WO2016190368A1 - Substrate processing method, resin composition, and method for producing electronic device - Google Patents

Substrate processing method, resin composition, and method for producing electronic device Download PDFInfo

- Publication number

- WO2016190368A1 WO2016190368A1 PCT/JP2016/065505 JP2016065505W WO2016190368A1 WO 2016190368 A1 WO2016190368 A1 WO 2016190368A1 JP 2016065505 W JP2016065505 W JP 2016065505W WO 2016190368 A1 WO2016190368 A1 WO 2016190368A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- group

- resin

- film

- processing method

- repeating unit

- Prior art date

Links

Images

Classifications

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/004—Photosensitive materials

- G03F7/038—Macromolecular compounds which are rendered insoluble or differentially wettable

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/004—Photosensitive materials

- G03F7/039—Macromolecular compounds which are photodegradable, e.g. positive electron resists

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/004—Photosensitive materials

- G03F7/09—Photosensitive materials characterised by structural details, e.g. supports, auxiliary layers

- G03F7/11—Photosensitive materials characterised by structural details, e.g. supports, auxiliary layers having cover layers or intermediate layers, e.g. subbing layers

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/26—Processing photosensitive materials; Apparatus therefor

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/26—Processing photosensitive materials; Apparatus therefor

- G03F7/30—Imagewise removal using liquid means

- G03F7/32—Liquid compositions therefor, e.g. developers

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/26—Processing photosensitive materials; Apparatus therefor

- G03F7/40—Treatment after imagewise removal, e.g. baking

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/027—Making masks on semiconductor bodies for further photolithographic processing not provided for in group H01L21/18 or H01L21/34

Definitions

- the present invention relates to a substrate processing method, a resin composition used in the substrate processing method, and an electronic device manufacturing method using the substrate processing method. More specifically, the present invention relates to a substrate processing method applicable to a semiconductor manufacturing process such as an IC, a circuit board such as a liquid crystal or a thermal head, and other photofabrication lithography processes. The present invention relates to a resin composition used, an electronic device manufacturing method using the substrate processing method, and an electronic device.

- a resist composition generally containing a photosensitive substance is used, a resist film is formed on a substrate to be processed, a predetermined region of the resist film is exposed, and then a resist film is formed.

- the exposed portion or the unexposed portion is removed by a development process to form a resist pattern, and the substrate to be processed is dry etched using the resist pattern as an etching mask.

- ultraviolet light such as ArF excimer laser light is used as exposure light for exposing the resist film.

- LSIs large-scale integrated circuits

- the required resolution may be less than the wavelength of exposure light.

- the exposure process margin such as the exposure margin and the focus margin is insufficient.

- it is effective to reduce the film thickness of the resist film and improve the resolution.

- the resist film thickness required for etching the film to be processed is increased. It will be difficult to secure.

- this resist pattern A process for etching the planarizing film using the mask as a mask and transferring the pattern to the planarizing film (hereinafter also referred to as “multilayer resist process”) has been studied.

- Patent Document 1 proposes a planarization film forming composition containing a polymer having an alkynyloxy group in the side chain as a resin composition for forming a planarization film having excellent etching resistance. Yes.

- step substrate a substrate having a concavo-convex structure

- the embedding performance with respect to the step substrate is excellent.

- membrane which has the outstanding etching tolerance is proposed.

- Patent Document 3 when the multilayer resist process includes an ion implant process, the dry etching resistance and the ion implantation resistance are high, and the alkaline water is used without damaging the substrate after the dry etching or after the ion implantation.

- a resin composition for forming an underlayer film that can form a peelable underlayer film has been proposed. Specifically, a resin composition containing a novolak resin having a lactone ring is disclosed as a resin composition for forming an underlayer film.

- the present invention has been developed in view of the above circumstances, and it is an object of the present invention to provide a substrate processing method capable of forming a high-resolution resist pattern and thereby enabling ultra-fine semiconductor elements. And Another object of the present invention is to provide a resin composition suitably used as a planarizing film or the like in this substrate processing method, and an electronic device manufacturing method using this substrate processing method.

- the present invention is as follows. [1] (A) a step of forming a first film on a substrate using a resin composition (a) containing a resin (P) having an Onishi parameter greater than 4.5; (B) forming a second film on the first film using an actinic ray-sensitive or radiation-sensitive resin composition containing a resin (A) whose polarity is changed by the action of an acid; (C) exposing the second film; and (D) The substrate processing method including the step of developing the exposed second film to form a pattern.

- the Onishi parameter of the resin (P) contained in the resin composition (a) is larger than the Onishi parameter of the resin (A) contained in the actinic ray-sensitive or radiation-sensitive resin composition, [1] The substrate processing method as described.

- the resin composition (a) contains, as the resin (P), at least one resin selected from the group consisting of a poly (meth) acrylic resin, a polyester resin, and a polyether resin.

- the substrate processing method according to any one of [9].

- the resin composition (a) contains at least a resin having a repeating unit represented by the following general formula (1-1) as the resin (P), according to any one of [1] to [10]. Substrate processing method.

- R 1 represents a hydrogen atom or an organic group.

- R 2 represents a hydrocarbon group having a hetero atom. However, for the number of carbon atoms contained in R 2, the ratio of the number of hetero atoms contained in R 2 is 0.30 or more.

- R 2 is a lactone structure-containing group, a carbonate structure-containing group, an acetal structure-containing group, a hydroxy group-containing group, or a group represented by the following general formula (P1).

- P1 The substrate processing method according to [11].

- R A represents a divalent hydrocarbon group which may contain a hetero atom.

- R B represents a monovalent hydrocarbon group which may contain a hetero atom.

- n represents an integer of 1 or more. When n is an integer of 2 or more, a plurality of R A may be the same or different.

- * Represents a bonding position with the remainder of the repeating unit represented by the general formula (1-1). However, the ratio of the number of heteroatoms to the number of carbon atoms contained in the general formula (P1) is 0.30 or more.

- the resin composition (a) contains at least a resin having a repeating unit represented by the following general formula (1-2) as the resin (P), according to any one of [1] to [12]. Substrate processing method.

- L represents an organic group.

- X represents —O—, —S—, —CO—, —CO—O—, or —O—CO—.

- the present invention it is possible to form a high-resolution resist pattern, thereby providing a substrate processing method that enables ultra-fine semiconductor elements. Further, according to the present invention, it is possible to provide a resin composition suitably used as a planarizing film or the like in this substrate processing method, and an electronic device manufacturing method using this substrate processing method.

- the schematic sectional drawing for demonstrating one process of the substrate processing method of this invention The schematic sectional drawing for demonstrating one process of the substrate processing method of this invention.

- the schematic sectional drawing for demonstrating one process of the substrate processing method of this invention The schematic sectional drawing for demonstrating one process of the substrate processing method of this invention.

- the schematic sectional drawing for demonstrating one process of the substrate processing method of this invention The schematic sectional drawing for demonstrating one process of the substrate processing method of this invention.

- the schematic sectional drawing for demonstrating one process of the substrate processing method of this invention The schematic sectional drawing for demonstrating one process of the substrate processing method of this invention.

- the notation that does not indicate substitution and non-substitution includes not only a substituent but also a substituent.

- the “alkyl group” includes not only an alkyl group having no substituent (unsubstituted alkyl group) but also an alkyl group having a substituent (substituted alkyl group).

- active light beam or “radiation” in the present specification refers to, for example, an emission line spectrum of a mercury lamp, far ultraviolet rays represented by excimer laser, extreme ultraviolet (EUV) rays, X rays or electron rays ( Electron Beam (EB).

- light means actinic rays or radiation.

- exposure in the present specification is not limited to exposure with far-ultraviolet rays such as mercury lamps and excimer lasers, X-rays and EUV light, but also with particle beams such as electron beams and ion beams, unless otherwise specified. Drawing is also included in the exposure.

- far-ultraviolet rays such as mercury lamps and excimer lasers, X-rays and EUV light

- particle beams such as electron beams and ion beams

- the substrate processing method of the present invention comprises: (A) a step of forming a first film on a substrate using a resin composition (a) containing a resin (P) having an Onishi parameter greater than 4.5; (B) forming a second film on the first film using an actinic ray-sensitive or radiation-sensitive resin composition containing a resin (A) whose polarity is changed by the action of an acid; (C) exposing the second film; and (D) developing the exposed second film to form a pattern.

- the Onishi parameter of the resin is defined as follows.

- (Onishi parameter of resin) ⁇ ⁇ (Onishi parameter of repeating unit) ⁇ (Mole fraction of repeating unit) ⁇

- the Onishi parameter of a repeating unit (unit) is defined as follows.

