SURGICAL STAPLING APPARATUS

BACKGROUND

Technical Field

The present disclosure relates generally to a surgical stapling

apparatus for applying surgical staples to body tissue and,more particularly,to a

surgical stapling apparatus for performing circular anastomosis of hollow tissue

structures.

Background of Related Art

Anastomosis refers to the surgical joining of separate hollow tissue

sections.Typically,an anastomosis procedure follows surgery in which a

diseased or defective section of a hollow tissue structure is removed,thus

requiring the joining of the remaining sections of the tissue structure.Depending

on the particular procedure being performed and/or other factors,the sections of

the tissue may be joined by circular anastomosis,e.g.,end-to-end anastomosis,

end-to-side anastomosis,or side-to-side anastomosis.

In a circular anastomosis procedure,the two sections of a tubular

organ are joined using a stapling apparatus that drives a circular array of staples

through each of the sections to join the sections to one another in end-to-end,

end-to-side,or side-to-side relation.Typically,any tissue within the newly

joined hollow tissue structure is simultaneously cored to clear the passage

defined by the hollow tissue structure.

A typical circular anastomosis apparatus includes an elongated shaft

having a handle portion at a proximal end and a staple holding component at a

distal end.An anvil assembly including an anvil rod and an attached anvil head

is mounted to the distal end of the elongated shaft adjacent the staple holding

component.In use,the two sections of the tubular organ to be joined are

clamped between the anvil head and the staple holding component.The clamped

sections are then joined to one another by driving one or more staples from the

staple holding component,through the tissue,and into the anvil head to form the

staples about the tissue.Examples of such circular anastomosis apparatuses are

described in U.S.Patent Nos.7,857,187to Milliman(“the Milliman'187patent”)

and6,945,444to Gresham et al.(“the Gresham'444patent”),the entire contents

of which are hereby incorporated by reference herein in their entireties.

Depending on the type,thickness,and/or other properties of the

tissue structures to be joined,it may be desirable to provide a different

“minimum tissue gap,”wherein the“minimum tissue gap”is defined as the

distance between the anvil head and the staple holding component when the

stapling apparatus is fully approximated.A need therefore exists for a tissue gap

adjustment mechanism that facilitates adjustment of the minimum tissue gap

between a plurality of tissue gap settings in a quick and efficient manner.

SUMMARY

A surgical stapling apparatus provided in accordance with the

present disclosure includes a handle portion,a body extending distally from the

handle portion,a stapling assembly supported on a distal end of the body,an

anvil assembly,a drive screw,and a tissue gap adjustment mechanism.The

drive screw is supported within the handle portion and is operably coupled to the

anvil assembly.The drive screw defines a transverse aperture and is movable

relative to the stapling assembly to move the anvil assembly relative to the

stapling assembly between a spaced-apart position and an approximated position.

The tissue gap adjustment mechanism is disposed within the handle portion and

includes a stop member,an asymmetrical polygonal washer,and a set screw.

The stop member is supported on the drive screw and includes first and second

flanges which define a transverse slot.The stop member is configured to abut a

stop surface within the handle portion to prevent further proximal movement of

the drive screw within the handle portion and set a minimum tissue gap between

the anvil assembly and the stapling assembly.The washer defines an

eccentrically positioned aperture and includes a plurality of pairs of opposed flat

sides.The washer is dimensioned to be positioned within the transverse slot

such that each of the pairs of opposed flat sides can be selectively positioned

between and in engagement with the first and second flanges.The set screw is

configured for insertion through the aperture of the washer,the transverse slot,

and the transverse aperture to fix the stop member relative to the drive screw.

The washer is repositionable about the set screw to position a selected pair of the

opposed flat sides between and in engagement with the first and second flanges.

At least two of the pairs of opposed flat sides when engaged with the first and

second flanges are spaced to position the aperture of the washer at different

locations in relation to the transverse slot such that the position of the stop

member in relation to the drive screw can be selectively varied by positioning a

different pair of opposed flat sides in engagement with the first and second

flanges to selectively change the minimum tissue gap.

In embodiments,the washer defines an octagonal configuration.

In embodiments,the washer is configured and dimensioned such that

the minimum tissue gap is adjustable between about4.55mm and about5.45mm.

In embodiments,the washer is configured and dimensioned such that

the minimum tissue gap is incrementally adjustable at a step size of about

0.15mm between about4.55mm and about5.45mm.

In embodiments,at least one indicator is disposed on the washer and

an indicator is disposed on at least one of the flanges for indicating a selected

setting of the tissue gap adjustment mechanism.

In embodiments,the set screw is configured to be loosened to

facilitate rotation of the washer about the set screw and is configured to be

tightened to fix the position of the washer and the stop member on the drive

screw.

In embodiments,an approximation knob extends from the handle.

The approximation knob is coupled to the drive screw and is selectively

actuatable to move the anvil assembly between the spaced-apart position and the

approximated position.

In embodiments,the drive screw defines a helical channel and the

approximation knob is coupled to a ball disposed within the helical channel such

that rotation of the approximation knob effects translation of the drive screw.

In embodiments,a firing assembly including a trigger coupled to the

handle and a firing link coupled to the stapling assembly is provided.The firing

link is configured for distal translation through the body in response to actuation

of the trigger to eject a plurality of surgical staples from the stapling assembly.

In embodiments,the handle is formed from first and second handle

sections that are releasably engagable with one another.

Another surgical stapling apparatus provided in accordance with the

present disclosure includes a stapling assembly,an anvil assembly,a drive screw

operably coupled to the anvil assembly,an approximation member,and a tissue

gap adjustment mechanism.The approximation member is coupled to the drive

screw and is selectively actuatable to move the drive screw relative to the

stapling assembly to move the anvil assembly relative to the stapling assembly

between a spaced-apart position and an approximated position.The tissue gap

adjustment mechanism includes a stop member supported on the drive screw.

The stop member includes first and second flanges which define a transverse slot.

The stop member is configured to limit movement of the drive screw relative to

the stapling assembly to set a minimum tissue gap between the anvil assembly

and the stapling assembly.An asymmetrical polygonal washer defining an

eccentrically positioned aperture and including a plurality of pairs of opposed

flat sides is dimensioned to be positioned within the transverse slot such that

each of the pairs of opposed flat sides can be selectively positioned between and

in engagement with the first and second flanges.A post is supported on the

drive screw.The post is positioned to axially fix the stop member relative to the

drive screw.The washer is repositionable about the post to position a selected

pair of the opposed flat sides between and in engagement with the first and

second flanges.At least two of the pairs of opposed flat sides when engaged

with the first and second flanges are spaced to position the aperture of the

washer at different locations within the transverse slot such that the position of

the stop member in relation to the drive screw can be selectively varied by

positioning a different pair of opposed flat sides in engagement with the first and

second flanges to selectively change the minimum tissue gap between the anvil

assembly and the stapling assembly.

In embodiments,the washer defines an octagonal configuration.

In embodiments,the washer is configured and dimensioned such that

the minimum tissue gap is adjustable between about4.55mm and about5.45mm.

In embodiments,the washer is configured and dimensioned such that

the minimum tissue gap is incrementally adjustable at a step size of about

0.15mm between about4.55mm and about5.45mm.

In embodiments,at least one indicator is disposed on the washer and

an indicator is disposed on at least one of the flanges for indicating a selected

setting of the tissue gap adjustment mechanism.

In embodiments,the surgical stapling apparatus further includes a

handle portion defining a proximal end and a distal end.The drive screw is

supported within the handle portion and the stop member is configured to abut a

stop surface within the handle portion to limit movement of the drive screw

relative to the stapling assembly to set the minimum tissue gap between the anvil

assembly and the stapling assembly.

In embodiments,the surgical stapling apparatus further includes a

body extending distally from the handle portion.The stapling assembly is

supported on a distal end of the body.

