WO2018109622A1 - Process for preparation of dydrogesterone - Google Patents

Process for preparation of dydrogesterone Download PDFInfo

- Publication number

- WO2018109622A1 WO2018109622A1 PCT/IB2017/057747 IB2017057747W WO2018109622A1 WO 2018109622 A1 WO2018109622 A1 WO 2018109622A1 IB 2017057747 W IB2017057747 W IB 2017057747W WO 2018109622 A1 WO2018109622 A1 WO 2018109622A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- compound

- formula

- give

- dydrogesterone

- reducing

- Prior art date

Links

- HVIRODNIXKHCNY-WPAGTLKASA-N C[C@](CC1)([C@@H](CC2)[C@H](CC3)[C@H]1[C@@](C)(C(O)=O)C3=O)[C@H]2C(C)=O Chemical compound C[C@](CC1)([C@@H](CC2)[C@H](CC3)[C@H]1[C@@](C)(C(O)=O)C3=O)[C@H]2C(C)=O HVIRODNIXKHCNY-WPAGTLKASA-N 0.000 description 1

Classifications

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07J—STEROIDS

- C07J15/00—Stereochemically pure steroids containing carbon, hydrogen, halogen or oxygen having a partially or totally inverted skeleton, e.g. retrosteroids, L-isomers

- C07J15/005—Retrosteroids (9 beta 10 alfa)

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07C—ACYCLIC OR CARBOCYCLIC COMPOUNDS

- C07C29/00—Preparation of compounds having hydroxy or O-metal groups bound to a carbon atom not belonging to a six-membered aromatic ring

- C07C29/132—Preparation of compounds having hydroxy or O-metal groups bound to a carbon atom not belonging to a six-membered aromatic ring by reduction of an oxygen containing functional group

- C07C29/136—Preparation of compounds having hydroxy or O-metal groups bound to a carbon atom not belonging to a six-membered aromatic ring by reduction of an oxygen containing functional group of >C=O containing groups, e.g. —COOH

- C07C29/143—Preparation of compounds having hydroxy or O-metal groups bound to a carbon atom not belonging to a six-membered aromatic ring by reduction of an oxygen containing functional group of >C=O containing groups, e.g. —COOH of ketones

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07C—ACYCLIC OR CARBOCYCLIC COMPOUNDS

- C07C45/00—Preparation of compounds having >C = O groups bound only to carbon or hydrogen atoms; Preparation of chelates of such compounds

- C07C45/27—Preparation of compounds having >C = O groups bound only to carbon or hydrogen atoms; Preparation of chelates of such compounds by oxidation

- C07C45/29—Preparation of compounds having >C = O groups bound only to carbon or hydrogen atoms; Preparation of chelates of such compounds by oxidation of hydroxy groups

- C07C45/298—Preparation of compounds having >C = O groups bound only to carbon or hydrogen atoms; Preparation of chelates of such compounds by oxidation of hydroxy groups with manganese derivatives

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07C—ACYCLIC OR CARBOCYCLIC COMPOUNDS

- C07C45/00—Preparation of compounds having >C = O groups bound only to carbon or hydrogen atoms; Preparation of chelates of such compounds

- C07C45/61—Preparation of compounds having >C = O groups bound only to carbon or hydrogen atoms; Preparation of chelates of such compounds by reactions not involving the formation of >C = O groups

- C07C45/62—Preparation of compounds having >C = O groups bound only to carbon or hydrogen atoms; Preparation of chelates of such compounds by reactions not involving the formation of >C = O groups by hydrogenation of carbon-to-carbon double or triple bonds

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07C—ACYCLIC OR CARBOCYCLIC COMPOUNDS

- C07C45/00—Preparation of compounds having >C = O groups bound only to carbon or hydrogen atoms; Preparation of chelates of such compounds

- C07C45/61—Preparation of compounds having >C = O groups bound only to carbon or hydrogen atoms; Preparation of chelates of such compounds by reactions not involving the formation of >C = O groups

- C07C45/64—Preparation of compounds having >C = O groups bound only to carbon or hydrogen atoms; Preparation of chelates of such compounds by reactions not involving the formation of >C = O groups by introduction of functional groups containing oxygen only in singly bound form

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07C—ACYCLIC OR CARBOCYCLIC COMPOUNDS

- C07C45/00—Preparation of compounds having >C = O groups bound only to carbon or hydrogen atoms; Preparation of chelates of such compounds

- C07C45/61—Preparation of compounds having >C = O groups bound only to carbon or hydrogen atoms; Preparation of chelates of such compounds by reactions not involving the formation of >C = O groups

- C07C45/65—Preparation of compounds having >C = O groups bound only to carbon or hydrogen atoms; Preparation of chelates of such compounds by reactions not involving the formation of >C = O groups by splitting-off hydrogen atoms or functional groups; by hydrogenolysis of functional groups

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07C—ACYCLIC OR CARBOCYCLIC COMPOUNDS

- C07C51/00—Preparation of carboxylic acids or their salts, halides or anhydrides

- C07C51/16—Preparation of carboxylic acids or their salts, halides or anhydrides by oxidation

- C07C51/31—Preparation of carboxylic acids or their salts, halides or anhydrides by oxidation of cyclic compounds with ring-splitting

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07J—STEROIDS

- C07J7/00—Normal steroids containing carbon, hydrogen, halogen or oxygen substituted in position 17 beta by a chain of two carbon atoms

- C07J7/0005—Normal steroids containing carbon, hydrogen, halogen or oxygen substituted in position 17 beta by a chain of two carbon atoms not substituted in position 21

- C07J7/001—Normal steroids containing carbon, hydrogen, halogen or oxygen substituted in position 17 beta by a chain of two carbon atoms not substituted in position 21 substituted in position 20 by a keto group

- C07J7/0015—Normal steroids containing carbon, hydrogen, halogen or oxygen substituted in position 17 beta by a chain of two carbon atoms not substituted in position 21 substituted in position 20 by a keto group not substituted in position 17 alfa

- C07J7/002—Normal steroids containing carbon, hydrogen, halogen or oxygen substituted in position 17 beta by a chain of two carbon atoms not substituted in position 21 substituted in position 20 by a keto group not substituted in position 17 alfa not substituted in position 16

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07J—STEROIDS

- C07J75/00—Processes for the preparation of steroids in general

- C07J75/005—Preparation of steroids by cyclization of non-steroid compounds

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07B—GENERAL METHODS OF ORGANIC CHEMISTRY; APPARATUS THEREFOR

- C07B2200/00—Indexing scheme relating to specific properties of organic compounds

- C07B2200/07—Optical isomers

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07C—ACYCLIC OR CARBOCYCLIC COMPOUNDS

- C07C2603/00—Systems containing at least three condensed rings

- C07C2603/02—Ortho- or ortho- and peri-condensed systems

- C07C2603/04—Ortho- or ortho- and peri-condensed systems containing three rings

- C07C2603/06—Ortho- or ortho- and peri-condensed systems containing three rings containing at least one ring with less than six ring members

- C07C2603/10—Ortho- or ortho- and peri-condensed systems containing three rings containing at least one ring with less than six ring members containing five-membered rings

- C07C2603/12—Ortho- or ortho- and peri-condensed systems containing three rings containing at least one ring with less than six ring members containing five-membered rings only one five-membered ring

- C07C2603/16—Benz[e]indenes; Hydrogenated benz[e]indenes

Definitions

- the present invention relates to a process for the preparation of dydrogesterone.

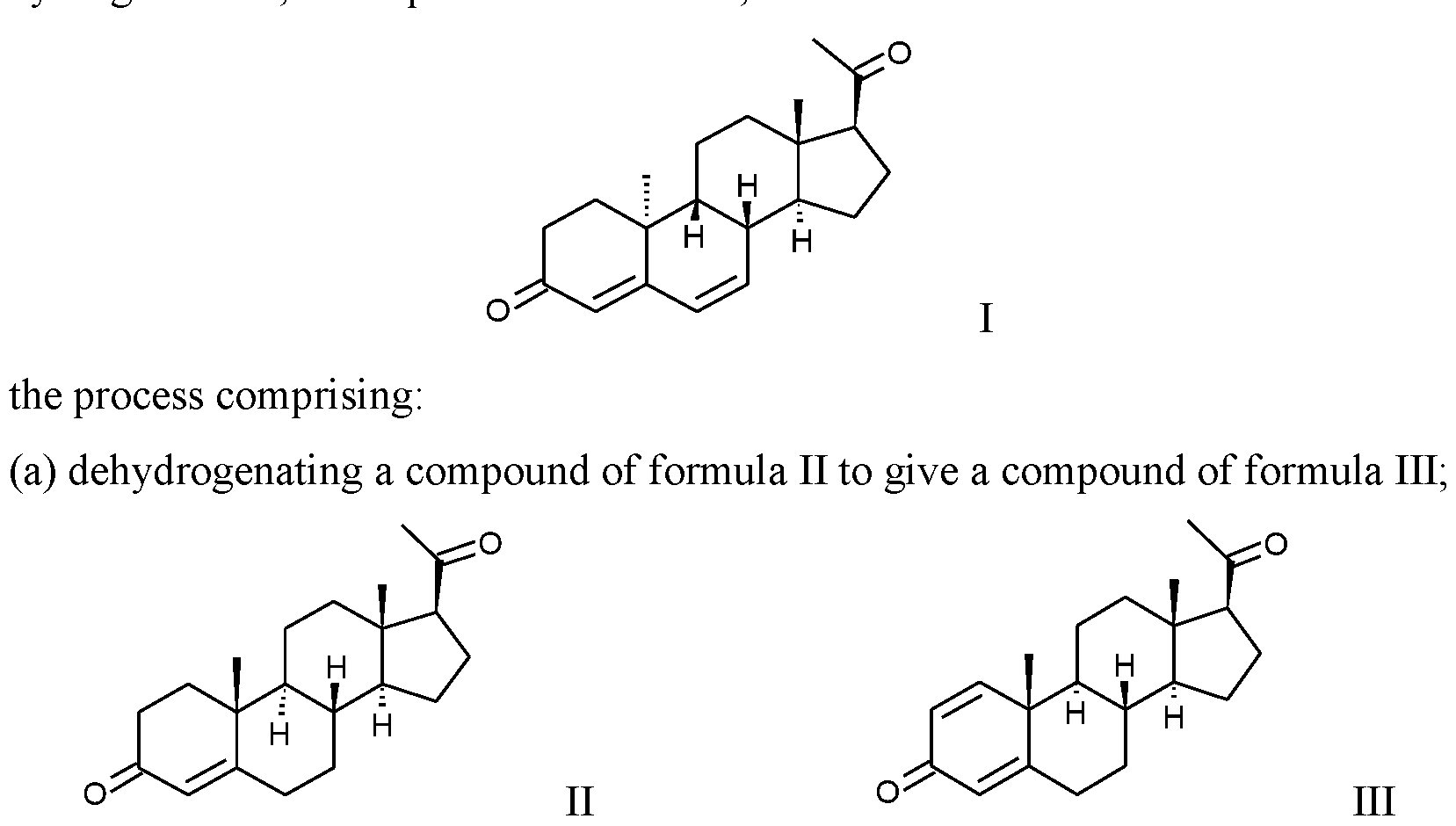

- Dydrogesterone also known as 9p,10a-pregna-4,6-diene-3,20-dione, is represented by the structure of formula I.