- (Onishi parameter of repeating unit) (total number of atoms in repeating unit) / ⁇ (number of carbon atoms in repeating unit) ⁇ (total number of oxygen atoms and sulfur atoms in repeating unit) ⁇

- resin (P) does not contain a sulfur atom, in the said definition, the number of sulfur atoms is 0.

- the substrate processing method of the present invention is also referred to as a second film (hereinafter referred to as “active light sensitive or radiation sensitive film” or “resist film”) formed using an actinic ray sensitive or radiation sensitive resin composition.

- a resin film (a) hereinafter referred to as “a flattening film” containing a resin (P) having an Onishi parameter greater than 4.5. It is also referred to as a “flattened film forming resin composition”).

- the resist film's etching resistance with respect to the planarization film's etching resistance is dramatically increased, and the resist film thickness is reduced. Therefore, it becomes possible to form a resist pattern with high resolution.

- step (E) a step of etching the first film (planarization film) using the pattern as a mask (hereinafter referred to as “step (E) ) ”)).

- the substrate processing method of the present invention further includes an implantation step (hereinafter also referred to as “step (F)”) for introducing metal ions into the substrate after the step (E).

- step (F) an implantation step for introducing metal ions into the substrate after the step (E).

- the substrate processing method of the present invention is a step of peeling the first film (planarization film) and the pattern using a liquid after the step (E) or the step (F). (Hereinafter also referred to as “step (G)”).

- a planarizing film (first film) is formed on a substrate 51 by using the planarizing film-forming resin composition (a). 81 is formed (step (A)).

- planarizing film-forming resin composition (a) contains a resin (P) having an Onishi parameter greater than 4.5. The details of the planarizing film-forming resin composition (a) will be described later.

- the method of forming a planarizing film on the substrate can be typically carried out by applying the planarizing film-forming resin composition (a) onto the substrate.

- the planarizing film-forming resin composition (a) is applied by a spin coating method.

- the film thickness of the planarizing layer is preferably 30 to 300 nm, more preferably 50 to 240 nm, and still more preferably 70 to 200 nm.

- the first film is preferably insoluble in the actinic ray-sensitive or radiation-sensitive resin composition used for forming the second film laminated thereon.

- insoluble means substantially insoluble.

- the average dissolution rate (the reduction rate of the first film) when the first film is immersed in the actinic ray-sensitive or radiation-sensitive resin composition for 1000 seconds may be 0.5 nm / second or less.

- the substrate may be a stepped substrate as shown in FIG. 1A or may not be a stepped substrate.

- a stepped substrate is a substrate in which at least one stepped shape is formed on the substrate.

- the substrate is not particularly limited, silicon, SiN, inorganic substrates such as SiO 2, SOG (Spin on Glass) coating-type inorganic substrate such as, IC (Integrated Circuit) semiconductor manufacturing process, such as, a liquid crystal, thermal head

- IC Integrated Circuit

- a substrate generally used in a circuit board manufacturing process or other photofabrication lithography process can be used.

- an underlayer film such as an antireflection film may be formed between the planarizing film and the substrate.

- an organic antireflection film, an inorganic antireflection film, and the like can be appropriately selected.

- the underlayer film material is available from Brewer Science, Nissan Chemical Industries, Ltd. Examples of the lower layer film suitable for the process of developing using a developer containing an organic solvent include the lower layer film described in International Publication No. 2012/039337.

- the film thickness of the planarizing film formed on the above-mentioned substrate means the height from the bottom surface on the stepped substrate to the top surface of the planarizing film when the substrate is a stepped substrate.

- the height from the bottom surface of the step substrate to the top surface of the step shape is preferably smaller than the thickness of the planarization film, for example, less than 200 nm.

- a stepped substrate As the stepped substrate, a substrate in which fins and gates are patterned on a flat substrate can be used.

- the planarization film forming resin composition (a) is applied onto the stepped substrate on which the fins and the gate are patterned in this way, and the film thickness of the formed planarization film is formed from the upper surface of the fins and the gate. It means not the height to the top surface of the planarizing film to be formed, but the height to the top surface of the planarizing film formed from the bottom surface on the stepped substrate as described above.

- the groove width is not more than the exposure wavelength (preferably 100 nm or less, more preferably 40 nm or less, usually 15 nm or more), and the depth is 100 nm or less (preferably 50 to 100 nm, more preferably 65 to A stepped substrate having a groove portion of 100 nm), a diameter of an exposure wavelength or less (preferably 100 nm or less, more preferably 40 nm or less, usually 15 nm or more), and a depth of 100 nm or less (preferably 50 to 100 nm, more preferably And a stepped substrate having a cylindrical recess of 65 to 100 nm).

- stepped substrate having the groove portions described above examples include a stepped substrate having a plurality of grooves repeatedly at equal intervals, for example, with a pitch of 20 nm to 200 nm (preferably 50 to 150 nm, more preferably 70 to 120 nm).

- a stepped substrate having a plurality of cylindrical recesses repeatedly at regular intervals with a pitch of 20 nm to 200 nm (preferably 50 to 150 nm, more preferably 70 to 120 nm), etc. Is mentioned.

- the substrate processing method of the present invention includes a preheating step (Prebake; PB1) between the step (A) and the step (B).

- the heating temperature in the preheating step (PB1) is preferably 70 to 130 ° C., more preferably 80 to 120 ° C.

- the heating time is preferably 30 to 300 seconds, more preferably 30 to 180 seconds, and still more preferably 30 to 90 seconds.

- the heating can be performed by means provided in a normal exposure / developing machine, and may be performed using a hot plate or the like.

- the preheating step (PB1) may include a plurality of heating steps.

- a resist film 52 (second film) is formed on the planarizing film 81 using an actinic ray-sensitive or radiation-sensitive resin composition (step (B )).

- step (B) as a method for forming the resist film 52 using an actinic ray-sensitive or radiation-sensitive resin composition, in the step (A), a planarizing film-forming resin composition (a The method similar to the method of forming the planarizing film using

- the film thickness of the resist film is preferably 50 to 800 nm, more preferably 80 to 500 nm, and still more preferably 100 to 300 nm.

- the substrate processing method of the present invention preferably includes a preheating step (Prebake; PB2) between the step (B) and the step (C).

- Prebake a preheating step

- the substrate processing method of the present invention preferably includes a post-exposure heating step (Post Exposure Bake; PEB) between the step (C) and the step (D).

- PEB Post Exposure Bake

- the heating temperature is preferably 70 to 130 ° C for both PB2 and PEB, more preferably 80 to 120 ° C.

- the heating time is preferably 30 to 300 seconds, more preferably 30 to 180 seconds, and even more preferably 30 to 90 seconds.

- the heating can be performed by means provided in a normal exposure / development machine, and may be performed using a hot plate or the like.

- Baking accelerates the reaction of the exposed area and improves the sensitivity and pattern profile.

- At least one of the preheating (PB2) step and the post-exposure heating step may include a plurality of heating steps.

- the resist film 52 is irradiated with actinic rays or radiation 71 through a mask 61 (that is, exposed), whereby the exposed resist film 53 is formed. (Step (C)).

- the wavelength of the light source used in the exposure apparatus is not limited, but examples include infrared light, visible light, ultraviolet light, far ultraviolet light, extreme ultraviolet light, X-rays, and electron beams.

- Step (C) may include a plurality of exposure steps.

- an immersion exposure method can be applied in the step (C).

- the immersion exposure method is a technique for increasing the resolving power and performing exposure by filling a liquid with a high refractive index (hereinafter also referred to as “immersion liquid”) between the projection lens and the sample.

- the resolving power and the depth of focus can be expressed by the following equations.

- k 1 and k 2 are coefficients related to the process.

- the immersion liquid is preferably a liquid that is transparent to the exposure wavelength and has a refractive index temperature coefficient as small as possible so as to minimize distortion of the optical image projected onto the resist film.

- Is an ArF excimer laser (wavelength; 193 nm) it is preferable to use water from the viewpoints of availability and ease of handling in addition to the above-mentioned viewpoints.

- an additive liquid that reduces the surface tension of water and increases the surface activity may be added in a small proportion.

- This additive is preferably one that does not dissolve the resist layer on the wafer and can ignore the influence on the optical coating on the lower surface of the lens element.

- an aliphatic alcohol having a refractive index substantially equal to that of water is preferable, and specific examples include methyl alcohol, ethyl alcohol, isopropyl alcohol, and the like.

- distilled water is preferable as the water to be used because it causes distortion of the optical image projected on the resist when an opaque material or impurities whose refractive index is significantly different from that of water are mixed with 193 nm light. Further, pure water filtered through an ion exchange filter or the like may be used.