A method of setting a minimum tissue gap tissue between an anvil

assembly and a stapling assembly of a surgical stapling apparatus is also

provided in accordance with the present disclosure.The surgical stapling

apparatus includes a handle portion,a body extending from the handle portion

and having the stapling assembly supported thereon,and a drive screw.The

drive screw is supported within the handle portion and is operably coupled to the

anvil assembly.The drive screw is movable relative to the stapling assembly to

move the anvil assembly relative to the stapling assembly.The method includes

positioning a stop member about the drive screw.The stop member includes

first and second flanges which define a transverse slot.The stop member is

configured to abut a stop surface within the handle portion to prevent further

proximal movement of the drive screw within the handle portion and set a

minimum tissue gap between the anvil assembly and the stapling assembly.The

method further includes positioning an asymmetrical polygonal washer defining

an eccentrically positioned aperture and including a plurality of pairs of opposed

flat sides between the first and second flanges such that a selected pair of the

opposed flat sides are positioned between and in engagement with the first and

second flanges to define a first minimum tissue gap.The method further

includes securing the stop member to the drive screw with the washer positioned

within the transverse slot and the selected pair of opposed flat sides positioned

between the first and second flanges.

In embodiments,the method further includes un-securing the stop

member from the drive screw,repositioning the washer to engage a different pair

of the opposed flat sides between the first and second flanges to axially

reposition the stop member relative to the drive screw to define a second

minimum tissue gap,and re-securing the stop member to the drive screw to fix

the position of the washer and the stop member on the drive screw.

In embodiments,the method further includes confirming a desired

position of the washer by viewing indicators disposed on the washer and at least

one of the flanges that indicate a selected position of the washer.

Another surgical stapling apparatus provided in accordance with the

present disclosure includes a handle portion defining a proximal end and a distal

end,a body extending distally from the handle portion,a stapling assembly

supported on a distal end of the body,a firing assembly,and a trigger lock

assembly.The firing assembly includes a firing trigger extending from the

handle portion,a firing link coupling the firing trigger to the handle portion,and

a pusher link coupled to the firing trigger and extending through the body.The

pusher link is movably supported for distal translation through the body in

response to actuation of the firing trigger to eject the plurality of surgical staples

from the stapling assembly.The trigger lock assembly includes a trigger lock

member and a biasing member.The trigger lock member is pivotably coupled to

the firing trigger and is movable relative to the firing trigger between a locked

position,wherein the trigger lock abuts the firing link to inhibit actuation of the

firing trigger,and an unlocked position,wherein the trigger lock is displaced

from the firing link to permit actuation of the firing trigger.In the locked

position of the trigger lock,the biasing member is positioned to bias the trigger

lock towards the locked position.In the unlocked position of the trigger lock,

the biasing member is positioned to bias the trigger lock towards the unlocked

position.

In embodiments,the biasing member includes a coiled portion and a

flat portion extending from the coiled portion.The flat portion is positioned to

engage and bias the trigger lock towards the locked position when the trigger

lock is disposed in the locked position and to engage and bias the trigger lock

towards the unlocked position when the trigger lock is disposed in the unlocked

position.

In embodiments,a first pivot member pivotably couples the firing

link to the firing trigger.In such embodiments,the coiled portion of the biasing

member may be disposed about the first pivot member.

In embodiments,the trigger lock includes an asymmetrical base

member defining first and second contact surfaces on opposite sides of the base

member.The biasing member is positioned to contact the first contact surface to

bias the trigger lock towards the locked position and to contact the second

contact surface to bias the trigger lock towards the unlocked position.

In embodiments,the base member of the trigger lock defines a

throughbore configured to receive a second pivot member for pivotably coupling

the trigger lock to the firing trigger.

In embodiments,the surgical stapling apparatus further includes an

anvil assembly configured to form the plurality of surgical staples ejected from

the stapling assembly about tissue and a drive screw supported within the handle

portion.The drive screw is operably coupled to the anvil assembly and is

movable relative to the stapling assembly to move the anvil assembly relative to

the stapling assembly between a spaced-apart position and an approximated

position

In embodiments,the surgical stapling apparatus further includes an

approximation knob extending from the handle portion.The approximation

knob is coupled to the drive screw and is selectively actuatable to move the anvil

assembly between the spaced-apart position and the approximated position.

In embodiments,the drive screw defines a helical channel and the

approximation knob is coupled to a ball disposed within the helical channel such

that rotation of the approximation knob effects translation of the drive screw.

In embodiments,the firing trigger includes a lockout member

configured to interface with the drive screw to prevent actuation of the firing

trigger when the anvil assembly is disposed in the spaced-apart position.

In embodiments,the drive screw defines a recess such that when the

anvil assembly is disposed in the approximated position,the recess is aligned

with the lockout member to permit actuation of the firing trigger.

In embodiments,the handle is formed from first and second handle

sections,the first and second handle sections being releasably engagable with

one another.

Another surgical stapling apparatus provided in accordance with the

present disclosure includes a handle portion defining a proximal end and a distal

end,a body extending distally from the handle portion,a stapling assembly

supported on a distal end of the body and including a plurality of surgical staples,

a firing assembly,and a trigger lock assembly.The firing assembly includes a

firing trigger coupled to and extending from the handle portion and a pusher link

coupled to the firing trigger and extending through the body.The pusher link is

movably supported for distal translation through the body in response to

actuation of the firing trigger to eject the plurality of surgical staples from the

stapling assembly.The trigger lock assembly includes a trigger lock member

and a biasing member.The trigger lock member is pivotably coupled to the

firing trigger and includes an asymmetrical base member defining first and

second contact surfaces on opposite sides of the base member.The trigger lock

is movable relative to the firing trigger between a locked position,wherein the

trigger lock abuts the firing link to inhibit actuation of the firing trigger,and an

unlocked position,wherein the trigger lock is displaced from the firing link to

permit actuation of the firing trigger.In the locked position of the trigger lock,

the biasing member is positioned to contact the first contact surface to bias the

trigger lock towards the locked position and,in the unlocked position of the

trigger lock,the biasing member is positioned to contact the second contact

surface to bias the trigger lock towards the unlocked position.

In embodiments,the biasing member includes a coiled portion and a

flat portion extending from the coiled portion.The flat portion is positioned to

contact the first contact surface to bias the trigger lock towards the locked

position when the trigger lock is disposed in the locked position and to contact

the second contact surface to bias the trigger lock towards the unlocked position

when the trigger lock is disposed in the unlocked position.

In embodiments,the firing assembly includes a firing link coupling

the firing trigger to the handle portion.

In embodiments,a first pivot member pivotably couples the firing

link to the firing trigger.The biasing member is at least partially disposed about

the first pivot member.

In embodiments,the base member of the trigger lock defines a

throughbore configured to receive a second pivot member for pivotably coupling

the trigger lock to the firing trigger.

In embodiments,the surgical stapling apparatus further includes an

anvil assembly configured to form the plurality of surgical staples ejected from

the stapling assembly about tissue,and a drive screw supported within the

handle portion.The drive screw is operably coupled to the anvil assembly and is

movable relative to the stapling assembly to move the anvil assembly relative to

the stapling assembly between a spaced-apart position and an approximated

position

In embodiments,the surgical stapling apparatus further includes an

approximation knob extending from the handle portion.The approximation

knob is coupled to the drive screw and is selectively actuatable to effect linear

movement of the drive screw and to move the anvil assembly between the

spaced-apart position and the approximated position.

In embodiments,the firing trigger includes a lockout member

configured to interface with the drive screw to prevent actuation of the firing

trigger when the anvil assembly is disposed in the spaced-apart position.

In embodiments,the drive screw defines a recess.When the anvil

assembly is disposed in the approximated position,the recess is aligned with the

lockout member to permit actuation of the firing trigger.

