the extrusion port 13 formed at the other end of the housing 11, and the housing 11. It has a screw 14.

- the reconstituted tobacco raw material supplied from the tank or the like to the extruder 10 via the supply port 12 is sent to the extrusion port 13 while being kneaded by the rotation of the screw 14, and is pressure-fed from the extrusion port 13 to the die 20.

- the discharge speed of the reconstructed tobacco sheet 1 discharged from the die 20 is determined according to the rotation speed of the screw 14.

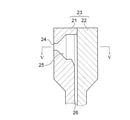

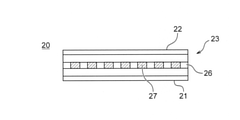

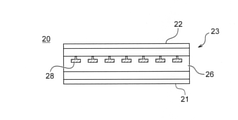

- FIG. 4 is a cross-sectional view showing a die of a reconstructed tobacco sheet manufacturing apparatus according to the first embodiment of the present invention.

- FIG. 5 is a cross-sectional view taken along the line VV shown in FIG.

- FIG. 6 is a side view of the die shown in FIG. 4 as viewed from the discharge port side.

- the die 20 is a housing 23 composed of a first block 21 and a second block 22, and a supply port 24 and a first block formed in the first block 21 and communicating with the extrusion port 13 of the extruder 10. It has a manifold 25 formed between the 21 and the second block 22 and in which the reconstituted tobacco raw material is stored, and a discharge port 26 communicating with the manifold 25.

- the discharge port 26 is formed in a slit shape on one side surface of the housing 23.

- the direction orthogonal to the longitudinal direction of the discharge port 26 is defined as the width direction of the discharge port 26.

- the length in the longitudinal direction of the discharge port 26 is referred to as an opening length

- the length in the width direction of the discharge port 26 is referred to as an opening width.

- the discharge port 26 may have a hole shape or a groove shape.

- the slit-shaped discharge port 26 adjusts the reconstituted tobacco raw material to a uniform thickness according to the opening width of the discharge port 26 when discharged from the die 20 regardless of the amount of water contained in the reconstructed tobacco raw material. , Formed into a sheet and extruded.

- the reconstituted tobacco raw material supplied from the extruder 10 to the die 20 via the supply port 24 is sent to the discharge port 26 through the manifold 25, and is discharged from the discharge port 26 as the reconstructed tobacco sheet 1 onto the drum body 32. Will be done.

- the drum dryer 30 has a shaft 31 and a drum body 32 that rotates about the shaft 31.

- the drum body 32 dries the reconstructed tobacco sheet 1 by, for example, steam sent into the drum body 32.

- the drum body 32 may be heated by a heater or the like.

- the scraper 40 is arranged so as to face the drum main body 32 over the entire length in the width direction of the drum main body 32 orthogonal to the rotation direction of the drum main body 32, and the tip portion thereof is adjusted so as to be in contact with or close to the drum main body 32. There is.

- the scraper 40 is arranged near the end of the drum body 32 on the downstream side in the rotation direction so that the reconstructed tobacco sheet 1 discharged on the upstream side in the rotation direction of the drum body 32 is sufficiently dried. There is.

- the reconstructed tobacco sheet 1 discharged onto the drum body 32 from the discharge port 26 of the die 20 is dried by the drum body 32 to which steam is sent into the inside, and the dried reconstructed tobacco sheet 1 is peeled off by the scraper 40. It is handed over to the subsequent process.

- the subsequent step is, for example, a step of cutting the reconstructed tobacco sheet 1 to a desired width, or a step of winding the cut reconstructed tobacco sheet onto a bobbin.

- the reconstructed tobacco sheet 1 has a step of pumping the reconstructed tobacco raw material to the supply port 24 of the die 20 by rotation of the screw 14 provided in the extruder 10, and the reconstructed tobacco raw material from the discharge port 26 of the die 20.

- the reconstructed tobacco sheet manufacturing apparatus includes a die for discharging the reconstructed tobacco raw material and a main drum for drying and transporting the reconstructed tobacco raw material discharged from the die.

- the die comprises a housing, a supply port formed in the housing to supply the reconstituted tobacco material, and a discharge port formed on one side of the housing to discharge the reconstituted tobacco material. Therefore, regardless of the amount of water contained in the reconstituted tobacco raw material, a reconstructed tobacco sheet having a uniform thickness can be obtained by a simple manufacturing process.

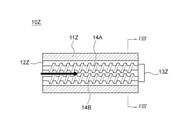

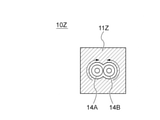

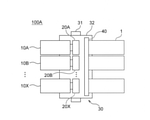

- FIG. 7 is a cross-sectional view showing an extruder of a reconstructed tobacco sheet manufacturing apparatus according to a second embodiment of the present invention.

- FIG. 8 is a cross-sectional view taken along the line VIII-VIII shown in FIG. 7.

- the apparatus for producing a reconstructed tobacco sheet according to the second embodiment of the present invention includes the extruder 10Z shown in FIGS. 7 and 8 in place of the extruder 10 shown in FIG. Since other configurations are the same as those of the first embodiment described above, the description thereof will be omitted.

- the extruder 10Z is rotatably arranged in the housing 11Z, the supply port 12Z formed at one end of the housing 11Z, the extrusion port 13Z formed at the other end of the housing 11Z, and the housing 11Z.

- a twin-screw extruder having a first screw 14A and a second screw 14B.

- the first screw 14A and the second screw 14B are arranged in parallel with each other and are configured to rotate in opposite directions.

- the reconstituted tobacco raw material supplied from the tank or the like to the extruder 10Z via the supply port 12Z is sent to the extrusion port 13Z while being kneaded by the rotation of the first screw 14A and the second screw 14B, and is sent from the extrusion port 13Z to the die 20. Is pumped to.

- the force for scraping the reconstructed tobacco raw material is increased, and even when the viscosity of the reconstructed tobacco raw material is very high. , Can be kneaded efficiently. Further, by using the first screw 14A and the second screw 14B that rotate in opposite directions, the shearing force for the reconstructed tobacco raw material can be increased, so that the binding of water to each other on the surface of the reconstructed tobacco raw material is promoted. , It is possible to improve the sheet formability at the time of extrusion.

- the extruder is a twin-screw extruder having a pair of screws arranged in parallel with each other and rotating in opposite directions. Therefore, even when the viscosity of the reconstituted tobacco raw material is very high, it can be efficiently kneaded. In addition, the sheet formability at the time of extruding the reconstructed tobacco raw material can be improved.

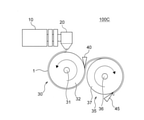

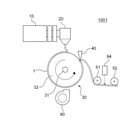

- FIG. 9 is a side view showing a reconstructed tobacco sheet manufacturing apparatus according to a third embodiment of the present invention.

- the reconstructed tobacco sheet manufacturing apparatus 100L has a degassing mechanism 2 for degassing the reconstructed tobacco raw material supplied to the extruder 10 in addition to the reconstructed tobacco sheet manufacturing apparatus 100 shown in FIG. To be equipped.

- the degassing mechanism 2 has an extruder 2A and a degassing chamber 2B. Since other configurations are the same as those of the first embodiment described above, the description thereof will be omitted.

- the extruder 2A has the same configuration as the extruder 10 shown in FIG.

- the extruder 2A pumps the reconstituted tobacco raw material supplied from a tank or the like (not shown) into the degassing chamber 2B.

- the extruder 2A may have the same configuration as the extruder 10Z shown in FIGS. 7 and 8.

- the degassing chamber 2B degass the reconstituted tobacco raw material pressure-fed from the extruder 2A using a vacuum pump or the like (not shown) and supplies it to the extruder 10.

- the degree of vacuum in the degassing chamber 2B can be adjusted by operating a valve provided in a degassing path (not shown).

- the degassing mechanism for degassing the reconstituted tobacco raw material supplied to the extruder is further provided. Therefore, it is possible to obtain a reconstructed tobacco sheet having high density, homogeneity, and high strength.

- the extruder 2A, the degassing chamber 2B, and the extruder 10 may be integrally configured to form an extruder having a degassing function.

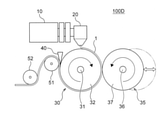

- FIG. 10 is a plan view showing a reconstructed tobacco sheet manufacturing apparatus according to a fourth embodiment of the present invention.

- the reconstructed tobacco sheet manufacturing apparatus 100A includes X extruders 10A to 10X and X dies 20A to 20X in place of the extruder 10 and die 20 shown in FIG.

- X may be 2 or more.

- X dies 20A to 20X may be connected to one extruder 10. Since other configurations are the same as those of the first embodiment described above, the description thereof will be omitted.

- Extruders 10A to 10X are connected to dies 20A to 20X, respectively. Further, the dies 20A to 20X are arranged along the longitudinal direction of the discharge port 26.

- the extruders 10A to 10X pump the reconstituted tobacco raw materials supplied from a tank or the like (not shown) to the dies 20A to 20X, respectively.

- the dies 20A to 20X discharge the reconstituted tobacco raw materials supplied from the extruders 10A to 10X onto the drum main body 32, respectively.

- the reconstructed tobacco in the above-mentioned latter step by adjusting the opening length of the discharge port 26 of the dies 20A to 20X to the width of the bobbin around which the reconstructed tobacco sheet 1 is wound in the above-mentioned subsequent step, the reconstructed tobacco in the above-mentioned latter step.

- the step of cutting the sheet 1 to a desired width becomes unnecessary.

- compositions of the reconstituted tobacco raw materials supplied to the extruders 10A to 10X different from each other, it is possible to manufacture a plurality of types of reconstructed tobacco sheets 1 with one drum dryer 30. Further, by selectively driving the set of the extruders 10A to 10X and the dies 20A to 20X, the manufacturing capacity of the reconstructed tobacco sheet manufacturing apparatus 100A can be easily adjusted.

- a plurality of dies are arranged along the longitudinal direction of the discharge port. Therefore, the step of cutting the obtained reconstructed tobacco sheet to a desired width can be omitted.

- the opening width of the discharge port 26 of the die 20 is constant, but in the reconstructed tobacco sheet manufacturing apparatus according to the fifth embodiment of the present invention, the die 20 has the opening width of the discharge port 26.

- the variable width mechanism is, for example, a screw.

- the variable width mechanism changes the opening width of the discharge port 26 by adjusting the gap between the first block 21 and the second block 22 shown in FIG. 6 according to the tightening amount of the screw.

- a plurality of screws may be provided so that the opening width of the discharge port 26 is different between the end portion and the center portion in the longitudinal direction of the discharge port 26. If the opening length of the discharge port 26 is larger than the opening width of the discharge port 26, the discharge state may differ in the longitudinal direction of the discharge port 26.

- the variable width mechanism may have an actuator such as a motor for driving a screw.