- the electrical resistance of water used as the immersion liquid is preferably 18.3 M ⁇ cm or more, the TOC (organic substance concentration) is preferably 20 ppb or less, and deaeration treatment is preferably performed.

- an additive that increases the refractive index may be added to water, or heavy water (D 2 O) may be used instead of water.

- a surface hydrophobized resin (HR) described later can be further added as necessary.

- HR surface hydrophobizing resin

- the receding contact angle of the resist film is preferably 60 ° to 90 °, more preferably 70 ° or more.

- the immersion head In the immersion exposure process, the immersion head needs to move on the wafer following the movement of the exposure head scanning the wafer at high speed to form the exposure pattern, so that the dynamic state is reached.

- the contact angle of the immersion liquid with respect to the resist film is important, and the resist is required to follow the high-speed scanning of the exposure head without remaining droplets.

- top coat An immersion liquid poorly soluble film (hereinafter also referred to as “top coat”) may be provided between the resist film and the immersion liquid in order to prevent the film from coming into direct contact with the immersion liquid.

- functions necessary for the top coat include suitability for application to the resist upper layer, transparency to radiation, particularly radiation having a wavelength of 193 nm, and poor immersion liquid solubility. It is preferable that the top coat is not mixed with the resist and can be uniformly applied to the resist upper layer.

- the top coat is preferably a polymer that does not contain aromatics from the viewpoint of transparency at 193 nm.

- hydrocarbon polymers acrylic ester polymers, polymethacrylic acid, polyacrylic acid, polyvinyl ether, silicon-containing polymers, and fluorine-containing polymers.

- a surface hydrophobized resin (HR) which will be described later, is also suitable as a top coat. When impurities are eluted from the top coat into the immersion liquid, the optical lens is contaminated. Therefore, it is preferable that the residual monomer component of the polymer contained in the top coat is small.

- a developer When removing the topcoat, a developer may be used, or a separate release agent may be used.

- a release agent a solvent having a small penetration into the resist film is preferable.

- the resolution can be improved.

- the exposure light source is an ArF excimer laser (wavelength: 193 nm)

- water it is preferable to use water as the immersion liquid. Therefore, the top coat for ArF immersion exposure is close to the refractive index of water (1.44).

- a topcoat is a thin film from a viewpoint of transparency and a refractive index.

- the top coat is not mixed with the resist film and further not mixed with the immersion liquid.

- the solvent used for the top coat is preferably a water-insoluble medium that is hardly soluble in the solvent used for the composition of the present invention.

- the topcoat may be water-soluble or water-insoluble.

- step (D) the exposed resist film 53 is developed to form a first pattern 54 (step (D)).

- the developer that can be used in the step of developing the resist film to form the first pattern may be an organic developer or an alkaline developer.

- step (D) as a first pattern, a step of forming a negative pattern using a developer containing an organic solvent, and as a first pattern, a step of forming a positive pattern using an alkaline developer.

- a step of forming a negative pattern using a developer containing an organic solvent as a first pattern, a step of forming a positive pattern using an alkaline developer.

- a step of forming a positive pattern using an alkaline developer can be preferably mentioned.

- the first pattern 54 may be a negative pattern or a positive pattern.

- the developer in the step of forming the first pattern by developing the resist film with a developer containing an organic solvent includes a ketone solvent, Polar solvents such as ester solvents, alcohol solvents, amide solvents, ether solvents, and hydrocarbon solvents can be used.

- ketone solvents include 1-octanone, 2-octanone, 1-nonanone, 2-nonanone, acetone, 2-heptanone (methyl amyl ketone), 4-heptanone, 1-hexanone, 2-hexanone, diisobutyl ketone, Examples include cyclohexanone, methylcyclohexanone, phenylacetone, methylethylketone, methylisobutylketone, acetylacetone, acetonylacetone, ionone, diacetylalcohol, acetylcarbinol, acetophenone, methylnaphthylketone, isophorone, and propylene carbonate.

- ester solvents include methyl acetate, butyl acetate, ethyl acetate, isopropyl acetate, pentyl acetate, isopentyl acetate, amyl acetate, cyclohexyl acetate, isobutyl isobutyrate, propylene glycol monomethyl ether acetate, ethylene glycol monoethyl ether acetate, diethylene glycol Monobutyl ether acetate, diethylene glycol monoethyl ether acetate, ethyl-3-ethoxypropionate, 3-methoxybutyl acetate, 3-methyl-3-methoxybutyl acetate, methyl formate, ethyl formate, butyl formate, propyl formate, ethyl lactate, Examples thereof include butyl lactate and propyl lactate.

- the alcohol solvents include methyl alcohol, ethyl alcohol, n-propyl alcohol, isopropyl alcohol, n-butyl alcohol, sec-butyl alcohol, tert-butyl alcohol, isobutyl alcohol, n-hexyl alcohol, n-heptyl alcohol, alcohols such as n-octyl alcohol and n-decanol, glycol solvents such as ethylene glycol, diethylene glycol and triethylene glycol, ethylene glycol monomethyl ether, propylene glycol monomethyl ether, ethylene glycol monoethyl ether, propylene glycol monoethyl ether, Diethylene glycol monomethyl ether, triethylene glycol monoethyl ether, methoxymethylbuta Glycol ether solvents such as Lumpur can be mentioned.

- ether solvent examples include dioxane, tetrahydrofuran, phenetole, and dibutyl ether in addition to the above glycol ether solvents.

- amide solvents include N-methyl-2-pyrrolidone, N, N-dimethylacetamide, N, N-dimethylformamide, hexamethylphosphoric triamide, 1,3-dimethyl-2-imidazolidinone and the like. Can be used.

- hydrocarbon solvent examples include aromatic hydrocarbon solvents such as toluene and xylene, and aliphatic hydrocarbon solvents such as pentane, hexane, octane and decane.

- a plurality of the above solvents may be mixed, or may be used by mixing with a solvent other than the above or water.

- the water content of the developer as a whole is preferably less than 10% by mass, and more preferably substantially free of moisture.

- the amount of the organic solvent used relative to the organic developer is preferably 90% by mass to 100% by mass, and preferably 95% by mass to 100% by mass with respect to the total amount of the developer.

- the organic developer is preferably a developer containing at least one organic solvent selected from the group consisting of ketone solvents, ester solvents, alcohol solvents, amide solvents and ether solvents.

- the vapor pressure of the organic developer is preferably 5 kPa or less, more preferably 3 kPa or less, and particularly preferably 2 kPa or less at 20 ° C.

- the vapor pressure of the organic developer is preferably 5 kPa or less, more preferably 3 kPa or less, and particularly preferably 2 kPa or less at 20 ° C.

- vapor pressure of 5 kPa or less examples having a vapor pressure of 5 kPa or less include 1-octanone, 2-octanone, 1-nonanone, 2-nonanone, 2-heptanone (methyl amyl ketone), 4-heptanone, 2-hexanone, diisobutyl ketone, Ketone solvents such as cyclohexanone, methylcyclohexanone, phenylacetone, methyl isobutyl ketone, butyl acetate, pentyl acetate, isopentyl acetate, amyl acetate, cyclohexyl acetate, isobutyl isobutyrate, propylene glycol monomethyl ether acetate, ethylene glycol monoethyl ether acetate, diethylene glycol Monobutyl ether acetate, diethylene glycol monoethyl ether acetate, ethyl-3-ethoxypropionate, 3-

- Specific examples having a vapor pressure of 2 kPa or less, which is a particularly preferable range, include 1-octanone, 2-octanone, 1-nonanone, 2-nonanone, 4-heptanone, 2-hexanone, diisobutyl ketone, cyclohexanone, and methylcyclohexanone.

- Ketone solvents such as phenylacetone, butyl acetate, amyl acetate, cyclohexyl acetate, isobutyl isobutyrate, propylene glycol monomethyl ether acetate, ethylene glycol monoethyl ether acetate, diethylene glycol monobutyl ether acetate, diethylene glycol monoethyl ether acetate, ethyl-3- Ethoxypropionate, 3-methoxybutyl acetate, 3-methyl-3-methoxybutyl acetate, ethyl lactate, butyl lactate, propyl lactate Ester solvents, n-butyl alcohol, sec-butyl alcohol, tert-butyl alcohol, isobutyl alcohol, n-hexyl alcohol, n-heptyl alcohol, n-octyl alcohol, n-decanol and other alcohol solvents, ethylene glycol, Glycol solvents such as di

- Glycol ether solvents such as phenetol and dibutyl ether, N-methyl 2-pyrrolidone, N, N- dimethylacetamide, N, N-dimethylformamide amide solvents, aromatic hydrocarbon solvents such as xylene, octane, aliphatic hydrocarbon solvents decane.