Another surgical stapling apparatus provided in accordance with the

present disclosure includes a handle portion defining a proximal end and a distal

end.The handle portion includes at least one support member and first and

second handle sections movably coupled to the at least one support member via

a pin-slot engagement such that the first and second handle sections are

translatable and rotatable relative to each other and the at least one support

member from a closed position,wherein the first and second handle sections are

in close alignment,and an open position,wherein the first and second handle

sections are separated from each other to expose an interior of the handle portion.

A body extends distally from the handle portion and a stapling assembly is

supported on a distal end of the body.The stapling assembly includes a plurality

of surgical staples.

In embodiments,the surgical stapling apparatus further includes a

firing assembly including a firing trigger and a pusher link coupled to the firing

trigger.The pusher link is configured for distal translation through the elongated

body portion in response to actuation of the firing trigger to eject the plurality of

surgical staples from the stapling assembly.

In embodiments,the firing trigger extends from the handle portion

and the first and second handle sections define cut-outs that cooperate to define a

slot when the handle sections are disposed in the closed position to permit

extension of the firing trigger therethrough.

In embodiments,the firing assembly includes a firing link coupling

the firing trigger to the handle portion.A pivot member may be provided for

pivotably coupling the firing link to each of the first and second handle sections.

In embodiments,each of the first and second handle sections

includes a threaded distal extension.A threaded bushing is disposed about the

body and is configured for engagement with the threaded distal extensions of the

first and second handle sections to retain the first and second handle sections in

the closed position and secure the body to the distal end of the handle portion.

In embodiments,the surgical stapling apparatus further includes an

anvil assembly and an approximation assembly operably coupled to the anvil

assembly.At least a portion of the approximation assembly is supported within

the handle portion via the at least one support member.The approximation

assembly is movable relative to the stapling assembly to move the anvil

assembly relative to the stapling assembly between a spaced-apart position and

an approximated position.

In embodiments,the at least one support member includes first and

second support members.The first and second support members support the

portion of the approximation assembly within the handle portion and are spaced-

apart from one another.

In embodiments,the at least one support member is configured to

abut a portion of the approximation assembly when the anvil assembly is

disposed in the approximated position to prevent further axial movement of the

anvil assembly in relation to the stapling assembly to set a minimum tissue gap

between the anvil assembly and the stapling assembly.

In embodiments,the approximation assembly includes an

approximation knob extending proximally from the handle portion.The

approximation knob is selectively rotatable relative to the handle portion to

move the anvil assembly relative to the stapling assembly.Each of the first and

second handle sections includes a threaded proximal extension.A threaded

collar disposed about the approximation knob is configured for engagement with

the threaded proximal extensions of the first and second handle sections to retain

the first and second handle sections in the closed position and rotatably secure

the approximation knob to the proximal end of the handle portion.

Another surgical stapling apparatus provided in accordance with the

present disclosure includes a handle portion defining a proximal end and a distal

end.The handle portion includes at least one support member and first and

second handle sections movably coupled to the at least one support member such

that the first and second handle sections are movable relative to each other and

the at least one support member from a closed position,wherein the first and

second handle sections are in close alignment,and an open position,wherein the

first and second handle sections are separated from each other to expose an

interior of the handle portion.The surgical stapling apparatus further includes a

body extending distally from the handle portion,a stapling assembly supported

on a distal end of the body and including a plurality of surgical staples,an anvil

assembly,and an approximation assembly operably coupled to the anvil

assembly.A portion of the approximation assembly is supported within the

handle portion via the at least one support member.The approximation

assembly is movable relative to the stapling assembly to move the anvil

assembly relative to the stapling assembly between a spaced-apart position and

an approximated position.

In embodiments,the first and second handle sections are movably

coupled to the at least one support member via a pin-slot engagement such that

the first and second handle sections are translatable and rotatable relative to each

other and the at least one support member from the closed position to the open

position.

In embodiments,each of the first and second handle sections

includes a threaded distal extension.A threaded bushing disposed about the

body is configured for engagement with the threaded distal extensions of the

first and second handle sections to retain the first and second handle sections in

the closed position and secure the body to the distal end of the handle portion.

In embodiments,the surgical stapling apparatus further includes a

firing assembly including a firing trigger and a pusher link coupled to the firing

trigger.The pusher link is configured for distal translation through the elongated

body portion in response to actuation of the firing trigger to eject the plurality of

surgical staples from the stapling assembly.

In embodiments,the firing trigger extends from the handle portion

and the first and second handle sections define cut-outs that cooperate to define a

slot when the handle sections are disposed in the closed position to permit

extension of the firing trigger therethrough.

In embodiments,the firing assembly includes a firing link coupling

the firing trigger to the handle portion.A pivot member may be provided for

pivotably coupling the firing link to each of the first and second handle sections.

In embodiments,the at least one support member includes first and

second support members supporting the portion of the approximation assembly

within the handle portion and being spaced-apart from one another.

In embodiments,the at least one support member is configured to

abut a portion of the approximation assembly when the anvil assembly is

disposed in the approximated position to prevent further movement of the anvil

assembly in relation to the stapling assembly to set a minimum tissue gap

between the anvil assembly and the stapling assembly.

In embodiments,the approximation assembly includes an

approximation knob extending proximally from the handle portion.The

approximation knob is selectively rotatable relative to the handle portion to

move the anvil assembly relative to the stapling assembly.Each of the first and

second handle sections includes a threaded proximal extension.A threaded

collar disposed about the approximation knob is configured for engagement with

the threaded proximal extensions of the first and second handle sections to retain

the first and second handle sections in the closed position and rotatably secure

the approximation knob to the proximal end of the handle portion.

BRIEF DESCRIPTION OF THE DRAWINGS

Various embodiments of the presently disclosed surgical stapling

apparatus are described herein with reference to the drawings wherein:

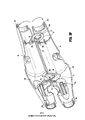

FIG.1is a top,side,perspective view from the distal end of the

presently disclosed surgical stapling apparatus;

FIG.2is a side,perspective view of the handle portion of the

surgical stapling apparatus of FIG.1wherein one of the handle sections has been

removed to shown the internal components of the handle portion;

FIG.3is an exploded,perspective view of the surgical stapling

apparatus of FIG.1;

FIG.3A is a top view of the proximal end of the surgical stapling

apparatus of FIG.1;

FIG.3B is transverse,cross-sectional view taken along section line

3B-3B of FIG.3A;

FIG.3C is transverse,cross-sectional view taken along section line

3C-3C of FIG.3A;

FIG.3D is a side,perspective view of the proximal end of the

surgical stapling apparatus of FIG.1illustrating disengagement of the bushing

and the collar from the handle portion;

FIG.3E is an enlarged,cross-sectional view of the proximal end of

the surgical stapling apparatus of FIG.1illustrating the initial separation of the

handle sections of the handle portion from a closed position towards an open

position;

FIG.3F is an enlarged,perspective view of the handle portion of the

surgical stapling apparatus of FIG.1with the handle sections of the handle

portion disposed in an open position;

FIG.4is an enlarged view of the area of detail indicated as“4”in

FIG.1;

FIG.5is an exploded,perspective view of the approximation

assembly of the surgical stapling apparatus of FIG.1;

FIG.5A is a side perspective view of an embodiment of the set

screw of the tissue gap adjustment mechanism;

FIG.6is a side,perspective view of the proximal end of the handle

portion of the surgical stapling apparatus of FIG.1with the handle sections

removed and the proximal portions of the firing assembly and approximation

assembly illustrated;

FIG.7is an enlarged view of the area of detail indicated as“7”in

FIG.6;

FIG.8is a side,perspective view of the approximation assembly of

the surgical stapling apparatus of FIG.1;

