WO2015147705A2 - Method for preparing a sterile nano emulsion of perfluoro-organic compounds - Google Patents

Method for preparing a sterile nano emulsion of perfluoro-organic compounds Download PDFInfo

- Publication number

- WO2015147705A2 WO2015147705A2 PCT/RU2015/000318 RU2015000318W WO2015147705A2 WO 2015147705 A2 WO2015147705 A2 WO 2015147705A2 RU 2015000318 W RU2015000318 W RU 2015000318W WO 2015147705 A2 WO2015147705 A2 WO 2015147705A2

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- pfos

- nanoemulsion

- aqueous solution

- emulsion

- stabilizing additive

- Prior art date

Links

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/14—Particulate form, e.g. powders, Processes for size reducing of pure drugs or the resulting products, Pure drug nanoparticles

- A61K9/19—Particulate form, e.g. powders, Processes for size reducing of pure drugs or the resulting products, Pure drug nanoparticles lyophilised, i.e. freeze-dried, solutions or dispersions

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K49/00—Preparations for testing in vivo

- A61K49/04—X-ray contrast preparations

- A61K49/0433—X-ray contrast preparations containing an organic halogenated X-ray contrast-enhancing agent

- A61K49/0447—Physical forms of mixtures of two different X-ray contrast-enhancing agents, containing at least one X-ray contrast-enhancing agent which is a halogenated organic compound

- A61K49/0461—Dispersions, colloids, emulsions or suspensions

- A61K49/0471—Perflubron, i.e. perfluoroctylbromide, C8F17Br emulsions

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/0012—Galenical forms characterised by the site of application

- A61K9/0019—Injectable compositions; Intramuscular, intravenous, arterial, subcutaneous administration; Compositions to be administered through the skin in an invasive manner

- A61K9/0026—Blood substitute; Oxygen transporting formulations; Plasma extender

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61P—SPECIFIC THERAPEUTIC ACTIVITY OF CHEMICAL COMPOUNDS OR MEDICINAL PREPARATIONS

- A61P7/00—Drugs for disorders of the blood or the extracellular fluid

- A61P7/08—Plasma substitutes; Perfusion solutions; Dialytics or haemodialytics; Drugs for electrolytic or acid-base disorders, e.g. hypovolemic shock

Definitions

- PFOS is insoluble in water and are themselves poor solvents for various water-soluble biologically active substances; therefore, for use as oxygen-transporting media, they are dispersed in an aqueous solution of a stabilizing additive until fine emulsions are formed.

- the task of the stabilizing additive is to form an adsorption layer around perfluorocarbon particles, while the physicochemical properties and nature of the stabilizing additive determine the stability of the dispersed system and its reactogenicity.

- the key parameters here are the bond strength of the surfactant with the "core" of the emulsion particle, the nature and density of the surfactant molecules on the surface of the particle.

- a mixture of PFOS receive by mixing the liquid components, and the pre-emulsion is obtained by passing the PFOS mixture through an aqueous solution of a stabilizing agent (proxanol), while passing the resulting pre-emulsion through the working chamber of the homogenizer, after complete mixing, they are passed through the working chamber of the homogenizer with temperature control at a pressure of 300-660 atm, followed by adding to the resulting emulsion of a sterile physiologically acceptable aqueous saline solution. The resulting PFOS nanoemulsion is frozen.

- a stabilizing agent proxanol

- RF patent 2393849 describes a method for producing a PFOS emulsion in which, before mixing, a mixture of PFOS and an aqueous solution of poloxamer are saturated with carbon dioxide, the preparation of a pre-emulsion and subsequent homogenization is carried out in an atmosphere of carbon dioxide, and a physiologically acceptable water-salt solution is added to the pre-emulsion.

- the present invention relates to a method for producing a sterile nano-emulsion of perfluororganic compounds (PFOS), which includes:

- the circulation loop in the method of the present invention includes a vessel for producing a PFOS preemulsion, a homogenizer, and pipelines connecting the vessel and the homogenizer.

- homogenization of the PFOS preemulsion is carried out at a pressure in the working chamber of the homogenizer in the range from 10 to 60.8 MPa, preferably in the range from 43, 1 to 45, 1 MPa, the working chamber of the homogenizer is thermostated to provide a process temperature of the range from 19 to 30 ° C, preferably from 20 to 26 ° C and carry out thermostating of the pipelines of the circulation circuit to ensure the process temperature of the pipelines in the range from 5 to 20 ° C preferably from 7 to 15 ° C.

- a mixture of PFOS in an aqueous solution of a stabilizing additive is pumped in the main circulation circuit through pipelines 4 and 6 through a homogenizer 5 at a working pressure in the homogenizer chamber of 10-60.8 MPa, when the homogenizer working chamber is cooled to 19-30 ° ⁇ and thermostats of pipelines 4 and 6 circulation loop at a temperature of 5-20 ° C. Carry out 9-15 cycles of homogenization to obtain PFOS preemulsion.

Abstract

The present invention relates to the chemical and pharmaceutical industry and presents a method for producing a stable, sterile nano emulsion of perfluoro-organic compounds (PFOC) with an average particle size of a maximum of 150 nm, preferably 30-100 nm, most preferably from 30 to 80 nm, for use in medicine and veterinary medicine, which method comprises filling a circulation circuit in an installation for producing nano emulsions of PFOC with an aqueous solution of stabilizing additive, preferably poloxamer, adding a mixture of PFOC to the aqueous solution of stabilizing additive, with subsequent homogenization of the resulting mixture of PFOC in the aqueous solution of stabilizing additive in order to produce a preliminary emulsion of PFOC having a required particle size, under thermostatic control of the operation of the working chamber of the homogenizer and pipes, adding the resulting preliminary emulsion of PFOC to an aqueous salt solution so as to produce nano emulsions of PFOC with a required concentration of PFOC, stabilizing additive and salts, keeping the nano emulsions of PFOC at a temperature of 2-10̊C, with optional preliminary packaging of the finished product into a sterile consumer pack, and freezing the finished product.

Description

СПОСОБ ПРИГОТОВЛЕНИЯ СТЕРИЛЬНОЙ НАНОЭМУЛЬСИИ ПЕРФТОРОРГАНИЧЕСКИХ СОЕДИНЕНИЙ METHOD FOR PREPARING STERILE NANOEMULSION OF PERFLUORORGANIC COMPOUNDS

Настоящее изобретение относится к химико-фармацевтической промышленности и представляет собой способ получения стабильной стерильной наноэмульсии перфторорганических соединений (ПФОС) для применения в медицине и ветеринарии в качестве газотранспортных заменителей донорской крови и полифункциональных перфторуглеродных препаратов для частичного поддержания транспорта газа, объема циркулирующей крови и не которых других физиологических параметров, а также в составе лекарственных средств для лечения системных и локальных нарушений кровотока, гипоксических и ишемических состояний, улучшения массообмена газов и метаболитов между кровью и тканями, поддержания функции изолированных органов и тканей, уменьшения явлений воспаления, проведения инфузионно- трансфузионной терапии при шоке и кровопотере. The present invention relates to the pharmaceutical industry and is a method for producing a stable sterile nano-emulsion of perfluororganic compounds (PFOS) for use in medicine and veterinary medicine as gas transport substitutes for donated blood and multifunctional perfluorocarbon preparations to partially maintain gas transport, circulating blood volume and some other physiological parameters, as well as in the composition of drugs for the treatment of systemic and local disorders blood flow, ischemic and hypoxic conditions, improved mass transfer of gases and metabolites between blood and tissues, preservation of function of isolated organs and tissues, reduce inflammation phenomena of infuzionno- transfusion therapy for shock and blood loss.

Уровень техники State of the art

Перфторуглеродные эмульсии представляют собой газопереносящие эмульсии на основе перфторорганических соединений, применяемые в медико- биологической области в качестве полифункциональных препаратов. С точки зрения коллоидной химии перфторуглеродные газопереносящие эмульсии - это прямые, концентрированные, высоко- и свободно- дисперсные, гетерогенные, термодинамически неустойчивые лиофобные коллоидные системы, обладающие избыточной свободной поверхностной энергией и огромной площадью газообмена (сорбционно активной поверхностью раздела фаз), в которых дисперсная фаза нерастворимых ультрадисперсных химически инертных перфторуглеродных частиц покрыта адсорбционно-сольватным слоем из поверхностно-активного вещества и сохраняет определенное время при низких температурах агрегативную устойчивость и равномерное распределение частиц дисперсной фазы по объему дисперсионной структурированной среды. Perfluorocarbon emulsions are gas-transferring emulsions based on organofluorine compounds used in the biomedical field as multifunctional preparations. From the point of view of colloid chemistry, perfluorocarbon gas-transporting emulsions are direct, concentrated, highly and freely dispersed, heterogeneous, thermodynamically unstable lyophobic colloidal systems with excess free surface energy and a huge gas exchange area (sorption active phase interface) in which the dispersed phase insoluble ultrafine chemically inert perfluorocarbon particles is coated with an adsorption-solvate layer of a surfactant and retains certain time at low temperatures, aggregative stability and uniform distribution of particles of the dispersed phase over the volume of the dispersed structured medium.

Высокая энергонасыщенность перфторуглеродных частиц и их ультрадисперсность приводит к особым свойствам и ставит их в особую переходную область (1(Г8 м) рядом с коллоидным (1 (Г9 м) и молекулярным (10"'° м) состоянием вещества. Это особенное состояние перфторуглеродных

дисперсных наносистем проявляется в их высокой биологической активности, в реакционной способности, в физическом взаимодействии с любыми веществами и газами. The high energy saturation of perfluorocarbon particles and their ultradispersity leads to special properties and puts them in a special transition region (1 (Г 8 m) next to the colloidal (1 (Г 9 m) and molecular (10 " ° ° m) state of the substance. This is a special state perfluorocarbon dispersed nanosystems is manifested in their high biological activity, in reactivity, in physical interaction with any substances and gases.

