WO2019012879A1 - 電動歯ブラシ、システム、ブラッシング部位検出方法およびプログラム - Google Patents

電動歯ブラシ、システム、ブラッシング部位検出方法およびプログラム Download PDFInfo

- Publication number

- WO2019012879A1 WO2019012879A1 PCT/JP2018/021986 JP2018021986W WO2019012879A1 WO 2019012879 A1 WO2019012879 A1 WO 2019012879A1 JP 2018021986 W JP2018021986 W JP 2018021986W WO 2019012879 A1 WO2019012879 A1 WO 2019012879A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- brushing

- main body

- electric toothbrush

- dentition

- output

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46B—BRUSHES

- A46B15/00—Other brushes; Brushes with additional arrangements

- A46B15/0002—Arrangements for enhancing monitoring or controlling the brushing process

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46B—BRUSHES

- A46B13/00—Brushes with driven brush bodies or carriers

- A46B13/02—Brushes with driven brush bodies or carriers power-driven carriers

- A46B13/023—Brushes with driven brush bodies or carriers power-driven carriers with means for inducing vibration to the bristles

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46B—BRUSHES

- A46B15/00—Other brushes; Brushes with additional arrangements

- A46B15/0002—Arrangements for enhancing monitoring or controlling the brushing process

- A46B15/0004—Arrangements for enhancing monitoring or controlling the brushing process with a controlling means

- A46B15/0006—Arrangements for enhancing monitoring or controlling the brushing process with a controlling means with a controlling brush technique device, e.g. stroke movement measuring device

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61C—DENTISTRY; APPARATUS OR METHODS FOR ORAL OR DENTAL HYGIENE

- A61C17/00—Devices for cleaning, polishing, rinsing or drying teeth, teeth cavities or prostheses; Saliva removers; Dental appliances for receiving spittle

- A61C17/16—Power-driven cleaning or polishing devices

- A61C17/22—Power-driven cleaning or polishing devices with brushes, cushions, cups, or the like

- A61C17/221—Control arrangements therefor

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61C—DENTISTRY; APPARATUS OR METHODS FOR ORAL OR DENTAL HYGIENE

- A61C17/00—Devices for cleaning, polishing, rinsing or drying teeth, teeth cavities or prostheses; Saliva removers; Dental appliances for receiving spittle

- A61C17/16—Power-driven cleaning or polishing devices

- A61C17/22—Power-driven cleaning or polishing devices with brushes, cushions, cups, or the like

- A61C17/224—Electrical recharging arrangements

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61C—DENTISTRY; APPARATUS OR METHODS FOR ORAL OR DENTAL HYGIENE

- A61C17/00—Devices for cleaning, polishing, rinsing or drying teeth, teeth cavities or prostheses; Saliva removers; Dental appliances for receiving spittle

- A61C17/16—Power-driven cleaning or polishing devices

- A61C17/22—Power-driven cleaning or polishing devices with brushes, cushions, cups, or the like

- A61C17/32—Power-driven cleaning or polishing devices with brushes, cushions, cups, or the like reciprocating or oscillating

- A61C17/34—Power-driven cleaning or polishing devices with brushes, cushions, cups, or the like reciprocating or oscillating driven by electric motor

- A61C17/3409—Power-driven cleaning or polishing devices with brushes, cushions, cups, or the like reciprocating or oscillating driven by electric motor characterized by the movement of the brush body

- A61C17/3481—Vibrating brush body, e.g. by using eccentric weights

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01C—MEASURING DISTANCES, LEVELS OR BEARINGS; SURVEYING; NAVIGATION; GYROSCOPIC INSTRUMENTS; PHOTOGRAMMETRY OR VIDEOGRAMMETRY

- G01C1/00—Measuring angles

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01C—MEASURING DISTANCES, LEVELS OR BEARINGS; SURVEYING; NAVIGATION; GYROSCOPIC INSTRUMENTS; PHOTOGRAMMETRY OR VIDEOGRAMMETRY

- G01C19/00—Gyroscopes; Turn-sensitive devices using vibrating masses; Turn-sensitive devices without moving masses; Measuring angular rate using gyroscopic effects

- G01C19/005—Measuring angular rate using gyroscopic effects

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46B—BRUSHES

- A46B2200/00—Brushes characterized by their functions, uses or applications

- A46B2200/10—For human or animal care

- A46B2200/1066—Toothbrush for cleaning the teeth or dentures

Definitions

- the present invention relates to an electric toothbrush capable of detecting a brushing site in a dentition, a system and a brushing site detecting method.

- the present invention also relates to a program for causing a computer to execute such a brushing site detection method.

- the toothbrush main body is provided with an acceleration sensor, and the x-axis direction, y-axis direction, z-axis obtained from the output of this acceleration sensor

- the acceleration component of each direction By moving the acceleration component of each direction in two steps, the movement amount in each of the x-, y-, and z-axis directions is calculated, and the brushing part in the dentition during brushing (in the same document, the dentition forms Point to the translational position in the plane).

- the direction around the longitudinal axis (y-axis) of the toothbrush is based on the gravity acceleration component obtained from the output of the acceleration sensor. What is sought is disclosed.

- a brush body is further provided with a gyro sensor (gyroscope), and the brush angle is determined by cumulatively adding (integrating) the output of the gyro sensor. Based on the brush angle determined in this manner, it can be known which of the front, rear and meshing surfaces of the teeth is brushed.

- an object of the present invention is to provide an electric toothbrush, a system and a brushing portion detection method capable of accurately determining the translational position of the brushing portion in the dentition.

- Another object of the present invention is to provide a program for causing a computer to execute such a brushing site detection method.

- the brushing site detection unit The angle formed by the longitudinal axis of the main body when the bristles of the head portion contact the brushing portion of the dentition with respect to the longitudinal axis of the main body when the bristles of the head portion contact the reference position of the dentition , Based on the output of the gyro sensor, Based on the angle, a corresponding point corresponding to the brushing portion is determined on the curved approximate curve corresponding to the dentition, and the coordinates of the corresponding point are set as the translational position of the brushing portion. .

- the term "brushing site” refers to a site brushed (hair is applied) by the hair among a plurality of sites defined by dividing the surface of the dentition in the oral cavity.

- the brushing portion in the dentition is specified by a combination of the translational position in the actual space where the dentition exists and which of the front surface, the back surface, and the meshing surface of the dentition is brushed.

- the "reference position" of a dentition refers to a position in the dentition at which the angle is measured.

- the brushing portion detection unit determines the translational position of the brushing portion in the dentition based on the output of the gyro sensor. That is, the brushing portion detection unit detects the bristles of the head portion in contact with the brushing portion of the dentition with respect to the vertical axis of the main body when the bristles of the head portion contact the reference position of the dentition.

- the angle formed by the longitudinal axis of the main body is determined based on the output of the gyro sensor.

- a corresponding point corresponding to the brushing portion is determined on the curved approximate curve corresponding to the dentition, and the coordinate of the corresponding point is set as the translational position of the brushing portion.

- the output of the gyro sensor is an angular velocity

- a vibration component from a drive motor that vibrates a brush (hair) is less likely to be included as noise.

