WO2017011320A1 - Rapidly dissolvable microneedles for the transdermal delivery of therapeutics - Google Patents

Rapidly dissolvable microneedles for the transdermal delivery of therapeutics Download PDFInfo

- Publication number

- WO2017011320A1 WO2017011320A1 PCT/US2016/041571 US2016041571W WO2017011320A1 WO 2017011320 A1 WO2017011320 A1 WO 2017011320A1 US 2016041571 W US2016041571 W US 2016041571W WO 2017011320 A1 WO2017011320 A1 WO 2017011320A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- microneedle

- pvp

- microneedles

- skin

- flexible

- Prior art date

Links

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L31/00—Materials for other surgical articles, e.g. stents, stent-grafts, shunts, surgical drapes, guide wires, materials for adhesion prevention, occluding devices, surgical gloves, tissue fixation devices

- A61L31/14—Materials characterised by their function or physical properties, e.g. injectable or lubricating compositions, shape-memory materials, surface modified materials

- A61L31/16—Biologically active materials, e.g. therapeutic substances

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K47/00—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient

- A61K47/30—Macromolecular organic or inorganic compounds, e.g. inorganic polyphosphates

- A61K47/32—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds, e.g. carbomers, poly(meth)acrylates, or polyvinyl pyrrolidone

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/0012—Galenical forms characterised by the site of application

- A61K9/0019—Injectable compositions; Intramuscular, intravenous, arterial, subcutaneous administration; Compositions to be administered through the skin in an invasive manner

- A61K9/0021—Intradermal administration, e.g. through microneedle arrays, needleless injectors

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L31/00—Materials for other surgical articles, e.g. stents, stent-grafts, shunts, surgical drapes, guide wires, materials for adhesion prevention, occluding devices, surgical gloves, tissue fixation devices

- A61L31/04—Macromolecular materials

- A61L31/048—Macromolecular materials obtained by reactions only involving carbon-to-carbon unsaturated bonds

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L2300/00—Biologically active materials used in bandages, wound dressings, absorbent pads or medical devices

- A61L2300/40—Biologically active materials used in bandages, wound dressings, absorbent pads or medical devices characterised by a specific therapeutic activity or mode of action

- A61L2300/416—Anti-neoplastic or anti-proliferative or anti-restenosis or anti-angiogenic agents, e.g. paclitaxel, sirolimus

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L2400/00—Materials characterised by their function or physical properties

- A61L2400/12—Nanosized materials, e.g. nanofibres, nanoparticles, nanowires, nanotubes; Nanostructured surfaces

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61M—DEVICES FOR INTRODUCING MEDIA INTO, OR ONTO, THE BODY; DEVICES FOR TRANSDUCING BODY MEDIA OR FOR TAKING MEDIA FROM THE BODY; DEVICES FOR PRODUCING OR ENDING SLEEP OR STUPOR

- A61M37/00—Other apparatus for introducing media into the body; Percutany, i.e. introducing medicines into the body by diffusion through the skin

- A61M37/0015—Other apparatus for introducing media into the body; Percutany, i.e. introducing medicines into the body by diffusion through the skin by using microneedles

- A61M2037/0053—Methods for producing microneedles

Definitions

- microneedle devices have become an attractive method to overcome the diffusion-limiting epidermis and effectively transport therapeutics to the body.

- Microneedles are arrays of micron-sized projections that pierce the skin to administer drugs, manually creating channels for the passage of a therapeutic.

- Biodegradable or water-soluble microneedles are of high interest due to their safety, low device complexity, and ability to deliver agents of nearly any size.

- the main limitation of biodegradable microneedles is their arduous manufacturing, requiring long vacuum and centrifugation steps to fill a mold.

- Figure 1 FDA New Molecular Entities (NME) approved from 2006-2010.

- Figure 2 The anatomy of the skin. 2

- FIG. 29 Transdermal drug delivery via microneedle devices. 29

- Figure 4 Schematics of the application strategies for the four main

- Figure 6 Polymer microneedle array manufactured by the Prausnitz group.

- Figure 7 Scheme depicting the PRINT process; (1) delivery sheet casting; (2) particle fabrication; (3) particle collection; (4) particle harvesting. 4

- FIG. 8 Schematics of the applications of traditional biodegradable microneedles made using PRINT.

- the backing is then removed.

- the needles (red) and substrate (yellow) are inserted into the skin.

- the backing is then dissolved with tap water.

- Figure 9 ESEM images of SU-8 Master template (A & B), PDMS template (C & D) and PFPE mold (E & F) and PVP microneedles (G & H) made from R2 SU-8 master (200 ⁇ squares, 200 ⁇ spacing). Needles show comparable lengths and tip radii. Scale bars on A, C, E, and G are 500 ⁇ . Scale bars for B, D, F, and H are 200 ⁇ .

- FIG 11 Inclined, rotated photolithography schematic for making microneedle master templates.

- An SU-8 coated wafer is placed on a tilted stage (18-25°) and exposed. The substrate was then rotated 90° about the surface normal and exposed once more. After a total of four exposures, the wafer is post-exposure baked (PEB) and developed, leaving a negative master template.

- PEB post-exposure baked

- Figure 12 DSC traces for harvesting layers investigated for the flexible, water- soluble harvesting layers.

- A VA64

- B VA64+2% triethyl citrate

- C VA64+2% triethyl citrate+0.5% fluorescein dye.

- Figure 13 Schematic of the PRINT process for making microneedles, including the fabrication of individual microneedles and harvesting onto the flexible, water- soluble substrate.

- a film of PVP red

- a perfluoropolyether mold green

- the filled mold is then separated from the film.

- B The filled mold is mated to a flexible, water- soluble substrate (yellow) for harvesting and passed through a heated nip at 65 °C. After separation, a microneedle array on the substrate remains.

- Figure 14 Array of PRINTed PVP microneedles harvested on engineered flexible substrate.

- Figure 15 Fluorescent drug surrogates incorporated into PRINT microneedles.

- Rhodamine B base shown with a chloride counter ion.

- DyLight 680 shown with a maleimide functional handle. 24 ' 25

- Figure 16 Confocal microscopic images of films and microneedles incorporating the selected fluorescent drug surrogates, rhodamine B and DyLight 680.

- Rhodamine B film Rhodamine B film

- Rhodamine B microneedle Rhodamine B microneedle

- DyLight 680 film DyLight 680 microneedle.

- Figure 17 Brightfield macroscopic images of a microneedle patch.

- microneedle array morphology showing reproducible needles. Scale bar is 200 ⁇ .

- B A curled microneedle array, showing the flexibility of the array. Scale bar is 1 cm.

- C A side view of a curled microneedle array, showing the size of the array in comparison to human fingers. Scale bar is 1 cm.

- Figure 18 Crystallography structures of the drug surrogate proteins selected for microneedle incorporation.

- Figure 19 Confocal microscopy and ESEM images of pre-microneedle films (top) and microneedles (bottom) containing protein drug surrogates. (Left)

- Figure 21 SEM images of 80 x 320 nm hydrogel PRTNT particles.

- Figure 22 Films and microneedles with bare (+) 80 x 320 nm particles incorporated via a variety of solvents at a loading of 10 wt%.

- A H 2 0,

- B ACN,

- C EtOH,

- D IP A,

- E MeOH.

- Figure 23 ESEM (left) and confocal microscopy (right) images of PVP microneedles and films loaded with 80 x 320 nm bare hydrogel particles.

- Figure 24 Films (above) and microneedles (below) loaded with 5 wt% 80 x 320 nm hydrogel particles. All particles have been tagged (during PRINTing) with 488 maleimide for ex vivo compatibility.

- A Bare (+) particles

- B PEGylated (neu) particles

- C Acetylated (-) particles.

- Figure 25 3 ⁇ 4 NMR traces for the starting product and final product show a complete disappearance of the alcohol at 3.8 ppm (A) and the appearance of methylene at 4.45 ppm and vinyl proteins around 5-5.6 ppm (B).

- A Z-DOL 4000,

- B 4K PFPE-dMA.

- FIG. 26 OCT images taken after the application of flexible (left) and rigid (right) PVP PRINT microneedle patches. Brackets indicate the different features imaged.

- A Air above the patch,

- B Backing layer

- C Murine skin.

- Figure 27 Brightfield macroscopic image after testing with microneedle patch for 10 s. The pattern of the microneedles can be seen on the skin. In the insert, a single piercing is highlighted. Scale bar is 400 ⁇ .

- Figure 28 Brightfield macroscopic images of a microneedle array before and after insertion into ex vivo mouse skin for 10 s. (A) Microneedle array before testing and, (B) Array after testing and removal. Scale bars are 400 ⁇ .