Основными параметрами эмульсий ПФОС, которые определяют их качество и перспективность использования являются: The main parameters of PFOS emulsions, which determine their quality and prospects of use, are:

1) средний диаметр частиц эмульсии ПФОС; 1) the average particle diameter of the emulsion PFOS;

2) распределение частиц эмульсии по диаметрам; 2) the distribution of particles of the emulsion in diameter;

3) период полувыведения ПФОС из организма; 3) the half-life of PFOS from the body;

4) токсичность эмульсии или ЛД50; 4) the toxicity of the emulsion or LD 50 ;

5) кислородная емкость эмульсии; 5) the oxygen capacity of the emulsion;

6) величина давления паров ПФОС; 6) the vapor pressure of PFOS;

7) стерильность эмульсии; 7) sterility of the emulsion;

8) возможность длительного хранения эмульсии; 8) the possibility of long-term storage of the emulsion;

9) токсичность стабилизирующей добавки; 9) the toxicity of a stabilizing additive;

10) реактогенность эмульсии. 10) the reactogenicity of the emulsion.

Сравнение этих показателей позволяет оценить полученные эмульсии ПФОС и определить преимущество одной эмульсии ПФОС перед другой. A comparison of these indicators allows us to evaluate the obtained PFOS emulsion and to determine the advantage of one PFOS emulsion over another.

Средний диаметр частиц эмульсий зависит как от свойств ПФОС, так и от способности стабилизирующей добавки (эмульгатора) снижать поверхностное натяжение на границе ПФОС-вода. Чем меньше величина поверхностного натяжения, тем легче протекает процесс эмульгирования и тем меньше средний диаметр частиц в полученной эмульсии. The average particle diameter of emulsions depends on both the properties of PFOS and the ability of a stabilizing additive (emulsifier) to reduce surface tension at the PFOS-water interface. The smaller the surface tension, the easier the process of emulsification and the smaller the average particle diameter in the resulting emulsion.

Эмульсии ПФОС с той или иной стабилизирующей добавкой должны иметь длительный срок хранения, а условия хранения должны быть простыми. Показателем хранения эмульсии ПФОС является изменение (увеличение) среднего диаметра частиц эмульсии при хранении. PFOS emulsions with one or another stabilizing additive should have a long shelf life, and storage conditions should be simple. An indicator of storage of PFOS emulsion is a change (increase) in the average particle diameter of the emulsion during storage.

Основными задачами при получении газотранспортных эмульсий ПФОС являются: The main tasks in obtaining gas transport emulsions PFOS are:

1) уменьшение среднего диаметра частиц эмульсий ПФОС и сужение распределения частиц эмульсии по диаметрам; 1) a decrease in the average particle diameter of the PFOS emulsions and a narrowing of the particle diameter distribution of the emulsion;

2) надежная стерилизация эмульсий ПФОС; 2) reliable sterilization of PFOS emulsions;

3) отсутствие токсичности эмульсий ПФОС;

4) увеличение сроков и упрощение условий хранения эмульсий ПФОС без значительного изменения среднего диаметра частиц и уширения распределения частиц по диаметрам. 3) lack of toxicity of PFOS emulsions; 4) increasing the time and simplifying the storage conditions of PFOS emulsions without significantly changing the average particle diameter and broadening the particle diameter distribution.

Известно, что качество перфторуглеродных эмульсий определяется физико-химическими свойствами выбранных ПФОС, физико-химическими свойствами и природой стабилизирующей добавки и технологией получения эмульсии. It is known that the quality of perfluorocarbon emulsions is determined by the physicochemical properties of the selected PFOS, physicochemical properties and the nature of the stabilizing additive and the technology for producing the emulsion.

ПФОС нерастворимы в воде и сами являются плохими растворителями для различных водорастворимых биологически активных веществ, поэтому для применения в качестве кислородпереносящих сред их диспергируют в водном растворе стабилизирующей добавки до образования тонкодисперсных эмульсий. PFOS is insoluble in water and are themselves poor solvents for various water-soluble biologically active substances; therefore, for use as oxygen-transporting media, they are dispersed in an aqueous solution of a stabilizing additive until fine emulsions are formed.

Задача стабилизирующей добавки состоит в формировании адсорбционного слоя вокруг частиц перфторуглеродов, при этом физико- химические свойства и природа стабилизирующей добавки определяют стабильность дисперсной системы и ее реактогенность. Ключевыми параметрами здесь являются прочность связи ПАВ с «ядром» частицы эмульсии, характер и плотность расположения молекул ПАВ на поверхности частицы. The task of the stabilizing additive is to form an adsorption layer around perfluorocarbon particles, while the physicochemical properties and nature of the stabilizing additive determine the stability of the dispersed system and its reactogenicity. The key parameters here are the bond strength of the surfactant with the "core" of the emulsion particle, the nature and density of the surfactant molecules on the surface of the particle.

Известны различные способы получения эмульсий ПФОС. Одна из технологий основана на методе измельчения масляной фазы с помощью воздействия ультразвука. Однако, энергия и мощность ультразвукового воздействия столь велики, что наряду с диспергированием приводят к разрыву связи C-F. В результате в водной фазе эмульсии появляются высокотоксичные концентрации ионов F~ и от их избыточного содержания эмульсию необходимо очищать посредством пропускания через ионообменную смолу. Кроме того, такая эмульсия имеет чрезвычайно широкую величину дисперсии. Various methods are known for preparing PFOS emulsions. One of the technologies is based on the method of grinding the oil phase using ultrasound. However, the energy and power of ultrasonic exposure are so great that, along with dispersion, lead to a break in the CF bond. As a result, highly toxic concentrations of F ~ ions appear in the aqueous phase of the emulsion, and the emulsion must be purified from their excessive content by passing through an ion exchange resin. In addition, such an emulsion has an extremely wide dispersion value.

Механическое диспергирование путем встряхивания или перемешивания позволяет получать только грубодисперсные эмульсии ПФОС с неприемлемым для медицинского использования размером - более 1 мм. Для получения тонкодисперсных эмульсий используют метод выдавливания вещества дисперсной фазы через тонкие отверстия в дисперсионную среду под большим давлением (метод экструзии), что приводит к разрыву движущейся струи жидкости на капли. Диспергирование вызывается градиентом давления и силами

гидравлического трения. Обычно производство эмульсий ПФОС осуществляют на гомогенизаторах высокого давления, что позволяет получить достаточно тонкую калиброванную эмульсию. Mechanical dispersion by shaking or mixing allows to obtain only coarse-dispersed emulsions of PFOS with a size unacceptable for medical use - more than 1 mm. To obtain finely dispersed emulsions, the method of extruding the dispersed phase substance through thin holes into the dispersion medium under high pressure (extrusion method) is used, which leads to the breaking of the moving liquid stream into droplets. Dispersion is caused by a pressure gradient and forces hydraulic friction. Typically, the production of PFOS emulsions is carried out on high pressure homogenizers, which makes it possible to obtain a sufficiently thin calibrated emulsion.

Гомогенизация достигается пропусканием смеси эмульгатора и перфторуглерода через малые отверстия с сечением 10~6— 10-8 м2 под давлением от 10,1 до 101,3 МПа. Для получения эмульсий ранее использовался одноконтурный способ, где перфторуглерод из отдельной емкости капельно подавался в емкость с эмульгатором (полоксамером), затем вся смесь подавалась в дезинтегратор и из него обратно в емкость с ПФОС и эмульгатором. Этот цикл повторялся многократно (от 5 до 15 циклов). Однако, эмульсия, полученная данным способом, не полностью удовлетворяет требованиям к размеру частиц, так как в составе остаются частицы с размером 400-450 нм, что увеличивает токсичность полученной эмульсии. Homogenization is achieved by passing a mixture of emulsifier and perfluorocarbon through small holes with a cross section of 10 ~ 6 - 10 -8 m 2 under a pressure of 10.1 to 101.3 MPa. To obtain emulsions, a single-circuit method was previously used, where perfluorocarbon from a separate container was drip fed into a container with an emulsifier (poloxamer), then the entire mixture was supplied to and from the disintegrator into a container with PFOS and an emulsifier. This cycle was repeated many times (from 5 to 15 cycles). However, the emulsion obtained by this method does not fully satisfy the requirements for particle size, since particles with a size of 400-450 nm remain in the composition, which increases the toxicity of the emulsion obtained.

Известен способ получения эмульсий ПФОС для медицинских целей, в котором для уменьшения реактогенности предлагается уменьшить средний размер и повысить монодисперсность частиц эмульсии. Это достигается за счет капельного введения смеси двух видов жидких ПФОС в водный раствор стабилизирующего агента, что предотвращает появление макроскопической границы раздела фаз, увеличивает время и поверхности контакта ПФОС и стабилизирующего агента на стадии получения предэмульсии. Субмикронная эмульсия получается в двухконтурной системе гомогенизации в процессе 12- кратной рециркуляции в контурах гомогенизатора при попеременном давлении. Однако, первый и второй контуры гомогенизатора используются попеременно, что замедляет процесс гомогенизации, так как возврат из второго контура в первый приводит к попаданию в уже измельченную тонкодисперсную эмульсию крупных частиц предэмульсии и даже капель ПФОС, неизбежно образующихся и задерживающихся на стенках камеры и трубок в первом контуре. A known method of producing emulsions of PFOS for medical purposes, in which to reduce reactogenicity it is proposed to reduce the average size and increase the monodispersion of the particles of the emulsion. This is achieved by the drip introduction of a mixture of two types of liquid PFOS into an aqueous solution of a stabilizing agent, which prevents the appearance of a macroscopic phase boundary, increases the time and contact surfaces of PFOS and a stabilizing agent at the stage of preparation of the emulsion. A submicron emulsion is obtained in a dual-circuit homogenization system during 12-fold recirculation in the homogenizer circuits under alternating pressure. However, the first and second circuits of the homogenizer are used interchangeably, which slows down the homogenization process, since returning from the second circuit to the first leads to the penetration of coarse pre-emulsion particles and even drops of PFOS into the finely divided emulsion, which inevitably form and linger on the walls of the chamber and tubes in the first circuit.