- the output of the gyro sensor is an angular velocity

- the angle can be obtained by first-order integration, so that it is difficult to be influenced by noise in the calculation process. Therefore, the translational position of the brushing portion in the dentition can be accurately determined.

- the brushing part detection unit sets a reference tangent which is in contact with the approximate curve at a reference point corresponding to the reference position, and makes the angle with respect to the reference tangent, A movable tangent in contact with the approximate curve is set, and a point at which the movable tangent is in contact with the approximate curve is determined as the corresponding point.

- the "movable tangent” means a tangent which is variably set according to the change of the angle, in other words, according to the change of the brushing portion in the dentition.

- the reference position of the dentition is a center of a front surface of the dentition.

- the brushing part detection unit can easily obtain the translational position of the brushing part by an analytical expression.

- a receiver capable of receiving setting parameters from the outside of the main body;

- the brushing part detection unit is characterized in that the coefficients a and b or the coefficient p can be variably set according to the setting parameter received through the reception unit.

- the brushing portion detection unit is characterized in that the brushing portion in the dentition is specified based on the output of the gyro sensor and the output of the acceleration sensor.

- the brushing portion detection unit identifies the brushing portion in the dentition based on the output of the gyro sensor and the output of the acceleration sensor. Thereby, the brushing part in a dentition can be pinpointed precisely.

- the brushing site detection unit Based on the direction of gravitational acceleration output by the acceleration sensor, the direction in which the hairs of the head portion are directed is determined around the longitudinal axis of the main body, and the teeth row according to the direction in which the hairs of the head portion are directed Determine which of the front, back, and mating surfaces of the The combination of the translational position of the brushing portion determined based on the output of the gyro sensor and the determination result as to which of the front surface, the rear surface and the meshing surface of the tooth row is brushed, in the tooth row It is characterized by specifying a brushing site.

- the brushing site detection unit Calculating a translational movement amount of the main body based on the acceleration of the main body output by the acceleration sensor for each predetermined aggregation unit period; When the translational movement amount of the main body is equal to or less than a predetermined first threshold value for a certain aggregation unit period, the translational position of the brushing portion determined on the basis of the output of the gyro sensor is calculated in the aggregation unit period. It is characterized in that a first correction process to be maintained is performed.

- the brushing part detection unit calculates the translational movement amount of the main body based on the acceleration of the main body output by the acceleration sensor for each predetermined aggregation unit period.

- the brushing part detection unit obtains, based on the output of the gyro sensor, the total unit period when the translational movement amount of the main body is equal to or less than a predetermined first threshold value for a certain total unit period.

- a first correction process is performed to maintain the translational position of the brushing portion. Therefore, for example, when the user while brushing teeth largely changes the direction of the longitudinal axis of the main body (especially the head portion) while stopping the translational movement of the main body (in particular, the head portion), before and after the change.

- the translational position of the brushing portion determined based on the output of the gyro sensor is maintained. Thereby, the accuracy of the determined translational position of the brushing site can be maintained.

- the brushing part detection unit calculates the translational movement amount of the main body based on the acceleration of the main body output by the acceleration sensor for each predetermined aggregation unit period. Then, when the translational movement amount of the main body is equal to or greater than a predetermined second threshold, the brushing portion detection unit shifts to a portion corresponding to the translational movement destination of the main body on the approximate curve and A second correction process is performed to determine the corresponding point based on the output of the sensor.

- the user while brushing teeth translates the main body, for example, jumping over the front lip side from the left buccal site to the right buccal site in the upper jaw dentition while hardly changing the orientation of the longitudinal axis of the main body In such a case, the translational position of the brushing portion in the dentition can be accurately determined.

- both the first correction process and the second correction process be performed for each of the aggregation unit periods.

- the electric toothbrush includes a transmitter capable of transmitting data regarding brushing to the outside of the main body.

- data regarding brushing refers to actual brushing time data for each part (data in which the identified brushing part is associated with the actual brushing time for that part) and other data regarding brushing. Including.

- the transmission unit can transmit data regarding brushing to the outside of the main body.

- the data can be received by a computer device provided outside the main body and used for various processes and applications.

- the system of the present invention includes the electric toothbrush and a computer device provided outside the body of the electric toothbrush in communication with each other.

- the "computer device” may be operated substantially as a computer regardless of its name.

- it may be a smartphone, a tablet terminal, or the like.

- a brushing procedure for brushing a plurality of parts in the dentition in a predetermined order and for a predetermined brushing setting period is defined.

- a brushing evaluation unit is provided for calculating an evaluation value representing the degree of agreement with the brushing procedure based on the brushing portion specified by the brushing portion detection unit.

- a brushing procedure is defined in which a plurality of parts in the dentition are brushed in a predetermined order and for a predetermined brushing setting period.

- the brushing evaluation unit calculates, based on the brushing portion specified by the brushing portion detection unit, an evaluation value representing the degree of agreement with the brushing procedure. Therefore, the user can know the degree of agreement (or disagreement) with the brushing procedure based on this evaluation value.

- the brushing site detection method of the present invention comprises A brushing site detection method for detecting a brushing site brushed by an electric toothbrush in a dentition, comprising:

- the above electric toothbrush is A head portion having a raised surface on which hairs are erected, a grip portion to be grasped by hand, and a main body having a neck portion connecting the head portion and the grip portion along the longitudinal direction;

- a gyro sensor mounted inside the main body and detecting an angular velocity of the main body;

- the above brushing site detection method is With respect to the longitudinal axis of the main body when the bristles of the head unit contact the reference position of the dentition in the real space where the dentition exists, the head portion with respect to the brushing portion of the dentition

- the difference angle between the vertical axes of the main body when the hairs of the hairs are in contact is determined based on the output of the gyro sensor, Based on the difference angle in the real space, the corresponding point corresponding to the brush

- the difference angle between the vertical axis of the main body and the bristles of the head portion in contact with the brushing portion of the head is determined based on the output of the gyro sensor.

- a corresponding point corresponding to the brushing portion is determined on the curved approximate curve corresponding to the dentition set in the data space, and the corresponding point

- the coordinates of the point are data representing the translational position of the brushing portion.

- the output of the gyro sensor is an angular velocity

- a vibration component from a drive motor that vibrates a brush (hair) is less likely to be included as noise.

- the differential angle can be obtained by performing the first-order integration, and it is difficult to be influenced by noise in the calculation process. Therefore, the translational position of the brushing portion in the dentition can be accurately determined.

- a program of the present invention is a program for causing a computer to execute the brushing site detection method.

- the translational position of the brushing portion in the dentition can be accurately determined.

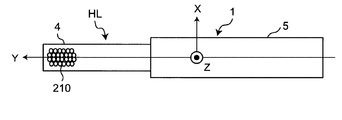

- FIG. 1A and FIG. 1B are views showing the appearance of the electric toothbrush according to the embodiment of the present invention as viewed obliquely from opposite sides. It is a figure which shows the longitudinal cross section when the said electric toothbrush is cut

- FIG. 7A shows a “standard” approximate curve which is a part of an ellipse.

- FIG. 7 (B) is a view showing a “long” approximate curve which is a part of another ellipse.

- FIG. 7C is a diagram showing an “small” approximate curve which is a part of yet another ellipse.