FIG.9is an enlarged view if the area of detail indicated as“9”in

FIG.8;

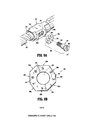

FIG.9A is an exploded,perspective view of the tissue gap

adjustment mechanism of the surgical stapling apparatus of FIG.1;

FIG.9B is an enlarged,top view of the adjustment washer of the

tissue gap adjustment mechanism of FIG.9A;

FIG.10is a perspective view of the staple pusher assembly of the

surgical stapling apparatus of FIG.1;

FIG.11is an exploded,perspective view of the staple pusher

assembly of FIG.10;

FIG.1lA is an enlarged,cross-sectional view of the proximal end of

the firing assembly with the trigger lock disposed in a locked position;

FIG.1lB is an enlarged,cross-sectional view of the proximal end of

the firing assembly with the trigger lock disposed in an unlocked position;

FIG.12is a side,perspective view from the distal end of the

elongated body portion of the surgical stapling apparatus of FIG.1;

FIG.13is an enlarged,perspective view of the proximal end of the

elongated body portion of FIG.12;

FIG.14is a perspective view from the distal end of the distal

bushing of the elongated body portion of FIG.12;

FIG.15is an exploded,perspective view of the elongated body

portion of FIG.12;

FIG.16is a perspective view from the proximal end of the proximal

bushing of the elongated body portion of FIG.12;

FIG.17is a perspective view of the distal end of the surgical

stapling apparatus of FIG.1including a safety cap disposed about the distal end

of the replaceable stapling assembly of the surgical stapling apparatus of FIG.1;

FIG.18is a perspective of the distal end of the surgical stapling

apparatus of FIG.1including the safety cap removed from the distal end of the

replaceable stapling assembly;

FIG.19is a perspective view from the proximal end of the

replaceable stapling assembly of the surgical stapling apparatus of FIG.1;

FIG.20is a perspective view from the distal end of the replaceable

stapling assembly of the surgical stapling apparatus of FIG.1;

FIG.21is an exploded,perspective view of the replaceable stapling

assembly of FIGS.19and20;

FIG.22is a longitudinal,cross-sectional view taken along section

line22-22of FIG.1;

FIG.23is an enlarged view of the area of detail indicated as“23”in

FIG.22;and

FIG.24is an enlarged view of the area of detail indicated as“24”in

FIG.22.

DETAILED DESCRIPTION OF EMBODIMENTS

Embodiments of the presently disclosed surgical stapling apparatus

will now be described in detail with reference to the drawings in which like

reference numerals designate identical or corresponding elements in each of the

several views.Throughout this description,the term″proximal″will refer to the

portion of the apparatus closest to the user and the term″distal″will refer to the

portion of the apparatus farthest from the user.

FIGS.1-24illustrate an embodiment of the presently disclosed

surgical stapling apparatus designated generally by reference numeral10.

Surgical stapling apparatus10includes a proximal handle portion20,an

elongated central body portion30,and a distal head portion40.Alternatively,it

may be desirable to have a substantially straight,shortened central body portion

in some surgical procedures,e.g.,the treatment of hemorrhoids.The length,

shape and/or the diameter of any of the proximal handle portion20,the central

body portion30,and the distal head portion40may also be selected to suit a

particular surgical purpose or procedure.Surgical stapling apparatus10further

includes an anvil assembly400coupled at the distal end of distal head portion

40.Anvil assembly400includes an anvil head assembly410and an anvil center

rod assembly420.Although not described in detail herein,anvil assembly400

may be configured to include any or all of the features of the anvil assemblies

described in the Milliman'187patent or the Gresham'444patent,previously

incorporated by reference herein in their entireties.

The various components of surgical stapling apparatus10described

hereinbelow are configured to facilitate the assembly and disassembly of

surgical stapling apparatus10,thus facilitating the disposal and replacement of

those components that are disposable and the sterilization and reassembly of

those components that are reusable.The materials used to form the various

components of surgical stapling apparatus10will depend upon the strength

requirements of the particular component and the use requirements of the

particular component,e.g.,whether the component is reusable or disposable.

The reusable components,for example,may generally be formed from

thermoplastics including polycarbonates,and metals including stainless steel and

aluminum,that are suited to withstand repeated sterilization procedures,e.g.,

autoclaving.

Referring to FIGS.1-3,proximal handle portion20of surgical

stapling apparatus10includes a stationary handle22,a firing trigger24,and a

rotatable approximation knob26.Stationary handle22is formed from first and

second releasably engagable handle sections22a,22b(FIG.3)that cooperate to

house and support the internal components of handle portion20,e.g.,the

proximal components of an approximation assembly200(FIG.3)and a firing

assembly300(FIG.3).Proximal handle portion20and the internal components

thereof will be described in greater detail below.

As mentioned above,stationary handle22is formed from first and

second handle sections22a,22b that cooperate to house and support the internal

components of handle portion20.Alternatively,stationary handle22may be

unitarily formed or formed from multiple handle sections.Handle sections22a,

22b can be configured as reusable,sterilizable components,or,alternatively,can

be configured as disposable components.

Referring specifically to FIG.3,each handle section22a,22b

includes a threaded distal extension22c,22d.Distal extensions22c,22d

cooperate to define a generally annular threaded member for releasably engaging

proximal bushing34of central body portion30.Engagement between distal

extensions22c,22d and proximal bushing34releasably secures outer tube32

and handle portion20to one another and also secures handle sections22a,22b

to one another at the distal ends thereof.As an alternative to threaded

engagement,proximal bushing34may be releasably engaged about distal

extensions22c,22d of handle sections22a,22b via any other suitable

mechanism including friction-fitting,snap-fitting,luer-locking,inter-fitting,etc.

Handle sections22a,22b further include threaded proximal extensions22e,22f,

respectively,that cooperate to define a generally annular threaded member for

releasably engaging collar27of approximation knob26.Similarly as above,

engagement between proximal extensions22e,22f and collar27rotatably

secures approximation knob26and handle portion20to one another and also

secures handle sections22a,22b to one another at the proximal ends thereof.

Collar27is rotatably secured to approximation knob26.Alternatively,collar27

can be formed separately from approximation knob26.

Referring also to FIGS.3A-3C,handle sections22a,22b are

pivotably coupled to one another via a pair of support members,e.g.,support

discs50,51,and a plurality of pin-slots engagements.Support discs50,51each

define an upper engagement portion52,53and a lower generally annular portion

54,55defining a respective aperture54a,55a.Upper engagement portions52,

53of support discs50,51are disposed within respective slots23a,23b(FIG.3A)

defined by cooperating slot portions of handle sections22a,22b.A pair of pins

56a,57a extend through respective apertures defined within handle sections22a,

22b on opposite sides of each of slots23a,23b and through slots56,57defined

through upper engagement portions52,53of support discs50,51to pivotally

secure handle sections22a,22b to support discs50,51and to one another.Slots

56,57are dimensioned to permit lateral translation of pins56a,57a along slots

56,57and relative to one another as well as rotation of pins56a,57a within slots

56,57.Apertures54a,55a defined by the lower portions54,55of support discs

50,51,respectively,are configured to receive rotatable sleeve210and indicator

bar270of approximation assembly200.The lower portions54,55of support

discs50,51are configured to position and support approximation assembly200

within stationary handle22.As will be described in detail below with respect to

the disassembly of stationary handle22,the slot-pin engagement of handle

sections22a,22b and support discs50,51allows for translational and rotational

movement of handle sections22a,22b relative to one another between a closed

position(FIG.3A),wherein stationary handle22encloses the proximal

components of approximation assembly200and firing assembly300,and an

open position(FIG.3F),wherein access to approximation assembly200and

firing assembly300is provided to facilitate replacement of any or all of such

components.

