WO2020013018A1 - Mouthpiece and production method for same - Google Patents

Mouthpiece and production method for same Download PDFInfo

- Publication number

- WO2020013018A1 WO2020013018A1 PCT/JP2019/026197 JP2019026197W WO2020013018A1 WO 2020013018 A1 WO2020013018 A1 WO 2020013018A1 JP 2019026197 W JP2019026197 W JP 2019026197W WO 2020013018 A1 WO2020013018 A1 WO 2020013018A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- mouthpiece

- subject

- state

- producing

- teeth

- Prior art date

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A63—SPORTS; GAMES; AMUSEMENTS

- A63B—APPARATUS FOR PHYSICAL TRAINING, GYMNASTICS, SWIMMING, CLIMBING, OR FENCING; BALL GAMES; TRAINING EQUIPMENT

- A63B71/00—Games or sports accessories not covered in groups A63B1/00 - A63B69/00

- A63B71/08—Body-protectors for players or sportsmen, i.e. body-protecting accessories affording protection of body parts against blows or collisions

Definitions

- the present invention relates to a mouthpiece and a method of manufacturing the mouthpiece.

- mouthpieces of various shapes and materials have been proposed as mouthpieces for sports or medical use.

- a mouthpiece whose main purpose is to protect teeth, intraoral tissues, or perioral tissues is required, and mouthpieces having a certain thickness or strength have been developed (for example, , Patent Document 1).

- mouthpieces have been developed not only to protect teeth and tissues around the mouth, but also to improve performance in sports.

- a mouthpiece that can be clenched in a central occlusal position, based on the hypothesis that if the teeth can clench in a central occlusal position, the maximum muscular strength is improved (Patent Document 1).

- stress hormone is released at a level that may adversely affect performance, for the purpose of suppressing or preventing the completion of clenching, even between clenching upper and lower molars

- a mouthpiece provided with a spacer so as to create a space has also been proposed (Patent Document 2).

- the present invention provides a mouthpiece for improving performance in sports and daily life, and a method for manufacturing the same.

- the muscles of the whole body when using the mouthpiece are manufactured. And improve the balance of the joints, and thus the performance in sports and everyday life.

- the muscles, nervous system, and inter-organ network of the whole body are considered to be interlocked with each other, but if so, an unbalanced state such as occurrence of tension in some muscles and joints has occurred. In some cases, adjustments are made to achieve balance in other muscles and joints.

- the correct position eg, neutral position

- the correct position is also set in other muscles or joints (eg, , Neutral position). Therefore, by using the mouthpiece according to the present invention, the temporomandibular joint is guided to a correct position (neutral position), so that the temporomandibular joint and related muscle groups are calibrated. It is considered that the whole body is calibrated by being fed back to the network or the inter-organ network, and as a result, performance in sports and daily life is improved.

- performance in sports and daily life is considered to be improved as compared with the conventional mouthpiece.

- agility, flexibility, or suppleness can be improved.

- the muscles and joints of the whole body can be maintained in a relaxed state, so that, for example, during sports, the airway is secured and breathing is smooth, and it is hard to be tired.

- symptoms caused by imbalanced muscle tone such as stiff shoulders and migraines are improved.

- FIG. 1 is a flowchart illustrating an example of a process of manufacturing a mouthpiece according to the present invention.

- FIG. 2 is a diagram showing a state in which the subject is standing or standing still on a horizontal plane in the step of checking the cover state.

- FIG. 3 is a diagram showing a state in which the subject has warped his head and upper body backward with respect to the vertical axis with respect to the horizontal plane in the step of checking the cover state.

- FIG. 4 shows the posture of FIG. 3 after the step of maintaining the posture of FIG. 3 and the relaxed state without the upper and lower teeth in contact with the posture of FIG.

- FIG. 3 is a diagram showing a state in which the line of sight is lowered from a horizontal plane while returning the head position to the head position in FIG.

- FIG. 5 is a view showing a state in which the cutting tool covers the dentition to be obtained in a bucco-lingual manner (left side in FIG. 5) and a state in which the tooth row is not covered (right side in FIG. 5).

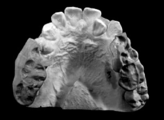

- FIG. 6 is a diagram showing that the lingual end of the molar of the mouthpiece is shaped like a pigeon tail of a chicken.

- FIG. 7 is a diagram showing a molding device used in a mouthpiece molding process and a dental model installed in the molding device.

- FIG. 8 shows, in the mouthpiece molding step, a step of using the cutting tool material obtained in the cutting tool acquisition step to store the position information of the resting position of the covered state confirmed in the step of confirming the covered state in the molding device.

- the step of producing a mouthpiece in the present invention includes (i) an impression taking step, (ii) a step of checking a covered state, and (iii) a mouthpiece forming step (FIG. 1).

- the (i) impression acquisition step in the present invention includes the step of acquiring information on the dentition of the subject's upper or lower jaw (dentition and perioral tissue), and the dentition based on the acquired dentition and the like. And a step of producing a model. Any method may be used as a method for acquiring information such as the dentition, for example, a method of acquiring a dentition using an impression material and a tray, and a method of scanning the inside of the oral cavity to obtain information on the dentition. There is a method of acquiring digital data. In this step, it is desirable to obtain information on the dentition and the like up to the cheek cheek transition.

- the process of producing a model of the dentition and the like based on the acquired information of the dentition and the like may be performed by using any M method.

- a plaster could be poured into the tooth impression to create a model, and digital data of information such as dentition was acquired by scanning the oral cavity and the like.

- a model can be manufactured using a 3D printer or a milling machine.

- the step of checking the state of the lid is as follows: (1) a step in which the subject stands still or standing on a horizontal plane (FIG. 2); (3) a step of relaxing the head backward 30 to 60 °, preferably 45 to 50 ° backward with respect to the vertical axis with respect to the horizontal plane (FIG. 3.

- the upper body may be slightly bent backward with the backward bending.

- the subject relaxes while the upper and lower jaw teeth are not in contact with each other while maintaining the posture of step (3).

- the subject returns the head position to the same head position as in the step (2) after the step (4) while maintaining the posture of the step (3) after the step (4).

- the eyes While lowering the line of sight from the horizontal plane by about 5 ° to 15 ° (Fig. 4 In this process, the eyes may be lowered after returning the head, or the head may be returned after the eyes are lowered, or the eyes may be lowered while lowering the head.

- the posture in this state with the head and eyes lowered is referred to as “resting position”, and the position of the chin in the resting position is referred to as “neutral position.”), And (6) the upper and lower jaws in the resting position of the subject

- the method includes a step of confirming a state of covering of the front teeth (anteria coupling). Note that the state of covering the front teeth confirmed here is the state of covering the front teeth when the position of the jaw is in the neutral position.

- step (1) of the step (ii) of checking the state of the cover in the present invention when standing, it is desirable to open the foot to the width of the shoulder and stand on a horizontal plane.

- the angle of the knee of the subject is set to approximately 90 ° on a chair placed on a horizontal surface, and all the soles are attached, and the seat is shallow and the waist is shallow. It is desirable to apply.

- the upper and lower jaw dental models obtained in the impression taking step are set to the position of the covered state confirmed in the (ii) covered state confirmation step.

- This is the step of molding the mouthpiece.

- this is a step of producing a mouthpiece with a jaw in a neutral position.

- the mouthpiece may be formed using any method.

- a model such as a tooth row obtained in the impression obtaining step can be installed, and the model is (ii) covered.

- the model of the tooth row etc. obtained in the impression taking process is used for the mouthpiece material.

- thermoplastic resin such as ethylene vinyl acetate, polyolefin, etc.

- the mouthpiece to be molded may cover the entire dentition, or may cover a part of the dentition (for example, only the molars).

- the lower surface or the upper surface of the mouthpiece is replaced with a tooth row to which the mouthpiece is attached. It is desirable to make the shape corresponding to the meshing with the tooth row that is paired with the gear.

- a method such as excavation or pressing a model of a tooth row facing a mouthpiece in a heat-softened state to leave an indentation can be appropriately selected.

- press the dental model in the covered state in the resting position and make an indentation see FIG. 8).

- the jaw of the mouthpiece wearer can easily fit in the resting position (neutral position).

- the cutting tool material obtained in the cutting tool obtaining step may be used.