- the main body when the bristles of the head contact with the brushing portion of the dentition with respect to the longitudinal axis (Y axis) of the main body when the bristles of the head contact with the reference position of the dentition in real space Is a diagram for explaining the difference angle ⁇ formed by the vertical axis (Y axis) of It is a figure explaining the process which calculates

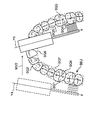

- FIGS. 1-10 When the vertical axis (Y axis) of the main body is in a horizontal posture and viewed from the side of the head (+ Y direction), it is a diagram showing the direction of the gravitational acceleration G output from the acceleration sensor. It is a figure which shows the state by which the head part (+ Y direction) was distribute

- 13 (A) to 13 (C) are diagrams showing sections for determining which of the front surface, the rear surface, and the meshing surface of the “left back tooth” of the dentition of the upper jaw is brushed.

- 13 (D) to 13 (F) are diagrams showing sections for determining which of the front surface, the rear surface, and the meshing surface of the “left back tooth” of the lower dentition tooth row is brushed.

- FIGS. 14 (A) to 14 (B) are diagrams showing sections for determining which of the front surface and the rear surface of the “front teeth” of the upper dentition is brushed.

- FIGS. 14 (C) to 14 (D) are diagrams showing sections for determining which of the front surface and the rear surface of the “front teeth” of the lower dentition is brushed.

- FIGS. 15 (A) to 15 (C) are diagrams showing sections for determining which one of the front surface, the rear surface, and the meshing surface of the “right back tooth” of the dentition of the upper jaw is brushed.

- FIGS. 15 (D) to 15 (F) are diagrams showing sections for determining which one of the front surface, the rear surface, and the meshing surface of the “right back tooth” of the lower jaw tooth row is brushed.

- FIGS. 1 (A) and 1 (B) show the appearance of an electric toothbrush (generally indicated by reference numeral 90) of an embodiment in which the dental plaque detection device of the present invention is incorporated, from diagonally opposite sides. It shows the spot.

- the electric toothbrush 90 has a head portion 4 on which the hairs 210 are erected, a grip portion 5 to be grasped by hand, and a neck portion 3 connecting the head portion 4 and the grip portion 5 in the longitudinal direction (Y Provided along the axial direction).

- the head portion 4 and the neck portion 3 are integrally configured as a brush member 2 which is detachable from the grip portion 5.

- the head portion 4, the neck portion 3 and the grip portion 5 are collectively referred to as a main body 1.

- the main body 1 has an elongated shape in the Y-axis direction for the convenience of brushing teeth.

- the charger 100 is illustrated in FIG. 1 (A).

- FIG. 2 shows a vertical cross section when the electric toothbrush 90 is cut along the longitudinal axis (Y axis).

- the grip 5 has a stem 6 provided so as to protrude from the outer casing of the grip 5 toward the neck 3.

- the stem 6 has a tubular shape whose tip is closed.

- the neck portion 3 of the brush member 2 is fitted and mounted so as to cover the stem 6. Since the brush member 2 is a consumable part, the brush member 2 is configured to be removable from the grip 5 so that it can be replaced with a new one.

- Hairs (brushes) 210 are erected on one surface (hair raising surface) 4 a of the head portion 4 of the brush member 2 so as to protrude about 10 mm to 12 mm from the hair raising surface 4 a by flocking in this example.

- the hairs 210 may be welded or bonded instead of flocking.

- a power switch S for turning on / off the power is provided on the outer surface of the grip 5 of the main body 1. Further, inside the grip unit 5, a motor 10 as a drive source, a drive circuit 12, a rechargeable battery 13 as a power supply unit, a coil 14 for charging, an acceleration sensor 15, a gyro sensor 16 and the like are mounted. When charging the rechargeable battery 13, charging can be performed in a noncontact manner by electromagnetic induction only by mounting the main body 1 on the charger 100 shown in FIG. 1A.

- a bearing 203 is provided inside the stem 6.

- the tip of an eccentric shaft 30 connected to the rotation shaft 11 of the motor 10 is inserted into the bearing 203.

- the eccentric shaft 30 has a weight 300 near the bearing 203, and the center of gravity of the eccentric shaft 30 is offset from its center of rotation.

- the drive circuit 12 supplies a drive signal (for example, a pulse width modulation signal) according to the operation mode to the motor 10 to rotate the rotary shaft 11 of the motor 10, the eccentric shaft 30 also rotates with the rotation of the rotary shaft 11. .

- the eccentric shaft 30 performs a motion to pivot around the rotation center because the center of gravity is shifted from the rotation center. Therefore, the tip end of the eccentric shaft 30 repeatedly collides with the inner wall of the bearing 203 to vibrate (move) the hair 210 at high speed.

- the acceleration sensor 15 is a commercially available product of a MEMS (Micro Electro Mechanical Systems) type, and outputs a signal representing an acceleration of three axes of X, Y, and Z.

- X, Y, Z indicate orthogonal coordinate systems fixed to the main body 1.

- the X axis is parallel to the napped surface 4 a

- the Y axis is in the direction from the grip 5 to the head 4 in the longitudinal direction of the main body 1.

- the Z axis is set to coincide with the direction from the raised surface 4 a to the tip of the hair 210.

- the gravitational acceleration vector is in the -Y direction, and when the tip of the hair 210 is directed downward, the gravitational acceleration vector is in the + Z direction.

- the output of each axis of the acceleration sensor 15 is input to a control unit 110 described later, and is used to specify a brushing portion (details will be described later).

- the gyro sensor 16 is a commercially available product of MEMS type in this example, and is a signal representing the angular velocity of three axes of X, Y and Z, that is, the angular velocity around Z axis, the angular velocity around X axis and the angular velocity around Y axis Output

- the output of each axis of the gyro sensor 16 is input to a control unit 110 to be described later, and is used together with the output of the acceleration sensor 15 to identify a brushing portion (details will be described later).

- FIG. 3 shows a block configuration of a control system of the electric toothbrush 90.

- a control unit 110 which forms the above-described drive circuit 12, a storage unit 115, an operation unit 130, and notification A unit 140, a communication unit 180, and a power supply unit 170 are provided.

- the drive part 101 represents the motor 10, the rotating shaft 11, the eccentric shaft 30, the bearing 203, and the weight 300 as stated above.

- the control unit 110 includes a CPU (central processing unit) operated by software in this example, and executes, in addition to the drive of the motor 10, a process for specifying a brushing portion in the dentition and other various processes. Also, the control unit 110 incorporates a timer that measures time.

- a CPU central processing unit

- the operation unit 130 includes the power switch S described above, and serves to turn on / off the power of the electric toothbrush 90 by the user.

- Storage unit 115 includes, in this example, an EEPROM (electrically rewritable non-volatile memory) capable of storing data non-temporarily.

- the storage unit 115 stores a control program for controlling the control unit 110.

- data relating to brushing such as data representing the actual brushing time for each part in the dentition (this is referred to as “actual brushing time data”) in connection with tooth brushing is a table Is stored as (described later).

- the notification unit 140 includes a red LED (Light Emitting Diode) lamp 140R and a green LED lamp 140G (see FIG. 1A), which are predetermined by lighting and extinguishing the LED lamps 140R and 140G. Inform the progress of tooth brushing for the brushing procedure.