- the object of the present invention is to provide a novel process for preparation of dydrogesterone.

- the present invention provides a process for the preparation dydrogesterone, a compound of formula I,

- Figure 1 is a characteristic XRPD of dydrogesterone

- the present invention provides a process for the preparation of

- the reaction may be carried out in the presence of dehydrogenating reagents selected from quinones such as 2,3-dichloro-5,6-dicyanobenzoquinone (DDQ), chloranil and the like; benzeneseleninic anhydride; thallium (III) acetate; or mixtures thereof.

- dehydrogenating reagents selected from quinones such as 2,3-dichloro-5,6-dicyanobenzoquinone (DDQ), chloranil and the like; benzeneseleninic anhydride; thallium (III) acetate; or mixtures thereof.

- the reaction may optionally be carried out in the presence of a catalyst selected from tert-tutyldimethylsilyl chloride, trifluorormethanesulfonic acid, salicylic acid, ⁇ -toluenesulfonic acid, benzoic acid, acetic acid, ⁇ , ⁇ - bis(trimethylsilyl)trifluoroacetamide and the like.

- a catalyst selected from tert-tutyldimethylsilyl chloride, trifluorormethanesulfonic acid, salicylic acid, ⁇ -toluenesulfonic acid, benzoic acid, acetic acid, ⁇ , ⁇ - bis(trimethylsilyl)trifluoroacetamide and the like.

- the reaction may be carried out in the presence of a solvent selected from hydrocarbons such as toluene, xylene, chlorobenzene, heptane, hexane and the like; ethers such as dimethyl ether, diethyl ether, diisopropyl ether, tert-butyl methyl ether, tetrahydrofuran, dioxane and the like; or mixtures thereof.

- a solvent selected from hydrocarbons such as toluene, xylene, chlorobenzene, heptane, hexane and the like; ethers such as dimethyl ether, diethyl ether, diisopropyl ether, tert-butyl methyl ether, tetrahydrofuran, dioxane and the like; or mixtures thereof.

- reaction mass containing the compound of formula III may be treated with a base or aqueous solution of base.

- the base may be selected from the group consisting of alkali or alkaline earth metal hydroxides such as sodium hydroxide, potassium hydroxide, calcium hydroxide, or alkali or alkaline metal carbonates or bicarbonates thereof such as sodium carbonate, potassium carbonate, sodium bicarbonate.

- alkali or alkaline earth metal hydroxides such as sodium hydroxide, potassium hydroxide, calcium hydroxide, or alkali or alkaline metal carbonates or bicarbonates thereof such as sodium carbonate, potassium carbonate, sodium bicarbonate.

- the reaction mass containing the compound of formula III may be heated with a base or aqueous solution of base in the temperature in the range of 40-80°C.

- reaction mass containing the compound of formula III may be heated with aqueous sodium bicarbonate solution in the temperature in the range of 50-60°C.

- the compound of formula III may be purified using a solvent selected from ethers such as dimethyl ether, diethyl ether, diisopropyl ether, tert-butyl methyl ether, tetrahydrofuran, dioxane and the like; esters such as methyl acetate, ethyl acetate, ⁇ -propyl acetate, tert-butyl acetate and the like; hydrocarbons such as toluene, xylene, chlorobenzene, petroleum ether, heptane, hexane and the like; or mixtures thereof.

- ethers such as dimethyl ether, diethyl ether, diisopropyl ether, tert-butyl methyl ether, tetrahydrofuran, dioxane and the like

- esters such as methyl acetate, ethyl acetate, ⁇ -propyl acetate, tert-buty

- the reaction may be carried out in the presence of oxidizing agents selected from sodium periodate, oxone-alkali metal carbonate, oxone-alkali metal bicarbonate, sodium hypochlorite, ozone-hydrogen peroxide, hydrogen peroxide, oxone, N-methylmorpholine N-oxide and the like; or mixtures thereof; optionally in the presence of catalytic 3,4,5,6-tetramethyl-2-iodoxybenzoic acid, ruthenium chloride hydrate, ruthenium oxide, osmium tetroxide, potassium permanganate and the like.

- oxidizing agents selected from sodium periodate, oxone-alkali metal carbonate, oxone-alkali metal bicarbonate, sodium hypochlorite, ozone-hydrogen peroxide, hydrogen peroxide, oxone, N-methylmorpholine N-oxide and the like; or mixtures thereof; optionally in the presence of catalytic 3,4,5,6-te

- the reaction may be carried out in the presence of a solvent selected from halogenated hydrocarbons such as dichloromethane, chloroform, carbon tetrachloride, ethylene dichloride and the like; nitriles such as acetonitrile, butyronitrile, isobutyronitrile, propionitrile and the like; esters such as methyl acetate, ethyl acetate, ⁇ -propyl acetate, tert-butyl acetate and the like; ethers such as dimethyl ether, diethyl ether, diisopropyl ether, tert-butyl methyl ether, tetrahydrofuran, dioxane and the like; amide solvents such as dimethylformamide, acetamide and the like; ketones such as acetone, ethyl methyl ketone, methyl isobutyl ketone and the like; water or mixtures thereof.

- halogenated hydrocarbons

- the compound of formula IV may be purified using a solvent selected from ethers such as dimethyl ether, diethyl ether, diisopropyl ether, tert-butyl methyl ether, tetrahydrofuran, dioxane and the like; esters such as methyl acetate, ethyl acetate, ⁇ -propyl acetate, tert-butyl acetate and the like; ketones such as acetone, ethyl methyl ketone, methyl isobutyl ketone and the like; hydrocarbons such as toluene, xylene, chlorobenzene, petroleum ether, heptane, hexane and the like; or mixtures thereof.

- ethers such as dimethyl ether, diethyl ether, diisopropyl ether, tert-butyl methyl ether, tetrahydrofuran, dioxane and the like

- esters

- the compound of formula IV may be purified by using above mentioned solvent systems by recrystallization.

- the reaction may be carried out in the presence of oxidizing agents selected from quinone compounds such as 2,3-dichloro-5,6-dicyanobenzoquinone, chloranil and the like; metal acetate salts such as lead tetraacetate-potassium acetate, lead tetraacetate-cupric acetate and the like; periodinane compounds such as phenyliodonium diacetate (PUD A); or mixtures thereof

- quinone compounds such as 2,3-dichloro-5,6-dicyanobenzoquinone, chloranil and the like

- metal acetate salts such as lead tetraacetate-potassium acetate, lead tetraacetate-cupric acetate and the like

- periodinane compounds such as phenyliodonium diacetate (PUD A); or mixtures thereof

- the reaction may optionally be carried out in the presence of a catalyst selected from tert-tutyldimethylsilyl chloride, trifluorormethanesulfonic acid, N,O-bis(trimethylsilyl)trifluoroacetamide, salicylic acid, ⁇ -toluenesulfonic acid, benzoic acid, acetic acid, pyridine and the like.

- a catalyst selected from tert-tutyldimethylsilyl chloride, trifluorormethanesulfonic acid, N,O-bis(trimethylsilyl)trifluoroacetamide, salicylic acid, ⁇ -toluenesulfonic acid, benzoic acid, acetic acid, pyridine and the like.

- the reaction may be carried out in the presence of a solvent selected from hydrocarbons such as benzene, toluene, xylene, chlorobenzene, heptane, hexane and the like; acids such as acetic acid, formic acid and the like; organic bases such as pyridine and the like; amide solvents such as dimethylformamide, acetamide and the like; or mixtures thereof.

- a solvent selected from hydrocarbons such as benzene, toluene, xylene, chlorobenzene, heptane, hexane and the like; acids such as acetic acid, formic acid and the like; organic bases such as pyridine and the like; amide solvents such as dimethylformamide, acetamide and the like; or mixtures thereof.

- the compound of formula V may be purified using a solvent selected from ethers such as dimethyl ether, diethyl ether, diisopropyl ether, tert-butyl methyl ether, tetrahydrofuran, dioxane and the like; esters such as methyl acetate, ethyl acetate, ⁇ -propyl acetate, tert-butyl acetate and the like; hydrocarbons such as toluene, xylene, chlorobenzene, petroleum ether, heptane, hexane and the like; or mixtures thereof.

- ethers such as dimethyl ether, diethyl ether, diisopropyl ether, tert-butyl methyl ether, tetrahydrofuran, dioxane and the like

- esters such as methyl acetate, ethyl acetate, ⁇ -propyl acetate, tert-buty

- the present invention provides dydrogesterone obtained by a process as described herein, with >99.5% purity and wherein the level of impurity A, impurity B or impurity C or impurity D is less than 0.15% w/w of dydrogesterone

- a suitable reducing agent includes, but is not limited to lithium borohydride, sodium borohydride, potassium borohydride, lithium aluminium hydride, sodium cyanoborohydride, sodium triacetoxyborohydride, diisobutyl aluminium hydride and the like; or reduction by catalytic hydrogenation using Raney nickel, palladium, platinum, rhodium catalyst.