- the bite obtaining step referred to herein means a step of obtaining a bite of the subject in the resting state of the covered state confirmed in (ii) the covered state confirming step. For example, (ii) after the step (6) in the step of checking the cover state, the subject was asked to open the mouth, a bite was placed in the mouth, and then closed and returned to the resting state of the resting state, and relaxed. By waiting the hardening of the cutting tool in the state, the cutting tool can be obtained.

- the tongue base falls down to the pharyngeal side by contacting the tongue with the anterior jig, and eventually the posture is collapsed, tension is generated, and the covered state of the resting position is affected. It is advisable to avoid the use of anterior jigs in order to prevent them from being lost.

- the bite is mainly acquired for the molar part, but may be the canine tooth or the entire dentition. Further, it is desirable that the bite material covers the dentition to be acquired in a near-mesio-lingual manner (see the left side of FIG. 5).

- the dentition to be acquired may be the entire dentition or a part of the dentition (for example, only the molars).

- the target dentition is the dentition (Particularly, the posterior row).

- the bite part of the molar part is put into position.

- the anterior tooth bite may be obtained.

- the bite obtaining step in the present invention may include a step of having the subject wear the bite after the bite is hardened, and confirming whether or not the jaw position is shifted. In this process, the opposing teeth contact each other when clenching because the subject does not feel discomfort left and right or back and forth, does not feel that the bite material is too high (too thick), or that the bite material is too low (too thin). Check if it is done.

- the mouthpiece molding step of the present invention may include a physical condition test step (see FIG. 1).

- a physical condition test step see FIG. 1.

- the physical condition test process the subject tested the flexibility test by bending forward and rotating, the balance test with one leg standing, the center of gravity track, and The difference between when the cutting tool is mounted and when it is not mounted is measured by performing a test, a center of gravity sway displacement test, and the like.

- the subject wears the bite bite so that the bite is attached rather than bitten. However, clenching or clenching may occur naturally when performing a heavy exercise.

- the physical condition test step when no significant difference is observed between the wearing and the non-wearing of the cutting tool, (ii) it is desirable to start over from the step of checking the covered state or the step of obtaining the cutting tool.

- the physical condition test step may be performed using a hardened cutting tool, or may be performed by performing a similar test using a molded mouthpiece.

- the mouthpiece according to the present invention is characterized in that the mouthpiece worn by the mouthpiece wearer at the time of wearing the mouthpiece has a neutral position.

- the lingual side shape of the mouthpiece manufactured according to the present invention takes into consideration the tongue position at the time of occlusion. Further, it is desirable that the mouthpiece has a shape that does not contact the back of the mouth or the pharynx. Specifically, it is desirable to have a shape and thickness that do not unnecessarily contact the tongue, and it is desirable that the lingual end of the molar is in a dovetail shape (see the left side of FIG. 6).

- Example 1 Impression Taking Step The molds of the upper and lower dentitions (including the cheek-to-cheek transition part) of the subject were obtained using an impression material and a tray, respectively. After that, a commercially available plaster is poured into the acquired tooth impression to create a model

- Step of Checking Covered State The subject, who was barefoot, was allowed to stand on a horizontal surface with his / her feet wide about the width of the shoulder and kept still, and the subject's upper and lower jaw teeth were not in contact. Thereafter, the subject was warped backward by about 45 ° with respect to the vertical axis with respect to the horizontal plane while maintaining that state, and while maintaining that posture, the upper jaw and lower jaw were weakened without contact with each other. I let it. Further, the subject was kept in that state for 25 seconds, after which the head position was returned to the vertical position, and the line of sight was lowered by about 10 ° from the horizontal plane (resting position). While maintaining the resting position, the subject confirmed the state of covering of the upper teeth (anterior coupling) of the upper and lower jaws.

- Mouthpiece forming step 2 After the step, the subject is opened while maintaining the resting position, a bite material (FP bite, manufactured by Feed Co., Ltd.) is put in the mouth, and the resting position confirmed in the step 2) The upper and lower jaws were closed so that the anterior teeth were covered (Anteria coupling), and the cutting of the bite material was awaited. The bite of the maxillary dentition was obtained. The bites were collected on the upper and lower jaw molars and canines, and the bite was collected so that the bite covered the dentition buccally and mesio-centrifugally.

- FP bite manufactured by Feed Co., Ltd.

- a flexibility test to measure flexibility in forward bending and rotation and a balance test in a standing state were performed for each of the subjects with and without the mouthpiece, with both the flexibility test and the balance test. , The performance with the mouthpiece attached was higher.

- Example 2 Preparation of Mouthpieces Mouthpieces for runners 1 and 2 as test subjects were prepared in the same manner as in Example 1 1) Impression obtaining step, 2) Cover state checking step, and 3) Mouthpiece molding After the process, each was created.

- Example 2 Running test The runners 1 and 2 wearing the mouthpiece of Example 2 were allowed to stand still at a starting position in a standing state at the starting point. Next, the runner 1 and the runner 2 were allowed to run about 30 m with full power together with a start signal, and travel data of a section (referred to as “target section”) between 20 m from the start point was obtained. In addition, the runner was equipped with a GPS measurement device (OptEye S5 manufactured by Catapult), and the running data was acquired. Here, the average speed (m / min) in the target section and the maximum speed (m / sec) in the target section were acquired as the traveling data.

- a GPS measurement device OEM manufactured by Catapult

- Example 2 The running data obtained in Example 2 and Comparative Example 1 were as shown in Table 1.

- the average speed is improved by 18.6 (m / min) when the mouthpiece is worn (Example 2) compared to when it is not worn (Comparative Example 1), and the maximum speed is 0.2 (m / sec). ) Improved.

- the average speed was improved by 17.7 (m / min) and the maximum speed was 0.3 (m) when the mouthpiece was worn (Example 2) compared to when it was not worn (Comparative Example 1). / Sec) improved.

Landscapes

- Health & Medical Sciences (AREA)

- General Health & Medical Sciences (AREA)

- Physical Education & Sports Medicine (AREA)

- Dental Tools And Instruments Or Auxiliary Dental Instruments (AREA)

Abstract

[Problem] All conventional mouthpieces are based on the assumption of clenching or biting of the mouthpiece. However, clenching hinders agility, flexibility and so on, making it easy to become tired. Furthermore, the act itself of continually clenching leads to fatigue, resulting in a reduction in performance, injury and breakdown. [Solution] As a result of producing a mouthpiece that causes the position of the temporomandibular joint to be at a position (neutral position) that enables a relaxed state in connection with the muscles and joints of the entire body, the balance between the muscles and joints of the entire body is improved when using the mouthpiece, and, furthermore, performance is improved in sports and daily life.

Description

本発明はマウスピース及びその製造方法に関するものである。

The present invention relates to a mouthpiece and a method of manufacturing the mouthpiece.

従来、スポーツ用又は医療用のマウスピースとして、様々な形状や材質のマウスピースが提案されてきた。例えば、スポーツの場面では、歯、口腔内組織、又は口腔周辺組織等を守ることを主たる目的としたマウスピースが求められ、一定以上の厚みや強度をもったマウスピースが開発されてきた(例えば、特許文献1)。

Conventionally, mouthpieces of various shapes and materials have been proposed as mouthpieces for sports or medical use. For example, in the case of sports, a mouthpiece whose main purpose is to protect teeth, intraoral tissues, or perioral tissues is required, and mouthpieces having a certain thickness or strength have been developed (for example, , Patent Document 1).

さらには、歯や口腔周辺組織等を守ることだけを目的とするのでなく、スポーツにおけるパフォーマンス向上をも目的とするマウスピースも開発されてきた。例えば、中心咬合位で歯を食いしばることができれば最大筋力が向上するとの仮説のもとで、中心咬合位で食いしばれるようにしたマウスピースが提案されている(特許文献1)。一方、食いしばりが行われるとパフォーマンスに悪影響を及ぼしうるレベルでストレスホルモンが放出されてしまうとの仮説のもと、食いしばりの完成を抑制ないし妨げる目的で、食いしばり時であっても上下の臼歯間にスペースが生じるようスペーサーを設けたマウスピースも提案されてきた(特許文献2)。

マ ウ ス Furthermore, mouthpieces have been developed not only to protect teeth and tissues around the mouth, but also to improve performance in sports. For example, there has been proposed a mouthpiece that can be clenched in a central occlusal position, based on the hypothesis that if the teeth can clench in a central occlusal position, the maximum muscular strength is improved (Patent Document 1). On the other hand, based on the hypothesis that when clenching is performed, stress hormone is released at a level that may adversely affect performance, for the purpose of suppressing or preventing the completion of clenching, even between clenching upper and lower molars A mouthpiece provided with a spacer so as to create a space has also been proposed (Patent Document 2).