- the notification unit 140 may include a buzzer (not shown), and may notify the progress of tooth brushing with respect to the brushing procedure by ringing the buzzer.

- the communication unit 180 is controlled by the control unit 110 to transmit various information (such as actual brushing time data) as a transmission unit to an external device through the network, or to transmit various information from an external device (described later)

- a setting parameter or the like is received as a receiving unit via a network and is passed to the control unit 110.

- Communication via this network is wireless communication (for example, BT (Bluetooth (registered trademark)) communication, BLE (Bluetooth (registered trademark) low energy) communication, etc.) in this example.

- the network is typically a home LAN (Local Area Network), a hospital LAN, but is not limited to this, and may be the Internet or the like.

- the power supply unit 170 includes the rechargeable battery 13 described above, and supplies power (DC voltage in this example) to each part in the electric toothbrush 90.

- upper and lower dentitions 98U and 98L are divided into 16 parts SQ1, SQ2,..., SQ16 (the boundary between adjacent parts is represented by a broken line) ing.).

- the maxillary dentition 98U includes the left buccal site SQ1, the left meshing surface site SQ8, and the left tongue site SQ7 at the left back teeth, and the anterior teeth at the anterior lip site SQ2, the anterior tongue site SQ6.

- the lower jaw teeth row 98L includes a left buccal site SQ9, a left meshing surface site SQ16, and a left tongue site SQ15 at the left back teeth, and an anterior tooth at the anterior lip site SQ10 and the anterior tongue site SQ14. And the right buccal site SQ11, the right meshing surface site SQ12, and the right tongue site SQ13 at the right back tooth.

- the range of the “front teeth” is divided as a range of 20 mm from the reference position BP0 which is the center of the front side to the left and right (that is, the range of 40 mm in width on the left and right).

- the "left back tooth” is divided as a range exceeding 20 mm from the center BP0 on the front side to the left.

- the “right back tooth” is divided as a range exceeding 20 mm from the center BP0 on the front side to the right.

- the upper jaw teeth 98U and the lower jaw teeth 98L are each shown in the following Table 1 according to the combination of the range of translational position along the dental arch and the front, meshing or rear surface. It is divided as follows.

- the surface of Table 1 has a range of translational positions (“left back teeth”, “front teeth”, “right back teeth”) raised on the front head, “front” raised on the front side, “meshing surface”

- the numbers SQ1 to SQ16 of the respective parts determined by the combination with which one of "" and "rear surface” are shown.

- a part (division) corresponding to a combination with the “meshing surface” is not set (it is indicated by a symbol “-”).

- the division of the dentition is not limited to this, and may be a finer division.

- the teeth may be divided into individual teeth along the dental arch, or the individual teeth may be further divided into left and right halves.

- FIG. 4 shows a schematic flow of processing in which the control unit 110 of the electric toothbrush 90 specifies a brushing portion in the dentition 98U, 98L as a brushing portion detecting method according to one embodiment.

- the brushing is performed in the order of increasing numbers in order from the position SQ1 to SQ8 in the upper denture row 98U shown in FIG. 6, and from the position SQ9 to SQ16 in the lower dentition row 98L.

- the brushing procedure is determined in advance.

- the control unit 110 rotates the motor 10 to vibrate the hair 210.

- the user applies the bristles 210 of the head portion 4 to the reference position BP0 (see FIG. 8) which is the center of the front surface of the dentition 98U. It is assumed that The user can easily align the hair 210 of the head unit 4 with the reference position BP0.

- the control unit 110 starts measuring the brushing time by the built-in timer.

- control unit 110 acts as a brushing portion detection unit, and based on the output of the gyro sensor 16, brushing in the dentition 98U or 98L (initially limited to the upper jaw denture 98U)

- the translational position of the part (represented by the code "BP") is determined (details will be described later).

- the control unit 110 acts as a brushing portion detection unit, and based on the output of the acceleration sensor 15, the bristles 210 of the head unit 4 face around the vertical axis (Y axis) of the main body 1.

- Direction (+ Z direction) is determined, and depending on the direction (+ Z direction) the bristles 210 of the head unit 4 are facing, any one of the front, rear and meshing surfaces of the row of teeth 98U or 98L is brushed It is determined whether it is present (details will be described later).

- step S4 the control unit 110 acts as a brushing portion detection unit, and the translational position of the brushing portion BP determined based on the output of the gyro sensor 16 and the front and rear surfaces of the teeth 98U or 98L.

- the brushing portion BP in the dentition 98U or 98L is specified by the combination with the determination result as to which of the meshing surfaces is being brushed.

- step S5 the control unit 110 determines whether or not the brushing setting period for the identified brushing site BP has elapsed, based on the measurement result of time by the built-in timer. If the brushing setting period for the portion BP has not yet elapsed (NO in step S5), the processing in steps S2 to S5 is repeated. In this example, the control unit 110 repeats the processing of steps S2 to S5 every 0.1 seconds as a processing unit period.

- step S5 when the brushing setting period for the specified brushing site BP has elapsed (YES in step S5), the control unit 110, for example, takes about 0.2 seconds for the green LED lamp 140G included in the notification unit 140.

- step S6 By temporarily turning on, the user is notified that the brushing setting period for the part BP has elapsed (step S6).

- step S7 When the user continues brushing (for example, NO in step S7) although the brushing setting period has been exceeded for one second or more for the portion BP, for example, in order to prevent over-polishing in step S6, for example

- the user may be warned by temporarily turning on the red LED lamp 140R for about 0.2 seconds, for example.

- the progress of the brushing procedure with respect to the brushing procedure may be notified by the ringing of the buzzer included in the notification unit 140.

- control unit 110 controls brushing part BP specified above.

- the actual brushing time for the part BP are recorded in the table prepared in the storage unit 115 as actual brushing time data for each part (step S8).

- the storage unit 115 may also record other information related to brushing.

- step S1 the control unit 110 starts measuring the brushing time by the built-in timer for the “next part”.

- step S9 the process is ended.

- step S2 shown in FIG. 4 the process of determining the translational position of the brushing portion based on the output of the gyro sensor 16

- control unit 110 works as a brushing part detection unit, and as shown in FIG. 9, in the data space DS in which the xy orthogonal coordinate system is defined, a tooth row 98U , 98L, and an approximate curve E1 corresponding to a part of the curved ellipse E is set.

- the approximate curve E1 is set to contact with the x axis in a convex manner at the origin O (0, 0) as a reference point.

- An ellipse E tangent to the x-axis at a point O (0, 0) in a convex manner, with a, b being positive coefficients (ie, a> 0, b> 0), (X / a) 2 + ⁇ (y + b) / b ⁇ 2 1 ...

- step S21 may not be performed each time the process of step S2, but may be performed only once after the power is turned on.

- the data of the approximate curve E1 may be stored in the storage unit 115 in advance.