- the die has a variable width mechanism capable of changing the length in the width direction of the discharge port. Therefore, it is possible to obtain a reconstructed tobacco sheet having a plurality of thicknesses without changing the die.

- the opening width of the discharge port so that the flow velocity of the reconstructed tobacco raw material at the discharge port of the die becomes uniform in the longitudinal direction of the discharge port, the occurrence of wrinkles is suppressed and the reconstructed tobacco sheet can be obtained. Can be molded flat.

- FIG. 11 is a side view showing a reconstructed tobacco sheet manufacturing apparatus according to a sixth embodiment of the present invention.

- the reconstructed tobacco sheet manufacturing apparatus 100B includes three extruders 61 to 63 and a die 70 in place of the extruder 10 and the die 20 shown in FIG.

- the number of extruders is not limited to three, and may be two or more. Since other configurations are the same as those of the first embodiment described above, the description thereof will be omitted.

- the extruders 61 to 63 are connected to the die 70.

- Raw materials are supplied to the extruders 61 to 63 from tanks and the like (not shown). At least one of the raw materials supplied to the extruders 61-63 contains a reconstituted tobacco raw material. Further, the raw materials supplied to the extruders 61 to 63 may be different raw materials from each other or may contain the same raw materials.

- the extruders 61 to 63 pump the supplied raw material to the die 70 using a screw or the like (not shown).

- the die 70 has a plurality of supply ports 71 to 73 to which a plurality of raw materials are supplied from the extruders 61 to 63, and a discharge port 74 formed in a slit shape on one side surface of the die 70.

- the raw materials supplied from the extruders 61 to 63 via the supply ports 71 to 73 are spread by a manifold (not shown) and then merged in the vicinity of the discharge port 74 to form a laminated reconstructed tobacco sheet. 1 is discharged onto the drum body 32.

- the die 70 may have a plurality of raw materials merged in the manifold.

- the reconstructed tobacco sheet 1 having a simple structure and having a multi-layered structure can be obtained by omitting the sheet bonding step. Further, by forming the sheet in multiple layers before drying the reconstructed tobacco sheet 1 with the drum dryer 30, the adhesion of each layer can be strengthened. Furthermore, by inserting a sheet that suppresses stickiness into the multi-layered sheet, the reconstructed tobacco sheet 1 can be wound onto the bobbin and from the bobbin without taking measures such as dusting and release paper. The feeding can be easily performed.

- the die has a plurality of supply ports to which a plurality of raw materials are supplied, and the plurality of raw materials are laminated and discharged from the discharge port. Therefore, the step of laminating a plurality of sheets can be omitted.

- FIG. 12 is a side view of the die of the reconstructed tobacco sheet manufacturing apparatus according to the seventh embodiment of the present invention as viewed from the discharge port side.

- the die 20 further has a partition 27 that divides the discharge port 26 into a plurality of regions along the longitudinal direction of the discharge port 26. That is, in FIG. 12, the slit-shaped discharge port 26 shown in FIG. 6 is intermittently opened. Since other configurations are the same as those of the first embodiment described above, the description thereof will be omitted.

- the reconstituted tobacco raw material supplied from the extruder 10 to the die 20 via the supply port 24 is sent to the discharge port 26 through the manifold 25, and is discharged from the discharge port 26 as the reconstructed tobacco sheet 1 onto the drum body 32. Will be done.

- the discharge port 26 is intermittently opened, the discharged reconstructed tobacco sheet 1 is already formed into a strip shape. Therefore, the reconstructed tobacco sheet 1 dried by the drum dryer 30 can be recovered as a strand as it is after the drying is completed.

- the die has a partition portion that divides the discharge port into a plurality of regions along the longitudinal direction of the discharge port. Therefore, the step of stranding the sheet can be omitted. Further, in the present invention, it is effective to use the die 20 having the partition portion 27 because the shape of the discharged reconstructed tobacco sheet is stable even before drying.

- FIG. 13 is a side view of the die of the reconstructed tobacco sheet manufacturing apparatus according to the eighth embodiment of the present invention as viewed from the discharge port side.

- the die 20 further has at least one raised portion 28 that faces the width direction of the discharge port 26 along the longitudinal direction of the discharge port 26.

- the cross-sectional shape of the raised portion 28 may be a triangle, a rectangle, a sinusoidal waveform, a T-shape, or the like. That is, in FIG. 13, the slit-shaped discharge port 26 shown in FIG. 6 is an opening having two widths, that is, the apex of the raised portion 28 or the side including the apex and the bottom of the raised portion 28. Since other configurations are the same as those of the first embodiment described above, the description thereof will be omitted.

- the reconstituted tobacco raw material supplied from the extruder 10 to the die 20 via the supply port 24 is sent to the discharge port 26 through the manifold 25, and is discharged from the discharge port 26 as the reconstructed tobacco sheet 1 onto the drum body 32. Will be done.

- the discharged reconstructed tobacco sheet 1 is already formed with strips having a cross-sectional shape corresponding to the raised portion 28. Therefore, the reconstructed tobacco sheet 1 dried by the drum dryer 30 can be recovered as the reconstructed tobacco sheet 1 in which the strips are formed as it is after the drying is completed.

- the die has at least one raised portion that faces the width direction of the discharge port along the longitudinal direction of the discharge port. Therefore, the reconstructed tobacco sheet can be reconstructed while omitting the step of passing the reconstructed tobacco sheet between the paired rollers and pressing the zigzag or corrugated shape, which has been performed with the conventional reconstructed tobacco sheet.

- Surface treatment eg, embossing

- FIG. 15 is a side view showing a reconstructed tobacco sheet manufacturing apparatus according to a ninth embodiment of the present invention.

- the reconstructed tobacco sheet manufacturing apparatus 100C includes a drum dryer (secondary drum) 35 and a scraper 45 in addition to the reconstructed tobacco sheet manufacturing apparatus 100 shown in FIG. Since other configurations are the same as those of the first embodiment described above, the description thereof will be omitted.

- the drum dryer 35 is arranged after the drum dryer 30 and is used in combination with the drum dryer 30.

- the drum dryer 35 has a shaft 36 and a drum body 37 that rotates about the shaft 36.

- the drum body 37 is heated, for example, by steam sent into the drum body 37.

- the drum body 37 may be heated by a heater or the like. Further, the drum dryer 30 and the drum dryer 35 are configured so that the temperature can be adjusted independently.

- the drum dryer 35 receives the reconstructed tobacco sheet 1 dried by the drum dryer 30 and peeled off by the scraper 40, and further dries and conveys the reconstructed tobacco sheet 1.

- the scraper 45 peels the reconstructed tobacco sheet 1 dried by the drum dryer 35 from the drum body 37.

- the drying distance of the reconstructed tobacco sheet 1 can be extended, and the drying capacity of the reconstructed tobacco sheet manufacturing apparatus 100C can be improved. Therefore, it is possible to cope with a reconstituted tobacco raw material having a large amount of water.

- the respective drum diameters are set to 1. It can be halved the drum diameter of one drum dryer. That is, the total volume of the two drum dryers can be reduced to half that of one drum dryer. Therefore, when two drum dryers are used, the required heat energy can be reduced to half that when one drum dryer is used.

- the sub-drum used in combination with the main drum is further provided, and the sub-drum is arranged after the main drum, and the reconstructed tobacco raw material conveyed by the main drum is used. Receive from the main drum and carry it further. Therefore, the reconstituted tobacco raw material dried and transported by the main drum can be further treated while extending the transport distance of the reconstituted tobacco raw material.

- the auxiliary drum is a drum dryer, but the auxiliary drum is not limited to this, and the auxiliary drum may be a cooling drum for cooling the reconstructed tobacco sheet 1 dried by the drum dryer 30.

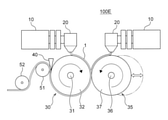

- FIG. 16 is a side view showing a reconstructed tobacco sheet manufacturing apparatus according to the tenth embodiment of the present invention.

- the reconstructed tobacco sheet manufacturing apparatus 100D includes a drum dryer (secondary drum) 35 in addition to the reconstructed tobacco sheet manufacturing apparatus 100 shown in FIG. Since other configurations are the same as those of the first embodiment described above, the description thereof will be omitted.

- the drum dryer 35 is arranged to face the drum dryer 30 and is used in combination with the drum dryer 30.

- the drum dryer 35 has a shaft 36 and a drum body 37 that rotates about the shaft 36.

- the shaft 36 is configured so that the gap between the drum dryer 30 and the drum dryer 35 can be arbitrarily adjusted by a drive mechanism (not shown).

- the drum body 37 is heated by, for example, steam sent into the drum body 37.

- the drum body 37 may be heated by a heater or the like.

- the drum dryer 30 and the drum dryer 35 are configured so that the temperature can be adjusted independently.

- the drum dryer 35 dries and conveys the reconstructed tobacco sheet 1 formed on the drum body 32 in cooperation with the drum dryer 30.

- the reconstructed tobacco sheet 1 conveyed by the drum dryer 30 and the drum dryer 35 is compressed as it passes through the gap between the drum dryer 30 and the drum dryer 35.

- the density of the reconstructed tobacco sheet 1 is reduced by the compaction effect of the drum dryer 30 and the drum dryer 35 at the time of ejection from the die 20. Can be enhanced. Further, by adjusting the gap between the drum dryer 30 and the drum dryer 35, it is possible to control the thickness of the reconstructed tobacco sheet 1 that has passed through the gap between the drum dryer 30 and the drum dryer 35.

- the compaction effect of the drum dryer 30 and the drum dryer 35 causes the reconstructed tobacco according to the distribution of the ejection speed at the time of ejection from the die 20. Wrinkles and the like generated on the sheet 1 can be eliminated.

- embossing the surface of the drum body 37 when the reconstructed tobacco sheet 1 passes through the gap between the drum dryer 30 and the drum dryer 35, the surface of the reconstructed tobacco sheet 1 is embossed. And the specific surface area can be expanded.

- the processing performed on the surface of the drum body 37 is not limited to the embossing processing, and may be slit processing or the like for cutting the reconstructed tobacco sheet 1.

- the sub-drum used in combination with the main drum is further provided, and the sub-drum is arranged to face the main drum and is discharged from the die in cooperation with the main drum. Transport the reconstituted tobacco raw material. Therefore, in cooperation with the main drum, the reconstituted tobacco raw material dried and transported by the main drum can be further treated.

- FIG. 17 is a side view showing a reconstructed tobacco sheet manufacturing apparatus according to the eleventh embodiment of the present invention.

- the reconstructed tobacco sheet manufacturing apparatus 100E includes an extruder 10 and a die 20 provided in the drum dryer 35 in addition to the reconstructed tobacco sheet manufacturing apparatus 100D shown in FIG. Since other configurations are the same as those of the tenth embodiment described above, the description thereof will be omitted.

- the extruder 10 provided in the drum dryer 35 is supplied with raw materials supplied from a tank or the like (not shown).