В патенте РФ 2122404 описан способ получения эмульсии путем струйного пропускания многокомпонентной смеси ПФОС и раствора проксанола через гомогенизатор под давлением 700-1000 атм и охлаждении при температуре от 24 до 34°С с дальнейшей циклической гомогенизацией под постоянным давлением 400-490 атм и при постоянном охлаждении. В предлагаемом способе

получения эмульсии за счет струйного пропускания смеси ПФОС вдвое сокращается время первого цикла гомогенизации, а регуляция и отслеживание режима давления в гомогенизаторе предотвращают процесс вторичного укрупнения частиц и обеспечивают мягкую «доводку» эмульсии до заданного размера частиц 0,03-0,05 мкм. RF patent 2122404 describes a method for producing an emulsion by spraying a multicomponent mixture of PFOS and a proxanol solution through a homogenizer under a pressure of 700-1000 atm and cooling at a temperature of 24 to 34 ° C with further cyclic homogenization under a constant pressure of 400-490 atm and with constant cooling . In the proposed method the preparation of an emulsion due to the jet transmission of the PFOS mixture reduces the time of the first homogenization cycle by half, and the regulation and monitoring of the pressure regime in the homogenizer prevents the process of secondary particle enlargement and provides a soft “refinement” of the emulsion to a predetermined particle size of 0.03-0.05 microns.

В патенте РФ 2206319 описан способ получения эмульсии в соответствии с которым перед смешиванием компонентов смесь жидких ПФОС и водный раствор стабилизирующего агента насыщают углекислым газом, после чего нагревают водный раствор стабилизирующего агента при температуре не выше 75°С. Затем смесь жидких ПФОС вводят несколькими струями в охлажденный водный раствор стабилизирующего агента при интенсивном перемешивании и поддуве углекислого газа, одновременно пропуская получаемую крупнодисперсную предэмульсию несколько раз через первый контур гомогенизатора, после чего измельченную предэмульсию подвергают гомогенизации во втором контуре гомогенизатора до получения требуемой дисперсности при поддуве углекислого газа, и добавляют водно-солевой состав. RF patent 2206319 describes a method for producing an emulsion, according to which, before mixing the components, the mixture of liquid PFOS and an aqueous solution of a stabilizing agent are saturated with carbon dioxide, and then the aqueous solution of a stabilizing agent is heated at a temperature of no higher than 75 ° C. Then, a mixture of liquid PFOS is introduced in several jets into a cooled aqueous solution of a stabilizing agent with vigorous stirring and blowing carbon dioxide, while passing the coarse pre-emulsion obtained several times through the first homogenizer circuit, after which the crushed pre-emulsion is homogenized in the second homogenizer circuit until the required dispersion is obtained under the required dispersion gas, and water-salt composition is added.

Насыщение смешиваемых компонентов углекислым газом и нагрев водного раствора стабилизирующего агента (проксанола) позволяет депирогенизировать раствор без пропускания через сорбенты, ухудшающие качество стабилизирующего агента и изменяющие его молекулярно-массовое распределение, а также поверхностно-активные свойства. Отклонения от указанных значений температуры ухудшают поверхностно-активные свойства стабилизирующего агента. Струйное введение жидких ПФОС в водный раствор стабилизирующего агента при интенсивном перемешивании и одновременном пропускании получаемой смеси через гомогенизатор высокого давления способствует ускорению процесса получения предэмульсии. Регулирование скорости подачи ПФОС, перемешивания и протока смеси через гомогенизатор осуществляется так, чтобы предотвратить образование макроскопической границы раздела фаз ПФОС/вода, что является необходимым условием для получения монодисперсной эмульсии. Saturation of the components to be mixed with carbon dioxide and heating of an aqueous solution of a stabilizing agent (proxanol) allows depyrogenization of the solution without passing through sorbents that impair the quality of the stabilizing agent and change its molecular weight distribution, as well as surface-active properties. Deviations from the indicated temperature values worsen the surface-active properties of the stabilizing agent. The jet introduction of liquid PFOS into an aqueous solution of a stabilizing agent with vigorous stirring and at the same time passing the resulting mixture through a high-pressure homogenizer accelerates the process of preparing a preemulsion. The feed rate of PFOS, mixing and the flow of the mixture through the homogenizer are controlled so as to prevent the formation of a macroscopic PFOS / water phase boundary, which is a necessary condition for obtaining a monodisperse emulsion.

В патенте РФ 2070033 описан способ получения перфторуглеродных эмульсий для медицинских целей, в котором смесь ПФОС получают

смешиванием жидких компонентов, а предэмульсию получают, пропуская смесь ПФОС через водный раствор стабилизирующего агента (проксанола), одновременно пропуская получаемую предэмульсию через рабочую камеру гомогенизатора, после полного смешивания пропускают через рабочую камеру гомогенизатора с термостатированием под давлением 300-660 атм, с последующим добавлением в полученную предэмульсию стерильного физиологически приемлемого водно-солевого раствора. Полученную наноэмульсию ПФОС замораживают. In the patent of the Russian Federation 2070033 describes a method for producing perfluorocarbon emulsions for medical purposes, in which a mixture of PFOS receive by mixing the liquid components, and the pre-emulsion is obtained by passing the PFOS mixture through an aqueous solution of a stabilizing agent (proxanol), while passing the resulting pre-emulsion through the working chamber of the homogenizer, after complete mixing, they are passed through the working chamber of the homogenizer with temperature control at a pressure of 300-660 atm, followed by adding to the resulting emulsion of a sterile physiologically acceptable aqueous saline solution. The resulting PFOS nanoemulsion is frozen.

Недостатками вышеописанного способа получения наноэмульсий ПФОС являются трудоемкость получения смеси ПФОС, связанная с тем, что отвешивают жидкие компоненты разной плотности для получения требуемого объема смеси ПФОС; термостатирование осуществляют только рабочей камеры гомогенизатора, что не обеспечивает необходимый температурный режим для получения предэмульсии со средним размером частиц 30-80 нм; давление в рабочей камере гомогенизатора выше 60 МПа является избыточным, и приводит к загеливанию водного раствора полоксамера; замораживание наноэмульсий ПФОС сразу после изготовления приводит к резкому укрупнению частиц наноэмульсий ПФОС, что уменьшает ее стабильность, сокращая срок ее хранения. The disadvantages of the above method for producing PFOS nanoemulsions are the complexity of obtaining a mixture of PFOS, due to the fact that the liquid components of different densities are weighed to obtain the required volume of the PFOS mixture; thermostating is carried out only by the working chamber of the homogenizer, which does not provide the necessary temperature for obtaining a preemulsion with an average particle size of 30-80 nm; the pressure in the working chamber of the homogenizer above 60 MPa is excessive, and leads to gelation of the aqueous poloxamer solution; the freezing of PFOS nanoemulsions immediately after manufacture leads to a sharp coarsening of the particles of PFOS nanoemulsions, which reduces its stability, shortening its shelf life.

В патенте РФ 2393849 описан способ получения эмульсии ПФОС в котором, перед смешиванием, смесь ПФОС и водный раствор полоксамера насыщают углекислым газом, процесс приготовления предэмульсии и последующей гомогенизации осуществляют в атмосфере углекислого газа, в предэмульсию добавляют физиологически приемлемый водно-солевой раствор. RF patent 2393849 describes a method for producing a PFOS emulsion in which, before mixing, a mixture of PFOS and an aqueous solution of poloxamer are saturated with carbon dioxide, the preparation of a pre-emulsion and subsequent homogenization is carried out in an atmosphere of carbon dioxide, and a physiologically acceptable water-salt solution is added to the pre-emulsion.

Недостатками этого способа получения наноэмульсий ПФОС являются насыщение смеси ПФОС и водного раствора полоксамера углекислым газом и осуществление процесса гомогенизации в атмосфере углекислого газа, что технологически сложно реализуемо и удорожает процесс изготовления наноэмульсий ПФОС. Объем производства наноэмульсий ограничен производительностью гомогенизатора. Водно-солевой раствор добавляется в предэмульсию с более высокой плотностью, что ухудшает смешение и увеличивает время этого процесса. Отсутствует стабилизация наноэмульсий

ПФОС перед замораживанием. The disadvantages of this method of producing PFOS nanoemulsions are the saturation of a mixture of PFOS and an aqueous solution of poloxamer with carbon dioxide and the implementation of a process of homogenization in an atmosphere of carbon dioxide, which is technologically difficult and makes the manufacturing process of PFOS nanoemulsions more expensive. The volume of production of nanoemulsions is limited by the performance of the homogenizer. The water-salt solution is added to the pre-emulsion with a higher density, which impairs mixing and increases the time of this process. No stabilization of nanoemulsions PFOS before freezing.

Целью настоящего изобретения было создание простого, технологичного и экономичного способа получения наноэмульсий ПФОС, позволяющего получить продукт с улучшенной стабильностью и упростить условия хранения наноэмульсий ПФОС без значительного изменения среднего диаметра частиц и уширения распределения частиц по диаметрам. The aim of the present invention was to provide a simple, technologically advanced and economical method for producing PFOS nanoemulsions, which allows obtaining a product with improved stability and simplifying storage conditions of PFOS nanoemulsions without significantly changing the average particle diameter and broadening the particle diameter distribution.

Авторами настоящего изобретения было неожиданно обнаружено, что предварительное заполнение циркуляционного контура установки для получения наноэмульсий ПФОС, который включает емкость для получения предэмульсии ПФОС, гомогенизатор и трубопроводы, связывающие емкость и гомогенизатор, раствором стабилизирующей добавки до добавления смеси ПФОС позволяет уменьшить средний диаметр частиц эмульсии и уменьшить распределение частиц по диаметрам, что, в свою очередь, значительно увеличивает стабильность эмульсии ПФОС и как результат увеличивает срок хранения продукта. The inventors of the present invention unexpectedly found that pre-filling the circulation loop of a plant for producing PFOS nanoemulsions, which includes a tank for producing a PFOS preemulsion, a homogenizer and pipelines connecting the tank and the homogenizer, with a solution of a stabilizing additive before adding a PFOS mixture, reduces the average particle diameter of the emulsion and reduces particle diameter distribution, which, in turn, significantly increases the stability of the PFOS emulsion and, as a result, increased ivaet shelf life of the product.