- the control unit 110 works as a brushing portion detection unit, and as shown in FIG. 8, the dentition 98U or 98L (in the example of FIG. ) In the real space RS where the bristles 210 of the head unit 4 are in contact with the reference position BP0 of the tooth row 98U with respect to the longitudinal axis (Y axis) Y0 of the main body 1

- the difference angle ⁇ formed by the vertical axis (Y axis) Y1 of the main body 1 when the bristles 210 of the head unit 4 are in contact with the brushing site BP is determined based on the output of the gyro sensor 16.

- the user applies the bristles 210 of the head 4 to the reference position BP0 which is the center of the front surface of the dentition 98U. Thereafter, the user applies the bristles 210 of the head 4 to another portion (brushing portion) BP of the dentition 98U or 98L according to the above-mentioned brushing procedure.

- the vertical axis (Y-axis) Y1 of the main body 1 when the 210 is in contact forms an angle (difference angle) ⁇ .

- the control unit 110 obtains the difference angle ⁇ based on the output (angular velocity) of the gyro sensor 16.

- the differential angle ⁇ can be obtained by performing first-order integration.

- the control unit 110 may perform the process of step S21 of FIG. 5 and the process of step S22 in parallel, or may perform the process of step S22 prior to the process of step S21.

- the control unit 110 works as a brushing part detection unit, and as shown in FIG. 9, in the data space DS, the reference position with respect to the approximate curve E1.

- a reference tangent corresponding to the x axis in this example

- a movable tangent that forms a difference angle ⁇ with respect to the reference tangent (x axis) and contacts the approximate curve E1 Set Q.

- the movable tangent line Q is variably set according to the change of the difference angle ⁇ , in other words, according to the change of the brushing portion BP in the tooth row 98U or 98L.

- control unit 110 obtains a point at which the movable tangent Q contacts the approximate curve E1 as the corresponding point P (step S25 in FIG. 5). Thereby, the corresponding point P on the approximate curve E1 can be determined by a relatively simple process.

- a movable tangent line Q is in contact with the approximate curve E1 at a point P (x 1 , y 1 ).

- the coordinates (x 1 , y 1 ) of the corresponding point P corresponding to the brushing portion BP on the approximate curve E 1 in the data space DS Can be found.

- the coordinates (x 1 , y 1 ) of the corresponding point P are data representing the translational position of the brushing portion BP.

- the equation (Eq. 6) is simplified by setting the center of the front surface of the dentition 98U to the reference position BP0.

- the center of the front surface of the row of teeth 98L may be set as the reference position BP0.

- the output of the gyro sensor 16 is an angular velocity

- the vibration component from the drive unit 101 (motor 10) since the output of the gyro sensor 16 is an angular velocity, the differential angle ⁇ can be obtained by performing the first-order integration, and it is difficult to be influenced by noise in the calculation process. Therefore, the translational position of the brushing portion BP in the dentition 98U or 98L can be accurately determined.

- the difference angle ⁇ in the real space RS is 45 °, and accordingly, the coordinates (x 1 , y 1 ) of the corresponding point P in the data space DS ((-17.5, -8.2) (unit mm) If so, the translational position of the brushing site BP belongs to the "front teeth" segment.

- step S3 (Determining which of the front, back, and mating surfaces is brushed)

- step S3 the process of step S3 shown in FIG. 4 (the direction in which the hairs 210 of the head portion 4 are oriented around the longitudinal axis (Y axis) of the main body 1 based on the output of the acceleration sensor 15 (+ Z direction Processing for determining which of the front, rear and meshing surfaces of the row of teeth 98U or 98L is brushed according to the direction (+ Z direction) the bristles 210 of the head unit 4 are facing) Will be described in detail with reference to FIG. 6 and FIGS.

- brushing is performed in the order of increasing numbers from the site SQ1 to SQ8 in the upper denture row 98U, and from SQ9 to SQ16 in the lower dentition row 98L. Furthermore, in the brushing procedure, at the time of brushing of each portion SQ1 to SQ16, the vertical axis (Y axis) of the main body 1 is horizontal as indicated by (HL) or (HR) and parentheses in FIG. 6 respectively. It is assumed that the head portion 4 (in the + Y direction) is oriented leftward or rightward with respect to the user's face in a state where the posture is taken.

- the reference symbol HL indicates that the head 4 (+ Y direction) is disposed leftward with respect to the face of the user, as shown in FIG.

- the code HR represents that the head 4 (+ Y direction) is disposed to the right with respect to the face of the user.

- FIG. 6 when the portions SQ1, SQ7, SQ8, SQ9, SQ15, SQ16 divided as "left back teeth" are brushed, it is set that the head portion 4 (+ Y direction) is disposed in the left direction HL. ing.

- the head portion 4 (+ Y direction) is set to be disposed in the right direction HR.

- These settings are necessarily required when brushing the "left back teeth” and the "right back teeth”, respectively.

- the portions SQ2, SQ6, SQ10 and SQ14 which are classified as "front teeth”, in this example they are set in the same direction as in the brushing of the portions immediately before. That is, when the portions SQ2 and SQ10 are brushed, it is set that the head portion 4 (+ Y direction) is disposed in the leftward direction HL. Further, when the portions SQ6 and SQ14 are brushed, it is set that the head portion 4 (+ Y direction) is disposed in the right direction HR.

- FIG. 10 shows the direction of the gravitational acceleration G output from the acceleration sensor 15 when viewed from the side of the head unit 4 (+ Y direction) with the vertical axis (Y axis) of the main body 1 taken in a horizontal posture. It shows.

- the direction (+ Z direction) that the hairs 210 of the head portion 4 are directed around the longitudinal axis (Y axis) of the main body 1 Is expressed as a rotation angle ⁇ around the vertical axis.

- the rotational angle ⁇ around the vertical axis is 0 ° vertically downward, and the vertical axis (Y axis) of the main body 1 takes a horizontal posture as shown in FIG. When viewed from the (+ Y direction), take a value within the range of 0 ° to 359.99 ° (up to two decimal places) counterclockwise.

- FIGS. 13 (A) to 13 (C) show sections for determining which of the front surface, the rear surface and the meshing surface of the “left back tooth” of the upper row of teeth 98U is brushed.

- the vertical axis (Y-axis) of the main body 1 takes a horizontal posture, and the head 4 (+ Y direction) is oriented leftward to the user's face, as shown in FIG. 13A. If the rotation angle ⁇ about the axis is in the range of 90 ° to 135 °, it is determined that the front surface (and hence the left buccal region) SQ1 is brushed. In that state, as shown in FIG.

- FIGS. 13D to 13F show sections for determining which of the anterior, posterior, and meshing surfaces of the left back tooth of the lower dentition row 98L is brushed.

- the vertical axis (Y-axis) of the main body 1 takes a horizontal posture, and the head portion 4 (+ Y direction) is arranged in the left direction HL with respect to the user's face, as shown in FIG. If the rotation angle ⁇ about the axis is in the range of 45 ° to 90 °, it is determined that the front surface (and hence the left buccal region) SQ9 is brushed. In that state, as shown in FIG.

- FIGS. 14 (A) to 14 (B) show sections for determining which of the front and back surfaces of the “front teeth” of the upper tooth denture 98U is brushed.

- the vertical axis (Y axis) of the main body 1 takes a horizontal posture, and the head 4 (+ Y direction) is arranged in the left direction HL with respect to the user's face, as shown in FIG. If the rotation angle ⁇ about the axis is in the range of 90 ° to 180 °, it is determined that the front surface (and hence the front lip side portion) SQ2 is brushed.