- the raw material supplied to the extruder 10 may or may not contain the reconstituted tobacco raw material.

- the extruder 10 pumps the supplied raw material to the die 20 using a screw or the like (not shown).

- the die 20 provided in the drum dryer 35 forms the raw material supplied from the extruder 10 into a sheet shape and discharges the raw material onto the drum main body 37.

- the sheets discharged from each of the die 20 provided in the drum dryer 30 and the die 20 provided in the drum dryer 35 are multi-layered when passing through the gap between the drum dryer 30 and the drum dryer 35.

- the sheets having different characteristics are bonded by passing the sheets discharged from the dies 20 provided in the drum dryer 30 and the drum dryer 35 through the gap between the drum dryer 30 and the drum dryer 35.

- the adhesion of each layer can be strengthened by making the sheets multi-layered before drying the tobacco sheet 1 reconstructed by the drum dryer 30 and the drum dryer 35. Further, by adjusting the gap between the drum dryer 30 and the drum dryer 35, it is possible to control the thickness of the reconstructed tobacco sheet 1 that has passed through the gap between the drum dryer 30 and the drum dryer 35.

- the sub-drum used in combination with the main drum and the die having the same configuration as the die provided on the main drum and discharging the discharge material to the sub-drum. Further prepare. Therefore, the step of laminating a plurality of sheets can be omitted.