- the reducing agent selected is sodium borohydride.

- the reaction may be carried out in the presence of a suitable solvent.

- the suitable solvent includes, but is not limited to alcohols such as methanol, ethanol, ⁇ -propyl alcohol, isopropyl alcohol, «-butyl alcohol, isobutyl alcohol, sec -butyl alcohol, tert-butyl alcohol, pentanol, octanol and the like; ethers such as dimethyl ether, diethyl ether, diisopropyl ether, tert-butyl methyl ether, tetrahydrofuran, dioxane and the like; esters such as methyl acetate, ethyl acetate, ⁇ -propyl acetate, tert-butyl acetate and the like; dimethyl formamide; dimethyl sulfoxide; dimethyl acetamide; water or mixtures thereof.

- the solvent selected is methanol.

- the compound of formula V is reduced to give the compound of formula VI, wherein the required diastereomer VI is obtained in 80% and the remaining diasteromers are obtained in 20%.

- the compound of formula VI may be purified using a solvent selected from alcohols such as methanol, ethanol, n-propyl alcohol, isopropyl alcohol, n-butyl alcohol, isobutyl alcohol, sec-butyl alcohol, tert-butyl alcohol, pentanol, octanol and the like; ethers such as dimethyl ether, diethyl ether, diisopropyl ether, tert-butyl methyl ether, tetrahydrofuran, dioxane and the like; esters such as methyl acetate, ethyl acetate, n-propyl acetate, tert-butyl acetate and the like; ketones such as acetone, ethyl methyl ketone, methyl isobutyl ketone and the like; or mixtures thereof.

- alcohols such as methanol, ethanol, n-propyl alcohol, isopropyl alcohol,

- a suitable oxidizing agent includes, but is not limited to manganese dioxide, barium manganate, and the like.

- the reaction may be carried out in the presence of a suitable solvent.

- the suitable solvent includes, but is not limited to halogenated hydrocarbons such as dichloromethane, chloroform, carbon tetrachloride, ethylene dichloride, and the like; alcohols such as methanol, ethanol, n-propyl alcohol, isopropyl alcohol, n- butyl alcohol, isobutyl alcohol, sec-butyl alcohol, tert-butyl alcohol, pentanol, octanol and the like; esters such as methyl acetate, ethyl acetate, ⁇ -propyl acetate, tert-butyl acetate and the like; hydrocarbons such as toluene, xylene, chlorobenzene, heptane, hexane and the like; or mixtures thereof.

- the solvent selected is dichloromethane.

- the compound of formula VI is oxidized to give the compound of formula VII, wherein the product is obtained in a diastereomeric mixture (20P-hydroxy:20a-hydroxy) with the ratio of 8:2.

- the compound of formula VII may be purified by column chromatography using ethyl acetate-hexane mixture, acetone-hexane mixture.

- the compound of formula VII may be purified using a solvent selected from alcohols such as methanol, ethanol, n-propyl alcohol, isopropyl alcohol, n-butyl alcohol, isobutyl alcohol, sec-butyl alcohol, tert-butyl alcohol, pentanol, octanol and the like; ethers such as dimethyl ether, diethyl ether, diisopropyl ether, tert-butyl methyl ether, tetrahydrofuran, dioxane and the like; esters such as methyl acetate, ethyl acetate, n-propyl acetate, tert-butyl acetate and the like; ketones such as acetone, ethyl methyl ketone, methyl isobutyl ketone and the like; hydrocarbons such as toluene, xylene, chlorobenzene, petroleum ether,

- alcohols such as

- the compound of formula V is selectively reduced to give the compound of formula VII.

- the compound of formula V is converted to the compound of formula VIII by a process comprising:

- the reducing agent may be selected from the group consisting of lithium borohydride, sodium borohydride, potassium borohydride, lithium aluminium hydride, sodium cyanoborohydride, sodium triacetoxyborohydride, diisobutylaluminium hydride and the like; or reduction by catalytic hydrogenation using Raney nickel, palladium, platinum, rhodium catalyst.

- the reducing agent selected is sodium borohydride.

- the temperature for selective reduction is preferably in the range of -25 to - 50°C.

- the solvent may be the same as disclosed for p.

- the compound of formula VII is reduced to give a compound of formula VIII.

- the reduction may be carried out by catalytic hydrogenation using Raney nickel, palladium/carbon, platinum, rhodium/alumina catalyst.

- the reaction may be carried out in the presence of a solvent selected from alcohols such as methanol, ethanol, n-propyl alcohol, isopropyl alcohol, n-butyl alcohol, isobutyl alcohol, sec-butyl alcohol, tert-butyl alcohol, pentanol, octanol and the like; esters such as methyl acetate, ethyl acetate, n-propyl acetate, tert-butyl acetate and the like; or mixtures thereof.

- a solvent selected from alcohols such as methanol, ethanol, n-propyl alcohol, isopropyl alcohol, n-butyl alcohol, isobutyl alcohol, sec-butyl alcohol, tert-butyl alcohol, pentanol, octanol and the like; esters such as methyl acetate, ethyl acetate, n-propyl acetate, tert-butyl

- the compound of formula VII is reduced to give the compound of formula VIII, wherein the required diastereomer VIII is obtained in 80% and the remaining diasteromers are obtained in 20%.

- the compound of formula VIII may be purified by column chromatography using ethyl acetate-hexane mixture, acetone-hexane mixture.

- the reaction may be carried out in the presence of a base selected from alkali metal hydroxides such as lithium hydroxide, sodium hydroxide, potassium hydroxide; alkaline earth metal hydroxides; alkali metal alcoholates such as lithium methoxide, sodium methoxide, potassium methoxide, rubidium methoxide, caesium methoxide, lithium ethoxide, sodium ethoxide, potassium ethoxide, sodium pentoxide, lithium tert-butoxide, sodium tert-butoxide, potassium tert- butoxide; alkaline earth metal alcoholates such as calcium ethoxide, magnesium isopropoxide; alkali metal carbonates such as sodium carbonate, potassium carbonate, caesium carbonate; alkaline earth metal carbonates; alkali metal bicarbonates such as sodium bicarbonate; n-butyl lithium; lithium diisopropylamide; sodium hydride; benzyltrimethylammonium hydroxide; proline;

- the reaction may be carried out in the presence of a solvent selected from alcohols such as methanol, ethanol, n-propyl alcohol, isopropyl alcohol, n-butyl alcohol, isobutyl alcohol, sec-butyl alcohol, tert-butyl alcohol, pentanol, octanol and the like; hydrocarbons such as toluene, xylene, chlorobenzene, heptane, hexane and the like; ethers such as dimethyl ether, diethyl ether, diisopropyl ether, tert- butyl methyl ether, tetrahydrofuran, dioxane and the like; halogenated hydrocarbons such as dichloromethane, chloroform, carbon tetrachloride, ethylene dichloride and the like; water or mixtures thereof.

- a solvent selected from alcohols such as methanol, ethanol, n-propyl alcohol, isoprop

- the compound of formula IX may be purified using a solvent selected from ethers such as dimethyl ether, diethyl ether, diisopropyl ether, tert-butyl methyl ether, tetrahydrofuran, dioxane and the like; alcohols such as methanol, ethanol, n-propyl alcohol, isopropyl alcohol, n-butyl alcohol, isobutyl alcohol, sec-butyl alcohol, tert-butyl alcohol, pentanol, octanol and the like; esters such as methyl acetate, ethyl acetate, n-propyl acetate, tert-butyl acetate and the like; ketones such as acetone, ethyl methyl ketone, methyl isobutyl ketone and the like; hydrocarbons such as toluene, xylene, chlorobenzene, petroleum ether, and the like.

- a suitable oxidizing agent includes, but is not limited to chromium trioxide, chromium trioxide-aqueous sulfuric acid, pyridinium chlorochromate, pyridinium dichromate, dimethyl sulfoxide-oxalyl chloride-triethylamine, 2-iodoxybenzoic acid, Dess-Martin periodinane, aluminium isopropoxide-acetone, 2,2,6,6- tetramethylpiperidin-l-yl)oxyl (TEMPO)-sodium hypochlorite, oxone-TEMPO, tetra-n-butylammonium bromide (TBAB)-TEMPO and the like.

- chromium trioxide chromium trioxide-aqueous sulfuric acid

- pyridinium chlorochromate pyridinium dichromate

- dimethyl sulfoxide-oxalyl chloride-triethylamine 2-iodoxybenzoic acid

- the reaction may be carried out in the presence of a solvent selected from ketones such as acetone, ethyl methyl ketone, methyl isobutyl ketone and the like; halogenated hydrocarbons such as dichloromethane, chloroform, carbon tetrachloride, ethylene dichloride, and the like; hydrocarbons such as toluene, xylene, chlorobenzene, heptane, hexane and the like; ethers such as dimethyl ether, diethyl ether, diisopropyl ether, tert-butyl methyl ether, tetrahydrofuran, dioxane and the like; dimethyl formamide; dimethyl sulfoxide; dimethyl acetamide; or mixtures thereof.

- ketones such as acetone, ethyl methyl ketone, methyl isobutyl ketone and the like

- halogenated hydrocarbons such as dichloromethane

- the compound of formula X may be purified using a solvent selected from ethers such as dimethyl ether, diethyl ether, diisopropyl ether, tert-butyl methyl ether, tetrahydrofuran, dioxane and the like; alcohols such as methanol, ethanol, n-propyl alcohol, isopropyl alcohol, n-butyl alcohol, isobutyl alcohol, sec-butyl alcohol, tert-butyl alcohol, pentanol, octanol and the like; esters such as methyl acetate, ethyl acetate, n-propyl acetate, tert-butyl acetate and the like; ketones such as acetone, ethyl methyl ketone, methyl isobutyl ketone and the like; hydrocarbons such as toluene, xylene, chlorobenzene, petroleum ether, and the like.