- FIGS. 14 (C) to 14 (D) show sections for determining which of the front surface and the rear surface of the “front teeth” of the lower row of teeth 98L is brushed.

- the vertical axis (Y axis) of the main body 1 takes a horizontal posture, and the head 4 (+ Y direction) is disposed in the left direction HL with respect to the user's face, as shown in FIG. If the rotation angle ⁇ about the axis is in the range of 0 ° to 90 °, it is determined that the front surface (and hence the front lip side portion) SQ10 is brushed.

- FIGS. 15 (A) to 15 (C) show sections for determining which of the front surface, the rear surface and the meshing surface of the “right back tooth” of the upper row of teeth 98U is brushed.

- the vertical axis (Y axis) of the main body 1 takes a horizontal posture and the head 4 (+ Y direction) is arranged in the right direction HR with respect to the user's face, as shown in FIG. If the rotation angle ⁇ about the axis is in the range of 90 ° to 135 °, it is determined that the back surface (and hence the right tongue side portion) SQ5 is brushed. In that state, as shown in FIG.

- FIGS. 15 (D) to 15 (F) show sections for determining which of the front, back and meshing surfaces of the “right back tooth” of the lower row of teeth 98L is brushed.

- the vertical axis (Y axis) of the main body 1 takes a horizontal posture, and the head 4 (+ Y direction) is oriented rightward HR with respect to the face of the user, as shown in FIG. If the rotation angle ⁇ about the axis is in the range of 45 ° to 90 °, it is determined that the rear surface (and hence the right tongue side portion) SQ13 is brushed. In that state, as shown in FIG.

- the correspondence relationship between the rotation angle ⁇ around the vertical axis and the front surface, rear surface, and meshing surface is as shown in Table 2 below.

- the surface of Table 2 shows the rotation angle ⁇ around the vertical axis when the head 4 (+ Y direction) is disposed in the leftward direction HL or the rightward direction HR.

- the front side of Table 2 is the front, meshing surface, back surface, front surface of the "front teeth", rear surface of the "left back teeth” of the upper jaw teeth 98U or lower jaw teeth 98L corresponding to the rotation angle ⁇ around the vertical axis ,

- the symbol "-" in the surface of Table 2 indicates that brushing can not occur.

- the rotation angle ⁇ in parentheses () indicates that brushing can occur but deviates from the brushing procedure described above. (Table 2) Correspondence between the rotation angle ⁇ around the vertical axis and the front, rear, and mating surfaces

- the control unit 110 sets the direction (+ Z direction) in which the hairs 210 of the head unit 4 face around the longitudinal axis (Y axis) of the main body 1 around the longitudinal axis. It is determined as the rotation angle ⁇ , and depending on the rotation angle ⁇ around the longitudinal axis, it can be determined which of the front surface, the rear surface and the meshing surface of the tooth row 98U or 98L is brushed.

- the control unit 110 determines that the translational position of the brushing portion BP determined based on the output of the gyro sensor 16 and either the front surface, the rear surface, or the meshing surface of the teeth 98U or 98L are brushed.

- the brushing portion BP in the dentition 98U or 98L can be specified by the combination with the determination result of whether it is being done. This makes it possible to specify the brushing portion BP in the dentition 98U or 98L with high accuracy.

- the user during tooth brushing does not substantially change the orientation of the vertical axis (Y axis) of the main body 1, for example, as shown in FIG. As indicated by MV2, there is a case where the main body 1 is largely translated and moved over from the left buccal site SQ1 to the right tongue site SQ5.

- the process of step S2 shown in FIG. An error occurs in the process of determining the translational position of the brushing site based on the output of the sensor 16).

- control unit 110 performs the correction process shown in the flow of FIG. 18 while repeating the processes of steps S2 to S5 in FIG.

- the control unit 110 performs second-order integration on the basis of the acceleration of the main body 1 output by the acceleration sensor 15 every 0.1 seconds as a processing unit period.

- the translational movement amount is represented by Acc_X, Acc_Y, Acc_Z

- velocity in the three axis directions is represented by v_X, v_Y, v_Z, respectively

- translation amount of the main body 1 in three axis directions is D_X, It is represented by D_Y and D_Z.

- step S42 the control unit 110 tabulates the translational movement amount Di of the main body 1 every 0.5 seconds as a preset tabulation unit period.

- the translational movement amount Di for each processing unit period is represented as D1, D2, D3, D4, D5

- the total translational movement amount D_total for a certain aggregation unit period is given by the following equation (Eq .10).

- D_total D1 + D2 + D3 + D4 + D5 ... (Eq. 10)

- step S43 the control unit 110 determines whether or not the total translational movement amount D_total is smaller than or equal to a predetermined first threshold value ⁇ 1 for a certain aggregation unit period.

- ⁇ 1 20 mm is set.

- the control unit 110 proceeds to step S44, and in the total unit period, the translational position of the brushing portion BP obtained based on the output of the gyro sensor 16 Is maintained (first correction processing).

- the user during tooth brushing substantially stops the translational movement of the main body 1 (particularly, the head portion 4), the longitudinal axis (Y axis) of the main body 1

- the translational position of the brushing portion BP obtained based on the output of the gyro sensor 16 is maintained before and after the change. Thereby, the accuracy of the determined translational position of the brushing portion BP can be maintained.

- the division of the dentition is more finely divided than that of Table 1, for example, when divided into individual teeth along the dental arch, the individual teeth are further divided into left and right halves. Accordingly, it is desirable to set the value of the first threshold ⁇ 1 smaller, for example, 10 mm or 5 mm, accordingly.

- step S45 the control unit 110 performs total for the total unit period. It is determined whether or not the translational movement amount D_total is equal to or greater than a predetermined second threshold value ⁇ 2.

- D_total ⁇ ⁇ 2 YES in step S45

- the control unit 110 shifts to a portion corresponding to the translational movement destination of the main body 1 on the approximate curve E1 in the data space DS.

- the corresponding point P is determined again based on the output (second correction process).

- the position is jumped from the left buccal site SQ1 to the right tongue site SQ5, for example, in the denture row 98U of the upper jaw, while hardly changing the direction of the longitudinal axis (Y axis) of the main body 1

- the control unit 110 shifts the x coordinate from a point near -a to a point near + a on the approximate curve E1 in the data space DS shown in FIG. Then, the corresponding point P is determined again based on the output (difference angle ⁇ ) of the gyro sensor 16.

- the translational position of the brushing portion BP in the dentition 98U or 98L can be accurately determined.

- the second-order integration is performed based on the output of the acceleration sensor 15 to calculate the translational movement amount Di of the main body 1 for each processing unit period. Therefore, it can be said that the calculated total translational movement amount D_total of the main body 1 is not accurate due to the influence of noise. However, the calculated total translational movement amount D_total of the main body 1 is extremely large (step S43 in FIG. 18) or almost no translational movement amount of the main body 1 (particularly, the head unit 4) There is no problem in using it for the determination of S45).

- control unit 110 determines that there is no need for correction, and the flow of FIG. The process returns to steps S2 to S5).