- An appropriate amount of a surfactant can be added to the organic developer as necessary.

- the surfactant is not particularly limited, and for example, an ionic or nonionic fluorine-based and / or silicon-based surfactant can be used.

- fluorine and / or silicon surfactants include, for example, JP-A No. 62-36663, JP-A No. 61-226746, JP-A No. 61-226745, JP-A No. 62-170950, JP-A-63-34540, JP-A-7-230165, JP-A-8-62834, JP-A-9-54432, JP-A-9-5988, US Pat. No. 5,405,720,

- the surfactants described in the specifications of US Pat. Preferably, it is a nonionic surfactant.

- it does not specifically limit as a nonionic surfactant, It is still more preferable to use a fluorochemical surfactant or a silicon-type surfactant.

- the amount of the surfactant used is usually 0.001 to 5% by mass, preferably 0.005 to 2% by mass, and more preferably 0.01 to 0.5% by mass with respect to the total amount of the developer.

- the organic developer may contain a basic compound as necessary.

- basic compounds include nitrogen-containing basic compounds, for example, nitrogen-containing compounds described in JP-A-2013-11833, particularly those described in [0021] to [0063], and resist compositions described in detail later. And basic compounds that may be used. When the organic developer contains a basic compound, an improvement in contrast during development, suppression of film loss, and the like can be expected.

- the alkali developer in the step of developing with an alkali developer to form the first pattern includes, for example, sodium hydroxide, potassium hydroxide, sodium carbonate, sodium silicate, metasilicic acid.

- Inorganic alkalis such as sodium and aqueous ammonia, primary amines such as ethylamine and n-propylamine, secondary amines such as diethylamine and di-n-butylamine, tertiary amines such as triethylamine and methyldiethylamine, dimethylethanol Alkaline aqueous solutions such as alcohol amines such as amine and triethanolamine, quaternary ammonium salts such as tetramethylammonium hydroxide and tetraethylammonium hydroxide, and cyclic amines such as pyrrole and piperidine can be used.

- alcohols and surfactants can be added in appropriate amounts to the alkaline aqueous solution.

- surfactant include those described above.

- the alkali concentration of the alkali developer is usually from 0.1 to 20% by mass.

- the pH of the alkali developer is usually from 10.0 to 15.0.

- a 2.38% mass aqueous solution of tetramethylammonium hydroxide is desirable.

- a developing method for example, a method in which a substrate is immersed in a tank filled with a developer for a certain period of time (dip method), a method in which the developer is raised on the surface of the substrate by surface tension and is left stationary for a certain time (paddle) Method), a method of spraying the developer on the substrate surface (spray method), a method of continuously discharging the developer while scanning the developer discharge nozzle on the substrate rotating at a constant speed (dynamic dispensing method) Etc.

- dip method a method in which a substrate is immersed in a tank filled with a developer for a certain period of time

- paddle a method in which the developer is raised on the surface of the substrate by surface tension and is left stationary for a certain time

- spray method a method of spraying the developer on the substrate surface

- the discharge pressure of the discharged developer (the flow rate per unit area of the discharged developer) is Preferably it is 2 mL / sec / mm 2 or less, More preferably, it is 1.5 mL / sec / mm 2 or less, More preferably, it is 1 mL / sec / mm 2 or less.

- the flow rate is no particular lower limit on the flow rate, but 0.2 mL / sec / mm 2 or more is preferable in consideration of throughput.

- the developer discharge pressure (mL / sec / mm 2 ) is a value at the developing nozzle outlet in the developing device.

- Examples of the method for adjusting the discharge pressure of the developer include a method of adjusting the discharge pressure with a pump or the like, and a method of changing the pressure by adjusting the pressure by supply from a pressurized tank.

- a step of stopping development may be performed while substituting with another solvent.

- the substrate processing method of the present invention includes, as step (D), a step of forming a negative pattern using a developer containing an organic solvent and a step of forming a positive pattern using an alkali developer. You may do it.

- step (D) a step of forming a negative pattern using a developer containing an organic solvent and a step of forming a positive pattern using an alkali developer. You may do it.

- US Pat. No. 8,227,183B, FIG. As described in 1 to 11 and the like, it can be expected to resolve a pattern having a line width that is 1 ⁇ 2 of the mask pattern.

- the substrate processing method of the present invention may include a cleaning step (rinsing step) using a rinsing liquid after the step (D).

- the rinsing solution used in the rinsing step after the step of developing with a developer containing an organic solvent is not particularly limited as long as the resist pattern is not dissolved, and a solution containing a general organic solvent can be used.

- a rinsing liquid containing at least one organic solvent selected from the group consisting of hydrocarbon solvents, ketone solvents, ester solvents, alcohol solvents, amide solvents and ether solvents is used. Is preferred.

- hydrocarbon solvent ketone solvent, ester solvent, alcohol solvent, amide solvent and ether solvent

- hydrocarbon solvent ketone solvent, ester solvent, alcohol solvent, amide solvent and ether solvent

- a rinse containing at least one organic solvent selected from the group consisting of ketone solvents, ester solvents, alcohol solvents, and amide solvents A step of washing with a liquid, more preferably, a step of washing with a rinsing liquid containing an alcohol solvent or an ester solvent, and particularly preferably a rinsing liquid containing a monohydric alcohol.

- a cleaning step is performed, and most preferably, a cleaning step is performed using a rinse solution containing a monohydric alcohol having 5 or more carbon atoms.

- examples of the monohydric alcohol used in the rinsing step include linear, branched, and cyclic monohydric alcohols. Specific examples include 1-butanol, 2-butanol, and 3-methyl-1-butanol. Tert-butyl alcohol, 1-pentanol, 2-pentanol, 1-hexanol, 4-methyl-2-pentanol, 1-heptanol, 1-octanol, 2-hexanol, cyclopentanol, 2-heptanol, 2 -Octanol, 3-hexanol, 3-heptanol, 3-octanol, 4-octanol and the like can be used, and particularly preferable monohydric alcohols having 5 or more carbon atoms are 1-hexanol, 2-hexanol, 4-methyl- Use 2-pentanol, 1-pentanol, 3-methyl-1-butanol, etc. Can.

- a plurality of the above components may be mixed, or may be used by mixing with an organic solvent other than the above.

- the water content in the rinse liquid is preferably 10% by mass or less, more preferably 5% by mass or less, and particularly preferably 3% by mass or less. By setting the water content to 10% by mass or less, good development characteristics can be obtained.

- the vapor pressure of the rinsing solution used after the step of developing with a developer containing an organic solvent is preferably 0.05 kPa or more and 5 kPa or less, more preferably 0.1 kPa or more and 5 kPa or less at 20 ° C. 12 kPa or more and 3 kPa or less are the most preferable.

- rinsing solution used in the rinsing step after the step of developing with an alkali developer pure water can be used, and an appropriate amount of a surfactant can be added.

- the cleaning method in the rinsing step is not particularly limited.

- a method of continuously discharging a rinsing liquid onto a substrate rotating at a constant speed (rotary coating method), a substrate in a bath filled with the rinsing liquid Can be applied for a certain period of time (dip method), a method of spraying a rinsing liquid on the substrate surface (spray method), etc.

- a cleaning process is performed by a spin coating method, and the substrate is washed at 2000 rpm or more after cleaning. It is preferable to rotate at a rotational speed of 4000 rpm to remove the rinse liquid from the substrate. It is also preferable to include a heating step (Post Bake) after the rinsing step.

- the developing solution and the rinsing solution remaining between the patterns and inside the patterns are removed by baking.

- the heating step after the rinsing step is usually performed at 40 to 160 ° C., preferably 70 to 95 ° C., usually 10 seconds to 3 minutes, preferably 30 seconds to 90 seconds.

- the planarizing film 81 is not substantially developed by the step (D).

- the planarizing film 81 is preferably not dissolved in the developer used in the step (D).

- the flattening film is not substantially developed.

- the flattening film is applied to a developing solution at room temperature (25 ° C.) measured using a QCM (Quartz Crystal Microbalance) sensor or the like.

- the average dissolution rate (decrease rate of the flattened film) when immersed for 1000 seconds is less than 0.1 nm / second, preferably less than 0.05 nm / second, more preferably less than 0.01 nm / second. Show.

- the planarizing film-forming resin composition (a) (and thus the planarizing film) contains a hydrophilic resin.

- the resin composition for flattening film formation (a) (and hence the flattening film) preferably contains a hydrophobic resin.

- the planarizing film 81 is etched using an etching gas 75 or the like, and the planarizing film 81 is subjected to the second process.