しかしながら、多くのスポーツでは、特定部位の最大筋力が増大したからといって必ずしもパフォーマンスが向上するわけではなく、俊敏性、柔軟性、速さ、しなやかさ、伸びといった要素が損なわれてしまえば、たとえ最大筋力が増大したとしてもパフォーマンスは低下してしまう。この点、歯を食いしばる又は噛みしめるという行為によって、俊敏性、柔軟性、速さ、しなやかさ、伸び等が低下することもあるため、スポーツのパフォーマンスを向上させるためには、歯を食いしばるという行為は避けられるべきであるといえる。他方で、従来の発明のように食いしばりの完成を抑制ないし妨げるために臼歯間にスペーサーを設けた場合、結果としてパフォーマンスの顕著な向上は見られなかった。

However, in many sports, increasing the maximum muscle strength in a specific area does not necessarily improve performance, but if factors such as agility, flexibility, speed, suppleness, and elongation are compromised, Even if maximum muscle strength increases, performance will decrease. In this regard, clenching or biting teeth may reduce agility, flexibility, speed, suppleness, elongation, etc.In order to improve sports performance, the act of clenching teeth is It can be said that it should be avoided. On the other hand, when a spacer is provided between the molars to suppress or prevent the completion of clenching as in the conventional invention, no remarkable improvement in performance has been observed as a result.

本発明は、スポーツや日常生活におけるパフォーマンス向上のためのマウスピース、及びその製造方法を提供するものである。

The present invention provides a mouthpiece for improving performance in sports and daily life, and a method for manufacturing the same.

従来のマウスピースでは、いずれもマウスピースの食いしばりや噛みしめを前提としていた。これに対して、本発明者らは、噛みしめることで、俊敏性や柔軟性等が妨げられ、ひいては疲労をしやすくし、また、そもそも噛みしめ続けること自体が疲労に繋がるため、結果としてパフォーマンスの低下や怪我や故障につながっているとの考察のもと、噛みしめることを目的とするのではなく咬合の中立位を想定したマウスピース及びその製造方法を開発し、本発明を完成させた。

In conventional mouthpieces, it was assumed that the mouthpiece clenched and clenched. On the other hand, the present inventors have found that, by biting, agility and flexibility are hindered, and thus fatigue is easily caused.Also, continuing to bite in the first place leads to fatigue, resulting in a decrease in performance. Based on the consideration that it leads to injury or failure, the present inventors have developed a mouthpiece and a method of manufacturing the mouthpiece, which are not intended to be bitten but intended to be in a neutral position of occlusion, and have completed the present invention.

より具体的には、顎関節の位置が全身の筋肉及び関節と連動した状態でリラックスした状態の位置(中立位)になるようにマウスピースを作製することで、マウスピース使用時の全身の筋肉及び関節のバランスを向上させ、ひいてはスポーツや日常生活におけるパフォーマンスを向上させることを実現した。

More specifically, by creating a mouthpiece such that the position of the temporomandibular joint is in a relaxed position (neutral position) in conjunction with the muscles and joints of the whole body, the muscles of the whole body when using the mouthpiece are manufactured. And improve the balance of the joints, and thus the performance in sports and everyday life.

本発明の作用メカニズムの詳細は明らかではないが、以下のようなものが考えられる。すなわち、全身の筋肉、神経系、及び臓器間ネットワークはそれぞれ連動していると考えられるところ、そうであるならば、一部の筋肉や関節等に緊張が生じるなどのアンバランスな状態が生じた場合には他の筋肉や関節等においてバランスを取ろうと調整が図られる一方で、ある筋肉や関節が正しい位置(例えば、中立位)にある場合には他の筋肉や関節においても正しい位置(例えば、中立位)にあろうと調整が図られるものと考えられる。したがって、本発明によるマウスピースを使用することにより顎関節が正しい位置(中立位)に誘導されることで、顎関節や関連筋群等の較正(キャリブレーション)が行われ、それが中枢神経系や臓器間ネットワーク等にフィードバックされることで、全身の較正(キャリブレーション)が行われ、その結果、スポーツや日常生活におけるパフォーマンスが向上するものと考えられる。

詳細 Although the details of the action mechanism of the present invention are not clear, the following may be considered. That is, the muscles, nervous system, and inter-organ network of the whole body are considered to be interlocked with each other, but if so, an unbalanced state such as occurrence of tension in some muscles and joints has occurred. In some cases, adjustments are made to achieve balance in other muscles and joints. On the other hand, when a certain muscle or joint is in the correct position (eg, neutral position), the correct position is also set in other muscles or joints (eg, , Neutral position). Therefore, by using the mouthpiece according to the present invention, the temporomandibular joint is guided to a correct position (neutral position), so that the temporomandibular joint and related muscle groups are calibrated. It is considered that the whole body is calibrated by being fed back to the network or the inter-organ network, and as a result, performance in sports and daily life is improved.

本発明によるマウスピースによれば、従来のマウスピースと比べ、スポーツや日常生活におけるパフォーマンスが向上するものと考えられる。例えば、俊敏性、柔軟性、又はしなやかさを向上をさせることができる。また、本発明によるマウスピースを使用することにより、全身の筋肉及び関節がリラックスした状態を維持することができ、これにより、例えば、スポーツ時には、気道が確保され呼吸がスムーズとなり、ひいては疲労しにくくなり、日常生活においては、肩こりや偏頭痛等の筋緊張の偏りで起こる症状が改善される。

According to the mouthpiece according to the present invention, performance in sports and daily life is considered to be improved as compared with the conventional mouthpiece. For example, agility, flexibility, or suppleness can be improved. In addition, by using the mouthpiece according to the present invention, the muscles and joints of the whole body can be maintained in a relaxed state, so that, for example, during sports, the airway is secured and breathing is smooth, and it is hard to be tired. In daily life, symptoms caused by imbalanced muscle tone such as stiff shoulders and migraines are improved.

以下、本発明の実施形態を説明する。ただし、以下の実施形態は、発明内容の理解を助けるためのものであり、本発明を限定するものではない。

Hereinafter, embodiments of the present invention will be described. However, the following embodiments are for helping to understand the contents of the invention, and do not limit the present invention.

<マウスピースの作製>

本発明におけるマウスピースの作製工程は、(i)印象採得工程、(ii)被蓋状態の確認工程、及び(iii)マウスピース成形工程を含む(図1)。 <Making a mouthpiece>

The step of producing a mouthpiece in the present invention includes (i) an impression taking step, (ii) a step of checking a covered state, and (iii) a mouthpiece forming step (FIG. 1).

本発明におけるマウスピースの作製工程は、(i)印象採得工程、(ii)被蓋状態の確認工程、及び(iii)マウスピース成形工程を含む(図1)。 <Making a mouthpiece>

The step of producing a mouthpiece in the present invention includes (i) an impression taking step, (ii) a step of checking a covered state, and (iii) a mouthpiece forming step (FIG. 1).

本発明における(i)印象採得工程は、被験者の上顎又は下顎の歯列等(歯列及び口腔周囲組織)の情報を取得する工程、及び採得した歯列等の情報に基づき歯列等の模型を作製する工程を含む。

歯列等の情報を取得する方法としては、任意の方法を用いればよく、例えば、印象材とトレーを使用して歯型を採得する方法や、口腔内をスキャン等することで歯列等情報のデジタルデータを取得する方法がある。この工程では、齦頬移行部まで歯列等の情報を採得することが望ましい。

また、採得した歯列等の情報に基づき歯列等の模型を作製する工程についても、M任意の方法を用いればよく、例えば、歯列等の情報の取得工程において、印象材とトレーを使用して歯型印象を採得した場合には、当該歯型印象に石膏を流し込んで模型を作製することができ、口腔内をスキャン等することで歯列等の情報のデジタルデータを取得した場合には、3Dプリンターやミリングマシンを用いて模型を作製することができる。 The (i) impression acquisition step in the present invention includes the step of acquiring information on the dentition of the subject's upper or lower jaw (dentition and perioral tissue), and the dentition based on the acquired dentition and the like. And a step of producing a model.