Referring to FIGS.4and5,stationary handle22defines an indicator

window25through which visual indicators276,278disposed on indicator bar

270may be viewed.Indicator window25may be formed via a hole or aperture

defined by one or both of handle sections22a,22b.Alternatively,indicator

window25may be formed from a transparent portion of one or both of handle

sections22a,22b.Visual indicators276,278are longitudinally-spaced along

indicator bar270and,when visible through indicator window25,indicate the

position of anvil assembly400(FIG.1)in relation to stapling assembly100,e.g.,

whether the anvil assembly400(FIG.1)is in a position spaced-apart from

stapling assembly100(visual indicator276)or an approximated position in

juxtaposed alignment with stapling assembly100(visual indicator278).

Approximation assembly200is detailed below.

Referring to FIGS.5-9,approximation assembly200of surgical

stapling apparatus10(FIG.1)includes an approximation knob26,a collar27,a

rotatable sleeve210,a drive screw220,a screw extension230,an anvil retainer

240,a screw stop250,and a tissue gap adjustment mechanism260.

Rotatable sleeve210includes a substantially cylindrical hollow

body portion211and a distal housing212that cooperate to define a central bore

213.A clip214is received within an annular groove214a formed about body

portion211.Support disc50,as mentioned above,is configured to receive body

portion211through aperture54a thereof.Clip214and distal housing212abut

support disc50on either side thereof to axially fix sleeve210and stationary

handle22relative to one another while permitting rotation of sleeve210in

relation to stationary handle22.

With particular reference to FIG.5,rotatable sleeve210further

includes a ball detent assembly215having a plug216and a detent member.In

an embodiment,the detent member includes a ball218.Ball218extends into

central bore213of rotatable sleeve210from a recess217of distal housing212

and is received in a helical channel221of drive screw220.Plug216includes a

body216a configured for receipt within recess217and defines a semi-spherical

concavity(not explicitly shown)for receiving a side of ball218opposite screw

220,and a head216b configured for engagement with distal housing212,e.g.,

via threaded-engagement,friction-fitting,etc.Once engaged with distal housing

212,plug216inhibits ball218from backing out of helical channel221of screw

220.In embodiments,the recess217can be defined only as a spherical recess

(not shown)on an inner wall of the distal housing212which is configured to

receive ball218.In this embodiment,the plug216is not required.

A proximal end of body portion211of rotatable sleeve210extends

through an opening21in a proximal end of stationary handle22.

Approximation knob26is affixed to the proximal end of body portion211of

rotatable sleeve210such that rotation of knob26causes concurrent rotation of

rotatable sleeve210.Approximation knob26may be releasably or permanently

affixed to rotatable sleeve210,e.g.,via snap-fitting,friction-fitting,an adhesive,

welding,and/or mechanical fasteners.Approximation knob26and/or the

proximal end of body portion211of rotatable sleeve210may include one or

more complementary protrusions and/or slots(not explicitly shown)to rotatably

fix approximation knob26relative to sleeve210.

Referring again to FIGS.5-9,a proximal portion220a of screw220

includes helical channel221and is dimensioned to be slidably positioned within

central bore213(FIG.5)of rotatable sleeve210.As mentioned above,ball218

(FIG.5)of ball detent mechanism215extends into helical channel221of screw

220.Since sleeve210is axially fixed with respect to stationary handle22,

rotation of sleeve210about screw220causes ball218(FIG.5)to move along

channel221of screw220to effect axial movement of screw220within

stationary handle22.Although shown having helical channel221configured to

receive ball218(FIG.5),it is envisioned that screw220may alternatively

include a helical thread(not shown)on an outer surface thereof configured to be

received within a channel or groove(not shown)formed on an inner surface of

sleeve210.Further,as an alternative to ball detent assembly215,approximation

assembly200may include a pin or other suitable mechanism for operably

coupling rotatable sleeve210and screw220to one another.

Distal portion220b of screw220defines a transverse slot227a and a

pair of throughbores227b formed perpendicular to transverse slot227a.

Transverse slot227a is configured to receive a proximal end of screw extension

230and throughbores227b are configured to receive pins226for securing

screw extension230to screw220.

Indicator bar270is positioned between proximal portion220a and

distal portion220b of screw220.Indicator bar270is seated within a

longitudinal recess272defined along screw220and may be secured therein in

any suitable manner,e.g.,via snap-fitting,friction-fitting,an adhesive,welding,

and/or mechanical fasteners.As detailed above,indicator bar270includes first

and second indicators276,278configured to be viewed through indicator

window25(FIG.4)to provide an indication that the anvil assembly400(FIG.1)

is in the spaced-apart position or the approximated position,respectively.

Indicators276,278may be of any suitable color(s),symbol(s)or may include

any other suitable feature,e.g.,reflective features,a light source(LED),etc.,to

facilitate the visualization of visual indicators276,278through window25(FIG.

4).Other suitable indicator mechanisms are disclosed in the Milliman'187

patent and the Gresham'444patent,previously incorporated by reference herein

in their entirety.

With continued reference to FIGS.5-9,screw extension230

includes a flexible flat band having proximal and distal portions232,234.

Although shown including only a single flexible flat band,it is envisioned that

screw extension230may include more than one flexible flat band.Alternately,

it is envisioned that screw extension230may have other than a flexible flat band

configuration.For example,screw extension230may be semi-circular or

circular in cross-section.The flexibility of screw extension230permits

movement of screw extension230through curved elongated outer tube32(FIG.

3).Proximal portion232of screw extension230includes a pair of holes233

dimensioned to receive pins226for securing proximal portion232of screw

extension230within transverse slot227a of screw220.Alternatively,other

fastening techniques may be used to secure screw extension230to screw220,

e.g.,welding,crimping,etc.Distal portion234of screw extension230is

configured to be received within a transverse slot241a formed in a proximal end

242of anvil retainer240to fasten anvil retainer240to distal end234of screw

extension230.In the illustrated embodiment,a pair of pins244extend through

a pair of openings241b defined in proximal end242of anvil retainer240and

holes235in distal portion234of screw extension230to secure screw extension

230to anvil retainer240.Alternately,distal portion234of screw extension230

may be secured within slot241a using any other fastening technique,e.g.,

screws,crimping,brazing,welding or the like,suitable for securing distal

portion234of screw extension230to anvil retainer240.

Anvil retainer240includes a trocar portion245a,a body portion

245b,and an attachment portion245c.Trocar portion245a includes a blunt

trocar tip247,although other configurations are also contemplated.Body

portion245b is substantially cylindrical and has a diameter which is larger than

the diameter of trocar portion245a.An annular protrusion248is disposed about

body portion245b of anvil retainer240and is configured to engage anvil

assembly400(FIG.1)to retain anvil assembly400(FIG.1)about anvil retainer

240.Alternatively,protrusion248need not be annular or may include different

attachment structure,e.g.,recesses,grooves,etc.

In use,when approximation knob26is manually rotated,rotatable

sleeve210is likewise rotated about the proximal portion220a of screw220.

Since sleeve210is axially fixed with respect to stationary handle22,and with

ball218(FIG.5)disposed within helical channel221of screw220,axial

rotation of sleeve210about screw220causes ball218to move along channel

221of screw220to thereby urge screw220to translate axially within stationary

handle22and relative to sleeve210.Upon axial translation of screw220,screw

extension230,which is fastened to the distal end of screw220,and anvil

retainer240,which is fastened to the distal end of screw extension230,are

moved axially through outer tube32of elongated body portion30.Thus,

referring particularly to FIG.1,with anvil assembly400releasably engaged

about the distal end of anvil retainer240,knob26may be rotated to effect

movement of anvil assembly400relative to stapling assembly100between an

unapproximated position spaced-apart from stapling assembly100and an

approximated position positioned adjacent to stapling assembly100.