Кроме того, авторами настоящего изобретения было неожиданно обнаружено, что выдерживание эмульсии ПФОС при температуре от 2 до 10°С в течение более 18 часов перед замораживанием готового продукта также позволяет значительно увеличить стабильность эмульсии ПФОС. In addition, the inventors of the present invention unexpectedly found that keeping the PFOS emulsion at a temperature of from 2 to 10 ° C for more than 18 hours before freezing the finished product also significantly improves the stability of the PFOS emulsion.

Краткое описание изобретения SUMMARY OF THE INVENTION

Настоящее изобретение относится к способу получения стерильной наноэмульсий перфторорганических соединений (ПФОС), который включает: The present invention relates to a method for producing a sterile nano-emulsion of perfluororganic compounds (PFOS), which includes:

- добавление смеси ПФОС к водному раствору стабилизирующей добавки; - adding a mixture of PFOS to an aqueous solution of a stabilizing additive;

- гомогенизацию смеси ПФОС с водным раствором стабилизирующей добавки с получением предэмульсии ПФОС; - homogenization of a mixture of PFOS with an aqueous solution of a stabilizing additive to obtain a pre-emulsion of PFOS;

- смешивание предэмульсии ПФОС с водно-солевым раствором с получением наноэмульсий ПФОС; - mixing the PFOS preemulsion with a water-salt solution to obtain PFOS nanoemulsions;

- выдерживание наноэмульсий ПФОС при температуре от 2 до 10°С в течение не менее 18 часов; - keeping PFOS nanoemulsions at a temperature of from 2 to 10 ° C for at least 18 hours;

- необязательное замораживание наноэмульсий ПФОС. - optional freezing of PFOS nanoemulsions.

В предпочтительном варианте способа по настоящему изобретению осуществляют предварительное заполнение циркуляционного контура установки

для получения наноэмульсии ПФОС водным раствором стабилизирующей добавки. In a preferred embodiment of the method of the present invention, the circulating circuit of the installation is pre-filled to obtain PFOS nanoemulsion with an aqueous solution of a stabilizing additive.

Настоящее изобретение также относится к способу получения стерильной наноэмульсии перфторорганических соединений (ПФОС), который включает: The present invention also relates to a method for producing a sterile nano-emulsion of perfluororganic compounds (PFOS), which includes:

- предварительное заполнение циркуляционного контура водным раствором стабилизирующей добавки; - pre-filling the circulation circuit with an aqueous solution of a stabilizing additive;

- добавление смеси ПФОС к водному раствору стабилизирующей добавки; - adding a mixture of PFOS to an aqueous solution of a stabilizing additive;

- гомогенизацию смеси ПФОС с водным раствором стабилизирующей добавки с получением предэмульсии ПФОС; - homogenization of a mixture of PFOS with an aqueous solution of a stabilizing additive to obtain a pre-emulsion of PFOS;

- смешивание предэмульсии ПФОС с водно-солевым раствором с получением наноэмульсии ПФОС; - mixing the PFOS preemulsion with a water-salt solution to obtain a PFOS nanoemulsion;

- необязательное замораживание наноэмульсии ПФОС. - optional freezing of PFOS nanoemulsion.

Циркуляционный контур в способе настоящего изобретения включает емкость для получения предэмульсии ПФОС, гомогенизатор и трубопроводы, связывающие емкость и гомогенизатор. The circulation loop in the method of the present invention includes a vessel for producing a PFOS preemulsion, a homogenizer, and pipelines connecting the vessel and the homogenizer.

В предпочтительном варианте способа по настоящему изобретению перед началом процесса осуществляют проверку герметичности циркуляционного контура путем его промывки, стерильным концентрированным водным раствором стабилизирующей добавки в объеме в 2-4 раза превышающим рабочий объем трубопроводов и рабочей камеры гомогенизатора при давлении в рабочей камере гомогенизатора 10-45,5 МПа, с последующим сливом раствора. In a preferred embodiment of the method of the present invention, before starting the process, the tightness of the circulation circuit is checked by washing it with a sterile concentrated aqueous solution of a stabilizing additive in a volume 2-4 times the working volume of the pipelines and the working chamber of the homogenizer at a pressure in the working chamber of the homogenizer 10-45, 5 MPa, followed by draining the solution.

В предпочтительном варианте способа по настоящему изобретению гомогенизацию предэмульсии ПФОС осуществляют при давлении в рабочей камере гомогенизатора в диапазоне от 10 до 60,8 МПа, предпочтительно в диапазоне от 43, 1 до 45, 1 МПа, осуществляют термостатирование рабочей камеры гомогенизатора для обеспечения технологической температуры в диапазоне от 19 до 30°С, предпочтительно от 20 до 26°С и осуществляют термостатирование трубопроводов циркуляционного контура для обеспечения технологической температуры трубопроводов в диапазоне от 5 до 20°С, предпочтительно от 7 до 15°С. In a preferred embodiment of the method of the present invention, homogenization of the PFOS preemulsion is carried out at a pressure in the working chamber of the homogenizer in the range from 10 to 60.8 MPa, preferably in the range from 43, 1 to 45, 1 MPa, the working chamber of the homogenizer is thermostated to provide a process temperature of the range from 19 to 30 ° C, preferably from 20 to 26 ° C and carry out thermostating of the pipelines of the circulation circuit to ensure the process temperature of the pipelines in the range from 5 to 20 ° C preferably from 7 to 15 ° C.

В предпочтительном варианте способа по настоящему изобретению циркуляционный контур содержит один или более дополнительных

гомогенизаторов, подключенных параллельно к основному гомогенизатору циркуляционного контура. In a preferred embodiment of the method of the present invention, the circulation circuit comprises one or more additional homogenizers connected in parallel to the main homogenizer of the circulation circuit.

В предпочтительном варианте изобретения гомогенизатор имеет более одной рабочей камеры, подключенных параллельно. In a preferred embodiment of the invention, the homogenizer has more than one working chamber connected in parallel.

В предпочтительном варианте способа по настоящему изобретению наноэмульсию ПФОС перед выдерживанием разливают в потребительскую тару. In a preferred embodiment of the method of the present invention, the PFOS nanoemulsion is poured into a consumer packaging before aging.

В наиболее предпочтительном варианте способа по настоящему изобретению потребительскую тару с наноэмульсией ПФОС перед замораживанием осторожно встряхивают до получения однородности содержимого. In the most preferred embodiment of the method of the present invention, the consumer packaging with PFOS nano-emulsion is gently shaken before freezing until the contents are uniform.

Потребительская тара, которую используют в способе по настоящему изобретению представляет собой стеклянные бутылки, флаконы, ампулы, шприц- тюбики, полимерные емкости, металлические баллоны, тубы. The consumer packaging used in the method of the present invention is glass bottles, vials, ampoules, syringe tubes, polymer containers, metal cylinders, tubes.

В предпочтительном варианте способа по настоящему изобретению способ проводят в асептических условиях. In a preferred embodiment of the method of the present invention, the method is carried out under aseptic conditions.

В предпочтительном варианте способа по настоящему изобретению водный раствор стабилизирующей добавки представляет собой 10-30 масс. % водный раствор, предпочтительно 10-20 масс.% водный раствор и в качестве стабилизирующей добавки используют полоксамеры, такие как сополимеры полиоксиэтилена и полиоксипропилена, предпочтительно полоксамеры с торговыми наименованиями Эмуксол 268 марки «А» и Killiphor P I 88 (Коллифор PI 88), С10-С22 жирные кислоты и/или их соли или триглицериды или фосфолипиды яичного желтка или сои. In a preferred embodiment of the method of the present invention, the aqueous solution of a stabilizing additive is 10-30 mass. % aqueous solution, preferably 10-20 wt.% aqueous solution and poloxamers, such as copolymers of polyoxyethylene and polyoxypropylene, preferably poloxamers with the trade names Emuxol 268 of the brand “A” and Killiphor PI 88 (Collifor PI 88), C are used as stabilizing additives 10 -C 22 fatty acids and / or their salts or triglycerides or phospholipids of egg yolk or soy.

В способе по настоящему изобретению в качестве смеси ПФОС используют смесь по меньшей мере одного быстро выводимого ПФОС, выбранного из С8-С10 ПФОС, например, перфтордекалина (ПФД) или перфтороктилбромида (ПФОБ) и, по меньше мере, одного медленно выводимого ПФОС, выбранного из С1 С12 ПФОС, например перфтортрипропиламина (ПФТПА), перфторметилциклогексилпиперидина (ПФМЦП) или перфтортрибутиламина (ПФТБА). In the method of the present invention, as a mixture of PFOS, a mixture of at least one rapidly withdrawn PFOS selected from C 8 -C 10 PFOS, for example perfluorodecalin (PFD) or perfluorooctyl bromide (PFOB) and at least one slowly removed PFOS, is used, selected from C 1 C 12 PFOS, for example perfluorotripropylamine (PFTPA), perfluoromethylcyclohexylpiperidine (PFMCP) or perfluorotributylamine (PFTA).

В предпочтительном варианте способа по настоящему изобретению смесь ПФОС для приготовления предэмульсии готовят смешиванием одного или более

жидких ПФОС. In a preferred embodiment of the method of the present invention, a PFOS mixture for preparing a pre-emulsion is prepared by mixing one or more liquid PFOS.

В способе по настоящему изобретению водно-солевой раствор включает NaCl и воду, и, необязательно, КС1, MgCl2, NaHCO3, NaH2PO4, Na2HPO4, глюкозу. In the method of the present invention, the water-salt solution comprises NaCl and water, and optionally KCl, MgCl 2 , NaHCO 3 , NaH 2 PO 4 , Na 2 HPO 4 , glucose.