Any method may be used as a method for acquiring information such as the dentition, for example, a method of acquiring a dentition using an impression material and a tray, and a method of scanning the inside of the oral cavity to obtain information on the dentition. There is a method of acquiring digital data. In this step, it is desirable to obtain information on the dentition and the like up to the cheek cheek transition.

In addition, the process of producing a model of the dentition and the like based on the acquired information of the dentition and the like may be performed by using any M method. When a tooth impression was obtained by using, a plaster could be poured into the tooth impression to create a model, and digital data of information such as dentition was acquired by scanning the oral cavity and the like. In such a case, a model can be manufactured using a 3D printer or a milling machine.

歯列等の情報を取得する方法としては、任意の方法を用いればよく、例えば、印象材とトレーを使用して歯型を採得する方法や、口腔内をスキャン等することで歯列等情報のデジタルデータを取得する方法がある。この工程では、齦頬移行部まで歯列等の情報を採得することが望ましい。

また、採得した歯列等の情報に基づき歯列等の模型を作製する工程についても、M任意の方法を用いればよく、例えば、歯列等の情報の取得工程において、印象材とトレーを使用して歯型印象を採得した場合には、当該歯型印象に石膏を流し込んで模型を作製することができ、口腔内をスキャン等することで歯列等の情報のデジタルデータを取得した場合には、3Dプリンターやミリングマシンを用いて模型を作製することができる。 The (i) impression acquisition step in the present invention includes the step of acquiring information on the dentition of the subject's upper or lower jaw (dentition and perioral tissue), and the dentition based on the acquired dentition and the like. And a step of producing a model.

Any method may be used as a method for acquiring information such as the dentition, for example, a method of acquiring a dentition using an impression material and a tray, and a method of scanning the inside of the oral cavity to obtain information on the dentition. There is a method of acquiring digital data. In this step, it is desirable to obtain information on the dentition and the like up to the cheek cheek transition.

In addition, the process of producing a model of the dentition and the like based on the acquired information of the dentition and the like may be performed by using any M method. When a tooth impression was obtained by using, a plaster could be poured into the tooth impression to create a model, and digital data of information such as dentition was acquired by scanning the oral cavity and the like. In such a case, a model can be manufactured using a 3D printer or a milling machine.

本発明における(ii)被蓋状態の確認工程は、(1)被験者が水平面上に立位又は座位で静止する工程(図2)、(2)被験者が身体を静止させ上顎と下顎の歯が接触していない状態でリラックスする工程、(3)被験者が、水平面に対する垂直軸に対して頭位を30~60°後方に、好ましくは45~50°後方に反らす工程(図3。頭位を後方に反らすことに伴い、上体もやや後方に反らせてもよい。)、(4)被験者が、工程(3)の姿勢を維持しながら、上顎と下顎の歯が接触していない状態でリラックスした状態を15~30秒維持する工程、(5)被験者が、工程(4)の後に、工程(3)の姿勢を維持しながら、頭位を工程(2)の際と同じ頭位へ戻しながら、目線を水平面から約5°~15°程度下方へ落とす工程(図4。なお、この工程では、頭位を戻した後に目線を下方へ落としても良いし、目線を下方へ落とした後に頭位を戻しても良いし、又は頭位を落としながら目線を下方へ落としても良い。頭位と目線を落としたこの状態の姿勢を「安静位」といい、安静位における顎の位置を「中立位」という。)、及び(6)被験者の安静位における上顎及び下顎の前歯の被蓋状態(アンテリアカップリング)を確認する工程を含む。なお、ここで確認されている前歯の被蓋状態は、顎の位置が中立位にある状態での前歯の被蓋状態ということになる。

In the present invention, (ii) the step of checking the state of the lid is as follows: (1) a step in which the subject stands still or standing on a horizontal plane (FIG. 2); (3) a step of relaxing the head backward 30 to 60 °, preferably 45 to 50 ° backward with respect to the vertical axis with respect to the horizontal plane (FIG. 3. The upper body may be slightly bent backward with the backward bending.), And (4) the subject relaxes while the upper and lower jaw teeth are not in contact with each other while maintaining the posture of step (3). (5) The subject returns the head position to the same head position as in the step (2) after the step (4) while maintaining the posture of the step (3) after the step (4). While lowering the line of sight from the horizontal plane by about 5 ° to 15 ° (Fig. 4 In this process, the eyes may be lowered after returning the head, or the head may be returned after the eyes are lowered, or the eyes may be lowered while lowering the head. The posture in this state with the head and eyes lowered is referred to as “resting position”, and the position of the chin in the resting position is referred to as “neutral position.”), And (6) the upper and lower jaws in the resting position of the subject The method includes a step of confirming a state of covering of the front teeth (anteria coupling). Note that the state of covering the front teeth confirmed here is the state of covering the front teeth when the position of the jaw is in the neutral position.

本発明における(ii)被蓋状態の確認工程のうち工程(1)については、立位の場合は肩幅程度に足を開いて水平面上に起立することが望ましい。他方で、座位とする場合には、水平面上に設置した椅子に、被験者の膝の角度が略90°になるようにし、足裏が全て付いている状態で、かつ、座面に浅く腰をかけるようにすることが望ましい。

(Ii) In the step (1) of the step (ii) of checking the state of the cover in the present invention, when standing, it is desirable to open the foot to the width of the shoulder and stand on a horizontal plane. On the other hand, in the case of the sitting position, the angle of the knee of the subject is set to approximately 90 ° on a chair placed on a horizontal surface, and all the soles are attached, and the seat is shallow and the waist is shallow. It is desirable to apply.

本発明における(iii)マウスピース成形工程は、(i)印象採得工程で取得した上顎及び下顎の歯列模型を、(ii)被蓋状態の確認工程で確認した被蓋状態の位置にしてマウスピースを成形する工程である。言い換えると、顎の状態が中立位でのマウスピースを作製する工程である。本工程では、任意の方法を用いてマウスピースを成形すればよく、例えば、(i)印象採得工程で取得した歯列等の模型を設置でき、かつ、当該模型を(ii)被蓋状態の確認工程で確認した安静位における被蓋状態で固定できる成形器(コンプレッサーを内蔵した成形器が好ましい)で、(i)印象採得工程で取得した歯列等の模型に、マウスピースの素材(例えば、エチレンビニルアセテート、ポリオレフィンなどの熱可塑性樹脂)を合わせ加圧加熱することで、模型の歯列に対応するマウスピースを成形することができる(図7及び図8参照)。成形されるマウスピースは、歯列全体を覆うものでもよいし、歯列の一部(例えば、臼歯列のみ)を覆うものであってもよい。

In the (iii) mouthpiece molding step of the present invention, (i) the upper and lower jaw dental models obtained in the impression taking step are set to the position of the covered state confirmed in the (ii) covered state confirmation step. This is the step of molding the mouthpiece. In other words, this is a step of producing a mouthpiece with a jaw in a neutral position. In this step, the mouthpiece may be formed using any method. For example, (i) a model such as a tooth row obtained in the impression obtaining step can be installed, and the model is (ii) covered. (I) The model of the tooth row etc. obtained in the impression taking process is used for the mouthpiece material. (For example, thermoplastic resin such as ethylene vinyl acetate, polyolefin, etc.) can be combined and heated under pressure to form a mouthpiece corresponding to the dentition of the model (see FIGS. 7 and 8). The mouthpiece to be molded may cover the entire dentition, or may cover a part of the dentition (for example, only the molars).