- the pattern 82 is converted (step (E)).

- the method for the etching treatment is not particularly limited, and any known method can be used, and various conditions and the like are appropriately determined according to the type of the layer subjected to the etching treatment.

- Proc. Of SPIE Vol. Etching can be performed in accordance with 6924, 692420 (2008), Japanese Patent Application Laid-Open No. 2009-267112, and the like.

- the 1st pattern can mention suitably the form containing a silicon atom.

- the actinic ray-sensitive or radiation-sensitive resin composition contains a silicon atom (for example, a resin having a silicon atom), so that the first pattern has a silicon atom (for example, a resin having a silicon atom). ) Is preferable.

- the etching rate of the flattening film is sufficiently higher than the etching rate of the first pattern by adopting the etching conditions in which the etching reaction hardly occurs for the film containing silicon atoms. It becomes easy to set various etching conditions. Thereby, the second pattern 82 in which the pattern of the first pattern 54 is transferred to the planarizing film 81 can be more easily formed.

- the substrate processing method of the present invention is a substrate processing method including an ion implantation process

- a predetermined region of the substrate 51 using the first pattern 54 and the second pattern 82 as a mask is performed.

- ion implantation for implanting ions 76 is performed. Any known method can be adopted as the ion implantation method.

- the first pattern 54 and the second pattern 82 may be removed (step (G)).

- the step (G) is not particularly limited as long as the first pattern and the second pattern can be removed.

- the etching treatment and liquid peeling hereinafter, “wet peeling”. It can also be suitably carried out by applying one or more kinds of treatment selected from.

- Liquids that can be used in wet stripping include, for example, ammonia, ammonia perwater consisting of ammonia, hydrogen peroxide, and water, tetramethylammonium hydroxide, tetraethylammonium hydroxide, tetrapropylammonium hydroxide, tetrabutylammonium hydroxide.

- the liquid that can be used in wet peeling is preferably an aqueous solution having a pH of greater than 8 at 25 ° C., and more preferably an aqueous solution having a pH of 9 to 14.

- the first pattern 54 and the second pattern 82 are removed without damaging the substrate 51.

- the first pattern 54 and the second pattern 82 are removed. Since it is preferable to selectively remove, it is preferable to adopt a process capable of selectively removing the first pattern 54 and the second pattern 82 in the above-described processing.

- the etching rate of the first pattern 54 is the etching rate of the second pattern 82 with respect to the first pattern 54. It is preferable to include a step of performing an etching process under conditions that are greater than the speed.

- the said process (E) may be the process which served as the process (G). That is, the etching process is performed on the planarizing film 81 using the first pattern 54 as a mask, and in the process of converting the planarizing film 81 into the second pattern 82, the etching process simultaneously performs the first process.

- the pattern 54 may be removed.

- the etching rate of the first pattern 54 can be approximately the same as the etching rate of the planarizing film 81.

- the above etching conditions can be achieved by appropriately adjusting the content of each composition of the resist composition and the planarizing film forming composition, the type of etching gas, and the like.

- the planarizing film 81 needs to be a layer containing a resin having an Onishi parameter greater than 4.5, as will be described later.

- the resin composition (a) is a resin composition used for forming the first film, contains a resin (P) described below, and typically further contains a solvent.

- the first film is formed on a stepped substrate (for example, a semiconductor substrate) or the like having an uneven surface, and has a role of providing a flat surface.

- the resin composition (a) (flattened film forming composition) used for forming the first film in the substrate processing method of the present invention is a resin having an Onishi parameter greater than 4.5 (hereinafter, “ Resin (P) ").

- the composition for forming a flattened film has such a structure, it is considered that a desired effect can be obtained.

- the etching resistance of the resist film (second film) with respect to the etching resistance of the planarization film (first film) is increased by making the Onishi parameter of the resin (P) larger than a specific value. Therefore, it is presumed that a resist pattern with high resolution can be formed because the thickness of the resist film can be reduced.

- the planarizing film-forming resin composition (a) contains a resin having an Onishi parameter greater than 4.5.

- the Onishi parameter of the resin (P) is preferably 20 or less, and more preferably 6.0 to 20.

- the Onishi parameter of the resin (P) is defined as follows as described above.

- Onishi parameter of resin ⁇ ⁇ (Onishi parameter of repeating unit) ⁇ (Mole fraction of repeating unit) ⁇ Moreover, the Onishi parameter of a repeating unit (unit) is defined as follows.

- Onishi parameter of repeating unit (total number of atoms in repeating unit) / ⁇ (number of carbon atoms in repeating unit) ⁇ (total number of oxygen atoms and sulfur atoms in repeating unit) ⁇

- Onishi parameter of A-1 used in the examples described later is calculated as follows.

- the second repeating unit from the left of A-1 has 23 total atoms, 7 carbon atoms, and 4 oxygen atoms, so the Onishi parameter is 23 / (7-4) ⁇ 7.7. It is.

- the third repeating unit from the left of A-1 has a total number of atoms of 23, a number of carbon atoms of 7, and a number of oxygen atoms of 4, so the Onishi parameter is 43 / (13-6) ⁇ 6.1 It is.

- the mole fraction of the first repeating unit from the left of A-1 is 0.3

- the mole fraction of the second repeating unit from the left of A-1 is 0.5

- the third repeating unit from the left of A-1 Since the molar fraction of the unit is 0.2

- the Onishi parameter of A-1 is 5.5 ⁇ 0.3 + 7.7 ⁇ 0.5 + 6.1 ⁇ 0 in consideration of the Onishi parameter of each repeating unit described above. .2 ⁇ 6.7.

- the Onishi parameter of the resin (P) means the Onishi parameter of the portion of the resin (P) remaining as a pattern after the lithography process.

- the Onishi parameter of the resin (P) is preferably larger than the Onishi parameter of the resin (A) contained in the actinic ray-sensitive or radiation-sensitive resin composition described later. Similar to the case where the Onishi parameter of the resin (P) is greater than 4.5, the etching resistance of the resist film (second film) with respect to the etching resistance of the planarization film (first film) is increased, and the effects of the present invention are further extracted. It becomes possible.

- the Onishi parameter of the resin (A) contained in the actinic ray-sensitive or radiation-sensitive resin composition has the same definition as the Onishi parameter in the resin (P) described above.

- the Onishi parameter (Xp) of the resin (P) contained in the resin composition (a) (flattening film forming composition) and the actinic ray-sensitive or radiation-sensitive resin composition is preferably 0 ⁇ Xp-Xa ⁇ 20, more preferably 3 ⁇ Xp-Xa ⁇ 20, and 8 ⁇ Xp-Xa More preferably, it is ⁇ 20.