- Figure 29 Image of murine skin after the application of a rhodamine-loaded

- microneedle patch for 10 min and less than 200 ⁇ _, of water to dissolve away that patch backing. Image was taken immediately after dispensing water onto the patch. The backing used was loaded with 0.1% fluorescein dye for imaging purposes. Scale bar is 1 cm.

- Figure 30 Brightfield macroscopic images of murine skin after fixation.

- A Control murine skin, not exposed to microneedles.

- B Murine skin after the insertion of rhodamine-loaded microneedles for 10 min. After insertion, the flexible backing was dissolved, and the skin was wiped clean before fixing. The dye can be seen throughout the skin after this processing, indicating that the drug surrogate diffused within the skin. Scale bar on all images is 1 cm.

- Figure 31 Brightfield microscopic images of skin sections after sectioning

- Figure 32 Fluorescent microscopy images of skin after sectioning.

- A Control skin

- B Skin after 10 second microneedle application

- C Skin after 10 minute microneedle application.

- Epidermis top.

- Scale bar is 35 ⁇ .

- Figure 33 Static Franz diffusion cell apparatus. 6

- Figure 34 Release profiles of rhodamine through ex vivo murine tissue over 24 h. It was seen that the microneedles delivered a significantly higher dose than the solution at all given times.

- Figure 35 Fluorescent microscopy images, shown as overlays with the brightfield channel, of skin after the application of a rhodamine drug surrogate for 24 hours on a Franz cell apparatus.

- A Control (no rhodamine applied),

- B rhodamine delivered via pre-microneedle solution, and

- C rhodamine delivered via microneedles.

- Epidermis top.

- Scale bar is 40 ⁇ .

- Figure 36 Fluorescent microscopy images, shown as overlays with the brightfield channel, of skin after the application of pre-microneedle films containing protein drug surrogates [(A) aldolase, (B) OVA].

- Epidermis top.

- Scale bar is 40 ⁇ .

- Figure 37 Release profiles of protein drug surrogates, aldolase and OVA, through ex vivo murine tissue over 24 h. It was seen that the smaller protein was able to permeate the skin at a much higher efficiency, up to 18% of the loaded dose.

- Figure 39 Release profiles of bare (+), PEGylated (neu), and acetylated (-) 80 x 320 nm PRINT hydrogel particles through ex vivo murine tissue over 24 h. It was seen that the microneedles showed no significant differences in release profile due to surface charge over this time period.

- Figure 40 Fluorescent microscopy images, shown as overlays with the brightfield channel, of skin after the application of microneedles loaded with 80 x 320 nm PRINT particles for 24 hours on a Franz cell apparatus.

- A control

- B bare particles

- C PEGylated particles

- D acetylated particles. Particles are show to be localized to the site of penetration with all surface charges.

- Figure 41 Nude mouse with a PRINT microneedle patch applied to the back. Patch is loaded with 0.1 wt% Dylight 680 cargo.

- Figure 42 Mice at three points during the time course small molecule dye study: (Top) All patches on, (Middle) two patches wiped, and (bottom) all patches wiped. The clean wipe after final water application is highlighted in the middle image.

- Figure 43 Organ harvest of a mouse after the conclusion (72 min) of the small

- Figure 44 Microscopy images of skin penetration studies performed on ex vivo

- Figure 47 PVP microneedles with encapsulated BuChE made from films cast in water.

- A 5 wt% BuChE,

- B 10 wt% BuChE,

- C 15 wt% BuChE,

- D 20 wt% BuChE,

- E 25 wt% BuChE.

- Scale bars are 200 ⁇ on all.

- Figure 48 Recovered BuChE activity after PRINT processing determined via a

- Figure 49 Confocal images of PVP microneedles and films loaded with fluorescein- tagged BuChE. Representative images of 0.1 wt% (top), 5 wt% (middle), and 25 wt% (bottom) BuChE are shown. With increased BuChE loading, the distribution of protein became increasingly more homogenous.

- Figure 50 Confocal microscopy images of microneedles loaded with 20 wt% BuChE tagged with an AlexaFluor 488 probe.

- Figure 51 Confocal (top) and ESEM (bottom) images of microneedles made with 5 wt% BuChE cast in either CAN (left) or EtOH (right).

- Figure 52 SEM of 1 ⁇ PRTNT particles composed of 90% BuChE.

- Figure 53 Confocal images of PVP films containing BuChE 1 ⁇ particles. (A) Non- crosslinked particles, and (B) Crosslinked BuChE 1 ⁇ particles.

- Figure 54 ESEM and confocal images of PRINT PVP microneedles incorporating 1 ⁇ BuChE PRINT particles, (top) Non-crosslinked, and (bottom) Crosslinked particles.

- Figure 55 SEM images of crosslinked 1 ⁇ BuChE particles after release from (A) PVP films and (B) PVP microneedles.

- Figure 56 Release profiles of BuChE through ex vivo murine tissue over 24 h. (A) BuChE alone, and (B) this enzyme in comparison to OVA and aldolase.

- Figure 57 Fluorescent microscopy images, shown as overlays with the brightfield channel, of skin after the application microneedles loaded with free tetrameric BuChE for 24 hours on a Franz cell apparatus.

- the enzyme is localized below the skin in select regions of the lower epidermis.

- Epidermis top.

- Scale bar is 40 ⁇ .

- Figure 58 Chest wall presentation of one patient with IBC.

- Figure 59 Structure of docetaxel.

- Figure 60 DSC trace of the 20 wt% docetaxel (in PVP) film, showing only a glass transition temperature at 38.91 °C.

- Figure 61 ESEM images of microneedles loaded with 5 wt% docetaxel. Scale bars are 100 ⁇ .

- Figure 62 Nu/Nu mouse from the microneedle MTD study after four weeks of dosing with 20 wt% docetaxel microneedle patch. Patch application location is outlined with a black circle. Skin conditions appear unchanged before and after each dose.

- Figure 63 Key white blood cell and red blood cell levels as determined from the microneedle MTD study on nude non-tumor bearing mice. Total WBC count, as well as lymphocyte, granulocyte, and monocyte individual levels, did not vary predictably with dose. Total red blood cell and platelet counts also did not show dose-dependent changes. All parameters were within the normal ranges for nu/nu mice.

- Figure 64 Nu/Nu tumor-bearing mouse (SUM149 model) with a 20 wt% docetaxel microneedle patch affixed to the skin directly above the tumor mass. Patch application location is outlined with a black circle.

- Figure 65 Chromatograms of a representative standard, film, and microneedle patch are shown. The PVP peak can be seen at 14.3 minutes and the docetaxel peak at 27.0 min all materials analyzed. Chromatograms are displayed as observed in ChemStation (Agilent).

- Figure 66 Drawing lithography for microneedle master fabrication, developed by Lee and Jung. 26

- A The glass transition history of the SU-8 polymer in the cooled- down temperature.

- B After the SU-8 contacted the patterned pillar, drawing lithography was performed.

- C Drawing caused the appearance of an extended conical -shaped bridge between the plate and pillar in the glass transition.

- D The desired liquid bridge was cured to generate a rigid structure.

- E The separation of the 3D microstructure bridge at the narrow necking position by isolation drawing produced the ultrahigh aspect ratio solid microneedle molds.

- Figure 67 Long, medium, and short microneedles to target the dermis, lower epidermis, and stratum corneum respectively.

- Figure 68 Structure of (A) docetaxel, (B) lipidized docetaxel with a C 4 alkyl chain, (C) lipidized docetaxel with a C 8 chain.

- microneedles as compared to the particle wt% charged, 2.5% 52

- Table 7 Glass transition temperatures (T g ) observed via DSC of VA64 substrates loaded with plasticizers and fluorescein dye 55

- Table 8 Microneedle depth of penetration as determined by OCT 69

- Table 13 Change in cholinesterase activity after high activity BuChE microneedle administration in vivo, as determined by the UNC Histology Core 101

- Table 14 Glass transition temperatures (T g ) of the PVP pre-microneedle films loaded with docetaxel 112

- Table 17 Study parameters for the determination of the MTD of patch-administered docetaxel to the skin 116

- Table 18 Average dose delivered with docetaxel per patch loading with a 1 cm 2

- IP A isopropanol IV intravenous

- PVME/MA poly(methylvinylether-co-maleic anhydride)

- ID, 2D, 3D one, two, or three dimensional

- microneedle device application in vivo was optimized on nude murine models, and it was shown that these devices efficaciously deliver small molecule drug surrogates to living tissue.

- the ability of the PRINT microneedles pierce excised human skin was shown, highlighting the capability of the technology to transition into a clinically-relevant product.