マウスピースを上顎又は下顎一方のみに装着することを想定したものを作製する場合には、本発明における(iii)マウスピース成形工程では、マウスピースの下面又は上面を、マウスピースを装着する歯列と対となっている歯列との噛み合わせに対応する形状になるようにすることが望ましい。また、このような形状を実現するために、掘削加工したり、加熱軟化した状態のマウスピースに対向する歯列の模型を押し付け圧痕を残したりするなどの方法を、適宜選択することができる。特に、上顎又は下顎一方のみに装着することを想定したものを作製する場合には、安静位における被蓋状態で歯列模型を押し付け圧痕を付けることで(図8参照)、マウスピース使用時に、マウスピース装着者の顎が安静位における位置(中立位)に収まりやすくなる。

In the case where a mouthpiece is assumed to be attached to only the upper jaw or the lower jaw only, in the (iii) mouthpiece molding step of the present invention, the lower surface or the upper surface of the mouthpiece is replaced with a tooth row to which the mouthpiece is attached. It is desirable to make the shape corresponding to the meshing with the tooth row that is paired with the gear. In addition, in order to realize such a shape, a method such as excavation or pressing a model of a tooth row facing a mouthpiece in a heat-softened state to leave an indentation can be appropriately selected. In particular, when manufacturing a device that is supposed to be attached to only the upper jaw or the lower jaw, press the dental model in the covered state in the resting position and make an indentation (see FIG. 8). The jaw of the mouthpiece wearer can easily fit in the resting position (neutral position).

本発明における(iii)マウスピース成形工程では、バイト採得工程で取得したバイト材を用いても良い。ここでいうバイト採得工程とは、(ii)被蓋状態の確認工程で確認した安静位の被蓋状態での被験者のバイトを採得する工程を意味する。例えば、(ii)被蓋状態の確認工程における工程(6)の後、被験者に開口してもらい、口内にバイト材を置き、その後、閉口させ安静位の被蓋状態へ戻してもらい、リラックスした状態でバイト材の硬化を待つことで、バイトを採得できる。

バ イ ト In the (iii) mouthpiece molding step of the present invention, the cutting tool material obtained in the cutting tool obtaining step may be used. The bite obtaining step referred to herein means a step of obtaining a bite of the subject in the resting state of the covered state confirmed in (ii) the covered state confirming step. For example, (ii) after the step (6) in the step of checking the cover state, the subject was asked to open the mouth, a bite was placed in the mouth, and then closed and returned to the resting state of the resting state, and relaxed. By waiting the hardening of the cutting tool in the state, the cutting tool can be obtained.

本発明におけるバイト採得工程では、舌がアンテリアジグに接触することで舌根が咽頭側へ落ち込み、ひいては姿勢が崩れたり、緊張が生じたりするなどして、安静位の被蓋状態が影響を受けてしまうことを防ぐため、アンテリアジグの使用を避けることが望ましい。また、バイト採得は、主として臼歯部を対象として行うが、犬歯が対象となってもよいし、歯列全体が対象となってもよい。

また、バイト材は、採得対象となる歯列を、頬舌近遠心的に覆うようにすることが望ましい(図5左側参照)。採得対象となる歯列は、歯列全体でもよいし、歯列の一部(例えば、臼歯列のみ)であってもよい。ただし、舌が前歯部分のバイト材に接触することで舌根が咽頭側へ落ち込み、ひいては姿勢が崩れたり、緊張が生じてしまったりすることを防ぐ観点からは、対象となる歯列は、歯列の一部(特に、臼歯列)であることが望ましい。 In the bite collecting step in the present invention, the tongue base falls down to the pharyngeal side by contacting the tongue with the anterior jig, and eventually the posture is collapsed, tension is generated, and the covered state of the resting position is affected. It is advisable to avoid the use of anterior jigs in order to prevent them from being lost. In addition, the bite is mainly acquired for the molar part, but may be the canine tooth or the entire dentition.

Further, it is desirable that the bite material covers the dentition to be acquired in a near-mesio-lingual manner (see the left side of FIG. 5). The dentition to be acquired may be the entire dentition or a part of the dentition (for example, only the molars). However, from the viewpoint of preventing the tongue root from falling into the pharyngeal side when the tongue comes into contact with the bite material of the anterior teeth, and thereby preventing the posture from collapsing and causing tension, the target dentition is the dentition (Particularly, the posterior row).

また、バイト材は、採得対象となる歯列を、頬舌近遠心的に覆うようにすることが望ましい(図5左側参照)。採得対象となる歯列は、歯列全体でもよいし、歯列の一部(例えば、臼歯列のみ)であってもよい。ただし、舌が前歯部分のバイト材に接触することで舌根が咽頭側へ落ち込み、ひいては姿勢が崩れたり、緊張が生じてしまったりすることを防ぐ観点からは、対象となる歯列は、歯列の一部(特に、臼歯列)であることが望ましい。 In the bite collecting step in the present invention, the tongue base falls down to the pharyngeal side by contacting the tongue with the anterior jig, and eventually the posture is collapsed, tension is generated, and the covered state of the resting position is affected. It is advisable to avoid the use of anterior jigs in order to prevent them from being lost. In addition, the bite is mainly acquired for the molar part, but may be the canine tooth or the entire dentition.

Further, it is desirable that the bite material covers the dentition to be acquired in a near-mesio-lingual manner (see the left side of FIG. 5). The dentition to be acquired may be the entire dentition or a part of the dentition (for example, only the molars). However, from the viewpoint of preventing the tongue root from falling into the pharyngeal side when the tongue comes into contact with the bite material of the anterior teeth, and thereby preventing the posture from collapsing and causing tension, the target dentition is the dentition (Particularly, the posterior row).

本発明におけるバイト採得工程において、臼歯部のバイトだけでは歯列弓の前後的安定性が維持できず、安静位における被蓋状態の再現性に不安がある場合には、臼歯部バイトをポステリアガイドとして用いて、前歯部バイトの採得を行ってもよい。

In the bite obtaining process of the present invention, if the bite of the molar part alone cannot maintain the longitudinal stability of the dental arch and there is anxiety about the reproducibility of the covered state in the resting position, the bite part of the molar part is put into position. Using the terrier guide, the anterior tooth bite may be obtained.

本発明におけるバイト採得工程は、バイト材の硬化後に被験者にバイト材を装着してもらい、顎位のズレの有無を確認する工程を含んでもよい。この工程では、被験者に、左右や前後に違和感がないか、バイト材が高すぎる(厚すぎる)と感じないか、バイト材が低すぎること(薄すぎること)で食いしばり時に対合歯同士が接触してしまわないか、等を確認する。

The bite obtaining step in the present invention may include a step of having the subject wear the bite after the bite is hardened, and confirming whether or not the jaw position is shifted. In this process, the opposing teeth contact each other when clenching because the subject does not feel discomfort left and right or back and forth, does not feel that the bite material is too high (too thick), or that the bite material is too low (too thin). Check if it is done.

本発明におけるマウスピース成形工程には、身体状況テスト工程を含んでもよい(図1参照)。身体状況テスト工程では、被験者は、硬化後のバイト材を装着した状態と装着しない状態それぞれで、前屈、回旋等での柔軟性テストや片足バランス立ちの状態でのバランステスト、重心動揺軌道跡テスト、重心動揺変位テスト等を行うことで、バイト材の装着時と非装着時の差異を計測する。なお、被験者は、バイト材を噛みしめるのではなく添える程度の咬合で装着する。ただし、負荷の高い運動を行う際には、自然に食いしばりや噛みしめが生じてもよい。

身体状況テスト工程において、バイト材の装着時と非装着時との間で有為な差が見られない場合は、(ii)被蓋状態の確認工程又はバイト採得工程からやり直すことが望ましい。なお、身体状況テスト工程は、硬化したバイト材を用いて行っても良いし、成形したマウスピースを用いて同様のテストを行うことで代替しても良い。 The mouthpiece molding step of the present invention may include a physical condition test step (see FIG. 1). In the physical condition test process, the subject tested the flexibility test by bending forward and rotating, the balance test with one leg standing, the center of gravity track, and The difference between when the cutting tool is mounted and when it is not mounted is measured by performing a test, a center of gravity sway displacement test, and the like. The subject wears the bite bite so that the bite is attached rather than bitten. However, clenching or clenching may occur naturally when performing a heavy exercise.

In the physical condition test step, when no significant difference is observed between the wearing and the non-wearing of the cutting tool, (ii) it is desirable to start over from the step of checking the covered state or the step of obtaining the cutting tool. The physical condition test step may be performed using a hardened cutting tool, or may be performed by performing a similar test using a molded mouthpiece.