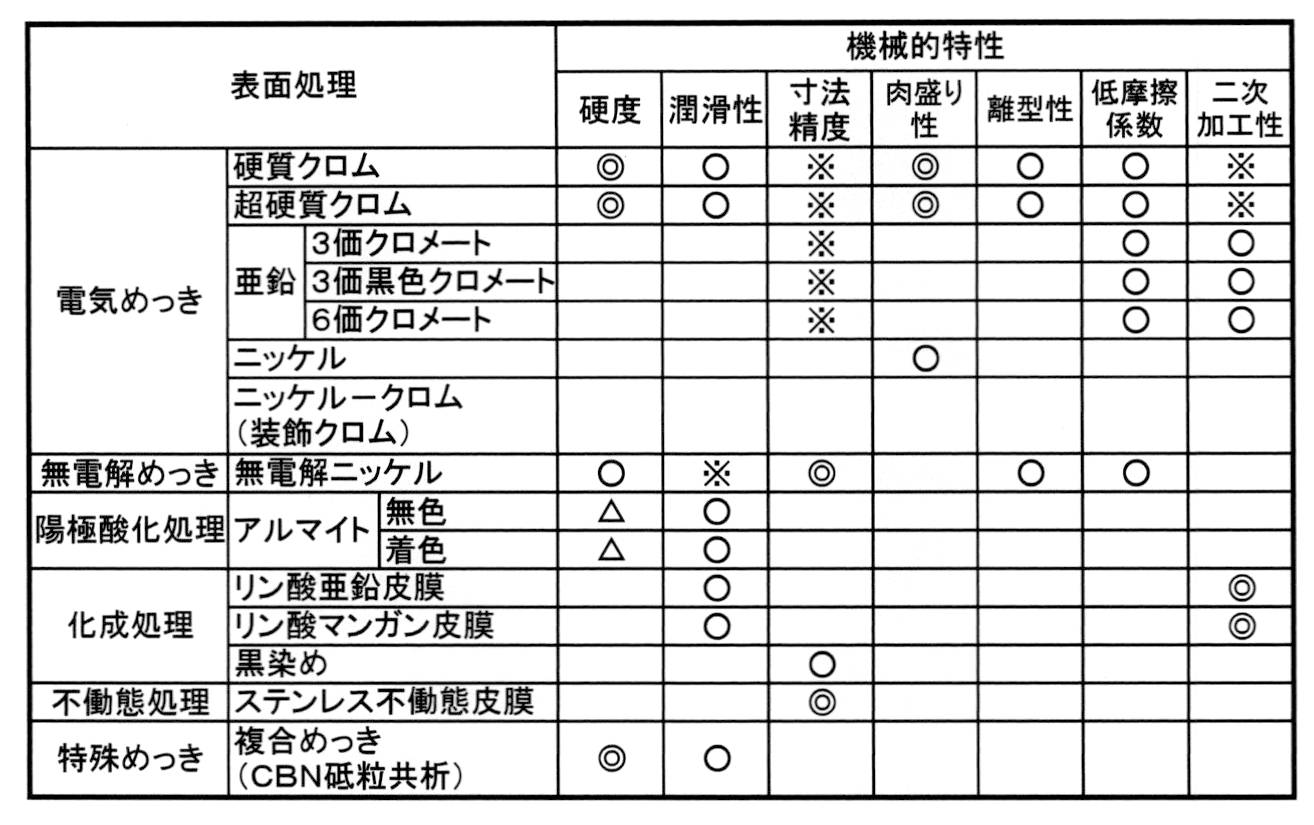

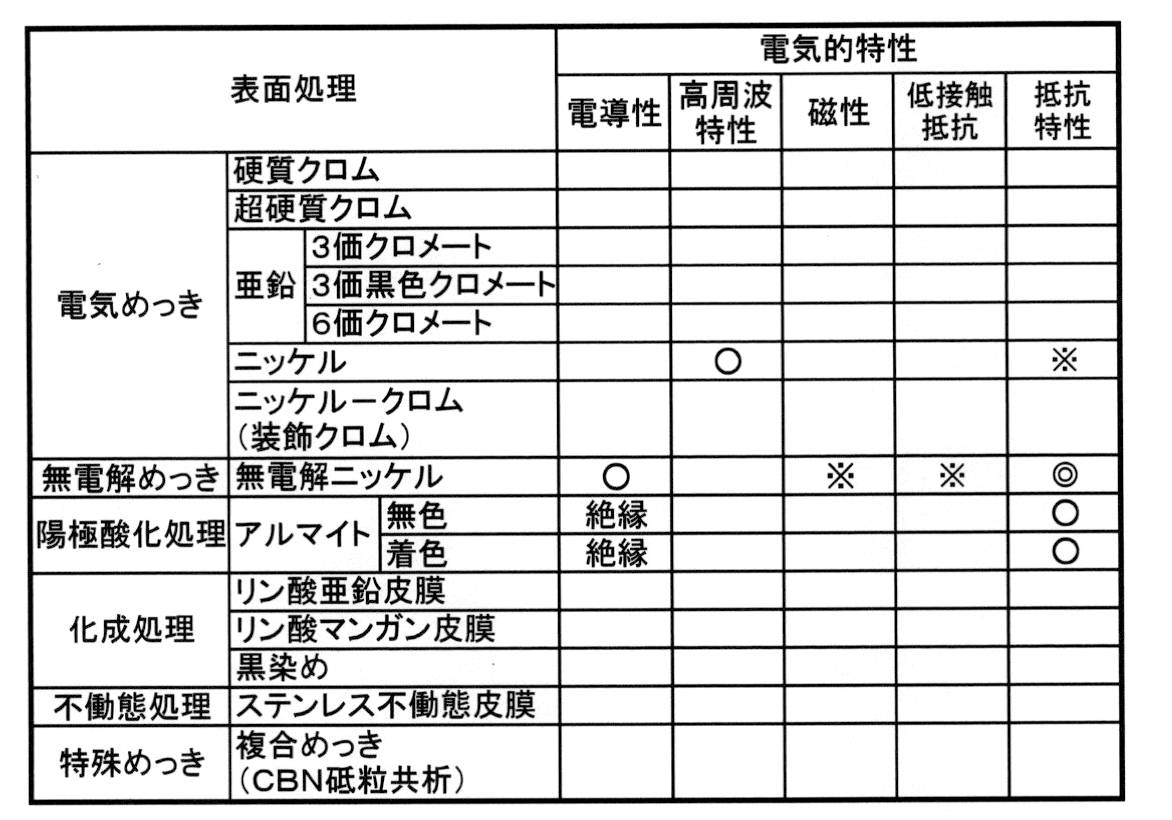

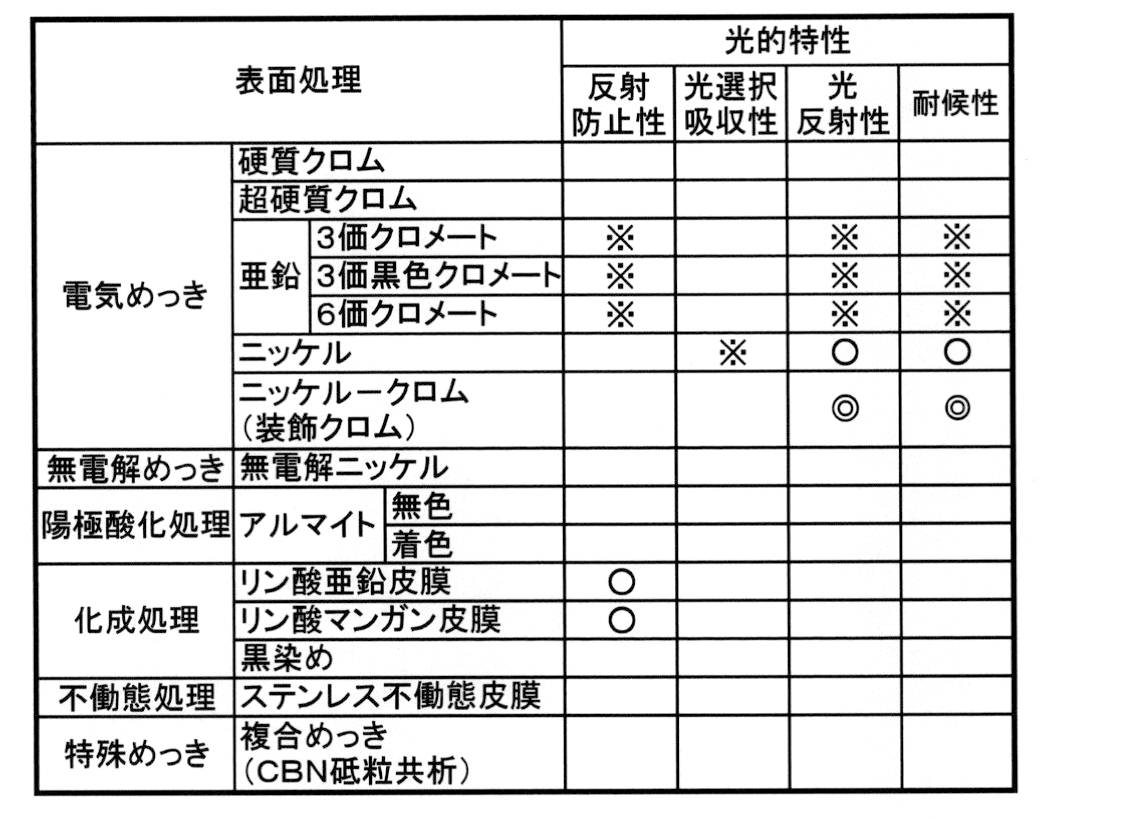

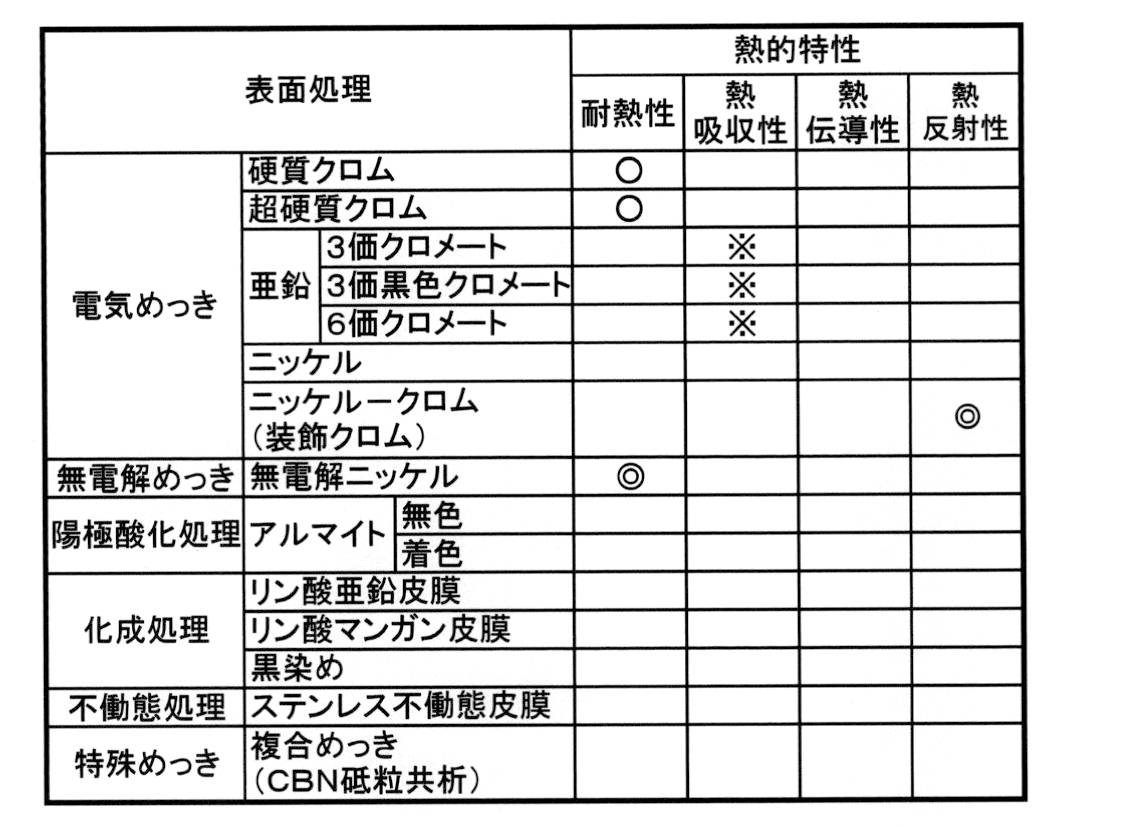

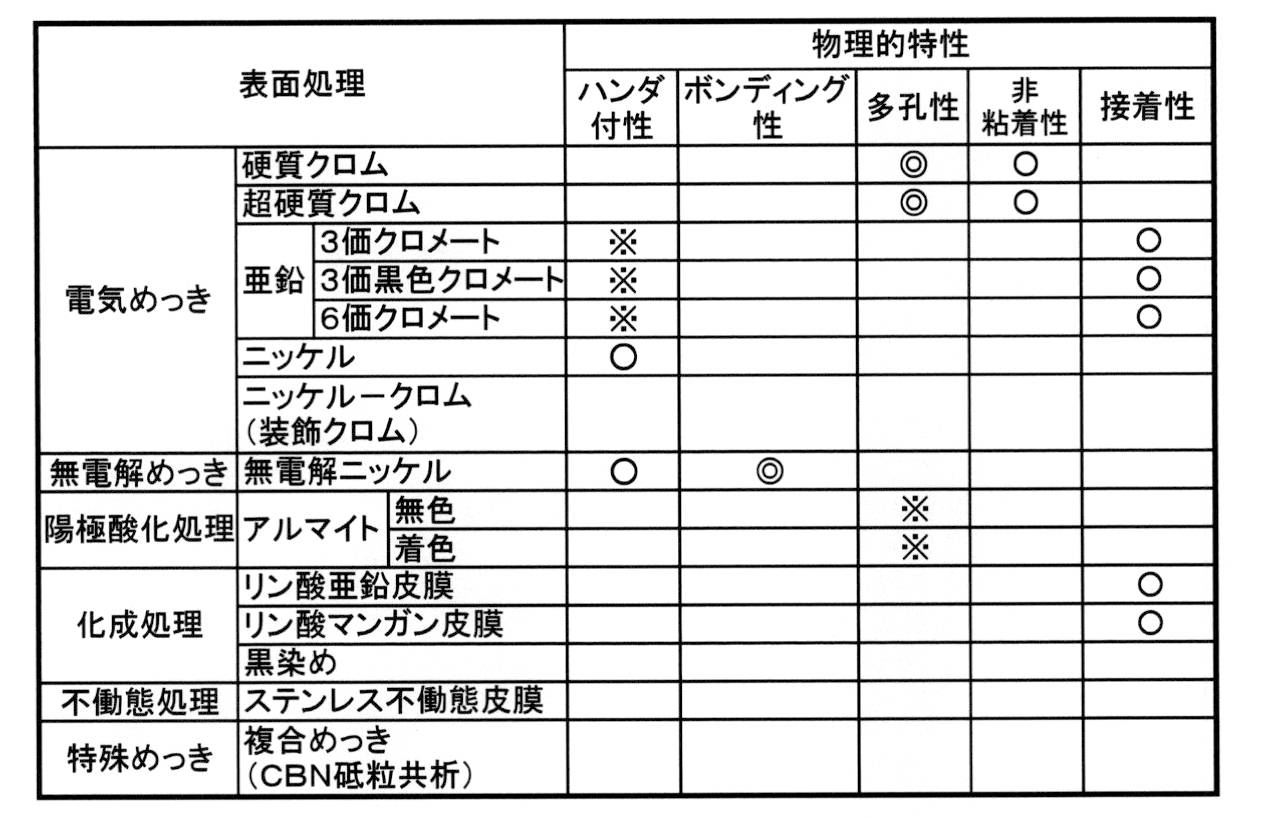

- the improvement of the characteristics is the improvement of wear resistance, corrosion resistance, peeling / releasability, and thermal conductivity

- the surface modification treatment is a chemical treatment such as plating or a physical treatment such as blasting. including. Examples of specific characteristics and surface modification treatment are shown in Tables 1 to 6. As a result, the surface characteristics of the drum body 32 of the drum dryer 30 and the drum body 37 of the drum dryer 35 are improved, and the usability and durability of the device can be improved.

- ⁇ indicates that it can be applied as a surface treatment regardless of the conditions of the extruded material or the apparatus. Further, in Tables 1 to 6, ⁇ indicates that it can be applied as a surface treatment if either the extruded material or the conditions of the apparatus are met. Further, in Tables 1 to 6, ⁇ indicates that it can be applied as a surface treatment if both the conditions of the extruded material and the apparatus are met.

- the main drum is subjected to surface modification treatment. Therefore, the characteristics of the surface of the main drum can be improved.

- the surface modification treatment may be applied to the sub drum, not limited to the main drum.

- FIG. 18 is a side view showing a reconstructed tobacco sheet manufacturing apparatus according to the thirteenth embodiment of the present invention.

- the reconstructed tobacco sheet manufacturing apparatus 100F includes a hot air blower (auxiliary drying apparatus) 80 in addition to the reconstructed tobacco sheet manufacturing apparatus 100 shown in FIG. Since other configurations are the same as those of the first embodiment described above, the description thereof will be omitted.

- the hot air blower 80 is arranged on the drying path of the drum dryer 30 so as to face the drum main body 32 of the drum dryer 30.

- the hot air blower 80 sends hot air to dry the reconstructed tobacco sheet 1 discharged onto the drum body 32 from the discharge port 26 of the die 20 from the surface side of the reconstructed tobacco sheet 1.

- the surface of the reconstructed tobacco sheet 1 is a surface that is not in contact with the drum body 32 of the reconstructed tobacco sheet 1.

- the hot air blower 80 is configured so that the drying capacity can be adjusted by unique parameters such as air volume, output, and hot air temperature. Further, the hot air temperature can be set to a temperature equal to or higher than normal temperature.

- the drying capacity of the reconstructed tobacco sheet manufacturing apparatus 100F can be improved. Therefore, with a simple structure, it is possible to cope with a reconstituted tobacco raw material having a large amount of water. Further, by using the hot air blower 80, both sides of the reconstructed tobacco sheet 1 can be dried at the same time.

- an auxiliary drying device is further provided, which is arranged to face the main drum and dries the reconstituted tobacco raw material discharged from the die. Therefore, the drying capacity of the reconstructed tobacco sheet manufacturing apparatus can be improved.

- the auxiliary drying device is a hot air blower, but the auxiliary drying device is not limited to this, and the auxiliary drying device may be an IR heater. Further, instead of the auxiliary drying device, a cooling device that sends cold air to the reconstructed tobacco sheet 1 may be provided.

- FIG. 19 is a side view showing a reconstructed tobacco sheet manufacturing apparatus according to the 14th embodiment of the present invention.

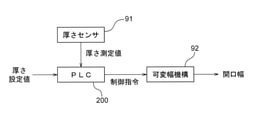

- FIG. 20 is a block diagram showing an opening width control in the reconstructed tobacco sheet manufacturing apparatus according to the 14th embodiment of the present invention.

- the reconstructed tobacco sheet manufacturing apparatus 100G includes a thickness detection sensor (state detection unit) 91 and a PLC (control unit) 200 in addition to the reconstructed tobacco sheet manufacturing apparatus 100 shown in FIG. To be equipped.

- the die 20 of the reconstructed tobacco sheet manufacturing apparatus 100G has a variable width mechanism 92 that can change the opening width of the discharge port 26 by using a motor as an actuator as shown in the fifth embodiment described above. Since other configurations are the same as those of the first embodiment described above, the description thereof will be omitted.

- the thickness detection sensor 91 is provided in the vicinity of the discharge port 26.

- the thickness detection sensor 91 detects the thickness of the reconstructed tobacco sheet 1 ejected from the die 20 in a non-contact manner using X-rays, a laser, ultrasonic waves, or the like, and as a thickness measurement value, a PLC (programmable logical controller). ) Output to 200.