В предпочтительном варианте способа по настоящему изобретению наноэмульсия ПФОС содержит 4,8-7,2 г/л натрия хлорида; 0,31-0,47 г/л калия хлорида; 0, 15-0,23 г/л магния хлорида (в пересчете на сухое вещество); 0,55-0,83 г/л натрия гидрокарбоната; 0, 16-0,24 г натрия фосфата однозамещенного (в пересчете на сухое вещество); 1 ,6-2,4 г/л глюкозы. In a preferred embodiment of the method of the present invention, the PFOS nano-emulsion contains 4.8-7.2 g / l sodium chloride; 0.31-0.47 g / l potassium chloride; 0, 15-0.23 g / l magnesium chloride (in terms of dry matter); 0.55-0.83 g / l sodium bicarbonate; 0, 16-0.24 g of sodium phosphate monosubstituted (in terms of dry matter); 1, 6-2.4 g / l glucose.

В предпочтительном варианте способа по настоящему изобретению рН наноэмульсии ПФОС составляет от 5 до 8, предпочтительно в диапазоне от 7,2 до 7,8, и для корректировки рН изменяют количественное содержание натрия гидрокарбоната и натрия фосфата однозамещенного. In a preferred embodiment of the method of the present invention, the pH of the PFOS nanoemulsion is from 5 to 8, preferably in the range from 7.2 to 7.8, and to adjust the pH, the quantitative content of sodium bicarbonate and sodium phosphate monosubstituted is changed.

В предпочтительном варианте способа по настоящему изобретению наноэмульсию ПФОС замораживают при температуре от -4 до -18°С, предпочтительно при температуре от -10 до -18°С. In a preferred embodiment of the method of the present invention, the PFOS nanoemulsion is frozen at a temperature of from -4 to -18 ° C, preferably at a temperature of from -10 to -18 ° C.

В предпочтительном варианте способа по настоящему изобретению наноэмульсию ПФОС выдерживают при температуре от 2 до 10°С, предпочтительно при температуре от 3 до 6°С, наиболее предпочтительно при температуре 4°С. In a preferred embodiment of the method of the present invention, the PFOS nanoemulsion is maintained at a temperature of from 2 to 10 ° C., preferably at a temperature of from 3 to 6 ° C., most preferably at a temperature of 4 ° C.

В предпочтительном варианте изобретения эмульсию выдерживают перед замораживанием в течение не менее 18 часов, предпочтительно в течение 18-30 часов, наиболее предпочтительно 24 часа. In a preferred embodiment of the invention, the emulsion is kept before freezing for at least 18 hours, preferably for 18-30 hours, most preferably 24 hours.

Подробное описание изобретения DETAILED DESCRIPTION OF THE INVENTION

На Фиг.1 представлена предпочтительная схема установки для получения нанэмульсии ПФОС для осуществления способа настоящего изобретения. Figure 1 presents a preferred setup for producing a PFOS nanemulsion for implementing the method of the present invention.

На представленной схеме емкость 1 представляет собой емкость для смеси ПФОС или раствора стабилизирующей добавки, трубопровод 2 соединяет емкость 1 с емкостью 3 циркуляционного контура для получения смеси ПФОС в растворе стабилизирующей добавки, трубопроводы 4 и 6 циркуляционного контура соединяют емкость 3 с гомогенизатором 5 высокого давления циркуляционного контура, трубопровод 7 соединяет циркуляционный контур с емкостью 8 для водно-солевого раствора для получения готовой наноэмульсии

ПФОС, трубопровод 9 предназначен для удаления готового продукта и/или фасовки готовой наноимульсии ПФОС в потребительскую тару. In the presented diagram, tank 1 is a tank for a mixture of PFOS or a solution of a stabilizing additive, pipeline 2 connects a tank 1 with a tank 3 of a circulation loop to obtain a mixture of PFOS in a solution of a stabilizing additive, pipelines 4 and 6 of a circulation loop connect a tank 3 with a high-pressure circulation homogenizer 5 circuit, pipeline 7 connects the circulation circuit with a tank 8 for water-salt solution to obtain a finished nanoemulsion PFOS, pipeline 9 is designed to remove the finished product and / or packaging the finished PFOS nano-emulsion in consumer packaging.

Способ осуществляют следующим образом. The method is as follows.

Для получения предэмульсии ПФОС смесь ПФОС подается капельно и/или струйно из емкости 1 по трубопроводу 2 в емкость 3 с раствором стабилизирующей добавки. В предпочтительном варианте изобретения до начала процесса водный раствор стабилизирующей добавки подается из емкости 1 в основной циркуляционный контур, включающий емкость 3, трубопроводы 4 и 6 и гомогенизатор 5 до полного заполнения контура. To obtain the PFOS preemulsion, the PFOS mixture is supplied dropwise and / or by jet from tank 1 through line 2 to tank 3 with a solution of a stabilizing additive. In a preferred embodiment of the invention, before the start of the process, an aqueous solution of a stabilizing additive is supplied from the tank 1 to the main circulation circuit, including the tank 3, pipelines 4 and 6 and the homogenizer 5 until the circuit is completely filled.

Смесь ПФОС в водном растворе стабилизирующей добавки прокачивается в основном циркуляционном контуре по трубопроводам 4 и 6 через гомогенизатор 5 при рабочем давлении в камере гомогенизатора 10-60,8 МПа, при охлаждении рабочей камеры гомогенизатора до 19-30°С и термостатировании трубопроводов 4 и 6 циркуляционного контура при температуре 5-20°С. Осуществляют 9-15 циклов гомогенизации для получения предэмульсии ПФОС. Затем предэмульсию ПФОС прокачивают по трубопроводу 7 в емкость 8 с водно-солевым раствором, где предэмульсия, постепенно проходя через водно-солевой раствор, удельный вес которого меньше удельного веса предэмульсии, равномерно смешивается с водно-солевым раствором с получением готовой наноэмульсии ПФОС. Далее готовый продукт по трубопроводу 9 перекачивают в дополнительную емкость или в потребительскую тару, где необязательно выдерживают при температуре 2-10°С в течение не менее 18 часов для стабилизации продукта, после чего продукт необязательно замораживают при температуре от -4 до -18°С. A mixture of PFOS in an aqueous solution of a stabilizing additive is pumped in the main circulation circuit through pipelines 4 and 6 through a homogenizer 5 at a working pressure in the homogenizer chamber of 10-60.8 MPa, when the homogenizer working chamber is cooled to 19-30 ° С and thermostats of pipelines 4 and 6 circulation loop at a temperature of 5-20 ° C. Carry out 9-15 cycles of homogenization to obtain PFOS preemulsion. Then the PFOS preemulsion is pumped through a pipe 7 into a container 8 with an aqueous-salt solution, where the pre-emulsion, gradually passing through an aqueous-salt solution, the specific gravity of which is less than the specific gravity of the pre-emulsion, is uniformly mixed with an aqueous-salt solution to obtain a finished PFOS nanoemulsion. Next, the finished product is pumped through pipeline 9 to an additional container or to a consumer container, where it is optionally kept at a temperature of 2-10 ° С for at least 18 hours to stabilize the product, after which the product is optionally frozen at a temperature of -4 to -18 ° С .

В предпочтительном варианте изобретения до начала процесса проводят проверку герметичности циркуляционного контура путем его заполнения водным раствором стабилизирующей добавки в количестве в 2-4 раза превышающим рабочий объем трубопроводов и рабочей камеры гомогенизатора при включенном гомогенизаторе при давлении 10-45,5 МПа с последующим сливом раствора. In a preferred embodiment of the invention, before the process is started, the tightness of the circulation circuit is checked by filling it with an aqueous solution of a stabilizing additive in an amount 2-4 times greater than the working volume of the pipelines and the working chamber of the homogenizer with the homogenizer turned on at a pressure of 10-45.5 MPa, followed by draining the solution.

Наноэмульсия ПФОС настоящего изобретения включает по меньшей мере одно быстро выводящееся ПФОС и по меньшей мере одно медленно

выводящееся ПФОС в количестве до 50 об.%, предпочтительно от 5 до 30 об.%, еще более предпочтительно от 10 до 20 об.%, стабилизирующую добавку в количестве до 10 мас.%, предпочтительно от 0,5 до 10 масс.%, более предпочтительно от 3,5 до 4,5 масс.%, соли, такие как NaCl, КС1, MgCl2, NaHCO3, NaH2PO4, Na2HPO4 и воду. The PFOS nanoemulsion of the present invention includes at least one rapidly releasing PFOS and at least one slowly excreted PFOS in an amount of up to 50 vol.%, preferably from 5 to 30 vol.%, even more preferably from 10 to 20 vol.%, a stabilizing additive in an amount of up to 10 wt.%, preferably from 0.5 to 10 wt.% , more preferably from 3.5 to 4.5 wt.%, salts such as NaCl, KCl, MgCl 2 , NaHCO 3 , NaH 2 PO 4 , Na 2 HPO 4 and water.

Соотношение быстро выводящегося и медленно выводящегося перфторированных соединений может составлять от 10: 1 до 1 : 10. The ratio of rapidly excreted and slowly excreted perfluorinated compounds can be from 10: 1 to 1: 10.

Водно-солевая часть готовой эмульсии ПФОС может содержать 82-123 мМ NaCl, и, необязательно, 4,2-6,3 мМ КС1, 1,6-2,4 мМ MgCl2, 6,6-9,9 мМ NaHCO3, 1 ,3-2 мМ NaH2PO4. Предпочтительно соотношение ионов Na и К поддерживается на уровне 10: 1-30: 1. The water-salt portion of the finished PFOS emulsion may contain 82-123 mM NaCl, and optionally 4.2-6.3 mM KCl, 1.6-2.4 mM MgCl 2 , 6.6-9.9 mM NaHCO 3 , 3-2 mM NaH 2 PO 4 . Preferably, the ratio of Na to K ions is maintained at 10: 1-30: 1.

В состав готовой эмульсии ПФОС также может входить глюкоза в количестве 8,9-13,3 мМ (или 1 ,6-2,4 г/л). The composition of the finished emulsion PFOS may also include glucose in the amount of 8.9-13.3 mm (or 1, 6-2.4 g / l).