身体状況テスト工程において、バイト材の装着時と非装着時との間で有為な差が見られない場合は、(ii)被蓋状態の確認工程又はバイト採得工程からやり直すことが望ましい。なお、身体状況テスト工程は、硬化したバイト材を用いて行っても良いし、成形したマウスピースを用いて同様のテストを行うことで代替しても良い。 The mouthpiece molding step of the present invention may include a physical condition test step (see FIG. 1). In the physical condition test process, the subject tested the flexibility test by bending forward and rotating, the balance test with one leg standing, the center of gravity track, and The difference between when the cutting tool is mounted and when it is not mounted is measured by performing a test, a center of gravity sway displacement test, and the like. The subject wears the bite bite so that the bite is attached rather than bitten. However, clenching or clenching may occur naturally when performing a heavy exercise.

In the physical condition test step, when no significant difference is observed between the wearing and the non-wearing of the cutting tool, (ii) it is desirable to start over from the step of checking the covered state or the step of obtaining the cutting tool. The physical condition test step may be performed using a hardened cutting tool, or may be performed by performing a similar test using a molded mouthpiece.

<マウスピース>

本発明におけるマウスピースは、マウスピース装着時におけるマウスピース装着者の脱力状態の顎の位置が中立位になる形状をしていることを特徴とするものである。 <Mouthpiece>

The mouthpiece according to the present invention is characterized in that the mouthpiece worn by the mouthpiece wearer at the time of wearing the mouthpiece has a neutral position.

本発明におけるマウスピースは、マウスピース装着時におけるマウスピース装着者の脱力状態の顎の位置が中立位になる形状をしていることを特徴とするものである。 <Mouthpiece>

The mouthpiece according to the present invention is characterized in that the mouthpiece worn by the mouthpiece wearer at the time of wearing the mouthpiece has a neutral position.

本発明により作製されるマウスピースは、その舌側形態が咬合時の舌ポジションを考慮したものになっていることが望ましい。また、マウスピースが口腔の奥や咽頭部に接触しない形状になっていることが望ましい。具体的には、舌に不必要に接触しない形状や厚さにすることが望ましく、また、臼歯の舌側末端が鳩尾状となっていることが望ましい(図6左側参照)。従来のマウスピースのように臼歯の舌側末端がマウスピースにより覆われていると、使用時に口腔の奥や舌に接触することで嘔吐反応等が生じ、舌が後退・退位したり、舌根が咽頭部へ落ち込んだりしてしまい、ひいては気道が減少し呼吸が困難となったり、姿勢が崩れたりするなどして、パフォーマンスの低下に繋がる。これに対し、臼歯部の舌側末端を鳩尾状の形状にするなど、その舌側形態が舌ポジションを考慮したものになっていることで、このような現象を防ぐことができる。

マ ウ ス It is desirable that the lingual side shape of the mouthpiece manufactured according to the present invention takes into consideration the tongue position at the time of occlusion. Further, it is desirable that the mouthpiece has a shape that does not contact the back of the mouth or the pharynx. Specifically, it is desirable to have a shape and thickness that do not unnecessarily contact the tongue, and it is desirable that the lingual end of the molar is in a dovetail shape (see the left side of FIG. 6). If the lingual end of the molar tooth is covered with a mouthpiece like a conventional mouthpiece, vomiting reaction occurs when using it by touching the back of the mouth or the tongue during use, causing the tongue to recede or recede, The patient may fall into the pharynx, resulting in a decrease in the airway and difficulty breathing, and a loss of posture, leading to poor performance. On the other hand, such a phenomenon can be prevented by taking the tongue position into consideration, for example, by making the lingual end of the posterior part into a dovetail shape, taking the tongue position into consideration.

以下、本発明の実施例及び比較例を説明する。ただし、以下の実施例及び比較例は、発明の内容の理解を助けるためのものであり、本発明を限定するものではない。

Hereinafter, Examples and Comparative Examples of the present invention will be described. However, the following examples and comparative examples are for helping understanding of the contents of the invention, and do not limit the invention.

<マウスピースの作製>

(実施例1)

1)印象採得工程

被験者の上顎及び下顎の歯列(齦頬移行部を含む。)の型を、印象材とトレーを使用して、それぞれ採得した。その後、取得した歯型印象に市販の石膏を流し込んで模型を作製 <Making a mouthpiece>

(Example 1)

1) Impression Taking Step The molds of the upper and lower dentitions (including the cheek-to-cheek transition part) of the subject were obtained using an impression material and a tray, respectively. After that, a commercially available plaster is poured into the acquired tooth impression to create a model

(実施例1)

1)印象採得工程

被験者の上顎及び下顎の歯列(齦頬移行部を含む。)の型を、印象材とトレーを使用して、それぞれ採得した。その後、取得した歯型印象に市販の石膏を流し込んで模型を作製 <Making a mouthpiece>

(Example 1)

1) Impression Taking Step The molds of the upper and lower dentitions (including the cheek-to-cheek transition part) of the subject were obtained using an impression material and a tray, respectively. After that, a commercially available plaster is poured into the acquired tooth impression to create a model

2)被蓋状態の確認工程

裸足の状態の被験者を、肩幅程度に足を開かせ水平面上に立たせて静止させた状態で、被験者の上顎と下顎の歯が接触していない状態にさせた。その後、被験者にその状態を維持させながら、水平面に対する垂直軸に対して頭位を約45°後方に反らさせ、その姿勢を維持しながら、上顎と下顎の歯が接触していない状態で脱力させた。さらに、被験者にその状態を25秒維持させ、その後、頭位を垂直位へ戻させ、目線を水平面から約10°程度下方へ落とさせた(安静位)。被験者に、安静位を維持させながら、上顎及び下顎の前歯の被蓋状態(アンテリアカップリング)を確認した。 2) Step of Checking Covered State The subject, who was barefoot, was allowed to stand on a horizontal surface with his / her feet wide about the width of the shoulder and kept still, and the subject's upper and lower jaw teeth were not in contact. Thereafter, the subject was warped backward by about 45 ° with respect to the vertical axis with respect to the horizontal plane while maintaining that state, and while maintaining that posture, the upper jaw and lower jaw were weakened without contact with each other. I let it. Further, the subject was kept in that state for 25 seconds, after which the head position was returned to the vertical position, and the line of sight was lowered by about 10 ° from the horizontal plane (resting position). While maintaining the resting position, the subject confirmed the state of covering of the upper teeth (anterior coupling) of the upper and lower jaws.

裸足の状態の被験者を、肩幅程度に足を開かせ水平面上に立たせて静止させた状態で、被験者の上顎と下顎の歯が接触していない状態にさせた。その後、被験者にその状態を維持させながら、水平面に対する垂直軸に対して頭位を約45°後方に反らさせ、その姿勢を維持しながら、上顎と下顎の歯が接触していない状態で脱力させた。さらに、被験者にその状態を25秒維持させ、その後、頭位を垂直位へ戻させ、目線を水平面から約10°程度下方へ落とさせた(安静位)。被験者に、安静位を維持させながら、上顎及び下顎の前歯の被蓋状態(アンテリアカップリング)を確認した。 2) Step of Checking Covered State The subject, who was barefoot, was allowed to stand on a horizontal surface with his / her feet wide about the width of the shoulder and kept still, and the subject's upper and lower jaw teeth were not in contact. Thereafter, the subject was warped backward by about 45 ° with respect to the vertical axis with respect to the horizontal plane while maintaining that state, and while maintaining that posture, the upper jaw and lower jaw were weakened without contact with each other. I let it. Further, the subject was kept in that state for 25 seconds, after which the head position was returned to the vertical position, and the line of sight was lowered by about 10 ° from the horizontal plane (resting position). While maintaining the resting position, the subject confirmed the state of covering of the upper teeth (anterior coupling) of the upper and lower jaws.