- the reaction may be carried out in the presence of dehydrogenating reagents selected from quinones such as 2,3-dichloro-5,6-dicyanobenzoquinone, chloranil and the like; benzeneseleninic anhydride; thallium (III) acetate.

- dehydrogenating reagents selected from quinones such as 2,3-dichloro-5,6-dicyanobenzoquinone, chloranil and the like; benzeneseleninic anhydride; thallium (III) acetate.

- the reaction may optionally be carried out in the presence of a catalyst selected from tert-tutyldimethylsilyl chloride, trifluorormethanesulfonic acid, salicylic acid, p-toluenesulfonic acid, benzoic acid, acetic acid, ⁇ , ⁇ - bis(trimethylsilyl)trifluoroacetamide and the like.

- a catalyst selected from tert-tutyldimethylsilyl chloride, trifluorormethanesulfonic acid, salicylic acid, p-toluenesulfonic acid, benzoic acid, acetic acid, ⁇ , ⁇ - bis(trimethylsilyl)trifluoroacetamide and the like.

- the reaction may be carried out in the presence of a solvent selected from hydrocarbons such as toluene, xylene, chlorobenzene, heptane, hexane and the like; alcohols such as methanol, ethanol, n-propyl alcohol, isopropyl alcohol, n-butyl alcohol, isobutyl alcohol, sec-butyl alcohol, tert-butyl alcohol, pentanol, octanol and the like; ethers such as dimethyl ether, diethyl ether, diisopropyl ether, tert- butyl methyl ether, tetrahydrofuran, dioxane and the like; or mixtures thereof.

- hydrocarbons such as toluene, xylene, chlorobenzene, heptane, hexane and the like

- alcohols such as methanol, ethanol, n-propyl alcohol, isopropyl alcohol,

- dydrogesterone may be purified by column chromatography using ethyl acetate-hexane mixture, acetone-hexane mixture.

- dydrogesterone may be purified by recrystallization using a solvent selected from ethers such as dimethyl ether, diethyl ether, diisopropyl ether, tert-butyl methyl ether, tetrahydrofuran, dioxane and the like; alcohols such as methanol, ethanol, n-propyl alcohol, isopropyl alcohol, n-butyl alcohol, isobutyl alcohol, sec-butyl alcohol, tert-butyl alcohol, pentanol, octanol and the like; esters such as methyl acetate, ethyl acetate, n-propyl acetate, tert-butyl acetate and the like; ketones such as acetone, ethyl methyl ketone, methyl isobutyl ketone and the like; halogenated hydrocarbons such as dichloromethane, chloroform

- dydrogesterone may be purified by column chromatography using ethyl acetate-hexane mixture followed by recrystallization using acetone.

- dydrogesterone may be purified by column chromatography using ethyl acetate-hexane mixture followed by recrystallization using acetone to give dydrogesterone with at least 99% purity, preferably >99.5% purity and more preferably free of impurities A and C.

- dydrogesterone may be purified by recrystallization a solvent selected from ethers such as dimethyl ether, diethyl ether, diisopropyl ether, tert-butyl methyl ether, ketones such as acetone, ethyl methyl ketone, methyl isobutyl ketone and the like; or mixtures thereof to obtain dydrogesterone in a purity of 99.5%.

- the compound of formula V is converted to dydrogesterone by a process comprising:

- the compound of formula V is converted to dydrogesterone by a process comprising:

- the compound of formula V is converted to dydrogesterone by a process comprising:

- the compound of formula V is converted to dydrogesterone by a process comprising:

- the compound of formula V is converted to dydrogesterone by a process comprising:

- the present invention provides use of a compound of formula IV,

- the present invention provides a process for the preparation of dydrogesterone, a compound of formula I, by a process comprising the manufacture of a compound of formula IV,

- the present invention provides a process for the preparation of dydrogesterone, a compound of formula I, by a process comprising the step of oxidatively decarboxylating a compound of formula IV to give a compound of formula V

- the present invention provides a process for the preparation of dydrogesterone, a compound of formula I, by a process comprising:

- the present invention provides a process for the preparation of dydrogesterone, a compound of formula I, by a process comprising: (i) subjecting 1 la-hydroxyprogesterone to ozonization to give lla-hydroxy-5,20- dioxo-3,5-seco-A-norpregnan-3-oic acid; (ii) optionally, reacting lla-hydroxy-5,20-dioxo-3,5-seco-A-norpregnan-3-oic acid with a base to give salt of lla-hydroxy-5,20-dioxo-3,5-seco-A-norpregnan-3-oic acid;

- EXAMPLE 7 Preparation of compound of formula IX To a stirred solution of compound of formula VIII (2.8g) in tert-butyl alcohol (28mL) was added sodium hydroxide powder (O. lg) at about room temperature. The reaction mixture was heated to about 50°C to about 55°C and stirred for about 30min at about the same temperature under nitrogen atmosphere. Methyl vinyl ketone in toluene solution was drop wise added to the reaction mixture which was stirred at about 50°C to about 55°C for about lh. The reaction mixture was cooled to about 5°C to about 10°C, quenched with glacial acetic acid, slowly warmed to about room temperature and stirred for about lh. The reaction mixture was concentrated under vacuum and the residue obtained was purified by silica gel column chromatography to give compound of formula IX as a pale yellow solid.

Abstract

The present invention relates to process for the preparation of dydrogesterone.

Description

PROCESS FOR PREPARATION OF DYDROGESTERONE

FIELD OF THE INVENTION

[0001] The present invention relates to a process for the preparation of dydrogesterone.

BACKGROUND OF THE INVENTION

[0002] Dydrogesterone, also known as 9p,10a-pregna-4,6-diene-3,20-dione, is represented by the structure of formula I.

[0003] The object of the present invention is to provide a novel process for preparation of dydrogesterone.

SUMMARY OF THE INVENTION

[0004] The present invention provides a process for the preparation dydrogesterone, a compound of formula I,

(b) oxidatively cleaving the compound of formula III to give a compound of formula IV;

(c) oxidatively decarboxylating the compound of formula IV to give a compound of formula V: and

(d) converting the compound of formula V to dydrogesterone, the compound of formula I.

BRIEF DESCRIPTION OF THE DRAWINGS

[0005] Figure 1 is a characteristic XRPD of dydrogesterone

DETAILED DESCRIPTION OF THE INVENTION

[0006] The present invention provides a process for the preparation of

dydrogesterone, a compound of formula I,

the process comprising:

(a) dehydrogenating a compound of formula II to give a compound of formula III;

(c) oxidatively decarboxylating the compound of formula IV to give a compound of formula V; and

(d) converting the compound of formula V to dydrogesterone, the compound of formula I.

[0007] In (a) of the process for the preparation of dydrogesterone, the compound of formula II is dehydrogenated to give the compound of formula III.

[0008] The reaction may be carried out in the presence of dehydrogenating reagents selected from quinones such as 2,3-dichloro-5,6-dicyanobenzoquinone (DDQ), chloranil and the like; benzeneseleninic anhydride; thallium (III) acetate; or mixtures thereof.

[0009] The reaction may optionally be carried out in the presence of a catalyst selected from tert-tutyldimethylsilyl chloride, trifluorormethanesulfonic acid, salicylic acid, ^-toluenesulfonic acid, benzoic acid, acetic acid, Ν,Ο- bis(trimethylsilyl)trifluoroacetamide and the like.

[0010] The reaction may be carried out in the presence of a solvent selected from hydrocarbons such as toluene, xylene, chlorobenzene, heptane, hexane and the like; ethers such as dimethyl ether, diethyl ether, diisopropyl ether, tert-butyl methyl ether, tetrahydrofuran, dioxane and the like; or mixtures thereof.

[0011] In one embodiment, the reaction mass containing the compound of formula III may be treated with a base or aqueous solution of base.

[0012] The base may be selected from the group consisting of alkali or alkaline earth metal hydroxides such as sodium hydroxide, potassium hydroxide, calcium

hydroxide, or alkali or alkaline metal carbonates or bicarbonates thereof such as sodium carbonate, potassium carbonate, sodium bicarbonate.

[0013] In one embodiment, the reaction mass containing the compound of formula III, may be heated with a base or aqueous solution of base in the temperature in the range of 40-80°C.

[0014] In one embodiment, the reaction mass containing the compound of formula III, may be heated with aqueous sodium bicarbonate solution in the temperature in the range of 50-60°C.

[0015] In one embodiment, the compound of formula III may be purified using a solvent selected from ethers such as dimethyl ether, diethyl ether, diisopropyl ether, tert-butyl methyl ether, tetrahydrofuran, dioxane and the like; esters such as methyl acetate, ethyl acetate, ^-propyl acetate, tert-butyl acetate and the like; hydrocarbons such as toluene, xylene, chlorobenzene, petroleum ether, heptane, hexane and the like; or mixtures thereof.

[0016] In (b) of the process for the preparation of dydrogesterone, the compound of formula III is subjected to oxidative cleavage to give a compound of formula

IV.

[0017] The reaction may be carried out in the presence of oxidizing agents selected from sodium periodate, oxone-alkali metal carbonate, oxone-alkali metal bicarbonate, sodium hypochlorite, ozone-hydrogen peroxide, hydrogen peroxide, oxone, N-methylmorpholine N-oxide and the like; or mixtures thereof; optionally in the presence of catalytic 3,4,5,6-tetramethyl-2-iodoxybenzoic acid, ruthenium chloride hydrate, ruthenium oxide, osmium tetroxide, potassium permanganate and the like.

[0018] The reaction may be carried out in the presence of a solvent selected from halogenated hydrocarbons such as dichloromethane, chloroform, carbon tetrachloride, ethylene dichloride and the like; nitriles such as acetonitrile, butyronitrile, isobutyronitrile, propionitrile and the like; esters such as methyl acetate, ethyl acetate, ^-propyl acetate, tert-butyl acetate and the like; ethers such as dimethyl ether, diethyl ether, diisopropyl ether, tert-butyl methyl ether, tetrahydrofuran, dioxane and the like; amide solvents such as dimethylformamide,

acetamide and the like; ketones such as acetone, ethyl methyl ketone, methyl isobutyl ketone and the like; water or mixtures thereof.