- PRINT microneedle devices were adapted to two therapeutically-relevant systems: the delivery of butyrylcholinesterase as a countermeasure against nerve gas overexposure, and the treatment of skin-invading breast cancers by introducing chemotherapeutics via microneedles.

- a method for fabricating a drug loaded polymeric microneedle comprising:

- a particle comprising a drug or biologic in a polymeric mold, wherein the particle is less than 100 nanometers, e.g., 90, 80, 70, 60, 50, 40, 30, 20, 10 or 5 nanometers in one dimension;

- liquid PVP composition to a polymeric microneedle mold, wherein the polymeric microneedle mold defines a plurality of cavities greater than 300 micrometers, e.g., 300-1,000 or more micrometers, 300-900 micrometers, 300-800 micrometers, 300-700 micrometers 300-600 micrometers, 300-500 micrometers, or 300-400 micrometers in depth, and wherein the liquid PVP fills the cavities of the polymeric microneedle mold;

- the polymeric microneedle mold defines a plurality of cavities greater than 300 micrometers, e.g., 300-1,000 or more micrometers, 300-900 micrometers, 300-800 micrometers, 300-700 micrometers 300-600 micrometers, 300-500 micrometers, or 300-400 micrometers in depth, and wherein the liquid PVP fills the cavities of the polymeric microneedle mold;

- PVP microneedles comprise up to 25 percent, e.g., 24, 23, 22, 21, 20, 19, 18, 17, 16, 15, 14, 13, 12, 11, 10, 9, 8, 7, 6, 5, 4, 3, 2, 1, 0.5, 0.001 percent, by weight of the drug or biologic.

- a flexible polymeric microneedle delivery device comprising:

- PVP polyvinylpyrrolidone

- a flexible PVP backing layer coupled with the PVP microneedles to provide a flexible PVP microneedle device

- the flexibility of the flexible PVP microneedle device provides greater than 50%, e.g., 55, 60, 65, 70, 75, 80, 85, 90, 95, 96, 97, 98, 99 or 100%, needle height penetration into skin;

- the PVP microneedles of the device are fully dissolvable in the skin within 10 minutes, e.g., less than 9, 8, 7, 6, 5, 4, 3, 2 or 1 minute(s), of application to the skin.

- a method for preparing a flexible microneedle drug delivery device comprising:

- PVP polyvinylpyrrolidone

- the flexible PVP microneedle device can be applied to skin of a patient in need of treatment, wherein the PVP microneedles of the flexible PVP microneedle device pierce the epidermis of the patient to a depth at least 50 percent, e.g., 55, 60, 65, 70, 75, 80, 85, 90, 95, 96, 97, 98, 99 or 100%, of the height of the microneedles;

- the flexible PVP microneedle device fully dissolves in contact with skin in less than 10 minutes, e.g., less than 9, 8, 7, 6, 5, 4, 3, 2 or 1 minute(s).

- each microneedle penetrates the skin a depth greater than about 75 percent of the height of the microneedle upon said application to the skin.

- the PVP microneedle fully dissolves in contact with skin for less than 5 minutes.

- the PVP microneedles comprise up to 25 percent, e.g., 24, 23, 22, 21, 20, 19, 18, 17, 16, 15, 14, 13, 12, 11, 10, 9, 8, 7, 6, 5, 4, 3, 2, 1, 0.5, 0.001 by weight of the drug, biologic or particle.

- the terms “hardening” and “hardened” refer to curing a liquid to form a solid. As such, the cured, hardened material has properties of a solid material as opposed to a liquid. A solid may be flexible.

- applying refers to allowing physical contact of one material with another material.

- Coupled refers to abutting or connecting one material and another material.

- the coupling can be by physical association, chemical, adhesive or electrostatic forces.

- the term "array” refers to a pre-determined pattern of elements.

- the microneedles are typically in an array, aligned relative to one another in a designed configuration, such as a row(s).

- the term "flexible” refers to a property of the material that allows for bending and pliability without breaking or substantial cracking.

- the flexibility of the backing material allows for penetration of the microneedles of the array into the skin.

- dissolvable and dissolved refer to the property of a solid material to pass or reduce into the surrounding milieu under certain conditions, such as when in contact with skin.

- the terms “fully dissolvable” and “fully dissolved” refer to a property of a solid material to reduce or pass essentially in entirety into the surrounding milieu under certain conditions.

- the dissolvable materials described herein pass into the milieu, thereby delivering the cargo dispersed in the material into the milieu.

- needle height refers to a measurement of the height of the needle from the tip to the base, i.e., the largest diameter.

- integral refers to a single structure having different components in contact with one another.

- the term “harvesting” refers to separating the particles and collecting the particles. The separating and collecting can be performed by means known to those of skill in this field.

- the term “patient” refers to a subject, which includes animals, such as mammals, including, but not limited to, primates (e.g., humans), cows, sheep, goats, horses, dogs, cats, rabbits, rats, mice and the like. In certain embodiments, the patient is a human.

- a patient "in need of treatment” refers to a patient having been diagnosed with a particular disease or condition to be treated.

- Standard delivery of drugs can be focused in four main categories: oral, inhaled, hypodermic injection, and transdermal application.

- Oral drugs commonly pills or liquids, are very familiar to patients and are generally low cost. However, the harsh environment of the gastrointestinal tract and likelihood of first pass metabolism by the liver limit the selection of drugs delivered orally. 6 Inhaled therapies allow the localized delivery of medication to the lungs with minimal side effects, but these generally are more costly than oral formulations. Additionally, the technique of administration affects the drug's effectiveness, for some common inhaled medications are administered by the patient or non-trained personnel.

- hypodermic injection (including intravascular, intramuscular, etc.) enables the delivery of sensitive therapeutics, but they induce pain, provide opportunities for accidental needle sticks that contribute to the spread of infectious disease, and produce sharp, biohazardous waste.

- intramuscular injections - common for vaccines - do not deliver doses to the optimum location to elicit an immune response; they penetrate into muscle, a region known to have a lower density of immunologically sensitive cells than skin. 3 11"13 Therefore, a large volume of active agent is used, leading to higher cost.

- Transdermal patches are effective for select time-released drugs (like nicotine and motion sickness medications), but the epidermis (specifically the stratum corneum) limits the diffusion of most drugs through the skin. 8"10 Clearly, the ability to transport therapeutics effectively into the body remains a significant challenge.

- the skin is the largest organ of the body, and is its first shield against microbial or viral invasion. 2 14 Seen in Figure 2, it is composed primarily of three layers: the epidermis, dermis, and subcutaneous fat. 2 15 The epidermis is the outer protective barrier of the skin, approximately 150-200 ⁇ thick. 2 The top epidermal layer, the stratum corneum or nonviable epidermis (10-15 ⁇ ), is comprised mainly of dead, keratin-rich skin cells, corneocytes; it is the skin' s main barrier of diffusion. Due to the densely-packed, lipophilic cell s layered 10- 1 5 ⁇ thick, molecules larger than 500 Dal tons ( Da) cannot passively breach this layer.

- the viable epidermis is composed of live skin cel ls and Langerhans cell s, the immune cell s of the epidermi s.

- the dermal layer is much more robust than the epidermis, functioning as the connectiv e tissue between the epidermis and subcutaneous fat.

- the j unction between the epidermal and dermal tissue is a complex glycoprotein structure, forming a 50 nm mechanical support that anchors the two layers.

- a therapeutic must pass through this structure to reach the rich network of capillaries approximately 200 ⁇ below the skin surface; it has been shown that therapeutic dermal reach is indicativ e of systemic exposure and absorption. 2

- the dermal layer also houses lymphatics, hair follicles, sweat glands, and is rich in dendritic

- Encapsulated nerve endings do reach the upper dermal layer of the skin, but it has been shown that these receptors respond to gentle pressure, not pain. 2 Pain receptors are located much deeper in the skin, at the junction of the dermal and subcutaneous layers.

- transdermal route therefore, has become a focus of innovative research in drug delivery after the approval of the first transdermal medication in 1981 (patches for the delivery of the motion sickness drug scopolamine). 9 Since then, more than thirty-five transdermal products have been approved in the US. 9 Research labs across the country have been focusing on how to overcome the passive diffusion limit of the skin and widen the scope of medications that can be delivered transdermally. While many approaches have been published and implemented, transdermal enhancement methods fall into three major categories: formulation-based, electrically-based, and structure-based (Table 1). Formulation-based and electrically-based methods are generally described as non-invasive methods of enhancement.

- Adding a chemical permeability enhancer, such as a fatty acid or surfactant, to the drug formulation allows for lipophilic molecules to be carried through the skin by disrupting the bilayer structure of the epidermis. 6 10 Even though this method is non-invasive, the excipients used can irreversibly damage the epidermis and cause high levels of skin irritation.