3)マウスピースの成形工程

2)工程の後、被験者に安静位を維持させたまま開口をさせて口内にバイト材(FPバイト、フィード株式会社製)を入れ、工程2)で確認した安静位における上顎及び下顎の前歯の覆蓋状態(アンテリアカップリング)になるよう閉口させ、バイト材の硬化を待ち、上顎歯列のバイトを採得した。なお、バイト採得の対象は上顎及び下顎の臼歯部及び犬歯とし、バイト材が歯列を頬舌近遠心的に覆うようにバイト採得を行った。 3) Mouthpiece forming step 2) After the step, the subject is opened while maintaining the resting position, a bite material (FP bite, manufactured by Feed Co., Ltd.) is put in the mouth, and the resting position confirmed in the step 2) The upper and lower jaws were closed so that the anterior teeth were covered (Anteria coupling), and the cutting of the bite material was awaited. The bite of the maxillary dentition was obtained. The bites were collected on the upper and lower jaw molars and canines, and the bite was collected so that the bite covered the dentition buccally and mesio-centrifugally.

2)工程の後、被験者に安静位を維持させたまま開口をさせて口内にバイト材(FPバイト、フィード株式会社製)を入れ、工程2)で確認した安静位における上顎及び下顎の前歯の覆蓋状態(アンテリアカップリング)になるよう閉口させ、バイト材の硬化を待ち、上顎歯列のバイトを採得した。なお、バイト採得の対象は上顎及び下顎の臼歯部及び犬歯とし、バイト材が歯列を頬舌近遠心的に覆うようにバイト採得を行った。 3) Mouthpiece forming step 2) After the step, the subject is opened while maintaining the resting position, a bite material (FP bite, manufactured by Feed Co., Ltd.) is put in the mouth, and the resting position confirmed in the step 2) The upper and lower jaws were closed so that the anterior teeth were covered (Anteria coupling), and the cutting of the bite material was awaited. The bite of the maxillary dentition was obtained. The bites were collected on the upper and lower jaw molars and canines, and the bite was collected so that the bite covered the dentition buccally and mesio-centrifugally.

1)の印象採得工程で得た歯列模型を用い、バイト採得工程によって得た硬化後のバイト材を用いて2)被蓋状態の確認工程で確認した安静位における覆蓋状態を再現し、その状態を成形器に記録させた(図7及び図8)。その後、マウスピース用シート(エチレン酢酸ビニルシート、山八歯材工業株式会社製)を素材とし、成形器と歯列模型を用いて加圧・加熱することで、上顎の歯列用マウスピースを成形した。さらに、成形されたマウスピースが硬化する前に、対向する歯列である下顎の歯列の模型を安静位における覆蓋状態の位置関係で押し付けることで、マウスピースの装着面の反対面に圧痕を付けた。

1) Using the dental model obtained in the impression acquisition step, using the hardened cutting tool material obtained in the cutting tool acquisition step, 2) Reproducing the cover state in the resting position confirmed in the cover state confirmation step. The state was recorded on a molding machine (FIGS. 7 and 8). After that, using the mouthpiece sheet (ethylene vinyl acetate sheet, manufactured by Yamahachi Tekko Kogyo Co., Ltd.) as a material, pressing and heating using a molding machine and a dentition model, the mouthpiece for the upper dentition was obtained. Molded. Further, before the molded mouthpiece is hardened, an indentation is formed on the surface opposite to the mouthpiece mounting surface by pressing the model of the lower dentition, which is the opposing dentition, in the positional relationship of the cover at rest. I attached.

被験者にマウスピースを装着させた状態と、装着させない状態それぞれについて、前屈及び回旋に関する柔軟性を測定する柔軟テスト及び片足立ちの状態でのバランステストを行ったところ、柔軟性テスト及びバランステスト共に、マウスピース装着時のパフォーマンスの方が高かった。

A flexibility test to measure flexibility in forward bending and rotation and a balance test in a standing state were performed for each of the subjects with and without the mouthpiece, with both the flexibility test and the balance test. , The performance with the mouthpiece attached was higher.

<走力試験>

(実施例2)

1)マウスピースの作製

被験者となる走者1及び走者2のためのマウスピースを、実施例1と同様の1)印象採得工程、2)被蓋状態の確認工程、及び3)マウスピースの成形工程を経て、それぞれ作成した。 <Running test>

(Example 2)

1) Preparation of Mouthpieces Mouthpieces for runners 1 and 2 as test subjects were prepared in the same manner as in Example 1 1) Impression obtaining step, 2) Cover state checking step, and 3) Mouthpiece molding After the process, each was created.

(実施例2)

1)マウスピースの作製

被験者となる走者1及び走者2のためのマウスピースを、実施例1と同様の1)印象採得工程、2)被蓋状態の確認工程、及び3)マウスピースの成形工程を経て、それぞれ作成した。 <Running test>

(Example 2)

1) Preparation of Mouthpieces Mouthpieces for runners 1 and 2 as test subjects were prepared in the same manner as in Example 1 1) Impression obtaining step, 2) Cover state checking step, and 3) Mouthpiece molding After the process, each was created.

2)走力試験

実施例2のマウスピースを装着した走者1および走者2に、スタート地点において、スタンディング状態のスタート姿勢で静止させた。次に、走者1および走者2に、スタートの合図と共に、約30mを全力で走行させ、スタート地点から20mの間の区間(「対象区間」という。)の走行データを取得した。なお、走者には、GPS計測用装置(Catapult社製 OptimEye S5)を装着させ、走行データを取得した。ここでは走行データとして、対象区間における平均速度(m/min)及び対象区間における最高速度(m/sec)を取得した。 2) Running test The runners 1 and 2 wearing the mouthpiece of Example 2 were allowed to stand still at a starting position in a standing state at the starting point. Next, the runner 1 and the runner 2 were allowed to run about 30 m with full power together with a start signal, and travel data of a section (referred to as “target section”) between 20 m from the start point was obtained. In addition, the runner was equipped with a GPS measurement device (OptEye S5 manufactured by Catapult), and the running data was acquired. Here, the average speed (m / min) in the target section and the maximum speed (m / sec) in the target section were acquired as the traveling data.

実施例2のマウスピースを装着した走者1および走者2に、スタート地点において、スタンディング状態のスタート姿勢で静止させた。次に、走者1および走者2に、スタートの合図と共に、約30mを全力で走行させ、スタート地点から20mの間の区間(「対象区間」という。)の走行データを取得した。なお、走者には、GPS計測用装置(Catapult社製 OptimEye S5)を装着させ、走行データを取得した。ここでは走行データとして、対象区間における平均速度(m/min)及び対象区間における最高速度(m/sec)を取得した。 2) Running test The runners 1 and 2 wearing the mouthpiece of Example 2 were allowed to stand still at a starting position in a standing state at the starting point. Next, the runner 1 and the runner 2 were allowed to run about 30 m with full power together with a start signal, and travel data of a section (referred to as “target section”) between 20 m from the start point was obtained. In addition, the runner was equipped with a GPS measurement device (OptEye S5 manufactured by Catapult), and the running data was acquired. Here, the average speed (m / min) in the target section and the maximum speed (m / sec) in the target section were acquired as the traveling data.

(比較例1)

マウスピースを装着していない状態の走者1および走者2に、実施例2と同様の走力試験を行ない、走行データを取得した。 (Comparative Example 1)

A running test similar to that of Example 2 was performed on the runners 1 and 2 without the mouthpiece, and running data was acquired.

マウスピースを装着していない状態の走者1および走者2に、実施例2と同様の走力試験を行ない、走行データを取得した。 (Comparative Example 1)

A running test similar to that of Example 2 was performed on the runners 1 and 2 without the mouthpiece, and running data was acquired.

実施例2および比較例1で取得した走行データは、表1のとおりであった。走者1については、マウスピース装着時(実施例2)が非装着時(比較例1)と比べ、平均速度は18.6(m/min)向上し、最高速度は0.2(m/sec)向上した。また、走者2については、マウスピース装着時(実施例2)が非装着時(比較例1)と比べ、平均速度は17.7(m/min)向上し、最高速度は0.3(m/sec)向上した。

走 行 The running data obtained in Example 2 and Comparative Example 1 were as shown in Table 1. With respect to runner 1, the average speed is improved by 18.6 (m / min) when the mouthpiece is worn (Example 2) compared to when it is not worn (Comparative Example 1), and the maximum speed is 0.2 (m / sec). ) Improved. For Runner 2, the average speed was improved by 17.7 (m / min) and the maximum speed was 0.3 (m) when the mouthpiece was worn (Example 2) compared to when it was not worn (Comparative Example 1). / Sec) improved.