- the PLC 200 may be built in the reconstructed tobacco sheet manufacturing apparatus 100G, or may be provided at a distance.

- the difference between the thickness setting value and the thickness measurement value is based on the thickness setting value which is the desired thickness of the reconstructed tobacco sheet 1 and the thickness measurement value from the thickness detection sensor 91.

- a control command is output to the variable width mechanism 92 so that it becomes zero, and the motor is controlled. As a result, the opening width of the discharge port 26 is changed, and the thickness of the reconstructed tobacco sheet 1 discharged from the die 20 changes.

- the sheet When the reconstructed tobacco sheet 1 is discharged from the die 20, the sheet may expand due to pressure release, and the thickness of the reconstructed tobacco sheet 1 may not match the opening width of the discharge port 26. Therefore, the thickness of the reconstructed tobacco sheet 1 can be adjusted to a desired thickness by feedback-controlling the opening width of the discharge port 26 with respect to the uncontrollable element of pressure release.

- the die has a variable width mechanism capable of changing the width direction length of the discharge port as an actuator, and the state detection unit is a reconstructed cigarette discharged from the die.

- the thickness of the raw material is detected, and the control unit controls the variable width mechanism based on the detection result by the state detection unit to change the length of the discharge port in the width direction. Therefore, the thickness of the reconstructed tobacco sheet can be adjusted to a desired thickness.

- FIG. 21 is a side view showing a reconstructed tobacco sheet manufacturing apparatus according to the fifteenth embodiment of the present invention.

- FIG. 22 is a block diagram showing discharge rate control in the reconstructed tobacco sheet manufacturing apparatus according to the fifteenth embodiment of the present invention.

- the reconstructed tobacco sheet manufacturing apparatus 100H includes a flow rate sensor (state detection unit) 93 and a PLC (control unit) 200 in addition to the reconstructed tobacco sheet manufacturing apparatus 100 shown in FIG. ..

- the screw 14 rotatably arranged in the housing 11 of the extruder 10 has a function as an actuator. Since other configurations are the same as those of the first embodiment described above, the description thereof will be omitted.

- the flow rate sensor 93 is provided in the vicinity of the discharge port 26.

- the flow rate sensor 93 detects the flow rate of the reconstructed tobacco sheet 1 discharged from the die 20 in a non-contact manner using a laser or the like, and outputs the flow rate measurement value to the PLC 200.

- the flow rate measurement value is used as a value for estimating the discharge speed of the reconstructed tobacco sheet 1 discharged from the die 20.

- the PLC 200 may be built in the reconstructed tobacco sheet manufacturing apparatus 100H, or may be provided at a distance.

- the PLC 200 is screwed so that the difference between the flow rate set value and the flow rate measured value becomes zero based on the flow rate set value which is the desired flow rate of the reconstructed tobacco sheet 1 and the flow rate measured value from the flow rate sensor 93.

- a control command is output to 14 to control the rotation of the screw 14. As a result, the ejection speed of the reconstructed tobacco sheet 1 ejected from the die 20 changes.

- the discharge speed of the reconstructed tobacco sheet 1 discharged from the die 20 varies to some extent due to the swell of the screw 14. Therefore, by feedback-controlling the discharge speed of the reconstructed tobacco sheet 1, the discharge speed of the reconstructed tobacco sheet 1 discharged from the die 20 can be kept within a certain range. Further, by keeping the discharge speed of the reconstructed tobacco sheet 1 constant, it is possible to prevent the reconstructed tobacco sheet 1 from dubbing on the drum dryer 30 and to prevent the reconstructed tobacco sheet 1 from being torn off due to an increase in tension. Can be done. Further, by keeping the discharge speed of the reconstructed tobacco sheet 1 constant, it is possible to suppress the variation in the thickness of the sheet due to the pressure release and stabilize the quality of the reconstructed tobacco sheet 1.

- an extruder for pumping the reconstituted tobacco raw material to the die is further provided, and the extruder has a screw rotatably arranged in the housing as an actuator.

- the state detection unit detects at least one of the flow rate and the discharge pressure of the reconstituted tobacco raw material discharged from the die, and the control unit controls the rotation of the screw based on the detection result by the state detection unit and discharges from the die.

- the discharge rate of the reconstituted tobacco raw material is changed. Therefore, the discharge speed of the reconstructed tobacco sheet discharged from the die can be kept constant.

- the discharge pressure of the reconstructed tobacco sheet 1 discharged from the die 20 is applied to the vicinity of the discharge port 26 or the inside of the die 20.

- a discharge pressure sensor for detection may be provided.

- the discharge pressure detected by the discharge pressure sensor can be used as a value for estimating the discharge speed of the reconstructed tobacco sheet 1 discharged from the die 20.

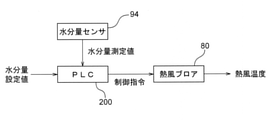

- FIG. 23 is a side view showing a reconstructed tobacco sheet manufacturing apparatus according to the 16th embodiment of the present invention.

- FIG. 24 is a block diagram showing hot air temperature control in the reconstructed tobacco sheet manufacturing apparatus according to the 16th embodiment of the present invention.

- the reconstructed tobacco sheet manufacturing apparatus 100I includes a water content sensor (state detection unit) 94 and a PLC (control unit) 200 in addition to the reconstructed tobacco sheet manufacturing apparatus 100 shown in FIG. Be prepared. Further, the reconstructed tobacco sheet manufacturing apparatus 100I has the hot air blower (auxiliary drying apparatus) 80 shown in the thirteenth embodiment described above as an actuator. Since other configurations are the same as those of the first embodiment described above, the description thereof will be omitted.

- the water content sensor 94 is provided after the scraper 40.

- the water content sensor 94 detects the water content of the reconstructed tobacco sheet 1 peeled off by the scraper 40 in a non-contact manner using infrared rays, microwaves, or the like, and outputs it to the PLC 200 as a water content measurement value.

- the hot air blower 80 is arranged on the drying path of the drum dryer 30 so as to face the drum main body 32 of the drum dryer 30.

- the PLC 200 may be built in the reconstructed tobacco sheet manufacturing apparatus 100I, or may be provided at a distance.

- the difference between the water content setting value and the water content measurement value is zero based on the water content setting value which is the desired water content of the reconstructed tobacco sheet 1 and the water content measurement value from the water content sensor 94.

- a control command is output to the hot air blower 80 to control the temperature of the hot air sent from the hot air blower 80.

- the water content of the reconstructed tobacco sheet 1 dried by the drum dryer 30 and the hot air blower 80 changes.

- the water content of the reconstructed tobacco sheet 1 dried by the drum dryer 30 and the hot air blower 80 varies depending on the environment, the season, and the like. Therefore, by feedback-controlling the water content of the reconstructed tobacco sheet 1, the water content of the reconstructed tobacco sheet 1 dried by the drum dryer 30 and the hot air blower 80 can be kept within a certain range. As a result, the quality of the reconstructed tobacco sheet 1 can be stabilized. Further, since the hot air blower 80 has higher responsiveness and is easier to control than the drum dryer 30, the water content of the reconstructed tobacco sheet 1 can be controlled in detail. Further, since the water content of the reconstructed tobacco sheet 1 can be automatically controlled, it is possible to eliminate the need for constant monitoring by the operator.

- the reconstructed tobacco raw material discharged from the die is dried and transported, and the reconstructed tobacco raw material disposed facing the drum and discharged from the die is dried.

- the state detection unit detects the water content of the reconstituted tobacco raw material dried by the drum and the auxiliary drying device, and the control unit assists based on the detection result by the state detection unit.

- the drying device is controlled to change the moisture content of the reconstituted tobacco raw material dried by the drum and the auxiliary drying device. Therefore, the water content of the reconstructed tobacco sheet dried by the drum and the auxiliary drying device can be kept within a certain range.

- the reconstructed tobacco sheet manufacturing apparatus 100G according to the 14th embodiment, the reconstructed tobacco sheet manufacturing apparatus 100H according to the 15th embodiment, and the reconstructed tobacco sheet manufacturing apparatus 100I according to the 16th embodiment are used. It may be combined arbitrarily.

- FIG. 25 is a side view showing a reconstructed tobacco sheet manufacturing apparatus according to the 17th embodiment of the present invention.

- the reconstructed tobacco sheet manufacturing apparatus 100J includes an addition mechanism 95 in addition to the reconstructed tobacco sheet manufacturing apparatus 100 shown in FIG. Since other configurations are the same as those of the first embodiment described above, the description thereof will be omitted.

- the addition mechanism 95 is provided in the vicinity of the discharge port 26, and a powdery or liquid fragrance is added to the reconstructed tobacco sheet 1 discharged from the die 20 by spraying.

- the installation position of the addition mechanism is not limited to the vicinity of the discharge port 26, and the addition mechanism may be provided on the drying path of the drum dryer 30.

- the reconstructed tobacco sheet 1 manufactured by the present invention has a smooth surface due to the pressure load on the die 20 and the shrinkage during drying on the drum dryer 30, so that the liquid permeability is low. Therefore, the fixability of the additive can be improved by adding the fragrance before or during the drying of the reconstructed tobacco sheet 1. Further, by providing the addition mechanism 95 in the reconstructed tobacco sheet manufacturing apparatus 100J, the step of adding the fragrance in the subsequent step becomes unnecessary.

- the fixing property of the additive can be improved by further providing an addition mechanism for adding the powdery or liquid fragrance on the downstream side of the die 20. ..

- FIG. 26 is a side view showing a reconstructed tobacco sheet manufacturing apparatus according to the eighteenth embodiment of the present invention.

- the reconstructed tobacco sheet manufacturing apparatus 100K includes a buffer mechanism 55 in addition to the reconstructed tobacco sheet manufacturing apparatus 100 shown in FIG. Since other configurations are the same as those of the first embodiment described above, the description thereof will be omitted.

- the buffer mechanism 55 is provided between the discharge port 26 and the drum dryer 30, and winds up the reconstructed tobacco sheet 1 discharged from the die 20 and temporarily holds it.

- the buffer mechanism 55 is suitable for a reconstituted tobacco raw material containing a small amount of water. Since the reconstructed tobacco sheet 1 before being dried by the drum dryer 30 has low strength, the structure of the buffer mechanism 55 is, for example, a fixed roller 56 and a movable roller 57 that can be moved according to the tension of the reconstructed tobacco sheet 1. Those having and are suitable.

- the buffer mechanism 55 moves the movable roller 57 so that the tension of the reconstructed tobacco sheet 1 becomes constant.