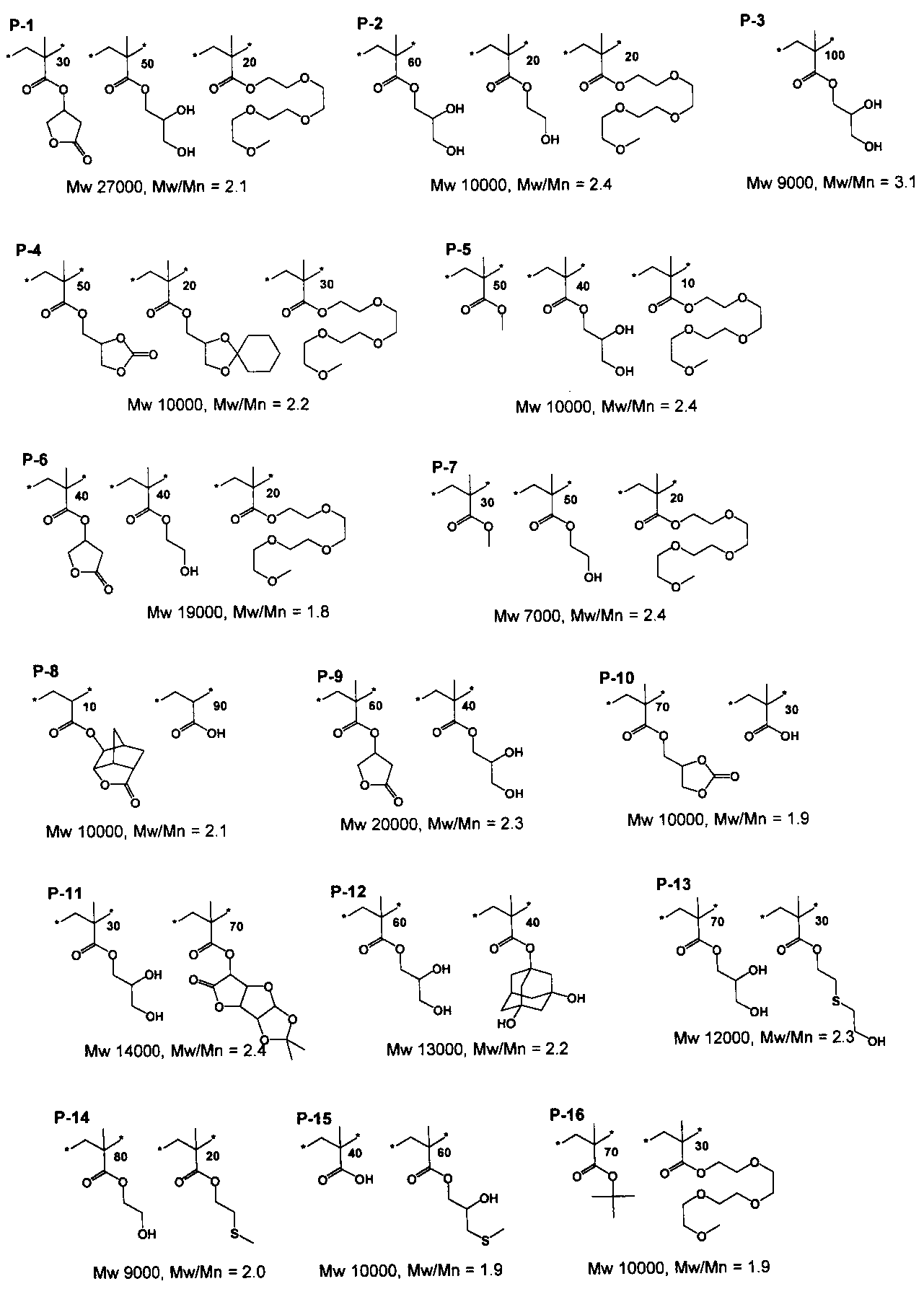

- the resin (P) is not particularly limited as long as the Onishi parameter is greater than 4.5, but specific examples thereof include poly (meth) acrylic resin, polyester resin, polyether resin, polystyrene resin, polyvinyl alcohol resin, poly Examples thereof include siloxane resins. Among these, at least one resin selected from the group consisting of a poly (meth) acrylic resin, a polyester resin, and a polyether resin is preferable.

- the resin (P) preferably does not contain an aromatic ring.

- the glass transition temperature (Tg) of the resin (P) is not particularly limited, but is preferably 200 ° C. or less, and more preferably 150 ° C. or less.

- the lower limit of Tg is not particularly limited, but is usually ⁇ 100 ° C. or higher. For reasons of better embedding and flatness, a lower Tg is preferred.

- Tg is measured using a differential scanning calorimeter (DSC).

- the weight average molecular weight of the resin (P) is not particularly limited, but is preferably 500 to 100,000, more preferably 20,000 or less, and more preferably 15,000 or less. More preferably, it is 1,000 or less.

- a weight average molecular weight is a standard polystyrene conversion value calculated

- the resin (P) preferably has a repeating unit represented by the following general formula (1-1).

- the resin (P) may have two or more types of repeating units represented by the following general formula (1-1).

- R 1 represents a hydrogen atom or an organic group.

- R 2 represents a hydrocarbon group having a hetero atom. However, for the number of carbon atoms contained in R 2, the ratio of the number of hetero atoms contained in R 2 is 0.30 or more.

- R 1 represents a hydrogen atom or an organic group.

- R 1 is preferably, for example, a hydrogen atom, a methyl group, a trifluoromethyl group, a hydroxymethyl group, or the like.

- R 2 represents a hydrocarbon group having a hetero atom.

- the hetero atom that R 2 has is not particularly limited, and specific examples include a nitrogen atom, an oxygen atom, and a sulfur atom. Of these, an oxygen atom is preferable.

- the hydrocarbon group having a heteroatom is not particularly limited, but an aliphatic hydrocarbon group having a heteroatom (for example, 1 to 10 carbon atoms) (straight, branched or cyclic), aromatic carbon having a heteroatom Examples thereof include a hydrogen group (for example, having 6 to 20 carbon atoms), an alicyclic heterocyclic group, an aromatic heterocyclic group, or a combination of these.

- the ratio of the number of the heteroatom contained in R 2 (hereinafter, also referred to as "hetero atom ratio”) is 0.30 or more. Especially, it is preferable that it is 0.50 or more.

- the upper limit of the heteroatom ratio is not particularly limited, but is usually 1.00 or less.

- R 2 examples include aliphatic hydrocarbon groups (eg, having 1 to 10 carbon atoms) (straight, branched or cyclic), aromatic hydrocarbon groups each having a heteroatom ratio of 0.30 or more. (For example, having 6 to 20 carbon atoms), a lactone structure-containing group, a carbonate structure-containing group, an acetal structure-containing group, a hydroxy group-containing group, or a group represented by the general formula (P1) described later. However, the lactone structure-containing group, the carbonate structure-containing group, the acetal structure-containing group, the hydroxy group-containing group, or the group represented by the general formula (P1) described later, each having a heteroatom content of 0.30 or more. It is preferable.

- the lactone structure-containing group is a group having a lactone structure (cyclic ester structure).

- lactone structure examples include a lactone structure in a “repeating unit having a lactone structure” which may be contained in the resin (A) described later.

- the carbonate structure-containing group represents a group containing a carbonate structure (cyclic carbonate structure).

- Specific examples of the carbonate structure include a cyclic carbonate structure in “a repeating unit having a cyclic carbonate structure” which may be contained in the resin (A) described later.

- the acetal structure-containing group represents a group containing an acetal structure.

- the acetal structure is represented by the following general formula (Q).

- R 1 to R 4 each independently represents a hydrocarbon group.

- R 1 to R 4 may combine with each other to form a ring.

- the hydrocarbon group as R 1 to R 4 is not particularly limited, and examples thereof include an aliphatic hydrocarbon group (for example, having 1 to 10 carbon atoms) (straight, branched or cyclic), aromatic And hydrocarbon groups (for example, having 6 to 20 carbon atoms). Of these, an aliphatic hydrocarbon group is preferable.

- the hydroxy group-containing group represents a group containing a hydroxy group (—OH). Of these, a hydrocarbon group containing a hydroxy group is preferred. Specific examples and preferred embodiments of the hydrocarbon group are the same as R 1 to R 4 in the general formula (Q).

- the hydroxy group-containing group is preferably a group containing two or more hydroxy groups.

- R A represents a divalent hydrocarbon group which may contain a hetero atom.

- R B represents a monovalent hydrocarbon group which may contain a hetero atom.

- n represents an integer of 1 or more. When n is an integer of 2 or more, a plurality of R A may be the same or different. * Represents a bonding position with the remainder of the repeating unit represented by the general formula (1-1).

- the ratio of the number of heteroatoms to the number of carbon atoms contained in the general formula (P1) is 0.30 or more.

- R A represents a divalent hydrocarbon group.

- Specific examples and preferred embodiments of the hydrocarbon group are the same as R 1 to R 4 in the above-described formula (Q).

- R B represents a monovalent hydrocarbon group.

- Specific examples and preferred embodiments of the hydrocarbon group are the same as R 1 to R 4 in the above-described formula (Q).

- n represents an integer of 1 or more. n is preferably an integer of 1 to 10.

- the ratio of the repeating unit (R 2 : lactone structure-containing group) represented by the above formula (1-1) in the resin (P) is preferably 10 to 80 mol%. More preferably, it is 10 to 60 mol%.

- the ratio of the repeating unit (R 2 : carbonate structure-containing group) represented by the above formula (1-1) in the resin (P) is preferably 10 to 80 mol%. More preferably, it is 10 to 50 mol%.

- the ratio of the repeating unit (R 2 : acetal structure-containing group) represented by the above formula (1-1) in the resin (P) is preferably 10 to 80 mol%. More preferably, it is 10 to 30 mol%.

- the ratio of the repeating unit represented by the above formula (1-1) in the resin (P) is 10 to It is preferably 80 mol%, more preferably 10 to 30 mol%.

- the proportion of the repeating unit represented by the above formula (1-1) in the resin (P) (having two or more repeating units represented by the above formula (1-1))

- the total ratio is not particularly limited, but is preferably 10 to 100 mol%, and more preferably 80 to 100 mol%.

- the resin (P) preferably has a repeating unit represented by the above formula (1-1) (R 2 : a group represented by the above formula (P1)), Among them, the ratio of the repeating unit represented by the above formula (1-1) (R 2 : group represented by the above formula (P1)) is more preferably 15 mol% or more, and among them, the above repeating unit represented by the formula (1-1): Apart from the (R 2 group represented by the above-mentioned formula (P1)), the repeating unit represented by the above formula (1-1) (R 2: More preferably, it has a group containing two or more hydroxy groups.