With additional reference to FIGS.9A-9B,approximation assembly

200further includes a screw stop250disposed about screw220and configured

to function as a proximal stop for defining the minimum tissue gap between

anvil assembly400and stapling assembly100(see FIG.1).More specifically,

when stapling device10is in a fully approximated position,screw stop250

abuts at stop surface formed at the distal end of distal housing212of rotatable

sleeve210,inhibiting further proximal translation of screw220within stationary

handle22,thereby defining the minimum tissue gap between anvil assembly400

and stapling assembly100(see FIG.1).Tissue gap adjustment mechanism260

adjustably couples screw stop250to screw200to facilitate adjustment of the

minimum tissue gap by adjusting the longitudinal position of screw stop250on

screw220.Tissue gap adjustment mechanism260is described in detail below.

Tissue gap adjustment mechanism260,as mentioned above,is

configured to selectively adjust the longitudinal position of screw stop250on

screw220,thereby enabling discrete adjustment of the minimum tissue gap

between anvil assembly400and stapling assembly100(see FIG.1).In

particular,tissue gap adjustment mechanism260may be configured to permit

adjustment of the minimum tissue gap through a plurality of pre-determined

interval steps,e.g.,a step size of about0.15mm,between about4.55mm and

about5.45mm,although a greater or lesser range and/or greater or lesser interval

step sizes are also contemplated,depending on a particular surgical purpose.

Any suitable number of intervals and/or varying step sizes may also be provided.

As best shown in FIG.9A,tissue gap adjustment mechanism260

includes a set screw262and an asymmetrical polygonal washer264,e.g.,an

asymmetrical octagonal washer(although other configurations are also

contemplated).Screw stop250includes a housing252that defines a central

bore253configured to receive screw220,and a transverse slot254configured

to receive set screw262.First and second spaced-apart flanges255a,255b

extend transversely from housing252on either side of transverse slot254for

retaining asymmetrical washer264therebetween.Screw220includes a

threaded aperture228(FIG.5)configured to receive threaded shaft265of set

screw262to retain screw stop250in a fixed position about screw220.Head

266of set screw262includes a slot267configured to receive a screw driver

(not shown)or other suitable tool for driving set screw262into or out of

threaded aperture228.As opposed to a slot267,other suitable tool-engaging

features,e.g.,recesses and/or protrusions,are also contemplated.For example,

as shown in FIG.5A,the set screw262includes a polygonal head,e.g.,a

pentagonal head,configured to be engaged by a ratchet or wrench.Further,as

opposed to set screw262received within threaded aperture228(FIG.5)of

screw220,screw220may include a post(not shown)or other suitable feature

supported thereon for receipt within and longitudinal positioning relative to

transverse slot254of stop member250.

Referring to FIGS.9A-9B,asymmetrical washer264defines an

aperture268and includes a plurality of outer peripheral flats or sides269a-269h,

e.g.,eight sides,although greater or fewer sides are also contemplated.Due to

the asymmetrical configuration of washer264,the position of set screw262

within transverse slot254of screw stop250is varied depending on which

opposed sides269a-269h of washer264are positioned between flanges255a,

255b.With threaded aperture228of screw220receiving threaded shaft265of

set screw262,varying the position of set screw262within transverse slot254

likewise varies the longitudinal position of screw stop250relative to screw220,

thereby varying the size of the minimum tissue gap.For example,as the screw

stop250is moved proximally on the screw220,the minimum tissue gap is

increased because the screw stop250will engage sooner.Sides269a-269h may

include indicators256and flange255a may also include an indicator258to

allow the user to readily ascertain the setting of tissue gap adjustment

mechanism260.The minimum tissue gap corresponding to each setting of an

exemplary configuration of asymmetrical washer264is provided in the

following table,although other configurations are also contemplated.

With general reference to FIGS.5-9B,in order to adjust the

minimum tissue gap,stationary handle22(FIG.1)is disassembled(or prior to

assembly),set screw262is loosened,and asymmetrical washer264is rotated

about set screw262and relative to screw stop250to the desired position.Once

the desired position is achieved,set screw262may be re-tightened to maintain

screw stop250in the desired position on screw220,thus defining the desired

minimum tissue gap.As an alternative to disassembling stationary handle22

(FIG.1),a hole or opening may be provided in stationary handle22(FIG.1)to

provide direct access to tissue gap adjustment mechanism260without the need

to disassemble stationary handle22(FIG.1).Alternatively,the tissue gap

adjustment mechanism260can be preset to one of the predefined settings by the

manufacturer.

Firing assembly300will now be described with reference to FIGS.

10and11.Firing assembly300includes trigger24,a firing link310,and a

pusher linkage320.Pusher linkage320includes an elongated pusher tube330,

a pusher link340,and a pusher end tube350.Pusher linkage320is configured

for transferring force from proximal handle portion20(FIG.1)to distal head

portion40(FIG.1)to fire stapling assembly100(FIG.1).Although shown as a

three-part assembly,it is envisioned that pusher linkage320may include one or

more additional sections.Optionally,firing assembly300includes a trigger lock

360,which will be described in further detail below.

Trigger24is configured for operable engagement by a user.Trigger

24may support a cushioned gripping surface(not shown)formed of neoprene,

rubber or the like.The cushioned gripping surface provides a non-slip

cushioned surface to make actuation of stapling apparatus10(FIG.1)more

comfortable to a surgeon.Alternatively,trigger24may be formed of perforated

stainless-steel or other metal to facilitate sterilization.The distal end of trigger

24includes a pair of flanges304a,304b each defining an opening305a,305b,

respectively.Flanges304a,304b are configured for pivotal connection with a

pair of flanges324formed on proximal end330a of elongated pusher tube330

of pusher linkage320by a pivot member308a.Alternatively,pusher linkage

320may include a coupling member(not shown)integrally formed with or

fixedly secured to proximal end330a of pusher tube330for pivotally

connecting trigger24with pusher linkage320.

Trigger24further includes a lockout feature,e.g.,protrusion306,

extending from a distal end of trigger24adjacent flanges304a,304b.

Protrusion306is configured to engage the distal end of screw220(FIG.5)of

approximation assembly200(FIG.5)when approximation assembly200(FIG.

5)is in an unapproximated position to prevent accidental actuation of trigger24

before the anvil assembly(FIG.1)has been moved to the approximated position.

When approximation assembly200(FIG.5)is in the approximated position,

recess225(FIG.5)formed in the distal end of screw220(FIG.5)is in

alignment with protrusion306,thereby permitting actuation of trigger24,i.e.,

pivotal movement of trigger24about pivot member308a towards stationary

handle22.A biasing member(not shown)may also be provided for biasing

trigger24towards an unactuated position and for returning trigger24to the

unactuated position after firing.

Referring still to FIGS.10and11,trigger24further includes a first

opening30la,a second opening30lb,a notch301c,and an indicator member

309.First opening30la in trigger24is configured to receive a pin308b for

pivotally connecting trigger24with firing link310.Second opening30lb in

trigger24is configured to receive a pin308c for pivotally connecting trigger24

with trigger lock360.Notch301c is configured to releasably retain protrusion

362of trigger lock360therein to retain trigger lock360in an unlocked position.

Indicator member309is fixedly retained within a third opening308d and is

configured to engage an indicator member318of firing link310to provide an

audible and/or tactile indication to a user as stapling apparatus10(FIG.1)is

fired.

Firing link310includes a distal end312pivotally secured to trigger

24by a pivot member308b received through opening30la.A proximal end314

of firing link310supports a pivot member316which is pivotally secured within

a slot31(FIG.3)formed on each internal wall of handle sections22a,22b(FIG.

3).Alternatively,the pivot member316can be formed integrally with the firing

link310.Pivot member316is free to move vertically within slots31(FIG.3).