- the buffer mechanism 55 By providing the buffer mechanism 55, it corresponds to the case where the discharge speed of the reconstructed tobacco sheet 1 discharged from the die 20 and the rotation speed of the drum body 32 cannot be synchronized due to the fluctuation of the discharge amount from the die 20 or the like. can do. Specifically, by feeding out the reconstructed tobacco sheet 1 held in the buffer mechanism 55 or temporarily holding the reconstructed tobacco sheet 1 in the buffer mechanism 55, the discharge speed of the reconstructed tobacco sheet 1 can be determined. The rotation speed of the drum body 32 can be relatively synchronized. Further, even when the device upstream or downstream of the buffer mechanism 55 causes a chocolate stop, by using the buffer mechanism 55, it is possible to prevent the entire reconstructed tobacco sheet manufacturing device 100K from stopping. ..

- the reconstructed tobacco is further provided with the buffer mechanism 55 for temporarily holding the reconstructed tobacco sheet 1 discharged from the die 20 on the downstream side of the die 20. It is possible to deal with the case where the discharge speed of the sheet 1 and the rotation speed of the drum main body 32 cannot be synchronized.

Abstract

This device for manufacturing a reconstituted tobacco sheet comprises: a die for discharging a reconstituted tobacco ingredient; and an extruder for force-feeding the reconstituted tobacco ingredient to the die by rotation of a screw provided in the interior so as to be capable of rotation. The die has: a housing; a feed port that is formed in the housing and to which the reconstituted tobacco ingredient is fed; and a discharge port that is formed on one side surface of the housing and that discharges the reconstituted tobacco ingredient.

Description

本発明は、再構成たばこシートの製造装置および製造方法に関する。

The present invention relates to a reconstructed tobacco sheet manufacturing apparatus and a manufacturing method.

従来、再構成たばこシートの製造方法として、圧延法、キャスト(スラリー)法、抄造法が知られている。これらの製造方法は、再構成たばこ原料に含まれる水分量に応じて選択される。また、これらの製造方法のそれぞれは、互いに異なる再構成たばこシートの製造装置によって実現される。

Conventionally, a rolling method, a cast (slurry) method, and a papermaking method are known as a method for manufacturing a reconstructed tobacco sheet. These production methods are selected according to the amount of water contained in the reconstituted tobacco raw material. In addition, each of these manufacturing methods is realized by different reconstructed tobacco sheet manufacturing devices.

圧延法は、特に50体積%以下の水分を含む再構成たばこ原料に適することが知られている。圧延法において、再構成たばこ原料の混練物は、回転ローラで圧延成形され、厚さが整えられた後、別途設けられた乾燥機で乾燥される。

The rolling method is known to be particularly suitable for reconstituted tobacco raw materials containing 50% by volume or less of water. In the rolling method, the kneaded product of the reconstituted tobacco raw material is rolled and molded by a rotary roller, the thickness is adjusted, and then the kneaded product is dried by a dryer provided separately.

キャスト(スラリー)法は、特に50体積%以上の水分を含む再構成たばこ原料に適することが知られている。キャスト(スラリー)法において、再構成たばこ原料の流動体は、回転ドラムまたはベルトコンベア上に連続的に展延され、ブレードと称される部材で所望の厚さに均された後、回転ドラムまたはベルトコンベアから剥離され、別途設けられた乾燥機で乾燥される(例えば、特許文献1参照)。

The cast (slurry) method is known to be particularly suitable for reconstituted tobacco raw materials containing 50% by volume or more of water. In the cast (slurry) method, the fluid of the reconstituted tobacco raw material is continuously spread on a rotary drum or belt conveyor, leveled to a desired thickness with a member called a blade, and then the rotary drum or It is peeled off from the belt conveyor and dried by a separately provided dryer (see, for example, Patent Document 1).

抄造法は、特に80体積%以上の水分を含む再構成たばこ原料に適することが知られている。抄造法において、再構成たばこ原料の流動体は、液体透過性のベルトコンベア上に連続的に展延され、圧搾ローラで水分が除去されかつ所望の厚さにされた後、別途設けられた乾燥機で乾燥される。

The papermaking method is known to be particularly suitable for reconstituted tobacco raw materials containing 80% by volume or more of water. In the papermaking method, the fluid of the reconstituted tobacco raw material is continuously spread on a liquid permeable belt conveyor, and after the water is removed by a squeezing roller and the desired thickness is obtained, a separately provided drying is performed. It is dried by the machine.

本発明の目的は、再構成たばこ原料に含まれる水分量によらず、簡素な製造工程で、均一な厚さの再構成たばこシートを得ることができる再構成たばこシートの製造装置および製造方法を提供することである。

An object of the present invention is to provide a reconstructed tobacco sheet manufacturing apparatus and a manufacturing method capable of obtaining a reconstructed tobacco sheet having a uniform thickness by a simple manufacturing process regardless of the amount of water contained in the reconstructed tobacco raw material. To provide.

本発明の第1形態によれば、再構成たばこシートの製造装置が提供される。この再構成たばこシートの製造装置は、再構成たばこ原料を吐出するダイと、内部に回転可能に配設されたスクリューの回転により、ダイに再構成たばこ原料を圧送する押出機と、を備え、ダイは、ハウジングと、ハウジングに形成され、再構成たばこ原料が供給される供給口と、ハウジングの一側面に形成され、再構成たばこ原料を吐出する吐出口と、を有する。これによれば、再構成たばこ原料に含まれる水分量によらず、簡素な製造工程で、均一な厚さの再構成たばこシートを得ることができる。

According to the first aspect of the present invention, a reconstructed tobacco sheet manufacturing apparatus is provided. This reconstructed tobacco sheet manufacturing apparatus includes a die for discharging the reconstructed tobacco raw material and an extruder for pumping the reconstructed tobacco raw material to the die by rotating a screw rotatably arranged inside. The die has a housing, a supply port formed in the housing and supplied with the reconstituted tobacco raw material, and a discharge port formed on one side of the housing to discharge the reconstituted tobacco raw material. According to this, it is possible to obtain a reconstructed tobacco sheet having a uniform thickness by a simple manufacturing process regardless of the amount of water contained in the reconstituted tobacco raw material.

本発明の第2形態によれば、第1形態において、押出機は、互いに平行に配設され、互いに反対方向に回転する一対のスクリューを有する二軸押出機である。これによれば、再構成たばこ原料の粘性が非常に高い場合であっても、効率的に混練することができる。また、これによれば、再構成たばこ原料押し出し時のシート成形性を高めることができる。

According to the second embodiment of the present invention, in the first embodiment, the extruder is a twin-screw extruder having a pair of screws arranged in parallel with each other and rotating in opposite directions. According to this, even when the viscosity of the reconstituted tobacco raw material is very high, it is possible to knead efficiently. Further, according to this, it is possible to improve the sheet formability at the time of extruding the reconstructed tobacco raw material.

本発明の第3形態によれば、第1形態または第2形態において、押出機に供給される再構成たばこ原料を脱気する脱気機構をさらに備えている。これによれば、密度が高く均質で、強度の高い再構成たばこシートを得ることができる。

According to the third embodiment of the present invention, the first or second embodiment further includes a degassing mechanism for degassing the reconstituted tobacco raw material supplied to the extruder. According to this, it is possible to obtain a reconstructed tobacco sheet having high density, homogeneity, and high strength.

本発明の第4形態によれば、再構成たばこシートの製造方法が提供される。この再構成たばこシートの製造方法は、押出機に設けられたスクリューの回転により、再構成たばこ原料をダイの供給口に圧送する工程と、ダイの吐出口から再構成たばこ原料をシート状に成形して吐出する工程と、を有する。これによれば、再構成たばこ原料に含まれる水分量によらず、簡素な製造工程で、均一な厚さを有し、かつ裁断された再構成たばこシートを得ることができる。

According to the fourth aspect of the present invention, a method for producing a reconstructed tobacco sheet is provided. The method for manufacturing this reconstructed tobacco sheet is a process of pumping the reconstructed tobacco raw material to the supply port of the die by rotating a screw provided in the extruder, and molding the reconstructed tobacco raw material into a sheet from the discharge port of the die. And discharge. According to this, regardless of the amount of water contained in the reconstituted tobacco raw material, it is possible to obtain a reconstituted tobacco sheet having a uniform thickness and being cut by a simple manufacturing process.

以下、本発明による再構成たばこシートの製造装置および製造方法について図面を用いて説明するが、各図において同一、または相当する部分については、同一符号を付して説明する。

Hereinafter, the reconstructed tobacco sheet manufacturing apparatus and manufacturing method according to the present invention will be described with reference to the drawings, but the same or corresponding parts in the drawings will be described with the same reference numerals.

第1実施形態:

図1は、本発明の第1実施形態に係る再構成たばこシートの製造装置を示す側面図である。図1において、再構成たばこシートの製造装置100は、押出機10、ダイ20、ドラムドライヤ(主ドラム)30、スクレッパ40およびローラ51、52を備える。ドラムドライヤ30は、軸31およびドラム本体32を有する。 First Embodiment:

FIG. 1 is a side view showing a reconstructed tobacco sheet manufacturing apparatus according to the first embodiment of the present invention. In FIG. 1, the reconstructed tobaccosheet manufacturing apparatus 100 includes an extruder 10, a die 20, a drum dryer (main drum) 30, a scraper 40, and rollers 51 and 52. The drum dryer 30 has a shaft 31 and a drum body 32.

図1は、本発明の第1実施形態に係る再構成たばこシートの製造装置を示す側面図である。図1において、再構成たばこシートの製造装置100は、押出機10、ダイ20、ドラムドライヤ(主ドラム)30、スクレッパ40およびローラ51、52を備える。ドラムドライヤ30は、軸31およびドラム本体32を有する。 First Embodiment:

FIG. 1 is a side view showing a reconstructed tobacco sheet manufacturing apparatus according to the first embodiment of the present invention. In FIG. 1, the reconstructed tobacco

押出機10は、図示しないタンク等から供給される再構成たばこ原料を、ダイ20に圧送する。ダイ20は、押出機10から供給される再構成たばこ原料を吐出し、これにより、再構成たばこ原料が再構成たばこシート1としてドラムドライヤ30のドラム本体32上に成形される。ドラムドライヤ30は、ドラム本体32上に成形された再構成たばこシート1を乾燥させるとともに搬送する。スクレッパ40は、ドラムドライヤ30で乾燥された再構成たばこシート1を、ドラム本体32から剥離する。ローラ51、52は、スクレッパ40で剥離された再構成たばこシート1の搬送を案内する。

The extruder 10 pumps the reconstituted tobacco raw material supplied from a tank or the like (not shown) to the die 20. The die 20 discharges the reconstituted tobacco raw material supplied from the extruder 10, whereby the reconstituted tobacco raw material is formed on the drum body 32 of the drum dryer 30 as the reconstructed tobacco sheet 1. The drum dryer 30 dries and conveys the reconstructed tobacco sheet 1 formed on the drum main body 32. The scraper 40 peels the reconstructed tobacco sheet 1 dried by the drum dryer 30 from the drum body 32. The rollers 51 and 52 guide the transport of the reconstructed tobacco sheet 1 peeled off by the scraper 40.