- Iontophoresis drives charged or neutral drugs across the skin by applying a small, constant electric potential to a reservoir of drug in contact with the skin. Charged drugs penetrate the skin via electrophoretic mobility, while the electroosmotic flow of water molecules carries in weakly or uncharged drug molecules. 6 9 This method can be used to transport molecules up to a few thousand Da through the stratum corneum. 6 9 Skin irritation can still occur because iontophoresis is not localized to this upper epidermal layer. Ultrasound increases the permeability of the skin by applying a pressure wave at a frequency much higher than what is detectible by the human ear.

- Skin ablation methods aim to physically change the structure of the skin by removing the stratum corneum, exposing the viable epidermis and applying a drug to this layer. This can be done in a variety of ways, from cosmetic microdermabrasion to sanding with emery paper. 9 While these methods have shown enhanced delivery, they do leave the skin without a protective barrier against infection after application that could invite the invasion of pathogens. Jet injection physically interrupts the stratum corneum by delivering a liquid or powdered drug with high pressured compressed gas.

- Microneedles are arrays of micron-sized projections for localized and systemic drug delivery. Considered minimally-invasive, these devices pierce the skin, like hypodermic needles, creating channels for the passage of a therapeutic (see Figure 3). 8"12>18 However, the small size of the micro-projections (typically 25 - 2000 ⁇ in length) allows them to enter the skin painlessly, for they only reach encapsulated nerve endings that serve as pressure receptors. 2 In fact, a number of studies involving human subjects have confirmed the painless nature of microneedle devices when administered to the forearm. 2 18"21 Depending on their physical geometry, microneedles can transport pharmaceutical agents of virtually any size, from small molecules to nano- and microparticles.

- microneedles 22-27 Tuning the length, strength, and geometry of the microneedles allows them to selectively target regions of the skin; for example, the viable epidermis, rich in Langerhans cells, could be targeted by shorter microneedles, while longer microneedles may deliver therapeutics to the dermal vasculature and lymphatics to facilitate systemic exposure. 28 A dose sparing effect for the therapeutic itself has been observed compared to traditional transdermal patches. 11 Additionally, the low complexity of microneedle devices may enable inexpensive fabrication and patient self- administration. Therefore, an optimized microneedle device could offer the efficacy of a hypodermic needle with the advantages of transdermal delivery.

- biodegradable microneedles encapsulate the drug of interest into the needle matrix, and the payload is released when the device dissolves in the skin.

- hollow microneedles have been developed for the introduction of a liquid drug matrix while the device remains in the skin. After application of a hollow needle array, a pump drives drug from an external reservoir through the skin; the device would be removed after dosing, as shown in Figure 4D.

- microneedles have been made from a wide variety of materials in numerous shapes, sizes, lengths, and configurations.

- 3 10"13 ' 22 ' 31 Predominately, the fabrication of microneedle arrays employs manufacturing techniques common to the microelectronics industry, such as injection molding, isotropic etching, bulk machining, reactive ion etching, photolithography, and two-photon polymerization.

- 2 ' 3 10 ' 32"35 The device material, desired geometry, and intended therapeutic payload influences which specific fabrication technology may be selected for device assembly.

- Figure 5 illustrates four microneedle devices made from common materials (metals, silicon, and biodegradable or water-soluble polymers) that represent recent advances in the field.

- Metal microneedles with an in-plane geography in which the microneedles are fabricated via laser etching in-plane with the backing then bent to be out-of-plane for application, can be seen in Figure 5A 18 .

- Solid silicon microneedles (Figure 5B) are commonly made via deep reactive ion etching through a chromium mask. 2 11 18

- Figure 5C a silicon wafer, first etched with an array of holes via deep reactive ion etching, was processed to create a microneedle around each hole via subsequent etching, resulting in an array of hollow silicon microneedles orders of magnitude smaller than a hypodermic needle.

- Polymeric microneedles (carboxym ethyl cellulose), made via molding technologies after the fabrication of a master template with traditional photolithography, are shown in Figure 5D 11 .

- Biodegradable or water-soluble microneedles have been of great interest to the microneedle community since the early 2000' s, when the limitations of metal and silicon microneedle products were reported by multiple groups. 38"40

- the non-biodegradable and non- biocompatible nature of metal and silicon have been postulated to limit the regulatory acceptability of such devices by the FDA. 2

- GRAS Generally Regarded As Safe

- the ideal microneedle product for market may be a biocompatible device.

- Such an apparatus is envisioned to be strong enough to penetrate the stratum corneum effectively, inexpensive, and compatible with a wide range of drug substances.

- the material should be dissolvable in aqueous environments to release its payload without posing immunogenic consequences. Healthy skin is only seen to be 60-70% hydrated, so the release kinetics of the encapsulated drug depends on the solubility of the material in such an environment. 41 Finally, manufacturing reproducible devices on a relevant scale of production is paramount for the success of the ideal biocompatible microneedle device.

- microneedle devices have utilized a number of materials to efficaciously deliver small molecules, biomolecules, and particulate cargo in preclinical ex vivo and in vivo studies.

- the Prausnitz group has pioneered many technologies with polymeric microneedles, such as the polyvinylpyrrolidone (PVP) devices shown in Figure 6 for the delivery of red fluorescent bovine serum albumin (BSA).

- PVP polyvinylpyrrolidone

- BSA red fluorescent bovine serum albumin

- PVME/MA Another water-soluble polymer, poly(methylvinylether-co-maleic anhydride)

- Donnelly et al. to mold microneedles for the delivery of theophylline, a hydrophilic drug with a molecular weight of 180 Da. 42

- CMC carboxymethyl cellulose

- poly(lactic-co-glycolic acid) poly(lactic-co-glycolic acid)

- other constituents - are common for the delivery of small molecules, large proteins, and nanoparticles.

- Table 2 summarizes recent advances in biodegradable and water-soluble microneedles, demonstrating the chemical and pharmaceutical diversity of this promising field. While such devices have shown great promise in animal models - including mice, rats, guinea pigs, and non-human primates - dissolving microneedles have only been translated to human testing with a limited number of technologies. 21 ' 39 ' 40 ' 42"44 Hirobe et al.

- microneedles made from a sodium hyaluronate/dextran/Povidone blend (without therapeutic cargo) to the forearms of the patients to assess dissolution kinetics, skin irritability, pain, and epidermal water loss;

- microneedles such as those developed by Corium

- 3M, Merck, NanoPass, and TheraJet have led other companies such as 3M, Merck, NanoPass, and TheraJet to set sights to commercialize this technology.

- 2 ' 43 ' 44 57 Due to the seemingly low dose delivered by the patch; long, arduous manufacturing; and lack of reproducibility across the patches, these devices are currently in the research stage only, and no commercial biodegradable microneedles are currently sold on the market. 2 ' 43 ' 44 ' 57 Without the ability to produce a clinically-relevant number of patches that maintain a reproducible size, shape, dose, and configuration, these elegant devices may remain in the lab.

- biodegradable microneedle devices could be applied to a number of disease models, opening the door for painless vaccines, routine injections, and novel cancer treatments.

- PRINT combines lithographic techniques common in the semiconductor industry with flexible, fluorinated molds, allowing for nanomaterials with precisely controlled size, shape, chemical composition, and surface characteristics to be manufactured. 4 ' 58"63

- the PRINT process employs a nonwetting, nonswelling mold, made from perfluoropolyether (PFPE); this photocurable polymer has a highly fluorinated surface, which provides a nonwetting interface that allows for organic materials to be removed cleanly.

- PFPE perfluoropolyether

- PRINT is a highly scalable, current good manufacturing practices (cGMP) compliant manufacturing technology.

- PRINT begins after the fabrication of a master template, a silicon wafer patterned with the feature size and shape of interest using traditional photolithography techniques.

- PFPE mixed with

- photoinitiator is then applied to the silicon master template and chemically cross-linked under ultraviolet (UV) light to create an elastomeric mold with cavities of the desired shape and size.

- UV ultraviolet

- the low surface energy of the PFPE allows for it to wet the entire surface of etched silicon wafer, resulting in faithful reproduction of the master template.

- a pre- particle solution (red) is mixed, containing a host of materials including polymers, monomers, drugs, nucleic acids, or any additional agent of interest.

- the pre-particle solution is then dispersed onto polyethylene terephthalate (PET), forming a thin film. Residual solvent is removed by heating the thin film, leaving a solid-state film that serves as the delivery sheet for the mold.

- PET polyethylene terephthalate

- PFPE mold Next, particle fabrication takes place, adhering the delivery sheet (red) to the PFPE mold (green).