[0019] In one embodiment, the compound of formula IV may be purified using a solvent selected from ethers such as dimethyl ether, diethyl ether, diisopropyl ether, tert-butyl methyl ether, tetrahydrofuran, dioxane and the like; esters such as methyl acetate, ethyl acetate, ^-propyl acetate, tert-butyl acetate and the like; ketones such as acetone, ethyl methyl ketone, methyl isobutyl ketone and the like; hydrocarbons such as toluene, xylene, chlorobenzene, petroleum ether, heptane, hexane and the like; or mixtures thereof.

[0020] In one embodiment, the compound of formula IV may be purified by using above mentioned solvent systems by recrystallization.

[0021] In (c) of the process for the preparation of dydrogesterone, the compound of formula IV is subjected to oxidative decarboxylation to give a compound of formula V.

[0022] The reaction may be carried out in the presence of oxidizing agents selected from quinone compounds such as 2,3-dichloro-5,6-dicyanobenzoquinone, chloranil and the like; metal acetate salts such as lead tetraacetate-potassium acetate, lead tetraacetate-cupric acetate and the like; periodinane compounds such as phenyliodonium diacetate (PUD A); or mixtures thereof

[0023] The reaction may optionally be carried out in the presence of a catalyst selected from tert-tutyldimethylsilyl chloride, trifluorormethanesulfonic acid, N,O-bis(trimethylsilyl)trifluoroacetamide, salicylic acid, ^-toluenesulfonic acid, benzoic acid, acetic acid, pyridine and the like.

[0024] The reaction may be carried out in the presence of a solvent selected from hydrocarbons such as benzene, toluene, xylene, chlorobenzene, heptane, hexane and the like; acids such as acetic acid, formic acid and the like; organic bases such as pyridine and the like; amide solvents such as dimethylformamide, acetamide and the like; or mixtures thereof.

[0025] In one embodiment, the compound of formula V may be purified using a solvent selected from ethers such as dimethyl ether, diethyl ether, diisopropyl ether, tert-butyl methyl ether, tetrahydrofuran, dioxane and the like; esters such as

methyl acetate, ethyl acetate, ^-propyl acetate, tert-butyl acetate and the like; hydrocarbons such as toluene, xylene, chlorobenzene, petroleum ether, heptane, hexane and the like; or mixtures thereof.

[0026] In (d) of the process for the preparation of dydrogesterone, the compound of formula V is converted to dydrogesterone by a process comprising:

(x) converting the compound of formula V to a com ound of formula VIII;

(y) reacting the compound of formula VIII with methyl vinyl ketone to give a compound of formula IX; and

(z) dehydrogenating the compound of formula IX to give dydrogesterone, the compound of formula I.

[0027] In one embodiment, the present invention provides dydrogesterone obtained by a process as described herein, with >99.5% purity and wherein the level of impurity A, impurity B or impurity C or impurity D is less than 0.15% w/w of dydrogesterone

[0028] In (x) of the above process, the compound of formula V is converted to the compound of formula VIII by a process comprising:

(p) reducing the compound of formula V to give a compound of formula VI;

(q) oxidizing the compound of formula VI to ive a compound of formula VII; and

(r) reducing the compound of formula VII to give the compound of formula VIII.

[0029] In (p) of the above process, the compound of formula V is reduced to give the compound of formula VI.

[0030] A suitable reducing agent includes, but is not limited to lithium borohydride, sodium borohydride, potassium borohydride, lithium aluminium hydride, sodium cyanoborohydride, sodium triacetoxyborohydride, diisobutyl aluminium hydride and the like; or reduction by catalytic hydrogenation using Raney nickel, palladium, platinum, rhodium catalyst. Preferably, the reducing agent selected is sodium borohydride.

[0031] The reaction may be carried out in the presence of a suitable solvent. The suitable solvent includes, but is not limited to alcohols such as methanol, ethanol, ^-propyl alcohol, isopropyl alcohol, «-butyl alcohol, isobutyl alcohol, sec -butyl alcohol, tert-butyl alcohol, pentanol, octanol and the like; ethers such as dimethyl

ether, diethyl ether, diisopropyl ether, tert-butyl methyl ether, tetrahydrofuran, dioxane and the like; esters such as methyl acetate, ethyl acetate, ^-propyl acetate, tert-butyl acetate and the like; dimethyl formamide; dimethyl sulfoxide; dimethyl acetamide; water or mixtures thereof. Preferably, the solvent selected is methanol.

[0032] In one embodiment, the compound of formula V is reduced to give the compound of formula VI, wherein the required diastereomer VI is obtained in 80% and the remaining diasteromers are obtained in 20%.

[0033] In one embodiment, the compound of formula VI may be purified using a solvent selected from alcohols such as methanol, ethanol, n-propyl alcohol, isopropyl alcohol, n-butyl alcohol, isobutyl alcohol, sec-butyl alcohol, tert-butyl alcohol, pentanol, octanol and the like; ethers such as dimethyl ether, diethyl ether, diisopropyl ether, tert-butyl methyl ether, tetrahydrofuran, dioxane and the like; esters such as methyl acetate, ethyl acetate, n-propyl acetate, tert-butyl acetate and the like; ketones such as acetone, ethyl methyl ketone, methyl isobutyl ketone and the like; or mixtures thereof.

[0034] In (q) of the above process, the compound of formula VI is oxidized to give the compound of formula VII.

[0035] A suitable oxidizing agent includes, but is not limited to manganese dioxide, barium manganate, and the like.

[0036] The reaction may be carried out in the presence of a suitable solvent. The suitable solvent includes, but is not limited to halogenated hydrocarbons such as dichloromethane, chloroform, carbon tetrachloride, ethylene dichloride, and the like; alcohols such as methanol, ethanol, n-propyl alcohol, isopropyl alcohol, n- butyl alcohol, isobutyl alcohol, sec-butyl alcohol, tert-butyl alcohol, pentanol, octanol and the like; esters such as methyl acetate, ethyl acetate, ^-propyl acetate, tert-butyl acetate and the like; hydrocarbons such as toluene, xylene, chlorobenzene, heptane, hexane and the like; or mixtures thereof. Preferably, the solvent selected is dichloromethane.

[0037] In one embodiment, the compound of formula VI is oxidized to give the compound of formula VII, wherein the product is obtained in a diastereomeric mixture (20P-hydroxy:20a-hydroxy) with the ratio of 8:2.

[0038] In one embodiment, the compound of formula VII may be purified by column chromatography using ethyl acetate-hexane mixture, acetone-hexane mixture.

[0039] In one embodiment, the compound of formula VII may be purified using a solvent selected from alcohols such as methanol, ethanol, n-propyl alcohol, isopropyl alcohol, n-butyl alcohol, isobutyl alcohol, sec-butyl alcohol, tert-butyl alcohol, pentanol, octanol and the like; ethers such as dimethyl ether, diethyl ether, diisopropyl ether, tert-butyl methyl ether, tetrahydrofuran, dioxane and the like; esters such as methyl acetate, ethyl acetate, n-propyl acetate, tert-butyl acetate and the like; ketones such as acetone, ethyl methyl ketone, methyl isobutyl ketone and the like; hydrocarbons such as toluene, xylene, chlorobenzene, petroleum ether, heptane, hexane and the like; or mixtures thereof.

[0040] In one embodiment, the compound of formula V is selectively reduced to give the compound of formula VII.

[0041] In one embodiment, the compound of formula V is converted to the compound of formula VIII by a process comprising:

(pi) directly reducing the compound of formula V to give a compound of formula VII;

(r) reducing the compound of formula VII to give the compound of formula VIII.

[0042] In (pi) of the above process the selective reduction is carried out by a process comprising reacting compound V with a reducing agent at a temperature in the range of 0 to -70°C to directly obtain a compound of formula VII.

[0043] The reducing agent may be selected from the group consisting of lithium borohydride, sodium borohydride, potassium borohydride, lithium aluminium hydride, sodium cyanoborohydride, sodium triacetoxyborohydride, diisobutylaluminium hydride and the like; or reduction by catalytic hydrogenation using Raney nickel, palladium, platinum, rhodium catalyst. Preferably, the reducing agent selected is sodium borohydride.

[0044] The temperature for selective reduction is preferably in the range of -25 to - 50°C. The solvent may be the same as disclosed for p.

[0045] In (r) of the above process, the compound of formula VII is reduced to give a compound of formula VIII.

[0046] The reduction may be carried out by catalytic hydrogenation using Raney nickel, palladium/carbon, platinum, rhodium/alumina catalyst.

[0047] The reaction may be carried out in the presence of a solvent selected from alcohols such as methanol, ethanol, n-propyl alcohol, isopropyl alcohol, n-butyl alcohol, isobutyl alcohol, sec-butyl alcohol, tert-butyl alcohol, pentanol, octanol and the like; esters such as methyl acetate, ethyl acetate, n-propyl acetate, tert-butyl acetate and the like; or mixtures thereof.

[0048] In one embodiment, the compound of formula VII is reduced to give the compound of formula VIII, wherein the required diastereomer VIII is obtained in 80% and the remaining diasteromers are obtained in 20%.

[0049] In one embodiment, the compound of formula VIII may be purified by column chromatography using ethyl acetate-hexane mixture, acetone-hexane mixture.

[0050] In (y) of the above process, the compound of formula VIII is reacted with methyl vinyl ketone to give the compound of formula IX.