ここで、再構成たばこ原料とは、多糖類(デンプンやデキストリン等)から選択される少なくとも1つの物質と、任意の液体の媒体として水またはアルコール(エタノールやプロピレングリコール等)または自ら選択される少なくとも1つの物質と、たばこ植物の細片または細粒とを含む混練物である。なお、再構成たばこ原料は、上記のものに限定されず、他の物質を含んでいてもよい。

Here, the reconstituted tobacco raw material is at least one substance selected from polysaccharides (starch, dextrin, etc.) and water or alcohol (ethanol, propylene glycol, etc.) or at least self-selected as a medium of any liquid. A kneaded product containing one substance and strips or granules of tobacco plant. The reconstituted tobacco raw material is not limited to the above, and may contain other substances.

図2は、本発明の第1実施形態に係る再構成たばこシートの製造装置の押出機を示す構成図である。また、図3は、図2に示した矢視III-IIIにおける断面図である。図2、3において、押出機10は、ハウジング11、ハウジング11の一端に形成された供給口12、ハウジング11の他端に形成された押出口13およびハウジング11内に回転可能に配設されたスクリュー14を有する。

FIG. 2 is a block diagram showing an extruder of the reconstructed tobacco sheet manufacturing apparatus according to the first embodiment of the present invention. Further, FIG. 3 is a cross-sectional view taken along the line III-III shown in FIG. In FIGS. 2 and 3, the extruder 10 is rotatably arranged in the housing 11, the supply port 12 formed at one end of the housing 11, the extrusion port 13 formed at the other end of the housing 11, and the housing 11. It has a screw 14.

タンク等から供給口12を介して押出機10に供給された再構成たばこ原料は、スクリュー14の回転によって混練されながら押出口13に送られ、押出口13からダイ20に圧送される。ここで、スクリュー14の回転速度に応じて、ダイ20から吐出される再構成たばこシート1の吐出速度が決定される。

The reconstituted tobacco raw material supplied from the tank or the like to the extruder 10 via the supply port 12 is sent to the extrusion port 13 while being kneaded by the rotation of the screw 14, and is pressure-fed from the extrusion port 13 to the die 20. Here, the discharge speed of the reconstructed tobacco sheet 1 discharged from the die 20 is determined according to the rotation speed of the screw 14.

図4は、本発明の第1実施形態に係る再構成たばこシートの製造装置のダイを示す断面図である。図5は、図4に示した矢視V-Vにおける断面図である。また、図6は、図4に示したダイを吐出口側から見た側面図である。図4~6において、ダイ20は、第1ブロック21および第2ブロック22からなるハウジング23と、第1ブロック21に形成され、押出機10の押出口13と連通する供給口24、第1ブロック21と第2ブロック22との間に形成され、再構成たばこ原料が貯留されるマニホールド25およびマニホールド25と連通する吐出口26を有する。

FIG. 4 is a cross-sectional view showing a die of a reconstructed tobacco sheet manufacturing apparatus according to the first embodiment of the present invention. FIG. 5 is a cross-sectional view taken along the line VV shown in FIG. Further, FIG. 6 is a side view of the die shown in FIG. 4 as viewed from the discharge port side. In FIGS. 4 to 6, the die 20 is a housing 23 composed of a first block 21 and a second block 22, and a supply port 24 and a first block formed in the first block 21 and communicating with the extrusion port 13 of the extruder 10. It has a manifold 25 formed between the 21 and the second block 22 and in which the reconstituted tobacco raw material is stored, and a discharge port 26 communicating with the manifold 25.

吐出口26は、ハウジング23の一側面にスリット状に形成されている。吐出口26の長手方向に直交する方向を、吐出口26の幅方向とする。また、吐出口26の長手方向長さを開口長さと称し、吐出口26の幅方向長さを開口幅と称する。なお、吐出口26は、孔状であってもよいし、溝状であってもよい。スリット状の吐出口26により、再構成たばこ原料は、再構成たばこ原料に含まれる水分量によらず、ダイ20からの吐出時に、吐出口26の開口幅に応じた均一な厚さに調整され、シート状に成形されて押し出される。

The discharge port 26 is formed in a slit shape on one side surface of the housing 23. The direction orthogonal to the longitudinal direction of the discharge port 26 is defined as the width direction of the discharge port 26. Further, the length in the longitudinal direction of the discharge port 26 is referred to as an opening length, and the length in the width direction of the discharge port 26 is referred to as an opening width. The discharge port 26 may have a hole shape or a groove shape. The slit-shaped discharge port 26 adjusts the reconstituted tobacco raw material to a uniform thickness according to the opening width of the discharge port 26 when discharged from the die 20 regardless of the amount of water contained in the reconstructed tobacco raw material. , Formed into a sheet and extruded.

押出機10から供給口24を介してダイ20に供給された再構成たばこ原料は、マニホールド25を通って吐出口26に送られ、吐出口26から再構成たばこシート1としてドラム本体32上に吐出される。

The reconstituted tobacco raw material supplied from the extruder 10 to the die 20 via the supply port 24 is sent to the discharge port 26 through the manifold 25, and is discharged from the discharge port 26 as the reconstructed tobacco sheet 1 onto the drum body 32. Will be done.

図1に戻って、ドラムドライヤ30は、軸31と軸31を中心として回転するドラム本体32とを有する。ドラム本体32は、例えばドラム本体32内部に送り込まれる蒸気によって再構成たばこシート1を乾燥させる。なお、ドラム本体32は、ヒータ等によって加熱されてもよい。

Returning to FIG. 1, the drum dryer 30 has a shaft 31 and a drum body 32 that rotates about the shaft 31. The drum body 32 dries the reconstructed tobacco sheet 1 by, for example, steam sent into the drum body 32. The drum body 32 may be heated by a heater or the like.

スクレッパ40は、ドラム本体32の回転方向に直交するドラム本体32の幅方向の全長にわたって、ドラム本体32と対向して配置され、先端部がドラム本体32と当接ないし近接するように調整されている。なお、スクレッパ40は、ドラム本体32の回転方向の上流側で吐出された再構成たばこシート1が十分に乾燥されるように、ドラム本体32の回転方向の下流側の端部近傍に配置されている。

The scraper 40 is arranged so as to face the drum main body 32 over the entire length in the width direction of the drum main body 32 orthogonal to the rotation direction of the drum main body 32, and the tip portion thereof is adjusted so as to be in contact with or close to the drum main body 32. There is. The scraper 40 is arranged near the end of the drum body 32 on the downstream side in the rotation direction so that the reconstructed tobacco sheet 1 discharged on the upstream side in the rotation direction of the drum body 32 is sufficiently dried. There is.

ダイ20の吐出口26からドラム本体32上に吐出された再構成たばこシート1は、内部に蒸気が送り込まれるドラム本体32によって乾燥され、乾燥された再構成たばこシート1は、スクレッパ40で剥離されて後段の工程に引き渡される。後段の工程とは、例えば再構成たばこシート1が所望の幅に裁断される工程や、裁断された再構成たばこシートがボビンに巻き取られる工程である。

The reconstructed tobacco sheet 1 discharged onto the drum body 32 from the discharge port 26 of the die 20 is dried by the drum body 32 to which steam is sent into the inside, and the dried reconstructed tobacco sheet 1 is peeled off by the scraper 40. It is handed over to the subsequent process. The subsequent step is, for example, a step of cutting the reconstructed tobacco sheet 1 to a desired width, or a step of winding the cut reconstructed tobacco sheet onto a bobbin.

すなわち、再構成たばこシート1は、押出機10に設けられたスクリュー14の回転により、再構成たばこ原料をダイ20の供給口24に圧送する工程と、ダイ20の吐出口26から再構成たばこ原料をシート状に成形して吐出する工程と、を含む製造方法によって製造される。

That is, the reconstructed tobacco sheet 1 has a step of pumping the reconstructed tobacco raw material to the supply port 24 of the die 20 by rotation of the screw 14 provided in the extruder 10, and the reconstructed tobacco raw material from the discharge port 26 of the die 20. Is manufactured by a manufacturing method including a step of forming a sheet into a sheet and discharging the tobacco.

以上のように、第1実施形態によれば、再構成たばこシートの製造装置は、再構成たばこ原料を吐出するダイと、ダイから吐出された再構成たばこ原料を乾燥させるとともに搬送する主ドラムと、を備え、ダイは、ハウジングと、ハウジングに形成され、再構成たばこ原料が供給される供給口と、ハウジングの一側面に形成され、再構成たばこ原料を吐出する吐出口と、を有する。そのため、再構成たばこ原料に含まれる水分量によらず、簡素な製造工程で、均一な厚さの再構成たばこシートを得ることができる。

As described above, according to the first embodiment, the reconstructed tobacco sheet manufacturing apparatus includes a die for discharging the reconstructed tobacco raw material and a main drum for drying and transporting the reconstructed tobacco raw material discharged from the die. The die comprises a housing, a supply port formed in the housing to supply the reconstituted tobacco material, and a discharge port formed on one side of the housing to discharge the reconstituted tobacco material. Therefore, regardless of the amount of water contained in the reconstituted tobacco raw material, a reconstructed tobacco sheet having a uniform thickness can be obtained by a simple manufacturing process.

第2実施形態:

図7は、本発明の第2実施形態に係る再構成たばこシートの製造装置の押出機を示す断面図である。また、図8は、図7に示した矢視VIII-VIIIにおける断面図である。本発明の第2実施形態に係る再構成たばこシートの製造装置は、図1に示した押出機10に代えて、図7、8に示した押出機10Zを備える。その他の構成は、上述した第1実施形態と同様なので、説明を省略する。 Second embodiment:

FIG. 7 is a cross-sectional view showing an extruder of a reconstructed tobacco sheet manufacturing apparatus according to a second embodiment of the present invention. Further, FIG. 8 is a cross-sectional view taken along the line VIII-VIII shown in FIG. 7. The apparatus for producing a reconstructed tobacco sheet according to the second embodiment of the present invention includes the extruder 10Z shown in FIGS. 7 and 8 in place of theextruder 10 shown in FIG. Since other configurations are the same as those of the first embodiment described above, the description thereof will be omitted.

図7は、本発明の第2実施形態に係る再構成たばこシートの製造装置の押出機を示す断面図である。また、図8は、図7に示した矢視VIII-VIIIにおける断面図である。本発明の第2実施形態に係る再構成たばこシートの製造装置は、図1に示した押出機10に代えて、図7、8に示した押出機10Zを備える。その他の構成は、上述した第1実施形態と同様なので、説明を省略する。 Second embodiment:

FIG. 7 is a cross-sectional view showing an extruder of a reconstructed tobacco sheet manufacturing apparatus according to a second embodiment of the present invention. Further, FIG. 8 is a cross-sectional view taken along the line VIII-VIII shown in FIG. 7. The apparatus for producing a reconstructed tobacco sheet according to the second embodiment of the present invention includes the extruder 10Z shown in FIGS. 7 and 8 in place of the

図7、8において、押出機10Zは、ハウジング11Z、ハウジング11Zの一端に形成された供給口12Z、ハウジング11Zの他端に形成された押出口13Z並びにハウジング11Z内に回転可能に配設された第1スクリュー14Aおよび第2スクリュー14Bを有する二軸押出機である。

In FIGS. 7 and 8, the extruder 10Z is rotatably arranged in the housing 11Z, the supply port 12Z formed at one end of the housing 11Z, the extrusion port 13Z formed at the other end of the housing 11Z, and the housing 11Z. A twin-screw extruder having a first screw 14A and a second screw 14B.