- the resin (P) may have a repeating unit other than the repeating unit represented by the formula (1-1) described above.

- a repeating unit having a heteroatom ratio of less than 0.30 in the above formula (1-1) can be used.

- the resin (P) preferably has a repeating unit represented by the following general formula (1-2).

- the resin (P) may have two or more types of repeating units represented by the following general formula (1-2).

- L represents an organic group.

- X represents —O—, —S—, —CO—, —CO—O—, or —O—CO—.

- L represents an organic group.

- the organic group include a hydrocarbon group, and specific examples and preferred embodiments of the hydrocarbon group are the same as R 1 to R 4 in the general formula (Q).

- the hydrocarbon group may have a substituent, and examples of the substituent include a hydrocarbon group having 1 to 20 carbon atoms and a hydroxy group.

- the hydrocarbon group may contain one or more functional groups.

- the functional group include —O—, —S—, —CO—, —CO—O—, and —O—. CO- and the like can be mentioned.

- the ratio of the repeating unit represented by the above formula (1-2) in the resin (P) (X: —O—) is preferably 20 to 100 mol%. 50 to 100 mol% is more preferable, and 80 to 100 mol% is more preferable.

- the ratio of the repeating unit represented by the above formula (1-2) in the resin (P) (having two or more repeating units represented by the above formula (1-2))

- the total ratio is not particularly limited, but is preferably 10 to 100 mol%, and more preferably 80 to 100 mol%.

- the content of the resin (P) is not particularly limited, but is preferably 10 to 100% by mass, and preferably 80 to 100% by mass in the total solid content. More preferred.

- one type of resin (P) may be contained, or two or more types of resins (P) may be used in combination.

- the resin composition (a) of the present invention may contain components other than the resin (P).

- components other than the resin (P) include resins other than the resin (P), solvents, surfactants, and the like.

- Specific examples of the solvent and the surfactant are the same as those of the actinic ray-sensitive or radiation-sensitive resin composition described later.

- the resin composition (a) of this invention contains a solvent.

- the actinic ray-sensitive or radiation-sensitive resin composition is a composition used for forming the second film, and contains a resin (A) whose polarity is changed by the action of an acid.

- the actinic ray-sensitive or radiation-sensitive resin composition further contains a compound that generates an acid upon irradiation with actinic rays or radiation, a hydrophobic resin, an acid diffusion controller, a solvent, a surfactant, or other additives. May be.

- Resin whose polarity is changed by the action of an acid is a resin whose polarity is changed by the action of an acid. It is preferable that the resin has a group (hereinafter referred to as “acid-decomposable group”) that is decomposed by the action of the above to increase polarity (hereinafter also referred to as “acid-decomposable group”).

- the polarity of the acid-decomposable resin changes greatly before and after irradiation with actinic rays or radiation, so that the dissolution contrast when developed with an alkali developer or an organic solvent developer is improved, and an alkali developer is used.

- a positive pattern is adopted.

- the development is carried out using an organic solvent-based developer, a negative pattern is obtained.

- the resin (A) contains a repeating unit having an acid-decomposable group.

- the repeating unit having an acid-decomposable group is preferably a repeating unit having a group that decomposes by the action of an acid to generate an alkali-soluble group.

- the resin (A) preferably includes a repeating unit having an acid-decomposable group.

- the acid-decomposable group refers to a group that decomposes by the action of an acid to generate a polar group.

- the acid-decomposable group preferably has a structure in which a polar group is protected by a group capable of decomposing and leaving by the action of an acid (leaving group).

- the polar group is not particularly limited as long as it is a group that is hardly soluble or insoluble in a developer containing an organic solvent, but a phenolic hydroxyl group, a carboxyl group, a fluorinated alcohol group (preferably a hexafluoroisopropanol group), a sulfonic acid group.

- the alcoholic hydroxyl group is a hydroxyl group bonded to a hydrocarbon group and means a hydroxyl group other than a hydroxyl group directly bonded on an aromatic ring (phenolic hydroxyl group).

- An aliphatic alcohol substituted with a functional group for example, a fluorinated alcohol group (such as a hexafluoroisopropanol group)) is excluded.

- the alcoholic hydroxyl group is preferably a hydroxyl group having a pKa (acid dissociation constant) of 12 or more and 20 or less.

- Preferred polar groups include carboxyl groups, fluorinated alcohol groups (preferably hexafluoroisopropanol groups), and sulfonic acid groups.

- a preferred group as the acid-decomposable group is a group in which the hydrogen atom of these groups is substituted with a group capable of leaving with an acid.

- Examples of the group capable of leaving with an acid include —C (R 36 ) (R 37 ) (R 38 ), —C (R 36 ) (R 37 ) (OR 39 ), —C (R 01) (R 02) (can be exemplified OR 39) or the like.

- R 36 to R 39 each independently represents an alkyl group, a cycloalkyl group, an aryl group, an aralkyl group or an alkenyl group.

- R 36 and R 37 may be bonded to each other to form a ring.

- R 01 and R 02 each independently represents a hydrogen atom, an alkyl group, a cycloalkyl group, an aryl group, an aralkyl group or an alkenyl group.

- the alkyl group of R 36 to R 39 , R 01 and R 02 is preferably an alkyl group having 1 to 8 carbon atoms, for example, methyl group, ethyl group, propyl group, n-butyl group, sec-butyl group, hexyl Group, octyl group and the like.

- the cycloalkyl group of R 36 to R 39 , R 01 and R 02 may be monocyclic or polycyclic.

- the monocyclic type is preferably a cycloalkyl group having 3 to 8 carbon atoms, and examples thereof include a cyclopropyl group, a cyclobutyl group, a cyclopentyl group, a cyclohexyl group, and a cyclooctyl group.

- the polycyclic type is preferably a cycloalkyl group having 6 to 20 carbon atoms.

- an adamantyl group norbornyl group, isobornyl group, camphanyl group, dicyclopentyl group, ⁇ -pinel group, tricyclodecanyl group, tetracyclododecyl group.

- Group, androstanyl group and the like Note that at least one carbon atom in the cycloalkyl group may be substituted with a heteroatom such as an oxygen atom.

- the aryl group of R 36 to R 39 , R 01 and R 02 is preferably an aryl group having 6 to 10 carbon atoms, and examples thereof include a phenyl group, a naphthyl group, and an anthryl group.

- the aralkyl group of R 36 to R 39 , R 01 and R 02 is preferably an aralkyl group having 7 to 12 carbon atoms, and examples thereof include a benzyl group, a phenethyl group and a naphthylmethyl group.

- the alkenyl group of R 36 to R 39 , R 01 and R 02 is preferably an alkenyl group having 2 to 8 carbon atoms, and examples thereof include a vinyl group, an allyl group, a butenyl group, and a cyclohexenyl group.

- the ring formed by combining R 36 and R 37 is preferably a cycloalkyl group (monocyclic or polycyclic).

- the cycloalkyl group is preferably a monocyclic cycloalkyl group such as a cyclopentyl group or a cyclohexyl group, or a polycyclic cycloalkyl group such as a norbornyl group, a tetracyclodecanyl group, a tetracyclododecanyl group or an adamantyl group.

- a monocyclic cycloalkyl group having 5 to 6 carbon atoms is more preferable, and a monocyclic cycloalkyl group having 5 carbon atoms is particularly preferable.

- the acid-decomposable group is preferably a cumyl ester group, an enol ester group, an acetal ester group, a tertiary alkyl ester group or the like. More preferably, it is a tertiary alkyl ester group.

- the resin (A) preferably has a repeating unit represented by the following general formula (AI) as a repeating unit having an acid-decomposable group.

- the repeating unit represented by the general formula (AI) generates a carboxyl group as a polar group by the action of an acid, and in a plurality of carboxyl groups, shows a high interaction due to hydrogen bonding.

- the pattern can be insolubilized or hardly soluble more reliably with respect to the solvent in the actinic ray-sensitive or radiation-sensitive resin composition described above.

- Xa 1 represents a hydrogen atom, an alkyl group, a cyano group, or a halogen atom.

- T represents a single bond or a divalent linking group.

- Rx 1 to Rx 3 each independently represents an alkyl group or a cycloalkyl group.

- Two of Rx 1 to Rx 3 may combine to form a ring structure.

- Examples of the divalent linking group of T include an alkylene group, —COO—Rt— group, —O—Rt— group, phenylene group and the like.

- Rt represents an alkylene group or a cycloalkylene group.

- T is preferably a single bond or a —COO—Rt— group.