[0051] The reaction may be carried out in the presence of a base selected from alkali metal hydroxides such as lithium hydroxide, sodium hydroxide, potassium hydroxide; alkaline earth metal hydroxides; alkali metal alcoholates such as lithium methoxide, sodium methoxide, potassium methoxide, rubidium methoxide, caesium methoxide, lithium ethoxide, sodium ethoxide, potassium ethoxide, sodium pentoxide, lithium tert-butoxide, sodium tert-butoxide, potassium tert- butoxide; alkaline earth metal alcoholates such as calcium ethoxide, magnesium isopropoxide; alkali metal carbonates such as sodium carbonate, potassium carbonate, caesium carbonate; alkaline earth metal carbonates; alkali metal bicarbonates such as sodium bicarbonate; n-butyl lithium; lithium diisopropylamide; sodium hydride; benzyltrimethylammonium hydroxide; proline; l,8-diazabicyclo[5.4.0]undec-7-ene or in the presence of mild acidic conditions such as sulfuric acid, p-toluenesulfonic acid, acetic acid, trifluoroacetic acid.

[0052] The reaction may be carried out in the presence of a solvent selected from alcohols such as methanol, ethanol, n-propyl alcohol, isopropyl alcohol, n-butyl alcohol, isobutyl alcohol, sec-butyl alcohol, tert-butyl alcohol, pentanol, octanol and the like; hydrocarbons such as toluene, xylene, chlorobenzene, heptane, hexane and the like; ethers such as dimethyl ether, diethyl ether, diisopropyl ether, tert- butyl methyl ether, tetrahydrofuran, dioxane and the like; halogenated hydrocarbons such as dichloromethane, chloroform, carbon tetrachloride, ethylene dichloride and the like; water or mixtures thereof.

[0053] In one embodiment, the compound of formula IX may be purified using a solvent selected from ethers such as dimethyl ether, diethyl ether, diisopropyl ether, tert-butyl methyl ether, tetrahydrofuran, dioxane and the like; alcohols such as methanol, ethanol, n-propyl alcohol, isopropyl alcohol, n-butyl alcohol, isobutyl alcohol, sec-butyl alcohol, tert-butyl alcohol, pentanol, octanol and the like; esters such as methyl acetate, ethyl acetate, n-propyl acetate, tert-butyl acetate and the like; ketones such as acetone, ethyl methyl ketone, methyl isobutyl ketone and the like; hydrocarbons such as toluene, xylene, chlorobenzene, petroleum ether, heptane, hexane and the like; or mixtures thereof.

[0054] In (z) of the above process, the dehydrogenation of the compound of formula

IX to give dydrogesterone is carried out by a process comprising:

(t) oxidizing the compound of formula IX to give a compound of formula X; and

(u) dehydrogenating the compound of formula X to give dehydrogesterone, the compound of formula I.

[0055] In (t) of the above process, the compound of formula IX is oxidized to give a compound of formula X.

[0056] A suitable oxidizing agent includes, but is not limited to chromium trioxide, chromium trioxide-aqueous sulfuric acid, pyridinium chlorochromate, pyridinium dichromate, dimethyl sulfoxide-oxalyl chloride-triethylamine, 2-iodoxybenzoic

acid, Dess-Martin periodinane, aluminium isopropoxide-acetone, 2,2,6,6- tetramethylpiperidin-l-yl)oxyl (TEMPO)-sodium hypochlorite, oxone-TEMPO, tetra-n-butylammonium bromide (TBAB)-TEMPO and the like.

[0057] The reaction may be carried out in the presence of a solvent selected from ketones such as acetone, ethyl methyl ketone, methyl isobutyl ketone and the like; halogenated hydrocarbons such as dichloromethane, chloroform, carbon tetrachloride, ethylene dichloride, and the like; hydrocarbons such as toluene, xylene, chlorobenzene, heptane, hexane and the like; ethers such as dimethyl ether, diethyl ether, diisopropyl ether, tert-butyl methyl ether, tetrahydrofuran, dioxane and the like; dimethyl formamide; dimethyl sulfoxide; dimethyl acetamide; or mixtures thereof.

[0058] In one embodiment, the compound of formula X may be purified using a solvent selected from ethers such as dimethyl ether, diethyl ether, diisopropyl ether, tert-butyl methyl ether, tetrahydrofuran, dioxane and the like; alcohols such as methanol, ethanol, n-propyl alcohol, isopropyl alcohol, n-butyl alcohol, isobutyl alcohol, sec-butyl alcohol, tert-butyl alcohol, pentanol, octanol and the like; esters such as methyl acetate, ethyl acetate, n-propyl acetate, tert-butyl acetate and the like; ketones such as acetone, ethyl methyl ketone, methyl isobutyl ketone and the like; hydrocarbons such as toluene, xylene, chlorobenzene, petroleum ether, heptane, hexane and the like; or mixtures thereof.

[0059] In (u) of the above process, the compound of formula X is dehydrogenated to give dydrogesterone.

[0060] The reaction may be carried out in the presence of dehydrogenating reagents selected from quinones such as 2,3-dichloro-5,6-dicyanobenzoquinone, chloranil and the like; benzeneseleninic anhydride; thallium (III) acetate.

[0061] The reaction may optionally be carried out in the presence of a catalyst selected from tert-tutyldimethylsilyl chloride, trifluorormethanesulfonic acid, salicylic acid, p-toluenesulfonic acid, benzoic acid, acetic acid, Ν,Ο- bis(trimethylsilyl)trifluoroacetamide and the like.

[0062] The reaction may be carried out in the presence of a solvent selected from hydrocarbons such as toluene, xylene, chlorobenzene, heptane, hexane and the like;

alcohols such as methanol, ethanol, n-propyl alcohol, isopropyl alcohol, n-butyl alcohol, isobutyl alcohol, sec-butyl alcohol, tert-butyl alcohol, pentanol, octanol and the like; ethers such as dimethyl ether, diethyl ether, diisopropyl ether, tert- butyl methyl ether, tetrahydrofuran, dioxane and the like; or mixtures thereof.

[0063] In one embodiment, dydrogesterone may be purified by column chromatography using ethyl acetate-hexane mixture, acetone-hexane mixture.

[0064] In one embodiment, dydrogesterone may be purified by recrystallization using a solvent selected from ethers such as dimethyl ether, diethyl ether, diisopropyl ether, tert-butyl methyl ether, tetrahydrofuran, dioxane and the like; alcohols such as methanol, ethanol, n-propyl alcohol, isopropyl alcohol, n-butyl alcohol, isobutyl alcohol, sec-butyl alcohol, tert-butyl alcohol, pentanol, octanol and the like; esters such as methyl acetate, ethyl acetate, n-propyl acetate, tert-butyl acetate and the like; ketones such as acetone, ethyl methyl ketone, methyl isobutyl ketone and the like; halogenated hydrocarbons such as dichloromethane, chloroform, carbon tetrachloride, ethylene dichloride, and the like; hydrocarbons such as toluene, xylene, chlorobenzene, heptane, hexane and the like; or mixtures thereof.

[0065] In one embodiment, dydrogesterone may be purified by column chromatography using ethyl acetate-hexane mixture followed by recrystallization using acetone.

[0066] In one embodiment, dydrogesterone may be purified by column chromatography using ethyl acetate-hexane mixture followed by recrystallization using acetone to give dydrogesterone with at least 99% purity, preferably >99.5% purity and more preferably free of impurities A and C.

In one embodiment, dydrogesterone may be purified by recrystallization a solvent selected from ethers such as dimethyl ether, diethyl ether,

diisopropyl ether, tert-butyl methyl ether, ketones such as acetone, ethyl methyl ketone, methyl isobutyl ketone and the like; or mixtures thereof to obtain dydrogesterone in a purity of 99.5%..

[0068] In one embodiment, the compound of formula V is converted to dydrogesterone by a process comprising:

(p) reducing the compound of formula V to give a compound of formula VI; and

(q) converting the compound of formula VI to dydrogesterone, the compound of formula I.

[0069] In one embodiment, the compound of formula V is converted to dydrogesterone by a process comprising:

(p) reducing the compound of formula V to give a compound of formula VI;

(q) oxidizing the compound of formula VI to ive a compound of formula VII; and

(r) converting the compound of formula VII to dydrogesterone, the compound of formula I.

[0070] In one embodiment, the compound of formula V is converted to dydrogesterone by a process comprising:

(q) oxidizing the compound of formula VI to give a compound of formula VII;

(r) reducing the compound of formula VII to ive a compound of formula VIII; and

(s) converting the compound of formula VIII to dydrogesterone, the compound of formula I.

[0071] In one embodiment, the compound of formula V is converted to dydrogesterone by a process comprising:

(p) reducing the compound of formula V to give a compound of formula VI;

(q) oxidizing the compound of formula VI to give a compound of formula VII;

(s) reacting the compound of formula VIII with methyl vinyl ketone to g compound of formula IX; and

(t) converting the compound of formula IX to dydrogesterone, the compound of formula I.

[0072] In one embodiment, the compound of formula V is converted to dydrogesterone by a process comprising:

(p) reducing the compound of formula V to give a compound of formula VI;

(q) oxidizing the compound of formula VI to ive a compound of formula VII;

(s) reacting the compound of formula VIII with methyl vinyl ketone to give a compound of formula IX;

(t) oxidizing the compound of formula IX to give a compound of formula X; and

(u) dehydrogenating the compound of formula X to give dydrogesterone, the compound of formula I.

[0073] In one embodiment, the present invention provides use of a compound of formula IV,

in the preparation of dydrogesterone.

[0074] In one embodiment, the present invention provides a process for the preparation of dydrogesterone, a compound of formula I, by a process comprising the manufacture of a compound of formula IV,

[0075] In one embodiment, the present invention provides a process for the preparation of dydrogesterone, a compound of formula I, by a process comprising the step of oxidatively decarboxylating a compound of formula IV to give a compound of formula V

[0076] In one embodiment, the present invention provides a process for the preparation of dydrogesterone, a compound of formula I, by a process comprising:

(i) mesylating 1 la-hydroxyprogesterone to give 1 la-mesyloxyprogesterone;

(ii) subjecting 1 la-mesyloxyprogesterone to ozonization to give lla-mesyloxy- 5,20-dioxo-3,5-seco-A-norpregnan-3-oic acid;

(iii) optionally, reacting lla-mesyloxy-5,20-dioxo-3,5-seco-A-norpregnan-3-oic acid with a base to give salt of lla-mesyloxy-5,20-dioxo-3,5-seco-A-norpregnan- 3-oic acid;

(iv) heating lla-mesyloxy-5,20-dioxo-3,5-seco-A-norpregnan-3-oic acid or salt thereof to give a compound of formula V; and

(v) converting the compound of formula V to dydrogesterone, the compound of formula I.