第1スクリュー14Aおよび第2スクリュー14Bは、互いに平行に配設され、互いに反対方向に回転するように構成されている。タンク等から供給口12Zを介して押出機10Zに供給された再構成たばこ原料は、第1スクリュー14Aおよび第2スクリュー14Bの回転によって混練されながら押出口13Zに送られ、押出口13Zからダイ20に圧送される。

The first screw 14A and the second screw 14B are arranged in parallel with each other and are configured to rotate in opposite directions. The reconstituted tobacco raw material supplied from the tank or the like to the extruder 10Z via the supply port 12Z is sent to the extrusion port 13Z while being kneaded by the rotation of the first screw 14A and the second screw 14B, and is sent from the extrusion port 13Z to the die 20. Is pumped to.

ここで、互いに逆方向に回転する第1スクリュー14Aおよび第2スクリュー14Bを用いることで、再構成たばこ原料を掻き込む力が増大し、再構成たばこ原料の粘性が非常に高い場合であっても、効率的に混練することができる。また、互いに逆方向に回転する第1スクリュー14Aおよび第2スクリュー14Bを用いることで、再構成たばこ原料に対する剪断力を増大させることができるので、再構成たばこ原料表面の水分同士の結合を促進し、押し出し時のシート成形性を高めることができる。

Here, by using the first screw 14A and the second screw 14B that rotate in opposite directions, the force for scraping the reconstructed tobacco raw material is increased, and even when the viscosity of the reconstructed tobacco raw material is very high. , Can be kneaded efficiently. Further, by using the first screw 14A and the second screw 14B that rotate in opposite directions, the shearing force for the reconstructed tobacco raw material can be increased, so that the binding of water to each other on the surface of the reconstructed tobacco raw material is promoted. , It is possible to improve the sheet formability at the time of extrusion.

以上のように、第2実施形態によれば、押出機は、互いに平行に配設され、互いに反対方向に回転する一対のスクリューを有する二軸押出機である。そのため、再構成たばこ原料の粘性が非常に高い場合であっても、効率的に混練することができる。また、再構成たばこ原料押し出し時のシート成形性を高めることができる。

As described above, according to the second embodiment, the extruder is a twin-screw extruder having a pair of screws arranged in parallel with each other and rotating in opposite directions. Therefore, even when the viscosity of the reconstituted tobacco raw material is very high, it can be efficiently kneaded. In addition, the sheet formability at the time of extruding the reconstructed tobacco raw material can be improved.

第3実施形態:

図9は、本発明の第3実施形態に係る再構成たばこシートの製造装置を示す側面図である。図9において、再構成たばこシートの製造装置100Lは、図1に示した再構成たばこシートの製造装置100に加えて、押出機10に供給される再構成たばこ原料を脱気する脱気機構2を備える。脱気機構2は、押出機2Aおよび脱気室2Bを有する。その他の構成は、上述した第1実施形態と同様なので、説明を省略する。 Third embodiment:

FIG. 9 is a side view showing a reconstructed tobacco sheet manufacturing apparatus according to a third embodiment of the present invention. In FIG. 9, the reconstructed tobaccosheet manufacturing apparatus 100L has a degassing mechanism 2 for degassing the reconstructed tobacco raw material supplied to the extruder 10 in addition to the reconstructed tobacco sheet manufacturing apparatus 100 shown in FIG. To be equipped. The degassing mechanism 2 has an extruder 2A and a degassing chamber 2B. Since other configurations are the same as those of the first embodiment described above, the description thereof will be omitted.

図9は、本発明の第3実施形態に係る再構成たばこシートの製造装置を示す側面図である。図9において、再構成たばこシートの製造装置100Lは、図1に示した再構成たばこシートの製造装置100に加えて、押出機10に供給される再構成たばこ原料を脱気する脱気機構2を備える。脱気機構2は、押出機2Aおよび脱気室2Bを有する。その他の構成は、上述した第1実施形態と同様なので、説明を省略する。 Third embodiment:

FIG. 9 is a side view showing a reconstructed tobacco sheet manufacturing apparatus according to a third embodiment of the present invention. In FIG. 9, the reconstructed tobacco

押出機2Aは、図1に示した押出機10と同様の構成を有している。押出機2Aは、図示しないタンク等から供給される再構成たばこ原料を、脱気室2Bに圧送する。なお、押出機2Aは、図7、8に示した押出機10Zと同様の構成を有していてもよい。

The extruder 2A has the same configuration as the extruder 10 shown in FIG. The extruder 2A pumps the reconstituted tobacco raw material supplied from a tank or the like (not shown) into the degassing chamber 2B. The extruder 2A may have the same configuration as the extruder 10Z shown in FIGS. 7 and 8.

脱気室2Bは、図示しない真空ポンプ等を用いて、押出機2Aから圧送された再構成たばこ原料を脱気し、押出機10に供給する。なお、脱気室2B内の真空度は、図示しない脱気経路に設けられたバルブを操作することで、調整することができる。

The degassing chamber 2B degass the reconstituted tobacco raw material pressure-fed from the extruder 2A using a vacuum pump or the like (not shown) and supplies it to the extruder 10. The degree of vacuum in the degassing chamber 2B can be adjusted by operating a valve provided in a degassing path (not shown).

ここで、再構成たばこ原料を脱気することで、再構成たばこ原料の空気層の発生、すなわち微小な気泡の発生を抑制することができるので、密度が高く均質で、強度の高い再構成たばこシート1を得ることができる。

Here, by degassing the reconstituted tobacco raw material, it is possible to suppress the generation of an air layer of the reconstructed tobacco raw material, that is, the generation of minute bubbles, so that the reconstructed tobacco has a high density, is homogeneous, and has high strength. Sheet 1 can be obtained.

以上のように、第3実施形態によれば、押出機に供給される再構成たばこ原料を脱気する脱気機構をさらに備えている。そのため、密度が高く均質で、強度の高い再構成たばこシートを得ることができる。なお、押出機2A、脱気室2Bおよび押出機10を一体的に構成し、脱気機能を有する押出機としてもよい。

As described above, according to the third embodiment, the degassing mechanism for degassing the reconstituted tobacco raw material supplied to the extruder is further provided. Therefore, it is possible to obtain a reconstructed tobacco sheet having high density, homogeneity, and high strength. The extruder 2A, the degassing chamber 2B, and the extruder 10 may be integrally configured to form an extruder having a degassing function.

第4実施形態:

図10は、本発明の第4実施形態に係る再構成たばこシートの製造装置を示す平面図である。図10において、再構成たばこシートの製造装置100Aは、図1に示した押出機10およびダイ20に代えて、X個の押出機10A~10XおよびX個のダイ20A~20Xを備える。なお、Xは、2以上であればよい。また、1個の押出機10に、X個のダイ20A~20Xが接続されてもよい。その他の構成は、上述した第1実施形態と同様なので、説明を省略する。 Fourth Embodiment:

FIG. 10 is a plan view showing a reconstructed tobacco sheet manufacturing apparatus according to a fourth embodiment of the present invention. In FIG. 10, the reconstructed tobaccosheet manufacturing apparatus 100A includes X extruders 10A to 10X and X dies 20A to 20X in place of the extruder 10 and die 20 shown in FIG. In addition, X may be 2 or more. Further, X dies 20A to 20X may be connected to one extruder 10. Since other configurations are the same as those of the first embodiment described above, the description thereof will be omitted.

図10は、本発明の第4実施形態に係る再構成たばこシートの製造装置を示す平面図である。図10において、再構成たばこシートの製造装置100Aは、図1に示した押出機10およびダイ20に代えて、X個の押出機10A~10XおよびX個のダイ20A~20Xを備える。なお、Xは、2以上であればよい。また、1個の押出機10に、X個のダイ20A~20Xが接続されてもよい。その他の構成は、上述した第1実施形態と同様なので、説明を省略する。 Fourth Embodiment:

FIG. 10 is a plan view showing a reconstructed tobacco sheet manufacturing apparatus according to a fourth embodiment of the present invention. In FIG. 10, the reconstructed tobacco

押出機10A~10Xは、それぞれダイ20A~20Xと接続される。また、ダイ20A~20Xは、吐出口26の長手方向に沿って配置されている。押出機10A~10Xは、図示しないタンク等から供給される再構成たばこ原料を、それぞれダイ20A~20Xに圧送する。ダイ20A~20Xは、押出機10A~10Xから供給される再構成たばこ原料を、それぞれドラム本体32上に吐出する。

Extruders 10A to 10X are connected to dies 20A to 20X, respectively. Further, the dies 20A to 20X are arranged along the longitudinal direction of the discharge port 26. The extruders 10A to 10X pump the reconstituted tobacco raw materials supplied from a tank or the like (not shown) to the dies 20A to 20X, respectively. The dies 20A to 20X discharge the reconstituted tobacco raw materials supplied from the extruders 10A to 10X onto the drum main body 32, respectively.

ここで、ダイ20A~20Xの吐出口26の開口長さを、上述した後段の工程において再構成たばこシート1が巻き取られるボビンの幅に合わせることにより、上述した後段の工程における、再構成たばこシート1を所望の幅に裁断する工程が不要になる。また、ダイ20A~20Xのそれぞれの開口幅を互いに異なるものにすることで、一台のドラムドライヤ30で複数の厚さの再構成たばこシート1を製造することができる。

Here, by adjusting the opening length of the discharge port 26 of the dies 20A to 20X to the width of the bobbin around which the reconstructed tobacco sheet 1 is wound in the above-mentioned subsequent step, the reconstructed tobacco in the above-mentioned latter step. The step of cutting the sheet 1 to a desired width becomes unnecessary. Further, by making the opening widths of the dies 20A to 20X different from each other, it is possible to manufacture the reconstructed tobacco sheet 1 having a plurality of thicknesses with one drum dryer 30.

また、押出機10A~10Xのそれぞれに供給される再構成たばこ原料の組成を互いに異なるものにすることで、一台のドラムドライヤ30で複数種類の再構成たばこシート1を製造することができる。さらに、押出機10A~10Xおよびダイ20A~20Xの組を選択的に駆動させることにより、再構成たばこシートの製造装置100Aの製造能力を容易に調整することができる。