Although not shown,it is contemplated that a spring may be supported within

handle sections22a,22b(FIG.3)to urge pivot member316towards the bottom

of slot31(FIG.3),as provided in the Milliman'187patent,the contents of

which was previously incorporated by reference.Indicator member318is

formed on distal end312of firing link310and is configured to engage indicator

member309formed on trigger24during firing of stapling apparatus10(FIG.1),

as mentioned above.

As noted above,pusher linkage320includes an elongated pusher

tube330,a pusher link340and a pusher end tube350.A spring335received

about proximal end330a of elongated pusher tube330is configured to bias

pusher linkage320proximally to a retracted position.Spring335is retained

about proximal end330a of elongated pusher tube330via a ring member332

and a clip333,although other configurations for retaining spring225about

proximal end330a of elongated pusher tube330are also contemplated.Ring

member332is positionable distally of spring335and includes a pair of opposed,

inwardly-extending protrusions332a configured for slidable receipt within

elongated recesses332b defined on opposed sides of pusher linkage320.Clip

333is configured for engagement about proximal end330a of elongated pusher

tube330proximally of spring335.The ring member332sbuts an inner wall of

a distal end of stationary handle22(FIG.2)such that spring335urges clip333

and pushes linkage320proximally.

Distal end330b of pusher tube330includes a pair of flanges336a,

336b each defining an opening337a,337b,respectively.Each of openings337a,

337b is configured to receive a pivot pin338a,338b,respectively,to pivotally

secure a proximal end340a of pusher link340with distal end330b of elongated

pusher tube330.Pusher link340includes an elongated member defining a

channel341(FIG.22)extending substantially the length thereof.As shown,

pusher link340may be slightly curved along the length thereof.Channel341

(FIG.22)is configured to receive screw extension230of approximation

assembly200therethrough(FIG.5).Proximal end340a of pusher link340

includes a first pair of flanges342a,342b each defining an opening343a,(not

shown)sized to receive respective pivot pin338a,338b for pivotally connecting

pusher link340and elongated pusher tube330.A distal end340b of pusher link

340includes a second pair of flanges344a,344b,each defining an opening345a,

345b sized to receive a pivot pin348a,348b,respectively,for pivotally

connecting pusher link340and pusher end tube350.

A proximal end350a of pusher tube350includes a pair of flanges

352a,352b each defining an opening353a,353b configured for receiving

respective pivot pins348a,348b for pivotally connecting pusher tube350with

pusher link340.A distal end350b of pusher end tube350is configured to

selectively engage the stapling assembly100(FIG.1),as will be detailed below.

With reference to FIGS.l lA and l lB,as noted above,firing

assembly300may optionally include trigger lock360.Trigger lock360

includes a body360a and a base361defining a throughbore for receiving a pin

308c.Pin308c is received within the throughbore of base361to pivotably

couple trigger lock360to trigger24.Base361defines a radially asymmetric

configuration,e.g.,a tear-drop cross-sectional configuration,forming a pair of

contact surfaces361a,361b on either side of the throughbore that receives pin

308c.Trigger lock360further includes a protrusion362extending from body

360a of trigger lock360.Trigger lock360is rotatable relative to trigger24

between an unlocked position,wherein protrusion362is received within notch

301c(FIG.11)of trigger24,and a locked position,wherein protrusion362is

received within cut-out363(FIG.11)of trigger24and free end364of body

360a of trigger lock360is disposed in close approximation or abutting relation

with firing link310to inhibit actuation of trigger24.

A biasing member307,e.g.,a torsion spring,is disposed about pivot

member308b,which,as mentioned above,is received through opening30la of

trigger24and distal end312of firing link310to pivotally secured firing link

310to trigger24.Biasing member307includes a coiled portion307a and a flat

portion307b.Coiled portion307a is disposed about pivot member308b,while

flat portion307b extends proximally from coiled portion307a along trigger24.

Coiled portion307a biases flat portion307b towards trigger24.More

specifically,in the locked position of trigger lock360,as shown in FIG.1lA,

flat portion307b of biasing member307is biased into contact with contact

surface361a of base361of trigger lock360to urge trigger lock360in a

counter-clockwise direction as viewed in FIG.1lA.In this position,biasing

member307maintains trigger lock360in the locked position and inhibits

accidental dislodgment of trigger lock360from the locked position.In the

unlocked position of trigger lock360,as shown in FIG.1lB,flat portion307b of

biasing member307is biased into contact with contact surface361b of base361

of trigger lock360to urge trigger lock360in a clockwise direction as viewed in

FIG.1lB.In this position,biasing member307maintains trigger lock360in the

unlocked position and inhibits accidental dislodgment of trigger lock360from

the unlocked position.Thus,biasing member307establishes a bistable

configuration of trigger lock360,e.g.,wherein trigger lock360is stable in both

the locked position and the unlocked position.

Other suitable trigger locks are described in U.S.Patent7,303,106to

Milliman et al.,hereby incorporated by reference here,and the Milliman'187

patent and the Gresham'444patent,previously incorporated by reference herein.

Firing assembly300may further include a feedback mechanism similar to that

disclosed in the Milliman'187patent,previously incorporated by reference

herein.

With reference to FIGS.12-16,elongated central body portion30of

surgical stapling apparatus10(FIG.1)includes a curved elongated outer tube32,

a proximal bushing34(FIG.16),and a distal bushing36(FIG.14).Outer tube

32is configured to slidably receive components of approximation assembly200

(FIG.3)and firing assembly300(FIG.3).Proximal bushing34is rotatably

coupled about outer tube32via a ring37and is configured to enable releasable

threaded engagement of the proximal end of outer tube32with stationary handle

22of handle portion20(FIG.6).Distal bushing36,is engaged about the distal

end of outer tube32,e.g.,via friction-fitting,snap-fitting,adhesion,or other

suitable engagement,and is configured to enable releasable engagement of

replaceable stapling assembly100(FIG.3)with the distal end of outer tube32.

Referring to FIGS.17-21,distal head portion40of surgical stapling

apparatus10(FIG.1)includes anvil assembly400(FIG.1),described above,

that is releasably engagable with the distal end of approximation assembly200

(FIG.3),and a replaceable stapling assembly100that is releasably engagable

with the distal end of elongated central body portion30(FIG.3).A safety cap

500(FIGS.17-18)is also provided for engagement about the distal end of

replaceable stapling assembly100when not in use,e.g.,during shipping and

storage.Replaceable stapling assembly100(or portions thereof)is configured

as a disposable component that is to be replaced with a new replaceable stapling

assembly100(or portions thereof)after each firing.The remaining components

of surgical stapling apparatus t0(FIG.t)are configured as reusable,sterilizable

components,although one or more of these components may alternatively be

configured as a disposable component.Other configurations are also

contemplated.Distal head portion40will be described in greater detail below.

Replaceable stapling assembly t00will now be described in detail

with respect to FIGS.17-21.Referring initially to FIGS.17-18,and as

mentioned above,a safety cap500is provided for engagement about the distal

end of replaceable stapling assembly t00when not in use,e.g.,during shipping

and storage.Safety cap500includes a disc member510configured for

positioning about the distal end of stapling assembly t00,a pair of outer arms

520,530extending proximally from disc member5t0,and a pair of inner posts

540,550extending proximally from disc member5t0.Each outer arm520,530

includes an inwardly-extending protrusion522,532disposed at its free end.

Protrusions522,532are configured for receipt within apertures524defined

within outer housing portion104of shell assembly102of stapling assembly t00

to retain safety cap500about the distal end of stapling assembly t00.Arms520,

530may be formed from a resiliently flexible material so as to bias protrusions

522,532into apertures524,although other engagement mechanisms for

releasably retaining safety cap500about the distal end of stapling assembly t00

are also contemplated.Inner posts540,550are configured for insertion into

stapling assembly t00to help retain safety cap500in position about the distal

end of stapling assembly t00and to inhibit distal movement of pusher back t t0

(FIG.21)as will be described below to prevent the inadvertent ejection of

staples“S”(FIG.21)from stapling assembly t00during shipping or the like.