[0077] In one embodiment, the present invention provides a process for the preparation of dydrogesterone, a compound of formula I, by a process comprising: (i) subjecting 1 la-hydroxyprogesterone to ozonization to give lla-hydroxy-5,20- dioxo-3,5-seco-A-norpregnan-3-oic acid;

(ii) optionally, reacting lla-hydroxy-5,20-dioxo-3,5-seco-A-norpregnan-3-oic acid with a base to give salt of lla-hydroxy-5,20-dioxo-3,5-seco-A-norpregnan-3-oic acid;

(iii) heating lla-hydroxy-5,20-dioxo-3,5-seco-A-norpregnan-3-oic acid or salt thereof to give lla-hydroxy-10P-des-A-pregnane-5,20-dione;

(iv) mesylating lla-hydroxy-10P-des-A-pregnane-5,20-dione to give 11a- mesyloxy-10P-des-A-pregnane-5,20-dione;

(v) heating lla-mesyloxy-10P-des-A-pregnane-5,20-dione to give a compound of formula V;

(vi) converting the compound of formula V to dydrogesterone, the compound of formula I.

[0078] The examples that follow are provided to enable one skilled in the art to practice the invention and are merely illustrative of the invention. The examples should not be read as limiting the scope of the invention as defined in the features and advantages.

EXAMPLES

[0079] EXAMPLE 1 Preparation of compound of formula III

To a stirred solution of progesterone (9g) in toluene was added 2,3-dichloro-5,6- dicyanobenzoquinone (9g) at about room temperature. The reaction mixture was heated to about 110°C to about 120 °C and stirred for about 4h to about 6h. The reaction mixture was cooled to about room temperature and filtered on hyflo bed. The filtrate was washed with aqueous sodium hydroxide solution followed by brine solution and concentrated. The solid obtained was treated with methyl tert-butyl ether and stirred for about lh at about room temperature. The reaction mixture was cooled to about 5°C to about 10°C and filtered to give compound of formula III as a brown color solid.

[0080] EXAMPLE 2 Preparation of compound of formula IV

To a stirred mixture of compound of formula III (50g) and ruthenium chloride hydrate in acetonitrile, carbon tetrachloride and water was added sodium periodate and the reaction mixture was stirred. After completion of reaction, water was added to the reaction mixture which was stirred for about lOmin and the two layers were separated. The organic layer was washed with brine solution, dried with sodium sulfate and concentrated. The residue obtained was purified by silica gel column chromatography to give pale yellow color semi-solid. The solid residue was treated with ether, stirred for about lh at about room temperature and filtered to give compound of formula IV as a white color solid.

[0081] EXAMPLE 3 Preparation of compound of formula V

To a stirred solution of compound of formula IV (8g) in toluene was added 2,3- dichloro-5,6-dicyanobenzoquinone at about room temperature. The reaction mixture was heated to about 70°C to about 80°C and stirred at about the same temperature. The reaction mixture was cooled to about room temperature and 5% aqueous sodium hydroxide solution was added to it. The reaction mixture was stirred for about lOmin and the two layers were separated. The aqueous layer was extracted with toluene and the combined organic layer was washed with brine solution and concentrated. The solid obtained was purified by silica gel column chromatography to give compound of formula V as yellow color solid.

[0082] EXAMPLE 4 Preparation of compound of formula VI

To a stirred solution of compound of formula V (6.3g) in methanol, was added sodium borohydride over a period of 30min. The reaction mixture was stirred for about lh to about 2h and cold glacial acetic acid was added drop wise to it to adjust the pH to about 7 to about 7.5. The reaction mixture was concentrated and the residue obtained was dissolved in dichloromethane and water at about room temperature. The reaction mixture was stirred for about lOmin and the two layers were separated. The organic layer was washed with brine solution, dried with sodium sulfate and evaporated to dryness to give compound of formula VI as a pale yellow solid.

[0083] EXAMPLE 5 Preparation of compound of formula VII

To a stirred solution of compound of formula VI (5.5g) in dichloromethane, was added activated manganese dioxide (11 Og) at about room temperature. The reaction mixture was heated to about 50°C to about 55°C and stirred for about 16h to about 20h at about the same temperature. The reaction mixture was filtered on hyflo bed and the filtrate was concentrated. The residue obtained was purified by silica gel column chromatography to give compound of formula VII as a yellow color solid.

[0084] EXAMPLE 6 Preparation of compound of formula VIII

To a suspension of 5% rhodium on alumina (3. lg) in ethanol (62mL) and 3N aqueous hydrochloric acid (120mL) saturated with hydrogen gas, was added a solution of compound of formula VII (6.2g) in ethanol (186mL). The reaction mixture was stirred for about 4h to about 5h at about room temperature under hydrogen pressure. After completion of reaction, the catalyst was removed by filtration on hyflo bed. The filtrate was neutralized with sodium bicarbonate and concentrated. To the obtained residue, was added water and tert-butyl methyl ether. The reaction mixture was stirred for about lOmin and the two layers were separated. The organic layer was washed with brine solution, dried with sodium sulfate and concentrated. The residue obtained was purified by column chromatography to give compound of formula VIII as a pale yellow color oil.

[0085] EXAMPLE 7 Preparation of compound of formula IX

To a stirred solution of compound of formula VIII (2.8g) in tert-butyl alcohol (28mL) was added sodium hydroxide powder (O. lg) at about room temperature. The reaction mixture was heated to about 50°C to about 55°C and stirred for about 30min at about the same temperature under nitrogen atmosphere. Methyl vinyl ketone in toluene solution was drop wise added to the reaction mixture which was stirred at about 50°C to about 55°C for about lh. The reaction mixture was cooled to about 5°C to about 10°C, quenched with glacial acetic acid, slowly warmed to about room temperature and stirred for about lh. The reaction mixture was concentrated under vacuum and the residue obtained was purified by silica gel column chromatography to give compound of formula IX as a pale yellow solid.

[0086] EXAMPLE 8 Preparation of compound of formula X

To a stirred solution of compound of formula ΓΧ (0.42g) in acetone was drop wise added cold solution of chromium trioxide (0.23g) in 6N aqueous sulfuric acid at about -10°C to about -5°C. The reaction mixture was stirred for about lh to about 2h, quenched with isopropyl alcohol and concentrated. The residue obtained was dissolved in water and tert-butyl methyl ether at about room temperature. The reaction mixture was stirred for about lOmin and the two layers were separated. The organic layer was washed with aqueous sodium bicarbonate solution followed by brine solution, dried with sodium sulfate, and concentrated to give compound of formula X as an off-white color solid.

[0087] EXAMPLE 9 Preparation of dydrogesterone

To a stirred solution of compound of formula X (0.25g) in tert-butyl alcohol was added chloranil (234.6mg) at about room temperature under nitrogen atmosphere. The reaction mixture was heated to about 75°C to about 85 °C and stirred for about 12h to about 16h. The reaction mixture was cooled to about room temperature and concentrated. The residue obtained was dissolved in aqueous sodium hydroxide solution and tert-butyl methyl ether. The reaction mixture was stirred for about lOmin and the two layers were separated. The organic layer was washed with aqueous sodium hydroxide solution followed by brine solution, dried with sodium sulfate and concentrated. The residue obtained was purified by silica gel column chromatography to give dydrogesterone as a pale yellow solid. The solid was stirred

in hexane for about lh at about room temperature, filtered to give dydrogesterone as a pale yellow to off-white color solid.

Purity: 99.25%

[0088] EXAMPLE 10 Preparation of compound of formula III

To a cooling solution (5-10°C) of progesterone (100 gm, 0.318 mol.) and cat. tert- Butyldimethylsilyl chloride (TBDMSC1) in 1,4 dioxane was added lot wise 2,3- dichloro-5,6-dicyano-benzoquinone (DDQ, 93.84 gm). The reaction mixture was stirred to 25-30 °C for 18-24 h. After completion of reaction, the reaction mass was quenched with aq. sodium bicarbonate solution and toluene. The mixture was heated and stirred at 50-60°C for 10-15 hrs. The product was extracted in toluene, washed with water and brine. The toluene layer was evaporated under vacuum to give crude solid. The crude mass was purified in mixture of isopropyl alcohol and water to yield compound III wet solid which on drying at 50-55°C in air oven gave compound III (85 gm), HPLC purity (90-95%).

[0089] EXAMPLE 11 Preparation of compound of formula IV

Aq. sodium hypochlorite solution (1800 ml) was added to a solution of acetonitrile (1600 ml), ethyl acetate (1600 ml), compound III (100 gm) and ruthenium (III) chloride trihydrate (5 gm), by maintaining the reaction temperature at 25-35°C. After completion of reaction, the reaction mass was quenched with an aq. solution of sodium dithionate. The product was extracted with ethyl acetate followed by washing with water and 10 % aq. sodium chloride to furnish crude compound IV, followed by stripping it with methyl tert.butyl ether and recrystallization from methyl tert.butyl ether. (Yield: 30-35%, purity: 88-93%).