- the “standard” approximate curve E1 which is a part of the ellipse E shown in FIG. 7A, was used to determine the translational position of the brushing site BP.

- the minor diameter 2a ′ 60.43 mm.

- a portion with a depth D2 ⁇ 60 mm and a width W2 ⁇ 60 mm may be used as the approximate curve E2.

- the minor diameter 2a ′ ′ 62.21 mm

- the major diameter 2b ′ ′ 135.

- a portion with a depth D3 ⁇ 50 mm and a width W3 ⁇ 60 mm may be used as the approximate curve E3.

- the actual brushing time data for each part acquired by the control unit 110 and other data related to brushing may be transmitted to the outside of the main body 1 through the communication unit 180 as a transmission unit.

- the data can be received by a computer device provided outside the main body 1 and used for various processes and applications.

- the dental arch of the subject in the real space RS is approximated by a curve (approximated curve E1, E2 or E3) corresponding to a part of the ellipse E in the data space DS. Absent.

- the dental arch of the subject in real space RS may be approximated by a parabola U in data space DS.

- the parabola U contacts the x axis in a convex manner at the origin O (0, 0).

- an approximate curve can be set by defining the coefficient p. Therefore, the process of obtaining the corresponding point P can be easily performed.

- FIG. 20 illustrates the configuration of a system (generally indicated by reference numeral 700) including the electric toothbrush 90 and the smartphone 600 described above.

- the system 700 includes an electric toothbrush 90 and a smartphone 600 as a computer device so as to be able to wirelessly communicate with each other via a network 900.

- the smartphone 600 includes a main body 600M, and a control unit 610, a storage unit 620, an operation unit 630, a display 640, a communication unit 680, and a power supply unit 690 mounted on the main body 600M.

- the smartphone 600 is a commercially available smartphone on which application software described later is installed.

- Control unit 610 includes a CPU and its auxiliary circuit, controls each unit of smartphone 600, and executes processing in accordance with programs and data stored in storage unit 620. For example, based on an instruction input through the operation unit 630, the data input from the communication unit 680 is processed, and the processed data is stored in the storage unit 620, displayed on the display 640, or communicated. Output via the unit 680.

- Storage unit 620 includes a RAM (Random Access Memory) used as a work area necessary for executing a program in control unit 610, and a ROM (Read) for storing a basic program to be executed by control unit 610. And “Only Memory”.

- a semiconductor memory memory card, SSD (Solid State Drive) or the like may be used as a storage medium of an auxiliary storage device for assisting the storage area of the storage unit 620.

- the operation unit 630 is, in this example, a touch panel provided on the display 640.

- a keyboard or other hardware operation device may be included.

- the display 640 includes a display screen which is an LCD (liquid crystal display element) or an organic EL (electroluminescence) display in this example.

- the display 640 displays various images on the display screen according to the control of the control unit 610.

- Communication unit 680 is configured to be capable of wireless communication (for example, BT communication, BLE communication, and the like) with electric toothbrush 90 via network 900 according to control by control unit 610.

- wireless communication for example, BT communication, BLE communication, and the like

- the power supply unit 690 includes a rechargeable battery in this example, and supplies power to each unit of the smartphone 600.

- the electric toothbrush program performs wireless communication with the electric toothbrush 90 to make various settings regarding the brushing procedure and the like on the electric toothbrush 90, data for specifying the brushing part BP from the electric toothbrush 90, and translation of the brushing part It is a program that receives the position (coordinate value), the direction in which the hair 210 of the head unit 4 is facing, the output value of the gyro sensor or the acceleration sensor, and the like and uses them for various processes.

- minor axis and major axis of the selected ellipse, and the dimensions (depth and width) of the portion of the selected ellipse used as the approximate curve are set by changing them continuously on the screen of the display 640. It may be possible.

- the specified brushing site BP is associated with the actual brushing time for the site BP, and the actual brushing time data for each site is provided in the table provided in the storage unit 115. It is recorded as In this example, as shown in Table 3, the actual brushing time is 7.2 seconds for the site SQ1 in the upper denture row 98U, 3.7 seconds for the site SQ2, and 6.9 seconds for the site SQ3. The value was .... The lower jaw tooth row 98L had values of 5 seconds for the portion SQ9, 4.6 seconds for the portion SQ10, 6.6 seconds for the portion SQ11, and so on.

- control unit 610 of smartphone 600 receives data (including actual brushing time data for each part) recorded in the table of storage unit 115 from electric toothbrush 90 via communication unit 680.

- the control unit 610 works as a brushing evaluation unit, and calculates an evaluation value (brushing evaluation value) representing the degree of agreement with the brushing procedure based on the actual brushing time data for each part.

- the brushing evaluation values are 90% for the part SQ1, 93% for the part SQ2, 77% for the part SQ3, ... in the upper denture row 98U. Further, in the lower dentition 98L, the value is 100% for the part SQ9, 92% for the part SQ10, 94% for the part SQ11, and so on.

- control unit 610 of smartphone 600 causes the display screen of display 640 to display these brushing evaluation values.

- the user can view the display screen of the display 640 to know the degree of matching or non-matching of his or her brushing procedure with the brushing procedure.

- the brushing procedure tends to be inconsistent with the above brushing procedure, for example, the tendency of the back surface of the left back tooth (section SQ7) and the back surface of the right back tooth (section SQ5) to be insufficiently brushed. be able to.

- users can improve their brushing practices.

- control part 110 of electric toothbrush 90 performed a function of a brushing part detection part, it is not restricted to this. While communicating between the electric toothbrush 90 and the smartphone 600 while brushing teeth, the control unit 610 of the smartphone 600 may execute part or all of the functions of the brushing part detection unit. In such a case, the configuration of the control unit 110 of the electric toothbrush 90 can be simplified. Thus, the control unit 110 can be configured by, for example, a logic IC (integrated circuit) instead of the CPU.

- control unit 110 of the electric toothbrush 90 performs basic identification (flow in FIG. 4, particularly steps S2 and S3) of the brushing portion BP in the function of the brushing portion detection unit

- control unit 610 of the smartphone 600 corrects A process (flow of FIG. 18) may be performed.

- the processing load can be distributed between the electric toothbrush 90 and the smartphone 600.

- a device such as a tablet terminal or a personal computer that substantially functions as a computer device may be used.

- the method of processing executed by the control unit 110 of the electric toothbrush 90 or the control unit 610 of the smartphone 600 described above is, as application software (computer program), CD (compact disc), DVD (digital universal disc), flash memory, etc.

- a non-transitory data can be recorded on a recordable storage medium.

- an xyz orthogonal coordinate system may be set in the data space, and an approximate curve inclined with respect to the horizontal xy plane may be set.