Величина рН готовой эмульсии ПФОС составляет от 5 до 8,0, предпочтительно от 7,2 до 7,8. The pH of the finished emulsion PFOS is from 5 to 8.0, preferably from 7.2 to 7.8.

Эмульсия ПФОС имеет средний размер частиц не более 150 нм, предпочтительно 30-100 нм, наиболее предпочтительно 30-80 нм. The PFOS emulsion has an average particle size of not more than 150 nm, preferably 30-100 nm, most preferably 30-80 nm.

Для получения эмульсий ПФОС по настоящему изобретению используют, как правило, одновременно два типа перфторорганических соединений. Одно из них выбирают из группы С8-С10, включающей, например перфтордекалин (ПФД) или перфтороктилбромид (ПФОБ), второе - из группы Си-С|2, содержащей, например перфтортрипропиламин (ПФТПА), перфторметилциклогексил- пиперидин (ПФМЦП) или перфтортрибутиламин (ПФТБА). Соединения первого типа быстро (в течение месяца) выводятся из организма, но не обеспечивают достаточной стабильности эмульсий, соединения же второго типа, напротив, придают эмульсии высокую стабильность, позволяющую хранить их без замораживания, но в течение длительного времени (от 8 месяцев до 2-х лет) не выводятся из организма. To obtain the PFOS emulsions of the present invention, as a rule, two types of organo perfluorine compounds are used simultaneously. One of them is selected from the group C 8 -C 10 , including, for example, perfluorodecalin (PFD) or perfluorooctyl bromide (PFOB), the second from the group C and -C | 2 containing, for example, perfluorotripropylamine (PFTPA), perfluoromethylcyclohexyl-piperidine (PFMCP) or perfluorotributylamine (PFTA). Compounds of the first type are rapidly eliminated from the body (within a month), but do not provide sufficient stability of the emulsions, while compounds of the second type, on the contrary, give the emulsion high stability, allowing them to be stored without freezing, but for a long time (from 8 months to 2- x years) are not excreted.

Могут быть также использованы многокомпонентные смеси из двух ПФОС, например, ПФД/ПФТБА, ПФД/ПФМЦП, ПФОБ/ПФТБА, Multicomponent mixtures of two PFOS can also be used, for example, PFD / PFTA, PFD / PFMTSP, PFOB / PFTA,

ПФОБ/ПФМЦП или из трех ПФОС, например ПФОБ/ПФД/ПФМЦП, ПФОБ/ПФД/ПФТБА или из четырех ПФОС, например,

ПФОБ ПФД/ПФМЦП/ПФТБА. PFOB / PFMTSP or of three PFOS, for example PFOB / PFD / PFMTSP, PFOB / PFD / PFTA or of four PFOS, for example PFOB PFD / PFMTSP / PFTA.

Специальные стабилизирующие добавки вводят для снижения среднего диаметра частиц эмульсии, увеличения дисперсности и стабильности при длительном хранении. Special stabilizing additives are introduced to reduce the average particle diameter of the emulsion, increase dispersion and stability during long-term storage.

В качестве стабилизирующей добавки предпочтительно используют нетоксичные неионогенные высокомолекулярные поверхностно-активные вещества (НПАВ), в частности полоксамеры (проксанолы, плюроники, коллифоры, эмуксолы). Их количество в эмульсиях ПФОС, по возможности, минимально и определяется только необходимостью удовлетворительного эмульгирования и гомогенизации ПФОС. Минимизация количества ПАВ связана и с тем, что они влияют на токсичность и реактогенность эмульсии ПФОС. As a stabilizing additive, non-toxic non-ionic high molecular weight surfactants (NSAS), in particular poloxamers (proxanols, pluronics, collifors, emuxols) are preferably used. Their amount in PFOS emulsions is, if possible, minimal and is determined only by the need for satisfactory emulsification and homogenization of PFOS. Minimizing the amount of surfactants is also associated with the fact that they affect the toxicity and reactogenicity of the PFOS emulsion.

Полоксамеры представляют собой сополимер полиэтиленоксида и полипропиленоксида общей формулы НО(С2Н4О),„(СзН6О)п(С2Н4О)„,'Н, где (m+m') варьируется от нескольких единиц до нескольких десятков; молекулярная масса составляет от 1000 до 20000, доля полиоксиэтиленовых блоков может составлять от 10 до 80% по массе. Poloxamers are a copolymer of polyethylene oxide and polypropylene oxide of the general formula HO (C 2 H 4 O), „(СЗН 6 О) p (С 2 Н 4 О)“, 'Н, where (m + m') varies from several units to several dozens; the molecular weight is from 1000 to 20,000, the proportion of polyoxyethylene blocks can be from 10 to 80% by weight.

В предпочтительном варианте настоящего изобретения используют полоксамер с торговым названием Проксанол 268, «Эмуксол 268» марки «А», Kolliphor PI 88 (Коллифор PI 88), Pluronic F68 (Плюроник F68), Synperonic F68 (Синпероник F68), Lutrol F68 (Лутрол F68). In a preferred embodiment of the present invention, a poloxamer is used under the trade name Proxanol 268, “Emuxol 268”, brand “A”, Kolliphor PI 88 (Collifor PI 88), Pluronic F68 (Pluronic F68), Synperonic F68 (Sinperonic F68), Lutrol F68 (Lutrol F68 )

В качестве стабилизирующей добавки также могут быть использованы С10- С22 жирные кислоты и/или их соли или триглицериды и фосфолипиды яичного желтка или сои. C 10 - C 22 fatty acids and / or their salts or triglycerides and phospholipids of egg yolk or soy can also be used as stabilizing additives.

В предпочтительном способе настоящего изобретения используют 10- 30масс% водный раствор стабилизирующей добавки, наиболее предпочтительно 10-20 масс.% водный раствор. In a preferred method of the present invention, a 10-30 mass% aqueous solution of a stabilizing additive is used, most preferably a 10-20 mass% aqueous solution.

Водно-солевой раствор, используемый в способе по настоящему изобретению представляет собой водный раствор солей, выбранных из NaCl, и, необязательно, КС1, MgCl2, NaHCO3 , NaH2PO4, Na2HP04. Водно-солевой раствор может содержать глюкозу. The aqueous salt solution used in the method of the present invention is an aqueous solution of salts selected from NaCl, and optionally KCl, MgCl 2 , NaHCO 3 , NaH 2 PO 4 , Na 2 HP0 4 . The water-salt solution may contain glucose.

Количество компонентов водно-солевого раствора, используемого для смешивания с предэмульсией ПФОС рассчитывается таким образом, чтобы

обеспечить в готовой эмульсии ПФОС следующее содержание солей: 82, 1- 123,2 мМ NaCl, 4,2-6,3 мМ КС1, 1,6-2,4 мМ MgCl2 6,6-9,9 мМ NaHC03, 1 ,3-2 мМ NaH2P04 и 8,9-13,3 мМ D-глюкозы или 4,8-7,2 г/л натрия хлорида; 0,31-0,47 г/л калия хлорида; 0, 15-0,23 г/л магния хлорида (в пересчете на сухое вещество); 0,55-0,83 г/л натрия гидрокарбоната; 0,16-0,24 г/л натрия фосфата однозамещенного (в пересчете на сухое вещество); 1 ,6-2,4 г/л глюкозы. The amount of components of the water-salt solution used for mixing with the PFOS preemulsion is calculated so that to provide the following salt content in the finished PFOS emulsion: 82, 1-123.2 mM NaCl, 4.2-6.3 mM KCl, 1.6-2.4 mM MgCl 2 6.6-9.9 mM NaHC0 3 , 1, 3-2 mM NaH 2 P0 4 and 8.9-13.3 mM D-glucose or 4.8-7.2 g / l sodium chloride; 0.31-0.47 g / l potassium chloride; 0, 15-0.23 g / l magnesium chloride (in terms of dry matter); 0.55-0.83 g / l sodium bicarbonate; 0.16-0.24 g / l sodium phosphate monosubstituted (in terms of dry matter); 1, 6-2.4 g / l glucose.

Ниже заявленное изобретение проиллюстрировано примерами, которые никоим образом не предназначены для ограничения объема заявленного изобретения. Below the claimed invention is illustrated by examples, which are in no way intended to limit the scope of the claimed invention.

ПРИМЕРЫ EXAMPLES

Пример 1. Получение наноэмульсии, содержащей 10 об.% ПФОС. Example 1. Obtaining a nanoemulsion containing 10 vol.% PFOS.