[0090] EXAMPLE 12 Preparation of compound of formula V

Into a dry RBF were charged chlorobenzene (10 L) and 2,3-dichloro-5,6-dicyano- benzoquinone DDQ (80 gm) and heated to 70-75°C. To the mixture was added lot wise compound IV (100 gm) at 70-75°C. The reaction mass was stirred for 12-15 h at 70-75°C. After completion of reaction, the reaction mass was quenched with 5 % aqueous NaOH solution and 3 L of water. The organic layer was washed with water and 10% brine solution. The solvent from organic layer was evaporated under reduced vacuum at 55-65°C gives compound V. The compound V was further

chromatographed on silica gel using mixture ethyl acetate and hexane to furnish pure compound V. (Yield: 28-38 gm)

[0091] EXAMPLE 13 Preparation of compound of formula VII

In clean and dry RBF, 3000 ml methanol, 300gm compound V where charged and chilled to -55°C. 22 gm of NaB]¾ 1st lot was charged and the reaction mass was stirred for 3- 4 h. 1 lg of IInd lot of NaBH4 was charged and the reaction mass was stirred for 4-5 h. The reaction mass was quenched with acetone. The solvent was distilled out from reaction mass. The product was extracted with methylene dichloride. The methylene dichloride layer was washed with potassium carbonate solution, sodium chloride solution and water. The solvent was distilled out from organic layer to obtain 280-300 gm of compound VII.

[0092] EXAMPLE 14 Preparation of compound of formula VIII

In a clean autoclave 6000 ml Ethyl acetate, 300 gm compound VII, 10% Pd/C were charged.30-3.5 kg hydrogen pressure was applied and maintained pressure for 24 h. The reaction mass was filtered and the solvent was distilled out from the filtrate and product was isolated by column chromatography (hexane: ethylcetate).

[0093] EXAMPLE 15 Preparation of dydrogesterone

In a clean and dry RBF, 400 ml tertiary butanol, 10 gm compound X, 10 gm chloranil, 20ml acetic acid were charged. The reaction mass was heated to 75-80°C and maintained at that temperature for 5.0-6.0 h. The solvent was distilled off from reaction mass and extracted the reaction mass with tert-butyl methyl ester and followed by washing out with NaOH solution and brine solution. The organic layer was treated with charcoal and filtered. The solvent was distilled out from filtrate and product was isolated with acetone, diethyl ether solution.

[0094] EXAMPLE 16 Purification of Dydrogesterone:

41.5 gm of dydrogesterone was dissolve in 747 ml acetone, 8.2 gm charcoal was charged and stirred the reaction mass for 30min. The charcoal was filtered and solvent was distilled off. A mixture of acetone and diisopropyl ether was charged to the above and the reaction mass was heated to 40-50°C and stirred for 30 min. The reaction mass was cooled 10-20°C, and stirred the mass for 2 h. The solid obtained was filtered and washed with diisopropyl ether followed by drying to obtain 37.5 gm dydrogesterone with purity 99.5 %.

Claims

1. A process for the p e, a compound of formula I,

the process comprising:

dehydrogenating a compound of formula II to give a compound of formula III;

(b) oxidatively cleaving the compound of formula III to give a compound of formula IV;

(c) oxidatively decarboxylating the compound of formula IV to give a compound of formula V; and

(d) converting the compound of formula V to dydrogesterone, the compound of formula I.

2. The process as claimed in claim 1 , wherein the step (a) is carried out in the presence of dehydrogenating reagent selected from the group consisting of 2,3-

dichloro-5,6-dicyanobenzoquinone, chloranil, benzeneseleninic anhydride, thallium (III) acetate, and mixtures thereof.

3. The process as claimed in claim 1, wherein the step (b) is carried out in the presence of oxidizing agent selected from the group consisting of sodium periodate, oxone-alkali metal carbonate, oxone-alkali metal bicarbonate, sodium hypochlorite, ozone-hydrogen peroxide, hydrogen peroxide, oxone, N-methylmorpholine N- oxide, and mixtures thereof.

4. The process as claimed in claim 1, wherein the step (c) is carried out in the presence of oxidizing agents selected from the group consisting of quinone compounds, metal acetate salts, periodinane compounds, and mixtures thereof.

5. The process as claimed in claim 1, wherein the compound of formula V is converted to dydrogesterone by a process comprising:

(x) converting the compound of formula V to a compound of formula VIII;

(y) reacting the compound of formula VIII with methyl vinyl ketone to give a compound of formula IX; a

(z) dehydrogenating the compound of formula IX to give dydrogesterone, the compound of formula I.

6. The process as claimed in claim 5, wherein the compound of formula V is converted to the compound of formula VIII by a process comprising:

(q) oxidizing the compound of formula VI to ive a compound of formula VII; and

(r) reducing the compound of formula VII to give the compound of formula VIII.

7. The process as claimed in claim 5, wherein the compound of formula V is converted to the compound of formula VIII by a process comprising:

(pi) directly reducing the compound of formula V to give a compound of formula VII; and

(r) reducing the compound of formula VII to give the compound of formula VIII.

8. The process claimed in claim 5, wherein the dehydrogenation of the compound of formula IX to give dydrogesterone is carried out by a process comprising:

(t) oxidizing the compound of formula IX to give a compound of formula X; and

(u) dehydrogenating the compound of formula X to give dehydrogesterone, the

9. The process as claimed in claim 1, wherein the compound of formula V is converted to dydrogesterone by a process comprising:

(p) reducing the compound of formula V to give a compound of formula VI; and

(q) converting the compound of formula VI to dydrogesterone, the compound of formula I.

10. The process as claimed in claim 1, wherein the compound of formula V is converted to dydrogesterone by a process comprising:

(p) reducing the compound of formula V to give a compound of formula VI;

(q) oxidizing the compound of formula VI to ive a compound of formula VII; and

(r) converting the compound of formula VII to dydrogesterone, the compound of formula I.

11. The process as claimed in claim 1, wherein the compound of formula V is converted to dydrogesterone by a process comprising:

(q) oxidizing the compound of formula VI to give a compound of formula VII;

(r) reducing the compound of formula VII to ive a compound of formula VIII; and

(s) converting the compound of formula VIII to dydrogesterone, the compound of formula I.

12. The process as claimed in claim 1, wherein the compound of formula V is converted to dydrogesterone by a process comprising:

(p) reducing the compound of formula V to give a compound of formula VI;

(q) oxidizing the compound of formula VI to give a compound of formula VII;

(s) reacting the compound of formula VIII with methyl vinyl ketone to give a compound of formula IX; and

(t) converting the compound of formula IX to dydrogesterone, the compound of formula I.

13. The process as claimed in claim 1, wherein the compound of formula V is converted to dydrogesterone by a process comprising:

(p) reducing the compound of formula V to give a compound of formula VI;

(q) oxidizing the compound of formula VI to ive a compound of formula VII;

(s) reacting the compound of formula VIII with methyl vinyl ketone to give a compound of formula IX;

(t) oxidizing the compound of formula IX to give a compound of formula X; and

(u) dehydrogenating the compound of formula X to give dydrogesterone, the compound of formula I.

14. Use of a compound of formula IV,

in the preparation of dydrogesterone.

15. A process for the preparation of dydrogesterone, a compound of formula I, by a process comprising the manufacture of a compound of formula IV,

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| IN201621042781 | 2016-12-15 | ||

| IN201621042781 | 2016-12-15 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2018109622A1 true WO2018109622A1 (en) | 2018-06-21 |

Family

ID=62559539

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/IB2017/057747 WO2018109622A1 (en) | 2016-12-15 | 2017-12-08 | Process for preparation of dydrogesterone |

Country Status (1)

| Country | Link |

|---|---|

| WO (1) | WO2018109622A1 (en) |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112409434A (en) * | 2020-11-27 | 2021-02-26 | 厦门欧瑞捷生物科技有限公司 | Synthesis method of dehydroprogesterone |

| CN112812146A (en) * | 2021-01-20 | 2021-05-18 | 江苏诺维尔医药科技有限公司 | Method for synthesizing dydrogesterone |

| CN113666981A (en) * | 2021-08-27 | 2021-11-19 | 江西百思康瑞药业有限公司 | Synthesis method of dydrogesterone |

| CN114057820A (en) * | 2021-11-15 | 2022-02-18 | 湖南科瑞生物制药股份有限公司 | Refining method of dydrogesterone |

| CN115894593A (en) * | 2022-11-12 | 2023-04-04 | 药康众拓(江苏)医药科技有限公司 | Preparation method of dydrogesterone and intermediate thereof |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3555053A (en) * | 1967-07-11 | 1971-01-12 | Philips Corp | 13beta-alkyl-9beta,10alpha-pregnanes |

| US3937700A (en) * | 1970-03-04 | 1976-02-10 | U.S. Philips Corporation | Novel 1,2-methylene-17α-acyloxy (or improved hydroxy)-9β, 10α-steroid compounds of the pregnane series, pharmaceutic preparations on the basis of the novel compounds and methods of producing said compounds and preparations |

| EP0152138B1 (en) * | 1984-02-15 | 1988-01-13 | Duphar International Research B.V | Method of preparing 9beta,10alpha-5,7-diene-steroids |

| WO2008113851A2 (en) * | 2007-03-22 | 2008-09-25 | Solvay Pharmaceuticals Gmbh | Novel c11 modified retrosteroids as progesterone receptor modulator compounds |

-

2017

- 2017-12-08 WO PCT/IB2017/057747 patent/WO2018109622A1/en active Application Filing

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3555053A (en) * | 1967-07-11 | 1971-01-12 | Philips Corp | 13beta-alkyl-9beta,10alpha-pregnanes |

| US3937700A (en) * | 1970-03-04 | 1976-02-10 | U.S. Philips Corporation | Novel 1,2-methylene-17α-acyloxy (or improved hydroxy)-9β, 10α-steroid compounds of the pregnane series, pharmaceutic preparations on the basis of the novel compounds and methods of producing said compounds and preparations |

| EP0152138B1 (en) * | 1984-02-15 | 1988-01-13 | Duphar International Research B.V | Method of preparing 9beta,10alpha-5,7-diene-steroids |

| WO2008113851A2 (en) * | 2007-03-22 | 2008-09-25 | Solvay Pharmaceuticals Gmbh | Novel c11 modified retrosteroids as progesterone receptor modulator compounds |

Non-Patent Citations (2)

| Title |

|---|

| BRUIN ET AL.: "Retro - steroids , A new class of compounds with sex-hormone action", PHILIPS TECHNICAL REVIEW, vol. 28, no. 3-4, 1967, pages 70 - 80, XP055495217 * |