Landscapes

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- Dentistry (AREA)

- Epidemiology (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Radar, Positioning & Navigation (AREA)

- Remote Sensing (AREA)

- General Physics & Mathematics (AREA)

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Biophysics (AREA)

- Brushes (AREA)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE112018003570.0T DE112018003570B4 (de) | 2017-07-11 | 2018-06-08 | Elektrische zahnbürste, system, bürststellenerfassungsverfahren und programm |

| CN201880030390.3A CN110612044B (zh) | 2017-07-11 | 2018-06-08 | 电动牙刷、系统、刷牙部位检测方法和存储介质 |

| US16/693,571 US11484113B2 (en) | 2017-07-11 | 2019-11-25 | Electric toothbrush, system, brushing site detection method, and computer-readable recording medium |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017-135687 | 2017-07-11 | ||

| JP2017135687A JP6953845B2 (ja) | 2017-07-11 | 2017-07-11 | 電動歯ブラシ、システム、ブラッシング部位検出方法およびプログラム |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US16/693,571 Continuation US11484113B2 (en) | 2017-07-11 | 2019-11-25 | Electric toothbrush, system, brushing site detection method, and computer-readable recording medium |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2019012879A1 true WO2019012879A1 (ja) | 2019-01-17 |

Family

ID=65001160

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2018/021986 Ceased WO2019012879A1 (ja) | 2017-07-11 | 2018-06-08 | 電動歯ブラシ、システム、ブラッシング部位検出方法およびプログラム |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US11484113B2 (cg-RX-API-DMAC7.html) |

| JP (1) | JP6953845B2 (cg-RX-API-DMAC7.html) |

| CN (1) | CN110612044B (cg-RX-API-DMAC7.html) |

| DE (1) | DE112018003570B4 (cg-RX-API-DMAC7.html) |

| WO (1) | WO2019012879A1 (cg-RX-API-DMAC7.html) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11346938B2 (en) | 2019-03-15 | 2022-05-31 | Msa Technology, Llc | Safety device for providing output to an individual associated with a hazardous environment |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102018216586A1 (de) | 2018-09-27 | 2020-04-02 | Siemens Aktiengesellschaft | Verblockungselement für Rotorwickelköpfe bei Turbogeneratoren mit Läuferkappe mit radialen Ventilationsbohrungen |

| JP7262084B2 (ja) * | 2020-02-07 | 2023-04-21 | パナソニックIpマネジメント株式会社 | 電動歯ブラシ |

| CN114577259A (zh) * | 2022-02-08 | 2022-06-03 | 深圳市云顶信息技术有限公司 | 一种刷牙信息反馈方法、装置、电子设备和存储介质 |

| CN115006035B (zh) * | 2022-05-30 | 2023-06-27 | 深圳市新博电科技开发有限公司 | 一种电动牙刷控制方法 |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2016532492A (ja) * | 2013-08-11 | 2016-10-20 | 王勇競 | オーラルケアシステム及び方法 |

| JP2017060662A (ja) * | 2015-09-25 | 2017-03-30 | サンスター株式会社 | 歯ブラシモジュール、及び歯磨支援システム |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5293101B2 (ja) | 2008-03-14 | 2013-09-18 | オムロンヘルスケア株式会社 | 電動歯ブラシ |

| FI20085488A0 (fi) * | 2008-05-23 | 2008-05-23 | Pump & Brush Finland Oy | Älykäs hammasharjamonitorointilaite |

| CN105029891B (zh) * | 2015-08-19 | 2017-08-29 | 秦立新 | 刷牙动作检测校正方法及系统、牙刷、远程控制装置 |

| CN105466422A (zh) * | 2015-12-02 | 2016-04-06 | 爱芽(北京)科技有限公司 | 一种检测牙刷在口腔内部位置变动算法 |

-

2017

- 2017-07-11 JP JP2017135687A patent/JP6953845B2/ja active Active

-

2018

- 2018-06-08 WO PCT/JP2018/021986 patent/WO2019012879A1/ja not_active Ceased

- 2018-06-08 CN CN201880030390.3A patent/CN110612044B/zh active Active

- 2018-06-08 DE DE112018003570.0T patent/DE112018003570B4/de active Active

-

2019

- 2019-11-25 US US16/693,571 patent/US11484113B2/en active Active

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2016532492A (ja) * | 2013-08-11 | 2016-10-20 | 王勇競 | オーラルケアシステム及び方法 |

| JP2017060662A (ja) * | 2015-09-25 | 2017-03-30 | サンスター株式会社 | 歯ブラシモジュール、及び歯磨支援システム |

Non-Patent Citations (1)

| Title |

|---|

| SAKA, TSUTOMU: "The studies on the factor analysis of the morphologic variation of the palatal vault. In relation to the maxillo-facial-cranial pattern", JAPANESE JOURNAL OF ORAL & MAXILLOFACIAL SURGERY, vol. 34, 3 March 1988 (1988-03-03), pages 451 - 469, XP055566988 * |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11346938B2 (en) | 2019-03-15 | 2022-05-31 | Msa Technology, Llc | Safety device for providing output to an individual associated with a hazardous environment |

| US12169234B2 (en) | 2019-03-15 | 2024-12-17 | Msa Technology, Llc | Safety device for providing output to an individual associated with a hazardous environment |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2019017418A (ja) | 2019-02-07 |

| DE112018003570B4 (de) | 2025-02-06 |

| JP6953845B2 (ja) | 2021-10-27 |

| US11484113B2 (en) | 2022-11-01 |

| CN110612044B (zh) | 2021-06-22 |

| CN110612044A (zh) | 2019-12-24 |

| DE112018003570T5 (de) | 2020-03-26 |

| US20200093253A1 (en) | 2020-03-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2019012879A1 (ja) | 電動歯ブラシ、システム、ブラッシング部位検出方法およびプログラム | |

| CN103764063B (zh) | 用于去除牙齿牙垢的口腔护理装置 | |

| JP5526825B2 (ja) | 口腔ケア装置 | |

| JP5482209B2 (ja) | 電動歯ブラシ | |

| CN109803558B (zh) | 智能牙刷 | |

| JP2019017418A5 (cg-RX-API-DMAC7.html) | ||

| US8393037B2 (en) | Electric toothbrush | |

| KR101574129B1 (ko) | 지능형 칫솔 모니터링 장치 | |

| CN109788845B (zh) | 智能牙刷 | |

| JP2019508183A (ja) | コンプライアンスの監視のための、視覚的認識を伴う口腔衛生システム | |

| CN107735047B (zh) | 电动牙刷装置和方法 | |

| JP6914939B2 (ja) | ブラッシングセッションのフィードバックを提供するための方法及びシステム | |

| US20110041269A1 (en) | Electric toothbrush | |

| RU2759877C2 (ru) | Способ определения ориентации головы пользователя во время чистки зубов | |

| EP3522751B1 (en) | Smart toothbrush | |

| US20190167399A1 (en) | Toothbrush and system | |

| JP2021122609A (ja) | 歯ブラシシステム、および歯ブラシシステム用プログラム | |

| TWI744048B (zh) | 刷牙系統及刷牙方法 | |

| JP2016106751A (ja) | 歯ブラシおよび歯磨き管理システム |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 18832736 Country of ref document: EP Kind code of ref document: A1 |

|

| DPE2 | Request for preliminary examination filed before expiration of 19th month from priority date (pct application filed from 20040101) | ||

| WWP | Wipo information: published in national office |

Ref document number: 112018003570 Country of ref document: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 18832736 Country of ref document: EP Kind code of ref document: A1 |

|

| WWG | Wipo information: grant in national office |

Ref document number: 112018003570 Country of ref document: DE |