Claims (6)

- マウスピースの作製方法であって、印象採得工程、被蓋状態の確認工程、及びマウスピース成形工程を含むことを特徴とする、マウスピースの作製方法。 (4) A method for producing a mouthpiece, the method comprising a step of obtaining an impression, a step of confirming a cover state, and a step of molding a mouthpiece.

- 請求項1のマウスピースの作成方法であって、該印象採得工程が、被験者の上顎又は下顎の歯列等(歯列及び口腔周囲組織)の情報を取得する工程、及び採得した歯列等の情報に基づき歯列等の模型を作製する工程を含むことを特徴とする、マウスピースの作製方法。 2. The method for producing a mouthpiece according to claim 1, wherein the step of obtaining the impression includes a step of acquiring information on a dental row or the like of the subject's upper or lower jaw (a dental row and a tissue around the oral cavity), and the captured dental row. A method for producing a mouthpiece, comprising a step of producing a model such as a tooth row based on information on the mouthpiece and the like.

- 請求項1又は2のマウスピースの作製方法であって、該被蓋状態の確認工程が、(1)被験者が水平面上に立位又は座位で静止する工程、

(2)被験者が身体を静止させ上顎と下顎の歯が接触していない状態でリラックスする工程、

(3)被験者が、水平面に対する垂直軸に対して頭位を30~60°後方に、好ましくは45~50°後方に反らす工程、

(4)被験者が、工程(3)の姿勢を維持しながら、上顎と下顎の歯が接触していない状態でリラックスした状態を15~30秒維持する工程、

(5)被験者が、工程(4)の後に、工程(3)の姿勢を維持しながら、頭位を工程(2)の際と同じ頭位へ戻しながら、目線を水平面から約5°~15°程度下方へ落とす工程、

及び(6)被験者の安静位における上顎及び下顎の前歯の被蓋状態(アンテリアカップリング)を確認する工程

を含むことを特徴とする、マウスピースの作製方法。 3. The method of manufacturing the mouthpiece according to claim 1, wherein the step of confirming the lid state includes: (1) a step in which the subject stands still or standing on a horizontal surface;

(2) a process in which the subject rests and relaxes without the upper and lower teeth in contact with each other;

(3) a step in which the subject turns the head backward 30-60 °, preferably 45-50 ° backward with respect to the vertical axis with respect to the horizontal plane;

(4) a step in which the subject maintains a relaxed state for 15 to 30 seconds in a state where the upper and lower jaw teeth are not in contact with each other while maintaining the posture of step (3);

(5) After the step (4), the subject returns the head position to the same position as in the step (2) while maintaining the posture of the step (3), and changes his / her eyes from a horizontal plane by about 5 ° to 15 °. ° drop downward,

And (6) a method for producing a mouthpiece, comprising a step of confirming a state of covering of anterior teeth of the upper and lower jaws in a resting position of the subject (anterior coupling). - 請求項1ないし3のマウスピースの作製方法であって、該マウスピース成形工程において、バイト材を用いることを特徴とする、マウスピースの作製方法。 (4) The method for producing a mouthpiece according to any one of (1) to (3), wherein a cutting tool is used in the mouthpiece molding step.

- マウスピース装着時におけるマウスピース装着者の脱力状態の顎の位置が中立位になる形状をしていることを特徴とするマウスピース。 (4) A mouthpiece characterized in that the jaw position in a weakened state of the mouthpiece wearer when the mouthpiece is worn is in a neutral position.

- 請求項5のマウスピースであって、臼歯部の舌側末端が鳩尾状の形状となっていることを特徴とするマウスピース。 The mouthpiece according to claim 5, wherein the lingual end of the molar portion has a dovetail shape.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2018-124069 | 2018-06-29 | ||

| JP2018124069 | 2018-06-29 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2020013018A1 true WO2020013018A1 (en) | 2020-01-16 |

Family

ID=69142506

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2019/026197 WO2020013018A1 (en) | 2018-06-29 | 2019-07-01 | Mouthpiece and production method for same |

Country Status (2)

| Country | Link |

|---|---|

| JP (1) | JP6834096B6 (en) |

| WO (1) | WO2020013018A1 (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP7072920B1 (en) * | 2020-11-30 | 2022-05-23 | 株式会社ホワイトライン | How to make a mouthguard |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2005000385A (en) * | 2003-06-11 | 2005-01-06 | Molten Corp | Mouthpiece molding material, and mouthpiece made thereof |

| US20110209714A1 (en) * | 2009-08-28 | 2011-09-01 | Makkar Athletics Group Inc. | Methods of preparing customized mouthpieces for enhancing athletic performance |

| JP6472101B1 (en) * | 2017-11-01 | 2019-02-20 | 俊郎 蟹江 | Mouth guard manufacturing method |

-

2019

- 2019-07-01 JP JP2019123252A patent/JP6834096B6/en active Active

- 2019-07-01 WO PCT/JP2019/026197 patent/WO2020013018A1/en active Application Filing

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2005000385A (en) * | 2003-06-11 | 2005-01-06 | Molten Corp | Mouthpiece molding material, and mouthpiece made thereof |

| US20110209714A1 (en) * | 2009-08-28 | 2011-09-01 | Makkar Athletics Group Inc. | Methods of preparing customized mouthpieces for enhancing athletic performance |

| JP6472101B1 (en) * | 2017-11-01 | 2019-02-20 | 俊郎 蟹江 | Mouth guard manufacturing method |

Non-Patent Citations (1)

| Title |

|---|

| ATSUMI, YOJIRO: "Relationship between Bite Raising Measurements of Mouthguards and Sports Performance of Athletes", JOURNAL OF SPORTS DENTISTRY, vol. 8, no. 1, March 2005 (2005-03-01), pages 50 - 56 * |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2020006169A (en) | 2020-01-16 |

| JP6834096B2 (en) | 2021-02-24 |

| JP6834096B6 (en) | 2021-05-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4848365A (en) | Method of in-situ custom fitting a protective mouthguard | |

| US6626180B1 (en) | Quadruple composite performance enhancing dental appliance | |

| US8297286B2 (en) | Physical rehabilitation and training aid: method of using musculoskeletal repositioning device | |

| US6257239B1 (en) | Dental appliance with anti-microbial additive | |

| JP6502529B2 (en) | Height-adjustable splint and method of making the same | |

| US6539943B1 (en) | Encapsulated composite dental appliance | |

| US6415794B1 (en) | Composite dental appliance with wedge | |

| US7918228B2 (en) | Musculoskeletal repositioning device | |

| US6598605B1 (en) | Non-softenable, impressionable framework for dental appliances | |

| US20160157962A1 (en) | Dental appliance detachably attached to the teeth, and fabricating method therefor | |

| US8585401B2 (en) | Mouthpiece for athletic performance enhancement | |

| KR101497493B1 (en) | Removable Dental Appliance Mounted On Teeth And Manufacturing Method Thereof | |

| US20140007884A1 (en) | Mouthpiece | |

| WO2011022834A1 (en) | Methods of preparing customized mouthpieces for enhancing athletic performance | |

| US8061358B2 (en) | Birthing aid: method of using musculoskeletal repositioning device | |

| JP4489503B2 (en) | Mouth guard | |

| US10085821B2 (en) | Guard for mouth | |

| WO2020013018A1 (en) | Mouthpiece and production method for same | |

| Chapman | The bimaxillary mouthguard: a preliminary report of use in contact sports | |

| JP6472101B1 (en) | Mouth guard manufacturing method | |

| RU153858U1 (en) | KAPPA FOR TREATMENT OF CHEWABLE MUSCULAR PARAFUNCTION | |

| JP2005118513A (en) | Boiling water softening type dentition compatible mouthpiece prevented from leaving indentation of mated tooth with hot water heat and providing favorable fitting property | |

| US20140224260A1 (en) | Guard for mouth | |

| CN206508393U (en) | A kind of simple electric shock device for preventing snoring | |

| JP7453124B2 (en) | mouth guard |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 19834966 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 32PN | Ep: public notification in the ep bulletin as address of the adressee cannot be established |

Free format text: NOTING OF LOSS OF RIGHTS PURSUANT TO RULE 112(1) EPC (EPO FORM 1205A DATED 14-04-2021) |

|

| NENP | Non-entry into the national phase |

Ref country code: JP |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 19834966 Country of ref document: EP Kind code of ref document: A1 |