Перед процессом гомогенизации проверяют герметичность циркуляционного контура путем его заполнения 13,3% водным раствором полоксамера Эмуксол 268 марки «А» в количестве в 2-4 раза превышающим рабочий объем трубопроводов и рабочей камеры гомогенизатора, при включенном гомогенизаторе при давлении 10-45,5 Мпа с последующим его сливом. Емкость 3 заполняют 2,52 л 13,3% водного раствора полоксамера Эмуксол 268 марки «А». Смесь ПФОС, включающую 0,56 л ПФД и 0,28 л ПФМЦП, постепенно (капельно) добавляют в 2,52 л 13,3% водного раствора полоксамера Эмуксол 268 марки «А». Давление в гомогенизаторе поддерживают в пределах от 43, 1 до 45,1 МПа и при охлаждении рабочей камеры до 20-26°С. Трубопроводы циркуляционного контура термостатируют для создания температуры в диапазоне 7-15°С. Осуществляют 13 циклов гомогенизации. Получают 3,36 л предэмульсии ПФОС, содержащей 25об% ПФОС со средним размером частиц 50-80 нм. 3,36 л полученной предэмульсии добавляют в 5,04 л водно-солевого раствора, содержащего в 1 ,7 раза больше растворенных солей (95,5 мМ NaCl, 5,0 мМ КС1, 2,2 мМ MgCl2, 8, 1 мМ NaHCO3, 1 ,5 мМ NaH2PO4, и 10,7 мМ глюкозы) по отношению к концентрации солей в наноэмульсии, в соотношении 1 : 1 ,5 соответственно. Получают 8,4 л наноэмульсии ПФОС, содержащей 10 об% ПФОС со средним размером частиц 50-80 нм.Before the homogenization process, the tightness of the circulation circuit is checked by filling it with a 13.3% aqueous solution of Poloxamer Emuxol 268 grade “A” in an amount 2-4 times the working volume of the pipelines and the working chamber of the homogenizer, with the homogenizer turned on at a pressure of 10-45.5 MPa followed by its discharge. Capacity 3 is filled with 2.52 l of a 13.3% aqueous solution of poloxamer Emuxol 268 grade "A". A mixture of PFOS, including 0.56 L of PFD and 0.28 L of PFMTSP, is gradually (dropwise) added to 2.52 L of a 13.3% aqueous solution of Poloxamer Emuxol 268 grade “A”. The pressure in the homogenizer is maintained in the range from 43.1 to 45.1 MPa and when the working chamber is cooled to 20-26 ° C. The pipelines of the circulation circuit are thermostated to create a temperature in the range of 7-15 ° C. Carry out 13 cycles of homogenization. Obtain 3.36 l of PFOS preemulsion containing 25% PFOS with an average particle size of 50-80 nm. 3.36 L of the resulting pre-emulsion is added to 5.04 L of a water-salt solution containing 1.7 times more dissolved salts (95.5 mm NaCl, 5.0 mm KCl, 2.2 mm MgCl 2 , 8, 1 mm NaHCO 3 , 1, 5 mM NaH 2 PO 4 , and 10.7 mM glucose) in relation to the concentration of salts in the nanoemulsion, in a ratio of 1: 1, 5, respectively. Get 8.4 l of PFOS nanoemulsion containing 10% PFOS with an average particle size of 50-80 nm.

Наноэмульсию ПФОС разливают в стерильную потребительскую тару и стабилизируют при температуре 4°С в течение 24 часов, после чего ее

замораживают при температуре - 15°С. PFOS nanoemulsion is poured into a sterile consumer container and stabilized at 4 ° C for 24 hours, after which it frozen at a temperature of - 15 ° C.

В соответствии с методикой, описанной в Примере 1 получают экспериментальную серию наноэмульсии ПФОС 4э со средним размером частиц 64 нм. In accordance with the procedure described in Example 1, an experimental series of PFOS 4e nanoemulsion with an average particle size of 64 nm is obtained.

Пример 2. Получение наноэмульсии, содержащей 10 об.% ПФОС. Example 2. Obtaining a nanoemulsion containing 10 vol.% PFOS.

Перед заполнением циркуляционного контура раствором стабилизирующей добавки проверяют герметичность циркуляционного контура путем его заполнения 10% водным раствором полоксамера Эмуксол 268 марки «А» в количестве в 2-4 раза превышающим рабочий объем трубопроводов и рабочей камеры гомогенизатора, при включенном гомогенизаторе при давлении 10-45,5 Мпа с последующим его сливом. Циркуляционный контур заполняют 3,36 л 10% водного раствора полоксамера Эмуксол 268 марки «А», после чего в него постепенно (струйно) добавляют смесь ПФОС, состоящую из 0,56 л ПФД и 0,28 л ПФМЦП. Давление в гомогенизаторе поддерживают в пределах от 43,1 до 45, 1 МПа и при охлаждении рабочей камеры до 20-26°С. Трубопроводы циркуляционного контура термостатируют для создания температуры в диапазоне 7- 15°С. Осуществляют 10 циклов гомогенизации. Получают 3,36 л предэмульсии ПФОС, содержащей 25 об% ПФОС со средним размером частиц 50-80 нм. 3,36 л полученной предэмульсии добавляют в 5,04 л водно-солевого раствора, содержащего в 1,7 раза больше растворенных солей (93,7 мМ NaCl, 5,1 мМ КС1, 1,9 мМ MgCl2, 7,5 мМ NaHCO3, 1 ,7 мМ NaH2PO4, и 1 1,2 мМ глюкозы) по отношению к концентрации солей в наноэмульсии, в соотношении 1 : 1,5 соответственно. Получают 8,4 л наноэмульсии ПФОС, содержащей 10 об% ПФОС со средним размером частиц 50-80 нм. Наноэмульсию ПФОС разливают в стерильную потребительскую тару и стабилизируют при температуре 4°С в течение 24 часов, после чего ее замораживают при температуре - 15°С. Before filling the circulation circuit with a solution of a stabilizing additive, the tightness of the circulation circuit is checked by filling it with a 10% aqueous solution of Emuxol 268 poloxamer grade “A” in an amount 2-4 times the working volume of the pipelines and the working chamber of the homogenizer, with the homogenizer turned on at a pressure of 10-45 5 MPa followed by its discharge. The circulation loop is filled with 3.36 L of a 10% aqueous solution of Emoxol 268 Poloxamer brand “A”, after which a mixture of PFOS consisting of 0.56 L of PFD and 0.28 L of PFMTSP is gradually (jet) added to it. The pressure in the homogenizer is maintained in the range from 43.1 to 45, 1 MPa and when the working chamber is cooled to 20-26 ° C. The pipelines of the circulation circuit are thermostated to create a temperature in the range of 7-15 ° C. Carry out 10 cycles of homogenization. Obtain 3.36 l of PFOS preemulsion containing 25 vol.% PFOS with an average particle size of 50-80 nm. 3.36 L of the resulting pre-emulsion is added to 5.04 L of a water-salt solution containing 1.7 times more dissolved salts (93.7 mm NaCl, 5.1 mm KCl, 1.9 mm MgCl 2 , 7.5 mm NaHCO 3 , 1, 7 mM NaH 2 PO 4 , and 1 1.2 mM glucose) in relation to the salt concentration in the nanoemulsion, in a ratio of 1: 1.5, respectively. Get 8.4 l of PFOS nanoemulsion containing 10% PFOS with an average particle size of 50-80 nm. PFOS nanoemulsion is poured into a sterile consumer container and stabilized at a temperature of 4 ° C for 24 hours, after which it is frozen at a temperature of -15 ° C.

В соответствии с методикой, описанной в Примере 2 получают экспериментальную серию наноэмульсии ПФОС Зэ со средним размером частиц 53 нм. In accordance with the procedure described in Example 2, an experimental series of PFOS Ze nanoemulsion with an average particle size of 53 nm is obtained.

Пример 3. Получение наноэмульсии, содержащей 10 об.% ПФОС. Example 3. Obtaining a nanoemulsion containing 10 vol.% PFOS.

Перед заполнением циркуляционного контура раствором стабилизирующей добавки проверяют герметичность циркуляционного контура

путем его заполнения 10% водным раствором полоксамера Lutrol F68 (Лутрол F68) в количестве в 2-4 раза превышающим рабочий объем трубопроводов и рабочей камеры гомогенизатора, при включенном гомогенизаторе при давлении 10-45,5 МПа с последующим его сливом. Циркуляционный контур заполняют 3,36 л 10% водного раствора полоксамера Эмуксола 268 марки «А», после чего в него постепенно (капельно) добавляют смесь ПФОС, состоящую из 0,56 л ПФД и 0,28 л ПФМЦП. Давление в гомогенизаторе поддерживают в пределах от 10 до 81 МПа и при охлаждении рабочей камеры до 19-28°С. Трубопроводы циркуляционного контура термостатируют для создания температуры в диапазоне 10-20 °С. Осуществляют 10 циклов гомогенизации. Получают 4,2 л предэмульсии ПФОС, содержащей 20 об.% ПФОС со средним размером частиц 50-80 нм. 4,2 л полученной предэмульсии добавляют в 4,2 л водно-солевого раствора, содержащего в 2 раза больше растворенных солей (100,7 мМ NaCl, 5,7 мМ КС1, 2, 1 мМ MgCl2, 7,9 мМ NaHCO3, 1 ,6 мМ NaH2PO4, и 1 1 ,0 мМ глюкозы) по отношению к концентрации солей в наноэмульсии, т.е. в соотношении 1 : 1 соответственно. Получают 8,4 л наноэмульсии ПФОС, содержащей 10 об% ПФОС со средним размером частиц 50-80 нм. Наноэмульсию ПФОС разливают в потребительскую тару и стабилизируют при температуре 4°С в течение 24 часов, после чего ее замораживают при температуре -16°С. Before filling the circulation circuit with a solution of a stabilizing additive, check the tightness of the circulation circuit by filling it with a 10% aqueous solution of the Lutrol F68 poloxamer (Lutrol F68) in an amount 2-4 times the working volume of the pipelines and the working chamber of the homogenizer, with the homogenizer turned on at a pressure of 10-45.5 MPa, followed by its discharge. The circulation circuit is filled with 3.36 l of a 10% aqueous solution of Emoxol 268 poloxamer grade “A”, after which a mixture of PFOS consisting of 0.56 l of PFD and 0.28 l of PFMTSP is gradually (dropwise) added to it. The pressure in the homogenizer is maintained in the range from 10 to 81 MPa and when the working chamber is cooled to 19-28 ° C. The pipelines of the circulation circuit are thermostated to create a temperature in the range of 10-20 ° C. Carry out 10 cycles of homogenization. Obtain 4.2 l of PFOS preemulsion containing 20 vol.% PFOS with an average particle size of 50-80 nm. 4.2 l of the resulting pre-emulsion is added to 4.2 l of a water-salt solution containing 2 times more dissolved salts (100.7 mm NaCl, 5.7 mm KCl, 2, 1 mm MgCl 2 , 7.9 mm NaHCO 3 , 1, 6 mM NaH 2 PO 4 , and 1, 0 mM glucose) in relation to the salt concentration in the nanoemulsion, i.e. in a ratio of 1: 1, respectively. Get 8.4 l of PFOS nanoemulsion containing 10% PFOS with an average particle size of 50-80 nm. PFOS nanoemulsion is poured into a consumer container and stabilized at a temperature of 4 ° C for 24 hours, after which it is frozen at a temperature of -16 ° C.