- the PFPE mold is mated to the delivery sheet and passed through a laminator; for matrices that require increased thermal conditions to fill, the laminator is heated. As the sheet (red) leaves the laminator, the mold is then split from the sheet. The cavities in the mold have been filled via capillary action with the particle matrix.

- the highly fluorinated surface of the PFPE leads to high chemical resistance, preventing the deformation of the PRINT mold when exposed to any residual organic solutions used in pre-particle films and assuring the fidelity of the produced particles to the original master template; no interconnecting or flash layer is observed.

- the solution solidifies as the mold cools to room temperature.

- the mold (green) is then laid on a harvesting film (yellow) and once again passed through the laminator.

- the harvesting film is made from a sacrificial adhesive, such as cyanoacrylate or low molecular weight polymers, which adhere the particles to the harvesting surface. 61 As the particles are removed from the mold, they maintain their shape and singularity. The particles on the harvesting film are then treated to remove the adhesive layer, creating a suspension of individual particles.

- novel microneedle devices could be made to overcome the manufacturing, cost, and reproducibility limitations of biodegradable and water- soluble microneedles discussed above.

- PRINT can be optimized for a wide variety of matrices, amenable to many cargos due to the mild conditions required.

- Microneedle devices made from an adapted PRINT platform could be applied to vaccine delivery, preventative medicine, cancers, etc. 12 13 ' 64

- biodegradable microneedles are made by filling a mold with a matrix containing the drug of interest; generally, multiple vacuum and centrifugation steps are required to completely fill the molds, arduous steps that lead to lengthy fabrication times and pose issues to scale-up manufacturing.

- a thick substrate, or backing layer is attached to the array of microneedles to form a patch. After preparing microneedle patches, they generally are administered as shown in Figure 8A.

- the microneedle patch is applied topically to pierce the skin and penetrate into the viable epidermis or dermis, depending on the physical dimensions of the needles. Due to skin's elastic qualities, the entirety of the needle does not enter the skin. 6 The needles are left in the skin for the duration of the treatment period, from minutes (min) to hours (h), and the substrate is then removed, extracting all parts of the needle that have not yet dissolved (usually 5-20% of each microneedle). 1 ' 3"5 Consequently, a portion of the drug contained in the patch is removed, leading to a lower delivered dose than what was intended for the device.

- FIG. 8B A schematic of a microneedle device made using PRINT can be seen in Figure 8B.

- an array of discrete microneedles would be manufactured and collected on a flexible, water-soluble substrate.

- Traditional microneedle arrays are often subject to the "bed of nails” effect, in which the force on each needle is distributed across the array, resulting in the inability of all needles to overcome the elasticity of the epidermis and pierce the skin. 6

- the flexibility of the substrate allows the array of highly-dense microprojections to avoid this effect and break the stratum corneum more efficiently. 6

- the needle patch remains in the skin long enough to allow the polymer to dissolve or degrade, releasing its drug cargo. The substrate would then be dissolved, leaving the entire microneedle array in the skin.

- a new mold shape must be created.

- a master template with the features of interest must be made.

- the intended microprojections i.e. high aspect-ratio square pyramids that come to a sharp tip - traditional photolithographic procedures could not be utilized to create the structures, for they are not equipped to make high aspect-ratio or tapered structures using light field masks.

- 16 17 By employing a tilted, rotated approach, the intended structures can be made accurately.

- the microneedle master templates are negative features; a positive replicate must be made as an intermediate before ideal molds can be created.

- PDMS polydimethylsiloxane

- PFPE perfluoropolyether

- Figure 9 shows Environmental Scanning Electron Microscopy (ESEM) images of each component of the development of the PRINT microneedle patches - masters, replicas, molds, and needles.

- Master templates were first prepared using a tilted-rotated photolithography approach adapted from Han et a/. 16,18,19 Briefly, a polished silicon wafer was coated with an anti- reflective layer; it was seen that this layer significantly reduced backside reflections and greatly increased the resolution of the resulting master templates (Figure 10). A thick layer of negative photoresist (SU-8) was applied to the wafer via spin coating. Next, a mask with 200 ⁇ x 200 ⁇ squares and 200 ⁇ spacing (base to base) was placed over the SU-8, and the complex was exposed to ultra-violet (UV) light at incidence angles of 18-25° (Figure 11). Both the mask dimensions and the incident angle of UV light determine the depth of the mold, and ultimately, the length of the microneedles.

- UV ultra-violet

- a positive replica of the master template was made as an intermediate.

- the replicas were fabricated using commercially available PDMS due to its low surface energy, ease of use, high flexibility, and low cost. 2

- the replicas showed notable reproducibility of the master templates, having comparable needle lengths and tip radii of curvature via ESEM ( Figure 9C- D).

- VaiUes Of V and "b" depend On the Mw of fia PFPE-diol; commefciaily

- each master template can be used to make hundreds of PDMS replicas, and each replica can be used to make at least fifty PFPE molds.

- Each PFPE mold can be used to create at least ten microneedle arrays via PRINT

- the substrate for the microneedle backing was designed to be flexible and water- soluble. This is desirable for two reasons: 1) to facilitate improved penetration of the stratum corneum by avoiding the "bed of nails” effect, and 2) to create a microneedle patch that is 100% dissolvable to eliminate sharp, hazardous biowaste.

- 6 A matrix of Luvitec VA64, a polyvinylpyrrolidone/polyvinylacetate blend, was selected due to its high water solubility and biocompatibility for topical use. 21 Thick films of this polymer cast in methanol were not sufficiently flexible; therefore, multiple plasticizers were studied to lower the glass transition temperature (T g ) of the film to impart flexibility.

- triethyl citrate and trimethyl citrate in 1-3 weight percent (wt%) loadings showed promise for use as substrates; these films were analyzed by thermal gravimetric analysis (TGA) and differential scanning calorimetry (DSC). TGA studies were done to determine the 95% degradation temperature of the materials to avoid decomposition in the DSC. The DSC scans can be found as Figure 12.

- PVP polyvinylpyrrolidone

- Rhodamine B was utilized for all ex vivo studies due to its low cost and availability, but could not be employed in live animal studies quantitatively; DyLight 680 was selected to overcome this limitation but was not used exclusively due to its high cost. Additionally, the differences in surface charge - rhodamine B positive at neutral pH (7.4) and DyLight 680 negative under the same conditions - demonstrated the ability of PRINT microneedles to load small molecules of either charge.

- rhodamine B or DyLight 680 (at a loading of 0.1- 1 wt% of total solids) was included in the matrix by mixing it into the PVP/water solution before film casting.

- Films including each drug surrogate were imaged via confocal microscopy to confirm cargo homogeneity (Figure 16).

- DSC analysis of each film (after storage at 30% relative humidity) was performed to determine the thermal properties of each material, an indication of its strength. 26

- the T g 's can be found in Table 3. It was found that the Tg's of the materials were not significantly altered by the addition of small molecule drug surrogates, resulting in no significant changes in the materials.

- the T g of the microneedle matrix is not the sole predictor of the ability of device to penetrate skin under force of thumb; it has been reported that the microneedles tip radius, aspect ratio, and needle density across an array all play a significant role in the force required to penetrate the epidermis. 27 Therefore, the thermal data served as a guide to demonstrate potential to serve as an effective device.

- FIG. 17 shows macroscopic images of microneedles loaded with the rhodamine B drug surrogate, B-C highlighting the flexibility of the arrays.

- Figure 16 shows confocal microscopy images of the microneedles, emphasizing the distribution of the drug surrogate throughout the needle matrix. It can be seen that the dyes permeate the entirety of the needle, but a slight increase in fluorophore density can be seen at the tip of the microneedle.

- the PVP microneedle matrix can encapsulate both positive and negative fluorescent drug surrogates, resulting in microneedle devices optimized for ex vivo and in vivo analysis.

- microneedle technology One of the most promising applications of microneedle technology is the delivery of protein or peptide therapeutics transdermally, due to the many disadvantages of introducing these macromolecular therapeutics via oral ingestion or hypodermic injection. 1 ' 5 ' 8,27

- Microneedles offer the advantage of delivering the therapeutic to the body without exposure to the gastrointestinal tract while eliminating the pain and safety concerns associated with needles. 1 ' 5 ' 8 27

- the delivery of proteins via microneedles has been successful with a variety of approaches: application of a topical solution containing the protein therapeutic before or after microneedle insertion via the "poke then patch” approach, coating the surface of microneedles with a lyophilized therapeutic formulation for dissolution upon application, infusion via pumping a solution containing the therapeutic though an array of hollow microneedles, and passive diffusion out of a biodegradable microneedle after encapsulation into the matrix itself.