Referring to FIGS.19-21,replaceable stapling assembly t00

includes a shell assembly102,a pusher back t t0,a cylindrical knife120,and a

staple guide cap130.Shell assembly102includes an outer housing portion104

and an inner guide portion106.Outer housing portion104defines a

throughbore105and includes a distal cylindrical section104a,a central conical

section104b,and a proximal cylindrical section104c.Distal cylindrical section

104a includes a slot105a and a plurality of recesses105b.Slot105a is

configured to receive a protrusion132formed on staple guide cap130to

properly align staple guide cap130with pusher back110.Recesses105b are

configured for engagement with tabs134formed on staple guide130for

securing staple guide cap130to staple back110.

Proximal cylindrical section104c of outer housing portion104of

shell assembly102includes a pair of tabs108formed an inner surface thereof.

Tabs108are configured to selectively engage threads38(FIGS.15-16)formed

on the inner surface of distal bushing36(FIGS.15-16)to releasably theradably

engage shell assembly102and outer tube32(FIG.15)with one another.In this

manner,shell assembly102of stapling assembly100may be removed from

stapling apparatus10(FIG.1)subsequent to use and stapling apparatus10(FIG.

1)may be reloaded with another stapling assembly100and reused.

Pusher back110includes a central throughbore111which is

slidably positioned about inner guide portion106of shell102.Pusher back110

includes a distal cylindrical section110a which is slidably positioned within

distal cylindrical section104c of outer housing portion104,a central conical

section110b,and a proximal smaller diameter cylindrical section110c.Pusher

back110further includes a pair of proximally-extending arm members125.

Arm members125each include a finger127that is configured for insertion into

and locking engagement within annular recess128a of collar128disposed at

distal end350b of pusher end tube350of pusher link320(see FIG.11).Thus,

with pusher link320(FIG.11)engaged with pusher back110,actuation of firing

trigger24(FIG.11)urges pusher back l l0distally through outer housing

portion104to eject staples“S”from stapling assembly l00.

With particular reference to FIG.21,distal cylindrical section1l0a

of pusher back l l0includes a plurality of distally extending fingers114

dimensioned to be slidably received within slots131formed in staple guide cap

130to eject staples“S”therefrom.Distal ends l14a of fingers114define a

groove for engaging staples“S.”Cylindrical knife120is retained within central

throughbore111of pusher back1l0by a pair of tabs121.Alternately,knife

120may be retained within pusher back1l0using adhesives,crimping,pins,etc.

A distal end of knife120includes a circular cutting edge122.A rigid bushing

140is supported in the proximal end of inner guide portion106of shell102.

Bushing140defines a throughbore dimensioned to slidably receive anvil

retainer240(FIG.5)and center rod assembly420of anvil assembly400(FIG.

1).

In operation,when pusher linkage320(FIG.l0)is advanced distally

in response to actuation of trigger24(FIG.l0),pusher back1l0is advanced

distally within outer housing portion104of shell assembly102.Advancement

of pusher back110advances fingers114through slots131of staple guide cap

130to advance staples“S”positioned within slots131and eject staples“S”from

staple guide cap130into staple deforming pockets(not shown)formed on an

opposed surface of anvil head assembly410of anvil assembly400(FIG.1).

Since knife120is secured to pusher back l l0,knife120is also advanced

distally to core tissue.

The use of surgical stapling apparatus l0,disassembly of surgical

stapling apparatus l0for sterilization of the reusable components and

replacement of the disposable components,and reassembly of surgical stapling

apparatus10for subsequent use is now described.Adjustment of tissue gap

adjustment mechanism260(FIG.9A)is also described and may be effected

during manufacturing,assembly,between uses,or at any other suitable point

where setting and/or changing the minimum tissue gap is desired.

With general reference to FIGS.1and22,in use,safety cap500

(FIGS.17-18)is initially removed from the distal end of stapling assembly100.

Next,distal head portion40of surgical stapling apparatus10inserted into an

internal surgical site,before or after engagement of distal head portion40with

the anvil assembly400.Next,anvil assembly400and stapling assembly100are

positioned adjacent tissue to be stapled.At this point,anvil assembly400is in

an unapproximated position and screw220of approximation assembly200

(FIGS.5-9)is in its distal-most position.This position of anvil assembly400

may be visually confirmed by viewing indicator276of indicator bar270(FIG.3)

through window25(FIG.4)formed in stationary handle22.As shown in FIG.

2,trigger lock360is disposed in the locked position at this point such that

actuation of firing trigger24is inhibited.Trigger24is further prevented from

being actuated by engagement of protrusion306(FIGS.10-11)of trigger24

with screw220(FIGS.5-9),as detailed above.

Once distal head portion40of surgical stapling apparatus10is

positioned as desired,anvil assembly400may be approximated relative to

stapling assembly100to clamp tissue therebetween via manipulating

approximation knob26.Tissue can be secured between anvil assembly400and

stapling assembly100using conventional techniques such as using purse-string

sutures,resilient bands,or the like.Knob26may be rotated to approximate

anvil assembly400relative to stapling assembly100to clamp tissue

therebetween until the minimum tissue gap between anvil assembly400and

stapling assembly100,which is set via tissue gap adjustment mechanism260

(FIG.9A),is achieved.Movement of the anvil assembly400to the

approximated position can be visually confirmed once visual indicator278(FIG.

3)is viewable through window25(FIG.4).

With anvil assembly400disposed in the approximated position and

tissue clamped between anvil head410and staple guide cap130of stapling

assembly100,firing assembly300(FIGS.10-11)may be actuated to staple and

core the clamped tissue.In order to allow for firing,trigger lock360is rotated

from the locked position to the unlocked position.In the approximated position

of anvil assembly400,recess225formed in screw220of approximation

assembly200(see FIGS.5-9)is aligned with protrusion306(FIGS.10-11)

formed on trigger24to permit actuation of trigger24,provided trigger lock260

is disposed in the unlocked position.

With trigger lock360and protrusion306(FIGS.10-11)no longer

inhibiting actuation of trigger24,surgical stapling apparatus10may be actuated.

In order to fire stapling apparatus10,trigger24is compressed towards

stationary handle22,which urges pusher link assembly320(FIGS.10-11)

distally through outer tube32to urge pusher back110(FIG.21).With

additional reference to FIG.21,distal translation of pusher back110relative to

staple guide cap130urges pusher back110to engage and eject staples“S”from

staple guide cap130,through tissue,and into anvil head410of anvil assembly

400,which form staples“S”about tissue.Knife120is moved concurrently with

pusher back110such that knife120is likewise advanced distally to core tissue.

Continuing with general reference to FIGS.1and22,in one

exemplary method of use,surgical stapling apparatus10is used to perform a

circular anastomosis.Typically,circular anastomoses are required during

procedures for removing a portion of a diseased vessel such as the colon or the

intestine.During such a procedure,the diseased portion of the vessel is removed

and the end portions of the remaining first and second vessel sections are joined

together using the surgical stapling apparatus10.

During such a procedure using the surgical stapling apparatus10,

prior to removing the diseased vessel portion from the diseased vessel,anvil

assembly400with a removable trocar(not shown)attached thereto is positioned

in the first vessel section on a first side of the diseased portion.A removable

trocar which is suitable for use with anvil assembly400is disclosed in the

Gresham'444patent,which,as discussed above,is incorporated herein by

reference in its entirety.After the diseased vessel portion is removed and the

open ends of the first and second vessel sections have been sutured,the distal

end of apparatus10is positioned in the second vessel section on the other side of