В соответствии с методикой, описанной в Примере 3, получают экспериментальную серию наноэмульсии ПФОС: серия Зс со средним размером частиц 53 нм. In accordance with the procedure described in Example 3, an experimental series of PFOS nanoemulsion is obtained: a series of Zc with an average particle size of 53 nm.

Методики способа получения наноэмульсии ПФОС Примеров 1 , 2 и 3 представляют собой стандартную технологию производства, дополненную стадией выдерживания наноэмульсии перед замораживанием в Примере 1 или дополненную стадией предварительного заполнения циркуляционного контура водным раствором стабилизирующей добавки в Примере 2 или дополненную как стадией выдерживания наноэмульсии перед замораживанием, так и стадией предварительного заполнения циркуляционного контура водным раствором стабилизирующей добавки в Примере 3. The methods of the method for producing PFOS nanoemulsion of Examples 1, 2 and 3 are a standard production technology supplemented by the stage of keeping the nanoemulsion before freezing in Example 1 or supplemented by the stage of pre-filling the circulation circuit with an aqueous solution of a stabilizing additive in Example 2 or supplemented by the stage of keeping the nanoemulsion before freezing, so and the stage of pre-filling the circulation circuit with an aqueous solution of a stabilizing additive in Example 3.

Пример 4 (контрольный). Получение наноэмульсии, содержащей 10 об. % ПФОС.

Перед процессом гомогенизации проверяют герметичность циркуляционного контура путем его заполнения 13,3% водным раствором полоксамера Эмуксол 268 марки «А» в количестве в 2-4 раза превышающим рабочий объем трубопроводов и рабочей камеры гомогенизатора, при включенном гомогенизаторе при давлении 10-45,5 МПа с последующим его сливом. Смесь ПФОС, включающую 0,56 л ПФД и 0,28 л ПФМЦП, постепенно (струйно) добавляют в 2,52 л 13,3% водного раствора полоксамера Эмуксол 268 марки «А». Давление в гомогенизаторе поддерживают в пределах от 10 до 81 МПа и при охлаждении рабочей камеры до 19-28°С. Трубопроводы циркуляционного контура термостатируют для создания температуры в диапазоне 10-20°С. Осуществляют 13 циклов гомогенизации. Получают 4,2 л предэмульсии ПФОС, содержащей 20 об.% ПФОС со средним размером частиц 50-80 нм. 4,2 л полученной предэмульсии добавляют в 4,2 л водно-солевого раствора, содержащий в 2 раза больше растворенных солей (102,3 мМ NaCl, 5,6 мМ КС1, 2,0 мМ MgCl2, 8,3 мМ NaHCO3, 1 ,8 мМ NaH2PO4, и 1 1,2 мМ глюкозы) по отношению к концентрации солей в наноэмульсии, т.е. в соотношении 1 : 1 соответственно, Получают 8,4 л наноэмульсии ПФОС, содержащей 10 об.% ПФОС со средним размером частиц 50-80 нм. Наноэмульсию ПФОС замораживают при температуре -17°С. Example 4 (control). Obtaining a nanoemulsion containing 10 vol. % PFOS. Before the homogenization process, the tightness of the circulation circuit is checked by filling it with a 13.3% aqueous solution of Poloxamer Emuxol 268 grade “A” in an amount 2-4 times the working volume of the pipelines and the working chamber of the homogenizer, with the homogenizer turned on at a pressure of 10-45.5 MPa followed by its discharge. A mixture of PFOS, including 0.56 L of PFD and 0.28 L of PFMTSP, is gradually (jet) added to 2.52 L of a 13.3% aqueous solution of Poloxamer Emuxol 268 grade “A”. The pressure in the homogenizer is maintained in the range from 10 to 81 MPa and when the working chamber is cooled to 19-28 ° C. The pipelines of the circulation circuit are thermostated to create a temperature in the range of 10-20 ° C. Carry out 13 cycles of homogenization. Obtain 4.2 l of PFOS preemulsion containing 20 vol.% PFOS with an average particle size of 50-80 nm. 4.2 L of the resulting pre-emulsion is added to 4.2 L of a water-salt solution containing 2 times more dissolved salts (102.3 mm NaCl, 5.6 mm KCl, 2.0 mm MgCl 2 , 8.3 mm NaHCO 3 , 1, 8 mM NaH 2 PO 4 , and 1 1.2 mM glucose) with respect to the salt concentration in the nanoemulsion, i.e. in a ratio of 1: 1, respectively, 8.4 L of PFOS nanoemulsion containing 10 vol.% PFOS with an average particle size of 50-80 nm is obtained. PFOS nanoemulsion is frozen at a temperature of -17 ° C.

По методике, описанной в Примере 4, получают контрольную серию наноэмульсии ПФОС 1к со средним размером частиц 58 нм. According to the method described in Example 4, a control series of PFOS 1k nanoemulsion with an average particle size of 58 nm is obtained.

Методика способа получения наноэмульсии ПФОС Примера 4 представляет собой стандартную технологию производства (контроль). The methodology for producing the PFOS nanoemulsion of Example 4 is a standard production technology (control).

Пример 5. Оценка влияния выдерживания наноэмульсии ПФОС или предварительного заполнения циркуляционного контура раствором стабилизирующей добавки на стабильность продукта. Example 5. Evaluation of the effect of aging PFOS nanoemulsion or pre-filling the circulation circuit with a solution of a stabilizing additive on the stability of the product.

Стабильность наноэмульсии ПФОС определяют по изменению размера части в процессе хранения. Нормальным средним размером частиц считается размер в диапазоне от 30 до 150 нм. The stability of the PFOS nanoemulsion is determined by the change in the size of the part during storage. A normal average particle size is considered to be a size in the range from 30 to 150 nm.

Наноэмульсию, полученную в Примерах 1 (серия 4э), 2 (серия Зэ) и 4 Nanoemulsion obtained in Examples 1 (series 4E), 2 (series Ze) and 4

(серия 1к), размораживают и определяют средний размер частиц при хранении при температуре 4°С и температуре -18°С.

Средний размер частиц эмульсий и распределение частиц по диаметрам измеряют на электронном микроскопе. (series 1k), thaw and determine the average particle size when stored at 4 ° C and -18 ° C. The average particle size of the emulsions and the particle diameter distribution are measured using an electron microscope.

Полученные данные представлены в Таблицах 1 и 2. The data obtained are presented in Tables 1 and 2.

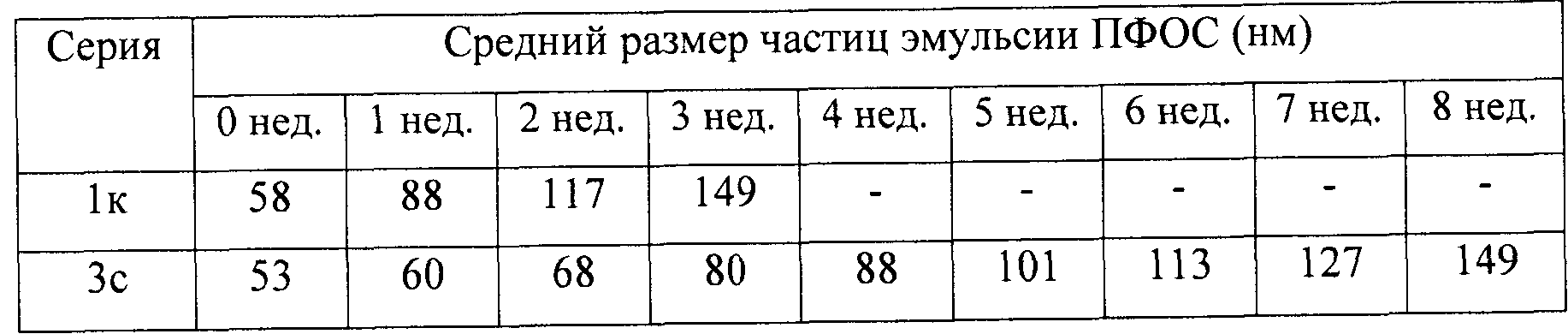

Таблица 1 Table 1

Стабильность наноэмульсии ПФОС при хранении при температуре Storage stability of PFOS nanoemulsion at temperature

Таблица 2table 2

Стабильность наноэмульсии ПФОС при хранении при температуре -18°С The stability of the PFOS nanoemulsion when stored at a temperature of -18 ° C

Представленные данные измерений среднего размера частиц эмульсии ПФОС показывают, что выдерживание наноэмульсии ПФОС перед замораживанием при температуре 4°С в течение 24 часов или предварительное заполнение циркуляционного контура раствором стабилизирующей добавки перед смешиванием компонентов существенно увеличивает срок хранения продукта по сравнению с контролем: The presented measurements of the average particle size of the PFOS emulsion show that keeping PFOS nanoemulsion before freezing at 4 ° C for 24 hours or pre-filling the circulation circuit with a solution of a stabilizing additive before mixing the components significantly increases the shelf life of the product compared to the control:

- срок хранения наноэмульсии ПФОС по Примеру 1 при температуре 4°С составляет 6 недель, что на 3 недели больше срока хранения контрольной серии по Примеру 4 (Таблица 1); - the shelf life of the PFOS nanoemulsion according to Example 1 at a temperature of 4 ° C is 6 weeks, which is 3 weeks longer than the shelf life of the control series according to Example 4 (Table 1);

- срок хранения наноэмульсии ПФОС по Примеру 2 при температуре 4°С составляет 4 недели, что на 1 неделю больше срока хранения контрольной серии по Примеру 4 (Таблица 1);

- срок хранения наноэмульсии ПФОС по Примеру 1 при температуре - 18°С составляет 48 месяцев, что на 24 месяца больше срока хранения контрольной серии по Примеру 4 (Таблица 2); - the shelf life of the PFOS nanoemulsion according to Example 2 at a temperature of 4 ° C is 4 weeks, which is 1 week longer than the shelf life of the control series according to Example 4 (Table 1); - the shelf life of the PFOS nanoemulsion according to Example 1 at a temperature of -18 ° C is 48 months, which is 24 months longer than the shelf life of the control series according to Example 4 (Table 2);