- PRINT microneedles may provide an attractive method to deliver protein therapeutics.

- 8 10

- Two model proteins - ovalbumin (OVA) and aldolase - were selected as protein drug surrogates for incorporation into PRINT microneedles (Figure 18).

- OVA a model protein antigen derived from avian egg, is approximately 45 kDa and has an isoelectric point (pi) of 4.6.

- 29 Aldolase an enzyme involved in gluconeogenesis derived from rabbit muscle, is much larger in size, 161 kDa, and has a pi of 8.5.

- the drug surrogate proteins were incorporated into the aqueous pre-microneedle solution (15-20 wt% total solids) and cast as solid-state films as described previously. It was determined that a protein loading of 20 wt% (80 wt% PVP comprising the solids composition) was the maximum loading that yielded a homogenous film. Additionally, DSC analysis revealed that pre-microneedle films loaded with up to 20 wt% showed T g 's above 40 °C, making them candidates to be strong enough for skin penetration. Microneedle patches were then fabricated via PRINT, merely modifying the nip temperature to protect the thermally- liable proteins.

- FIG. 20A shows the NativePAGE results as compared to a ladder. The bands at 45 kDa, corresponding to the OVA protein, can be seen in lanes 2-5, representing the pre-microneedle solution, film, patch, and unconsumed film (due to the space between features in the mold, fundamental to the PRINT process) respectively.

- nanocarriers for controlled subcutaneous release, including increased efficacy, dose sparing, and improved safety.

- APC's antigen presenting cells

- Langerhans cells in the epidermal layer (20-25% of the surface area) make the skin an ideal route of administration for vaccines; both innate and adaptive immune responses are generated in the skin upon the uptake of antigens by these APC's.

- Microneedle vaccines have been fairly limited due to the fragility of the cargos, but nanocarriers offer many advantages, including: mimicking the size and shape of the pathogen, inherently protecting vaccine antigens and adjuvants, showing an improved immunogenicity from the delivery of soluble subunits, and providing a dose sparing effect that results in a lower required dose for human vaccination. 27, 35-38 Many strategies have been employed to incorporate nanoparticles into a microneedle-based drug delivery system;

- hydrogel PRINT nanoparticle was selected as the particulate drug surrogate of interest.

- the hydrogel matrix comprised mainly of hydroxy tetraethylene glycol monoacrylate (HP4A), results in particles that are inherently non-immunogenic, and this advantage - as well as their versatility of chemical modification - made them ideal for the investigation of how particle surface charge plays a role in microneedle encapsulation and subsequent release.

- Particles were made via a continuous roll-to-roll PRINT process, as optimized by Perry et. al.

- a 3.5 wt% solution of the particle composition (found in Table 4) was prepared, and solid-state films were cast on a highly charged poly(ethylene terephthalate) (PET) sheet.

- PET poly(ethylene terephthalate)

- the film was then mated with a thin PFPE mold and sent through a pressure nip before curing under a UV-LED lamp.

- the cured particles were transferred to a harvesting layer composed of polyvinyl alcohol (PVOH); this layer was selectively dissolved in water, leaving the intact hydrogel particles in solution.

- PVOH polyvinyl alcohol

- the bare (non-modified) particles were visually characterized via scanning electron microscopy (SEM), and dynamic light scattering (DLS) was employed to determine the size, polydispersity index (PDI), and surface charge ( ⁇ -potential) (Table 5 and Figure 21).

- SEM scanning electron microscopy

- DLS dynamic light scattering

- the resulting PEGylated particles showed a surface charge of +24.3 mV, a more neutral ⁇ - potential (characterization data shown in Table 5).

- particles were acetylated with acetic anhydride to quench any unreacted amines, yielding particles with a negative surface charge.

- the PEGylated particles in dimethylformamide (DMF) were mixed with an excess of pyridine and acetic anhydride, subsequently quenched with borate buffer (pH 9.5), then resuspended in water to form an aqueous particle suspension.

- the resulting acetylated particles showed a surface charge of -16.4 mV, a negitave ⁇ -potential ideal for our studies (characterization data shown in Table 5).

- Pre-microneedle films were made by mixing a 15-40 wt% total solids solution (90 wt% PVP, 10% bare 80 x 320 nm particles, the maximum particle concentration that resulted in homogenous films) in each solvent, drop-casting each onto plastic sheets, and allowing the films to dry for 24-48 h; a majority of the casting solvent (95- 99%) evaporates after this time, making the casting solvent itself a minor constituent of the resultant films. Films were then mated to microneedle molds and PR NTed using the optimized conditions for manufacturing with small molecule drug surrogates. Films and microneedles were visualized via confocal microscopy, as seen in Figure 22.

- Particles were generally more localized to the tip of the microneedles resulting from ACN casting, while the MeOH microneedles showed a homogenous distribution of particles throughout the needle; it should be noted, however, that the difference in distribution was much more stark at a loading of 10 wt%. Therefore, to determine the ideal casting solvent for these microneedles, the final loading, or particle wt% of the fabricated patch, was determined and compared to the particle wt% charged (2.5 wt%). To do so, microneedle patches made with both ACN and MeOH were massed, dissolved in sterile water, and centrifuged to create a pellet of particles; residual PVP was removed via three centrifugal water washes.

- microneedle patches were fabricated using the optimized PRINT process for 80 x 320 nm hydrogel particles, incorporating separately the bare, PEGylated, and acetylated particles.

- a particle loading of 5 wt% total solids was optimized for further ex vivo experiments with the purpose of ensuring both high loading and distribution homogeneity.

- ESEM and confocal images of the resulting microneedle patches can be seen as Figure 24.

- the particles of all three surface charges distribute throughout the microneedles, showing the ability of PVP PRINT microneedles to encapsulate "large" drug surrogates of various charges.

- Rigid SU-8 2150 (MicroChem) microneedle templates were fabricated using a tilted- rotated UV lithography approach. 15 16 18 19

- a single crystalline silicon (Si[100J) wafer was coated with an antireflective coating consisting of a CrO x /Cr multilayer. The thickness of the CrO x layer was chosen to minimize reflections of 365 nm UV light from the substrate.

- the substrate was then spin-coated with 600 ⁇ thick SU-8 and soft baked at 100 °C for 8 h.

- the coated silicon wafer was cleaved into squares pieces, which were then attached to a light-field mask of 200 ⁇ x 200 ⁇ chromium squares.

- the substrate was then exposed to filtered UV light incident at angles between 18-25°. The exposure was performed in four 450 mJ/cm 2 increments in which the substrate was rotated 90° about its surface normal between each exposure.

- the PEB was performed at 65 °C for 30 min. At the end of the PEB, the temperature was slowly ramped down to room temperature and the substrate was allowed to relax for 60 min. The unusually low-temperature PEB and the subsequent gentle cooling steps were critical to reduce stress in the SU-8, which can cause the template to break.

- the substrate was then developed with propylene glycol monomethyl ether acetate (PGMEA) in an ultra-sonic bath for 10 min and rinsed with IPA. This development sequence was repeated three times to ensure the molds were fully developed.

- PGMEA propylene glycol monomethyl ether acetate

- Templates were sputter-coated with a 100 nm -thick layer of gold to facilitate PDMS release. Templates were characterized by ESEM (FEI Quanta 200). Optimal masters had 200 ⁇ base widths, 385 ⁇ heights, and 10 ⁇ tip radii.

- Replicas of the SU-8 templates were made by casting a thick layer of silicone (Sylgard 184, Dow Corning) over the master.

- the PDMS was degassed in a vacuum desiccator for 2 h before centrifugation for 20 min at 3000 g and 4 °C; this process was then repeated once.

- the replica was left to cure under vacuum overnight at RT and was finished with a 2 h bake in a 65 °C oven.

- Templates were characterized by ESEM (FEI Quanta 200).

- PFPE dimethacrylate the monomer utilized to make PRF T-compatible molds, was synthesized in house with the molecular weight of 4 kDa.

- ZDOL 4000 50 g, 13.2 mmol

- 1, 1,1-3,3- pentafluorobutane 45 mL

- 2-isocyanatoethylmetha-crylate 4.4 g, 28.2 mmol

- DBU 50 ⁇ .

- Optimized PDMS templates were used to create PRINT molds using the PFPE dimethacrylate.

- a 0.2 wt% solution of 2,2-diethoxyacetophenone (98%, Acros) in PFPE dimethacrylate was drop-cast onto the replica, and a flexible plastic sheet was applied to serve as a supportive backing.

- decomposition temperature was determined; the upper temperature limit for the DSC experiments was to be no more than 50 °C lower than the 95% decomposition temperature for each material.