- Rt is preferably an alkylene group having 1 to 5 carbon atoms, more preferably a —CH 2 — group, — (CH 2 ) 2 — group, or — (CH 2 ) 3 — group. More preferably, T is a single bond.

- the alkyl group of Xa1 may have a substituent, and examples of the substituent include a hydroxyl group and a halogen atom (preferably a fluorine atom).

- the alkyl group for X a1 preferably has 1 to 4 carbon atoms, and examples thereof include a methyl group, an ethyl group, a propyl group, a hydroxymethyl group, and a trifluoromethyl group, and a methyl group is preferable.

- X a1 is preferably a hydrogen atom or a methyl group.

- the alkyl group of Rx 1 , Rx 2 and Rx 3 may be linear or branched, and is a methyl group, ethyl group, n-propyl group, isopropyl group, n-butyl group, isobutyl. Group, t-butyl group and the like are preferable.

- the number of carbon atoms of the alkyl group is preferably 1 to 10, and more preferably 1 to 5.

- Examples of the cycloalkyl group of Rx 1 , Rx 2 and Rx 3 include polycyclic rings such as a monocyclic cycloalkyl group such as cyclopentyl group and cyclohexyl group, norbornyl group, tetracyclodecanyl group, tetracyclododecanyl group and adamantyl group. Are preferred.

- the ring structure formed by combining two of Rx 1 , Rx 2 and Rx 3 includes a monocyclic cycloalkane ring such as cyclopentyl ring and cyclohexyl ring, norbornane ring, tetracyclodecane ring, tetracyclododecane ring, adamantane ring

- a polycyclic cycloalkyl group such as is preferable.

- a monocyclic cycloalkane ring having 5 or 6 carbon atoms is particularly preferable.

- Rx 1 , Rx 2 and Rx 3 are preferably each independently an alkyl group, more preferably a linear or branched alkyl group having 1 to 4 carbon atoms.

- Each of the above groups may have a substituent, and examples of the substituent include an alkyl group (1 to 4 carbon atoms), a cycloalkyl group (3 to 8 carbon atoms), a halogen atom, an alkoxy group (carbon 1 to 4), a carboxyl group, an alkoxycarbonyl group (2 to 6 carbon atoms), and the like, and 8 or less carbon atoms are preferable.

- a substituent having no hetero atom such as an oxygen atom, a nitrogen atom, or a sulfur atom is more preferable (for example, More preferably, it is not an alkyl group substituted with a hydroxyl group, etc.), more preferably a group consisting of only a hydrogen atom and a carbon atom, and particularly preferably a linear or branched alkyl group or a cycloalkyl group. .

- Rx 1 to Rx 3 are each independently an alkyl group, and it is preferable that two of Rx 1 to Rx 3 are not bonded to form a ring structure.

- an increase in the volume of the group represented by —C (Rx 1 ) (Rx 2 ) (Rx 3 ) as a group capable of decomposing and leaving by the action of an acid can be suppressed, and after the exposure step and the exposure step In the post-exposure heating step that may be performed, the volume shrinkage of the exposed portion tends to be suppressed.

- repeating unit represented by the general formula (AI) are given below, but the present invention is not limited to these specific examples.

- Rx represents a hydrogen atom, CH 3 , CF 3 , or CH 2 OH.

- Rxa and Rxb each independently represents an alkyl group (preferably an alkyl group having 1 to 10 carbon atoms, more preferably 1 to 5 carbon atoms).

- Xa 1 represents a hydrogen atom, CH 3 , CF 3 , or CH 2 OH.

- Z represents a substituent, and when a plurality of Zs are present, the plurality of Zs may be the same as or different from each other.

- p represents 0 or a positive integer. Specific examples and preferred examples of Z are the same as specific examples and preferred examples of the substituent that each group such as Rx 1 to Rx 3 may have.

- the resin (A) preferably has a repeating unit described in paragraphs [0057] to [0071] of JP-A No. 2014-202969 as a repeating unit having an acid-decomposable group.

- the resin (A) may have a repeating unit that generates an alcoholic hydroxyl group described in paragraphs [0072] to [0073] of JP-A-2014-202969 as a repeating unit having an acid-decomposable group. Good.

- One type of repeating unit having an acid-decomposable group may be used, or two or more types may be used in combination.

- the content of the repeating unit having an acid-decomposable group contained in the resin (A) is based on the total repeating units of the resin (A), It is preferably 20 to 90 mol%, more preferably 40 to 80 mol%.

- the resin (A) has a repeating unit represented by the above general formula (AI), and the content of the repeating unit represented by the above general formula (AI) with respect to all the repeating units of the resin (A) is 40 mol. % Or more is preferable.

- the resin (A) preferably contains a silicon atom (hereinafter referred to as “Si atom”), and more preferably contains a repeating unit having a Si atom.

- Si atom silicon atom

- the etching resistance is increased. In this case, the thickness of the second film can be reduced, and the resolution of the pattern is improved.

- the content of Si atoms in the resin (A) is preferably 1 to 30% by mass, more preferably 8 to 30% by mass, and further preferably 13 to 30% by mass. preferable.

- the Si content of the resin (A) means the Si content of the resin (A) in a portion remaining as a pattern after the lithography process.

- the repeating unit having both an Si atom and an acid-decomposable group corresponds to both a repeating unit having an Si atom and a repeating unit having an acid-decomposable group.

- a resin composed of only a repeating unit having both an Si atom and an acid-decomposable group corresponds to a resin containing a repeating unit having an Si atom and a repeating unit having an acid-decomposable group.

- the repeating unit having Si atoms is not particularly limited as long as it has Si atoms.

- a silane repeating unit (—SiR 2 —: R 2 is an organic group)

- a siloxane repeating unit (—SiR 2 —O—: R 2 is an organic group)

- a (meth) acrylate repeating unit having a Si atom and vinyl-based repeating units having Si atoms.

- the repeating unit having a Si atom preferably has a silsesquioxane structure.

- it may have a silsesquioxane structure in a main chain or in a side chain, it is preferable to have in a side chain.

- silsesquioxane structure examples include a cage-type silsesquioxane structure, a ladder-type silsesquioxane structure (ladder-type silsesquioxane structure), a random-type silsesquioxane structure, and the like. Of these, a cage-type silsesquioxane structure is preferable.

- the cage silsesquioxane structure is a silsesquioxane structure having a cage structure.

- the cage silsesquioxane structure may be a complete cage silsesquioxane structure or an incomplete cage silsesquioxane structure, but may be a complete cage silsesquioxane structure. preferable.

- the ladder-type silsesquioxane structure is a silsesquioxane structure having a ladder-like skeleton.

- the random silsesquioxane structure is a silsesquioxane structure having a random skeleton.

- the cage silsesquioxane structure is preferably a siloxane structure represented by the following formula (S).

- R represents a monovalent organic group.

- a plurality of R may be the same or different.

- the organic group is not particularly limited, and specific examples include a halogen atom, a hydroxy group, a nitro group, a carboxy group, an alkoxy group, an amino group, a mercapto group, and a blocked mercapto group (for example, blocked (protected) with an acyl group).

- Mercapto groups include acyl groups, imide groups, phosphino groups, phosphinyl groups, silyl groups, vinyl groups, hydrocarbon groups optionally having heteroatoms, (meth) acryl group-containing groups and epoxy group-containing groups. Can be mentioned.

- halogen atom examples include a fluorine atom, a chlorine atom, a bromine atom, and an iodine atom.

- hetero atom of the hydrocarbon group that may have a hetero atom include an oxygen atom, a nitrogen atom, a sulfur atom, and a phosphorus atom.

- hydrocarbon group that may have a hetero atom examples include an aliphatic hydrocarbon group, an aromatic hydrocarbon group, or a group obtained by combining these.

- the aliphatic hydrocarbon group may be linear, branched or cyclic. Specific examples of the aliphatic hydrocarbon group include a linear or branched alkyl group (particularly 1 to 30 carbon atoms), a linear or branched alkenyl group (particularly 2 to 30 carbon atoms), Examples thereof include a linear or branched alkynyl group (particularly 2 to 30 carbon atoms).

- aromatic hydrocarbon group examples include aromatic hydrocarbon groups having 6 to 18 carbon atoms such as a phenyl group, a tolyl group, a xylyl group, and a naphthyl group.

- the repeating unit having a Si atom is preferably represented by the following formula (I).

- L represents a single bond or a divalent linking group.

- Examples of the divalent linking group include an alkylene group, —COO—Rt— group, —O—Rt— group and the like.

- Rt represents an alkylene group or a cycloalkylene group.

- L is preferably a single bond or a —COO—Rt— group.