- DSC was used to determine the T g 's of the substrates. Samples (5-10 mg) were crimped into aluminum pans and heated from -20 °C to 100-120 °C at a rate of 5 °C/min, cooled at a rate of 10 °C/min to -20 °C, and heated again in a second cycle. T g 's were determined from the second heating cycle. Results of these studies can be found in Table 7. After analysis, triethyl citrate in 2% loading was selected as the optimal plasticizer for the flexible substrates in VA64. Select substrates were loaded with 0.5 wt% fluorescein (pure, Acros) for imaging by mixing the dye into the solution prior to casting.

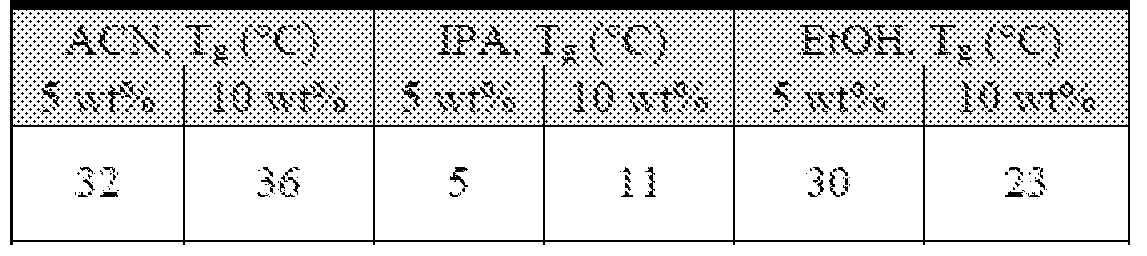

- Table 7 Glass transition temperatures (T g ) observed via DSC of VA64 substrates loaded with plasticizers and fluorescein dye.

- DyLight 488, acetic anhydride, tnethylamine, borate buffer (pH 9.5), pyridine, DMF, and IPA were purchased through Fisher Scientific, and AlexaFluor 488 via Life Technologies.

- Polyvinyl alcohol (M w 2 kDa) (PVOH) was bought from Acros Organics.

- Methoxy- PEG(5k)-succinimidyl carboxy methyl ester was purchased from Creative PEGworks. All commercial materials were used as received.

- PET sheets and PRINT molds (80 x 80 x 320 nm) were obtained from Liquidia Technologies. HP4A was synthesized in-house as previously described. 44

- Hydrogel 80 x 320 nm PRINT particles were fabricated via PRINT in a continuous roll-to-roll manner (Liquidia Technologies), optimized previously by Perry et al. u'u Pre- particle solutions, using the composition described in Table 4, were prepared in IPA (3.5 wt% solids).

- a thin film of the pre-particle solution was drawn onto corona-treated PET using a #3 Mayer rod (R.D. Specialties) at a speed of 12 ft/min. Simultaneously, solvent evaporation was achieved by exposing the film to a hot air dam derived from heat guns. The dried film

- delivery sheet (delivery sheet) was laminated at 80 PSI to 80 x 320 nm PRINT mold, followed by

- Particles were harvested manually by splitting the harvesting sheet from the mold and dissolving the PVOH in a bead of water (1 mL of water per 5 ft of harvesting sheet). Any large particulates were removed by passing the particle suspension through a 2 ⁇ filter (Agilent). Centrifugation (Eppendorf Centrifuge 5417R) at 21,000 g for 15 min was employed to remove the excess PVOH. The supernatant was removed and the particles were resuspended in sterile water; a total of four washes produced a pure solution of 80 x 320 bare hydrogel particles.

- a subset of the PEGylated particles was then acetylated to create a particle with a negative surface charge for microneedle encapsulation.

- a solution of 5 mg/mL of PEGylated particles (in DMF) was mixed with an excess of pyridine (50 ⁇ ) and acetic anhydride (70 ⁇ ). The solution was left to shake for 30 min at RT at 1400 RPM (Eppendorf). The particles were washed via centrifugation, once with DMF and once with a borate buffer (pH 9.5) to quench the reaction and remove any acetic acid that may have resulted via a side reaction. The particles were returned to an aqueous suspension via four centrifugal washes as outlined above.

- Particles were characterized post-fabrication (bare), after PEGylation, and at the conclusion of acetylation. Particle concentrations in situ were determined via TGA (Q5000IR, TA Instruments). Electron microscopy images were taken via Scanning Electron Microscopy (SEM); particles were dispersed on a silicon wafer and coated with -1.5 nm of gold- palladium alloy (Hitachi S-4700, FEI Helios Nanolab 600) before imaging. A Zetasizer Nano ZS Particle Analyzer (Malvern Instruments Inc.) was employed to determine ⁇ -potential measurements; analysis of all particle types was conducted on aqueous dispersions at a concentration of -20 ⁇ g/mL.

- the filled mold was mated to the aforementioned flexible, water-soluble substrate, covered with a plastic sheet, and passed through a heated nip at 105 °C. The mold and plastic sheet were then removed, leaving a 100% water soluble microneedle patch.

- Microneedles incorporating small molecule dye drug surrogates were prepared identically to the blank microneedles (2.4.6.1), with one small modification: the chosen dye [rhodamine B (99%, Acros) or DyLight 680 (Fisher Scientific)] was mixed into the pre- microneedle solution (15-20 wt% total solids) at a loading of 0.1-1 wt% of total solids. All other fabrication parameters remained consistent.

- Proteins were tagged with fluorescein or AlexaFluor 488 prior to microneedle encapsulation.

- OVA with AlexaFluor 488 conjugate (Life Technologies) was purchased pre- tagged; aldolase from rabbit muscle (Sigma) was tagged with an AlexaFluor 488 NHS Ester (Life Technologies).

- NHS fluorescein (Thermo Scientific) due to its low cost. To do so, protein in phosphate buffered saline (PBS) was mixed with the probe (in DMF) at a molar excess of dye (3 : 1) and allowed to mix for 1 h at RT.

- the tagged protein was separated from the unreacted dye via centrifugal filtration with a 3 kDa filter (Millipore) at 14,000 RPM at 4 °C for 25 min.

- the tagged protein was dialyzed overnight using a 20 kDa molecular weight cut-off dialysis device (Thermo Scientific) at RT before use.

- the tagged OVA and aldolase were mixed into the pre-microneedle solution at a 15- 20 wt% loading of total solids, the remaining solids comprised solely of PVP.

- the solutions were made in sterile water at a 15-20 wt%.

- Microneedles incorporating proteins were made using the protocol for small molecule dye microneedles, with the additional change of lowering the temperature of the nip to 77-82 °C in order to maintain protein functionality post processing.

- Bare hydrogel particles (80 x 320 nm) made via PRINT as described in 2.4.5.2, and incorporated into microneedles via a variety of casting solvents.

- IP A, EtOH, MeOH, and ACN were also investigated as casting solvents. All solvents were purchased from Fisher Scientific and used as received.

- the microneedle formulation comprised of 10 wt% nanoparticles and 90 wt% PVP. Pre-microneedle solutions were made at 40 wt%, excluding those cast in water (15 wt%). Films of each solution were drop-cast onto plastic sheets and allowed to dry at RT for 24-48 hours before use. Microneedles were then PRINTed identically to the optimized conditions for fabrication of blank microneedles (2.4.6.1).

- microneedle composition was altered slightly, with loadings of 2.5-5 wt% particles. Needles made with PEGylated and acetylated particles were also made with loadings of 2.5-5 wt% particles, under the optimized conditions for fabricating blank microneedles (2.4.6.1).

- Microneedle patches and films were characterized with ESEM (FEI Quanta 200), confocal microscopy (Zeiss LSM 700), and brightfield macroscopy (Leica-Wild M420 Macroscope). Thermal properties of the microneedle films were determined via TGA

- OVA protein structure was assessed via a NativePAGE gel (Life Technologies), purchased as a kit and used according to manufacturer recommendations. Briefly, samples containing OVA (pre-microneedle solution, film, microneedle patches, and unconsumed film) were dissolved in buffer (sample buffer, Life Technologies) and diluted to concentrations of -0.04-0.02 ⁇ g/ ⁇ L. The gel was loaded with 25 ⁇ . of sample per well; a protein and OVA standard were also added at the appropriate concentration. Cathode and anode running buffer, containing a Coomassie G-250 stain, were prepared and loaded into the running cell along with the prepared gel. After securing the electrodes, the gel was allowed to run at 150 V at room temperature for 100-120 min.

- Aldolase activity was assessed via a BioVision activity assay and used in accordance with the manufacturer's instructions.

- the relative activity was determined by comparing samples containing aldolase (pre-microneedle solution as well as pre- and post- processed films) to aldolase standards. Processed films were treated by passing them through a laminator at 77-82 °C, mimicking microneedle manufacturing conditions. All films were dissolved in PBS, and 50 ⁇ . was added to wells of a black 96 well plate. A 50 ⁇ . reaction mix (prepared using assay buffer, enzyme mix, developer, and substrate) was added to each well and the plate was mixed.

- NADH nicotinamide adenine dinucleotide

- PRINT microneedles fabricated from polyvinylpyrrolidone (PVP) have been seen to show consistent geometry, high reproducibility, and can load cargos of virtually any desirable size and charge.

- Thermal analysis, differential scanning calorimetry (DSC) performed on the materials suggests that the PVP microneedles are strong, with glass transition temperatures (Tg's) well above room temperature.

- Tg's glass transition temperatures

- the flexibility of the microneedle arrays may lead to an increased depth of penetration compared to conventional microneedles, for they can roll gently into the tissue and avoid the "bed of nails” effect.

- the water-soluble backing layer eliminates the need to remove the array, which may increase the payload of the devices to the skin.

- PRINT microneedles need to be tested on skin models to determine the efficacy of these devices to penetrate the stratum corneum and deliver their cargo.

- Model skin is typically one of two materials: a polymeric network that simulates the nature of this barrier (a pore size of -0.45 ⁇ ) or human skin equivalents, tissue engineered scaffolds made by culturing human skin cells in a 3D gel. 4"6 While it was first thought that skin was an homogenous barrier, it is now know each layer serves a specific defensive purpose, displaying unique physical properties at each level.

- Murine and human skin have also been shown to respond identically to the application of permeation enhancers. 4 Undeniably, many of these discrepancies arise from the difference in thickness of murine and human skin; while skin from the mouse is typically 300-500 ⁇ in thickness across 70% of its surface area, human skin varies widely in thickness, ranging from 600-3,000 ⁇ depending on location. 4"5 16 Due to the consistency afforded by murine tissue, nude mice were utilized as the animal model in all preliminary studies for their ability to correlate ex vivo results to in vivo studies; the potential of PRINT microneedle devices for translation to the clinic was investigated through trials with excised human tissue.

- PRINT microneedle devices were applied to excised murine skin to determine if the materials were strong enough to pierce the stratum corneum via studies with Optical

- OCT Coherence Tomography

- OCT optical depth ranging

- FIG. 26 Representative images of microneedles of the flexible and rigid backings can be seen as Figure 26. Images depict microneedle patches (upper part of the frame) inserted into the tissue (lower part of the frame); for clarification, brackets indicate the microneedles and skin.

- PRINT microneedles were seen to overcome the stratum corneum and pierce the epidermis in both configurations, demonstrating clearly the efficacy of the PVP microneedles.

- the microneedles with a flexible backing pierced the skin in a more reproducible pattern than those with the rigid backing. The microneedle piercing showed consistent spacing across the tissue.

- Table 8 Microneedle depth of penetration as determined by OCT.

- Equation 1 The rate of transport, according to these laws, is expressed in Equation 1, where C is the initial concentration of drug, Co the donor concentration, K the partition coefficient, D the diffusion coefficient, and h the thickness of the barrier (stratum corneum). 4 7 It has been seen that a partition coefficient (octanol/water) of above 2.4 greatly increased the uptake of salicylates and anti-inflammatory drugs when a liquid formulation was applied to the skin. 7 22 The charge of the drug has a different effect on transport depending on permeation pathway; for example, if diffusing through the skin intracellularly, neutral drugs have been shown to permeate more effectively, but those transported transcellularly (through cell internalization) may be more effective with charged therapeutics due to their ability to interact with the charged cell. 7 ' 24 25 dC _ KCDo Equation 1 dt h

- Optimized PRINT microneedle arrays loaded with rhodamine B were fabricated as described in Chapter 2.

- 3 Patches were administered to ex vivo murine skin samples to assess the ability of these microneedle arrays to penetrate skin and release cargo.

- Murine skin excised from the back of nu/nu mice was used as described for the studies with blank microneedles. Flexible patches were "rolled” on and pressed into the skin with the gentle force of a thumb.

- Three different experimental conditions were compared: control (no microneedles applied), patches left in the skin for 10 s and then removed, and patches left in the skin for 10 min followed by the dissolution of the substrate with water.

- FIG. 27 shows a greyscale image of a murine skin specimen after the application of microneedles for 10 s. The locations of epidermal breach can be seen on the skin; this was verified by histology. Additionally, the microneedles showed evidence of dissolution within the skin after 10 s. The drug surrogate could be visually perceived within sites of microneedle insertion and could not be wiped from the surface. Further brightfield macroscopic images of the patches after removal also showed at least half of the microneedle length had dissolved within this 10 s time period, seen in Figure 28.

- Haematoxylin stains the nuclei of cells via a dye-metal complex; the oxidation product of haematoxylin, hematein, forms a complex with aluminum ions, termed "hemalum". 27

- the hemalum colors cell nuclei by binding to DNA, resulting in dark purple/blue color.

- Eosin Y traditionally colors eosinophilic structures, such as intracellular or extracellular proteins, including most of the cell cytoplasm. 27 This acidic dye adheres to the basic backbone of the proteins, staining the structures shades of pink.

- eosin Y is shown to have a broad fluorescence spectrum, emitting from 530-600 nm with a maximum of 545 nm, while rhodamine B is observed to have a maximum emission at 580 nm. 27-29 Therefore, half of the sections were left unstained to observe the rhodamine B fluorescence without the interference of eosin.

- the kinetics of drug release from the microneedles was investigated using a Franz diffusion cell apparatus, the gold standard of ex vivo testing for transdermal formulations. 5 ' 6

- the apparatus is used to model the behavior of the formulation when applied to skin; in these studies, the tissue is thought of as a membrane, for in vivo behavior does not identically replicate the profiles obtained from a Franz diffusion cell due to the rich network of biological processes happening in skin. 5

- the studies are ultimately considered a good way of assessing therapeutic ability to cross the stratum corneum in vivo.

- the Franz diffusion cell shown in Figure 33, consists of a donor compartment, a membrane, and a receptor compartment with a sampling port; the receptor compartment is insulated with a water jacket.

- Receptor fluid usually phosphate buffered saline (PBS)

- PBS phosphate buffered saline

- the membrane is anchored in place with a clamp, then the drug formulation is applied through the donor compartment onto the membrane; the entire device is submerged in 37 °C water to fill the jacket at body

- any rhodamine removed from the surface of the tissue with the wipes was extracted with PBS and quantified by equating solution fluorescence (taken at 590 nm on a plate reader) to mass via a standard curve; the applied dose was subsequently determined by subtracting this amount from the patch dose. Aliquots of the receptor solution were taken at various time points over 24 h, and the delivered dose of the rhodamine was also determined by correlating

- Figure 34 shows the percent delivered dose of rhodamine for both the solution and microneedles. It was seen that the microneedles greatly increased the amount of rhodamine that permeated the skin at every time point. After 24 h, 17% of the dose applied to the skin had been released from the microneedles, while only 6% of the dose of the solution reached the receptor compartment. This stark difference shows that PRF T microneedles are an effective permeation enhancer for even small molecule therapeutics. Additionally, it was seen that the kinetics of transport are quite different. Rhodamine delivered via solution showed a percent delivered dose that increased linearly through the duration of the experiment. The microneedles, however, show non-linear release, slowing considerably after 12 h. These kinetic profiles outline the differences in passive diffusion and enhancing permeation with microneedle devices.

- FIG. 36 shows brightfield and fluorescent overlays, taken simultaneously on an upright microscope, of skin after the application of an aldolase (A) and OVA (B) film; no visible fluorescence from either protein could be detected below the stratum corneum, supporting the hypothesis that it cannot diffuse.

- A aldolase

- B OVA

- microneedles were fabricated with 20 wt% protein (as outlined in Chapter 2), and patches were imaged via IVIS to determine the dose of protein per patch (-0.06 mg of each protein). Devices were applied to full thickness murine skin for 8 min before patch dissolution. After application, the skin was transferred to the Franz cell; receptor solution was sampled at various time points over 24 hours. The delivered dose of each protein was also determined by equating fluorescence to mass via a standard curve collected on standard plate reader; emission was read at 550 nm due to the AlexaFluor 488 tag on both proteins. Upon cell termination, the skin was fixed,

- Figure 37 shows the delivery profiles of each protein to the receptor compartment over 24 hours.

- both proteins were able to permeate the skin, a feat shown to be impossible without this physical enhancement.

- the OVA was shown to diffuse through the full thickness tissue at a much quicker rate than the aldolase. While it is postulated that the size of the protein mainly influences this behavior, the charge of the protein upon release from the PVP microneedle may play a role.